Page 1

TTWS Series

THERMAL WEAPON SIGHTS

OPERATOR’S MANUAL (TTWS Series) REVISION 4 – APRIL, 2014

operator’s manual

Important Export Restrictions! Commodities, products,

technologies and services contained in this manual are

subject to one or more of the export control laws and

regulations of the U.S. Government and they fall under the

control jurisdiction of either the US Department of State or the

US BIS-Department of Commerce. It is unlawful and strictly

prohibited to export, or attempt to export or otherwise transfer

or sell any hardware or technical data or furnish any service to

any foreign person, whether abroad or in the United States, for

which a license or written approval of the U.S. Government is

required, without first obtaining the required license or written

approval from the Department of the U.S. Government having

jurisdiction. Diversion contrary to U.S. law is prohibited.

Page 2

Register your product warranty online at

www.atncorp.com/warranty

Manual (TTWS Series) Revision 4 – April, 2014

The information in this manual furnished for information use only, is subject to

change without notice, is not to be construed as a commitment by ATN Corp.

ATN Corp. assumes no responsibility or liability for any errors or inaccuracies

that may appear in this book.

© 2014 ATN Corp. All right reserved.

Page 3

SAFETY SUMMARY

STUDY CAREFULLY THIS MANUAL BEFORE TURNING ON

AND OPERATING THIS PRODUCT.

CAUTIONS

The TTWS Series Thermal Digital Riflescopes are precision

electro-optical instruments and requires careful handling. To provide safe use of the systems the following instructions should be

observed:

• Do not dismantle the device.

• Keep the device clean; protect it from moisture, sharp temperature drops and shocks.

• Be careful not to touch the glass surfaces. If you put finger-prints on, or contaminate the glass surfaces, use only

clean and soft materials to clean it.

• Do not leave the device in on position during stops in operation.

• Remove the batteries from the device for the period of storage.

CAUTION:

THIS PRODUCT CONTAINS NATURAL RUBBER LATEX

WHICH MAY CAUSE ALLERGIC REACTIONS.

a

Page 4

WARNING

Do not permanently attach the scope to dynamic-mount applications that continuously transmit vibration (such as on vehicles or

heavy machinery).

WARNING

Do not point the scope directly at any high-intensity objects that you

must not view with your eyes (such as the sun or a welding arc). If

you do, you will damage the scope.

WARNING

Operating TTWS Series outside of its specified operating temperature range or voltage range can cause permanent damage and will

void the warranty.

WARNING

Use the power button to turn the scope off before you remove power

(remove batteries or disconnect external power supply).

WARNING

TTWS Series operates over a wide operating temperature range

(-20°C to +60°C). Not all lithium batteries are specified over this

same temperature span. Check the manufacturer’s specifications

of your selected battery to verify the valid temperature range.

WARNING

Do not use any battery other than a CR-123A lithium battery. DO

NOT use any battery(ies) providing a (combined) voltage greater

than 12.0 volts.

WARNING

Do not install batteries of different types (lithium with lithium-ion

rechargeable). All batteries must be of the same type.

WARNING

Do not replace batteries in a possibly explosive environment, such

as a gas station (or any place where you must turn off your vehicle

engine). If you do, sparks can cause an explosion.

b

Page 5

WARNING

Remove the batteries before you store the riflescopes for extended

periods (2 weeks or more).

WARNING

Do not carry batteries in pockets containing metal objects such as

coins, keys, etc. Metal objects can cause the batteries to short circuit and become very hot. In the case of lithium batteries, a short

circuit could cause them to explode.

WARNING

Observe battery manufacturer’s guidelines for safe handling and

proper disposal of batteries.

EQUIPMENT LIMITATIONS

• The TTWS Series detector spectral band (7 to 14 mkm) provides a better penetration through smoke, smog, dust, water

vapor etc.

• Infrared radiation does not travel through glass and therefore

the scope does not sense objects if they are behind a glass

window.

c

Page 6

TABLE OF CONTENTS

CHAPTER 1. INTRODUCTION . . . . . . . . . . . . . . . . . 1-1

1.1. General Information . . . . . . . . . . . . . . . . . . . . 1-2

1.1.1. Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.2. Reports . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.3. Storage . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.4. Warranty Information . . . . . . . . . . . . . . . . . . . 1-2

1.2. Description and Data . . . . . . . . . . . . . . . . . . . 1-5

1.2.1. Description . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.2.2. TTWS Standard Components . . . . . . . . . . . . . . . 1-7

1.2.3. Specifications . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.2.4. Mechanical Function . . . . . . . . . . . . . . . . . . 1-11

1.2.5. Optical Function . . . . . . . . . . . . . . . . . . . . . 1-11

1.2.6. Electrical Function . . . . . . . . . . . . . . . . . . . 1-12

CHAPTER 2. ASSEMBLY AND PREPARATION . . . . . . . . 2-1

2.1. Preparation . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.1. Preparation for Use . . . . . . . . . . . . . . . . . . . . 2-2

2.1.2. Examination for Operation . . . . . . . . . . . . . . . . 2-3

2.2. Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.1. Remove/installation of Quick Release Mount (QRM) . . . 2-4

2.2.2. Video Output . . . . . . . . . . . . . . . . . . . . . . . 2-5

CHAPTER 3. OPERATION . . . . . . . . . . . . . . . . . . . 3-1

3.1. General Information . . . . . . . . . . . . . . . . . . . . 3-2

3.1.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2. Controls and Indication . . . . . . . . . . . . . . . . . . 3-2

3.2. Operating procedure . . . . . . . . . . . . . . . . . . . 3-3

3.2.1. Turning On . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.2. Focusing . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.2.3. ISM – Interactive Symbology Menu . . . . . . . . . . . . 3-5

