Page 1

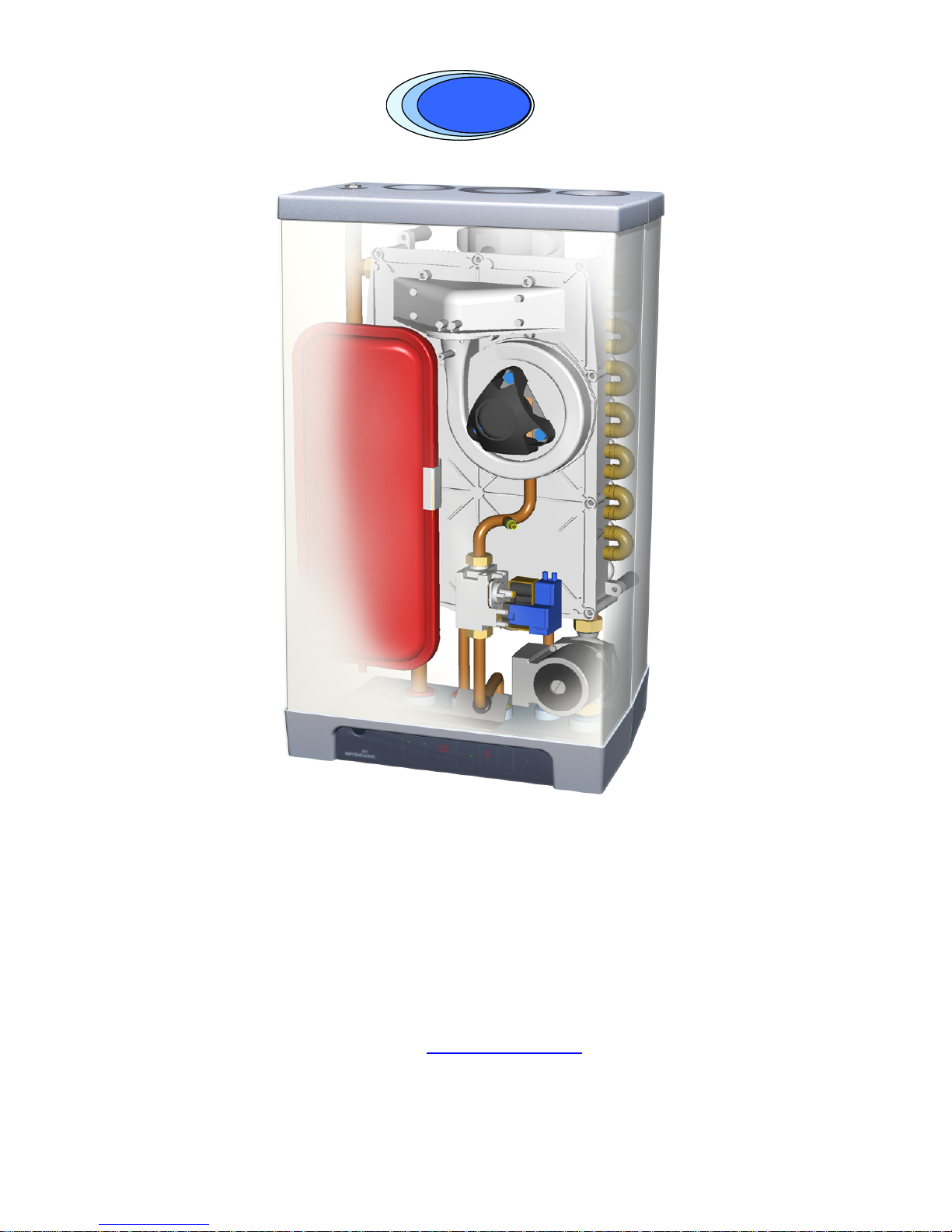

Atmos InterCombi

ATMO

S

ATMO

S

Installation Instructions

Atmos Heating Systems

West March

Daventry

Northants, NN11 4SA

Tel: 01327 871990

Fax: 01327 871905

e-mail:

sales@atmos.uk.com

internet: www.atmos.uk.com

Issue 1.4.05

Page 2

© 2005 Atmos Heating Systems

The information provided applies to the product in the standard model. Atmos Heating

Systems can therefore not be held liable for any damage resulting from the product

specifications that deviate from the standard model.

The information provided has been compiled with the utmost care. However, Atmos

Heating Systems cannot be held liable for any faults in the information nor for the

consequences thereof.

Atmos Heating Systems cannot be held liable for any damage resulting from the

activities carried out by third parties.

To be changed without prior notice

2

Page 3

TABLE OF CONTENTS

1. Safety Regulations 7

1.1 General.......................................................................................................................................................................7

1.2 CH system...................................................................................................................................................................7

1.3 Gas system.................................................................................................................................................................7

1.4 Electrical system.........................................................................................................................................................7

1.5 Domestic water system...............................................................................................................................................7

1.6 Flue discharge and air supply.....................................................................................................................................7

2. Description of the Appliance 8

2.1 General.......................................................................................................................................................................8

2.2 Operation....................................................................................................................................................................8

2.3 Operating conditions...................................................................................................................................................8

2.4 PC interface..............................................................................................................................................................10

2.5 Test programmes......................................................................................................................................................11

2.5.1 Frost protection................................................................................................................................................11

3. Main Components 12

3.1 Accessories...............................................................................................................................................................13

4. Installation 14

4.1 Overall dimensions....................................................................................................................................................14

4.2 Unpacking the appliance............................................................................................................................... ............15

4.3 Additional dimensions...............................................................................................................................................15

4.4 Boiler location............................................................................................................................................................16

4.4.1 Installation in a kitchen cupboard.....................................................................................................................16

4.4.2 Installation in an airing cupboard......................................................................................................................16

4.4.3 Remove front panel..........................................................................................................................................16

4.5 Mounting...................................................................................................................................................................17

4.5.1 Fitting the mounting strip..................................................................................................................................17

4.5.2 Fitting the mounting strip and the mounting bracket.........................................................................................17

4.5.3 Fitting the top connecting frame.......................................................................................................................17

4.5.4 Installation connections....................................................................................................................................17

4.6 Mount the appliance..................................................................................................................................................18

4.7 Fit the pipework cover...............................................................................................................................................18

5. Connections 19

5.1 Connect the CH system............................................................................................................................................19

5.1.1 Expansion vessel.............................................................................................................................................19

5.1.2 Thermostatic radiator valves............................................................................................................................19

5.1.3 System bypass.................................................................................................................................................19

5.1.4 Underfloor heating............................................................................................................................................20

5.2 Hot water system......................................................................................................................................................21

5.2.1 Appliance with pre-heating by solar system.....................................................................................................21

5.3 Connecting the gas supply........................................................................................................................................22

5.4 Electrical connection.................................................................................................................................................22

5.4.1 Electrical connections.......................................................................................................................................22

5.4.2 Room thermostat on/off....................................................................................................................................23

5.4.3 Outside temperature sensor.............................................................................................................................23

5.5 Flue discharge and air supply...................................................................................................................................24

5.5.1 Twin-pipe connection.......................................................................................................................................24

5.5.2 Concentric connection......................................................................................................................................24

5.5.3 Pipe, materials and insulation..........................................................................................................................24

5.5.4 Flue terminal clearances..................................................................................................................................25

5.5.5 Flue system......................................................................................................................................................25

5.6 Pipe lengths..............................................................................................................................................................26

5.6.1 Equivalent lengths............................................................................................................................................26

5.6.2 Example of 80mm twin pipe calculation...........................................................................................................26

5.6.3 Example of 80/125mm concentric pipe calculation..........................................................................................26

3

Page 4

5.6.4 Outlet arrangements.........................................................................................................................................27

5.6.5 Flue discharge pipe and air supply pipe...........................................................................................................27

5.7 Outside wall outlet for twin pipe terminal - horizontal................................................................................................28

5.8 Outside wall and roof outlet concentric terminal horizontal.......................................................................................30

5.9 Roof outlet combination and twin pipe terminal - vertical..........................................................................................31

5.10 Roof outlet prefabricated chimney............................................................................................................................. 34

5.11 Roof outlet and air supply from the outside wall........................................................................................................35

5.12 Air supply from the outside wall and a roof outlet with common discharge system...................................................36

5.13 Roof outlet CLV system............................................................................................................................................37

6. Commissioning 38

6.1 Fill and de-aerate the appliance and the system.......................................................................................................38

6.1.1 CH system........................................................................................................................................................38

6.1.2 Hot water supply...............................................................................................................................................38

6.1.3 Gas supply.......................................................................................................................................................38

6.2 Commissioning of the appliance...............................................................................................................................39

6.3 System Shutdown.....................................................................................................................................................40

6.3.1 Frost protection................................................................................................................................................40

7. Setting and Adjustment 41

7.1 Directly via operating panel.......................................................................................................................................41

7.2 Settings through the service code.............................................................................................................................41

7.3 Parameters................................................................................................................................................................42

7.4 Setting maximum CH power......................................................................................................................................43

7.5 Setting pump position................................................................................................................................................43

7.6 Weather-dependent control.......................................................................................................................................44

7.7 Conversion to other gas type....................................................................................................................................44

7.8 Gas-air control...........................................................................................................................................................44

7.9 Setting gas-air control...............................................................................................................................................45

8. Faults 47

8.1 Burner does not ignite...............................................................................................................................................48

8.2 Burner ignites with much noise.................................................................................................................................48

8.3 Burner resonates.......................................................................................................................................................49

8.4 No heating (CH)........................................................................................................................................................49

8.5 Reduced output.........................................................................................................................................................50

8.6 CH does not reach the correct temperature..............................................................................................................50

8.7 No hot water (HW)....................................................................................................................................................50

8.8 Hot water does not reach the correct temperature....................................................................................................51

9. SERVICING THE BOILER 52

10. Technical Specifications 53

10.1 Electrical diagram......................................................................................................................................................54

11. CE Declaration 55

4

Page 5

This manual

Using this manual you can safely install and maintain this appliance.

Carefully follow the instructions.

In case of doubt, contact Atmos Heating Systems.

Keep these instructions near the appliance.

Abbreviations and names used

Description To be referred

to as

High Efficiency HE

Atmos InterCombi wall-mounted gas heater Appliance

Appliance with piping for central heating CH system

Appliance with piping for domestic water HW system

Icons

The following symbols are used in this manual:-

CAUTION

Procedures that, when not carried out with due care,

may result in damage to the product or the

environment or in personal injury.

Service and technical support

For information about specific adjustments, installation, maintenance

and repair activities, please contact:

Atmos Heating Systems,

West March,

DAVENTRY,

Northants, NNII 4SA

www.atmos.uk.com

5

Page 6

Guarantee conditions

Considering the conditions mentioned below, Atmos guarantees towards

the recognised installer the soundness of the materials used, as well as

the good operation of its Central Heating products, if applied for their

intended use. When the occasion arises, we should be given the

opportunity to ascertain ourselves, if necessary on the spot, of the validity

of the guarantee claim.

