Atmos Multi, Multi 24/80, Multi 24 / 80 Plus, Multi 32 / 80 Plus Installation & Servicing Instructions Manual

Page 1

ATMOS MULTI version 2002 Page 1

Page 2

ATMOS MULTI version 2002 Page 2

Page 3

Table of Contents

Section Page

Section Page

Introduction 1

1. Installation Regulation 2

2. General Information 2

3. Technical Data 3

4. Schematic of Boiler 4

5. Operation and

q Appliance construction

q Operating principle

Controls and function

q

q User's programme

6

6

7

8

9

6. Installation Requirements 9

§ Gas supply

§ Electrical supply

§ Terminal location

§ Flue system

§ Condensate disposal

§ Discharge pipes

§ Existing systems

9

9

10

10

11

12

14

7. Boiler Installation 14

§ Unpacking the boiler

§ Minimum clearances

§ Boiler location

§ Wall mounting the boiler

§ Connecting the flue system

§ Connecting the c/heating

§ Connecting the mains water

§ Connecting the discharge pipes

§ Connecting the domestic hot

§ Connecting the gas supply

§ Connecting the condensate

§ Connecting the electrical supply

14

15

15

16

17

18

19

20

21

21

22

22

8. Commissioning 25

§ Filling the heating system

§ Filling the domestic hot water

§ Appliance operation

§ System balancing

25

26

26

27

9. System Shutdown 28

§ Central heating circuit

§ Domestic hot water

§ Draining the boiler

§ Disposal of appliance

28

28

28

28

10. Inspection & Servicing 28

§ Boiler pre-service inspection

§ Auxiliary equipment

§ Servicing the boiler

§ Completion

29

30

30

32

11. Component Replacement 33

12. Malfunctions 37

Appendices.

1. Spare part list

2. Combined safety & condensate discharge

3. Fault finding

4. Guarantee stipulations

ATMOS MULTI version 2002 Page 3

Page 4

Introduction

The Atmos Multi gas fired storage combination boiler

that meets the requirements of Statutory Instrument

'The Boiler (Efficiency) Regulations' and is deemed to

meet the requirements of:

q Gas Appliance Directive 90/396 EEC

q Efficiency Directive 92/42/ EEC

q Low Tension Directive 73/23 EEC (modified from

93/68) and;

q Electromagnetic Compatibility Directive 89/396 EEC

(modified from 93/68)

Atmos Heating Systems declare that the materials used

in the manufacturer of this appliance are non-hazardous

and that no substances harmful to health are contained

within the appliance.

The Atmos Multi must be installed in accordance with

these instructions and the regulations currently in

force. Please read these instructions fully before

installation and leave with the boiler for future

reference.

Atmos Heating Systems accepts no responsibility for

unsatisfactory performance of the appliance or flue

arising from the failure to comply with these installation

instructions.

On completion of installation the appliance must be

commissioned and the following explained to the user:

q The operating principle of the appl iance

q The appl iance controls and display

q Starting up, filling and de-aerating the appliance

q Shutting down and draining

q Annual inspection and maintenance

Atmos Heating Systems have a policy of continuing

improvement in the design and performance of its s

products. The right is therefore reserved to vary

specifications without notice.

For advice or information contact Atmos Heating

Systems by telephone or e-mail.

Atmos Heating Systems is part of the Benchmark

scheme. All our boilers include the Benchmark

Logbook and we advise all our installations to be

carried out to Benchmark standards.

ATMOS MULTI version 2002 Page 4

Page 5

1. Installation Regulations.

1.1 A qualified registered installer in accordance with

the Gas Safety (Installation and Use) Regulations;

October 1994 must only install this appliance. Failure to

install appliances correctly could lead to prosecution.

1.2. The manufacturer instructions must not be taken as

overriding statutory requirements.

1.3 The installation of this appliance must be in

accordance with the relevant requirements of the Gas

Safety (Installation and Use) Regulations 1984 as

amended, Building Regulations, Building Standards

(Scotland), lEE Wiring Regulations (BS 7671), Health

and Safety Document No.635 (Electricity at Work

Regulations) and local Water Authority bye laws.

1.4 Installation should also be in accordance with the

relevant recommendations contained within the current

versions of the following British Standards.

q BS 6798 Specification for installation of gas fired

hot water boilers of rated input not exceeding 60

kW.

q BS 5449 Central Heating for Domestic Premises.

q BS 5546 Installation of gas hot water supplies for

domestic purposes.

q BS 5440 Flues and Ventilation for gas appliances of

rated input not exceeding 60 kW. (Part 1 Flues).

q BS 5440 Flues and Ventilation for gas appliances of

rated input not exceeding 60kw (Part 2 Air Supply).

q BS 6891 Installation of low pressure gas pipework

installations up to 28mm (R1).

Reference should also be made to British Gas Guidance

Notes for the Installation of Domestic Gas Boilers.

1.5. To ensure that the installation will perform to the

highest standards, the system and components should

conform to any other relevant British Standards in

addition to those mentioned in these instructions.

1.6. For Installation in Ireland the appliance must be

installed in compliance with I.S.813 ‘Installation of gas

appliances’.

1.7. Asbestos and CFC’s are not used in the

manufacture of these products.

2. General Information.

2.1 The Atmos Multi is a wall mounted, fully automatic gas

fired condensing combination boiler designed to provide

'unvented' domestic hot water at mains pressure via an

integral hot water storage cylinder.

2.2 Classified as an 'Unvented hot water system' the

installation of the Atmos Multi falls within the scope of the

Building Regulations 1995 (Part G.). These require that a

competent per son as defined in the Approved Document G3

must only undertake the installation of an unvented system.

2.3 For central heating applications the Atmos Multi is

suitable only for use on a fully pumped, pressurised, sealed

primary system with a design (cold) pressure of between 0.5

and 2.5 bar.

2.4 The boiler may be installed in any room or internal space

without the need for purpose made ventilation, although

attention is drawn to the current IEE Wiring Regulations with

respect to installation in a room containing a bath or shower.

In such installations, it must not be possible for a person

using the bath or shower to touch any mains electricity fed

switch or boiler control.

2.5 In areas where the temporary hardness of the supplied

water exceeds 200mg/litr e, a proprietary in-line scale control

device such as the 'Hydroflow' (available from Atmos

Heating Systems) should be fitted in the cold feed to the

boiler.

2.6 Although fitted with an automatic air release valve it

should be ensured that the boiler's heat exchanger is not a

natural collecting point for air. Air vents must be fitted at the

highest positions of the heating flow and return pipes and at

any other point in the system where air is likely to collect.

2.7 The Atmos Multi is suitable to accept pre-heated water

such as that supplied from solar panel installations.

2.8 To ensure economic use of domestic hot water, it is

recommended that pipe runs between the boiler and taps be

in 15mm copper, as short as possible and, where practical, be

insulated to reduce heat loss.

2.9 Where the boiler is intended for use on Propane gas the

boiler must not be installed in a room or internal space below

ground level.

ATMOS MULTI version 2002 Page 5

Page 6

Page 7

24/80

24 /

80 Plus

32 / 80 Plus

32 / 80 Plus

CONDENSING MODE (Return < 55°C)

Heat Output to radiators kW min

-

max 7·3 - 22·5

7·3 - 22·5

9·8 - 29 9·8 - 29·9 Maximum heat to radiators Btu/hr

76,800

76,800

99,000

102,000

Gross efficiency ma

x - min 98 - 91% 98 - 91% 98 - 91 %

98 - 91% NON

-

CONDENSING MODE (80/60°C flow/return)

Maximum heat to radiators Btu/hr

73,400

73,400

94,200

97,300

Gross efficiency max

-

min 93 - 87% 93 - 87% 93 - 86% 93 - 86% Seasonal efficiency (Sedbuk certified) %

91 3 91·3 91 91 Gas flow rate m3/hr natural gas min/max

0 8 - 2·6 0·8 - 3·3 1·1 -3·5 0.4 – 1.25 HOT WATER SYSTEM

Maximum heat to hot water kW

17·4 26·4 27·6 28·5 Hot water flow rate maximum litres/min at 2bar

25 25 25 25

Reheat time from 10 to 60°C minutes

20 12 11 10

Hot water at 40°C instantaneously (litres)

133 133 133 133 Hot water per hour at 40°C (litres)

450 700 725 750 Hot water per hour at 40°C (gallons)

100 150 160 165 EMISSIONS

NOx (average) emission ppm

18 18 19 19

COMMON DATA

Hot water temperature setting range

60 to 70°C

Central heating setting range

60 to 90°C

Hot water tank capacity

80 litres

Primary water capacity

2 2 litres

Hot water expansion vessel capacity

5 litres

C/ heating expansion vessel capacity

8 to18 litres

Maximum supply pressure

12 bar

Electrical Connection

220/240V

Outlet pressure hot and cold water

3·5 bar

CONNECTIONS

Air supply pipe diameter

80 mm

Flue pipe diameter

80 mm

Heating flow and return

22 mm

Hot water outlet

15 mm

Cold water supply

22 mm

Gas pipe connection

½" BSPM

Safety Valve discharge connection

22 mm

Condensate discharge

drain connection

32 mm

Underfloor heating flow connection

½" BSPF

DIMENSIONS AND WEIGHT

Height

1080 mm

Width

525 mm

Depth

495 mm

Minimum distance above floor

600 mm

Weight empty

70 kg

Weight full

150kg

3.Technical Data

Natural Gas & Propane Natural Gas Propane

ATMOS MULTI version 2002 Page 7

Page 8

ATMOS MULTI version 2002 Page 8

Page 9

ATMOS MULTI version 2002 Page 9

Page 10

5. Operation and construction

The Atmos Multi is a fully automatic, gas fired, high

efficiency central heating boiler providing unvented

domestic hot water at mains pressure via an integral 80

litre copper hot water storage tank.