3.2.4. Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.2.5. Brightness . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

i

Page 7

3.2.6. Zoom . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.2.7. Color Modes . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.2.8. Manual Image Refresh / Calibration . . . . . . . . . . . 3-9

3.2.9. Reticle Color . . . . . . . . . . . . . . . . . . . . . . 3-10

3.2.10. Reticle Pattern . . . . . . . . . . . . . . . . . . . . . 3-10

3.2.11. New Firmware Change Guide . . . . . . . . . . . . . 3-11

3.2.12. Shut Down Operations . . . . . . . . . . . . . . . . . 3-11

CHAPTER 4. MAINTENANCE INSTRUCTIONS . . . . . . . . 4-1

4.1. Preventive Maintenance Checks and Services (PMCS) . 4-2

4.1.1. Purpose of PMCS . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.2. Frequency of Performing PMCS . . . . . . . . . . . . . 4-2

4.2. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.2. Troubleshooting Procedures . . . . . . . . . . . . . . . 4-4

4.3. Maintenance Procedures . . . . . . . . . . . . . . . . . 4-5

4.3.1. Scope Maintenance . . . . . . . . . . . . . . . . . . . . 4-5

4.3.2. Cleaning Procedures . . . . . . . . . . . . . . . . . . . 4-5

4.3.3. Preparing for Extended Storage . . . . . . . . . . . . . 4-6

ii

Page 8

HOW TO USE THIS MANUAL

• Usage

You must familiarize yourself with the entire manual before operating the equipment. Read and follow all warning notices.

• Manual Overview

The table of contents includes the paragraph number, paragraph

title, and page number. An index provides additional references to

the subject contents.

iii

Page 9

CHAPTER 1

INTRODUCTION

1-1

Page 10

1.1. GENERAL INFORMATION

1.1.1. SCOPE

This manual contains instructions for use in operating and maintaining the TTWS Series Thermal Digital Riflescopes. Throughout

this manual, the TTWS Series will be referred to as the scope or

TTWS.

1.1.2. REPORTS

Reports from the user on recommendations for improvements are

encouraged. Send reports to the address below.

American Technologies Network Corp.

1341 San Mateo Avenue

South San Francisco, CA 94080

(800) 910-2862

(650) 989-5100

(650) 875-0129 fax

info@atncorp.com

www.atncorp.com

1.1.3. STORAGE

Storage of TTWS should be done in the factory packing and after a

thorough PMCS as outlined in Section 4.1 of this manual. This will

ensure the scope remains in mission ready condition during storage. Batteries should be stored separately from the scope.

The scope should not be placed on the floor, in any area exposed to

high temperatures or direct sunlight. Presence of acid and alkaline

vapor, as well as of other aggressive admixtures in the air is unacceptable.

1.1.4. WARRANTY INFORMATION

ONE YEAR PRODUCT WARRANTY

This product is guaranteed to be free from manufacturing defects in

material and workmanship under normal use for a period of 1 (one)

years from the date of purchase. In the event a defect that is covered

1-2

Page 11

by the foregoing warranty occurs during the applicable period stated

above, ATN, at its option, will either repair or replace the product, and

such action on the part of ATN shall be the full extent of ATN’s liability,

and the Customer’s sole and exclusive remedy. This warranty does

not cover a product (a) used in other than its normal and customary

manner; (b) subjected to misuse; (c) subjected to alterations, modi

fications or repairs by the Customer of by any party other than ATN

without prior written consent of ATN; (d) special order or “close-out”

merchandise or merchandise sold “as-is” by either ATN or the ATN

dealer; or (e) merchandise that has been discontinued by the manu

facturer and either parts or replacement units are not available due to

reasons beyond the control of ATN. ATN shall not be responsible for

any defects or damage that in ATN’s opinion is a result from the mis

handling, abuse, misuse, improper storage or improper operation,

including use in conjunction with equipment which is electrically or

mechanically incompatible with or of inferior quality to the product,

as well as failure to maintain the environmental conditions specified

by the manufacturer. This warranty is extended only to the original

purchaser. Any breach of this warranty shall be waived unless the

customer notifies ATN at the address noted below within the applica

ble warranty period.

The customer understands and agrees that except for the foregoing

warranty, no other warranties written or oral, statutory, expressed or

implied, including any implied warranty of merchantability or fitness

for a particular purpose, shall apply to the product. All such implied

warranties are hereby and expressly disclaimed.

LIMITATION OF LIABILITY

ATN will not be liable for any claims, actions, suits, proceedings,

costs, expenses, damages or liabilities arising out of the use

of this product. Operation and use of the product are the sole

responsibility of the Customer. ATN’s sole undertaking is limited

to providing the products and services outlined herein in accordance with the terms and conditions of this Agreement. The provision of products sold and services performed by ATN to the

Customer shall not be interpreted, construed, or regarded, either

expressly or implied, as being for the benefit of or creating any

obligation toward any third party of legal entity outside ATN and

the Customer; ATN’s obligations under this Agreement extend

solely to the Customer. ATN’s liability hereunder for damages,

regardless of the form or action, shall not exceed the fees

or other charges paid to ATN by the customer or custom-

1-3

Page 12

er’s dealer. ATN shall not, in any event, be liable for special,

indirect, incidental, or consequential damages, including,

but not limited to, lost income, lost revenue, or lost profit,

whether such damages were foreseeable or not at the time

of purchase, and whether or not such damages arise out of a

breach of warranty, a breach of agreement, negligence, strict

liability or any other theory of liability.

PRODUCT WARRANTY REGISTRATION

In order to validate the warranty on your product, ATN must

receive a completed Product Warranty Registration Card

for each unit or complete warranty registration on our website at www.atncorp.com. Please complete the included

form and immediately mail it to our Service Center: ATN

Corporation, 1341 San Mateo Avenue, South San Francisco, CA

94080.