The guarantee includes:

1. The guarantee is limited to the free redelivery of the parts showing material

or manufacturing faults that are not the result of normal wear and the like

during the guarantee period, entirely at our discretion. These parts should be

returned to us prepaid mentioning the defect and they will be our property

after replacement.

2. The guarantee period for parts is 2 years as from the date of installation.

However, the following parts have been excluded from guarantee: ignition

probe, ionisation pin, glass fuse, thermocouple and de-aerator.

3. The period of guarantee for the heat exchanger of the appliance is 5 years,

provided that if corrosion leaks occur that can, at our discretion, not be

remedied on the spot, we only deliver this part of the boiler for a fee of old for

new, calculated from the installation date at the time of replacement.

4. A copy of the completed Benchmark Boiler Commission Certificate must be

returned as proof of correct commissioning.

5. The guarantee shall no longer be valid when it is established that the

defects, damage or excessive wear are due to improper use or injudicious

treatment or to unskilful repair, adjustment, installation or maintenance by

non-approved installers.

6. The guarantee is no longer valid when the defect is the result of deposition of

scale (harmful to the appliance and the system). Surface damage and

transport damage are outside the scope of the guarantee. The right to

guarantee lapses if the boiler has not had a yearly service by an approved

service agent. The instructions of installation and use that we supply for the

respective appliances must be fully observed.

7. The guarantee is only valid if the return slip of the certificate of guarantee

has been returned to us within 8 days after the installation, signed by the

buyer. By signing the guarantee card, the buyer declares that he agrees with

the good state of the delivery.

8. If the installer's company was terminated before expiration of the guarantee

period, the user can make an appeal to our guarantee obligations towards

the installer.

Environment

When the appliance needs replacement, your installer may

arrange for disposal. Should this not be possible, then

make enquiries with your local council about the

possibilities for re-use or environmental-friendly processing

of the materials used, or contact a scrap dealer about

disposal.

Various plastics and metals have been used in producing

the appliance. Also, the appliance contains electronic

components that are electronic waste.

Intended use

The appliance as described in this documentation is intended for heating

rooms with a central heating system and/or for supplying hot water. Any

other use is outside the scope of intended use for this appliance. Any

liability for damage resulting from improper use shall not be accepted.

6

Page 7

1. SAFETY REGULATIONS

The appliance must be installed in accordance with the Gas Safety

(Installation and Use) Regulations; October 1994. Failure to install appliances

correctly could lead to prosecution.

Atmos Heating Systems does not accept any liability for damage or injury

caused by not (strictly) observing the current safety regulations and

instructions, nor by negligence while installing the Atmos InterCombi wallmounted gas heater and any accompanying accessories.

The manufacturer’s instructions must NOT be taken as overriding statutory

requirements.

The regulations are mentioned separately for the different disciplines.

1.1 General

The entire system should comply with the valid (safety) regulations, as

mentioned in:-

• This installation manual.

• Gas Safety (Installation and Use) Regulations

• The appropriate Building Regulations.

• Health and Safety Document No 635 (Electricity at Work Regulations)

• The Water Fittings Regulations or local Water byelaws.

1.2 CH system

The entire system should comply with the valid (safety) regulations, as

mentioned in:-

•

BS 5449 Central Heating for Domestic Premises.

1.3 Gas system

The entire system should comply with the valid (safety) regulations, as

mentioned in:-

•

BS 6798 Specification for installation of gas fired hot water boilers of rated input

not exceeding 60 kW

.

•

BS 6891 Installation of low pressure gas pipework installations up to 28mm

(R1).

• I.S.813 Installation of Gas Appliances (for installations in Ireland).

• British Gas Guidance Notes for the Installation of Domestic Gas Boilers.

1.4 Electrical system

The entire system should comply with the valid (safety) regulations, as

mentioned in:-

• BS 7671 The IEE Wiring Regulations.

1.5 Domestic water system

The entire system should comply with the valid (safety) regulations, as

mentioned in:-

•

BS 5546 Installation of gas hot water supplies for domestic purposes.

1.6 Flue discharge and air supply

The flue discharge and the air supply system should comply with:-

•

BS 5440 Flues and Ventilation for gas appliances of rated input not exceeding

60 kW. (Part 1 Flues and Part 2 Ventilation).

7

Page 8

2. DESCRIPTION OF THE APPLIANCE

2.1 General

The Atmos InterCombi wall-mounted gas boiler is a balanced flue

appliance, designed for delivering heat to the water of a CH system and

the domestic hot water.

The air supply and flue discharge can be connected to the appliance by

means of two separate pipes. A concentric connection can be delivered

upon request. The appliance has been inspected together with the

Atmos combination lead-through, but the appliance can also be

connected to combination terminals that comply with the universal test

requirements for combination terminals and that have a gas certification.

The appliance can also be fitted to an optional mounting bracket, a

frame with top connection and various connecting sets. These are

supplied separately.

The Atmos InterCombi wall-mounted gas boiler has the CE quality mark

and the Gas certification labels HE (Sedbuck A), SV , NZ (Solar

compatible) and CW Class 5 (Hot water performance rating 1 to 6,

where 6 is the highest) and IP44.

It is possible to use the appliance for hot water or for heating only. The

system that is not used does not need to be connected.

The appliance as delivered is suitable for natural gas (G20). A

conversion kit for propane (G31) can supplied upon request.

2.2 Operation

The Atmos InterCombi wall-mounted gas heater is a modulating high

efficiency boiler. This implies that the power is adjusted to the heat

demand.

In the aluminium heat exchanger two separate copper circuits have been

integrated.

Because of the separated circuits for central heating and hot water, the

heating and the hot water supply can operate independently of each

other. The hot water supply has priority over the heating. They cannot

work simultaneously.

The appliance has been provided with an electronic burner controller

that controls the fan with each heat demand from the heating system or

the hot water supply, opens the gas valve and ignites the burner and

continuously monitors the flame and controls it dependent on the power

required.

2.3 Operating conditions

A code indicates the operating condition of the appliance on the service

display of the operating panel.

- Off

The appliance is not operating, but there is electrical power. There is no

response to any demand for hot domestic hot water or CH water. The

frost protection is active though. This means that the pump starts

running and the heat exchanger is heated when the temperature of the

water present here drops below 4 °C. When the frost protection is

activated, code

7 appears (heating of the heat exchanger).

8

Page 9

Waiting position

The LED of the on/off key and if necessary one of the LED’s of the

domestic hot water comfort function are on. The appliance is ready for

responding to the demand for CH or domestic hot water.

0 Pump overrun

After the operation of the CH, the pump has an overrun. This overrun time

is set to the value according to table 4 at the factory. This setting can be

changed. Also, the controller will automatically run the pump for 10

seconds, once every 24 hours, to prevent it from getting stuck. This

activation of the pump takes place at the time of the last heat demand. In

order to change this time, set the room thermostat higher for a while at the

desired time.

1 Required temperature reached

The burner controller can temporarily block the heat demand and stop the

burner. This blocking takes place because the required temperature has

been reached. When the temperature has dropped sufficiently, the

blocking is cancelled.

2 Self-test

The burner controller regularly checks the connected sensors. During the

check, the controller does not carry out any other tasks.

3 Ventilate

At starting the appliance the fan is first brought to the starting speed.

When reaching the starting speed, the burner is ignited. Code

3 is also

visible when after stopping the burner post-purge takes place.

4 Ignite

When the fan has reached the ignition speed, the burner is ignited by

means of electric spark ignition. During ignition the code

4 appears. If

the burner is not ignited, another ignition attempt is made after about

5 seconds. If the burner has still not fired after the fourth ignition attempt,

the controller indicates a fault. See § 8.1.

5 CH operation

An on/off thermostat can be connected to the controller, if necessary in

combination with an outside sensor. See Electrical diagram. When heat is

demanded by a thermostat signal, the fan runs (code

3 ) and the burner is

ignited (code 4 ), followed by the CH operating condition (code 5 ).

During CH operation, the fan speed and hence the power of the appliance

is adjusted. This is done in such a way, that the temperature of the CH

water is controlled towards the set CH supply temperature. In the case of

an on/off thermostat, the CH supply temperature is set at the operating

panel. In the case of an outside sensor, the CH supply temperature is

determined by the weather dependent control programmed in the burner

controller.

9

Page 10

During CH operation, the demanded CH supply temperature is displayed

on the operating panel. The resistance R in the Electrical diagram can

be removed when the room thermostat does not need any anticipation

current.

During CH operation, the CH supply temperature can be set between

30ºC and 90ºC and the set CH supply temperature is displayed on the

operating panel. During CH operation, the actual CH supply temperature

can be read by pressing the service key.

6 Domestic hot water operation

The hot water supply has priority over the heating. When the flow switch

detects a domestic hot water demand of more than 2 l/min, the CH

demand is interrupted. After starting the fan (code

3 ) and ignition of the

burner(code 4 ), the controller goes to domestic hot water operation

(code 6 ).

During domestic hot water operation, the fan speed and hence the

power of the appliance is controlled by the controller on the basis of the

set domestic hot water temperatures. The domestic hot water

temperature can be set between 50ºC and 60ºC. The set temperature is

displayed on the operating panel.

During domestic hot water operation, the actual domestic hot water

supply temperature can be read by pressing the service key.

7 Heating the appliance

For a quick supply of domestic hot water, a comfort function has been

provided in the controller. This function keeps the heat exchanger at the

correct temperature. This comfort function has the following settings:-

• Off: (Both LEDs off.) The heat exchanger is not kept warm,

delaying the supply of domestic hot water. When there is no

demand for domestic hot water, the comfort function can be

switched off.

• On: The comfort function of the appliance is continuously

activated. The appliance always supplies domestic hot water

immediately.

• Eco: The comfort function is self-learning. The appliance is

inactivated during the night or after a long absence. The appliance

adjusts to the user pattern of the domestic hot water requirements.

The eco mode is the most efficient hot water method.

2.4 PC interface

The controller has an interface for a PC. With a special cable and

accompanying software, a PC can be connected. This provision makes it

possible to follow the behaviour of the controller, the appliance and the

heating system during a long period.

10

Page 11

2.5 Test programmes

In the burner controller, there is provision for putting the appliance into a

test status.

By activating a test programme, the appliance will become active with a

fixed fan speed without intervention of the control functions. The safety

functions remain active though.

Simultaneously press + and – to switch off the test programme.

