Page 1

English

AtmoSafe

Operating Instructions

GA1GB.220101.0

2017-02 Index: 14

Page 2

Table of contents

1.0 Introduction

1.1 Notes on operating instructions ............................3

1.2 Function ................................................................3

1.3 Explanation of symbols .........................................3

2.0 For your safety ............................................... 4-5

3.0 Intended use ........................................................6

4.0 Setting up and starting up

4.1 Illustrations ........................................................ 7-9

5.0 Operation

5.1 Initial start-up ......................................................10

5.2 Assembly ............................................................10

5.2.1 Installation together with a surgical device .........10

5.2.2 Main lter ............................................................10

5.2.3 Hose ....................................................................10

5.2.4 Prelter ................................................................11

5.2.5 Check on supply voltage ..................................... 11

5.3 Settings ............................................................... 11

5.4 Display elements.................................................12

5.5 Aspiration ............................................................12

5.6 Options................................................................12

5.7 Service level.................................................. 13-14

6.0 Cleaning and care

6.1 General information on cleaning and disinfection 15

6.2 Reprocessing of hoses and secretion canister ...15

6.3 Cleaning and disinfecting the surface of the unit 15

7.0 Maintenance and Service .................................16

8.0 Troubleshooting ................................................17

9.0 Accessories and spare parts

9.1 Accessories .........................................................18

9.2 Spare parts .........................................................18

10.0 Technical data ...................................................19

11.0 Disposal .............................................................20

12.0 Notes on EMC .............................................. 21-23

ATMOS

MedizinTechnik GmbH & Co. KG

Ludwig-Kegel-Straße 16

79853 Lenzkirch

Germany

Phone +49 7653 / 689-0

Fax: +49 7653 / 689-190

+49 7653 / 689-493 (Service Center)

atmos@atmosmed.de

www.atmosmed.com

2

All rights regarding these operating instructions, in particular

the right of reproduction and dissemination, and that

of translation, are reserved. No part of these operating

instructions may be reproduced in any form (by photostat,

microlm, or other processes) without prior written

permission of ATMOS MedizinTechnik GmbH & Co. KG

or by using electronic systems processed, duplicated, or

disseminated. The information contained in these operating

instructions may be changed or amended without prior

announcement and does not represent any liability on the

part of ATMOS MedizinTechnik GmbH & Co. KG.

© ATMOS MedizinTechnik GmbH & Co. KG, 1999

Printed by: ATMOS MedizinTechnik GmbH & Co. KG

Page 3

1.0 Introduction

!

1.1 Notes on Operating Instructions

• These operating instructions contain important notes

on how to operate the ATMOSafe safely, correctly and

effectively. Therefore, they are intended not only for new

operating personnel to be instructed in its use, but also

for use as a reference manual. They help to avoid risks,

and also to reduce repair costs and down-times. Furthermore, reliability and service-life of the equipment will be

increased. For these reasons these operating instructions

must always be kept available near the device.

Prior to rst use please peruse the chapter 2.0 “For your

safety”.

The basic principles are:

Judicious and careful work provides best protection

against accidents!

Maintenance and repair work may be carried out only by

expert personnel authorised by ATMOS. In case of repairs

you should insist that only original spare parts are used. You

will then have the warranty that operational safety, readiness

for work and the value of your device will be preserved.

• The product ATMOafe bears CE marking CE according

to the EC Directive of the council for medical products

93/42/EEC and meets the basic requirements of Appendix I of the directive.

• The product ATMOSafe complies with all applicable

requirements of the Directive 2011/65/EC restricting the

use of certain hazardous substances in electrical and

electronic equipment (“RoHS”).

• The declaration of conformity and our general standard

terms and conditions can be obtained on our website at

www.atmosmed.com.

• The quality management system applied at ATMOS has

been certied according to international standards EN

ISO 13485.

• ATMOS will supply a service manual containing detailed

circuit descriptions and schematics as well as information on adjustment and servicing to service organizations

authorized by ATMOS.

• Reprints (also in extracts) only with permission in written

form by ATMOS.

Short cuts / symbols contained in these operating

instructions:

• Indicating a list

- Subdivision of a list/activity

The recommended sequence must be followed in each

case!

) Indicating particularly important advice!

ª Describing the effect of an activity

1.2 Function

• The AtmoSafe is an electrically operated medical device,

cleaning the air in medically used rooms from fume and

gas constituents arising from vaporising of human or

animal tissue. This fume arises typically when using laser

or electro-surgical devices and is consisting as a rule of

water vapour, aerosol, and organic gases.

• The AtmoSafe improves the environmental conditions in

the operating theatre:

- Reduction of the dust load by removing respirable

particles

- Improvement of view

- Removal of foul-smelling and partly toxic organic

gases

- Evacuation and ltering of hazardous bio-aerosol

(ltration of viruses)

• The AtmoSafe draws in the fume-laden air through a de-

vice positioned at the surgical application part or through

a separate hose, manually held near the application part.

By means of a high-efciency lter the drawn-in air is

cleaned of the hazardous matter and returned again into

the ambient air.

• Cleaning of the air refers to constituents like aerosol,

which is being retained by means of an ULPA high-efciency particle lter, as well as to organic gases, which,

amongst other characteristics, feature a smell unpleasant

for human beings, retained by a special gas lter.