OBTAINING WARRANTY SERVICE

To obtain warranty service on your unit, End-user must notify ATN

service department by calling 800-910-2862 or 650-989-5100 or

via e-mail service@atncorp.com to receive a Return Merchandise Authorization number (RMA). When returning please take or

send the product, postage paid, with a copy of your sales receipt

to our service center, ATN Corporation at the address noted

above. All merchandise must be fully insured with the correct postage; ATN will not be responsible for improper postage or, missing or damaged merchandise during shipment. When sending

product back, please clearly mark the RMA# on the outside of the

shipping box. Please include a letter that indicates your RMA#,

Name, Return Address, reason for service return, Contact information such as valid telephone numbers and/or e-mail address

and proof of purchases that will help us to establish the valid start

date of the warranty. Product merchandise returns that do not

have an RMA listed may be refused or a significant delay

in processing may occur. Estimated Warranty service time is

10-20 business days. End-user/customer is responsible for

postage to ATN for warranty service. ATN will cover return postage/shipping after warranty repair to end-user/customer only if

product is covered by aforementioned warranty. ATN will return

product after warranty service by domestic UPS ground and/

or domestic mail. Any other requested, required or international

shipping method the postage/shipping fee will be the responsibility of the end-user/customer.

1-4

Page 13

1.2. DESCRIPTION AND DATA

1.2.1. DESCRIPTION

a. Purpose

The TTWS Series Thermal Digital Riflescopes combines the ergonomic features of a handheld and the convenience of weapon

mounting. Based on the proven 324x256 or 336x256 or 640x512

microbolometer core, the TTWS is an ideal product for force protection, border patrol officers, police SWAT and special operations

forces providing them the tools they need to be successful in all

field conditions both day and night. Uncooled thermal imaging cuts

through dust, smoke, fog, haze, and other battlefield obscurants. Its

use cannot be detected as it emits no visible light or RF energy and

operates without the use of illuminators or IR lights.

b. Features

TTWS has the following important features:

• High resolution digital thermal imaging

• Compact, lightweight and durable housing

• True magnification

• High end OLED display

• Four-colors reticle system

• Rapid start-up in 3 seconds

• Up to 8 hours operation with three lithium batteries

• One-Year Warranty

• Aluminum constructed body with class 3 hard ano dized coating

• Digital Tactical Menu with quick view icons

• Memory Recall preserves operational settings

• Power-off safety feature prevents accidental shut down

• Recoil rated up to .308 caliber

• Polarity: white hot / black hot / color

• Thermal images viewable in up to 12-tone color pallet.

• Five reticle patterns: duplex, post, post with dot, standard

crosshair, ballistic

1-5

Page 14

• Four reticle colors: red, green, white, black

• Ten-step brightness control

• Flexible battery cartridge can run on 1, 2, or 3 batteries

• Batteries: (3) 3V lithium (CR123A) – AA optional (qty 4)

• Battery life: 8 hours (3V)

