Page 1

ATN PVS-7

NIGHT VISION GOGGLES

operators’s manual

Important Export Restrictions! Commodities, products,

technologies and services contained in this manual are

subject to one or more of the export control laws and

re gu la ti on s of the U.S. Go ve rn me nt a nd t hey fal l u nd er t he

control jurisdiction of either the US Department of State

or the US BIS-Department of Commerce. It is unlawful

and strictly prohibited to export, or attempt to export or

o th er w ise t ransf er o r s e ll an y h ar d wa re or te c hn ic al da ta or

fu rni sh an y s er vice to a ny fo re ign pe rs on, wh et her a bro ad

or in the United States, for which a license or written

approval of the U.S. Government is required, without

first obtaining the required license or written approval

from the Department of the U.S. Government having

jurisdiction. Diversion contrary to U.S. law is prohibited.

Page 2

This pro ducT conTa ins naTur al rubbe r laTe x whi ch

may cause allerg ic re acTions.

Manual (PVS-7 ) Revision 2 - March 20 08

The informati on in this manual furnished for inform ation use only, is subject to

change without notice, is not to be construed as a commitment by ATN Corp.

ATN Corp. assumes no responsibility or liability for any errors or inaccuracies that may appear in this book.

© 2008 ATN Corp. All right reserved.

CAUTION:

Page 3

SAFETY SUMMARY

CAUTIONS

• The ATN PVS-7 is a precision optical instrument and should be

handled carefully to prevent its damage.

• Do not scratch the external lens surfaces or touch them with your

fingers.

• To protect the image intensifier, keep the lens cap on the objective lens on when the device is not in use or when it is checked out

in daylight conditions.

• The IR illuminator produces a light that is invisible to a naked

eye for use in conditions of extreme darkness. However, this IR

light can be detected by somebody else who use a night vision

device.

• If you use the rubber eyecups for a long time period, you may

suffer from skin inflammation. If you find any symptoms, consult a

doctor immediately.

a

Page 4

NOTES

• Do not test the device in daylight conditions even with the daylight filter/lens cap on for more than ten (10 ) minutes.

• To protect the device from damage do not direct it to the bright

light sources (a fire, headlights of the automobile, lanterns, etc.).

• The purpose of the built-in IR illuminator is to view at close distances up to 3 meters when additional illumination is needed.

b

Page 5

EQUIPMENT LIMITATIONS

To avoid physical and equipment damage when using the ATN

PVS-7, carefully read and understand the following equipment

limitations.

• The equipment requires some night light (moonlight, starlight,

etc.) to operate. The level of equipment performance depends

upon the level of light.

• Night light reduces by passing through the clouds, while operating under trees, at building shadows, etc.

• The equipment is less effective when viewing into shadows and

other darkened areas.

• The equipment is less effective when viewing through the rain,

fog, sleet, snow or smoke.

• The equipment will not “see” through the dense smoke.

c

Page 6

TABLE OF CONTENTS

pg.

SAFETY SUMMARY a

CHAPTER 1: Introduction 1-1

Section I: General Information 1-2

1-1 Scope 1-2

1-2 Reporting Equipment Improvement

Recommendations (EIR) 1-2

1-3 Glossary 1-2

1- 4 Administrative Stowage 1- 4

Section II: Equipment Description 1-5

1-5 Equipment Characteristics, Capabilities

and Features 1-5

1- 6 Equipment Capabilities 1-8

1-7 Specifications 1-8

Section III: Operation principles 1-11

1-8 Mechanical Functions 1-11

1-9 Optical and Electrical Functions 1-12

1-10 Consumable Items 1-13

CHAPTER 2: Operating Instructions 2-1

Section I: Operating Procedures 2-2

2-1 General 2-2

2-2 Controls and Indicators 2-2

Section II: Preventive Maintenance Checks

and Services (PMCS) 2-5

2-3 Purpose of PMCS 2-5

24 Frequency of Performing PMCS 2-5

2-5 Performance of PMCS 2-5

Section III: Assembly and Preparation 2-10

2-6 Preparation of Use 2-10

2-7 Installation of the Quick Disconnect

Helmet Mount Assembly 2-21

2-8 O perating Procedures 2-23

2-9 Preparation for Stowage 2-31

i

Page 7

CHAPTER 3: Maintenance Instructions 3-1

Section I: Troubleshooting Procedures 3-2

3-1 Troubleshooting 3-2

Section II: Maintenance Procedures 3-6

3-2 Cleaning the PVS-7 3-6

3-3 Head Mount Maintenance 3- 6

APPENDIX A : System Optional Equipment A-1

FOR TECHNICAL INFORMATION INFO -1

ii

Page 8

iii

Page 9

CHAPTER 1

INTRODUCTION

1-1

Page 10

SECTION I: GENERAL INFORMATION

1-1 SCOPE

This manual provides operation and maintenance instructions for

the PVS -7 Night Vision Goggle (which shall be designated a goggle or PVS-7 throughout this manual). The PVS-7 is a self-contained night vision device that enables improved night vision us-

ing ambient light from the night sky (moon, stars, sky glow, etc.).

1-2 REPORTING EQUIPMENT IMPROVEMENT

RECOMMENDATIONS (EIR)

Reports from the user on recommendations for improvements are

encouraged. Send reports to the address below:

American Technologies Network Corp.

1341 San Mateo Avenue

South San Francisco, CA 94080

(800) 910-2862

(650) 989-5100

(650) 875-0129 fax

www.atncorp.com

info@atncorp.com

1-3 GLOSSARY

BLACK SPOTS. These arc cosmetic blemishes in the image intensifier of the PVS-7 or dirt or debris between the lenses.

BRIGHT SPOTS. These can be defects in the image area produced by the PVS-7 . This condition is caused by a flaw in the film

on the micro-channel plate. A bright spot is a small, non-uniform,

bright area that may flicker or appear constant. Bright spots usually go away when the light is blocked out and arc cosmetic blemishes that are signal induced.

BROWPADS. Three hook-and-pile browpads are provided to adjust the head mount to fit different head sizes. The thin brow pad

(fits on a large head) comes attached to the head mount and the

thick or medium (fits on a smaller head) brow pads are stored in

the carrying case.

1-2

Page 11

CHICKEN WIRE. An irregular pattern of dark thin lines in the field

of view either throughout the image area or in parts of the image

area. Under the worst-case condition, these lines will form hexagonal or square wave-shaped lines.

DARK (OR DARK AREA). A place in which there is very little light.

It docs not mean total darkness. Generally, this means conditions

similar to a quarter- moon or starlit night.

DEMIST SHIELDS. The two demisting shields are used to prevent the eyepiece lenses from becoming fogged.

DIOPTER. A unit of measure used to define eye correction. Adjustments to the eyepiece focus ring will change diopter and provide a clearer image.

EDGE GLOW. There is a defect in the image area of the PVS-7.

Edge glow is a bright area ( sometimes sparkling) in the outer portion of the viewing area.

EMISSION POINT. A steady or fluctuating pinpoint of bright light

in the image area that does not go away when all light is blocked

from the objective lens. The position of an emission point within

the image area does not move. An emission point should not be

confused with a point light source in the distance.

FIXED-PATTERN NOISE. This is a cosmetic blemish in the im-

age area characterized by a faint hexagonal (honeycomb) pattern

throughout the viewing area that most often occurs at high light

level s or whe n vie wing ve r y bri g ht l ight s. F ixe d - pat t ern noise is i nherent in the structure of the fiber optics and can be seen in ever y

image intensifier if the light level is high enough.

FLASHING. This is a defect in the image area of the PVS-7 . The

image appears to flicker or flash.

FLICKERING. See “flashing”.

IMAGE-INTENSIFIER ASSEMBLY. An electro-optical device that

detects and amplifies ambient light to produce a visual image.

INFINITY FOCUS. Adjustment of the objective lens so that a distant object, such as a star or the point light on a distant tower,

forms the sharpest image

1-3

Page 12

INTERMITTENT OPERATION. This is a defect in the image area of

the PVS-7 . Sec “ flashing”.

LIGHT INTERFERENCE FILTER (LIF). This is a tear-protection fil-

ter for the goggle. Use of this filter will result in a slight reduction in

system gain.

MICROCHANNEL PLATE. A current-multiplying optical disk that

intensifies the electron image produced by the photocathode.

PHOTOCATHODE. The input optic of an image intensifier that absorbs light energy and in turn releases electrical energy in the form

of an electron image.

SACRIFICIAL WINDOW. A replaceable sacrificial window is supplied to protect the objective lens assembly during operation in adverse conditions.

SCINTILLATION. A faint, random, sparkling effect throughout the

image area. Scintillation is a normal characteristic of the image

intensifier assembly and should not be confused with emission

points. Scintillation is more pronounced under low-light conditions.

Also called “video noise”.

SHADING. The viewed image should be a full circle. If shading is

present, you will not see a fully circular image. Shading is indicative

of .i dying photocathode and is caused by a defective vacuum seal

of the im age inten sifier. Sh adi ng is ver y dar k an d you cann ot see an

image through it.

1-4 ADMINISTRATIVE STOWAGE

Administrative stowage of equipment should be done in the factory-supplied container and after a thorough PMCS as outlined in

Chapter 3 of this manual. This will ensure the PVS-7 remains in a

mission ready-condition during storage.

1-5 WARRANTY INFORMATION

This item shall conform to design, manufacturing, and performance

requirements and be free from defects in material and workmanship

for a period of two (2) years from the date of acceptance. If item is

defective, notify ATN or point of purchase contact.