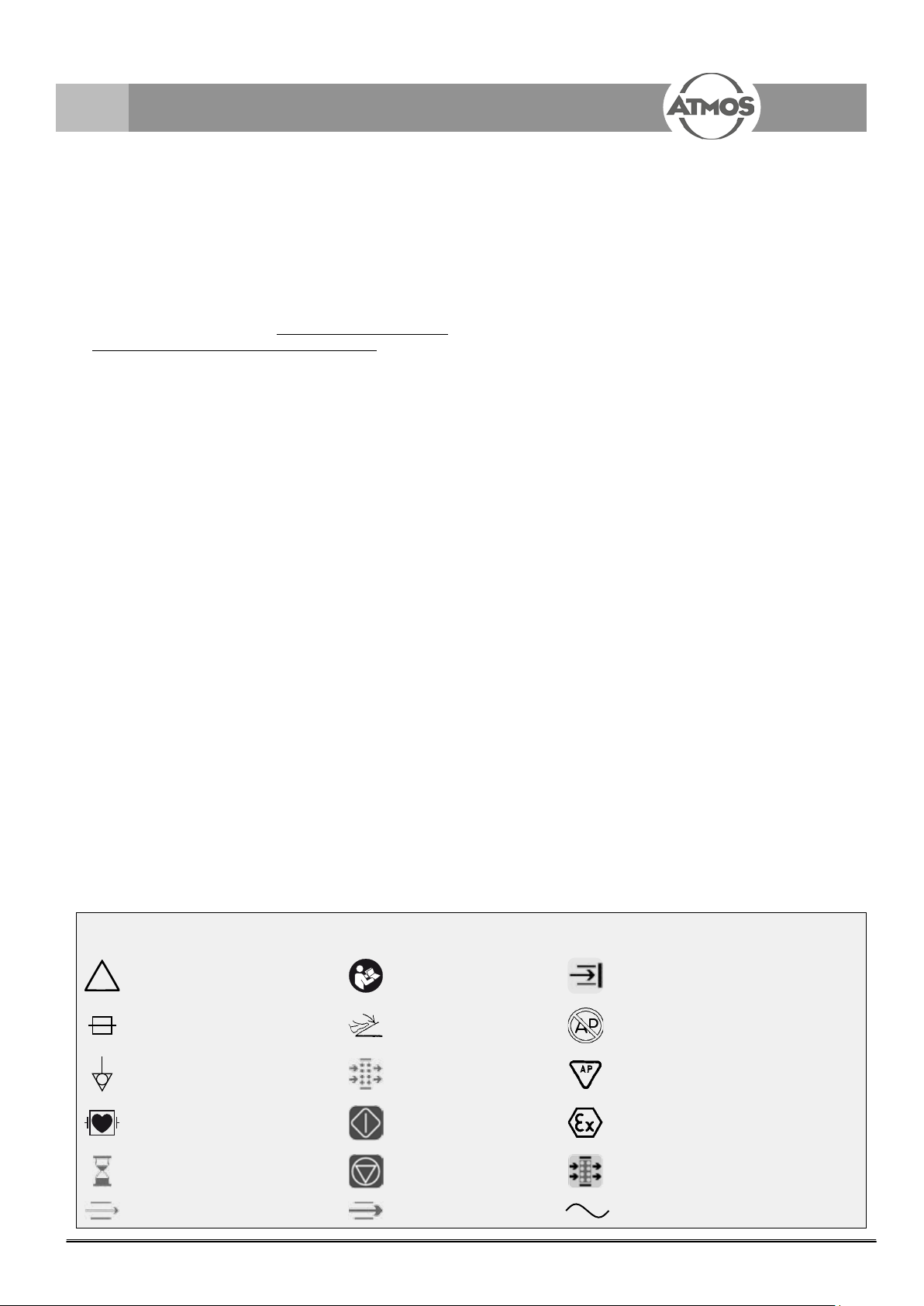

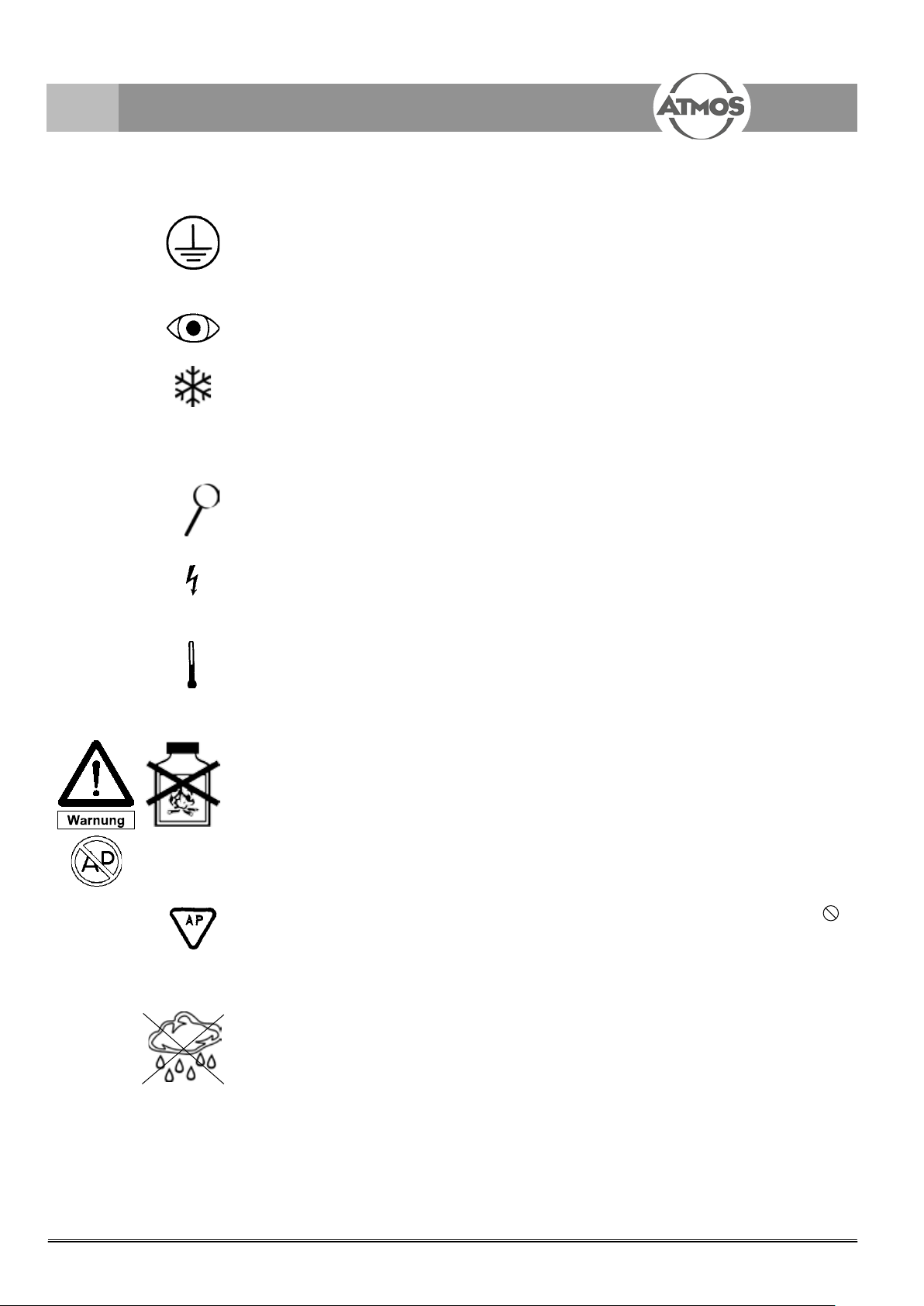

1.3 Explanation of symbols

Caution, observe operating

instructions!