1-6

Page 15

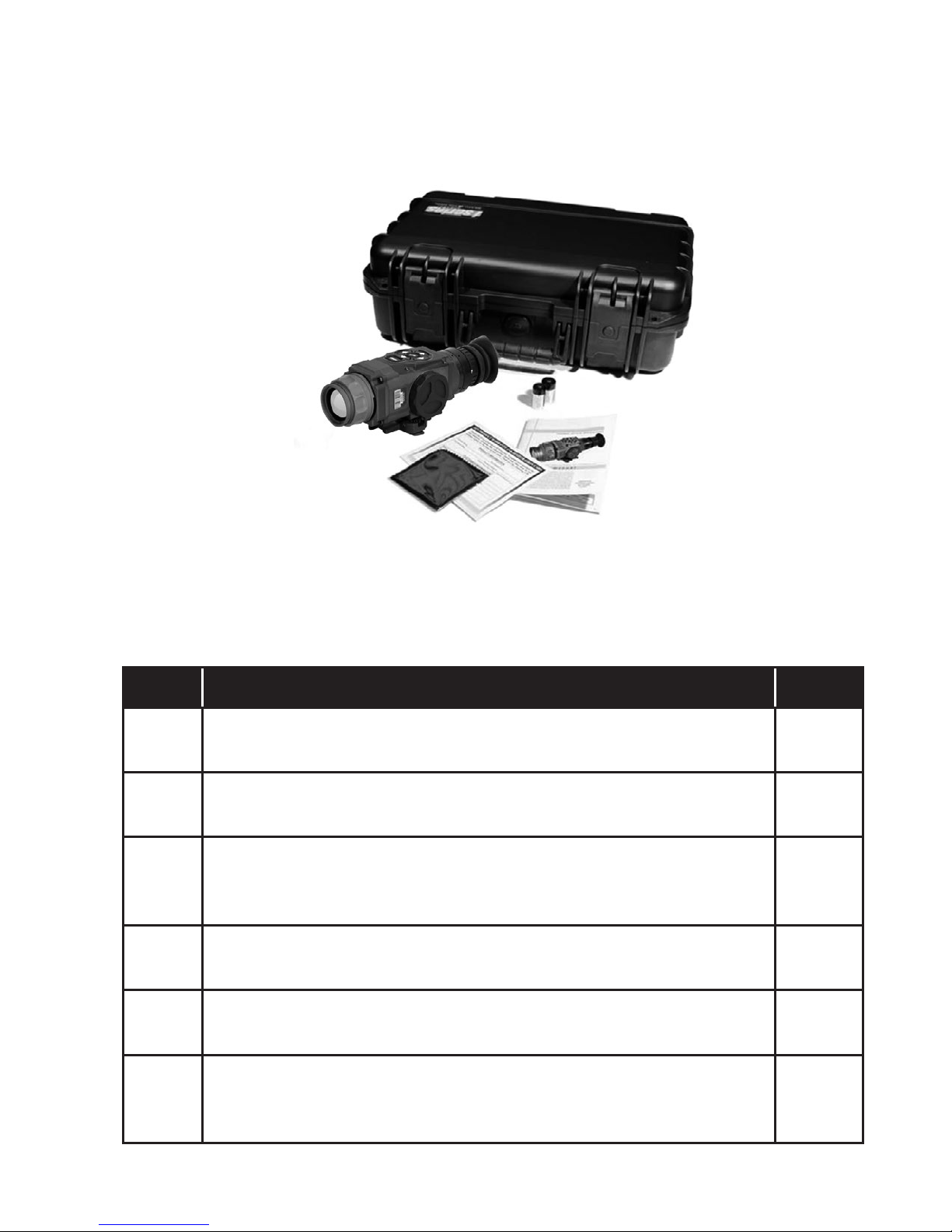

1.2.2. TTWS STANDARD COMPONENTS

The TTWS standard components are shown in Figure 1.3. and presented in Table 1.1.

FIGURE 1.3. TTWS STANDARD COMPONENTS

TABLE 1.1. TTWS STANDARD COMPONENTS

ITEM DESCRIPTION QTY

1

2

3

4

5

Scope

The thermal imaging scope.

Quick Release Mount

Used to mount scope to weapon.

Hard Storage Case

A protective case used for shipping/storing TTWS and

accessories.

Lens Tissue

Uses for cleaning of lenses surface.

Lithium Battery CR1223A

Three CR123A lithium batteries used to power the unit.

1

1

1

1

3

Operator’s Manual

6

Provides equipment description, use of operator controls and preventative maintenance checks and service.

1

1-7

Page 16

5-40x

TTWS-640

2.5-20x

TTWS-640

1.5-12x

TTWS-640

1.1-9x

TTWS-640

9-36x

TTWS-320

4.5-18x

TTWS-320

800x600

<50 mK

1.2.3. SPECIFICATIONS

TABLE 1.2. SPECIFICATIONS

3.5-14x

TTWS-320

3-12x

TTWS-336

1.5-6x

TTWS-336

1.25-5x

TTWS-320

ITEM

19 19 30 50 50 100 19 30 50 100

24°x18° 21°x16° 12.5°x9.7° 9°x7° 6°x4.7° 3°x2.4° 21°x16° 21°x16° 12.5°x9.7° 6° x 4.7°

2.5x, 5x 3x, 6x 6x,12x 7x, 14x 9x, 18x 18x, 36x 2.2x, 4.5x, 9x 3x, 6x, 12x 5x, 10x, 20x 10x, 20x, 40x

The following tables provide information pertaining to the operational, electrical, mechanical,

optical and environmental characteristics for the sights.

1-8

Sensor (microbolometer) 320x240 336x256 336x256 320x240 336x256 336x256 640x512 640x512 640x512 640x512

Frame rate 60 Hz 60 or 3 0 Hz 60 or 3 0 Hz 6 0 Hz 6 0 or 30 Hz 60 or 30 Hz 30 Hz 30 Hz 30 Hz 30 Hz

Material VoX

Image Size

(output resolution)

Optical Magnification 1.25 1.5 3 3.5 4,5 9 1.1 1,5 2,5 5

E-Zoom

Eye Relief, mm 28

Field of View

Video output Digital NTSC / PAL

Display Color OLED matrix, SVGA< 800x600, Color background + color reticules

Thermal

Sensitivity, mK

Spectral Response, μm 7-14

Focal length

(H x V), deg

of the lens, mm

Page 17

5-40x

TTWS-640

2.5-20x

TTWS-640

1.5-12x

TTWS-640

1.1-9x

TTWS-640

9-36x

TTWS-320

4.5-18x

TTWS-320

14

3.5-14x

TTWS-320

3-12x

TTWS-336

1.5-6x

TTWS-336

1.25-5x

TTWS-320

ITEM

500 750 1100 1250 1500 2500 750 1100 1500 2500

225 300 400 520 600 1100 300 400 600 1100

135 180 225 290 360 600 180 225 360 600

1100 1650 2425 2550 3300 5000 1650 2425 3300 5000

495 660 875 1000 1320 2200 660 875 1320 2200

observation only, in E-Zoom due to the lack of this feature.)

300 400 525 650 800 1400 400 525 800 1400

TT WS’s Reticle will Automatically Adjust its position when using E-Zoom (Note: Most thermal scopes allow the user to use the scope for

Diameter

of exit pupil, mm

Distance of the human

detection, m

Distance of the human

recognition, m

(w/o zoom)

Distance of the human

Identification, m

(w/o zoom)

Distance of the vehicle

detection, m

(w/o zoom)

Distance of the vehicle

recognition, m

(w/o zoom)

Distance of the vehicle

Identification, m

(w/o zoom)

Reticle Multiple Reticles to Choose From

(w/o zoom)

Reticle Color Red, Green, Blue, White & Black

Smart Zoom

Brightness adjustment Manual

Sharpness adjustment Automatic

Polarity control White hot / Black hot / Multiple Color Modes

1-9

Page 18

5-40x

TTWS-640

2.5-20x

TTWS-640

1.5-12x

TTWS-640

1.1-9x

TTWS-640

9-36x

TTWS-320

4.5-18x

TTWS-320

Yes

3.5-14x

TTWS-320

3-12x

TTWS-336

1.5-6x

TTWS-336

1.25-5x

TTWS-320

ITEM

203x69x73 262x94x73 171x69x73 203x69x73 203x69x73 262x94x73 171x69x73 171x69x73 203x69x73 262x94x73

Start up time, sec <3

Waterproof Waterproof / Dustproof

Battery type 3 x CR123A battery type

1-10

Battery Life, h 8+

Weight, grams 850 1417 710 850 850 1417 710 710 850 1417

Dimensions

Mounting bracket MIL-STD 1913 Picatinny (Quick)

(L x W x H), mm (without

bracket)

Output computer

set up

Video output Yes

Low Battery Indicator Yes

Iconology Quick access, Icon driven feature controls

Housing Aircraft Aluminum 6061 T6 w/ class III hard anodized coating

Objective lens Janus, full MIL SPEC, DLC (Diamond Like Carbon) coating

* ATN reserves the right to change the above specifications at any time without notice.