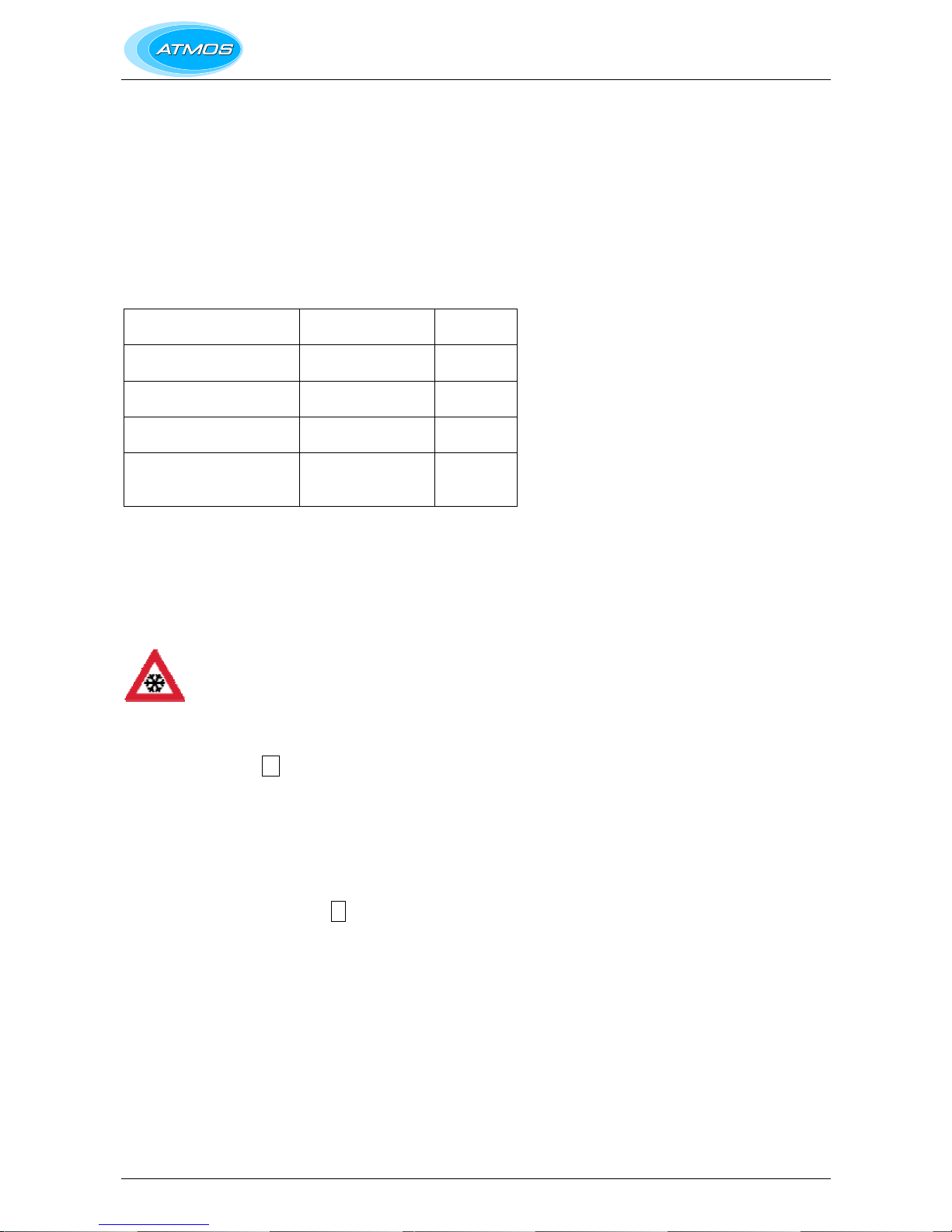

Test programmes

Description of programme Key combinations Display

reading

Burner on with minimum CH

power

"service" and "-" “L”

Burner on with maximum

CH power

"service" and “+” (1x) “h”

Burner on with maximum

HW power

"service" and "+" (2x) "H"

Switch off test programme "+" and "-" Current

operating

condition

2.5.1 Frost protecti on

The boiler has provision for protecting its heat exchanger as described

below.

NOTE! However to avoid the condensate freezing, the boiler must be

installed in a FROST-FREE room.

• In order to avoid freezing of the appliance (heat

exchanger), it has an appliance frost protection.

When the temperature of the heat exchanger drops

to 5ºC, the burner will be activated and the pump

will start running until the temperature of the heat

exchanger reaches10ºC.

Code

7 is given when the appliance frost

protection intervenes (heating heat exchanger).

• When the system (or a part thereof) can freeze, a

frost thermostat should be installed in the area to

be protected. Connect this according to the wiring

diagram. See § 10.1.

Remark

When the appliance is out of action (

- on the service display), the

appliance frost protection is still active. However, there will be no

response to heat demand from an (external) frost thermostat.

11

Page 12

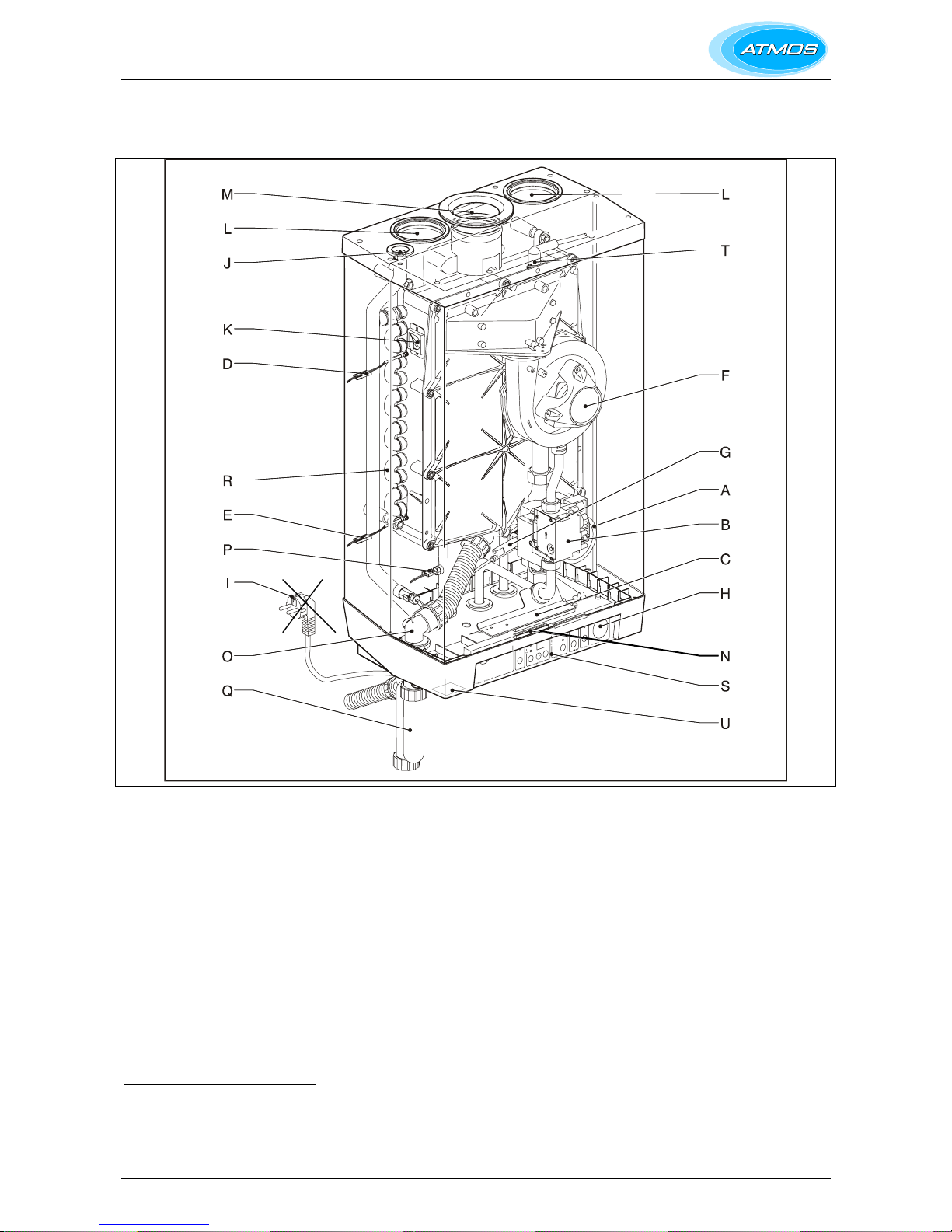

3. MAIN COMPONENTS

A CH pump L Air supply

B Gas valve M Flue discharge

C Burner controller with operating panel N Connecting block / terminal list X

D Supply sensor S1 O Condensate discharge

E Return sensor S2 P Hot water sensor S3

F Fan Q Siphon

G Flow switch R Heat exchanger

H Pressure gauge S Operating panel and display

I 1m connecting cable 230 V ~

( Note: Plug must be removed)

T Ionisation/ignition probe

J Manual air vent U Position type plate

K Sight glass and mirror

Additional Components supplied :T-piece & ½" Pressure relief safety valve, 3 bar (supplied in boiler box)

Valve set (supplied separately with boiler)

12

Page 13

3.1 Accessories

Description

Pipe mounting bracket

• Connection supply and return 22 mm diameter

• Connection cold and hot water 15 mm diameter

• Connection gas ½" female thread

• Mounting strip boiler

• Bag with fixings

Mounting frame for top pipe connection

Pipework cover

Outside sensor

Conversion set to Propane (LPG or G31)