Equipment safety fuse Foot switch

Potential equalisation Filter Anaesthetic-tested

Application part type CF, de-

protected

Delayed stop period Stop Display: Filter to be changed

Base ow Operation ow Alternating current

Follow operating

instructions! (blue)

Start

Display: Air passage blocked

Unit must not be exposed to explosive

anaesthetic gases

Protected for use in explosive

atmospheres

3

Page 4

2.0 For your safety

2.0 For your safety

• The AtmoSafe has been designed in accordance with IEC 601/ EN 60601. The equipment con-

forms to VDE Safety Class I. It must only be connected to a properly installed earthed socket.

• Before connecting the device it needs to be checked whether the requested mains voltage of

the device matches the mains voltage of the mains power supply.

• The AtmoSafe may be used only by trained staff under supervision (IEC 601-1 / EN 60601-1).

• Following transportation at low temperatures (<0°C) the appliance must be held for up to six

hours at ambient temperature before rst start-up. If the AtmoSafe is not acclimatized, it may

not be used.

• The suction hose must never come into direct contact with the evacuation position in order to

avoid suction adherence on the tissue.

• Check device, power cable, accessories, connection cables and hoses for damage before

start-up. Defect cables and hoses must be replaced immediately. Check functions of the device

prior to using it!

• Disconnection from supply network only by pulling the mains plug! First the plug is to be pulled

from the wall socket. Then disconnect the connection line from the device.

• Never touch plug or line with wet hands.

• Please observe the ambient conditions stated in the technical data (chapter 10.0).

• Pay attention to maximum stability of the installation surface.

• The device must only be operated in rooms designated for medical use. The AtmoSafe is not

designed to be used in an explosion-hazardous environment. Explosion-hazardous areas

may be caused by the use of ammable anaesthetics, skin cleansing products and skin disinfectants. The suction opening of the hose should not lie on the oor Evacuation of explosive

endogenous gases (e.g. methane) from the intestinal tract is also prohibited.

• The foot switch must be suitable for use in areas subject to explosion hazards. Foot switches

used on operation theatres must have a watertight switching element (IPX 8).

• This product is not re-sterilizable. Repeated reuse of components which are marked with a

is forbidden. In case of repeated reuse these components lose their function and there is a

high infection risk.

• The AtmoSafe may be operated only in rooms used for medical purposes, but not in areas

subject to explosion hazards and in oxygen rich environments.

2

• Do not allow any liquid to get into the device or be sucked in. If liquids have penetrated the

device, it may not be operated again until it has been checked by the customer service centre.

• The AtmoSafe meets the immunity to interference requirements of IEC 601-1-2 / EN 60601-1-2

EMC

„Electromagnetic Compatibility – Medical Electrical Devices“.

4

Page 5

2.0 For your safety

• ATMOS is not liable for personal injury and damage to property if

- no original ATMOS parts are being used,

- the advice for use in these operating instructions is not being observed,

- assembly, new settings, alterations, extensions and repairs have been carried out by person-

nel not authorised by ATMOS.

Sterile

Hospital

Grade

• In the surgical invasive sterile area sterile parts only may be used. Hoses, application parts, as

well as instruments, must be used either as sterile single-use part or sterilised multiple-use part.

• Power cables must correspond to the applicable national regulations. The suitability for medical

applications must be ensured in particular.

• In case of leaks in the system the indication for suction adherence may fail.

• With very low power setting at the HF surgical device auto activation may possibly not function.

• In case of high electromagnetic and performance-related interference the sensitivity of

auto activation must be reduced.

• Please note: A medical insulating transformer with earth leakage monitor or any similar safety

system acc. to EN 60 601-1 is required, if several devices are connected over one common

power supply. The transformer must correspond to the power consumption of all the devices to be

connected.

5

Page 6

3.0 Intended use

Name: AtmoSafe

Main functions: Smoke extraction system for use in con-

junction with smoke or gas producing medical appliances,

like laser and high-frequency surgical appliances, cauter-

ises, oscillation saw, and methods like the removal of bone

cement in revision endoprosthetics.

Medical indications / application: For extraction and

ltering of evaporated burn-off products arising with thermal

medical operations by vaporisation of tissue.

For extraction and ltering of aerosols, emitted by

oscillation saws (e.g. in autopsy).

For extraction and ltering of vapours arising when two com-

ponent adhesives or cement mixtures are mixed and used

(e.g. in implant surgical work).

Specication of the main function: The AtmoSafe draws

in the fume-laden air through a device positioned at the surgical application part or through a separate hose, manually

held near the application part. By means of a high-efciency

lter the drawn-in air is cleaned of the hazardous matter and

returned again into the ambient air. Cleaning of the air refers

to constituents like aerosols, which is being retained by

means of an ULPA high-efciency particle lter.

Application organ: No specic application organ

Application time: Short-term use on the patient

(< 30 days).

Application site: The application site is the clinical, outpa-

tient as well as the practices area. The application of the

device may only be performed by medically trained and

introduced staff .

Contraindications: No application outside of the medical

sector. No suction of ammable, corrosive and explosive

substances.

The product is: X active □ not active

Sterility: Not necessary

Single-use product / reprocessing: The device and part of

the accessories are reusable. For information on reprocessing and disinfection, please see the operating instructions.