Page 19

1.2.4. MECHANICAL FUNCTION

The mechanical adjustments of the TTWS sights allow for physical differences between individual operators using the system. The

scope functions include the Keypad, Output Connector, Eyepiece

Diopter Adjustment Ring, Focusing Ring, Battery Module, Accessory

Rail, and Weapon Mount. The controls are identified in Figure 1.4.

FOCUSING

RING

WEAPON MOUNT

RELEASE

KEYPAD

DIOPTER

ADJUSTMENT RING

BATTERY

MODULE

WEAPON MOUNT

ADJUSTER

RUBBED

EYEGUARD

FIGURE 1.4. TTWS MECHANICAL CONTROLS

1.2.5. OPTICAL FUNCTION

The optical functions include an objective lens, thermal imaging

detector, display and eyepiece. Infrared energy is emitted proportionally to the temperature of an object. The warmer the object,

the more energy it emits. The infrared energy from the objects is

focused by the optics, onto an infrared detector. The information

OUTPUT

CONNECTOR

ACCESSORY

RAIL

WEAPON

MOUNT

1-11

Page 20

from infrared detector is passed to electronics for image processing. The signal processing circuitry translates the infrared detector

data into an image that can be viewed on the built-in OLED display.

The image is observed through an eyepiece by operator.

1.2.6. ELECTRICAL FUNCTION

The electronic circuit is powered by replaceable four 3V lithium batteries (CR123A). Power from the batteries is supplied to the components through the Power button.

1-12

Page 21

CHAPTER 2

ASSEMBLY AND PREPARATION

2-1

Page 22

2.1. PREPARATION

2.1.1. PREPARATION FOR USE

This chapter contains the information necessary to prepare the

scope for operation. This includes unpacking, examination for

damage, and batteries installation.

a. Unpacking

The following steps must be accomplished prior to each mission

where the sight is used.

1. Open carrying case, remove the scope and check contents for

completeness.

2. Inspect the scope for obvious evidence of damage to optical

surfaces, body, eyecups, operation buttons, etc. Ensure that all

optical surfaces are clean and ready for use. Clean with lens

tissue.

b. Installation of Batteries

WARNING

The lithium battery contains sulfur dioxide gas under pressure.

Do not heat, puncture, disassemble, short circuit, attempt to

recharge or otherwise tamper with the batteries.

Turn off equipment if battery compartment becomes unduly

hot. If possible,

wait until the batteries have cooled before removing them.

If you inhale sulfur dioxide, seek medical attention.

The TTWS will operate with 1, 2 or 3 CR123A Lithium batteries type.

For best battery performance use all 3 batteries.

Install CR123A Lithium batteries as follows.

1. Remove the battery module by unscrewing it counter clockwise.

2. Observe polarity, by placing the negative side of the battery

against the spring, and insert the 3.0 Volt CR 123A Lithium batteries into the battery module.

2-2

Page 23

3. Replace battery module into the housing. Screw clockwise until

finger tight.

FIGURE 2.1. LOADING BATTERY MODULE

FIGURE 2.2. INSTALL BATTERY MODULE

2.1.2. EXAMINATION FOR OPERATION

Before getting started, make sure to follow these steps:

1. Push Power button on the scope.

2. Make sure that the luminance in ocular is present.

3. Observe the scene, and adjust the diopter and/or lens for opti-

mal image clarity.

2-3

Page 24

2.2. ASSEMBLY

2.2.1. REMOVE/INSTALLATION OF QUICK RELEASE

MOUNT (QRM)

ARMS #17 Lever Quick Release Mount (QRM) is used for fast

installation/removing the TTWS on MIL-STD-1913/Picatinny rail.

FIGURE 2.3. LEVER QUICK RELEASE MOUNT

FIGURE 2.4. QUICK RELEASE MOUNT ADJUSTMENT

1. To open the QRM, slide the cam latch forward (arrow A).

2-4

Page 25

2. Place the scope onto rail. Be sure to engage the recoil lug into

the groove on the top mounting surface of the rifle.

3. Turn the cam backwards pushing the latch to close the mount

(arrow B).

4. The QRM may be adjusted to eliminate excessive play when

mounted on the rail by using the adjustment knob on the lever to

release the lever from the adjuster.

2.2.2. VIDEO OUTPUT

This version of the TTWS Sightng System is equipped with the

added feature of being able to connect directly to a remote video

monitor or recorder via an integrated 8 PIN port.

This version of the TTWS Sighting System is equipped with the

added feature of being able to connect directly to a remote video

monitor or recorder via an integrated 8 PIN port.

To use this feature, the following optional components are required

(see illustrations below):

1. 8 PIN-to-BNC adapter.

FIGURE 2.6. VIDEO CABLE WITH 8 PIN TO RCA

FIGURE 2.5. WITH VIDEO CABLE

2-5

Page 26

2. BNC Plug to RCA Jack Adapter

FIGURE 2.7. RCA JACK ADAPTER

3. RCA style video cables

FIGURE 2.8. RCA CABLES

Connection Setup:

1. Connect the 8 PIN-to-BNC (Figure 2.6.) cable to the sights

8 PIN port.

2. Connect the BNC Plug to RCA Jack Adapter (Figure 2.7.), to the

8 PIN-to-BNC cable.

3. Connect the Yellow (video) plug of the RCA Cables (Figure 2.8.),

to the RCA jack adapter.