5.1 Construction of the appliance

A heat exchanger consisting of three concentric

channels is positioned in the centre of the boiler's

integral hot water tank. (Fig.1).

q Hot flue gas released from a fully modulating, pre-

mix burner positioned at the top of the heat

exchanger, is driven downwards through the heat

exchanger's middle channel.

q The second surrounding channel is divided into

eight smaller central heating water channels, which

together promote the transfer of heat from the heat

exchanger to water within the boiler's primary

circuit.

q The third surrounding channel is divided into

small air channels. These together with the

inner copper wall of the hot water tank forms a

double partition between the central heating and

stored hot water.

While the hot water tank is completely insulated by

means of insulation shell sections, the hot water tank

itself along with the boiler's other components is

housed behind a removable outer steel appliance

casing, constructed in such a manner to ensure the

enclosed appliance space is ventilated.

Operation of the Atmos Multi boiler is controlled and

monitored by an electronic control unit that sends and

processes information to and from the boiler's various

temperature and control components. Along with

controlling the boiler's operation the control unit also

provides a diagnostic programme that simplifies fault

finding by automatically sending a fault code to a

'Status/error code display ' window located on the

control unit's fascia.

Central heating & Hot water circuit

When there is a demand for domestic hot water or

central heating, the water within the boiler primary

circuit is pumped through the heat exchanger from the

bottom to top via the central heating water channels to

a three way valve.

If there is a demand for hot water only, water within the

primary circuit circulates through the heat exchanger

only.

If there is a demand for central heating only, the threeway valve changes position allowing the heated

primary water to flow from the heat exchanger to the

central heating syst em.

Where there is a demand for both domestic hot water

and central heating the three-way valve stays in a midposition, supplying heated water to both systems.

Flue gas circuit

The burners combustion air fan drives hot flue gases

produced by the combustion process from the top to

the bottom of the heat exchanger. Cooling of the flue

gases occur as they flow through the flue gas channels

towards their point of exit. On cooling the water vapour

suspended within the flue gas condenses, transferring

its latent heat as sensible heat to the cooler water

within the heat exchanger. The resultant condensate

ATMOS MULTI version 2002 Page 10

Page 11

then falls to the bottom of the heat exchanger where it

is automatically discharged via the boiler's condense

drain point.

5.2 Operating principle of the appliance

q No heat demand

The appliance will carry out a self-test every 24

hours when the connected to an available

electrical supply. For this test the boiler's

integral central heating pump will run for 3

minutes and the three-way valve will switch to

central heating in order to prevent the pump

from seizing.

q Meeting the heat demand (continuous

comfort mode)

If there is demand for heating and domestic hot

water at the same time, the hot water demand

has priority over the heating demand. This is

achieved by constant regulation of the threeway valve from the control unit. The

'continuous comfort' mode may be switched off

if not required.

The central heating is controlled using a

standard 24V room thermostat or modulating

room thermostat. The domestic hot water

temperature is controlled by a 'user' setting,

which is adjusted via the control unit.

q Heat supply

When there is a demand for central heating, the

boiler's integral central heating pump and

combustion fan are automatically switched on.

Burner ignition occurs on the combustion fan

reaching its regulated speed. If no flame signal

is detected after 5 seconds, three more attempts

for burner ignition will be made within a 15second period, after which the appliance will

shut down.

On a loss of flame the appliance will carry out

four restart attempts, after which the appliance

will shut down. If the temperature of the central

heating water reaches 90°C, the burner will

automatically be extinguished. The appliance

has an anti -cycling time of 3 minutes during

which the burner will not re-ignite. The anti cycling period may be changed via the control

panel to 6 minutes or alternatively, switched

off.

On reaching the heating demand the burner will shut

down and the central heating pump continues to run

for a further one-minute period after which, the threeway valve will switch to domestic hot water heating.

The pump will then run in hot water heating mode for

20 minutes (Factory setting). The pump running

times may be adjusted to suit individual system

requirements (see separately available Atoms Multi

Service Manual).

An insufficient heating water flow rate will be

detected by the high limit thermostat, which on

activation will cause the appliance to shut down.

q Combustion

The appliance is equipped with a continuously

modulating burner. The burner's heat input may be

manually set to suit individual system requirements

by adjustment of the fan pressure via a mechanical

gas -air connection. The appliance heat input

automatically reduces as the central heating flow

temperature reaches 80°C or higher.

q Most Efficient Start

Most Efficient Start is a comfortable energy saver,

which ensures that the home is heated as efficiently

as possible. When there is a central heating demand

the appliance always starts heating the home on a

low burner heat input. The amount of time at which

the burner continues to operate at low input

depends upon the heating demand of the heating

system.

After either first connecting the appliance to the

power supply, resetting following shut down or

following a 180 minute period with no heat demand,

the burner will operate on a low heat input for 3

minutes, thereafter it is self adjusting.

ATMOS MULTI version 2002 Page 11

Page 12

5.3 Controls and function.

The function mode of the appliance and the

central heating water pressure are indicated on

the electronic control unit's front fascia (fig 2),

located at the bottom left of the appliance

q Diagnostic display (fig 2 (1))

The boiler's operating status is indicated on the

diagnostic display. The various status codes are

explained in table 1. A flashing display or letter

symbol indicates that a boiler malfunction or

appliance lockout has occurred. The procedure to

follow is given in Section 12 of these instructions.

q Central Heating Display (fig 2 (4))

The central heating display may be set to indicate

either the central heating water pressure (factory

setting) or central heating water temperature. (See

'User's programme' page 9)

If the central heating water pressure is too low or

too high, a warning symbol ‘C’ is shown on the

diagnostic display. Further information is given in

Section 12 of these instructions

q Hot water button (fig 2 (6))

If required the heating of domestic hot water may be

switched off using the hot water button. Pressing

the button once will turn off the indicator light and

curtail the hot water demand.

q Set button (fig 2 (2))

The set button is used to initiate an integral

programme to allow changes to be made to the

boiler's factory settings and other installation and

service activities. To protect agai nst accidental use

the set button has to be depressed for a period of 5

seconds before activation occurs. Further

information on this subject can be found in the

separately available Atmos Multi Service Manual.

ATMOS MULTI version 2002 Page 12

Page 13

q Reset button. (fig 2 (3))

A lockout situation following a malfunction is

cancelled using the reset button. The button is

also used to exit the 'User's programme'.

5.4 User's programme

Along with giving operation and fault status

codes down to component level the electronic

control also permits the manual setting of the

boilers operational perimeters.

While the factory set parameters are suitable

for 90% of installations, in some cases such as

the elderly, infirm or very young for example, a

lower radiator surface temperature or domestic

hot water temperature may be desirable.

The Atmos Multi in-built user's programme

allows the user or installer to tailor suit certain

operational perimeters such as the domestic

hot water temperature, to the end users

requirements.

Access to the user's program me is gained by

pressing the control unit's 'Set' button for a

period of 5 seconds until a letter 'b' appears in

the diagnostic display window. Incremental

scrolling through the operational perimeters is

then obtained by re-pressing the 'Set' button.

The current setting for the selected operational

perimeter appears in the central heating water

display window. Pressing the 'Hot water'

button enables the setting to be changed to the

required value.

The user programme is terminated

automatically after five minutes from when the

last input action was carried out. Alternatively,

exit from the programme is achieved by

pressing the 'Reset' button.

Operational perimeters accessible via the users'

programme are given in Table 2, the factory settings

being underlined.

Further information on setting operation perimeters

is given in the Atmos Multi Service Manual.

6. Installation Requirements.

6.1 Gas supply

The gas meter and supply pipe must be capable of

delivering the required quantity of gas to the boiler

(refer to Technical Data page 3) in addition to the

demand from any other appliances within the

property. On final connection of the gas supply to

the boiler, the properties complete gas installation,

including the meter, must be tested for gas

soundness and purged as described in BS6891.

6.2 Electrical supply

The boiler requires a 230/240 V~50 Hz mains supply

fused at 3amp

The Atmos Multi is supplied factory wired complete

with 1·2m of mains cable. All electrical connections

to the mains supply must be made in full accordance

with the current I.E.E. regulations.

The boiler must be earthed and connected via a

double pole isolating switch fused to 3 amp or

alternatively, by the use of a 3 amp fused three pin

plug and unswitched shuttered socket outlet. The

point of connection must be readily accessible,

adjacent to the appliance and provide complete

electrical isolation for the boiler and control

system.

ATMOS MULTI version 2002 Page 13

Page 14

6.3 Flue terminal clearances.

The flue terminal must be sited

with minimum clearance dist ances

as specified in figure 3.

A terminal guard (available from

Atmos Heating Systems) must be

fitted if the terminal is sited less

than 2m above ground level.

Where the flue terminates within

1m of a plastic or painted gutter or

within 500mm of painted eaves

then protection should be

provided in the form of an

aluminium shield at least 1m in

length, fitted to the underside of

the gutter or painted surface.

Please note !

Due to the low flue gas

temperature, 'pluming' will occur

at the flue terminal. Care should

be taken to ensure that the

discharge plume will not cause

annoyance to the customer or

neighbours. It is generally

recommended that flues should

discharge vertically at roof level,

where pluming is not normally a

problem

6.4 Flue system.

The flue system must be installed

in accordance with BS5440:1.

Horizontal flue gas discharge pipe

runs must always be installed

with a minimum 0·5% incline

towards the point of termination.

