Page 1

Gebrauchsanweisung

ATMOS Aqua clean

Water Supply System

530.2120.B

502.1200.B

2014-08 Index: 07

Operating instructions

English

Page 2

2

ATMOS

Phone + 49 7653 689-0

Fax

+ 49 7653 689-392 (Sales Germany)

+ 49 7653 689-391 (Export)

E-Mail: atmos@atmosmed.de

www.atmosmed.de

MedizinTechnik GmbH & Co. KG

Ludwig-Kegel-Str. 16

79853 Lenzkirch

Germany

Further information, accessories, consumables and

spare parts are available from:

Table of Contents

1.0 Introduction ............................................................... 3-6

1.1 Notes on operating instructions ...................................... 3

1.2 Intended use .................................................................. 3

1.3 Function ......................................................................... 4

1.4 Scope of supply .............................................................. 5

1.5 Transport and storage ................................................... 5

1.6 Explanation of pictures and symbols .............................. 6

2.0 For your Safety ............................................................. 7

3.0 Setting up and starting ........................................... 8-11

3.1 Installation in the auxiliary housing ................................ 8

3.2 Hose connections .......................................................... 8

3.2.1 Initial connection of the chemical bottle ........................ 8

3.3 Explanation of the controls ............................................. 9

3.4 Connection conditions for ATMOS S 61 Servant ......... 10

3.5 Connection conditions for irrigation and stimulation

devices ..........................................................................11

4.0 Cleaning and disinfection ......................................... 12

4.1 Disinfectant / Changing the chemical bottle ................. 12

4.1.1 Disinfectant .................................................................. 12

4.2 Care and cleaning ........................................................ 13

5.0 Maintenance .............................................................. 14

5.1 Regular checks ............................................................ 14

6.0 Retrofi tting ............................................................. 15-26

6.1 Retrofi tting at ATMOS S 61 Servant ........................ 15-20

6.1.1 Tubing .......................................................................... 17

6.1.2 Retrofi tting of a delay PCB ........................................... 18

6.1.3 Delayed switching circuit for Aquastop ......................... 19

6.1.4 Water connections ....................................................... 20

6.2 Retrofi tting at ATMOS Servant 5 / 5 C..................... 21-26

6.2.1 Drilling .......................................................................... 21

6.2.2 Tubing .......................................................................... 22

6.2.3 Add-on kit ..................................................................... 22

6.2.4 Delayed switching circuit for Aquastop until 2005 ........ 23

6.2.4.1 Delayed switching circuit for Aquastop from 2006 ....... 24

6.2.5 Water connections until 2005 ....................................... 25

6.2.5.1 Water connections from 2006 ...................................... 26

7.0 Troubleshooting ......................................................... 27

8.0 Accessories and spare parts .................................... 27

9.0 Technical information ........................................... 28-29

9.1 Structure ....................................................................... 28

9.2 Electrical connections, control PCB ............................. 29

9.3 Wiring diagram ............................................................. 29

10.0 Technical specifi cations ............................................ 30

11.0 Disposal ...................................................................... 31

12.0 Notes on EMC ........................................................ 32-34

ATMOS General Terms and Conditions

Page 3

3

1.0 Introduction

1.1 Notes on operating instructions

● The product ATMOS Aqua clean bears CE marking according to the EC Directive of

the council for medical products 93/42/EEC and meets the essential requirements

of Appendix I of the Directive.

● The product ATMOS Aqua clean complies with all applicable requirements of the directive

2011/65/EC restricting the use of certain hazardous substances in electrical and electronic

equipment (“RoHS”).

● The declaration of conformity can be obtained on our website at www.atmosmed.com.

● The quality management system applied at ATMOS has been certified according to

international standards EN ISO 9001 and EN ISO 13485.

● The product ATMOS Aqua clean fulfils the EN 1717 by the integrated free flow outlet.

● Prior to start-up please peruse chapter 2.0 „For your safety“, in order to be prepared for any

possible dangerous situations.

● These operating instructions are based on the version of the ATMOS Aqua clean available at the

print date. The same applies to the applied safety-related standards.

●

Subject to alterations, errors excepted.

1.2 Intended use

These operating instructions contain important notes on how to operate the ATMOS Aqua clean safely, correctly and effectively. Their reading helps to avoid risks, and also to reduce repair costs and

down-time. That increases, amongst other things, the reliability and service-life of the device.