4. Connect the opposite end of the yellow male RCA cable to the

monitor’s yellow RCA plug.

Operation:

1. Turn on the system by pressing the POWER button.

2. Let screen image settle before transferring video to the monitor.

3. Press the “Up” and “Down” arrow buttons simultaneously, as

show in the photo above. The Video image will now be able to

2-6

Page 27

be viewed through the TTWS eyepiece and the monitor at the

same time.

FIGURE 2.9. OPERATION SWITCHBOARD

The user, while looking through the TTWS eyepiece, will be able to

tell if video is being displayed on the monitor, because the VID icon

will be visible in the bottom left corner of the eyepiece.

4. To turn off the Remote Video Output, repeat step 3.

NOTE

The image seen in the TTWS sight will be smaller than its

actual resolution, due to the video processing differing from

that of a monitor.

To utilize image capture and review follow next:

1. With no menu visible press and hold the “Enter” button until a

camera icon appears on screen. (Figure 2.10.)

2. Images are captured by pressing the enter button quickly.

3. To turn off image capture press and hold the “Enter” button

until the camera icon disappears from the display. Images can be

viewed by entering “Menu 3” (Screenshot) and pressing the left

and right arrow buttons. Pressing the down button “trash can icon”

button will erase all captured images.

2-7

Page 28

FIGURE 2.10. CAMERA ICON ON SCREEN

How to download images to PC.

1. Install ATN Interface Software on your PC.

2. With TTWS On plug in image capture cable to TTWS and PC.

3. Open “ATN Scope Interface” software.

4. Click on menu named: Settings.

5. Select “Connect”

6. Choose the correct port for the TTWS cable.

7. Click on menu named: Settings.

8. Select “Image Directory”

9. Choose a location to save the images to.

10. Click on menu item “Download Images”

FIGURE 2.11. IMAGE CAPTURE CABLE

2-8

Page 29

CHAPTER 3

OPERATION

3-1

Page 30

3.1. GENERAL INFORMATION

3.1.1. GENERAL

This section contains instructions for operation of TTWS. The function of controls and indicators is explained.

CAUTION

The TTWS scope is a precision electron-optical instru-

ment and must be handled carefully at all times.

3.1.2. CONTROLS AND INDICATION

The TTWS scope is designed to adjust for different users and corrects for most differences. The controls for the scope are shown or

described in Figure 3.1. and Tables 3.1.

FIGURE 3.1. CONTROLS

3-2

Page 31

TABLE 3.1. CONTROLS AND INDICATION

ITEMS

1 POWER Button

2 ENTER Button Used to select or enter selection

3 Up Arrow

4 Down Arrow

5 Left Arrow

6 Right Arrow

CONTROLS

AND INDICATORS

FUNCTIONS

Controls scope power. To turn the unit on

and off press the button

Digital Zoom, Reticle Color, Elevation Up

Adjustment

Brightness, Calibration, Elevation Down

Adjustment

Polarity, Reticle Type, Windage Left

Adjustment

Color Modes, Reticle Adjustment,

Windage Right Adjustment

3.2. OPERATING PROCEDURE

3.2.1. TURNING ON

Open the objective lens cover.

NOTE

The objective lens cover protects the scope from inadvertent

exposure to extremely high levels of radiant flux. Never leave

the scope with the objective lens cover off.

To turn the unit on press the button labeled POWER.

After a warm-up time of approximately 3 seconds, video of the thermal scene appears.

NOTE

During the warm-up time, a logo comes into view on the monocular display. Next the thermal image replaces the logo.

3-3

Page 32

FIGURE 3.2. SWITCHBOARD OF TTWS

3.2.2. FOCUSING

To focus the scope you need to adjust the diopter first. The scope

has an adjustable eyepiece with a range of +2 to -6 diopter. Simply

turn the diopter clockwise until it stops. Then concentrate on any

object and slowly turn the diopter back counter clockwise until the

grain in the image is sharp. Then rotate the eyecup to accommodate use over the left or right eye.

The TTWS models have ability to focus either long range or short.

Focus the front lens to rotate it until the image and the grain are

both sharp.

FIGURE 3.3. FOCUS ADJUSTMENT

3-4

Page 33

NOTE

The front lens should be readjusted for viewing objects at different distances. Rotate the focusing ring clockwise for far

focus, counterclockwise for near focus.

3.2.3. ISM – INTERACTIVE SYMBOLOGY MENU

The TTWS features the all new ISM interactive symbology menu

that enables you to easily navigate through the features and modes

without having to go into a complex menu structure. Every mode

and option can be found on one of the following ISM screens:

ZOOM INDICATOR

(1X, 2X, 4X – 8X FOR 640)

1X

POLARITY

WHITE HOT /

BLACK HOT

COLOR MODES

(10 STEPS)

BRIGHTNESS LEVEL

(6 STEPS)

FIGURE 3.4. ISM MAIN MENU

3-5

Page 34

RETICLE COLOR

RETICLE

PATTERN

(5 OPTIONS)

CAL

CALIBRATION (NUC)

CLOSE LENS CAP BEFORE CAL

FIGURE 3.5. ISM RETICLE MENU

RETICLE ADJUST

WINDAGE

AND ELEVATION

3.2.4. POLARITY

The function of polarity switching is accessible only in Black and

White models.

WHITE HOT BLACK HOT

FIGURE 3.7. DISPLAY POLARITY MODES

POLARITY button switches the direct display mode into the reverse

one, i.e. from hot-white/cold-black into hot-black/cold-white mode.

If the polarity is white-hot, the image will be with hotter objects displayed as white, and the rest of the image displayed as black, and

vice versa: with hotter objects displayed as black, if the polarity is

black-hot.

3-6

Page 35

To select polarity go to ISM Main menu and push left arrow button to

cycle between white hot and black hot polarities.