1-4

Page 13

SECTION II: EQUIPMENT DESCRIPTION

1-5 EQUIPMENT CHARACTERISTICS,

CAPABILITIES AND FEATURES

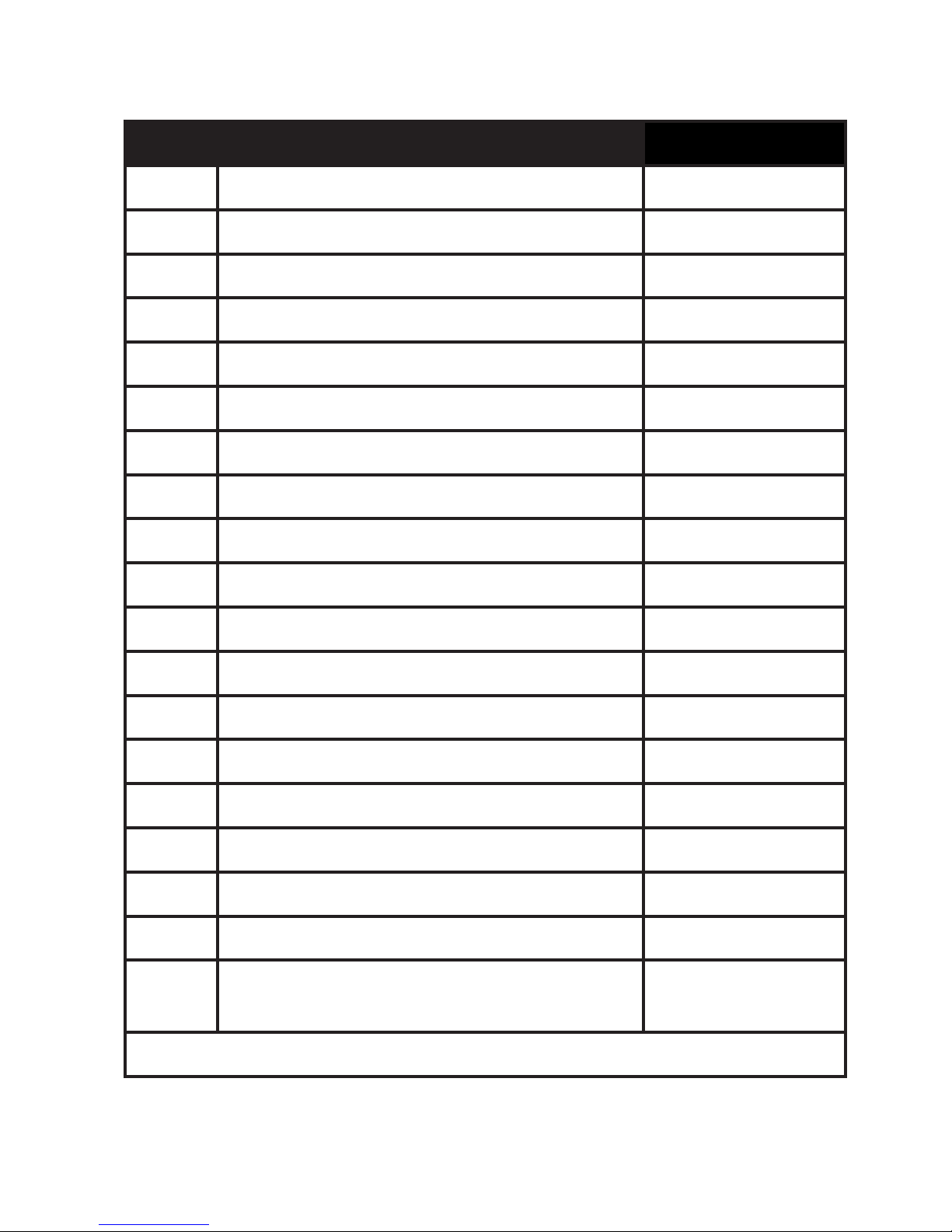

The PVS-7 includes the items shown in Figure 1-1. See Table 1-1 for

Standard Components and Figure 1-1 for Optional Equipment.

A. Goggle Assembly. The goggle assembly (see Figure 1-2) con-

sists of four primary sub-assemblies; a simple objective lens, a

wired housing assembly, an image intensifier tube (IIT) assembly

(not shown) and a rear cover assembly. The wired housing assem-

bly contains a built-in battery compartment, attached battery cap

and the RESET/OFF-ON-IR/PULL switch.

B. H ead m ount Ass e mbly. The adju stabl e, c ushi o ned h ead mount

assembly secures the goggle to the operator’s head for night viewing providing freehand support for use with a weapon, protective

mask or other purposes. The thin brow pad (used for larger heads)

comes attached to the head mount and the thick or medium brow

pads (for smaller heads) arc stored in the carrying case.

C. Carrying Case. The canvas carrying case is provided for transportation and protection of the PVS-7, head mount assembly, batteries and accessories. Two slide keepers arc provided for belt

attachment A carrying case strap is also provided which can be

attached to the two D-rings on the back of the carrying case. The

case has a zipper closure.

D. Demist Shields. The two demist shields are used to prevent the

eyepiece lenses from becoming fogged.

E. Sacrificial Window. A replaceable sacrificial window is supplied to protect the objective lens during operation in adverse conditions.

F. IR Spot/Flood Lens. This item focuses the IR light for a narrow

beam (spot) or wide-angle (flood) beam illumination.

1-5

Page 14

17*

1

18

16

15

12*

13

4

5

2

3*

6

11*

10

8

14

Figure 1-1. PVS-7 Components

1-6

9

Page 15

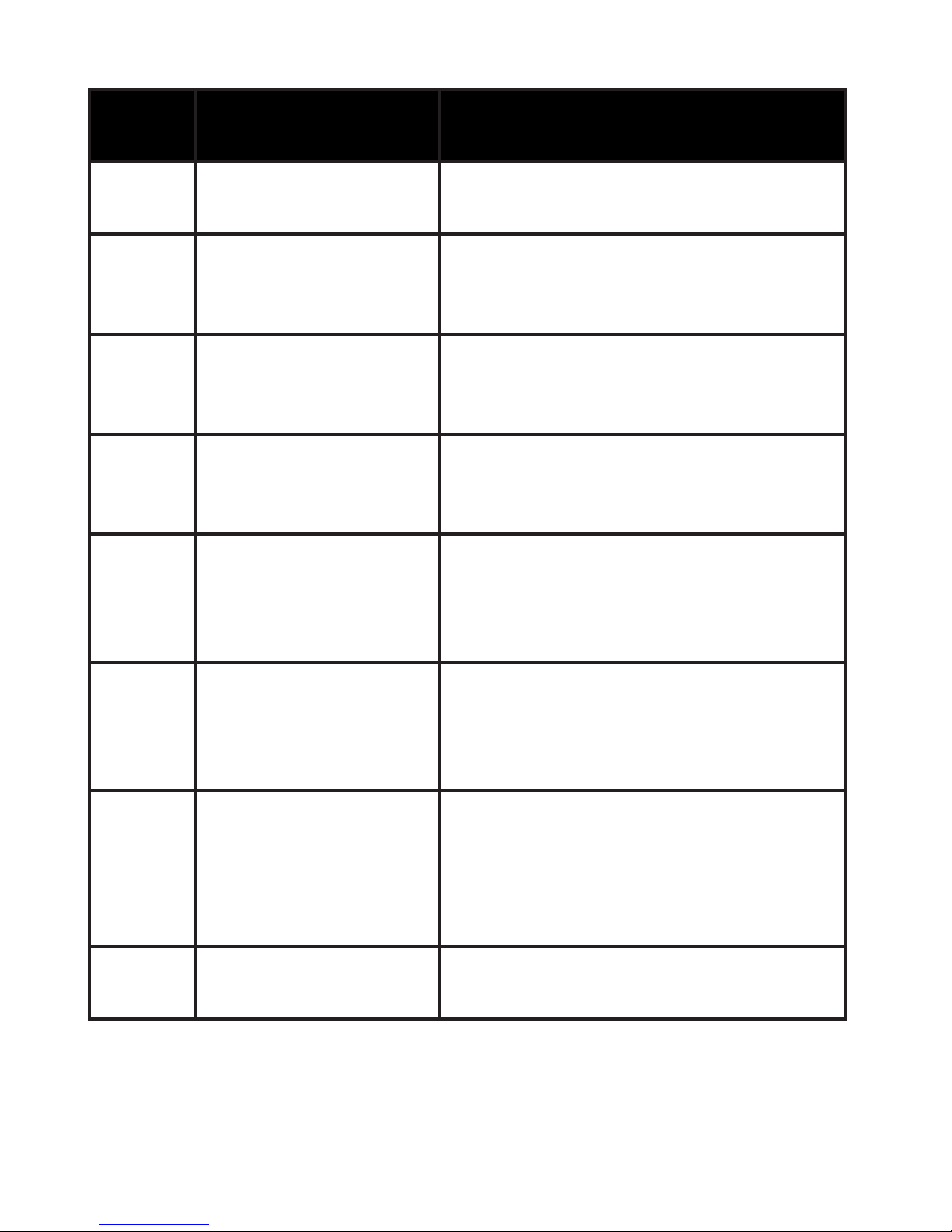

Table 1-1. System Components

ITEM DESCRIPTION PART NO.

1 Head mount Assembly ATN3144268

2 Thin Brow Pad ATN3144280

3* Compass ATN31874 30

4 Medium Brow Pad ATN3144435

5 Large Brow Pad ATN3144436

6 Operator’s Manual PVS-OM-007

7 Lens Paper (Not Shown) -

8 Shoulder Strap Assembly ATN3144267

9 Light Interference Filter ATN5009737

10 Sacrificial Window ATN3144264

11* IR Spot / Flood Lens ATN3187441

12* Image intensifier Tube

13 Demist Shield Assembly ATN31442632

14 PVS-7 Assembly ATN-PVS7-001

15 AA Alkaline Batteries B-3058/U

16 Carrying Case ATN31873 92

17* Helmet Mount Assembly ATN3256390

18 Neck Cord ATN3260933

19* Shipping/Storage Case

ATN31873 93

(Not Shown)

*Optional equipment or Equipment having variants

1-7

Page 16

G. Compass. This item enables the operator to see azimuth readings in the goggle’s illumination viewing area.

H. Neck Cord. This additional authorized item enables the user

to attach the compass or 3X magnifier lens to his/her self to guard

against dropping or losing these items

I. Optional Equipment. Optional equipment includes demist

shield s, s acr ifi c ial win dow. Lig ht Inter ference Filte r (LIF), com pass ,

helmet mount assembly and an IR spot/flood lens (see Figure 1-1).

Also included is a shipping and storage case. The PVS-7 may be

supplied in hard shipping and storage case. Batteries may also be

stored in the shipping and storage case.

1-6 EQUIPMENT CAPABILITIES

The PVS-7 is a hand-held, head mounted or helmet mounted night

vision system that enables walking, driving, weapon firing, shortrange surveillance, map reading, vehicle maintenance and administering first aid in both moonlight and starlight. Each unit allows for

vertical adjustment (by using head straps), fore-and-aft adjustment,

objective lens focus, eyepiece focus and eye relief distance adjust-

ment. The goggle also equipped with an infrared (IR) light-emitting

diode (or illuminator) and a low battery LED indicator. The goggle

automatically shuts off when disconnected from the head mount

or helmet mount or flipped up on the helmet mount. There is also a

high light cutoff feature that shuts off power to the goggle when it is

exposed to high levels of light for 70 (± 30) seconds.

1-7 SPECIFICATIONS

The following tables provide information pertaining to the operational, electrical, mechanical, optical and environmental characteristics for the goggles.