6

Page 7

4.0 Setting up and starting up

4.1 Illustrations

Fig. 1. AtmoSafe Overall view

Operator panel

Mains lter

Filter locking

7

Page 8

4.0 Setting up and starting up

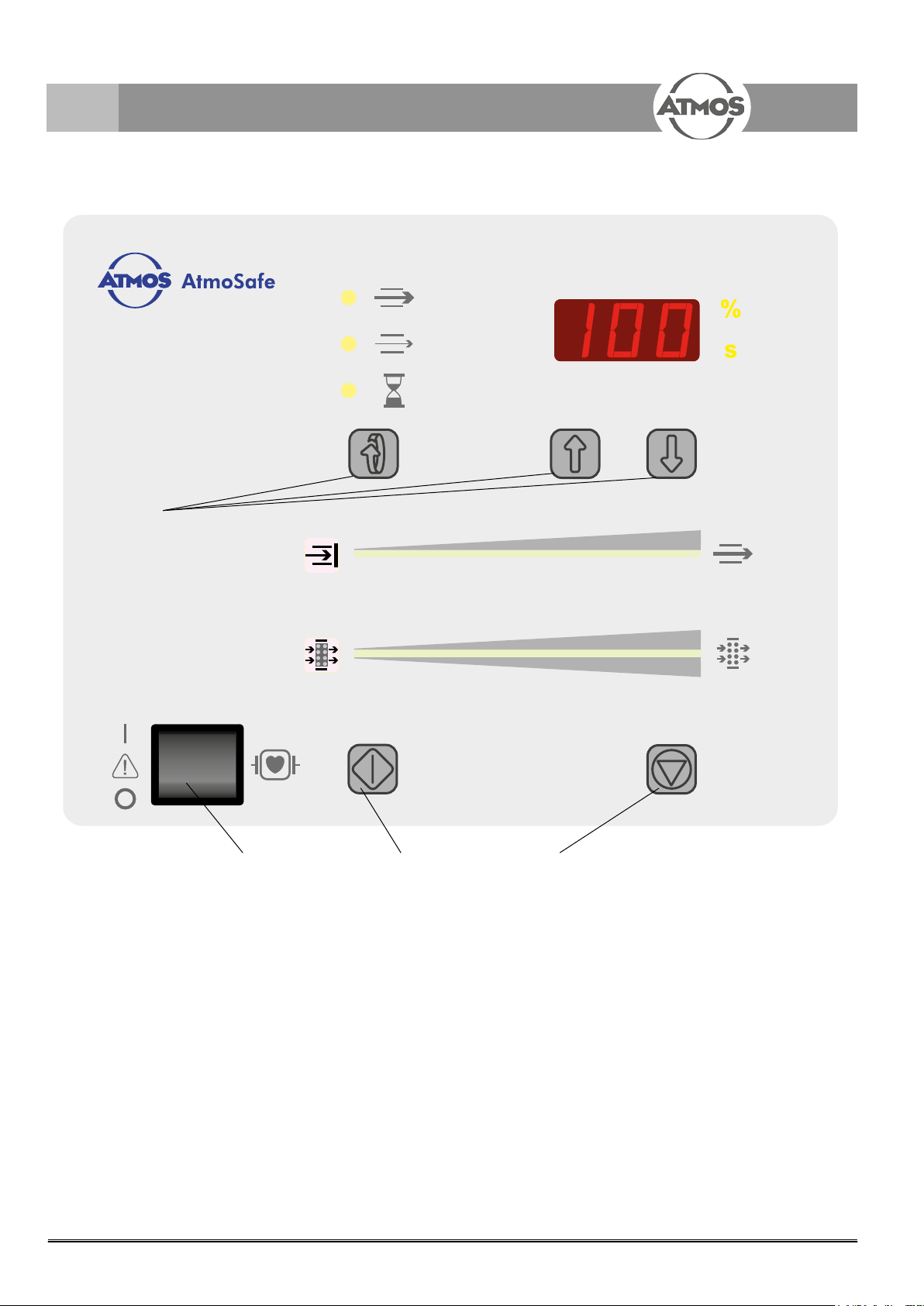

Fig. 2. Display and control elements

ON/OFF switch

Start button manual

Stop button manuel

Presetting buttons

Air ow display

Filter capacity display

8

Page 9

4.0 Setting up and starting up

Fig. 3. AtmoSafe Rear view

Mains supply

Equipment safety fuse

Non-heating apparatus mains connection for

an HF surgical device

Connection for potential equalization

Activation input

9

Page 10

5.0 Operation

5.1 Initial starting up

Prior to shipment each AtmoSafe is being inspected by the manufacturer for function and safety.

In order to make sure that the appliance is working safely after transport and installation, the

following points should be observed: The user should put the appliance into operation only if the

manufacturer or the supplier

Peruse safety information in part 2.0 prior to starting up the device for the rst time.

1. has carried out a functional test on the appliance at the place of operation

2. has instructed the person responsible for operating the device on how to handle the device

by means of the operating instructions.

6h

14

Following transportation at low temperatures (<0°C) the appliance must be held for up to six

hours at ambient temperature before rst start-up. When the device has not been acclimatised

evacuation cannot be activated The device is protecting itself.

5.2 Assembly

The device has to be positioned on a stable base; attention must be paid to the load carrying

capacity.

The base must not be soft (foamed material or similar), so that the exhaust air openings are not

covered.

5.2.1 Installation together with a surgical device

The power cable of the surgical device must be tted with an inlet connector for non-heating apparatus according to IEC 320.

This inlet connector for non-heating apparatus is plugged into the auxillary mains socket (, Fig.

3) on the rear of the AtmoSafe. The AtmoSafe is now controlling the power input of the surgical

device by means of the internal ISA device (Internal Synchronous Activation) and, in this way,

effects auto activation. Auto activation means that the evacuation mode is switched on as soon as

the thermal surgical function of the surgical device (Cut, coag,...) is activated.

Prior to rst use of the surgical device auto activation must be calibrated once. How the AtmoSafe

is to be adapted to the surgical device is said in Chapter 5.7.5 Calibration of auto activation.

10

Auto activation of the AtmoSafe works with most surgical devices in the power range 50 W...1400

W (for inst. ERBE ICC 350, ICC 50,...)

Only compatible devices may be connected to the auxiliary mains socket (,Fig. 3).

5.2.2 Main lter

• After having taken off the packaging and the plugs, please slide the main lter (, Fig. 1, p. 15)

into the lter shaft of the unit until it locks. Take care that the lter cover is on the right side.

When there is no main lter in the unit evacuation cannot be activated.

5.2.3 Hose

• After having taken off the packaging the hose (Ø 22 mm) is put with one end onto the connecting nipple of the main lter.

Page 11

5.0 Operation

Scroll

+

_

5.2.4 Prelter

• Please put the prelter onto the hose, preferably at the open hose end. The prelter protects

the hose and the main lter against coarse contamination. For more exibility at the hose end

near the eld of operation, the lter can be installed between the hose and the main lter. The

direction of ow must be taken care of, it is shown on the prelter. You must use only a clean

and dry lter.

5.2.5 Check on supply voltage

• Please check whether the mains voltage data shown on the fuse drawer (, Fig. 3, p. 17) of

the device agree with the values of the mains supply network, and then connect the AtmoSafe

to the supply network.

) If the AtmoSafe is used for surgical procedures, we recommend connecting it to the equipoten-

tial bonding connection of the room via connection.

The AtmoSafe is now ready for operation.

5.3 Settings

5.3.1 Presettings general

The values for operation ow, base ow, and delay can be set individually. By using the scroll button the desired parameter to be changed can be selected. The currently set ow value is shown

in the display in percent. The value can be set in % - related to the total rating of the device - by

1%-steps. The currently set delay is shown in the display in seconds. By means of the arrow buttons the value can be increased or reduced. With prolonged pressing of the corresponding arrow

button

5.3.2 Base ow

or , setting speed increases, so that also larger changes can be effected quickly.