These operating instructions serve not only for new operating personnel to be instructed in its use,

but also for use as a reference manual. Reproduction of these instructions – even in part – only with

the written permission of ATMOS.

These operating instructions must always be kept available near the device.

Care and safety inspections in conjunction with professional execution provide for operational safety

and readiness for use of your ATMOS Aqua clean and are therefore a must besides regular

cleaning.

Repair work and safety inspections may be carried out only by expert personnel authorised by

ATMOS. By applying only original spare parts you will have the guarantee that operational safety,

readiness for work and the value of your ATMOS Aqua clean will be preserved.

Name: ATMOS® Aqua Clean

Main functions:

Device for water separation and decontamination system for

hoses used in ENT treatment units and diagnostic devices.

Med. indications/ application:

Ear irrigation, thermal nystagmus stimulation

Specifi cation of the main function:

• The ATMOS Aqua Clean separates decontaminated water

from the fresh water by the integrated free fl ow outlet.

• The decontamination of water and hoses is enabled by the

use of a special disinfectant (ATMOS Green & Clean WK).

Application organ:

Mouth to pharynx, auditory canal to the ear drum and the

nasal cavities

Application time:

Temporary application (less than 60 minutes)

Application site:

Application sites are clinics and practices for ENT doctors

and phoniatrists. The examination with the water separation

and decontamination system may only be executed by medically trained persons.

Contraindications: No

The product is: X active □ not active

Sterility:

The water separation and decontamination system is not a

sterile product.

Single use product / reprocessing:

The device and part of the accessories are reusable. For

information on reprocessing and disinfection please see the

operating instructions.