1-8

Page 17

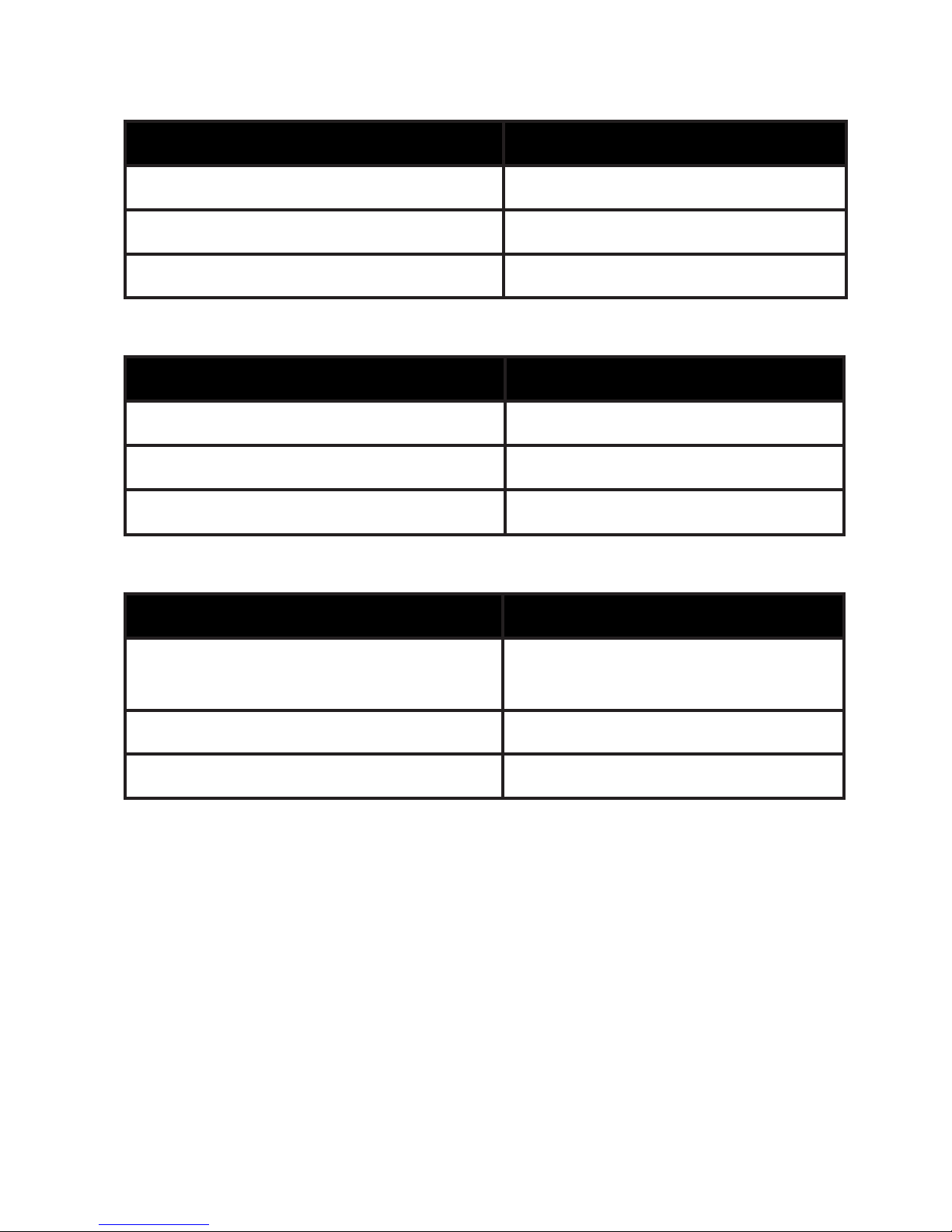

Table 1-2. Operator Adjustment Limits

ITEM LIMITS

Interpupillary Distance 55 to 71 mm

Diopter Focus +2 to -6 diopters

Objective Focus 25 cm to infinit y

Table 1-3. Electrical Data

ITEM LIMITS

Dower Source Battery (3 VDC ma x.)

Battery Requirements 2 AA Alkaline or

1 Lithium (BA-5567/ U)

Table 1-4. M echanical Data

ITEM LIMITS

Shipping and Storage Case Size: Approx. 17 ”x12 ”x7 ”

Weight: 6.7 lbs.

Soft Carrying Case Size: Approx. 14”x8 ”

Soggle (See NOTE) Weight 1.5 lbs

NOTE

The weight of the PVS-7 does not include accessories.

1-9

Page 18

Table 1-5. Optical Data

ITEM LIMITS

Magnification 1.0X

Field of View 40°

Eyepiece Focus +2 to -6 diopters

Focus Range 25 cm ( 9.8”) to infinity

Table 1-6. Environmental Data

ITEM LIMITS

Operating Temperature -40°C to +50°C

Storage Temperature -50°C to +70°C

Illumination Required Overcast starlight to moon-

light

Waterproof 1 meter for 30 min.

1-10

Page 19

SECTION III: OPERATION PRINCIPLES

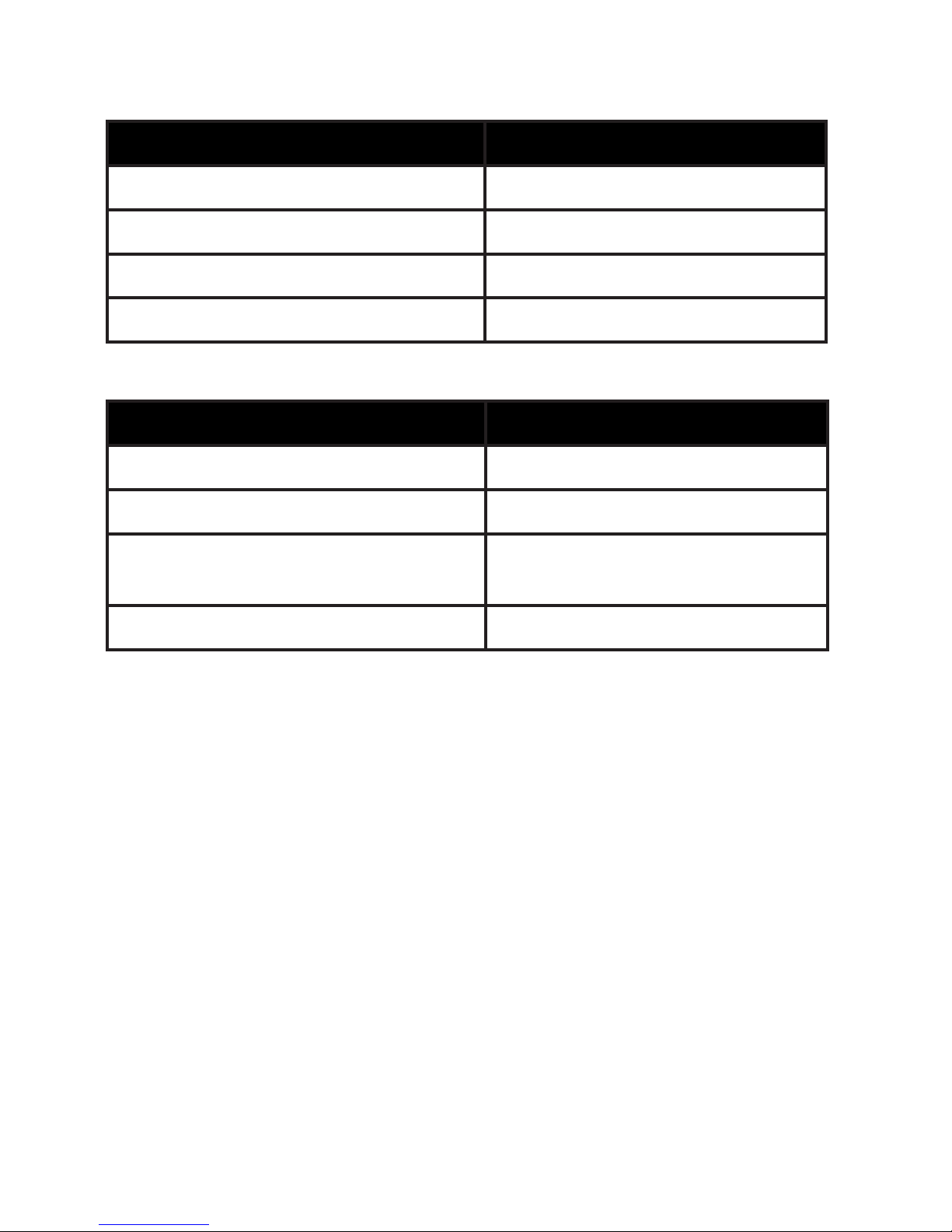

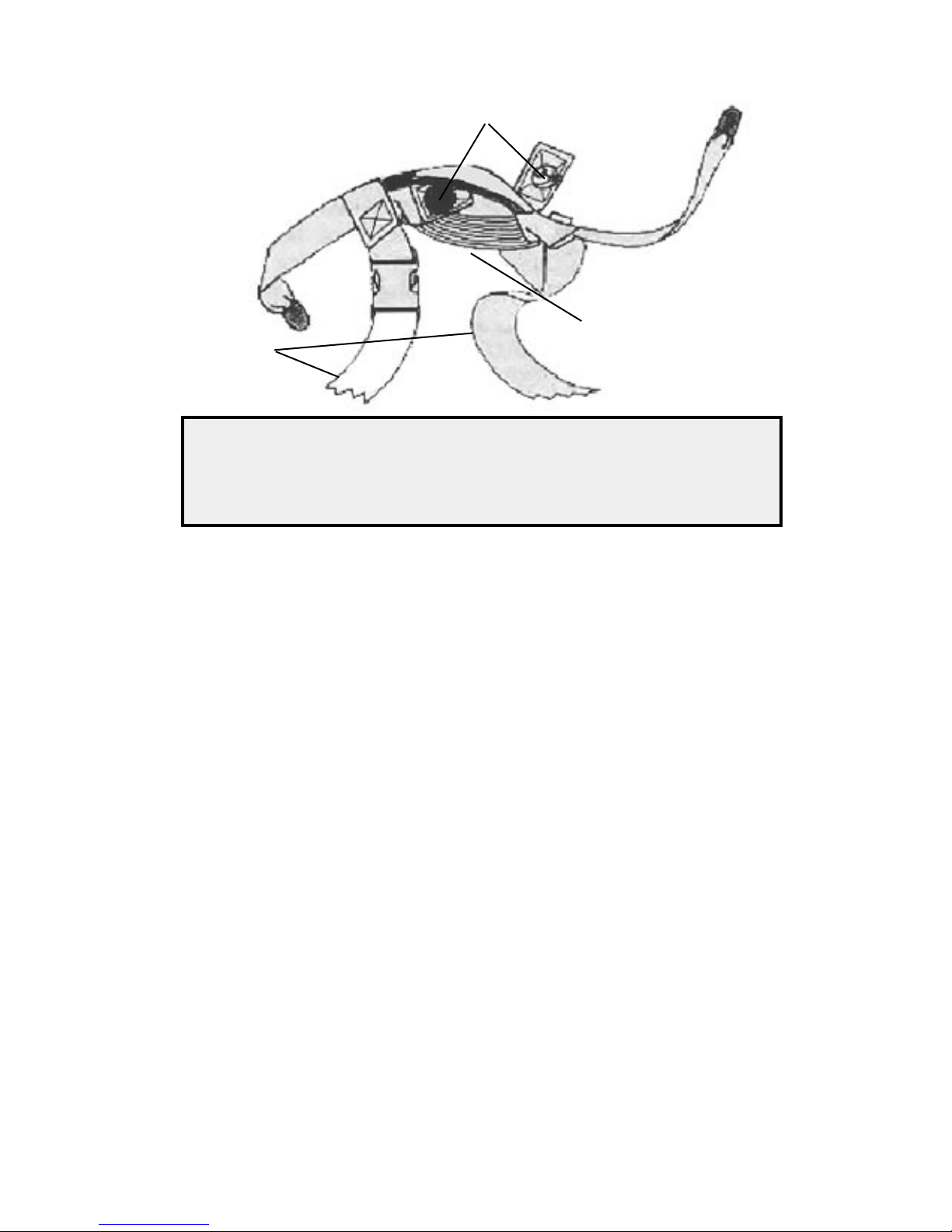

1-8 MECHANICAL FUNCTIONS

Mech anical ad j ustm e nts of t he PVS -7 al low for physical dif fere n ces

between individual operators using the system. The goggle’s functions include the power switch, interpupillary adjustment, release

latch, eye relief adjustment, diopter adjustment, IR spot/flood focus

(optional), compass illumination (optional), and objective lens focus. The mechanical controls are identified in Figure 1-2.

Latch

Eye

Objective

Lens Focus

Relief

Lens C ap

Knob

Interpupillary Adj.

Diopter

Adj. Ring

RESET/OFF-ON-

IR/PULL Swith

Knob

IR Spot / Flood Focus Knob

Compass

Illumination

Button

(underneath)

Figure 1-2. Mechanical Controls for PVS-7

1-11

Page 20

1-9 OPTICAL AND ELECTRICAL FUNCTIONS

The optical functions include an objective lens, image intensifier, a

collimator lens and two eyepieces. The objective lens collects light

reflected from the night scene by the moon, stars or night sky and

inverts the image and focuses that image on the image intensifier.