This incline will prevent

condensation from gathering in

the flue gas discharge pipe, and

will also reduce the chance of

icicles forming over horizontal

pipe ends in extreme weather

conditions. On horizontal

terminations the air supply pipe

must be led to outside with a

minimum 0·3% angle to prevent

the ingress of rainwater. Similarly,

provisions should be made to

prevent the ingress of rainwater

into the air supply pipe on

vertical terminations.

Figure 3: Flue terminal locations

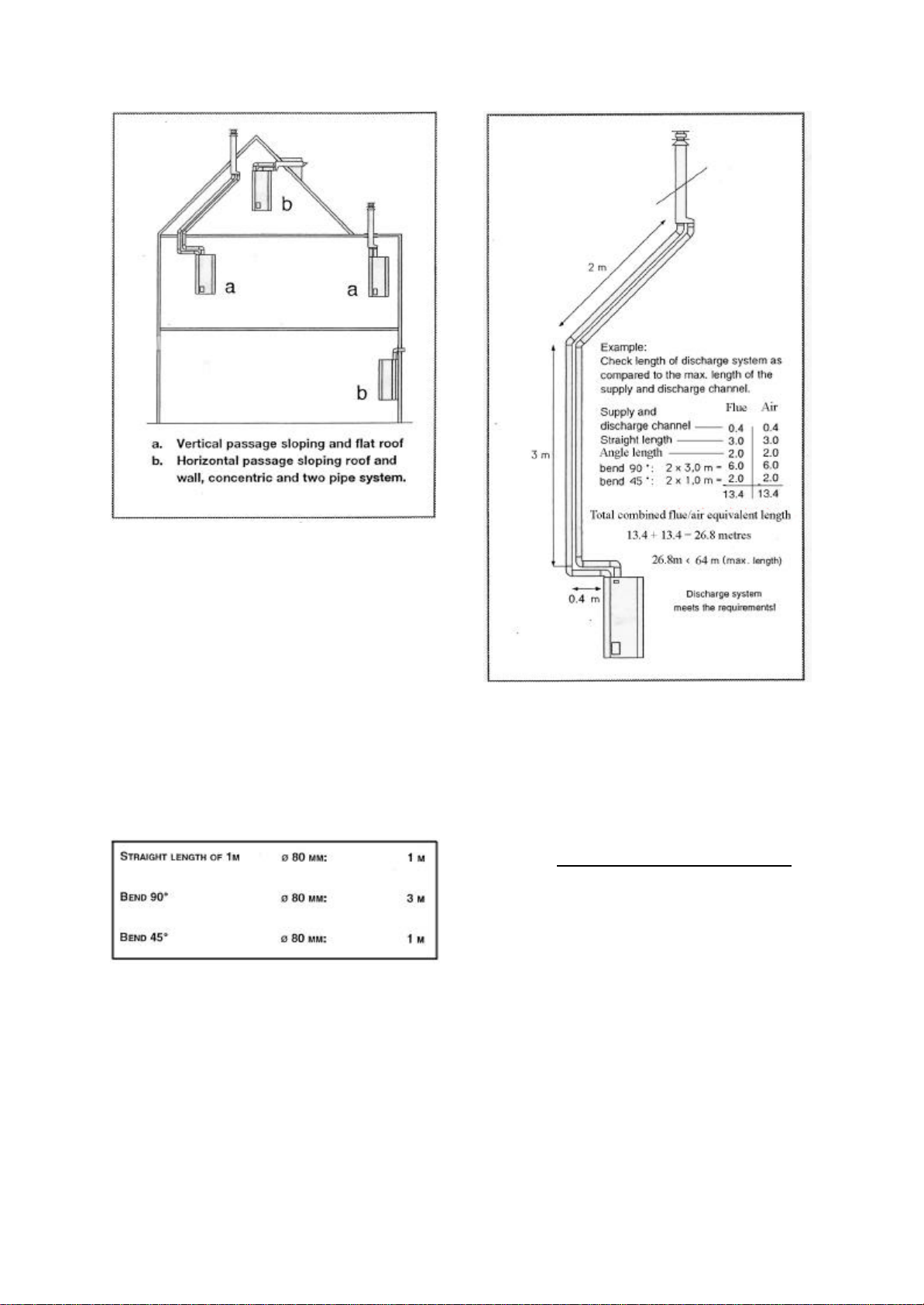

Depending upon the boiler location and flue configuration required, two

different flue systems are available for use with the Atmos Multi boiler:

q 125/80mm concentric system for use on vertical roof systems up to

a maximum equivalent length of 64m, and;

q 80/80 twin pipe system which enables separate air intake and flue

gas discharge pipes to be fitted to the appliance, allowing a

combined total equivalent flue length of 64m

The maximum equivalent flue length of the flue system must not be

exceeded. If exceeded the boiler will not malfunction but its heat-output

capacity will be reduced. The connected gas/air regulator will however,

always ensure optimum combustion is maintained.

Examples of various flueing options and configurations are given in

figure 4.

ATMOS MULTI version 2002 Page 14

Page 15

Figure 4: Examples of flueing options.

The equivalent length of the required flue system's

configuration can be calculated from the resistance

factors given for the individual flue components in

table 3. In the worked example (fig 5) the maximum

permitted combined length for a 80mm dia. twin flue

is 64metres at a pressure of 100 Pa. Account has

already been taken of the resistance of the balanced

flue terminal. This can therefore be ignored in the

calculation.

Table 3. Flue resistance factors

Figure 5: Worked flue length example.

6.5 Condensate disposal.

Provisions must be made for the safe disposal of

condensate produced when the Atmos Multi is in

operation. The condensate drainage pipework must

be run in an acid resistant m aterial such as plastic

waste pipe. Copper or steel pipe must not be used.

The pipework must incorporate a minimum 1:20

downward slope towards its point of termination,

which ideally should be an internal soil or waste pipe

to avoid the possible risk of freezing. Alternatively,

where this not possible the condensate may be

discharged into an external gulley or purpose -built

soakaway.

The condensate pipework must be protected against

freezing and any pipework external to the property

must be encased in waterproof insulation and be

restricted to a maximum length of 3m.

ATMOS MULTI version 2002 Page 15

Page 16

6.5 Discharge pipes.

It is a requirement of Building Regulation G3 that any

discharge from an unvented system should be

visible at both the tundish and final point of

discharge. Where this is not possible or practical

however, the discharge must be clearly visible at one

of these locations.

The discharge pipe from the tundish should

terminate in a safe place where there is no risk to

persons in the vicinity of the discharge.

While it is permissible to combine the discharge

pipes from the Atmos Multi temperature & pressure

relief valve and expansion pressure relief valve, the

tundish and Atmos Multi boiler must be located in

the same space. The tundish must also be within

500mm of the combi ned temperature & pressure relief

valve and installed in a vertical position.

While a minimum 300mm of vertical discharge pipe

must exist below the tundish, the discharge pipe

itself should be of metal construction and, unless its

total equivalent length exceeds 9m, be one pipe size

larger than the nominal outlet of the combined

temperature & pressure relief valve.

Where the total equivalent length of the discharge

pipe exceeds 9m the pipe must be increased by one

pipe size for each additional 9m length. For example a

discharge pipe having an equivalent length of

between 9 and 18m must be two pipe sizes larger

than the nominal outlet of the combined temperature

& pressure relief valve, between 18 and 27m three

pipe sizes larger, and so on. Bends must be taken

into account when calculating the flow resistance.

See Figure 6 and Table 4 for a typical discharge

arrangement and worked example.

Note. An alternative approach for sizing discharge

pipes would be to follow BS 8700: 1987 Specification

for design installation, testing and maintenance of

services supplying water for domestic use within

buildings and their curtilages. Appendix E, section

E2 and tables 21.

The discharge pipe must be installed with a

continuous fall towards its point of termination,

which ideally should be below a fixed grating and

above the water seal in a trapped gully. Where this is

not possible or practical then the discharge pipe may

terminate either:

q At low level discharge above external surfaces

such as car parks, hard standings, grassed areas

and so on, providing that termination is a

maximum of 100mm above the surface and a wire

cage or similar guard is fitted to prevent contact

with any discharge, while still maintaining

visibility, or;

q At high level into a metal hopper and m etal

down pipe with the end of the discharge pipe

being clearly visible or alternatively, onto a flat

roof capable of withstanding high temperature

discharges of water. Such termination however,

must not be within 3m of any plastic guttering

and the tundish must be clearly visible in order

to detect any occurrence of discharge.

In cases where a single common discharge pipe

serves a number of units, such as in a block of flats,

the number of units served should be limited to a

maximum of six. The common di scharge pipe should

be at least one pipe size larger than the largest

individual discharge pipe to be connected.

Where the Atmos Multi is installed in a property

where discharge from the unit may not be apparent,

such as in the case of blind, infirm or di sabled

people, then consideration should be given to the

installation of an audible electronically operated

device to warn when discharge takes place.

Combined Safety discharge and condensate pipe

Subject to the approval of the Local Building

Inspector, the Safety discharge pipe and condensate

discharge pipe may be combined into a single

common discharge pipe. A schematic layout for such

an arrangement is given in Appendix 2 of these

instructions.

ATMOS MULTI version 2002 Page 16

Page 17

Worked example:

The example below is for a G ½ temperature relief

valve with a discharge pipe (D2) having 4 No. 22mm

elbows and length of 7m from the

tundish to the point of discharge.

From Table 1

Maximum resistance allowed for a straight length of

22mm copper discharge pipe (D2) from a G ½

temperature relief valve is: 9.0m

Subtract the resistance for 4 No. 22mm elbows at

0.8m each =3.2m

Therefore the maximum permitted length equates

to 5.8m which is less than the actual length of 7m.