Interface cable

13

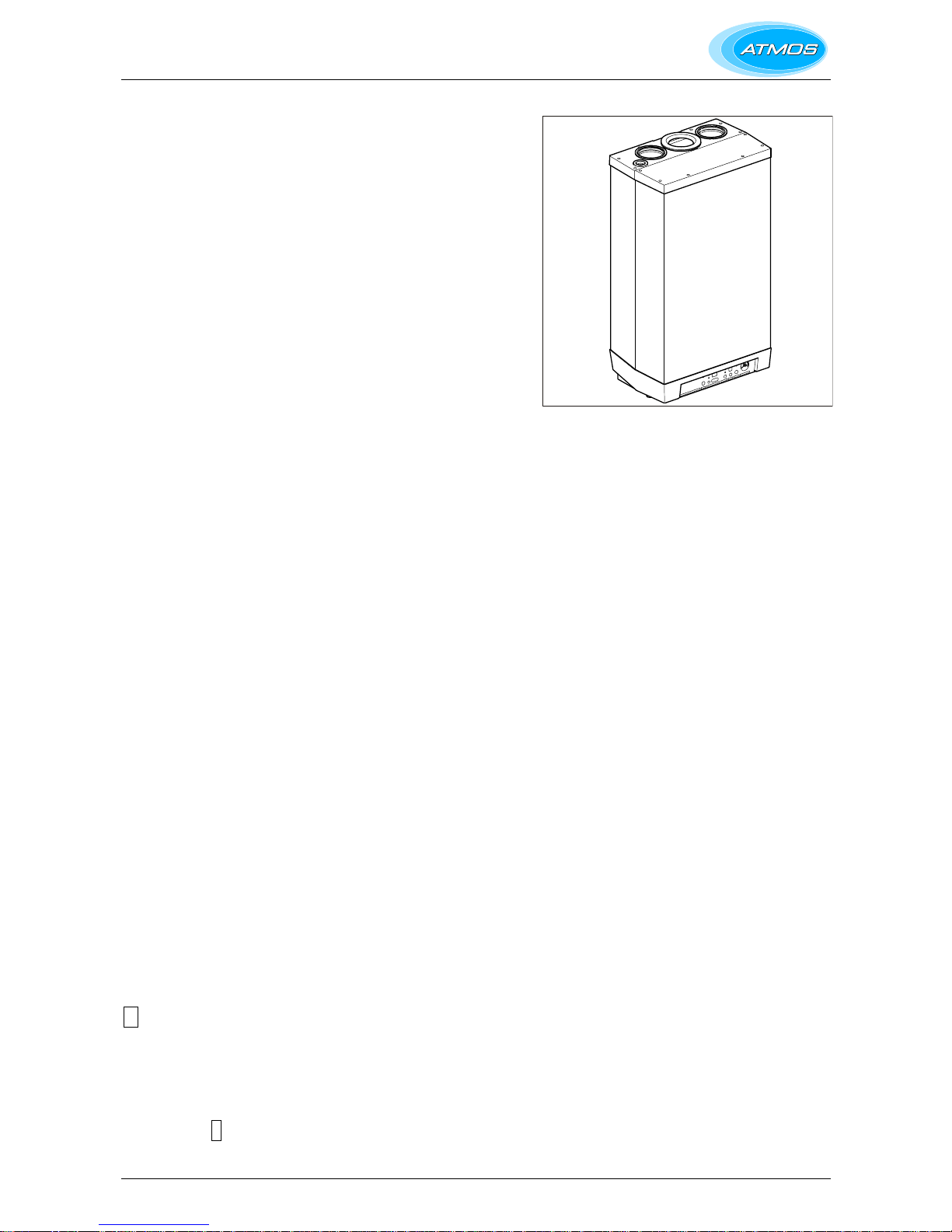

Page 14

4. INSTALLATION

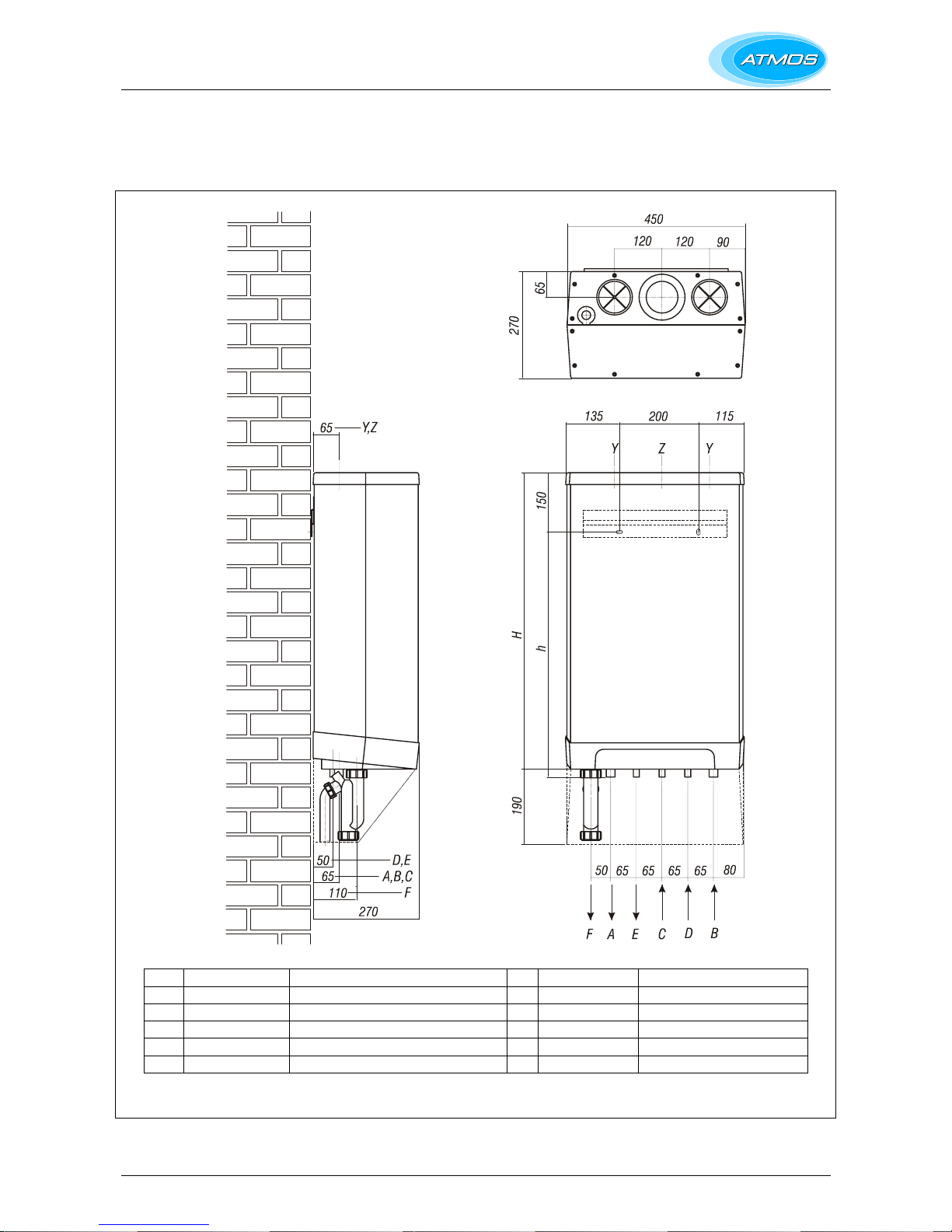

4.1 Overall dimensions

A= CH flow 22 mm diameter h= 710mm InterCombi HE 32

B= CH return 22 mm diameter I

C= Gas 15 mm diameter H= 810mm InterCombi HE 32

D= Cold water 15 mm diameter

E= Domestic hot water 15 mm diameter Z= Flue gas outlet 80 mm diameter

F= Condensate 32 mm dia (after siphon 25 mm dia flexible) Y= Air supply inlet 80 mm diameter

14

Page 15

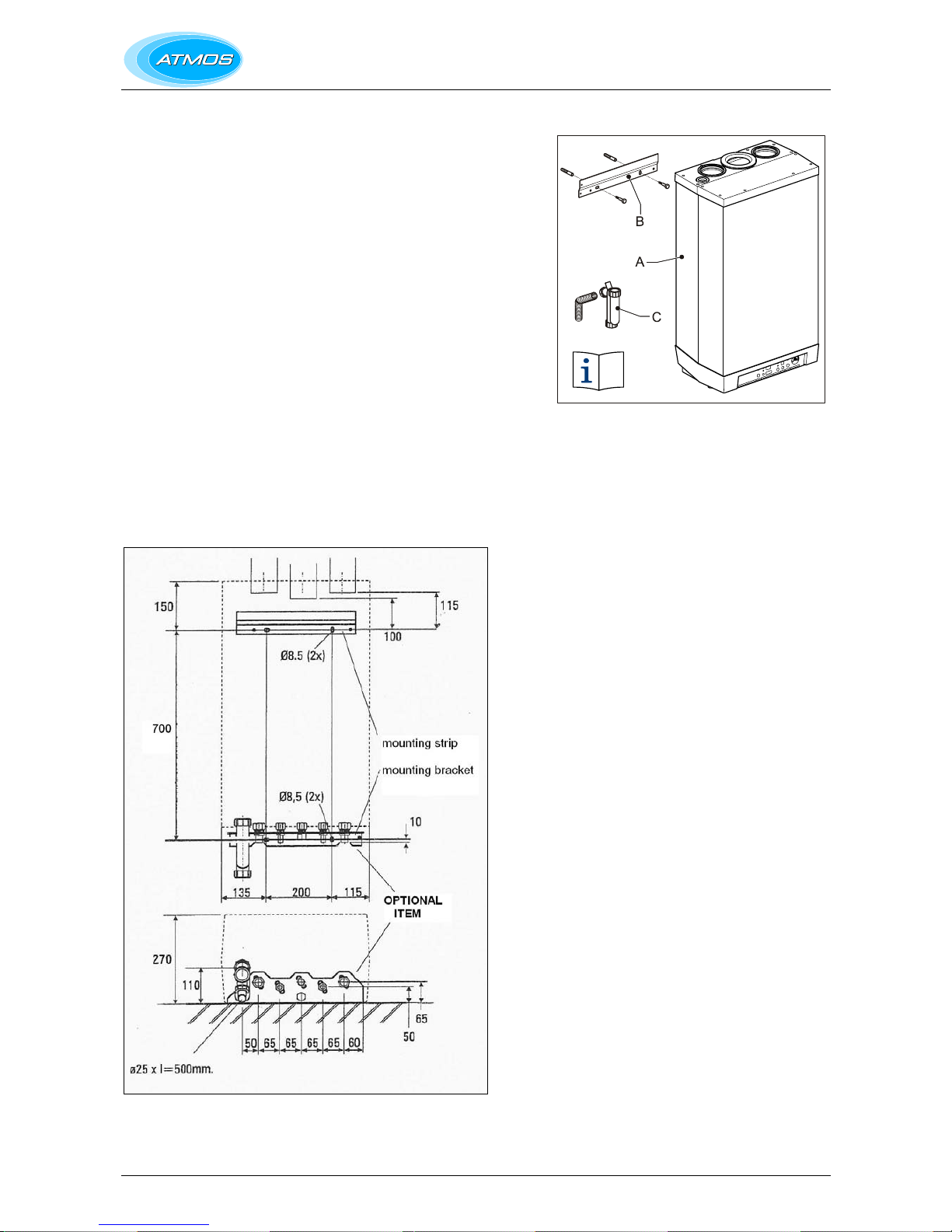

4.2 Unpacking the appliance

1. Unpack the appliance.

2. Check the content of the packaging. This consists of:-

• Appliance (A)

• Mounting strip (B)

• Siphon (C)

• T-piece & ½" Pressure relief safety valve, 3 bar

• Installation instructions

• Guarantee card

• Valve set (supplied separately with boiler)

3. Check the appliance for any damage: report damage to the Supplier

immediately.