The electrical functions include the following.

A. Power Source. The electronic circuit is powered by replaceable

batteries - either a 3.0 Volt lithium battery (BA-5567/U) or two AA

1.5 Volt alkaline batteries (BA-3O5S / U).

B. Electrical Principles. Power from the batteries is supplied to

the components through the RESET/OFF-ON-IR/PULL switch as

follows:

RESET/OFF Position. With the switch in the OFF position, the circuit is not energized either to the image intensifier or the IR illuminator. Also, turn the switch to this position to reset after automatic

shutoff or high light cutoff.

ON Posi tio n. Power is drawn fr om the battery c omp artm ent to energize the goggle. When the voltage drops to 2.4 VDC, a low battery

indicator at the right eyepiece blinks indicating approximately 30

minutes of operating time.

IR /PULL Position. Power is drawn from the battery compartment to

energize the goggle and IR light source and a steady red indicator

light in the left eyep iec e. The IR is momentarily turned on by turn ing

the switch past ON without pulling the knob.

C. Automatic Shutoff. When the goggle is removed from the head

mount or helmet mount while in operation, they will automatically

shut off. This prevents enemy detection of the green glow of the

image intensifier. To turn the goggle back on, turn the switch to RESET/ OFF and then to ON again.

D. High Light Cutoff. The goggle will automatically shut off after

70 (±30) seconds of operation in daylight or bright room light. Individual bright lights (headlights, flashlights or other concentrated

light sources) will not actuate the high light cutoff function unless

focused directly on the high light detector located on the front of the

1-12

Page 21

goggle. To turn the goggle back on, turn the switch to RESET/OFF

position and then to ON again.

1-10 CONSUMABLE ITEMS

Items listed in the Table 1-7 are recommended for operator maintenance.

Table 1-7. Consumable Items

ITEM LIMITS

Lens Paper -

Color Swabs -

Alcohol -

1-13

Page 22

1-14

Page 23

CHAPTER 2

OPERATING INSTRUCTIONS

2-1

Page 24

SECTION I: OPERATING PROCEDURES

2-1 GENERAL

This section contains instructions for placing the PVS-7 in operation

and to operate it under normal conditions. The function of controls

and indicators is explained.

CAUTION

THE PVS-7 IS A PRECISION ELECTRO-OPTICAL INSTRUMENT

AND MUST BE HANDLED CAREFULLY AT ALL TIMES.

2-2 CONTROLS AND INDICATORS

The PVS-7 is designed to adjust for different users and corrects for

most differences in eyesight. The controls and indicators for the

PVS-7 are shown or described in Figure 2-1 and Tables 2-1 and

2-2.

7

6

5

3

4

Figure 2-1. PVS-7 Controls and Indicators

12

10

11

1

2

2-2

Page 25

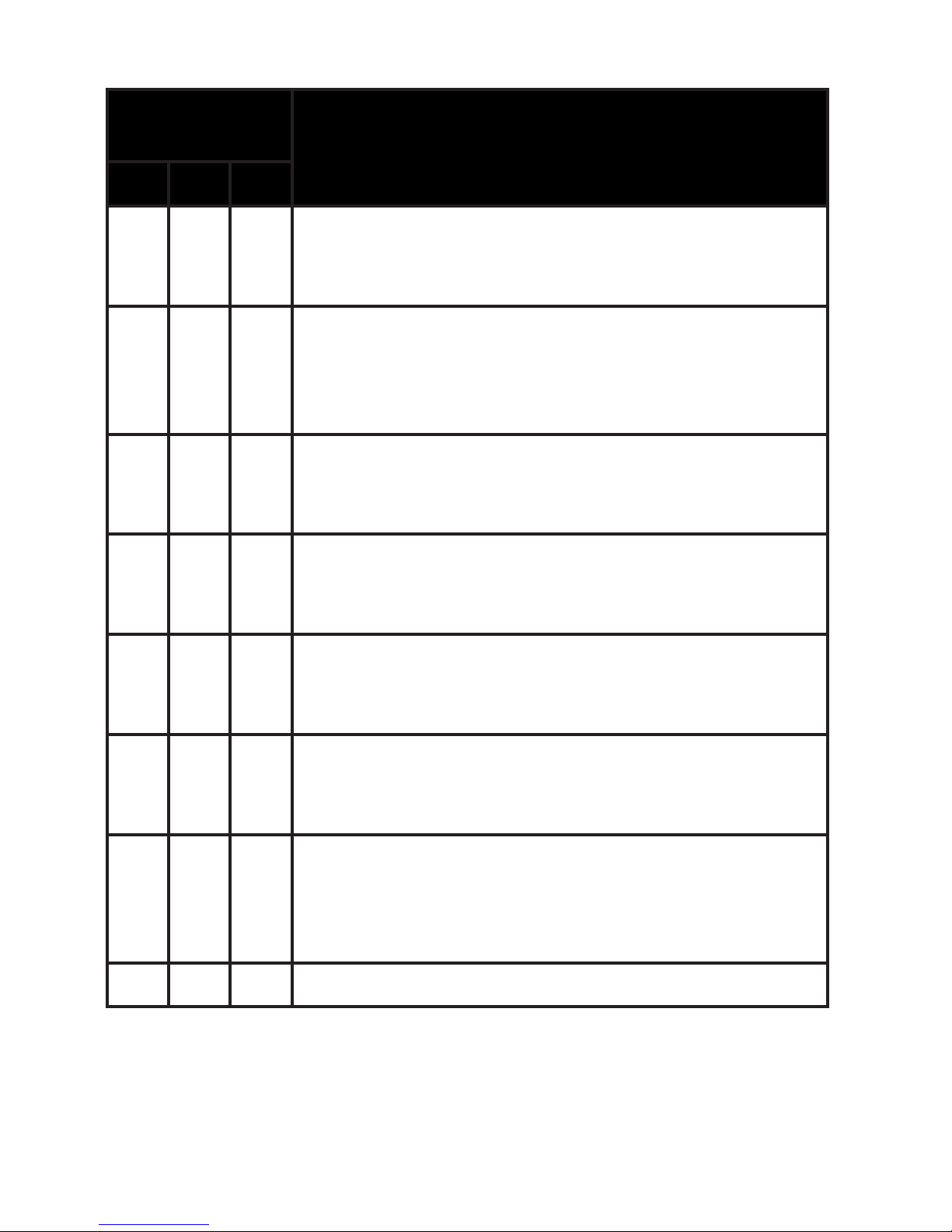

Table 2-1. Controls and Indicators

ITEMS CONTROLS AND

INDICATORS

1 RESET/OFF-ON-

IR/PULL

FUNCTIONS

Controls goggle and IR light power. ON or OFF.

RESET/ OFF S am e as system

OFF. Also resets goggle after automatic shutoff or highlight cutoff.

ON Goggle activated.

IR/PULL Pull switch out and turn

clockwise to activate goggle and

IR. Illuminates LED indicator in left

eyepiece.

NOTE

Some PVS-7’s contain an additional momentary IR function. For

momentary IR, continue to turn the switch knob clockwise, past

ON and without pulling. The switch will return to the ON position

when released.

2 RESET/OFF-ON-

Defines the switch positions.

IR/PULL Label

3 IR Spot / Flood Lens Focuses the IR light for a narrow

beam (spot) or wide angel (flood)

beam illumination.

4 Compass Illumina-

tor Button

Pressing this button activates the

compass illuminator LED which

makes compass readings visible

in the goggle viewing area. Additional pressure will make the

image brighter The image disappears when the button is released

2-3

Page 26

ITEMS CONTROLS AND

FUNCTIONS

INDICATORS

5 Objective Focus Focuses objective lens. Adjusts for

sharpest image of viewed object.

6 Battery Polarity In-

dicator

The feature, molded into the PVS7, shows the proper orientation of

the batteries.

7 Latch Latch used for separation of gog-

gle assembly from head mount/

helmet mount assembly.

8 LED On Indicator

(Not Shown)

When illuminated (left eyepiece)

it indicates that the IR illumination

is on.

9 Low Battery Indica-

tor (Not Shown)

When illuminated (right eyepiece)

it indicates a low battery condition

with less than 30 minutes of battery life remaining.

10 Diopter Adjustment

Focuses eyepiece lens for each

Ring

eye without the need for glasses.

Adjusts for sharper image of intensifier screen.

11 Interpupillary Ad-

justment

Adju sts for dis tance bet ween

eyes by sliding the eyepieces either together or apart so each eye

can observe the entire field at the

same time

12 Eye Relief Adjusts the distance between your

eyes and the goggle.

2-4

Page 27

SECTION II: PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

2-3 PURPOSE OF PMCS

PMCS is performed daily when the PVS-7 is in use to ensure that

the sight is ready at all times. Procedures are a systematic inspection of the goggle that will enable you to discover defects that might

cause the PVS -7 to fail on a mission.

2-4 FREQUENCY OF PERFORMING PMCS

The frequency of PMCS per forming PMCS is follows :

A. Daily when the PVS -7 is in use.

B. Weekly when in a standby condition.

C. Semi -an nually when stor e d in depo t or adminis trati ve sto w age.

2-5 PERFORMANCE OF PMCS

Preventive maintenance checks and services shall be performed

following the sequence and inspection procedures indicated in

Table 2-2

Table 2-2. Preventive Maintenance Checks and Services

B = Before Operation; D = During Operation; A = After Operation

IN TE RVA L &

SEQUENCE NO. ITEM TO BE INSPECTED/

PROCEDURE

B D A

1 GOGGLE - Check for completeness, includ-

ing accessories. Check for dirt and moisture

on external surfaces and parts. Clean and dry

with lint-free cloth.

2 SHIPPING CASE - Check for dirt, moisture

and mil d ew. C lean wit h mi l d de ter g ent and water. Dry with lint-free cloth.

2-5

Page 28

IN TE RVA L &

SEQUENCE NO. ITEM TO BE INSPECTED/

PROCEDURE

B D A

3 CARRYING CASE - Check for dirt, moisture

and mil d ew. C lean wit h mi l d de ter g ent and water. Dry with lint-free cloth.

4 BATTERIES - Remove batteries. Check for

corrosion on terminals and dirt or moisture in

battery cap. Clean battery cap with dry cloth.

Replace batteries if corroded.

5 LENSES - Check for dirt and moisture. Clean

with lens paper or brush and/or alcohol and

cot ton swabs

6 EYECUPS - Check for dirt, dust, cracked or

torn cups. Inspect for bent, broken or improperly fitting eyecup.

7 INTERPUPILLARY ADJUSTMENT - Slide

each eyepiece back and forth to check for

binding or looseness.

8 OBJECTIVE LENS FOCUS KNOB - Rotate

obj e c tive le n s fo c us k n ob to ens ure fre e move-

ment (range is approximately 1/3 turn).

9 NECK CORD & LENS CAP- Check for cracked,

torn or missing lens cap. Inspect cord for cuts,

damage or frayed ends. Re-tie ends if necessary.

10 LATCH - Inspect for damage.

2-6

Page 29

IN TE RVA L &

SEQUENCE NO. ITEM TO BE INSPECTED/

PROCEDURE

B D A

11 RESET/OFF-ON-IR/PULL SWITCH - Remove

any batteries and turn the switch from RESET/

OFF to ON or IR/PULL. Each position should

have a definite stopping point. Inspect for broken or missing knob.

HEAD MOUNT

12 STRAPS AND PADS - Check for cuts tears,

fraying, holes, cracks or defective fasteners.