Therefore calculate the next largest size (28mm) .

Maximum resistance allowed for a straight length of

28mm-pipe (D2) from a G ½ temperature relief valve

is: 18m

Subtract the resistance for 4 No. 28mm elbows at 1.0

m each = 4m Therefore the maximum permitted

length equates to 14m.As the actual length is 7m a

28mm (D2) copper pipe will be satisfactory.

ATMOS MULTI version 2002 Page 17

Page 18

6.6 Existing systems.

All re-circulatory water systems are subject to

corrosion unless an appropriate water treatment is

applied. To prevent the risk of corrosion sludge

accumulates within an existing system causing

boiler noise and circulation problems along with

possible pump and valve damage, existing heating

systems must be thoroughly flushed to ensure that

all sludge and debris is removed prior to installing

the boiler.

Where a cleaning agent is used for this purpose

only Sentinel X400 is recommended. Atmos Heating

Systems do not recommend the any other cleaning

agent. The use of non-recommended cleaning

agents will invalidate the boiler's guarantee.

Note. When after flushing and cleaning of the

system has taken place there is any possibility of

any debris remaining in the system, it is

recommended that a 'Y' strainer is fitted on the boiler

Return pipe.

7. Boiler Installation.

7.1 Unpacking

Due to the boilers dry weight of 75kg it is

recommend that either a sack barrow or two men are

employed to carry the boiler to its chosen position.

The boiler must be carried and stored horizontally

on the wooden pallet provided. Under no

circumstances must it be stored vertically.

The appliance is protected by a cardboard box and

delivered as standard with:

q Mounting bracket

q Fixing pack consisting of 2 wall plugs, 2 bolts

and 2 washers

q Burner inspection window

q Automatic de-aerator

q Siphon

q Template

q Guarantee registration card, Operating

instructions and Installation instructions

In addition the boiler is supplied with;

q WRAC mains water kit including UV3 cold

water inlet manifold, an 8 litre blue expansion

vessel, safety valve and pipe connections and;

q Robokit sealed system expansion vessel

including wall bracket and safety valve.

Using a knife, cut open the bottom tray of the box

and remove the top box from the bottom tray (fig. 7).

Figure 7: Unpacking boiler

Check the appliance immediately after unpacking.

Any damage must be reported immediately to your

supplier.

The packaging consists of corrugated cardboard,

wood and cellulose oil, and can therefore be

recycled as waste paper. Do not throw away the

packaging, but ask the local refuse collection

service where it can be taken.

Remove the appliance casing to prevent accidental

damaged during installation as follows (fig. 8):

i) Remove the two screws 'a' of the control panel.

ii) Unclick the catches 'b' at the top and bottom of

the appliance and remove case by lifting upwards.

ATMOS MULTI version 2002 Page 18

Page 19

Figure 8: Removing the appliance case.

Figure 10: Dimensions & minimum clearances

7.2. Minimum clearances.

For servicing and maintenance purposes, a minimum

clearance of 600mm to the front, 150mm above,

750mm below and 100mm to either side of the boiler

case is required. (fig. 9 & fig 10)

7.3 Boiler location.

The Atmos Multi is not suitable for external

installations.

While the appliance itself is provided with integral

Figure 9: Dimensions & minimum clearances

frost protection it must however, be installed in a

room that stays free of frost even in extremely cold

conditions. This is to prevent pipes or the safety

valves from freezing. If the selected room does not

ATMOS MULTI version 2002 Page 19

Page 20

meet this requirement, measures must be taken to

protect the safety valves and pipes against freezing.

The appliance must be installed on a flat vertical

wall that is capable of taking the weight of the

boiler. Do not fix directly onto low load bearing or

plasterboard walls.

For low load bearing and plasterboard walls a

special designed mounting frame incorporating

support legs should be employed. Contact Atmos

Heating Systems for this optional item .

On a lightweight block wall, heavy duty Rawplugs

must be used in place of the supplied wall plugs and

bolts.

The boiler may be fitted on or adjacent to a wall

comprising of a combustible material without the

need for a special thermal insulation barrier.

Due to the appliance being self-ventilating, it

remains relatively cool during operation. Generally

there is no requirement to provide purpose made

ventilation to an airing cupboard or compartment in

which the appliance is installed

A cupboard or compartment used to enclose the

appliance must however, be designed and

constructed specifically for the purpose and comply

with Building Regulations. The cupboard or

compartment must also be of sufficient size to

permit access for inspection and servicing or

removal of the boiler.

7.4. Wall mounting the boiler

Taking into account the clearances required for

servicing and maintenance, tape the provided

template onto the chosen wall position, ensuring it

is level and the correct way up.

Mark the position of the fixing holes for the boiler

mounting bracket. Drill the fixing holes using a

16mm drill bit and fit the mounting brack et using the

supplied fixing plugs and bolts.

Fit the appliance onto the mounting bracket as

follows (fig. 11):

a. Place the mounting indication point level with

the top side of the mounting bracket and

position the corners of the back of the casing

level with each end of the mounting bracket.

b. Put the bottom of the boiler against the wall.

c. Carefully lower the appliance onto the wall

bracket.

Note!

A lifting handle with red plastic covers on each

end is provided for lifting the boiler onto the

mounting bracket. Do not lift with other parts of

the boiler, as it may cause damage. To comply with

Health & Safety Regulations, Atmos Heating

Systems recommend that the boiler be lifted into

position by the use of two men.

Figure 11: Mounting the boiler

Warning : The fixings supplied are suitable

only for brick or solid block walls. When full

the Atmos Multi weighs 150kg and must not

be fitted directly onto walls with low load

bearing capacities.

ATMOS MULTI version 2002 Page 20

Page 21

7.5. Connecting the flue system.

Prior to connection of the boiler's flue system please

refer to sections 6.3 & 6.4 of these instructions.

The flue and air duct supplied by Atmos Heating

Systems are an integral part of the boiler and care

must be taken on their installation to ensure that all

joints are airtight and correctly made.

The standard horizontal flue kit supplied with

the boiler consists of a twin pipe terminal plate,

an 850mm length of 80mm diameter aluminium

duct and two 90º bends.

The flue and air ducts may be extended by

means of extensions, (available on request from

Atmos Heating Systems) to a maximum

combined length of 64m. The use of each

additional 90° or 45° bend however, reduces

the maximum permitted flue length by 3m and

1m respectively.

The duct and fittings are push fitted together being

sealed by the fittings integral 'O' ring. (fig 12).

On assembly it must be ensured that aluminium duct

is square and burr free prior to being pushed into

the fitting. Failure to do so may result in damage to

the sealing 'O' ring.

When connecting to the twin pipe terminal plate it is

important to ensure that the plate is fitted the

correct way up and the flue discharge and air inlet

ducts are connected to the correct terminal. (fig 13)

On installing the flue system it is recommended that

a 85mm diameter core drill is used when cutting

through the properties external wall.

For concentric and vertical roof systems refer to

separate installation instructions supplied with the

flue assembl ies.

Figure 12: Twin pipe joint

Figure 13: Twin pipe terminal plate

ATMOS MULTI version 2002 Page 21

Page 22

7.6.Connecting the central heating circuit.

Important Note!

The Atmos Multi is suitable for use on a

sealed heating system only. It must not be

connected to an open vented heating

system.

22mm diameter connections for the central heating

circuit flow and return pipes are located on the

underside of the appliance. (fig 14) The flow pipe

being colour coded red, the return pipe colour coded

blue.

Figure 14: Boiler flow & return connections .

Locate and fit the separately supplied automatic air

vent to the boiler's top right corner (fig 15). Once

fitted loosen the automatic air vent's cover cap.

Figure 15: Automatic air vent

The system must comply with the requirements of

BS5449 and to avoid corrosion and leaks, be

airtight, closed and connected in accordance with

Benchmark procedure.

When connecting the boiler to a heating system

containing plastic pipew ork the following must be

noted:

q In a floor heating system, the plastic

hoses/pipes used must either meet BS7291 having a

class 'S' rating or DIN 4726/4729 having an air

permeability less than 0·1 g/m³ at 40ºC.

q In a radiator system, the plastic hoses/pi pes

used must either meet BS7291 having a class 'S'

rating or DIN 4726/4729 having an air permeability

less than 0·1 g/m³ at 85ºC in a twenty four hour

period.

Connection of the Atmos Multi to a heating system

containing non-diffusion barrier oxygen permeable

plastic pipe or class 'H' plastic pipe will invalidate

the boilers guarantee.

It is important that there is a by-pass on the central

heating circuit to ensure that the system water is

able to flow through the boiler's heat exchanger at

all times. Thi s may be achieved by leaving at least

one radiator permanently open. Alternatively, a

pressure differential regulator valve (fig16) that

provides an automatic system by pass is available

on request from Atmos Heating Systems.

Figure 16: Pressure differential regulator valve

Before connection to the central heating system the

system must be must be thoroughly flushed in

accordance with the guidance given in BS7593.

ATMOS MULTI version 2002 Page 22

Page 23

A sealed system 'Robokit' is supplied with each

Atmos Multi boiler. Expansion vessels are available

in 8,12 or 18 litre sizes with the Robokit,

and are coloured RED. Table 5 provides guidance

to the size of expansion vessel required for systems

fitted with steel panel radiators in a two-storey

house. Consult Atmos Heating Systems for further

information and advice for non-standard systems.

Note. The red primary expansion vessel must not be

confused with the blue secondary expansion vessel

intended for use on the domestic hot water circuit.