Base ow

Operation ow

Delay

Also during interruptions of work, i.e. when there is no activation signal received from the laser or

the HF surgical device or from the foot switch received, the device works with reduced intensity. In

order to be able to set the ow intensity of this base ow you should activate the scroll button repeatedly until the indicating light next to the base ow symbol lights up. Now, you press the arrow

buttons until the desired value is obtained. This value can be set between 0 and 30 %. The base

ow is switched off after a certain period of time (work’s setting = 2 min). This time, i.e. the base

ow time, can be set on the service level. (See also chapter 5.7 Service level).

5.3.3 Operation ow

During the surgical operation, i.e. when there is an activation signal received from the laser or

from the HF surgical device or from the foot switch, the device shall extract the fumes which

develop with full intensity. In order to be able to set the ow rate of this operation ow you should

activate the scroll button repeatedly until the indicating light next to the operation ow symbol

lights up. Now, you press the arrow buttons until the desired value is obtained.

5.3.4 Delay

In order to prevent activation and de-activation of operation ow at short intervals during the frequent

interruptions between cutting and coagulation phases the ow continues for a certain period of time

after the end of the cutting / coagulation procedure (i.e. after the activation signal is off). In order to

be able to set the delay period of this operation ow you should activate the scroll button repeatedly until the indicating light next to the delay symbol lights up. Now, you press the arrow buttons

until the desired value is obtained. Adjustments from 0...100 sec are possible as well as “O ", i.e.

unlimited delay. With the adjustment “0 the start button or a connected foot switch has following

function (operated once = 'on', operated once again = 'off ').

11

Page 12

5.0 Operation

5.4 Display elements

5.4.1 Flow indication

This points out the air resistance arising in the air passage (through the hose and lter system).

When all the green bars are lit up, the suction resistance is low. The less bars are lit, the lower

the ow. The display permits to draw conclusions, for inst. regarding the degree of blocking of the

prelter.

When the system is completely blocked, all the green bar indicators are off, and the display on the

left lights up red.

5.4.2 Filter capacity

The display of lter capacity permits quick assessment of the current lter status. The more green

bar indicators are lit up, the more capacity there is still left. With full exhaustion of lter capacity

the green indicators are off, and the display on the left lights up red.

5.5 Aspiration

Flow

Filter

Please ensure that for invasive treatment the following parts are sterile with each new patient:

- Suction hose incl. suction jets or suction set.

- All parts extending into the operating eld, in particular those near or in contact with the

patient.

• Switch on the AtmoSafe by means of power switch (, Fig.2, p. 16).

• Please ensure that the suction hose is correctly positioned, i.e. that no sensitive parts or swabs

or similar, are sucked in.

• Please activate now the ow by pressing the start button or the connected foot switch. The

device will continue to work as long as the button is pressed. Thereafter, the ow will continue

for the duration of the set delay period (see Chapter 5.3.4).

5.6 Options

5.6.1 Foot switch (Art. No. see accessories)

• Explosion-protected switch (AP safety) for switching ow on and off.

- Connect the foot switch.

- When pressing the foot switch the ow is switched on. After releasing the foot button the

device will continue to work for the duration of the set delay period.

- The function of the foot button is the same as that of the start button.

12

Page 13

5.0 Operation

Scroll

Main switch

5.7 Service level

The service level permits the user to change certain ex work's settings.

You will reach the service level by pressing the SCROLL button (, Fig. 2, p. 16) and then switch-

ing on the device by means of the power switch (, Fig. 2, p.16). Then in the display will appear:

Basic program - Display "S 0 “

Button Description

Selection of service sub-program (plus)

Selection of service sub-program (minus)

Exit form service mode

Calling the corresponding sub-program

Sub-programs – overview

Display Description

S 0 Change brightness of display

S 1 Automatic activation on / off

S 2 Suction adherence indication on / off

S 3 Change base ow period

S 4 Calibration on auto activation (automatic)

S 5 Calibration on auto activation (manual)

5.7.1 S 0 Change brightness of display

Display: 0 0 ..... 010 (Brightness value)

Button Description

Brightness +

Brightness -

Return (incl. store)

Description:

Brightness can be set between 0 and 10.

5.7.2 S 1 Automatic activation on / off

Display: 1 0 (Activation off) 1 1 (Activation on)

Button Description

Activation on

Activation off

Return (incl. store)

Description:

The activation by means of the integrated current sensor can be switched on and off as required

13

Page 14

5.0 Operation

5.7.3 S 2 Suction adherence indication on / off

Display: 2 0 (Suction adherence indication off) 2 1 ((Suction adherence indication on)

Button Description

Suction adherence indication on

Suction adherence indication off

Return (incl. store)

Description:

The suction adherence indication can be switched on and off as required Suction adherence indication can be switched on and off as required.

5.7.4 S 3 Change base ow period

Display: 300 .... 399 (Base ow period in seconds)

Button Description

Base ow period +

Base ow period -

Return (incl. store)

Description:

Here the base ow period can be set. The device remains in base ow mode, as determined by

this setting. Thereafter the device is switched off. With setting 99 there is no time limit for the base

ow.

5.7.5 S 4 Calibration on auto activation (automatic)

Display: 499 .... 400 (Potentiometer setting in %)

Button Description

Start of calibration

Termination

Following auto-calibration manual postprocessing takes place automatically (see S 7).

Description:

Prior to starting auto-calibration the corresponding surgical device must be connected and activated. The set position should be the minimum setting. The device will then search automatically

for the corresponding setting value. For validation, automatic calibration is always followed by

manual calibration (see S 7).

5.7.6 S 5 Calibration on auto activation (manual)

Display: 500 .... 599 (Potentiometer setting in %) All LEDs (on = activation takes place, off =

no activation)

Button Description

Activation threshold + (less sensitive)

Activation threshold – (more sensitive)

Return (incl. store)

Description:

Here sensitivity of automatic activation can be set. For doing this, the corresponding HF device

must be connected. The setting must be done in a manner that with activated surgical device the

LEDs are lit, and with non-activated surgical device the LEDs are not lit.

14

Page 15

6.0 Cleaning and care

6.1 General information on cleaning and

disinfection

• For disinfection, you may use all surface and instrument

disinfectants listed on page 32.

) There are disinfectants which can cause discolouration of

plastic parts, like the lter case, etc.; this however does

not effect the function of the parts.

) Always observe the concentration specications and

instructions by the respective manufacturer!

6.2 Reprocessing of the hoses

) Please ensure that the following parts have been disin-

fected before treating a new patient:

- Suction hose incl. suction jets or suction set.

• Washing and disinfecting in an automatic cleaner and

disinfector is also possible.

Thermal disinfection is carried out at 93° C.

• After disinfecting the parts are to be mounted again

(Chapter 5.0 “Operation”).