13 SOCKET - Check for dirt, dust or corrosion.

Insert goggle latch into socket to verify secure

attachment of goggle to head mount. If necessar y, clean socket with water.

14 FORE-AND-AFT ADJUSTMENT - Press the

socket-release button and check for free motion. Inspect for damage.

OPTIONAL HELMET MOUNT

15 STRAPS - Inspect for cuts; tears: fraying;

holes cracks or defective fasteners

13 SOCKET - Check for dirt, dust or corrosion.

Insert goggle latch into socket to verify secure

attachment of goggle helmet mount. If necessar y, clean socket with water.

17 FORE-AND-AFT ADJUSTMENT - Press the

socket-release button and check for free motion. Inspect for damage.

18 FLIP-UP/AUTO OFF - With goggle on, flip-up

and verify auto off function operation.

2-7

Page 30

IN TE RVA L &

SEQUENCE NO. ITEM TO BE INSPECTED/

PROCEDURE

B D A

19 TILT ADJUSTMENT - Verify knob locks tilt in

place and full range of tilt is available with knob

loosened.

20 SOFT CARRYING CASE - Remove all items

an d sh ake ou t lo ose dir t o r fore ign mat eri al. In spect for tears, cuts, excess wear or damage

to mounting clips.

21 SHOULDER STRAP ASSEMBLY - Inspect for

cuts, tears or excess wear of damaged clips.

NOTE

Damaged optional items (compass, IR spo/flood, sacrificial

window, demist shields) do not cause the entire end item to

be “not fully mission capable”. However, the damaged item

should be replaced as soon as practical to restore full capability of the system.

ACCESSORY ITEMS

11 DEMIST SHIELDS - Inspect for dirt, dust

scratches or damage. If necessary, clean

when shields are dry and with dry lens paper

only.

23 LIGHT INTERFERENCE FILTER (LIF) - In-

spect for dirt dust, scratches or damage. If

necessary, clean with water and dry with lens

paper.

24 IR SPOT/FLOOD LENS - Rotate IR focus lens

to ensure free movement.

2-8

Page 31

IN TE RVA L &

SEQUENCE NO. ITEM TO BE INSPECTED/

PROCEDURE

B D A

25 COMPASS ASSEMBLY - Inspect for dirt, dust

scratches or damage. If necessary, clean with

water and dr y with lens paper.

Install compass assembly and turn on goggle.

When the illumination button is depressed, the

compass should be visible.

26 3X/5X AFOCAL MAGNIFIER LENS - Check

lens for scratches or damage. Check mating

to objective lens by screwing in or pressing on

with adapter installed.

2-9

Page 32

SECTION III: ASSEMBLY AND

PREPARATION

2-6 PREPARATION FOR USE

This chapter contains the information necessary to prepare the

goggle for operation. This includes unpacking, examination for

goggle damage, battery installation, sacrificial window installation

and head mount installation and adjustments.

A. Unpacking. The following steps must be accomplished prior to

each mission where the PVS -7 is used.

CAUTION

RELIEVE AIR PRESSURE INSIDE SHIPPING AND STORAGE CASE BY PRESSING RELIEF VALVE BUTTON LOCATED

NEAR THE CARRYING CASE HANDLE BEFORE RELEASING

LATCHES.

1. Release the two latches securing top of shipping and storage

case and open top.

2. Check contents of shipping and storage case for completeness.

(see Figure 1-1.)

3. Remove the carrying case from the shipping and storage case.

Ope n c arr ying cas e ( Figure 1-1) , remove th e PVS -7 and che c k c ontents for completeness.

4. Inspect the goggle for obvious evidence of damage to optical

surfaces, body, eyecups. RESET/OFF-ON-IR/PULL switch, battery cap, etc. Ensure that all optical surfaces are clean and ready for

use. Clean with lens paper.

B. Installation of Batteries.

CAUTION

TO PROTECT THE IMAGE INTENSIFIED KEEP THE LENS CAP

ON THE OBJECTIVE LENS WHEN THE GOGGLE IS NOT IN USE

OR WHEN CHECKED OUT IN DAYLIGHT CONDITIONS.

NOTE

Operation of the PVS-7 under daylight conditions will activate the high

light cut off in 70 (±30) seconds, causing the goggle to shutdown.

2-10

Page 33

WARNING

THE LITHIUM BATTERY CONTAINS SULFUR DIOXIDE GAS

UNDER PRESSURE.

DO NOT HEAT, PUNCTURE, DISASSEMBLE, SHORT CIRCUIT,

ATTEMPT TO RECHARGE OR OTHERWISE TAMPER WITH THE

BATTERIES.

TU R N O FF EQ UI PM ENT IF BAT TE RY C OM PA RTM ENT B EC OM ES

UNDULY HOT. IF POSSIBLE, WAIT UNTIL THE BATTERIES HAVE

COOLED BEFORE REMOVING THEM.

BATTERIES HAVE SAFETY VENTS TO PREVENT EXPLOSION.

WHEN THEY ARE VENTING GAS, YOU WILL SMELL IT (VERYIRRITATING) OR HEAR THE SOUND OF GAS ESCAPING. WHEN

THE SAFETY VENTS HAVE OPERATED, THE BATTERIES ARE

FAIRLY SAFE FROM BURSTING, BUT STILL MUST BE HANDLED

WITH EXTREME CARE BECAUSE OF HEAT.

IF YOU INHALE SULFUR DIOXIDE, SEEK MEDICAL ATTENTION.

The PVS-7 will oper ate wit h eit her of t he t wo b atte r y t ypes iden tifi e d

in Table 2-3. Batteries are not supplied with the PVS-7 and must be

obtained.

Table 2- 3. Estimated Batter y Life

BATTERY TYPE NEGLIGIBLE

IR USAGE

IR USAGE 10%

OF THE TIME

Lithium (BA-5567/U) 47- 85 Hours 36 - 65 Hours

AA Alkaline (BA-3058/U) 89 -160 Hours 68 - 123 Hours

NOTE

The battery data in Table 2-3 represents operation under room temperature. When operating under cooler conditions, battery life will

decrease.

CAUTION

MAKE CERTAIN THE RESET/OFF-ON-IR/PULL SWITCH IS IN

THE OFF POSITION BEFORE INSTALLING BATTERIES.

Install either two (2) AA batteries or one (1) BA-5567/U lithium battery as follows. Do not attempt to mix battery types in the compartment.

2-11

Page 34

1. Remove the battery cap by turning it counterclock wise.

2. Check to ensure the o-ring is present. If not, replace it.

3. Observe polarity, as indicated on the outside of the batter y compartment, and insert either two AA, 1.5 Volt batteries or one 3.0 Volt

BA-5567/U lithium battery into the battery compartment, plus (+)

end first. (Sec Figure 2-2.)

4. Replace battery cap by pushing and turning it clockwise. Tighten

it firmly to ensure a watertight seal.

C. Installation of the Eyecups. Perform the following procedure to

install the eyecups onto the PVS-7. Refer to Figure 2-2.

1. Carefully press each eyecup over the diopter cell retainer.

2. Rotate each eyecup into proper viewing position. Adjust for best

eye fit. The eyecups must seal around your eyes and prevent the

green glow from escaping.

Alkaline

Batteries

(size AA)

Lithium

Battery

Bat ter y Cup

with O - ring

Eyecup

Figure 2-2. Bat tery and Eye cap Istallation

2-12

Page 35

Compass

Figure 2-3. Installation of Demist Shields, Sacrificial

Demist

Shields

IR Spot / Flood Lens

Sacrificial

Window

LIF

Window

D. Installation of the Demist Shields. Perform the following pro-

cedure to install the demist shields on the diopter lenses. Refer to

Figure 2-3.

CAUTION

IF THE DEMISTING SHIELDS NEED TO BE CLEANED, MAKE

SURE THE SHIELDS ARE DRY AND USE DRY LENS PAPER. IF

THE DEMIST SHIELDS ARE WIPED WHILE WET OR WITH WET

LENS PAPER, YOU WILL DAMAGE THE COATING.

NOTE

If inclement operating conditions are known to exist (e.g. significant

te mperature c han ge a nd h igh humi d ity), i nst all the dem ist s hie lds to

minimize diopter lens fog prior to execution of mission.

1. Carefully remove the eyecups.

2. Carefully press a demist shield onto each eyepiece. Be careful

not to smudge the eyepieces or demist shields.

3. Replace the eyecups (see paragraph 2-6, C).

2-13

Page 36

E. Installation of the sacrificial Window. Perform the following

procedure to install the sacrificial window. Refer to Figure 2-3.

CAUTION

IF ADVERSE OPERATING CONDITIONS (DUST OR SAND),

ARE KNOWN TO EXIST, ATTACH THE SACRIFICIAL WINDOW

TO PROTECT THE OBJECTIVE LENS FROM SCRATCHES OR

OTHER DAMAGE.

1. If the compass assembly or lens cap is in place, remove it.

2. Carefully push the sacrificial window over the objective lens until it stops. Turn the sacrificial window clockwise until it snaps into

place.

F. Installation of the Compass Assembly.

Figure 2-4. Installation of Compass

NOTE

a. Prepare the PVS-7 for operation (paragraph 2-6).

b. Leave LIF in place when installing the compass assembly.

c. Ensure the Neck cord is secured to the compass and clothing

before installing.

1. If the sacrificial window or lens cap is in place, remove it.

2. Turn the PVS-7 on.

3. Rotate the objective lens focus completely counterclockwise

(while looking through the goggle).

2-14

Page 37

4. Press the compass assembly onto the objective lens at an angle

using your left hand. Slowly turn the compass assembly counterclockwise until it is in the vertical position (with compass illumination but ton pointing down). See Figure 2-3.

5. Ensure that the compass fits tightly to the PVS -7.

NOTE

The o-ring must be in place in the compass assembly in order for

the compass to fit properly.

6. Refer to paragraph 2- 6, F for operation of the compass.

G. Installation of the Light Interference Filter. Perform the fol-

lowing procedure to install the light interference filter (LIF) onto the

objective lens assembly.

Figure 2-5. Installation of the Light Interference Filter

1. Remove the container/wrench from the carrying case pouch.).

2. If the lens cap, compass assembly, or sacrificial window is on the

objective lens of the PVS-7, remove it.

3. Carefully open the container/wrench and remove the LIF.

4. Hold the LIF by the notched end and thread it clockwise into the

end of the objective lens (see Figure 2- 5) .

5. Using the ridged side of the container/wrench as a wrench, engage the ridges on the container with the ridges on the LIF and

tighten the LIF hand tight.

6. Plac e th e empt y container /wrench ba ck int o t he pouc h in th e carrying case.

2-15

Page 38

7. Replace the lens cap or the sacrificial window onto the end of the

objective lens and over the LIF.

CAUTION

BE CAREFUL NOT TO TOUCH THE GLASS SURFACES. IF YOU

GET FINGERPRINTS OR CONTAMINATION ON THE GLASS

SURFACES, USE LENS PAPER TO CLEAN THE LIF. IF MOISTURE IS NEEDED, USE YOUR BREATH TO MIST THE SURFACE

OF THE GLASS.

DO NOT OVER-TIGHTEN THE LIF INTO THE OBJECTIVE LENS.

NOTE

The lens cap, compass assembly, or the sacrificial window will fit

onto the end of the objective lens with the LIF in place.

H. Installation of the IR Spot / Flood Lens.

1. Press the IR spot/flood lens over the IR source until it is tight

against the goggle. Refer to Figure 2- 6.