Table 5: Required expansion vessel

Where required, the boiler offers the facility for an

independent towel rail circuit to be installed via the

purpose supplied towel rail connection (fig 16a)

This allows for the separate heating of a radiator

when the boiler is operating in either central heating

or hot water mode. To prevent hot water circulation

within the central heating system when the boiler is

operating in domestic hot water only mode, the

towel rail circuit return must be the last connection

on the return pi pe to the boiler.

Note. When utilised, the towel rail circuit must be

carefully balanced to avoid short-circuiting of the

main central heating system.

Figure 16a Towel rail connection

Figure 17: Pre-assembly kit

From the pre-assembly kit (fig 17) select the

Assembly 1 and fit to the 22mm central heating

return on the boiler, utilising the 22mm compression

straight connector supplied.

Using the wall bracket supplied, fit the Red

expansion vessel to the wall in close proximity to

the boiler. Connect the expansion vessel to the

15mm pipe connection g. This can be with either

15mm copper tube or alternatively, using optional

ATMOS MULTI version 2002 Page 23

Page 24

flexible hose connections available as an optional

extra from Atmos Heating Systems. The connection

to the expansion vessel utilises a ¾ female x ½ male

threaded adaptor and the washer provided must be

fitted internally. The other end has a 15mm

compression fitting.

Fit the filler loop from the cold water main to the

second 15mm pipe connection d, ensuring that the

loop is fitted in the right direction as indicated on

the arrow stamped on the non-return valve.

Fit the heating system safety valve into the ½"

BSPF connection, pointing in the direction shown

ready for connection into the discharge pipe. (fig

18)

7.7.Connecting the mains cold water.

Each Atmos Multi boiler is supplied with a mains

pressure kit comprising the following components:

q UV3 manifold including pressure reducing valve

pre-set at 3.5 bar. (Altecnic)

q ½" Caleffi safety relief valve set at 6bar.

q 8 litre blue potable expansion vessel (Altecnic)

q Expansion vessel mounting bracket.

q 22mm x 15mm compression reducing set.

q Black plastic tundish. (Altecnic), and;

q ¼" BSPM drain cock.

The mains pressure kit must be assembled as shown

in fig 18 in the following manner:

Figure 18: Mains pressure kit assembly

q Connect the UV3 manifold to the boilers15mm

cold water inlet supply pipe (colour coded blue),

using the 22mm x 15mm compression reducing set

supplied.

q Connect the 22mm incoming cold water main

supply to the inlet of the UV3 combined 22mm stop

tap and pressure reducing valve.

q Locate and fit the 6bar safety relief valve, by

push fitting into its fixing socket on the UV3

manifold. A small grub screw located in the side of

the manifold is provided to lock the valve in

position, by means of the Allen key provided.

q The 22mm branch 'E' is provided for the cold

water system of the house, where equal hot and

cold water pressures are required. If this facility is

not required, the branch may be blanked off using

the blanking plug provided.

q Locate and fit the supplied ¼" BSPM drain-off

cock to the manifold's socket 'G'. The fitting of this

drain off cock enables 90% of the water content of

the hot water tank to be drained.

q Fix the Blue 8 litre potable expansion vessel

adjacent to the 'primary' heating expansion vessel

using the wall brackets provided.

q Connect the potable expansion vessel's ¾" boss

to connection 'H' on the UV3 manifold using 15mm

ATMOS MULTI version 2002 Page 24

Page 25

copper pipe.

r no circumstances must any valve be

installed between the expansion vessel and

Important Note!

Unde

connection 'H' on the UV3 manifold.

q Connect the 6 bar safety valve discharge pipe as

described in Section 7.6 of these instructions.

Warning!. Failure to install the above components

correctly is dangerous, and renders the system

unsafe. Furthermore the copper tank guarantee is

invalidated.

7.8.Connecting the safety discharge pipes.

The safety discharge pipes must be assembled as

shown in fig 19 in the following manner:

Figure 19: Safety discharge pipes

Test Hole

copper tee and pipe.

q Connect the black tundish as illustrated. The

tundish must be located in a position where it is

clearly visible to the householder and away from

any electrical devices or wires.

q Connect the 'primary' heating expansion vessel's

pressure relief valve discharge outlet to the under

side of the tundish using a 22mm x15mmx 22mm

copper tee

q A straight vertical pipe with a minimum length of

300mm must be provided below the tundish before

the fitting of any bends.

q The discharge pipe must be ran to an external

drain, terminating in a safe place where there is no

risk to persons in the vicinity of the discharge. The

discharge pipe must consist of metal, preferably

copper.

q If the length of discharge is more than 9m

equivalent length (a bend has an equi valent length

of 0·8m) a larger pipe must be fitted. (see Section 6.5

of these instructions).

q The discharge pipe must have a continuous fall

towards its point of termination, in order to drain

effectively.

q The discharge pipe point of termination should

ideally be below a fixed grating and above the water

seal in a trapped gully. If this is not possible then

refer to Section 6.5 of these instructions for

acceptable alternative discharge terminations.

q The discharge pipe must not be used for any

other pur pose.

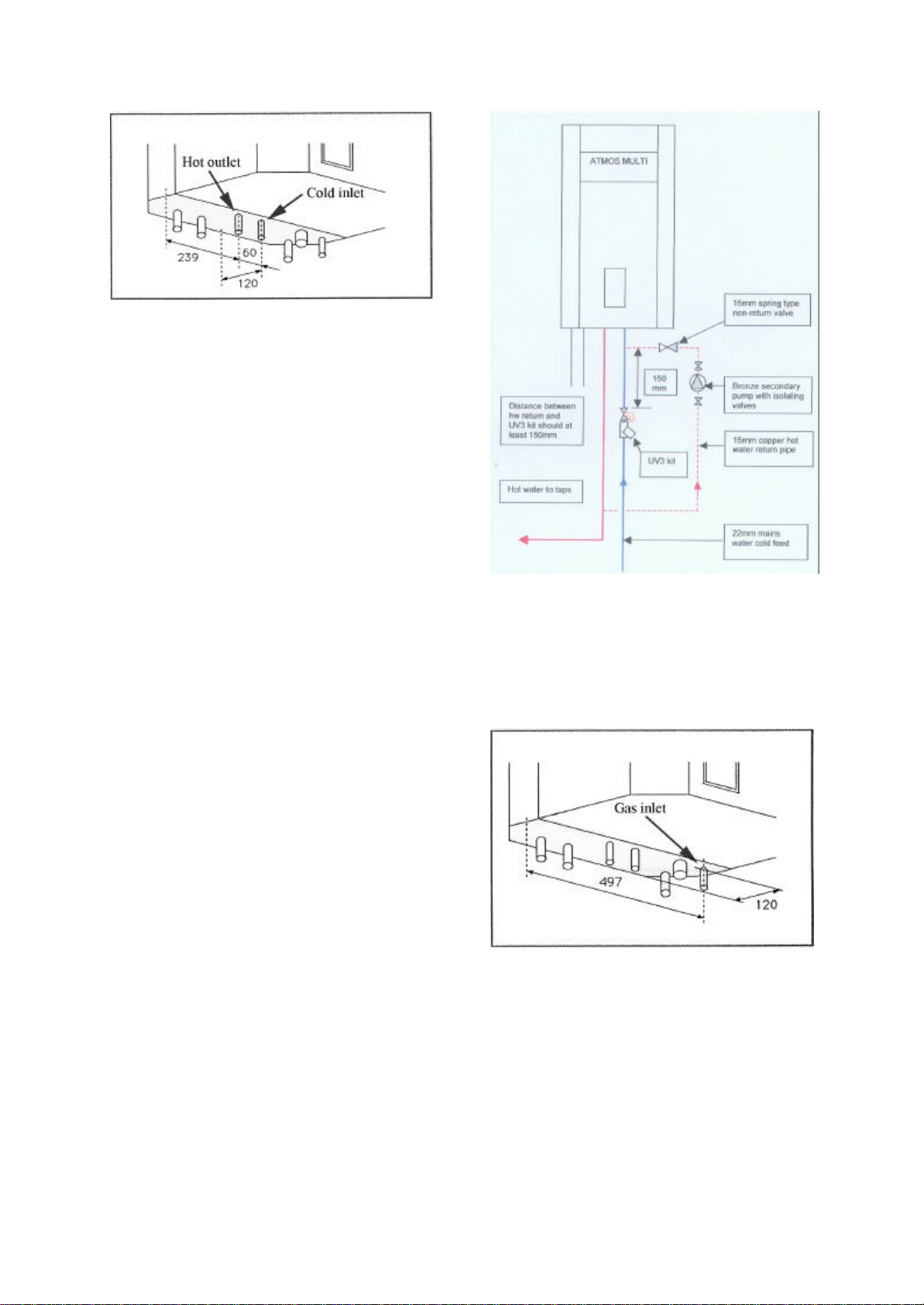

7.9.Connecting the domestic hot water supply.

The cold water inlet and hot water outlet connection

points for supplying domestic hot water are located

on the underside of the appliance (fig 20). The cold

water inlet being colour coded blue, the water outlet

colour coded red.

Figure 20: Hot water connections.

q Connect the boiler's integral temperature &

pressure relief valve discharge outlet and the

discharge outlet of the 6 bar pressure relief valve

fitted to the UV3 manifold, by means of a 15mm

ATMOS MULTI version 2002 Page 25

Page 26

The cold water inlet to the boiler must be made via

the UV3 manifold. The properties hot water supplies

are connected to the boiler via the 15mm diameter

hot water outlet connection.

The boiler's minimum domestic hot water

temperature setting is 60°C., the installation of a

thermostatic mixing valve is recommended to reduce

the hot water temperature at the tap.