3.2.5. BRIGHTNESS

Brightness allows you to dim or increase the brightness of the display.

To cycle through the BRIGHTNESS steps go to ISM Main menu and

push the down arrow button for brightness adjustment. Each short

push of the buttons will cycle through the BRIGHTNESS modes,

correspondingly, in stepwise way.

NOTE

Levels 1 to 6 range from full dim to full bright.

3.2.6. ZOOM

324x256 and 336x256 models have 2 steps of digital zoom (factor

of 2x and 4x). 640x512 models have 3 steps of digital zoom (factor of

2x, 4x and 8x).

To cycle through the digital zoom steps go to ISM Main menu and

push Up arrow button.

When ZOOM button is pushed first time, the scope will digitally

zoom a scene by 2 times the scopes optical magnification. When

the zoom button is pushed the second time the scope will digitally

zoom a scene by 4 times the scopes optical magnification for TTWS

models with the 324x256 or 336x256 core. To reset the magnification to the default optical magnification press ZOOM button third

time. For TTWS models with the 640x512 core when the zoom

button is pushed the third time the scope will digitally zoom a scene

by 8 times the scopes optical magnification. To reset the magnification to the default optical magnification press ZOOM button fourth

time.

NOTE

Resolution decreases with each step of digital magnification.

The reticle has a built in compensation to shift and stay on the target

during digital zoom operations as depicted in Figure 3.8.

3-7

Page 36

NO ZOOM

RETICLE ON TARGET

RETICLE SHIFTS 2X

FIGURE 3.8. ZOOM

2X ZOOM

4X ZOOM

RETICLE SHIFTS 4X

3.2.7. COLOR MODES

The TTWS has 10 additional color pallets to choose from in addition

to the white hot and black hot polarity.

Fusion, Rainbow, Globow, Ironbow1, Ironbow2, Sepia, Color1,

Color2, Ice Fire, Rain.

To select a different colors mode go to ISM Main menu and push

Right arrow button to cycle through the 10 additional pallets. To go

back to Black hot – white hot mode push left arrow button in ISM

Main menu.

IRONBOW COLOR 1 GLOBOW

3.2.8. MANUAL IMAGE REFRESH / CALIBRATION

Degradation of the image (image blurring) is caused by charge

accumulation on the detector array.

To use the calibration icon go to ISM Reticle menu and push down

arrow button to maintain an optimum thermal image. During this

refresh, the video will freeze for approximately 0.5 second.

3-8

FIGURE 3.9. COLOR MODES

Page 37

IMPORTANT:

To Perform calibration of unit. Cover front lens with cap or

hand and push Calibration button to calibrate image. Failure to do this step may result in degradation of the image.

Degradation may consist of unusual blurriness or ghost

like spots in the image. During use if you see any degradation of image please recalibrate the scope.

Perform a calibration upon every substantial environmental temperature change.

NOTE

While performing very frequent Refreshes can provide the

best possible image quality but also can substantially decrease

the battery life.

DURING CAL

CORRECT VIEW

FIGURE 3.10. CALIBRATION (NUC)

CORRECT CAL

IF LENS IS COVERED

INCORRECT CAL

IF LENS IS NOT COVERED

3.2.9. RETICLE COLOR

Your scope has Four reticle colors to choose from: red, green,

white, black, the latest firmware also includes many bonus colors.

To select reticle colors go to ISM Reticle menu and push Up arrow

button to cycle through the reticle colors.

RED WHITE BLACK GREEN

FIGURE 3.11. RETICLE ADJUSTMENT

3-9

Page 38

3.2.10. RETICLE PATTERN

Your scope has many reticle types/patterns to choose from: duplex,

post, post with dot, open cross hair, standard crosshair.

To select reticle type go to ISM Reticle menu and push Left arrow

button to cycle through the reticle patterns.

BALLISTIC

DUPLEX

POST POST W/DOT

FIGURE 3.12. RETICLE PATTERNS

CROSSHAIR

W/DOT

3.2.11. NEW FIRMWARE CHANGE GUIDE

A Reticle Position Indicator has been incorporated, in order for the

operator to have visual confirmation of the reticle position change.

The “X” and “Y” indicators give a pixel by pixel indication of the

movements being made. The indicator is only visible when in the

Reticle adjustment menu.

1) Reticle Adjustment Procedure:

• The Reticle adjustment remains one the second level menu, on

the Right hand side.

a) Press the Right menu button to enter the Reticle Adjustment level

(Fig ure 3.13) .

3-10

Page 39

RETICLE

ADJUSTMENT

ICON

FIGURE 3.13

b) This Menu will now appear (depicted in Figure 3.14).

X= 0

Y= 0

FIGURE 3.14

c) The Right/Left and Up/Down arrows may now be pressed to

move the Reticle position.

d) The example in Figure 3.15 illustrates a new Reticle position.

X= 20

Y= 35

FIGURE 3.15

3 -11

Page 40

e) When the Reticle has been adjusted to the desired position,

press the Center button. This “SV?” Icon will appear (Figure 3.16).

X= 20

Y= 35

SV?

FIGURE 3.16

f) To insure the new Reticle position is saved, continue holding the

Center button down until the “OK” icon appears (Figure 3.17).

X= 20

Y= 35

OK

FIGURE 3.17

g) This position is now the new “Zero”.

h) Pressing the Center button now, will continue the rotation through

the menu’s as normal.

Temporary adjustments:

Should you want to temporarily make a windage or range adjustment, repeat steps A through E, but, only hold the button down

momentarily (i.e. not long enough for the “OK” to appear).

This will not save the settings, so that when the TTWS is turned off,

the Reticle will return to it’s saved position.

3-12

Page 41

3.2.12. SHUT DOWN OPERATIONS

To finish the work, perform the following:

1. Use the POWER button to turn the scope off.

2. Hold down the POWER button (3 seconds) until the ? icon goes

away then release the POWER button. This is a safety so the

system is not accidentally turned off.