Recommended instrument disinfectants

Disinfectant Producer

GIGASEPT FF Schülke & Mayr, Norderstedt

Sekusept PLUS Henkel, Düsseldorf

Mucozit-T Merz & Co., Frankfurt/Main

Recommended surface disinfectants

Disinfectant Producer

TERRALIN Schülke & Mayr, Norderstedt

QUATOHEX Braun, Melsungen

Incidin Plus Henkel, Düsseldorf

Pursept-A Merz & Co., Frankfurt/M.

(Disinfection spray

or disinfection cloth)

6.3 Cleaning and disinfecting the

surface of the unit

) You must disconnect the mains plug before cleaning and

disinfecting the unit casing.

) Wipe-disinfection:

Wipe the unit surface with a cloth moistened with a

cleaning or disinfecting solution. Do not allow any liquid

to get into the device. The cleaning agents and disinfectants listed in the next section are all suitable.

) If liquid has penetrated the unit, it may not be operated

again until it has been checked by the authorised customer service centre.

) Do not use disinfectants containing alcohol.

15

Page 16

7.0 Maintenance and Service

The base device is maintenance-free.

Filter replacement:

• As described in operating instructions, section 5.2.2 Main

lter.

Preventive maintenance of evacuation

system:

• Prior to every use a visual inspection of the device,

hoses, main and prelter and mains power cable must be

performed.

When using further accessories, like liquid vessel, foot

switch or activation sensors, also these should be subjected to a visual check.

• Replace any damaged parts immediately.

• The unit does not require any further maintenance.

Corrective maintenance of system:

• Any changes or repairs may - with due regard to the

special requirements for medical products - be carried

out only by the manufacturer or by persons expressly

authorised by the latter.

• Please comply with the country-specic guidelines re-

garding regular testing especially for the electrical safety.

ATMOS recommends a test every 24 months.

Sending in the device

1. Remove and properly dispose of consumables.

2. Clean and disinfect the product and accessories according to the operating instructions.

3. Place used accessories with the product.

4. Fill in the form QD 434 „Delivery complaint / return shipment“ and the respective decontamination certicate.

• This form is enclosed to each delivery and can be found

at www.atmosmed.com.

5. The device must be well padded and packed in suitable

packaging.

6. Place the form QD 434 „Delivery complaint / return shipment“ and the respective decontamination certicate in

an envelope.

7. Afx the envelope to the outside of the package.

8. Send the product to ATMOS or to your dealer.

16

Page 17

8.0 Troubleshooting

Abhilfe

– Netzstecker sitzt schlecht

– keine Netzspannung

– Sicherung defekt

– Anschluß an Steckdose überprüfen

– Haussicherung überprüfe n

– Sicherung vom Service austauschen lassen

– Und ichte S tellen in Schlauc hlei t ung e n

– Hauptfilter ist verblockt

– Vorfilter ist verblockt

– Schlauchleitungen auf festen Sitz überprüfen

– Hauptfilter wechseln

– Vorfilte r wechseln

– Kalibrierfehle r des interne n

– K und endi e nst muß die K alib ri e rung vor O rt durchfüh re n

Abhilfe

– Netzstecker sitzt schlecht

– keine Netzspannung

– Sicherung defekt

– Anschluß an Steckdose überprüfen

– Haussicherung überprüfe n

– Sicherung vom Service austauschen lassen

– Und ichte S tellen in Schlauc hlei t ung e n

– Hauptfilter ist verblockt

– Vorfilter ist verblockt

– Schlauchleitungen auf festen Sitz überprüfen

– Hauptfilter wechseln

– Vorfilte r wechseln

– Kalibrierfehle r des interne n

Drucksensors

– K und endi e nst muß die K alib ri e rung vor O rt durchfüh re n

– Üb ertemperatur (>69°C) oder

– Gerät ausschalten und warten bis die Temperatur im Geräte-

Abhilfe

– Netzstecker sitzt schlecht

– keine Netzspannung

– Sicherung defekt

– Anschluß an Steckdose überprüfen

– Haussicherung überprüfe n

– Sicherung vom Service austauschen lassen

– Und ichte S tellen in Schlauc hlei t ung e n

– Hauptfilter ist verblockt

– Vorfilter ist verblockt

– Schlauchleitungen auf festen Sitz überprüfen

– Hauptfilter wechseln

– Vorfilte r wechseln

– Kalibrierfehle r des interne n

Drucksensors

– K und endi e nst muß die K alib ri e rung vor O rt durchfüh re n

– Üb ertemperatur (>69°C) oder

Untertemperatur (<0°C)

– Gerät ausschalten und warten bis die Temperatur im Geräte-

inneren sich wieder normalisiert hat.

– Datenfehler auf der Hauptplatine – Gerät aus- und wiedereinschalten. Sollte jetzt die Festsaug-

Abhilfe

– Netzstecker sitzt schlecht

– keine Netzspannung

– Sicherung defekt

– Anschluß an Steckdose überprüfen

– Haussicherung überprüfe n

– Sicherung vom Service austauschen lassen

– Und ichte S tellen in Schlauc hlei t ung e n

– Hauptfilter ist verblockt

– Vorfilter ist verblockt

– Schlauchleitungen auf festen Sitz überprüfen

– Hauptfilter wechseln

– Vorfilte r wechseln

– Kalibrierfehle r des interne n

Drucksensors

– K und endi e nst muß die K alib ri e rung vor O rt durchfüh re n

– Üb ertemperatur (>69°C) oder

Untertemperatur (<0°C)

– Gerät ausschalten und warten bis die Temperatur im Geräte-

inneren sich wieder normalisiert hat.

– Datenfehler auf der Hauptplatine – Gerät aus- und wiedereinschalten. Sollte jetzt die Festsaug-

erkennung nicht mehr funktionieren, muß der Kundendienst vor

Ort eine K a lib rier ung vor ne hme n.

– Gebläse ohne Lei stung – Gerät aus- und wiedereinschalten. Bei erneutem Fehler Kunden-

The AtmoSafe was subjected to a thorough quality control in the factory. If however any problems should occur, you can possibly eliminate these personally, if observing the following notes.

Error indication Possible cause Remedy

• Device does not start - Power plug is tted badly - Check connection at wall socket

- No mains voltage - Check main fuse

- Defect fuse - Have fuse replaced by service

• Insufcient ow - Leaks in hose lines - Check hose lines for rm seating

- Main lter is blocked - Replace main lter

- Prelter is blocked - Replace prelter

• Display

• Display

- Calibration defect of intern pressure sensor

- Excess temperature (>69°C) or

sub temperature (<0°C)

- Service must carry out calibration on site

- Switch off device and wait until

temperature inside the device

returns to normal

• Display

• Display

- Data fault on main board - Switch device off and on again.