7.9 Hot water secondary circulation.

While there is no separate secondary return

connection on the boiler, a secondary re-circulation

loop may be installed. Where required, the

secondary return should be taken to the cold water

feed of the storage tank, immediately after the UV3

manifold. The return must not pass through the UV3

manifold. If the secondary return loop has a volume

in excess of 1 litre, a larger potable expansion vessel

should be used. Contact Atmos Heating Systems

for further advice.

A non-return valve must be fitted to the return loop

to prevent the back flow of cold water to the hot

water taps. (Fig 20a)

7.10.Connecting the gas supply.

The gas pipe inlet connection is located on the

underside of the appliance being colour coded in

yellow. (Fig 21)

Figure 21: Gas inlet connection

Figure 20a Hot water secondary circulation

Check the boiler's data plate to ensure that the

appliance has been set for the correct gas supply.

The boiler is available for either Natural Gas (G20) or

propane (G31).

For Natural gas the supply pipe must have a

minimum diameter of 22mm. The meter governor

should deliver a dynamic pressure of 20mbar for

natural gas or 37mbar for propane.

ATMOS MULTI version 2002 Page 26

Page 27

The ¼ turn gas tap provided must be fitted

immediately to the boiler to enable complete gas

isolation to the boiler during maintenance and

servicing work.

To prevent the ingress of foreign matter and

possible damage to the gas-regulating block, the

gas supply pipe must be checked for contaminants

prior to connection to the boiler.

On final connection of the gas supply to the boiler,

the complete gas installation, including the meter,

must be tested for gas soundness and purged as

described in BS6891.

7.11. Connecting the condensate siphon

The connector for the condensate water discharge

is located on the underside of the appliance (fig. 22).

Figure 22: Condensate connection.

Locate and connect the supplied siphon to the

boilers condensate drain connection via 32mm dia

plastic pipe. The siphon should be fitted so its

outlet is angled towards the rear wall and left with

an open connection to the purposely installed 32mm

dia condensate drainage pipe work. (fig 23)

For condensate drainage pipework refer to Section

6.5 of these instructions.

Figure 23: Condensate discharge arrangement.

7.12. Connecting the mains electricity.

Warning! The electrical wiring of the

Atmos Multi is complete and must

not be changed or adapted in any

All electrical connections to the mains supply must

be made in full accordance with the current I.E.E.

regulations.

The boiler must be earthed and connected via a

double pole isolating switch fused to 3 amp or

alternatively, by the use of a 3 amp fused three pin

plug and unswitched shuttered socket outlet

Where possible, it is recommended that the

appliance is protected against electrical surges by

the fitting of an anti -surge device.

On connection it is essential that correct polarity be

observed. If polarity is reversed, the control unit will

lock and a malfunction alert ‘L’ will be displayed on

the control panel. Should this occur, the wiring must

be reversed to its correct polarity and the boiler restarted

A facility for the connection for a 24V AC room is

ATMOS MULTI version 2002 Page 27

Page 28

located behind the control unit front fascia.

Important Note!

Under no circumstances must any electrical

power be input to the room thermostat terminals.

Care must also be taken to avoid induced

voltages caused by the running of the

thermostat cables along side other main voltage

cables.

On connection the room thermostat's heat

accelerator must be set at 0·12A. The maximum

permissible resistance of the room thermostat circuit

is 22 Ohms. Where a clock thermostat is employed,

the closed-circuit current must not exceed 20mA

when there is no demand for heat.

It is recommended that the room thermostat is not

set lower than 15ºC during the winter months.

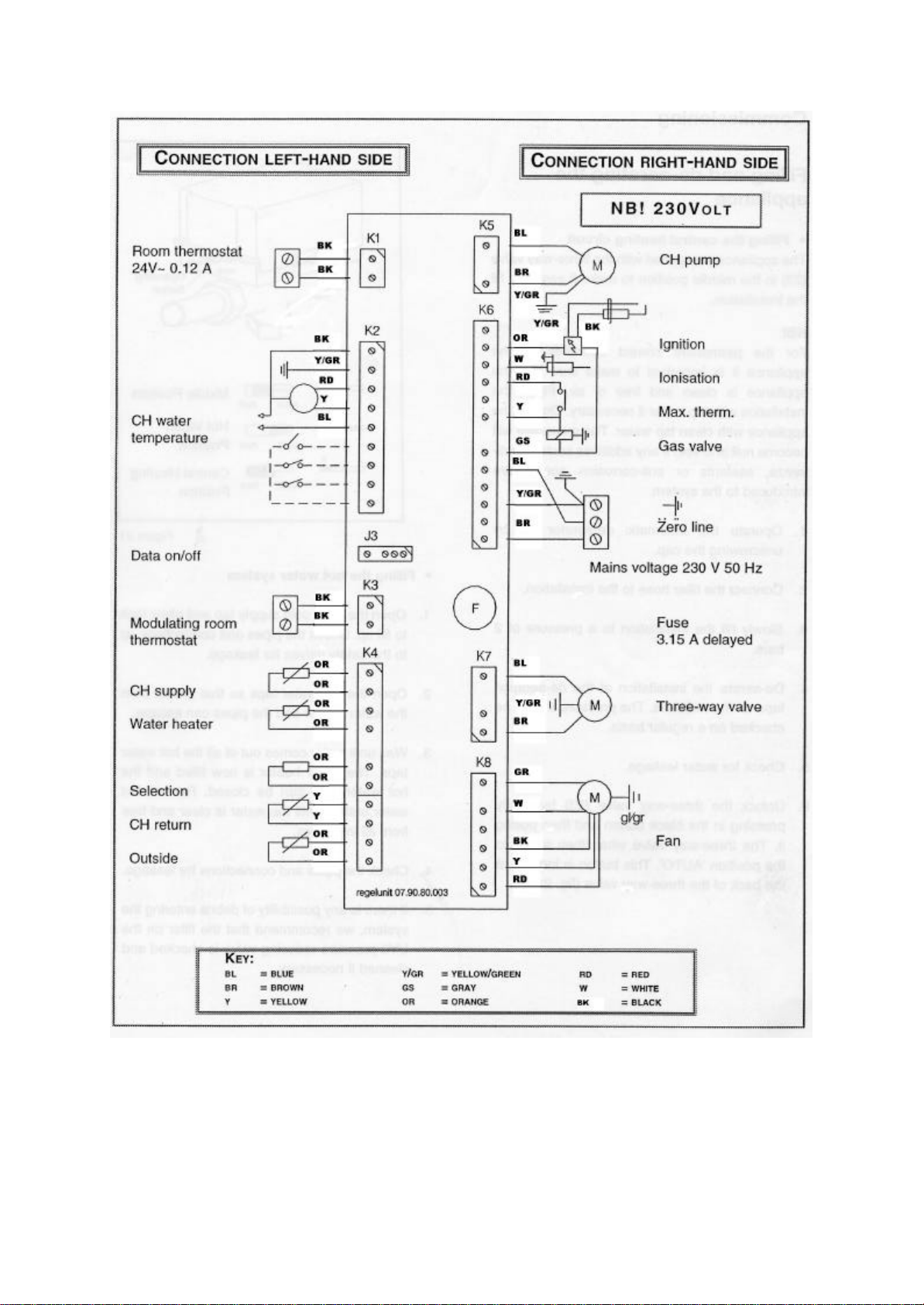

Figure 24: Atmos Multi wiring diagram .

Where a 'wireless' room thermostat is employed

consult the thermostat's manufacturer instructions

for installation.

A wiring diagram of the Atmos Multi is given as

figure 24.

ATMOS MULTI version 2002 Page 28

Page 29

8. Commissioning.

Note: We include Benchmark Logbooks with

every boiler and advise that they are filled in during

the commissioning procedure.

ATMOS MULTI version 2002 Page 29

Page 30

8.1 Filling the heating system.

Warning! The Atmos Multi must not be operated

in a waterless condition.

On completion of the boiler installation and

ensuring that all water connections are correctly

made and tight, the boiler may be filled with clean

water by fitting the supplied filling hose and

opening the two Robokit manual filling valves. (fig

25)

Figure 25: Filling hose connection.

q Test the operation of the system’s outlet safety

valve by turning the valve knob anti -clockwise until

water is released, at which point the valve must be

closed and re-set.

q Continue to fill the system until all air has been

expelled, leaving the system pressure at a nominal

2bar.

q Check the system for water soundness,

rectifying where necessary and remove the system

filling hose.

Figure 27: Three-way valve

On filling:

q Ensure that the boiler's automatic air vent

sealing cap is loose.

q Slowly fill the installation until a system

pressure of 2bar is obtained.

q Vent each system radiator and purpose fitted air

vent in turn starting with the lowest in the system.

The system pressure should be regularly monitored

during this process and topped up when required.

q Air must be vented from the boiler pump by

unscrewing the pump’s integral vent plug (fig 26)

and allowing water to bleed for a few seconds,

taking care not to allow water to splash onto the

boiler's electric parts. This process may have to be

repeated two or three times during the filling

process.

Figure26: Venting the pump

To aid filling the boiler is supplied with its integral

three way valve locked in the middle position. On

completion the valve must be unlocked by lightly

ATMOS MULTI version 2002 Page 30

Page 31

pressing and then pulling the black button located

on the rear of the valve. (fig. 27).The three way

valve will then return to the 'Auto' position.

Where required Sentinal X100 may be added to the

system water in accordance to its manufacturer

instructions. Atmos Heating Systems do not

recommend the use of any other inhibitor or

additive. The use of a non-recommended inhibitor

or additive will invalidate the boiler's guarantee.