4.3 Additional dimensions

The diagram shown below gives additional dimensions primarily for the

mounting arrangement using the OPTIONAL mounting bracket.

15

Page 16

4.4 Boiler location

The appliance can be fitted to a mounting frame. The assembly or just

the appliance should be mounted to a wall with sufficient bearing

strength.

In case of light wall constructions, resonance sounds may occur. There

must be an earthed electrical supply within a distance of 1 m from the

appliance. If the appliance is installed as an open appliance, the

installation room should have been provided with the required openings

for the boiler air supply.

In order to avoid freezing of the condensate discharge, the appliance

should be installed in a frost-free room.

Keep 5 cm free space above the appliance in order to be able to remove

the front panel from the casing.

4.4.1 Installation in a kitch en cupboard

Make sure there is sufficient ventilation above and below the appliance.

When the appliance is placed in a small cupboard, ventilation openings

of at least 50 cm

2

must be made.

4.4.2 Installation in an airing cup board

Compartment ventilation is not required for a standard airing cupboard

(eg 0.6 x 0.6 x 2.3m high).

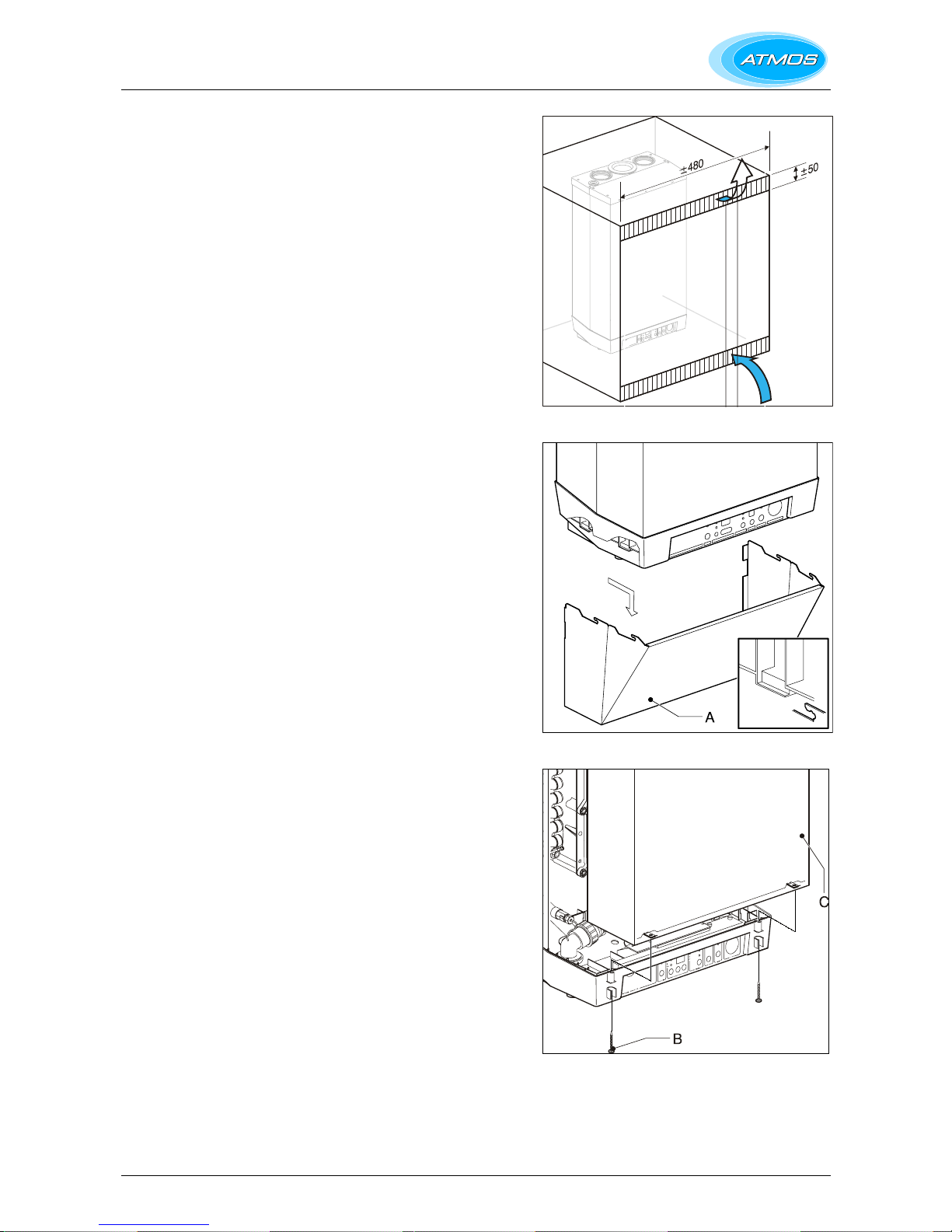

4.4.3 Remove front panel

Remove the pipework cover and the front panel for carrying out work on

the appliance as follows:-

1. Remove the pipework cover (A), if used, forwards.

2. Unscrew both screws (B) at the bottom of the appliance.

3. Lift the front panel (C) and remove it forwards.

16

Page 17

4.5 Mounting

A

B

B

C

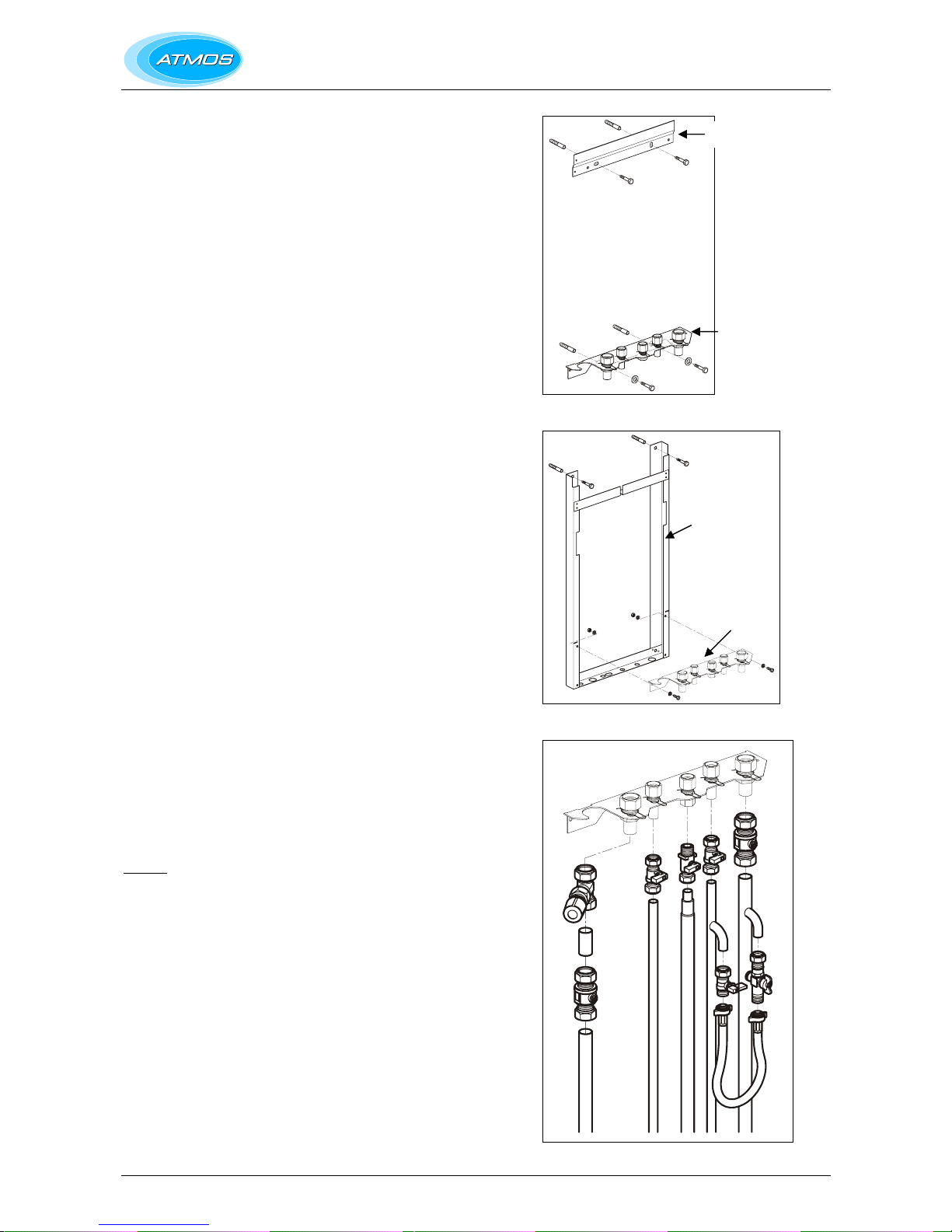

Depending on the mounting option ordered, the following mounting

methods are available:-

Mounting strip (A) alone,

OR mounting strip (A) and optional pipe mounting bracket (B),

OR top connecting frame (C) and pipe mounting bracket (B), which are

both optional items. This arrangement allows for vertical pipes from

above at the rear.

Note that when the pipe mounting bracket is used, the pipes can be

connected before installing the appliance.

4.5.1 Fitting the mounting strip

1. Fasten the mounting strip horizontally to the wall, using the

fastening materials supplied.

2. Mount the appliance.

3. Mount the parts of the various connecting sets.

Note that the 3 bar pressure relief valve must be installed on the

boiler side of the CH flow valve (see diagram).

4.5.2 Fitting the mounting strip and the mounting bracket

1. Fasten the mounting strip and the pipe mounting bracket

horizontally to the wall according to the drilling pattern, using the

fastening materials supplied.

2. Mount the parts of the various connecting sets.

Note that the 3 bar pressure relief valve must be installed on the

boiler side of the CH flow valve (see diagram).

4.5.3 Fitting the top connecting frame

1. Fasten the frame vertically to the wall, using the fastening materials

supplied.

2. Fasten the pipe mounting bracket to the frame using the fastening

materials supplied.

3. Mount the parts of the various connecting sets.

Note that the 3 bar pressure relief valve must be installed on the

boiler side of the CH flow valve (see diagram).

4. Slide the connecting pipes into the frame.

Caution

The appliance is wider than the frame.

4.5.4 Installation co nnections

1. Make the various connections to the valves (see diagram).

2. Install a filling loop (not supplied) between the cold water inlet pipe

and the CH return connection.

3. Install an overflow pipe from the pressure relief valve, using 2 x 90

0

bend to step the pipe to the rear so that it will enter the condensate

discharge pipe.

17

Page 18

4.6 Mount the appliance

1. Check whether the clamping rings are straight in the couplings.

2. Place the appliance: slide it top-down over the mounting strip. Make

sure that the pipes simultaneously slide into the clamp fittings.