Should now suction adherence indication no longer work,

customer service must carry out

calibration on site.

- Blower does not work - Switch device off and on again.

With renewed defect inform

service.

17

Page 18

9.0 Accessories and spare parts

9.1 Accessories

Operating instructions ........................... GA1GB.220101.0

Connection line for electric equipotential bonding

(possibly only in operating theatre) .................. 008.0596.0

Foot switch for AtmoSafe, suitable for

use in Zone M (not for operating theatre),

explosion-protected, IPX 1 ............................... 445.0061.0

OP foot switch for AtmoSafe, suitable for use in

Zone M, explosion-protected, IPX 8 .................445.0068.0

Standard rail set 25 x 10 mm / 315 mm for lateral

mounting to AtmoSafe .....................................445.0064.0

Hose holder for insertion into standard rails

(25 x 10 mm or 30 x 10 mm), for air hoses with

Ø 22 mm ..........................................................445.0066.0

Surgical handle, with integrated suction chan-

nel, with standard international plug-connection

HF surgical devices, incl. air hose 10 mm, 2.5 m,

ESU cable length 3 m .....................................445.0062.0

Fume evacuation handle of clip-on type, for adap-

tion of mono-polar standard surgical handle, incl.

air hose Ø 10 mm and length 2.5 m .................445.0063.0

9.2 Spare parts

AtmoSafe compl. base package .....................445.0000.0

Air hose, Ø 22 mm (W), 2.10 m, for single-use, of

E.V.A. ............................................................... 005.0200.0

Air hose Ø 22 mm, L = 2.70 m made of

Hytrel, connecting sockets made of silicone

temperature-resistant up to 200 °C .................. 005.0201.0

Air hose Ø 22 mm, L = 2.10 m temperature-resist-

ant up to 200 °C ............................................... 005.0203.0

Air hose, internal Ø = 10 mm, L = 1.8

m, temperature-resistant up to 200 °C, made of

hytrel, connecting sockets made of silicone .....005.0204.0

Connection hose straight,

Ø 22 mm (M) to Ø 22 mm (M) .......................... 000.0683.0

Connection hose straight,

Ø 22 mm (M) to Ø 10 mm (M) .......................... 000.0689.0

Connection hose straight,

Ø 22 mm (F) to Ø 10 mm (M) ..........................000.0688.0

Funnel, at on one side, of PP, with connection in

Ø 22 mm (F) .................................................... 000.0687.0

Suction tube, plastic, with ISO cone 22 mm (M) for

suction hose Ø 22 mm (F) ...............................445.0055.0

Air hose Ø 10 mm, of various lengths .............. On request

Articulated arm with 3 joints for attaching to normal standard rails (25 x 10 mm),

extended length approx. 1.3 m, with 5 hose hold-

ers for hose with Ø 22 mm ............................... 445.0060.0

18

Prelter, in-line, (HEPA), with ISO connections in

Ø 22 mm (M/F) ................................................. 445.0044.0

Main lter unit for AtmoSafe,

multi-stage gas lter + ULPA particle lter,

micro-biocidal-coated compatible with the envi-

ronment ............................................................ 445.0040.0

Page 19

10.0 Technical data

Mains voltage (incl. tolerance) AtmoSafe WORLD: 100...230VAC ± 10% (total range 90...253VAC) can be

arranged by user / installer by inserting the correct fuse drawer

AtmoSafe EUROPE: 230 V ± 10 %

Mains frequencies (incl. tolerance) 50...60 Hz +/-1%

Mains supply Device inlet connector for non-heating apparatus

Auxiliary-mains power socket (IEC 320) 120 V / 9.7 A - 230 V / 6.3 A

Power consumption Max. 400 W

Blower air ow (free-ow) 1600 l/min

Device air ow 650 l/min electronically controlled

Activation Automatic activation, front-panel button, signal at activation input, optionally by

foot switch

Operation mode Suitable for continuous operation

Protective measures (Fuses,...) The power pack is tted with fusible cutouts 5 x 20. The motor of the blower is

thermally protected.

Fuse (Breaking capacity H) 100 V: T4A (125 V) / 120 V: T4A (125 V) / 230V: 3.15A (250 V)

Acclimatisation rules (Prior to start-up): 6 h acclimatisation after transport at low temperature

Maintenance The base device is maintenance-free. Filter change and change of single-use

articles (by user).

Designed freedom from maintenance >10 Years (20,000h) (blower, bearings, rubber parts, etc.)

Corrective maintenance (Acc. to DIN 31051 Measures for restoring the desired condition): Corrective

maintenance by ATMOS or by customer service authorised by ATMOS in

accordance with the country-specic regulations (in Germany DIN VDE 0751).

Period tests Recommended: Testing every 24 months.

Ambient conditions (In operation and in transport / storage):

Ambient temperatures In operation: +10 ... +40°C / in transport and storage: - 40 ... +70°C

Air humidity 5...95 % (without condensation)

Air pressure + 700...1060 hPa

Weight 14 kg

Dimensions (H x W x D) H 210 mm x W 368 mm x D 410 mm

Noise level Max. 52 dB(A)@1 m (as per ISO 7779)

Interfaces (Input and output) suction hose connection 7/8”(22 mm), equipotential bonding,

activation input, mains connection

Protection class I

MPG Class Class I

Applied part

Mains lter ULPA, retention = 99.9999 % @ 0.01μm

CF

debrillator-protected

19

Page 20

11.0 Disposal

Disposal of base device:

• Packaging consisting of cardboard and foamed polystyrene can be fully recycled or returned to your supplier.

• The AtmoSafe does not contain any hazardous materials.

• The housing is recyclable.

• The components of the product can be disposed like

normal electronic scrap Recyclable materials should be,

as far as possible and reasonable, delivered separately

to a recycling organisation.

Disposal of accessories:

• The main lter and other accessories are biologically

contaminated material and have to be disposed of by

specialist rms in compliance with given regulation.

20

Page 21

12.0 Notes on EMC

• Medical electrical equipment is subject to special precautions with regard to EMC and must be installed acc. to following EMC

notes.

• Portable and mobile HF communication facilities can inuence medical electrical equipment.

• The use of other accessories, other converters and cables than stated may lead to an increased emission or a reduced inter-

ference immunity of the equipment or system.

12.1 Guidelines and Manufacturer's Declaration - Emissions

The AtmoSafe is intended for use in the electromagnetic environment specied below. The customer or user of the AtmoSafe

should ensure that it is used in such an environment.