Figure 2-6. Installation of the IR Spot / Flood Lens

I. Installation and Adjustment of the Head Mount Assembly.

Perform the following procedures for donning the head mount.

NOTE

Do not don the head mount while the PVS-7 is attached to it.

2-16

Page 39

Headband

Socket

Assembly

Browpad

Neckpad

Socket

Release

Button

Chin Cup

Sliding Bar

Buckles

Chin Strap

Adjustment

Figure 2-7. PVS-7 Head Mount Adjustments

1. Prior to donning the head mount, loosen the four chin straps so

the ends of each strap arc approximately two inches from the slid-

ing bar buckles (See Figure 2-7)

2. Snap the front and rear snaps in place.

NOTE

If the head mount is too loose, remove the attached thin brow pad

and replace with either the medium or large brow pad, stored in the

carrying case. Refer to Chapter 3, paragraph 3-4 for removal and

replacement of the brow pads.

3. With both hands, grasp the neck pad assembly and pull the harness over your head and the neck pad down to the back of your neck.

2-17

Page 40

4. Holding th e c hin cu p in posi tio n o n c hin, adj ust both re ar chin cup

assembly straps until you feel light pressure against your chin. (DO

NOT TIGHTEN).

5. Maintain the position of the chin cup and remove any slack from

the front and rear chin straps. (DO NOT TIGHTEN).

6. Ensure that the cross-strap assembly is not twisted and remove

slack by adjusting the vertical adjustment strap at the neck pad.

7. Adjust chin strap and vertical adjustment until the chin cup and

headband assembly arc in comfortable but firm position.

NOTE

After installing the PVS-7, minor strap adjustments may be necessary to achieve comfort.

8. Refer to paragraph 2-7, A for operating procedures of head mount

assembly.

J. Installation of Head Mount Assembly with Protective Mask.

Perform the following procedures for donning the head mount with

a protective mask.

1. Place protective mask on your head per the instructions provided

with the mask.

WARNING

WHEN INSTALLING THE HEAD MOUNT OVER THE PROTECTIVE

MASK, BE CAREFUL NOT TO BREAK THE PROTECTIVE MASK

SEAL AROUND YOUR FACE.

2. Install the head mount assembly per instructions in paragraph

2-6, I.

NOTE

It may be necessary to remove the brow pad when wearing the head

mount over a protective mask.

K. Installation of the Head Mount Assembly with the PASGT

Helmet. Install the head mount assembly per the instructions in

paragraph 2-6, I.

L. Installation of the Head Mount Assembly with the M1 Helmet.

Install the head mount assembly per the instructions in paragraph

2-6. I.

2-18

Page 41

M. Installation of th e Helm et Mount As sembly ( O ptional) to th e

PASGT Helmet.

1. Remove mount as sembly from the carr ying case. Refer to Figure

2-5 for the helmet mount features.

Catch

Helmet

Strap

Tilt

Adjustment

Buckle

Lever

Side

Button

Socket

Front Bracket

Rear

Bracket

Figure 2-8. Helmet Mount Features

2. With the catch in forward most position, place the strap over the

top of the helmet, center and hook the rear bracket onto the rear

of the helmet. Center the front bracket, hook in on the front of the

helmet and hold it in place. (See Figure 2-8.)

3. With the buckle-lever open, take up the slack in the strap using

catch. Close the buckle lever.

4. Place the helmet upside down with the helmet mount facing you.

NOTE

Steps 5 and 6 describe the installation of the nape strap to the chinstrap. To accomplish these steps, it may he necessary to unthread

the chinstrap from the helmet.

5. Thread the chinstrap through the right end of nape strap and

snap nape strap fastener tab closed. (Refer to Figure 2-9.)

6. Thread chin strap through the left end of nape strap and snap

nape strap fastener tab closed. (Refer to Figure 2- 9.).

2-19

Page 42

Nape Strap Fastener Tabs

Nape

Straps

Loop the nape strap fastener tabs around the corners

of the chin strap and snap closed. After closure, the

snaps will be on the outside, away from your chin.

Chin Strap

Figure 2-9. Nape Strap Installation

7. Disengage the nape strap latch on the lef t side of the nape strap.

8. Don the helmet.

9. Engage the nape strap at the nape strap latch. Tension the chinstrap and nape strap for a secure and stable fit. The brow of the

helmet should be parallel with the ground.

2-7 INSTALLATION OF THE QUICK DISCONNECT

HELMET MOUNT ASSEMBLY

1. Remove the helmet mount assembly from the carrying case.

Make sure the helmet mount is complete. Refer to Figure 2-7 for the

helmet mount components and features.

CAUTION

TO PREVENT POSSIBLE EQUIPMENT DAMAGE, REMOVE

BOTH THE GOGGLES AND THE MOUNT ASSEMBLY FROM

THE HELMET WHEN NOT REQUIRED FOR IMMEDIATE USE.

THE CLIP/STRAP ASSEMBLY CAN REMAIN IN PLACE ON THE

HELMET.

2-20

Page 43

2. If the mount assembly and clip/strap assembly are connected,

remove the mount assembly. To do this, push the release lever at

the top center of the mount and slide the t wo assemblies apart.

3. Adjust the clip / strap assembly to fit the helmet size being used.

4. With the catch in the most extended position, place the strap over

the top of the helmet, center and hook the rear bracket onto the

rear of the helmet. Center the front bracket hook on the front of the

helmet and hold it in place.

5. With the buckle lever open, take up the slack in the clip/strap assembly using the catch. Close the buckle lever.

6. If the PASGT helmet has its cloth cover and camouflage strap

installed, it will be necessary to slide the camouflage strap up (at

about a 30°-45° angle) at the front of the helmet (see Figure 2-7).

Helmet

Mounting

Clip

Tilt

Adjustment

Socket

Release Lever

Figure 2-10. Quick Disconnect Helmet Mount Features

7. Disengage the nape strap latch on the lef t side of the nape strap.

8. Don the helmet. Do not fasten the helmet chinstrap.

9. Engage the nape strap at the nape strap latch. Tension the nape

strap for a stable fit, then install and tension the helmet chin-strap.

The brow of the helmet should be parallel to the ground and the

helmet stable on the head.

10. To install the mount assembly into the clip/strap assembly,

place its top flange to the top groove of the mounting clip and then

2-21

Page 44

press to the mount assembly bottom until it locks into place with a

click (see Figure 2-7).

2-8 OPERATING PROCEDURES

This section contains operating procedures for using the PVS-7 as

a hand-held, head mounted or helmet mounted goggle. Prior to operating the goggle, ensure that all the steps in paragraph 2-6 have

been read and performed.

A. Head Mounted Operation. Perform the following procedures

for head mounted operation.

CAUTION

OPERATE THE PVS-7 ONLY UNDER DARKENED CONDITIONS

OR USE THE LENS CAP TO COVER THE OBJECTIVE LENS FOR

DAYLIGHT CONDITIONS.

NOTE

Proper objective focus cannot be obtained while the objective

lens cap with pinhole is covering the objective lens. Proper objective focus must be done in the dark with the objective lens cover

removed.

1. Ensure that the batteries are installed per paragraph 2-6, B.

2. Don the head mount per instructions in paragraph 2- 6, I.

NOTE

Paragraphs 2-6, J, 2-6, K and 2-6, L provide additional information

required when installing the head mount with a protective mask,

PASGT or M1 helmet.

To make it easier to align the goggle, eyecups and diopter eyepiec-

es to the eyes, depress the socket-release button (See Figure 2-4)

and slide the head mount socket all the way forward before attaching the goggles.

3. Align the PVS-7 ‘s latch (Figure 2-1) to the head mount socket

(See Figure 2-4). Press and hold down the latch lever while install-

ing the goggle into the head mount socket. Release the latch when

the goggle is fully engaged in the socket.

2-22

Page 45

4. Set your eye relief by depressing the socket-release button and

move the PVS-7 back toward your eyes until the eyecups comfortably seal around your eyes.

5. Turn the RESET/OFF-ON-IR / PULL switch ON.

6. Adjust the interpupillary distance (Figure 2-1) by sliding the eyepieces together or apart so each eye can observe the entire field of

view at the same time. The eyepieces adjust independently.

7. Readjust the vertical strap assembly (see Figure 2-4) for vertical

adjustment of the head mount until the PVS-7 is properly aligned

with your eyes.

NOTE

The sharpest image will be observed only when the objective lens

and both eyepieces are properly focused. The objective lens focus adjustment is used to focus on objects at varying distances.

The diopter adjustment rings are used to focus your eyes (without

glasses) on the image intensifier screen. These adjustments operate independently and must be made separately.

8. Fold the right eyecup over the eyepiece with your right thumb or

forefinger to obstruct the view through the right eyepiece. Rotate

the left diopter adjustment ring for the clearest view of the image

intensifier screen.

9. Fold the left eyecup over the eyepiece with your left thumb or

forefinger to obstruct the view through the left eyepiece. Rotate the

right diopter adjustment ring for the clearest view on the image intensifier screen.

10. Adjust the eye relief distance by pressing the socket release

button (See Figure 2-4) and sliding the PVS-7 fore or aft to obtain

a full field of view of the image. Readjust the diopter rings for best

image.

NOTE

Any readjustment of eye relief requires readjustment of the diopter

rings.

11. Adjust the objective lens focus (Figure 2-1) while observing an

object until the sharpest image is obtained.

2-23

Page 46

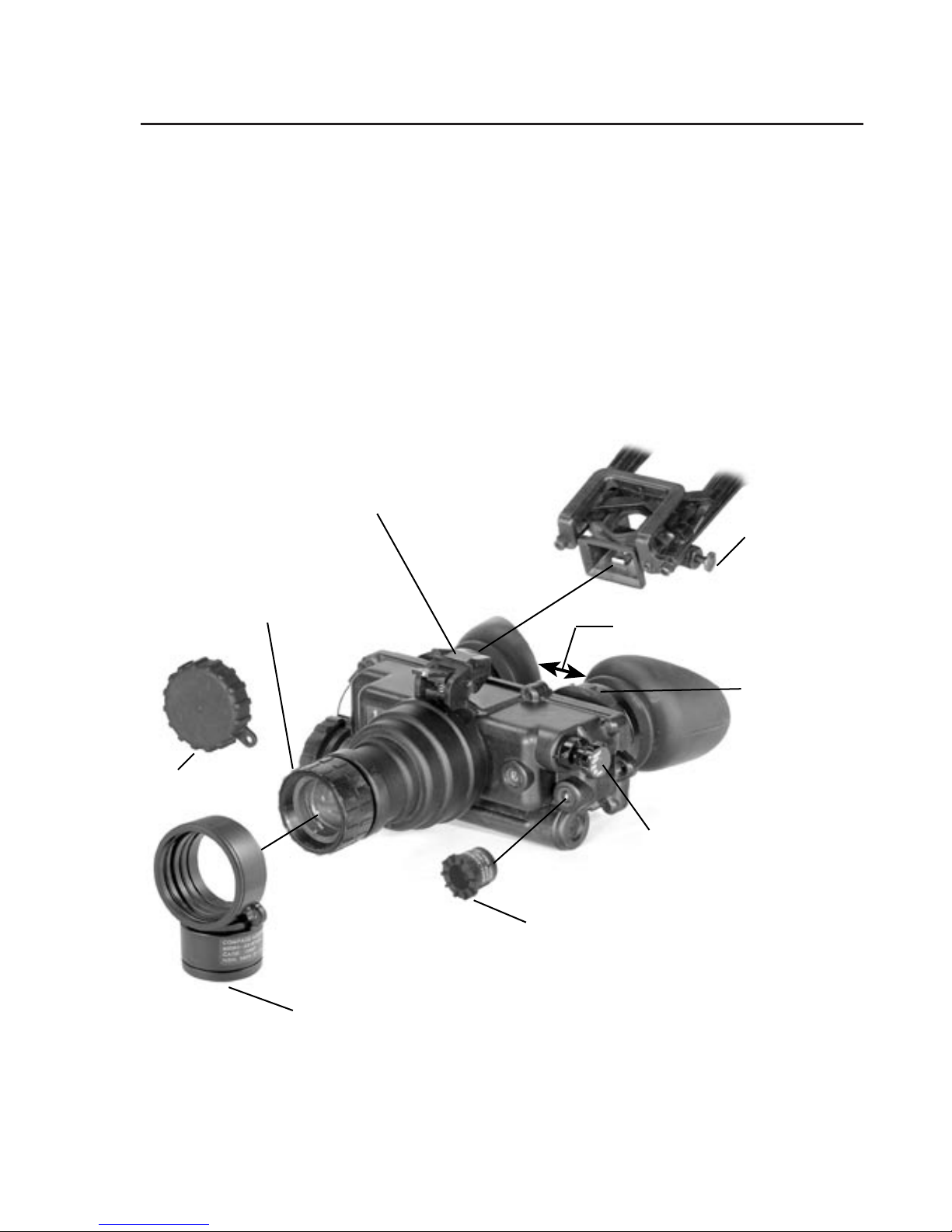

B. Helmet Mounted Operation. Perform the following procedures

for helmet mounted operation.