3. The flexible tube from the condensate siphon should be inserted

into an open waste pipe of not less than 32 mm diameter. If

connected to a soil pipe or waste system, the waste pipe must

include a trap (similar to arrangement for washing machine).

The 15 mm safety discharge copper pipe from the pressure relief

safety valve may also be taken into this pipe (as shown in the

diagram, §5.1) or, alternatively, taken to a safe discharge position

on the outside wall of the building.

4. Tighten the clamping fittings to the mounting bracket.

5. Mount the air supply and the flue discharge.

6. Close the air supply opening that is not used with the plug supplied.

4.7 Fit the pipework cover

1. Insert the four hooks of the pipework cover in the slots of the

appliance.

2. Slide the cover backwards, sliding the hooks into the slots and

locking the cover.

18

Page 19

5. CONNECTIONS

5.1 Connect the CH system

1. Flush the CH system thoroughly.

2. Mount the supply and return pipes to the mounting bracket.

All pipes must be mounted tension-free in order to avoid ticking of

the pipes.

Existing connections must not be twisted in order to avoid leaks at

the connections with the external pipes.

The CH system should have been provided with.

• A filling loop in the return pipe directly below the appliance.

• A drain tap at the lowest point of the system.

• A pressure relief valve of 3 bar in the supply pipe at a

maximum distance of 500 mm from the appliance.

Between the appliance and the pressure relief valve there must

not be a shut-off valve or a constriction

• An expansion tank in the return pipe (see also 5.1.1).

• A non-return valve when pipes are running upward at a short

distance from the appliance. This prevents a gravity effect

during domestic hot water operation of the appliance.

5.1.1 Expansion vessel

The appliance is fitted with a 6 litre expansion vessel which is adequate

for a system with a water volume not exceeding 100 litres, typically 8

radiators. For larger volume systems, an additional expansion vessel

must be fitted. Contact Atmos for advice in these cases.

5.1.2 Thermo static radiator valves

Building regulations require a room thermostat to be fitted on all

installations. Do not fit a thermostatic valve on the radiators in the room

where the thermostat is situated, otherwise the controls will not function

correctly.

5.1.3 System bypass

A bypass is not generally required. If, however, the heating system uses

2 port valves which close fully (‘S’ plan), a bypass should be fitted before

the valves.

19

Page 20

5.1.4 Underfloor heating

For a good operation of the domestic hot water supply, there must be no

undesired circulation through the appliance caused by a second pump of

the CH circuit.

Connect underfloor heating with an electric shut-off valve (two-way

valve) to prevent circulation through the appliance when there is no

demand for central heating.

A. Boiler

B. Pump

C. Thermostatic control valve

D. Spring-operated non-return valve

E. Electrical shut-off valve 230 V ~

F. Radiators

G. Room/clock thermostat

H. Maximum thermostat

20

Page 21

L/min

Bar

5.2 Hot water system

1. Flush the system thoroughly.

2. Mount the cold and hot water pipe to the mounting bracket.

Remarks

• To comply with the Water Regulations, the max. length of an

uninsulated hot water pipe with a diameter of 15 mm is 12 m; and

the max. length of an uninsulated hot water pipe with a diameter of

12 mm is 20 m.

Note that it s preferable to insulate the hot water pipes.

• When the appliance is used for hot water supply only, the heating

function can be switched off with the service code on the operating

panel. The CH system does not need to be connected or filled.

• If the appliance is shutdown during the winter, the domestic hot

water should be drained to prevent freezing. For this, the cold

water connection at the bottom of the appliance must be

disconnected.

A (Not applicable)

B. InterCombi HE32

X. Water pipe pressure in bar

Y. Water flow rate in l/minute ± 10%

5.2.1 Appliance with pre-heating by solar system

A connecting set for appliances with the NZ label "Suitable for preheating by solar system" is available upon order.

A. Thermostatic mixing valve 40° - 90° (set to 60°)

B. Hot water

C. Mixed water out

D. T max 90°C

E. Cold water

F. Cold water in

G. Inlet combination

H. Flow switch

Remark

• In combination with the solar energy system, a thermostatic mixing

valve set to 60°C must always be placed downstream of the

appliance.

21

Page 22

5.3 Connecting the gas supply

1. Install a gas filter in the connection of the appliance when the gas

can be polluted.

2. Connect the appliance gas valve to the gas pipe.

3. Check the boiler's data plate to ensure that the appliance has been

set for the correct gas supply. The boiler is supplied for Natural Gas

(G20). A propane (G31) gas conversion set is available and an

appropriate sticker is included (see §7.7).

4. The meter governor should deliver a dynamic pressure of 20mbar

for natural gas or 37mbar for propane.

5. To prevent the ingress of foreign matter and possible damage to the

gas-regulating block, the gas supply pipe must be checked for

contaminants prior to connection to the boiler.

6. On final connection of the gas supply to the boiler, the complete gas

installation, including the meter, must be tested for gas soundness

and purged as described in BS6891.

5.4 Electrical connection

CAUTION

The appliance requires a 230 V ac 50 Hz mains supply, and

must be earthed and connected via a double pole isolating

switch fitted with a 3 amp fuse. The switch must be readily

accessible, within 1m of the appliance, and provide

complete electrical

isolation for the boiler and control

system.

The appliance is supplied factory wired complete with 1 m

of mains cable. (Note – the plug must be removed from the

cable). All electrical connections to the mains supply must

be made in full accordance with the current I.E.E.

regulations (BS 7671).

Isolate the supply by opening the double pole switch

when carrying out maintenance activities.

1. Remove the pipework cover forwards.

2. Unscrew the screws (A) in order to gain access to the space of the

burner controller (B).

3. The cover plate hinges open downwards. Here hold the display

window.

4. Consult § 5.4 and § 10.1 for making connections.

5. After having made the required connections, connect the appliance

to a switched supply, as given above.

5.4.1 Electrical connections

Temperature control Connector X4 Remarks

Room thermostat 6 - 7 Outside temperature sensor 8 - 9 External economy switch 4 - 5 Remove link

Frost thermostat 6 - 7 Parallel through

room thermostat

Power 24 V dc (3VA) 6= +, 9= - Power supply

available for clock

thermostat, etc

22

Page 23

5.4.2 Room thermo stat on/off

1. Connect the room thermostat. See § 5.4.1.

2.

The terminal block for the connection for a volt free room thermostat, or

time clock, is X4 on the control panel. The terminals are wired to the

input circuit of the control unit, which has its own 24V dc ‘wetting

voltage’

.

3.

If using a room thermostat with heat accelerator, this must be set at

0·1A.

4.

The maximum permissible resistance of the room thermostat circuit

and cable is 15 Ohms.

5.

Where a 'wireless' room thermostat is employed, consult the

manufacturer’s instructions for installation.

Note -

Under no circumstances must any electrical power be input to

the room thermostat terminals. It is a volt-free switch.

Note - Care must also be taken to avoid induced voltages caused by

the running of the thermostat cables along side mains voltage cables.

5.4.3 Outside temperature sensor

The appliance has a connection for an outside temperature sensor. The

outside temperature sensor can be applied in combination with an on/off

room thermostat.

Connect the outside temperature sensor. See § 5.4.1.

See Weather-dependent control § 7.6 for the setting of the CH

temperature line.

23

Page 24

5.5 Flue discharge and air supply

Two different flue systems are available from Atmos for use with this

appliance:-

• 80mm twin pipe system which enables separate air intake and flue

pipes to be fitted to the appliance.

• 80/125mm concentric system.

Maximum lengths are specified in § 5.6 and must not be exceeded.

Note - A special concentric through the wall flue kit (60/100mm) is

available from Atmos.

5.5.1 Twin-pipe connection

1. When using the right-hand air supply, the sealing cap and the

insulating foam lying beneath must be moved to the left-hand air

supply.

2. Locate the pipes for the air supply and flue discharge in the supply

and discharge stubs. The in-built silicone sealing ring provides an

airtight connection.

5.5.2 Concentric connection

Using the concentric adapter set, the standard two-pipe connection can

be changed into a concentric connection.

1. Seal the open air supply connections in the appliance with the

sealing cap delivered with the set (foam plug).

2. Remove the sealing ring around the flue discharge in the appliance.

3. Fit the sealing ring ø 116 x 110 mm.

4. Fit the adapter on the flue discharge.

5.5.3 Pipe, materi als and insulation

Pipe Diameter Material

Air supply ø 80 mm According to the local regulations of

fire department and/or power

company.

Single wall aluminium, galvanized

steel plate, stainless steel or plastic.

If necessary insulated with 10 mm

vapour-tight insulating material or

plastic.

Flue discharge ø 80 mm Aluminium single wall 1.5mm thick.

Insulation - 10 mm vapour-tight insulating

material when there is a chance of

condensation on the outside,

caused by a low wall temperature

and a high room temperature with a

high humidity.

24

Page 25

5.5.4 Flue terminal clearances

The flue terminal must be sited with minimum

clearance distances as shown in the diagram.

A terminal

g

uard must be fitted if the terminal

is sited less than 2m above ground level.

Where the flue terminates within 1m of

a

plastic or painted gutter or within 500mm o

f

painted eaves, then protection should be

provided in the form of an aluminium shield a

t

least 1m in length, fitted to the underside o

f

the gutter or painted surface.

Please Note!

Due to the low flue gas temperature, 'pluming

'

will occur at the flue terminal. Care should b

e

taken to ensure that the discharge plume wil

l

not cause annoyance to the customer o

r

neighbours. It is generally recommended tha

t

flues should discharge vertically at roof level.

In this position, pluming is not normall

y a

problem.

5.5.5 Flue system

The flue system must be installed in accordance with BS5440:1.

Horizontal flue pipe runs must always be installed with a minimum slope of

50 mm/metre towards the boiler. This will prevent condensation from

gathering in the flue pipe, and will also reduce the chance of icicles

forming over horizontal pipe ends in the Winter.

25

Page 26

5.6 Pipe lengths

As the resistance of the flue discharge and air supply pipes increases,

the capacity of the appliance will decrease. The maximum allowed

power decrease is 5%.

The resistance of the air supply and the flue discharge depends on the

length, the diameter and all components of the pipe system. The total

allowed pipe lengths of the air supply and the flue discharge are given

below:-

Note for twin pipes

The total pipe length is:The length of all straight pipe lengths and the

lengths of the equivalent pipe lengths of bends.

The maximum length of the air supply and flue

discharge 80mm pipes added together is 60 m.

Note for concentric pipes

The total pipe length is:The length of all straight pipe lengths and the

lengths of the equivalent pipe lengths of bends.

The maximum length of the 80/125mm concentric

pipe is 24 m for horizontal pipe and 27 m for vertical

pipe.