Emissions Test Compliance Electromagnetic Environment - Guidance

RF Emissions acc.to CISPR 11 Group 1 The AtmoSafe uses RF energy only for its internal

function. Therefore, its RF emissions are very

low and are not likely to cause any interference in

nearby electronic equipment.

RF Emissions acc. to CISPR 11 Class B

Harmonic emissions according to IEC

61000-3-2

Voltage uctuations/icker according to

IEC 61000-3-3

Class A

Corresponds

The AtmoSafe is suitable for use in all establishments, including domestic, and those directly

connected to the public low-voltage power supply

network that supplies buildings used for domestic

purposes.

The device may not be used directly next to other devices or piled up with other devices. If operation next to or piled with

other devices is necessary, please watch the device to check its intended operation in this arrangement.

11.2 Guidelines and Manufacturer's Declaration - Immunity

The AtmoSafe is intended for use in the electromagnetic environment specied below. The customer or user of the device

should ensure that it is used in such an environment.

Immunity Test IEC 60601- Test Level

Electrostatic discharge

(ESD) according to IEC

61000-4-2

Fast electrical transient/

burst IEC 61000-4-4

Surges IEC 61000-4-5 1 kV

Magnetic eld at power

frequency 50/60 Hz acc.

to IEC 61000-4-8

± 6 kV Contact

± 8 kV Air

± 2 kV Mains

± 1 kV I/Os

Differential

1 kV

Common

3 A/m 3 A/m Power frequency magnetic elds should

Compliance

Level

± 6 kV Contact

± 8 kV Air

± 2 kV Mains

Inapplicable

2 kV

Differential

1 kV

Common

Electromagnetic Environment - Guidance

Floors should be wood, concrete, or ceramic

tile. If oors are synthetic, the relative

humidity should be at least 30 %.

Mains power quality should be that of a

typical commercial or hospital environment.

Mains power quality should be that of a

typical commercial or hospital environment.

be that of a typical commercial or hospital

environment.

21

Page 22

12.0 Notes on EMC

Immunity Test IEC 60601- Test Level Compliance Level Electromagnetic Environment - Guid-

ance

Voltage Dips / Dropout

IEC 61000-4-11

< 5 % UT

(> 95 % Dip of the U

For 0.5 cycles

40 % U

T

(60% Dip of the UT)

For 5 cycles

< 5 % U

)

T

(> 95 % Dip of the U

For 0.5 cycles

T

Mains power quality should be that of a

typical commercial or hospital environment. If

)

T

the user of the AtmoSafe demands continued

function even in case of interruptions of the

energy supply, it is recommended to supply

40 % U

T

(60% Dip of the UT)

the Atmosafe from an uninterruptible current

supply or a battery.

For 5 cycles

NOTE U

70% U

T

(30 % Dip of the UT)

For 25 cycles

< 5 % U

(>95 % Dip of the U

T

T

For 5 sec

is the mains alternating current prior to application of the test levels.

T

70% U

(30 % Dip of the UT)

For 25 cycles

< 5 % U

)

(>95 % Dip of the U

For 5 sec

T

T

)

T

12.3 Guidelines and Manufacturer's Declaration - Immunity

The AtmoSafe is intended for use in the electromagnetic environment specied below. The customer or user of the device

should ensure that it is used in such an environment.

Immunity Test

Conducted RF IEC

61000-4-6

Radiated

HF disturbances

according to IEC

61000-4-3

IEC 60601- Test

Level

3 V

eff

150 kHz to 80 MHz

3 V/m

80 MHz to 2.5 GHz

Compliance Level Electromagnetic Environment - Guidance

3 V

eff

3 V/m

Portable and mobile communications equipment should

be separated from the AtmoSafe incl. the cables by no

less than the distances calculated/listed below.

Recommended distances:

d = (3.5 / V1) * √(P)

d = (3.5 / E1) * √(P) 80-800 MHz

d = (7 / E1) * √(P) 0.8-2.5 GHz

22

where „P“ is the max. power in watts (W) and d is the

recommended separation distance in meters (m).

Field strengths from xed transmitters, as determined by

an electromagnetic site (a) survey, should be less than

the compliance level (b).

Interference may occur in the vicinity of equipment

containing following symbol:

Page 23

12.0 Notes on EMC

NOTE 1 By 80 MHz and 800 MHz the higher frequency range applies.

NOTE 2 These guidelines might not be applicable in all cases. The emanation of electromagnetic waves is affected by ab-

sorption and reection of buildings, objects and people.

a The eld strength of stationary transmitters, such as base stations of cellular phones and mobile terrain radio

equipment, amateur radio transmitters, cbm broadcast and TV stations cannot be predestined exactly. To determine

the electromagnetic environment in regard to stationary transmitters, a study of the location is to be considered. If the

measured eld strength at the location where the AtmoSafe is used exceeds the above compliance level, the AtmoSafe is

to be observed to verify the intended use. If abnormal performance characteristics are noted, additional measures might

be necessary, e. g. a changed arrangement or another location for the device.

b Over the frequency range of 150 kHz to 80 MHz, eld strengths should be lower than 3 V/m.

12.4 Recommended safety distance between portable and mobile

RF Communications equipment and the AtmoSafe

The AtmoSafe is intended for use in electromagnetic environment in which radiated disturbances are controlled. The customer

or user of the AtmoSafe can help prevent electromagnetic interference by maintaining a minimum distance between portable

and mobile RF Communications equipment and the AtmoSafe as recommended below, according to the maximum output power

of the communications equipment.

Safety distance, depending on transmit-frequency m

Nominal output of the trans-

mitter

W

0.01 0.12 0.12 0.24

0.1 0.37 0.37 0.74

1 1.2 1.2 2.4

10 3.69 3.69 7.38

100 11.66 11.66 23.32

For transmitters for which the maximum nominal output is not indicated in the above table, the recommended safety distance

d in meters (m) can be determined using the equation belonging to the respective column whereas P is the maximum nominal

output of the transmitter in watts (W) acc. to manufacturer´s specication.

NOTE 1 By 80 MHz and 800 MHz the higher frequency range applies.

NOTE 2 These guidelines might not be applicable in all cases. The emanation of electromagnetic waves is affected by ab-

sorption and reection of buildings, objects and people.

150 kHz to 80 MHz

d = [ 3.5 / 3] √P

80 MHz to 800 MHz

d = [ 3.5 / 3] √P

800 MHz to 2.5 GHz

d = [ 7.0 / 3] √P

23

Page 24

ATMOS MedizinTechnik GmbH & Co. KG

Ludwig-Kegel-Straße 16

79853 Lenzkirch / Germany

Phone: +49 7653 689-0

atmos@atmosmed.de

www.atmosmed.com

Loading...

Loading...