Note! For existing central heating systems the final

system water must have a pH value of between 6.5

and 8.

8.2 Filling the domestic hot water system.

q Open the UV3 combined stop tap and pressure

reducing valve and allow the storage tank to fill with

water. Check the pipework and connections up to

the safety valves for leaks.

q Vent the domestic hot water system by opening

all hot water outlets until water is discharged.

q Turn off the hot water outlets once the

discharge water is clear and free from impurities.

q Check the system for water soundness,

rectifying where necessary.

Note! If there was any possibility of debris entering

the domestic hot water circuit during filling, the filter

on the UV3 pressure-reducing valve must be

removed and cleaned as necessary. (fig 28)

8.3 Appliance operation.

The appliance may be put into operation by the

follow procedure:

q With the appliance manual gas tap in the 'off'

position, switch on the electrical supply to the

boiler. If a letter 'L' appears on the diagnostic

display the boiler has been wired with reversed

polarity.

q Check that the water pressure in the central

heating circuit is approximately 2 bar at the

appliance. If the central heating water pressure is

below 0·5 bar or higher than 3 bar a letter 'C'

Figure 28: UV3 cold water filter

alternating with the work status of the appliance will

be shown by a warning report on the diagnostic

display. (see Section 12.). If this report is shown the

appliance will only run at its minimum capacity.

q Switch off the domestic hot water heating by

pressing the 'Hot water' button on the operating

panel. The 'on' indication light will go out.

q Open the appliance gas tap and purge the gas

supply if necessary via the measurement nipple

provided for measuring the pre-pressure (fig. 29).

Figure 29:

q Set the room thermostat at its highest position.

The appliance will now start (status report Code 2º).

If the hot water temperature is under 8ºC, the frost

protection will cut in and the boiler will automatically

ATMOS MULTI version 2002 Page 31

Page 32

revert to raising the hot water temperature above

water the room thermostat also makes a

15ºC (status report Code 3•).

Note! If air is still present in the gas supply, the

boiler's burner may attempt to ignite once or several

times. After four start attempts a flame malfunction

will be indicated (flashing 3•). If this occurs, unlock

the control unit by pressing the reset button. The

appliance will now run for the first 3 minutes at the

lowest capacity and will switch to its maximum

capacity until the central heating water temperature

has fallen below 80ºC. The appliance modulates

between 80ºC and 90ºC.

q If the boiler's burner fails to ignite after 3 reset

attempts, re-purge the gas supply, using the prepressure measurement nipple. Otherwise consult the

Atmos Multi Service Manual.

q Ensure that the appliance is functioning

correctly by undertaking the following inspections

and noting the results and work carried out on the

Service Card located on the front of the boilers

storage tank insulation shells:

1. Visual inspection of the combusti on flame

2. Measurement of the gas flow rate by watch &

meter.

3.Measurement of either the O2 or CO2 percentage

concentration within the flue gases by flue gas

analysis.

4.Measurement of gas pre-pressure

q The procedure required to undertake

inspections 1, 2 & 3 are detailed in Section 10 of

these instructions. The procedure for inspection 4

is as follows:

v The measurement of gas pre-pressure must be

taken during burner operation at maximum heat

input via the measurement nipple provided on the

gas valve. (fig 22). The gas pre pressure reading

must be at least 20mbar.

q Check the burner's gas rate by stopwatch and

meter. On the maximum input of 24kW or 32kW

(depending on boiler model) the time taken to use 24

litres or 32 litres of gas respectively should be 33

seconds (± 2seconds.)

Note! The appliance burner pressure is factory set

and sealed. The burner pressure can only be

measured using precisely calibrated CO2 or O2

measuring instruments. If an inaccuracy is found

when checking the appliance gas rate then consult

the separately available Atmos Multi Service

Manual or contact Atmos Heating Systems.

q Set the room thermostat to its minimum setting.

q Switch on the hot water heating by pressing the

hot water button. The 'on' indication light will

illuminate. The thr ee-way valve will switch over to

the water heater position and the burner will ignite

to the stored domestic hot water. (status report

Code 1•).

q While the stored domestic water is heating,

check that expansion water is entering the tundish

of the discharge system.

q Reset the room thermostat back to the desired

position.

Note!

If during the heating of the stored domestic

demand for heating, the hot water and central

heating demand will be met simultaneously

(status report Code 4•).

The following codes may also appear on the

diagnostic display during the commissioning

process:

§ (1•) Heat demand water heater

§ (2•) Heat demand central heating

§ (3•) Heat demand water heater and

§ (4•) Heat demand water heater and

8.4 System balancing.

For efficient boiler operation the heating system

must be correctly balanced to ensure that all

C/heating, priority water heater

heating

C/heating, supply to both.

ATMOS MULTI version 2002 Page 32

Page 33

radiators are heating up evenly and a required

temperature differential of 20ºC is present between

the boiler's heating flow and return connections.

The required water flow rate through the appliance

is 0·8 m³/h and 1·2 m³/h for the Atmos Multi 24 and

32 models respectively. The maximum permissible

system resistance to enable the boiler pump to

achieve these flow rates is 3·1m and 2·1m

respectively. (fig 30)

Figure 30: Available pump outputs

9. System shutdown.

9.1 Central heating circuit.

q Leave the appliance connected to the main

electrical supply.

q Turn the room thermostat to its minimum

setting. The domestic water heater will remain

at its set temperature setting.

Note! On shutting down the central heating system

it is recommended not to set the room thermostat

lower than 15ºC during the winter months. To

prevent the installation from freezing it is

recommended leave all radiator valves fully or

partially open.

9.2 Domestic hot water.

q Leave the appliance connected to the main

electrical supply.

q Switch off the domestic hot water by pressing

the 'Hot water' button. The ‘on’ indication light

will go out. (The stored water is protected

against freezing in winter months by an

automatic frost protection that activates on a

water temperature of 15ºC).

Note! The heating and domestic hot water

installation must be independently protected from

frost. The boiler's built-in frost protection facility

will only safeguard the appliance itself.

9.3 Draining the boiler

Hot water tank

q Turn off the cold water mains stop tap and

open the domestic hot taps.

q Connect a flexible hose from the black drain tap

on the UV3 manifold, into the tundish. The

water from the hot water tank will now flow into

the waste pipe via the funnel of the Safety

Valve group.

Alternatively, the tank may be drained via the safety

valve on the UV3 manifold. The valve head should

be rotated through 90º and held open until water

stops flowing.

Central heating circuit.

q Switch off the boiler electrical supply.

q Set the three-way valve (fig 27) at the middle

position by pressing in the black button until it

locks

q Allow the installation to drain using the

purpose fitted drain cocks.

9.5 Disposal of the appliance

The Atmos Multi is made of a number of primary

materials, especially copper, aluminium and steel.

These materials can easily be separated and

recycled at the end of the life span of the appliance.

Therefore do not throw away the appliance, but

make enquiries at your local council or a scrap

dealer.

10. Routine Inspection and Servicing.

To ensure continued efficient operation of the

Atmos Multi it must be checked and serviced as

necessary at regular intervals. The frequency of

servicing depends upon the individual installation

conditions and usage, but must be a minimum of

once per year.

The extent of the servicing required is determined

by the operating condition of the appliance when

ATMOS MULTI version 2002 Page 33

Page 34

tested by a fully qualified engineer.

Only competent engineers such as a Corgi

registered installer must carry out any service work.

10.1 Boiler pre-service inspection.

Warning!

Turn off the boiler electrical supply before

removing the appliance casing. The fan, gas

valve, three-way valve and central heating

pump are mains fed with 22OV

The annual inspection of the boiler comprises of the

following:

1. Visual inspection of the flame

2. The measurement of the O2 or CO2

concentration in the flue gas

3. Measuring the gas rate.

4. Inspecting the ionisation flow.

5. Inspecting the ai r inlet filter.

6. Inspecting the siphon.

Note! The inspection results and any

servicing work undertaken must be noted on

the service card located on the front of the

hot water storage tank insulation shells.

1. Visual inspection of the flame

The flame must be assessed after one minute of

combustion at the low position or high position.

q Low position

Viewed from top to bottom on the combustion seat

the burner flame picture must have the presence of a

light blue flame.

A completely red flame indicates that the supplied

air/gas mixture is gas rich, an entirely dark blue

flame indicates an air rich mixture.

If the flame picture is correct there is no need to

measure the O2 or CO2 concentration of the flue gas

and point 2 of the inspection can be left aside. If the

flame picture is not correct, the O2 or CO2

percentage of the flue gas must be measured.

q High position

Viewed from top to bottom on the combustion seat

the burner the burner flame picture must have the

presence of an entirely blue flame. The air/gas

mixture setting of the high position are determined

by the setting of the low position.

If the flame picture is not correct, the O2 or CO2

percentage of the flue gas must be measured.