5.6.1 Equivalent len gths

Bend at 90° R/D=1 2 m

Bend at 45° R/D=1 1 m

Elbow at 90° R/D=0.5 4 m

Elbow at 45° R/D=0.5 2 m

Note – The type supplied by Atmos are Elbows.

For smaller twin pipe diameters, the maximum pipe length is reduced as

follows:-

70mm dia: 0.59 x max. pipe length for 80mm dia.

60mm dia: 0.32 x max. pipe length for 80mm dia.

50mm dia: 0.15 x max. pipe length for 80mm dia.

Note that Atmos only supply 80mm twin pipes

5.6.2 Example of 80mm twin pipe cal culation

See diagram.

Pipe Pipe lengths Total pipe lengths

Flue discharge L1 + L2 + L3 + 2 x 2 m 13 m

Air supply L4 + L5 + L6 + 2 x 2 m 12 m

Total length 25m

5.6.3 Example of 80/125mm concentric pipe calculation

With 3 elbows at 90°, the max straight length of concentric pipe that can

be used is 24m – 3x4m = 12m.

26

Page 27

5.6.4 Outlet arrangements

Appliance

category

Materials Supplier

Terminal Atmos C13

Other parts

Terminal

Terminal of Prefabricated

chimney

C33

Other parts

All materials C43

At the CLV system

Inlet grid C53

Other parts and discharge

cover

C63 All materials and terminal

Inlet grid

Main duct

C83

Other parts

5.6.5 Flue discharg e pipe and air supply pipe

The mounting below applies to all outlets:-

1. Slide the flue discharge pipe into the discharge stub of the appliance.

2. Slide the flue discharge pipes into each other.

From the appliance all pipes must be slid into the previous one.

3. Mount a non-vertical flue discharge pipe in a slope to the appliance

(min. 50 mm/m).

4. Mount the folded seams directed upwards in a horizontal part.

5. Tape up non-gastight connections with heat and moisture-resistant

aluminium tape.

The mounting below applies to all air supply pipes:-

1. Slide the air supply pipe into the supply stub of the appliance.

2. Tape up non-airtight connections with moisture-resistant tape.

3. Fit insulation, if necessary.

27

Page 28

5.7 Outside wall outlet for twin pipe terminal -

horizontal

Appliance category: C13

CAUTION

Pipes for connecting the air supply and the flue discharge

between the appliance and the terminal must have a

diameter of 80 mm.

A. Atmos twin pipe terminal horizontal. To be extended for a balcony

outlet with one or two standard pipes (diameter 80 mm).

B. Outlet grid.

C. Wall cover plate (2x).

Maximum pipe length

See §5.6.

Flue discharge pipe and air supply pipe

For mounting, see § 5.6.5.

Mounting twin pipe terminal

1. Make two openings of diameter 90 mm at the place of the outlet.

2. Cut the pipes to the correct length.

3. Slide the supply and discharge pipes into the openings.

4. Cover the openings with wall cover plates.

5. Mount the outlet grids to the supply and discharge pipes.

6. Attach them to the pipes.

7. Ensure the pipes slope back to the appliance.

28

Page 29

Mounting a twin pipe terminal extension pipe(s) for balcony outlet

When the free outlet is hindered by an eave, balcony, gallery or anything

else, the air supply pipe and the flue discharge pipe must be extended to

at least the front side of the overhanging part.

When the air supply is not disturbed by obstacles, such as a console or

separating wall, and when the outlet is not at the edge of a building, the

air supply pipe does not need extension.

1. Extend the flue discharge pipe and, if necessary, also the air supply

pipe of the terminal with standard flue discharge and air supply

pipes to the correct length required.

2. Slide the flue discharge pipe and, if necessary, also the air supply

pipe into the discharge and supply pipes of the terminal.

3. Ensure the pipes slope back to the appliance.

4. Mount the outlet grids to both pipes.

29

Page 30

5.8 Outside wall and roof outlet concentric terminal

horizontal

Appliance category: C13

CAUTION

Pipes for connecting the air supply and the flue discharge

between the appliance and the terminal must have a

diameter of 80 mm.

A. Atmos concentric terminal horizontal.

For outside wall or roof outlet horizontal.

B. Atmos concentric pipe.

For extension of a balcony/gallery outlet.

Maximum pipe length

See §5.6.

Flue discharge and air supply pipes

For mounting, see § 5.6.5.

Mounting 80/125mm horizontal terminal

B

1. Make an opening of diameter 130 mm at the place of the outlet.

2. Shorten the terminal to the length required.

3. Mount the outlet grid and attach this to the inside pipe.

4. Slide the terminal into the opening and fit rosettes to cover the

opening.

5. Ensure the pipes slope back to the appliance.

30

Page 31

Mounting of combination extension pipe for balcony/gallery outlet

When the free outlet is hindered by an eave, balcony, gallery or anything

else, the combination terminal must be extended to at least the front side

of the overhanging part.

1. Mount the combination extension pipe to the combination terminal.

2. Shorten the combination terminal or the combination extension pipe

to the correct length required.

3. Mount the outlet grid and attach this to the inside pipe.

4. Mount the combination terminal and combination extension pipe in

a slope to the appliance.

5.9 Roof outlet combination and twin pipe terminal -

vertical.

Appliance category: C33

CAUTION

When the Atmos combination terminal - vertical cannot be

applied, the air supply and the flue discharge must be

separated.

Atmos combination terminal - vertical.

31

Page 32

Maximum pipe length

See §5.6.

Flue discharge pipe and air supply pipe

For mounting, see § 5.6.5.

Mounting of combination terminal - vertical

1. Mount a vertical terminal roof pile with lead flashing at the place of

the outlet on a pitched roof.

On a flat roof an adhesive plate for a pipe of diameter 126 mm must

be applied.

2. Dismount the manifold of the combination terminal (C).

3. Slide the combination terminal(C) from the outside to the inside.

With a pitched roof through the vertical terminal tile with shell.

With a flat roof through the adhesive plate.

4. Mount the manifold of the combination terminal (C) and lock it with

a sheet-metal screw or pop rivet.

32

Page 33

Mounting of twin pipe terminal - vertical

CAUTION

The outlets of the flue discharge and air supply should be

placed in the same pressure area.

The air supply from the pitched roof area and the flue

discharge by means of a constructional chimney is also

possible, but not the other way around.

1. Mount a double-walled flue terminal (diameter 80 mm) with Giveg

discharge cover on a pitched roof at the place of the outlet.

2. Mount a ventilating passage (diameter 80 mm) with cross-cut in the

corresponding roof passage tile for the air supply.

3. Mount for the flue discharge a double-walled flue terminal (diameter

80 mm) with Giveg discharge cover at the place of the outlet.

Mount with a flat roof or a constructional chimney and for the air

supply a ventilating passage (diameter 80 mm) with cross-cut in the

corresponding adhesive plate.

CAUTION

Two outlets must be at a distance of at least 200 mm from

each other.

33

Page 34

5.10 Roof outlet prefabricated chimney

Appliance category: C33

When there is little space in a shaft, a roof outlet through a prefabricated

chimney may be necessary.

The prefabricated chimney must comply with the minimum lengths

shown. The supplier must guarantee the proper operation of the

prefabricated chimney with respect to wind attack, ice formation, rain

ingress, etc.

In view of the different models and requirements, the prefabricated

chimneys must be adjusted to the local situation: a gas certificate is not

required.

CAUTION

The connection of the air supply and the flue discharge

between the appliance and the prefab chimney must be

made in pipes of diameter 80 mm.

Maximum pipe length

See §5.6.

Flue discharge and air supply pipes

For mounting, see § 5.6.5.

Mounting of prefabricated chimney

The outlet can be made at any place in the pitched or flat roof surface.

34

Page 35

5.11 Roof outlet and air supply from the outside wall

Appliance category: C53

CAUTION

The air supply (A) in the outside wall must be provided

with an Atmos inlet grid.

A. Flue discharge (B) through a prefabricated chimney or through a

double-walled roof passage diameter 80 mm with Giveg discharge

cover.

Maximum pipe length

See §5.6.

Flue discharge pipe and air supply pipe

For mounting, see § 5.6.5.

Mounting of air supply - horizontal

The air supply (A) can be made at any place in the outside wall.

1. Make an opening of diameter 90 mm at the place of the supply.

2. Shorten the air supply pipe to the correct length out of the wall.

3. Mount the Atmos inlet grid and attach this to the pipe.

4. Slide the air supply pipe into the opening and cover the opening

with a rosette, if necessary.

5. Mount the air supply at the place of the outside wall terminal in a

slope to the outside, to prevent rain from entering.

Mounting flue terminal - vertical

1. Mount a roof tile with shell in a pitched roof surface at the place of

the outlet.

Mount an adhesive plate suitable for a double-walled flue terminal

diameter 80 mm (outside diameter 96 mm) in a flat roof.

2. Slide the double-walled flue terminal from the outside to the inside

through the roof terminal.

The outlet must protrude at least 500 mm above the roof surface.

35

Page 36

5.12 Air supply from the outside wall and a roof outlet

with common discharge system

Appliance category: C83

An air supply from the outside wall and a roof outlet with common

discharge system is allowed.

CAUTION

The air supply (A) in the outside wall must be provided

with an Atmos inlet grid.

The flue discharge (B) must be provided with a pulling

discharge cover.

The minimum bore of the common discharge system

Diameter for InterCombi

Number of

appliances

HE 32

2 130

3 150

4 180

5 200

6 220

7 230

8 250

9 270

10 280

11 290

12 300

Maximum pipe length

The maximum length of the air supply and flue discharge pipes

between appliance and common flue discharge and air supply

together is 75 metres.

Flue discharge pipe and air supply pipe

For mounting, see § 5.6.5.

Common flue discharge

The outlet of the flue discharge can be made at any place in the pitching

roof surface, provided that the outlet in the roof surface has the same

orientation as the air supply in the outside wall. With a flat roof the outlet

of the flue discharge must be made in the 'free' outlet area.

Apply a condensate discharge.

CAUTION

The common discharge system must be provided with a

pulling discharge cover.

When the common discharge system is located in the

outside air, the discharge pipe must be double-walled or

insulated.

36

Page 37

Remark

The common discharge system has been inspected in combination with

the appliance.

5.13 Roof outlet CLV system

Appliance category: C43

CAUTION

A roof outlet through a Combination Air supply-Flue

discharge system (CLV system) is allowed.

For the common flue discharge cover and air supply cover

a certificate of incorporation from the Gastec-Gasinstituut

is required.

The common air supply and the common flue discharge may be made

concentrically or separately.

Maximum pipe length

The maximum length of the air supply and flue discharge pipes

between appliance and CLV system together is 75 metres.

Flue discharge pipe and air supply pipe

For mounting, see § 5.6.5.

Remark

The passage of the common supply and discharge system should be

given by the manufacturer of the CLV system.