1. Ensure that batteries are installed per paragraph 2- 6, B.

2. Don the helmet mount per instructions in paragraph 2- 6. M.

3. Place the PVS-7 in the socket of the helmet mount. (See Figure

2-4.) Set your eye relief by depressing the side buttons and carefully move the goggles fore or aft until the eyecups comfortably seal

around t he eyes . R eadjust the helmet stra ps as requir ed for ver tical

adjustment.

4. Turn power switch to ON. Adjust the tilt by using the tilt adjust-

ment lock knob (Figure 2-4) until you obtain a comfortable viewing

angle.

5. Adjust the interpupillary distance (Figure 2-1) by sliding the eyepieces together or apart so each eye can observe the entire field

of view at the same time. The eyepieces adjust independently. If

necessary, readjust the eye relief.

Helmet

Release Lever

Figure 2-11. Quick Disconnect Helmet Mount Features

NOTE

Mounting

Clip

Tilt

Adjustment

Socket

The sharpest image will be observed only when the objective lens

and both eyepieces are properly focused. The objective focus

adjustment is used to focus on objects at varying distances. The

diopter adjustment rings are used to focus your eyes (with or with-

2-24

Page 47

out glasses) on the image intensifier screen. These adjustments

operate independently and must be made separately.

6. Fold the right eyecup over the eyepiece with your right thumb or

forefinger to obstruct view through the right eyepiece. Rotate the

left diopter adjustment ring for the clearest view on the image intensifier screen.

7. Fold the left eyecup over the eyepiece with your left thumb or

forefinger to obstruct view through the left eyepiece. Rotate the

right diopter adjustment ring for the clearest view on the image intensifier screen.

K. Adjust the eye relief distanc e by pressing the socket release but-

ton (see Figures 2- 4, 2-5) and sliding the PVS-7 fore or aft to obtain

a full field of view of the image. Readjust the diopter rings for the

best image.

NOTE

Any readjustment of eye relief requires readjustment of the diopter

rings.

9. Adjust the objective lens focus (Figure 2-1) while observing an

object until the sharpest image is obtained.

10. To flip up, place an open hand under the goggle, grasp the goggle and rotate up and rearward until the latch is firmly engaged.

NOTE

The PVS-7 will be turned off automatically when flipped up. The

PVS-7 will not turn on automatically when flipped down.

11. To flip down, grasp the goggle housing and rotate down and

forward until the latch is firmly engaged.

12. Turn t he s witc h to the RES ET/ OFF posi t ion, the n to the O N po s i tion to resume viewing.

C. Hand-Held Operation

CAUTION

OPERATE THE PVS-7 UNDER DARKENED CONDITIONS ONLY

OR USE HE LENS CAP TO COVER THE OBJECTIVE LENS FOR

DAYLIGHT CONDITIONS.

2-25

Page 48

NOTE

When using the PVS-7 without a mounting device, make sure to

place the neck cord around your neck.

1. Ensure that the batteries are installed per paragraph 2-6, B.

2. Turn the RESET/0FF- ON -IR/PULL switch to ON.

3. Adjust the interpupillary distance (Figure 2-1) by sliding the eyepieces together or apart so each eye can observe the entire field of

view at the same time. The eyepieces adjust independently.

NOTE

The sharpest image will be observed only when the objective lens

and both eyepieces are properly focused. The objective focus

adjustment is used to focus on objects at varying distances. The

diopter adjustment rings are used to focus your eyes (with or without glasses) on the image intensifier screen. These adjustments

operate independently and must be made separately.

4. Hold the PVS-7 with your left hand and fold the left eyecup over

the eyepiece with your left thumb or forefinger to obstruct view

through the left eyepiece. Rotate the right diopter adjustment ring

for the clearest view on the image intensifier screen.

5. Hold the PVS-7 with your right hand and fold the right eyecup

over the eyepiece with your right thumb or forefinger to obstruct

view through the right eyepiece. Rotate the left diopter adjustment

ring for the clearest view on the image intensifier screen.

6. Readjust the objective lens assembly while observing an object

until the sharpest image is obtained.

D. Operation with Compass Assembly

NOTE

The objective lens focus can be fine tuned after installation, but in

order to obtain an accurate reading, the compass must be vertical.

(The compass image must be level).

1. Install per paragraph 2-6, F.

2. If necessary, to more clearly view your distant object, adjust the

objective focus slightly by gripping the compass and turning clockwise.

2-26

Page 49

3. To view the compass through the PVS-7, grip the compass with

index finger on top and thumb on illumination button on the bottom

(Figure 2-1). Press button slightly with thumb until proper brightness

is obtained. The image should appear as shown in Figure 2-8.

Figure 2-12. View Through Installed Compass

NOTE

Increase brightness slowly: if brightness is increased too quickly,

excessive brightness may burn a temporary image into the image

intensifier. The goggle must be focused at or near infinite for proper

compass operation.

4. The compass readings should change when you move your head

from side to side. Rotate or tap compass slightly to ensure compass

is operating correctly. Hold the PVS-7 in a level position to assure

live rotation of the compass scale.

WARNING

THE COMPASS ILLUMINATOR CAN BE SEEN BY OTHERS USING

NIGHT VISION DEVICES.

NOTE

The compass reading is the magnetic North, not true North. The

compass reading is within 2° of correct absolute magnetic bearing.

Compass readings with a mounted PVS-7 (head mount or helmet

mount) can be up to ±15° of correct absolute, magnetic bearing.

This occurs most in the East (90°) to West (270°) and less in the

2-27

Page 50

North (0°) to South (360°) reading. If the compass is inadvertently

magnetized this could cause an additional 15° error.

5. The tick mark closest to the center of the lighted display is the

compass bearing. The tick marks are in degrees, with longer marks

every five degrees and bearing labels every 10 degrees.

E. Use of the 3X or 5X Magnifier Lens Assembly. The 3X or 5X

magnifier len s a ssembly can b e threaded d irectly into the 1X ob jec -

tive lens, with the light interference filter (LIF) and sacrificial window

removed. It can also be threaded into the focus ring adapter and

slipped on over the end of the objective lens with the LIF installed.

NOTE

The Neck cord can be used to tether the magnifier to your person to

prevent losing the lens if it is dropped. To use the Neck cord, tie the

end without the clip tightly around the magnifier and attach the clip

to a buttonhole, belt loop or other convenient point.

Figure 2-13. PVS-7 with Magnifier Lens Assembly Installed

F. Infrared (IR) Operations

WARNING

THE IR ILLUMINATOR IS A LIGHT THAT IS INVISIBLE TO THE

UNAIDED EYE FOR USE DURING CONDITIONS OF EXTREME

DARKNESS. HOWEVER, THE LIGHT FROM THE ILLUMINATOR

CAN BE DETECTED BY THE ENEMY USING NIGHT VISION

DEVICES.

2-28

Page 51

1. Pull the RESET/OFF-ON-IR/PULL switch knob (Figure 2-1) out

and rotate clockwise to the IR position. With the PVS-7 held to the

eyes, observe that a red light appears in the left eyepiece. This indic ates that the IR i llu min at or is o per ating. Wh en s pri ng loaded momentary IR position is used, the illuminator should only flash on.

2. To Operate with the IR Spot/Flood Lens: Pull the RESET/OFFON-IR/PULL switch knob out and rotate clock-wise to the IR position. With the PVS-7 held to the eyes, turn the IR spot/flood until you

have achieved the optimum illumination of the desired distance.

Turn the RESET/OFF-ON-IR/PULL switch counterclockwise to the

ON position. Observe that the red indicator disappears.

2-9 PREPARATION FOR STOWAGE

A. Shutdown. Perform the following procedures to shut down the

PVS-7.

1. Turn the RESET/OFF-ON-IR / PULL switch to the OFF position.

2. Remove the PVS-7 from the head mount or helmet mount (if so

equipped) by depressing the latch lever (Figure 2-1) and removing

the PVS-7 from the head mount socket.

B. Packaging Af ter Use.

1. Unscrew the battery cap and remove the battery(ies).

2. Inspect the battery compartment for corrosion or moisture. Clean

and dry if necessar y.

3. Replace the battery cap.

4. Remove the demist shields, sacrificial window or compass assembly if installed. Install the lens cap.

NOTE

Prior to placing the PVS-7 assembly into the carrying case, ensure

the goggle and case are free of dirt, dust and moisture.

5. Place demist shields, batteries, carrying case strap, lens paper,

sacrificial window, manual, LIF, brow pads, head mount, helmet

mount and compass into the carr ying case (see Figure 1-1).

6. Place the PVS-7 (objective lens down) into the shallow pocket of

the carrying case.

2-29

Page 52

7. Place the carrying case into the shipping/storage case (Figure

2-10); close and latch it.

8. Return to storage area.

Figure 2- 10. PVS -7 Shipping /storage case

2-30

Page 53

CHAPTER 3

MAINTENANCE INSTRUCTIONS

3-1

Page 54

SECTION I: TROUBLESHOOTING

PROCEDURES

3-1 TROUBLESHOOTING

Table 3-1 lists common malfunctions that you may find with your

equipment. Perform the tests, inspections and corrective actions in

the order they appear in the table.

This table cannot list all the malfunctions that may occur, all the

tests and inspections needed to find the fault, or all the corrective

actions to correct the fault. If the equipment malfunction is not listed

or actions listed do not correct the fault, notify your maintainer.