3. Return the scope to the case.

STEP 1

PRESS

AND HOLD

POWER

BUTTON

AND SEE “?”

STEP 2

RELEASE

POWER

BUTTON

WHEN “OK”

APPEARS

ON SCREEN

FIGURE 3.14. POWER DOWN

3-13

Page 42

3-14

Page 43

CHAPTER 4

MAINTENANCE INSTRUCTIONS

4-1

Page 44

4.1. PREVENTIVE MAINTENANCE

CHECKS AND SERVICES (PMCS)

4.1.1. PURPOSE OF PMCS

PMCS is performed daily when in use to be sure that the sight is

ready at all times. Procedures listed in Table 4.1. are a systematic

inspection of TTWS that will enable you to discover defects that

might cause the sight to fail on a mission.

4.1.2. FREQUENCY OF PERFORMING PMCS

The frequency of performing PMCS is as follows:

a. Daily when the sight is in use.

b. When it is removed from the case for any reason.

TABLE 4.1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

SEQ.

NO.

1

2 Sight Body

3

4

5 Lenses

ITEM TO

CHECK

Completeness

Front

Lens Cap

Battery

Compartment

CHECKING

PROCEDURE

Inventory items by means

of comparing with the data

specified in this manual.

Inspect for missing screws

or connector cap.

Inspect for cuts, tears and

dirt. Clean as required.

Check for corrosion, springs

tension.

Inspect for cleanliness,

scratches, chips or cracks.

Clean as required.

NOT FULLY MISSION

CAPABLE IF:

Items missing.

Screws or connector cap missing.

Cap torn or cut.

Springs corroded

or damaged.

Chipped, cracked

or if scratches

hinder vision

through the sight.

6

Objective

Lens

4-2

Check to ensure the objective lens is not loose.

Objective lens

loose.

Page 45

SEQ.

NO.

ITEM TO

CHECK

7 Focus Ring

CHECKING

PROCEDURE

Check to ensure:

— the focus ring cannot be

moved along the sight body;

— there is free rotation of

the focus ring (more than

3/4 turn).

NOT FULLY MISSION

CAPABLE IF:

Focus ring able to

move along sight

body. Focus ring

cannot be rotate

8

Rubber

Eye-cup

Inspect for cuts or tears

Rubber Eye-cup

torn or cut

AFTER CHECKING PROCEDURES

9

Replace protective covers on the lenses. Remove the batteries.

Return the scope and all accessories to the storage case.

4-3

Page 46

4.2. TROUBLESHOOTING

4.2.1. GENERAL

This section contains information for locating and removal most of

the TTWS operating troubles which may occur. Each malfunction

for an individual component or assembly is followed by a list of tests

or inspections that will help determine probable causes and corrective action to take. Perform the tests/inspections and corrective

actions in the order listed.

This manual cannot list all possible malfunctions that may occur, or

all tests or inspections and corrective actions. If a malfunction is not

listed (except when malfunction and cause are obvious), or is not

corrected by listed corrective actions, contact to the service center.

4.2 .2. TROUBLESHOOTING PROCEDURES

Troubleshooting procedures are listed in Table 4.2.

TABLE 4.2. TROUBLESHOOTING PROCEDURES

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Image is absent

Cannot achieve

a sharp image of

the object.

Batteries are missing or

improperly installed.

Batteries are dead. Replace batteries.

Batteries contact surfaces or contact springs

dirty or corroded.

Objective and output

lenses dirty.

Damaged optical components.

Insert batteries or install

correctly.

Clean the contact surfaces with a pencil eraser

and/or alcohol and cotton

swabs.

Clean thoroughly the

lenses surfaces.

Send the sight to the

service center.

The batteries have a low

The brightness

set too low.

voltage.

Factory alignment

broken.

4-4

Replace the batteries.

Send the scope to the

service center.

Page 47

4.3. MAINTENANCE PROCEDURES

4.3.1. SCOPE MAINTENANCE

The TTWS maintenance consists of external inspection of its components for serviceability, cleaning and installation of the standard and optional accessories. Maintenance instructions covered

elsewhere in this manual (PMCS, troubleshooting, etc.) are not

repeated in this section.

CAUTION

The TTWS is a precision electron-optical instrument and must

be handled carefully at all times to prevent damage.

4.3.2. CLEANING PROCEDURES

a. Cleaning the scope

1. Gently brush off any dirt from the sight body using only a clean

soft cloth.

2. Moisten the cloth with fresh water and gently wipe the external

surfaces (except lenses).

3. Dry any wet surfaces (except lenses) with another dry and clean

soft cloth.

4. Using lens brush, carefully remove all loose dirt from the lenses.

5. Slightly dampen a cotton swab with ethanol and lightly and

slowly wipe the lenses.

Clean the glass surfaces by circular movements from the center to

the edge, not touching the lens holder and changing cotton swab

after each circular stroke.

Repeat this step until the glass surfaces are clean.

b. Cleaning of accessories

Clean accessories with a soft brush (cloth) and soap and water as

required.

CAUTION

Dry thoroughly each item before replacing into the storage

case.

4-5

Page 48

4.3.3. PREPARING FOR EXTENDED STORAGE

To prepare the TTWS for extended storage, perform the following:

6. Check the scope for serviceability as outlined in item 4.1 of this

manual.

7. Remove the batteries.

8. Clean the scope and accessories.

9. Replace all items in the case.

4-6

Page 49

4-7

Page 50

For customer service and technical support, please contact

American Technologies Network Corp.

1341 San Mateo Avenue, South San Francisco, CA 94080

phone: 800-910-2862, 650-989-5100; fax: 650-875-0129

www.atncorp.com

©2014 ATN Corporation

Loading...

Loading...