37

Page 38

6. COMMISSIONING

6.1 Fill and de-aerate the appliance and the system

WARNING

Connect the appliance to the mains voltage only after

filling and de-aerating!

6.1.1 CH system

WARNING

When an additive is added to the CH water, this should

be suitable for the materials used in the appliance, such

as copper, brass, stainless steel, steel, plastic and

rubber.

1. Use the filling loop to fill the system to a maximum pressure of 1 to

2 bar with a cold system.

2. De-aerate the appliance with the manual air vent (A).

Alternatively, an automatic air vent can be mounted to the appliance

instead of the manual air vent.

3. De-aerate the system with the manual air vents on the radiators.

4. Fill up the CH system when the pressure has dropped too low as a

result of the de-aerating.

5. Check all joints for leaks.

6. Fill the siphon with water (important).

6.1.2 Hot water sup ply

1. Open the main tap in order to pressurise the hot water part.

2. De-aerate the heat exchanger and the pipe system by opening a

hot water tap.

Leave the tap open until all the air has left the system.

3. Check all joints for leaks.

6.1.3 Gas supply

1. De-aerate the gas pipe with the inlet pressure measuring nipple on

the gas valve.

2. Check the connections for leaks.

3. Check the inlet pressure and the burner pressure. See Gas and air

control.

38

Page 39

6.2 Commissioning of the appliance

After having carried out the above operations, the appliance can be

commissioned.

1. Switch on the electrical supply to the appliance.

The appliance will carry out a self-test:

2 (on service display).

After completing the self-test, the appliance goes to standby: - (on service

display).

2. Press the on/off button in order to put the appliance into operation.

The boiler is heated and on the service display appear

3 , 4 , 7 and 9 .

Check the pump rotation.

3. Set the pump position on the basis of the set maximum power and the

resistance of the system on the water side. For the head of the pump and the

pressure loss of the appliance, see § 7.1.

4. Set the room thermostat higher than the room temperature. The appliance

will now switch to CH operation:

5 on service display.

5. Heat the system and the appliance to about 80ºC.

6. Check the temperature difference between the supply and return of the

appliance and the radiators. This should be about 20°C. At this stage set the

maximum power on the service panel. See Setting of maximum power. If

necessary, change the pump position and/or the radiator valves. The

minimum flow-through is:-

• 200 l/h at a set power of 7.0 kW

• 750 l/h at a set power of 26.2 kW

7. Switch off the electrical supply to the appliance.

8. De-aerate the appliance and the system after cooling down. (fill up if

necessary)

9. Check the heating and the hot water supply for proper operation.

10. Instruct the User about filling, de-aerating and the operation of the heating

and the hot water supply.

Remarks

• The appliance has been provided with an electronic burner controller that

ignites the flame and continuously monitors this at each heat demand from

the heating or from the hot water supply.

• The circulation pump starts running at each heat demand of the boiler. The

pump has an overrun time of 1 minute. The overrun time can be changed if

necessary. See Installer settings.

• The controller will automatically run the pump for 10 seconds, once every 24

hours, to prevent it from getting stuck. This activation of the pump takes

place at the time of the last heat demand. In order to change this time, set

the room thermostat higher for a while at the desired time.

• The pump does not run for hot water supply.

39

Page 40

6.3 System Shutdown

CAUTION

Drain the appliance and the system when the mains

voltage has been disconnected and there is a chance of

freezing.

1. Drain the appliance using the filling/drain tap.

2. Drain the system at the lowest point.

3. Close the main valve for the cold water supply to the boiler.

4. Drain the appliance by disconnecting the domestic hot water

connections underneath the appliance or opening hot water taps.

6.3.1 Frost protecti on

• In order to avoid freezing of the condensate discharge pipe, the

appliance should be installed in a frost-free room.

• In order to avoid freezing of the appliance (heat exchanger), it has

an appliance frost protection. When the temperature of the heat

exchanger drops to 5ºC, the burner will be activated and the pump

will start running until the temperature of the heat exchanger

reaches10ºC.

• When the system (or a part thereof) can freeze, a frost thermostat

should be installed in the area to be protected. Connect this

according to the wiring diagram. See § 10.1.

Note!

The external frost thermostat is not active when the appliance has been

switched off at the operating panel or when the mains voltage has been

interrupted.

40

Page 41

7. SETTING AND ADJUSTMENT

The functioning of the appliance is mainly determined by the (parameter)

setting in the burner controller. A part of this can be set directly via the

operating panel, while another part requires an Installer code to be

entered before settings can be changed.

7.1 Directly via operating panel

The following settings can be made directly via the operating panel.

Appliance on/off

The appliance is activated by means of the on/off button.

When the appliance is working, the green LED will be lit. When the

appliance is off, one bar on the service display (

-- ) is lit to indicate the

presence of voltage.

The maximum CH supply temperature

During CH operation (the LED CH is lit), the CH supply temperature can

be changed using the + and - keys. When the appliance is not working,

a selection can be made using the ‘temperature’ button. Use this button to

select ‘ch’ and set the temperature. Confirm the setting by pressing the

reset

key.

Domestic hot water temperature

During domestic hot water operation, the water temperature can be set

between 50ºC and 60ºC using the

+ and - keys.

Domestic hot water comfort

The domestic hot water comfort function can be set using the ‘hw store’

key and it has the following settings:-

• Eco: The comfort function is self-learning. The appliance is inactivated

during the night or after a long absence. The appliance adjusts to the User

pattern of the domestic hot water requirements.

• On: The comfort function of the appliance is continuously activated. The

appliance always supplies domestic hot water immediately.

• Off: (Both LED's off) The heat exchanger is not kept warm, delaying the

supply of hot domestic hot water. When there is no demand for hot

domestic hot water or for the direct supply of this, the comfort function can

be switched off.

Reset button

When a locking fault is indicated by means of a flashing figure on the service

display, the appliance can be restarted by pressing the reset key for 5 seconds.

Check the nature of the fault by means of the fault codes under 7.1 and solve the

problem, if possible, before resetting the appliance.

7.2 Settings through the service code

The burner controller of the appliance has been set in the factory

according to the parameters of § 7.3.

These parameters can only be changed with the service code. Proceed as

follows to activate the program memory:

1. Set the appliance in the off mode using the on/of key (

- on the service

display).

2. Simultaneously press the service and reset keys, until a

0 appears on the

service and the temperature displays.

41

Page 42

3. Using the “+” and “-“ keys, set 15 (service code) on the temperature display.

4. Press the “service” key to confirm the code.

5. Set using the “service” key the parameter to be set on the service display.

6. Set using the “+” and “-“ keys the parameter to the required value on the

temperature display.

7. After having entered all required changes, press the “reset” key

until

-- appears on the service display.

8. Switch on the appliance again using the “on/off” key.

The burner controller has now been reprogrammed.

By pressing the selection key “ch/hw” (left hand key of “temperature”

keys), the factory settings of the parameters are restored.

Remark - This can only be done if the service code has been set.

7.3 Parameters

Parameter Setting Factory

setting

Description

InterCombi

HE 32

0 Service code [15] - Access to installer settings. The service code must be entered

(=15).

1 System type 0 0 = standard

1 = heating only operation + indirect hot water tank

2 = hot water only operation

3 = heating only opration

2 CH pump continuous 0 0 = pump overrun only

1 = pump continuously active

2 = CH pump continuously active with external MIT switch

3 Set CH power 70 Setting maximum CH load

4 Set hw power 99 Setting maximum hw power

5 Min. supply temperature of

the control line

25 Setting range 10°C to 25°C (Weather-dependent control)

6 Min. outside temperature of

the control line

-7 Setting range -9°C to 10°C (Weather-dependent control)

7 Max. outside temperature of

the control line

25 Setting range 15°C to 30°C (Weather-dependent control)

8 CH pump overrun time after

CH operation

1 Setting range 0 - 15 minutes

9 CH pump overrun time after

boiler operation

2 Setting range 0 - 15 minutes (does not apply to Kombi

appliance)

A Position three-way or two-

way valve

0 0 = confirmed during CH operation

1 = confirmed during hw operation

C Steps modulation 0 0 = step modulation off during CH operation

1 = step modulation on during CH operation

D Minimum speed/ output 25 Setting range 25 to 40%

40=propane

E Min. supply temperature

during OT demand

(OT = OpenTherm

thermostat)

40 Setting range 10°C to 60°C. If the OT thermostat demands a

supply temperature that is below this set value, the heat

demand cannot be met.

F Starting speed 70 Setting range 70 to 99%

H Max. fan speed 45 Setting range 40 to 50 (40 = 4000 rpm, 50 = 5000 rpm) The

absolute maximum speed can be set through this parameter.

42

Page 43

7.4 Setting maximum CH power

The maximum CH power is set to 70% in the factory. When the CH

system requires more or less power, the maximum CH power can be

changed by adjusting the fan speed. See table: Setting CH power.

This table gives the relation between the fan speed and the appliance

power.

Setting CH power

Press loss/pump lift (m head)

Flow (litres/hr)

Required CH power Setting on service display

InterCombi HE 32

(approxt kW) (% of the maximum speed)

26.2 85

22.7 75

19.7 65

16.7 55

13.7 45

10.6 35

7.0 25

Caution

The power slowly increases while burning (modulation by time) and

decreases as soon as the set supply temperature is reached.

7.5 Setting pump position

The switch for setting the pump position is located on the connecting box

of the CH pump

1. Set the pump position on the basis of the set maximum power and

the resistance of the system on the water side. See diagram:

Pressure loss and pump lift, type Ups 50-130, positions 1, 2 and 3.

2. Check the temperature difference between the supply and return of

the appliance: this should be about 20°C.

The minimum flow-through Set power

200 l/h 7.0 kW

750 l/h 26.2 kW

A. (Not applicable)

B. InterCombi HE32

I Pump position 1

II Pump position 2

III Pump position 3

X Flow-through in litres/hr

Y Pressure loss / pump lift in metres head

43

Page 44

T supply °C

7.6 Weather-dependent control

When the outside sensor is connected, the supply temperature is

automatically controlled dependent on the outside temperature in

accordance with the set control line.

The T set CH (= CH supply temperature) is set via the temperature

display. If required, the control line can be adjusted by the service code.

See § 7.3.

X. T outside °C

Y. T supply °C

A. factory setting

B. example

T outside °C

7.7 Conversion to other gas type

CAUTION

Activities on the gas-containing parts should only be

executed by a qualified registered installer.

When the appliance is connected to another gas type than the type for

which the manufacturer has set the appliance, the gas setting ring must

be replaced. Conversion sets for other gas types can be ordered.

Conversion of the gas setting ring

1. Switch off the electrical supply to the appliance .

2. Close the gas tap.

3. Remove the front cover of the appliance.