Table 3-1. Operator’s Troubleshooting

MALFUNCTION TEST / INSPECTION CORRECTIVE ACTION

1. Goggle fails

to activate

2. IR indicator

fails to activate

3. Poor image

quality

Visual

Check for defective, missing or impr operly installe d

battery(ies)

Visual Refer to higher level of

Check objective lens

or eyepiece focus

Turn switch to RESET/

OFF position and then

ON

Replace battery(ies) or

install correctly

If PVS-7 still fails to activate, refer to higher level

of maintenance

maintenance

Refocus

Check for fogging or

dir t on lens

3-2

Clean lens surface

Page 55

MALFUNCTION TEST / INSPECTION CORRECTIVE ACTION

4. Light visible

around eyecup

5. Diopter adjustment cannot be made

6. Interpupillary adjustm e n t c an n o t

be made (left &

right eye)

Check eye relief distance

Chec k eyecup for

resiliency

Check to see if the

diopter adjustment

ring is bent or broken

Defective eyepiece

assembly

Readjust for proper eye

relief distance

If eyecups defective, refe r to hig her level of m a intenance

If damaged, refer to higher level of maintenance

Refer to higher level of

maintenance

7. Battery cap

difficult to turn

8. PVS-7 does

n o t sh u t o f f

when removed

f r o m h e a d

mo unt during

Check for dirt or grit

Clean

in threads

Visually inspect for

the presence of an

o-ring

Check for damaged battery cap or

If o-ring is missing: refer

to higher level of maintenance

If damaged, refer to high-

er level of maintenance

threads on battery

compartment

Visual Return both the PVS-7

and head mount to higher

level of maintenance

operation

3-3

Page 56

MALFUNCTION TEST / INSPECTION CORRECTIVE ACTION

9. Head straps

can n ot b e ti g htened

10. Head

mount or

helmet mount

socket and

goggle do not

catch

11. Helmet

mount will

not tighten to

helmet

Check for defective

buckles, fasteners

If damaged, refer to higher level of maintenance

or straps

Check socket or

Clean socket and latch

latch for dirt

Check socket or

latch for damage

If damaged; return both

head mount or helmet

mount and PVS-7 to

higher level of mainte nance

Visual If damaged, refer to

higher level of mainte nance

12. LIF will not

thread in or

obstructs view

13. IR spot/

flood lens will

not adjust

14. Co mpas s

does not illuminate

15 Com p as s

will not stay on

the PVS-7

Check for dirt in

Clean threads

threads

Check for damaged

assembly

If damaged, refer to

higher level of mainte nance

Visual Refer to higher level of

maintenance

Visual Refer to higher level of

maintenance

Visual Possibly missing an o-

ring

Refer to higher level of

3-4

maintenance

Page 57

MALFUNCTION TEST / INSPECTION CORRECTIVE ACTION

16 Com p as s

display is not

clear

17. PVS-7 does

n o t sh u t o f f

when exposed

to high light test

under day light

or bright room

light.

Visual Make sure the PVS-7 is

focused for infinity. If so

and compass display is

sti ll n ot c l ear refer to h igh-

er level of maintenance

Perform the following tests under day

light or bright room

light

Place the lens cap

o n t h e o bje c t ive

len s. Turn PVS -7

on and observe that

they shut off within

70 (± 30) se conds

after energized

Turn goggle off and

then on to re-energize

If damaged, refer to high-

er level of maintenance

3-5

Page 58

SECTION II: MAINTENANCE PROCEDURES

3-2. CLEANING THE PVS-7

CAUTION

THE PVS-7 IS A PRECISION ELECTRO-OPTICAL INSTRUMENT

AND MUST BE HANDLED CAREFULLY. DO NOT SCRATCH THE

EXTERNAL LENS SURFACES OR TOUCH THEM WITH YOUR

FINGERS.

Clean the goggl e with water if nec es sar y and dr y thoroughly. Clean

lenses with lens paper (and water if necessary, except for demist

shields).

CAUTION

WIPING DEMIST SHIELDS WITH LENS PAPER WHILE WET CAN

DAMAGE THE COATING.

3-3. HEAD MOUNT MAINTENANCE

A. Brow Pad Replacement. Replace the brow pad when cracked,

torn or contaminated. Perform the following procedure to remove

and replace the brow pads.

CAUTION

FOR PROTECTION OF THE IMAGE INTENSIFIER, DISCONNECT

THE PVS-7 FROM THE HEAD MOUNT PRIOR TO REPLACING

BROW PADS.

1. Firmly grasp the head mount and remove the old brow pad.

2. Gently press on the new brow pad. Lightly smooth out any wrinkles in the new brow pad.

B. Neck Pad Re-installation. During operation of the goggle, it

is possible for the neck pad to become separated from its position

on the headband. Perform the following procedure to reinstall the

neck pad.

1. Lift the upper headband strap retention tab (see Figure 3-1) allowing the neck pad strap to be inserted underneath.

2. Slip the neck pad strap all the way under the upper strap retention tab and then pull the lower part of the neck pad strap under the

lower strap retention.

3-6

Page 59

Lower Strap

Retention Tab

Lower Strap

Retention Tab

Lower Strap

Retention Tab

Figure 3 -1. Re-installing the N eck Pad

3. Repeat steps 1 and 2 for the other side of the headband and neck

pad if necessary.

C. Lacing the Sliding Bar Buckles. While donning and adjusting the head mount, it is possible for a strap to slip out of a slide

fastener. Perform the following procedure to replace the strap and

sliding bar buckle.

1. Thread the strap from the inside of the buckle over the move-

able sliding bar ( see Figure 3 -2 ). Thread the strap back through the

buckle but this time under the sliding bar and over the serrated part

of the buckle.

2. Pull the strap through the buckle and tighten as necessar y.

3. Repeat steps 1 and 2 for any other straps and buckles that may

have come undone.

Moveable

Fixed

Sliding Bar

Figure 3 -2. Lacing the Sliding Bar Buckles

Serrated Bar

3-7

Page 60

APPENDIX A

SYSTEM OPTIONAL EQUIPMENT

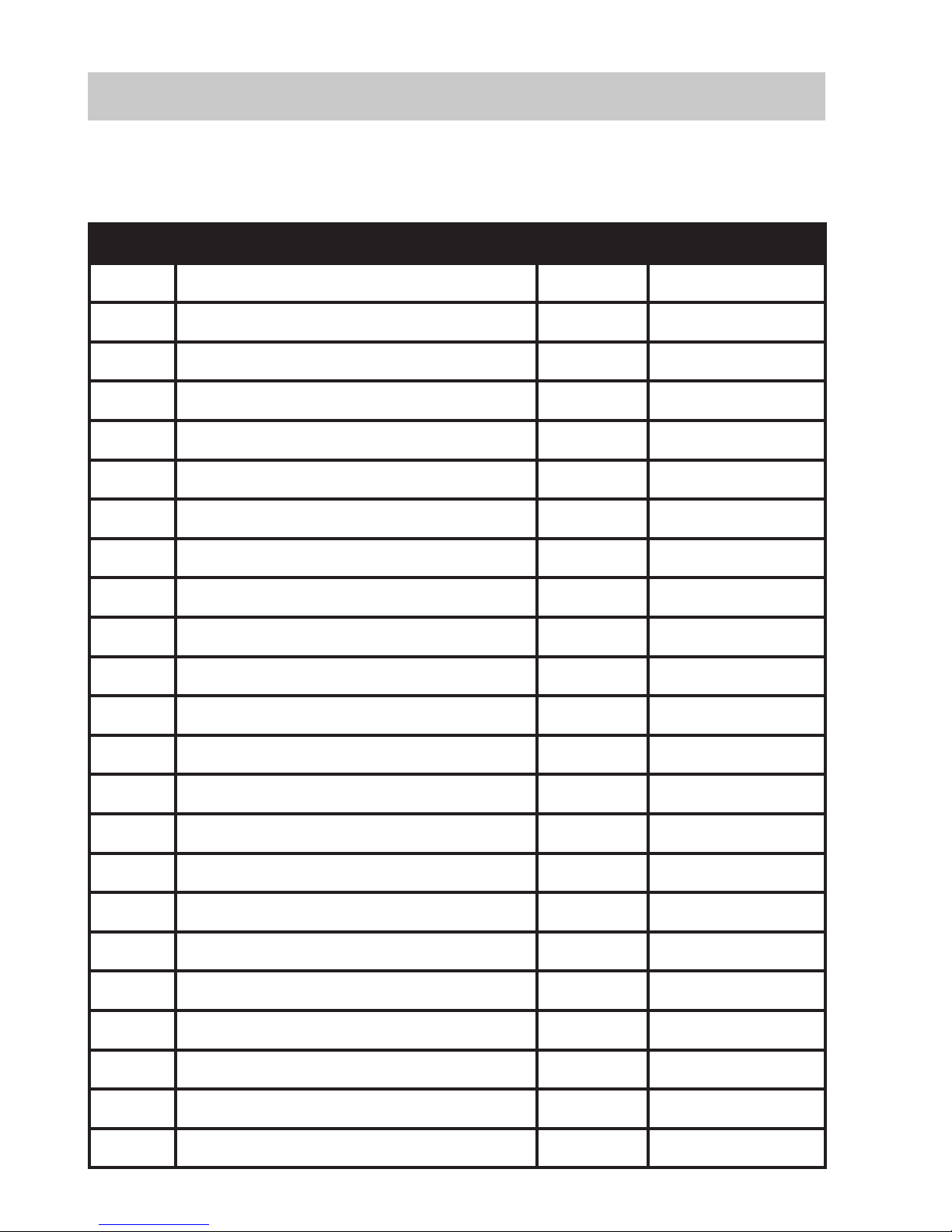

Table A-1. System Optional Equipment

ITEM DESCRIPTION QUANT PART NO

1 He lmet Mount Assy. 1 ATN3256390

2 Ob jective Filter As s y., LIF 1 ATN500 9737

3 Sacrificial Window Assy. 1 AT N314 42 64

4 Demist Shield Assy. 2

5 Case, Shipping/Storage 1 ATN3187393

6 Battery, Lithium 1 B-5567/U

7 3X A loca l Le n s As sy. 1 ATN500 9717

8 Ki t Ad a pter, 3X Afo cal, 7D 1 AT N5009718

9 5X Afocal Lens Assy. 1 ATN50 09719

10 Kit Adapter, 5X Afocal, 7D 1 ATN50 09720

11 O bj. Le ns., 3X, 7D 1 AT N5009721

12 Obj. Lens., 4X , 7D 1 ATN5009722

13 Obj. Lens., 6X, 7D 1 ATN50 09723

14 Sacri f icial Filter Assy.. 75mm 1 ATN314 4 2 6 5

15 Sacrifi cial Filter Assy., 108mm 1 AT N314 42 66

ATN31442632

16 Sacrifi c ial Filter Assy., 16 2mm 1 ATN 314 42 67

17 Lens Cover Assy., 75mm 1 ATN5009724

18 Lens Cover Assy., 10 8mm 1 AT N5009725

19 Lens Cover Assy., 162 m m 1 AT N5009726

20 Tr ipod Adapter Assy., (4X /6X) 1 ATN3187394

21 Shipping Case Assy. 1 ATN 31873 95

22 M ount Assy., 7D- S PH -5CG 1 AT N31873 96

23 O bject i ve Len s As sy., 5 4mm 1 ATN 5 009710

A-1

Page 61

FOR TECHNICAL INFORMATION

ATN CORP.

1341 San Mateo Avenue

South San Francisco, CA 94080

(800) 910-2862

(650) 989- 5100 tel.

(650) 875-0129 fax

www.atncorp.com

info@atncorp.com

INFO -1

Page 62

FOR NOTE

INFO-2

Page 63

INFO-3

Page 64

For customer service and

technic al support, please contact

American Technologies Network Corp.

North American Office:

1341 San Mateo Avenue

South San Francisco, CA 94080

phone: 800-910-2862, 650-989-5100

fax: 650-875-0129

www.atncorp.com

©2008 ATN Corporation

Loading...

Loading...