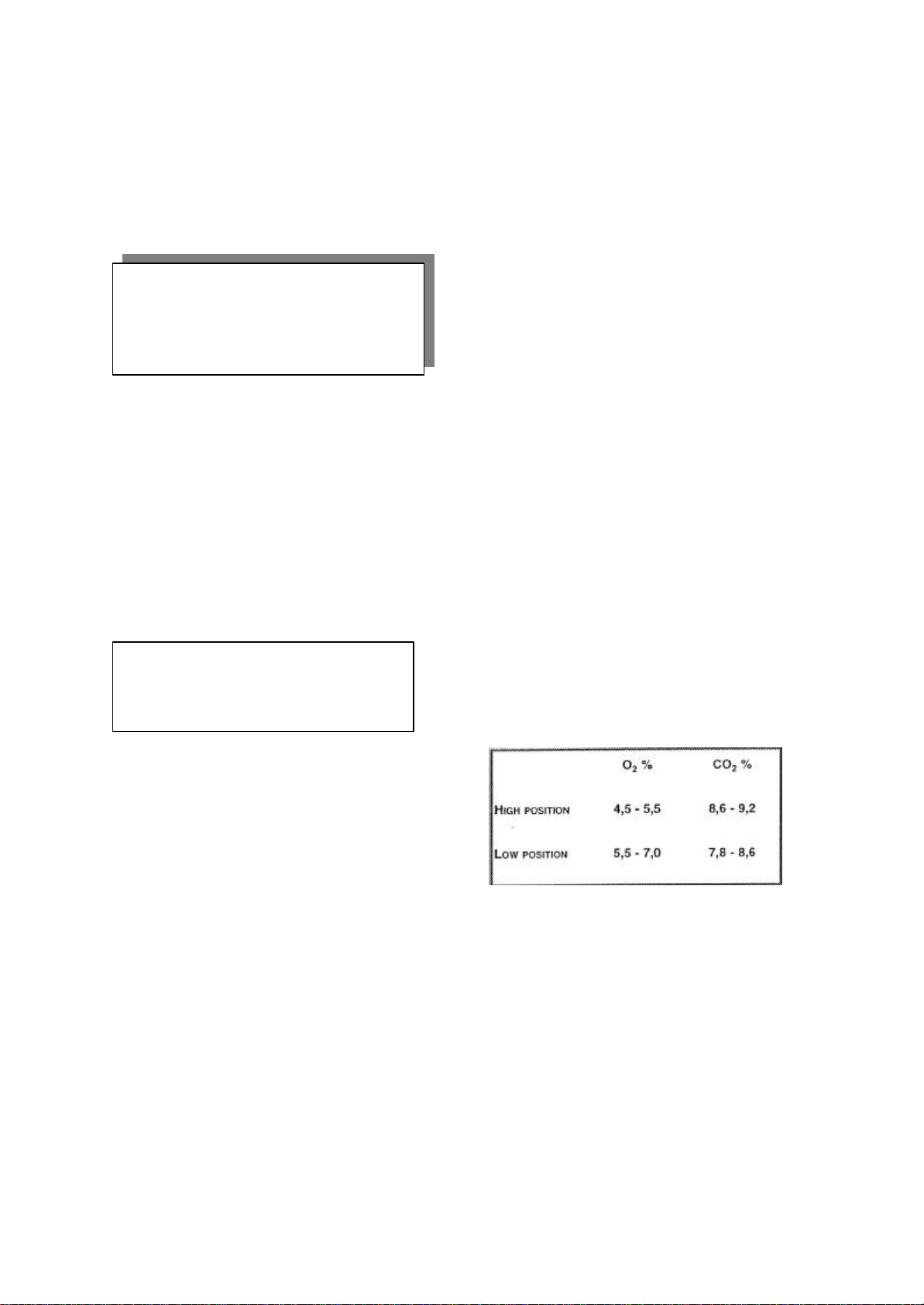

2. Measuring the O2 or CO2 concentration of the

flue gas.

The O2 or CO2 measurement of the flue gas must be

undertaken using an analyser calibrated to a

precision of < 0,2%.

Measurements of the flue gas O2 or CO2

concentration must be taken at both the burner's

low and high input capacity settings. The low input

setting must be the first measurement.

On initial start up the burner fires on high input

capacity prior to reverting to low input capacity for

3 minutes. After which per iod the burner again

reverts back to high input capacity.

The measured O2 or CO2 must fall within the limits

given in table 6.

Table 6. O2 and CO2 limits

Note the measured values on the service card

situated in the inside of the appliance. Compare the

new values with those measured when the

appliance was put into operation and/or during the

previous inspections. If the differences between the

two values are considerable, consult the Atmos

Multi Service Manual or contact Atmos Heating

Systems.

3. Mea suring the gas rate.

ATMOS MULTI version 2002 Page 34

Page 35

Check the burner's gas rate by stopwatch and meter.

On the boilers maximum burner input of 24kW or

32kW (depending on boiler model) the time taken to

use 24 litres or 32litres of gas respectively should be

33 seconds (± 2seconds.)

Note! If the flue's 80mm-diameter gas discharge duct

is longer than 10 metres at the gas rate will be

adversely affected and the measured time will in this

case increase by 2%.

Note the measured value on the appliance service

card. Compare the measured time with the value(s)

recorded last time the appliance was put into

operation and/or the previous annual inspection.

If the measured time falls outside of the tolerances,

inspect the air supply and flue gas discharge

system and the heat exchanger of the appliance for

soiling, and clean where necessary (see Section

10.3).

5. Measuring CO2 percentage of the flue gases.

Use a Flue gas analyser with a precision of <0.2% to

check the CO2 percentage of the Flue gases.

Flue gas samples can be taken from the test hole at

the left-hand side of the outlet casing. (See fig. 19)

6. Inspecting the lonization flow.

The ionisation flow of the burner can be read off via

the Service Programme of the control unit. Consult

the Atmos Multi Service Manual for the access

procedure for the Service Programme. The

ionisation flow should be greater than 30 for both

the low and high positions. If there are differences

the ionisation probe must be examined and replaced

as necessary (see Section 11.4).

7. Inspecting the air inlet filter.

The air inlet filter situated on the appliance's

combustion air inlet must be inspected for damage

and cleaned or replaced where necessary.

8. Inspecting the siphon.

Remove the siphon cap at the bottom of the

appliance and check the cap for the presence of

aluminium oxide.. If a quantity of aluminium oxide is

present, the heat exchanger will require cleaning

(see Section 5.2). The siphon cap must be firmly

replaced following inspection.

10.2 Auxiliary equipment inspection.

The annual inspection of the boiler's auxiliary

equipment comprises of checking the following:

1. Operation of safety relief valves

2. Operation of pressure reducing valve

3. Expansion vessels pre-charge

1. Safety relief valves.

Three safety relief valves are fitted to the system,

two are external to the boiler and one internal. The

valves operation may be checked by rotating the

cap of the valve through 90º, which will result in a

discharge of water from the valve. If there is no

discharge, check that the system is correctly

pressurised, if so replace the defective valve.

Check that there is no discharge leak when the

valves are returned to their closed position.

2. Pressure reducing valve

Turn off the cold water supply and remove the

pressure reducing valve's head from the UV3

manifold. Check the gauze filter and clean or replace

as necessary.

Check the water pressure at the valve outlet is no

higher than 3·5bar. If the pressure is higher than

3·5bar then recalibrate or replace the valve as

necessary.

3. Expansion vessels

q Domestic hot water vessel. (Blue)

Turn off the mains cold water supply stop tap and

depressurise the hot water system. Apply a suitable

air pressure gauge to the vessels air valve. The

pressure should be 3·5bar. If below 3·5bar the vessel

must be re-pressurised or replaced.

ATMOS MULTI version 2002 Page 35

Page 36

Before servicing the boiler, isolate the

q Heating system vessel (Red)

Isolate the boiler and depressurise the heating

system. Follow the procedure for the domestic hot

water vessel ensuring the pre charge pressure is as

stated on the expansion vessel label. (Normally 1·5

bar)

10.3 .Servicing the boiler.

Warning!

electrical supply and close the boiler's gas

service control tap. Allow the boiler to cool

before commencing work.

Gas soundness checks must always be carried out

following servicing of any gas-carrying component.

Following servicing work, electrical system safety

checks must always be undertaken using a suitable

instrument prior to reinstating the electrical supply

to the appliance.

Correct boiler servicing comprises of the following:

1. Cleaning the appliance outlet casting.

2. Inspecting the burner unit.

3. Cleaning the heat exchanger.

4. Inspect air supply/flue gas discharge system.

5. Unvented hot water tank inspection.

1. Cleaning the outlet casting

Using a 8mm socket, release the 3 fixing nuts

securing the outlet casting to the base of the heat

exchanger and remove the casting by gently

separating it from the push fit connection with the

condensate tr ap. (fig 31)

Remove the flue baffle by turning its base locking

'T' bar through 90º.

Inspect the outlet casting and baffle, cleaning where

necessary.

Figure 31: Outlet casting

Figure 32: Flue baffle

2. Inspecting the burner unit

Disconnect the gas supply from the gas valve via

the connecting joint union and release the 3 fixing

nuts securing the burner to the inlet casting, using

an 8mm socket. (fig 33)

Disconnect the push on electrical connections to

the fan, high temperature thermostat, ignition

electrode and ionisation electrode.

Figure 33: Removing burner assembly.

ATMOS MULTI version 2002 Page 36

Page 37

The heat exchanger must be cleaned on at least

Do not use a brush with metallic bristles, as this

will

Lift and remove the burner assembly from the

appliance.

Inspect the ignition electrode and check the

electrode's distances between the burner and earth

pin are 5mm and 3·5mm respectively. (fig 34).

Replace or adjust the electrode as necessary

Inspect the ionisation electrode and check the

distance between the electrode and the burner is

10mm. Replace or adjust the electrode as necessary

Figure 34: Ignition electrode.

Inspect the fan and the inner grating of the burner

and clean where necessary using a soft brush or

compressed air.

Inspect the inlet casting sealing gasket and replace

if necessary. (fig 35)

Figure 35: Inlet casting seal

3. Cleaning the heat exchanger.

Inspect the heat exchanger from the topside of the

appliance and remove any deposits from the heat

exchanger and fins using a soft brush.

Important!

every third service inspection.

damage the heat exchanger.

A purpose made heat exchanger cleaning brush