Page 4

4

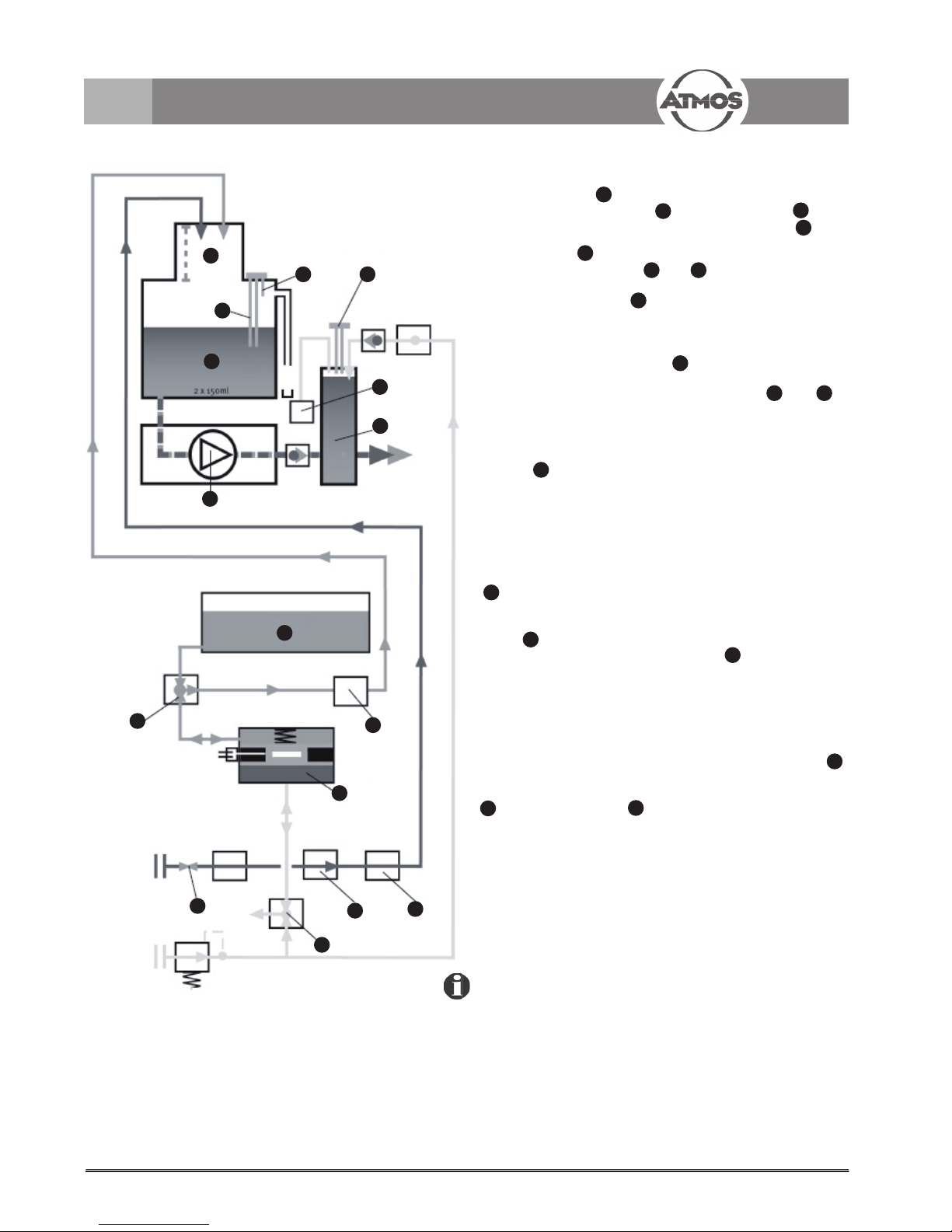

1.3 Function

When the water tap is opened and the system is

switched on, the dosing valve and the safety valve open

and 150 ml water are supplied to the mixing container .

The water level in the mixing container is monitored by an

electronic probe . Once the contact on the probe is

set off, the magnetic valves and (compressed

air/chemical) open. This activates the compressed air driven

double-membrane pump , causing 1.75 ml hydrogen

peroxide to be withdrawn from the chemical bottle and

added to the mixing container.

If the water level drops below probe A, the dosing valve

opens again until overfl ow probe is reached. By the

time the water reaches this probe, the mixing container has

been fi lled with 300 ml of water. Magnetic valves and

open again, and add another 1.75 ml of chemical to the mixing

container. This ensures that the required concentration of

disinfectant in the solution is continuously maintained.

In the mixing container, the water inlet is in the form of a

cascade , ensuring that the ATMOS Aqua clean is

separated from the water supply, as required by the DVGW

(The German Gas and Water Association) (DIN 1988, Part 4).

This ensures that water contaminated with micro-organisms

or mixed with chemicals cannot fl ow back into the water

supply system.

If a water-fed unit is activated, the decontaminated water

fl ows from the mixing container, via the pressure container

and to the appropriate instrument.

Naturally, this causes the water level in the pressure container

to fall, together with the water pressure. A pressure-sensitive

switch , fi tted to the pressure container and adjusted

to 3.5 bar, activates the membrane pump , which is

responsible for emptying the mixing container, fi lling the

pressure container and maintaining the required water fl ow

pressure.

An air cushion in the pressure container compensates the

water level. If necessary, the air cushion is topped up with

compressed air (magnetic valve 4) - all this is done to ensure

a stable water jet for the instrument. The air cushion probe

ensures that the air pressure is kept constant.

The disinfectant is withdrawn from the chemical bottle

. A disinfectant sensor controls the chemical

existence. If no more chemical can be withdrawn (e.g. the

chemical bottle is empty), an error message occurs.

Please note that only ATMOS Green&Clean WK

may be used, as the electrical sensors are adjusted

to this product!

1.0 Introduction

10

5

9

14

12

11

13

4

6

15

16

1

2

3

7

8

1

2

3

4

6

7

8

9

10

11

12

13

14

15

16

Fig. 1

5

6

7

Page 5

5

1.0 Introduction

1.4 Scope of supply

Prior to dispatch, this ATMOS Aqua clean was subjected to

an extensive functional test and has been carefully

packed.

Nevertheless, please compare the contents of the shipment

on completeness immediately upon receipt (see delivery

note).

● ATMOS Aqua clean

● bottle support

● 1 l ATMOS Green & Clean WK

● connecting kit

1.5 Transport and storage

● The transport of the device may be effected only in a

dispatch carton upholstered and offering suffi cient pro-

tection.

● Please document and report damages in transit

immediately. For complaints or return deliveries, please

use the enclosed form QD 434 Delivery complaint/

Return shipment. The form QD 434 can also be

downloaded from the internet www.atmosmed.de

(see Fig. 2).

● Ambient conditions:

Transport/Storage: +5...+40 °C;

05...95 % air humidity

non-condensing at air

pressure 700...1060 hPa

Operation: +15...+40 °C;

05...95 % air humidity

non-condensing at air

pressure 700...1060 hPa

Fig. 2

Page 6

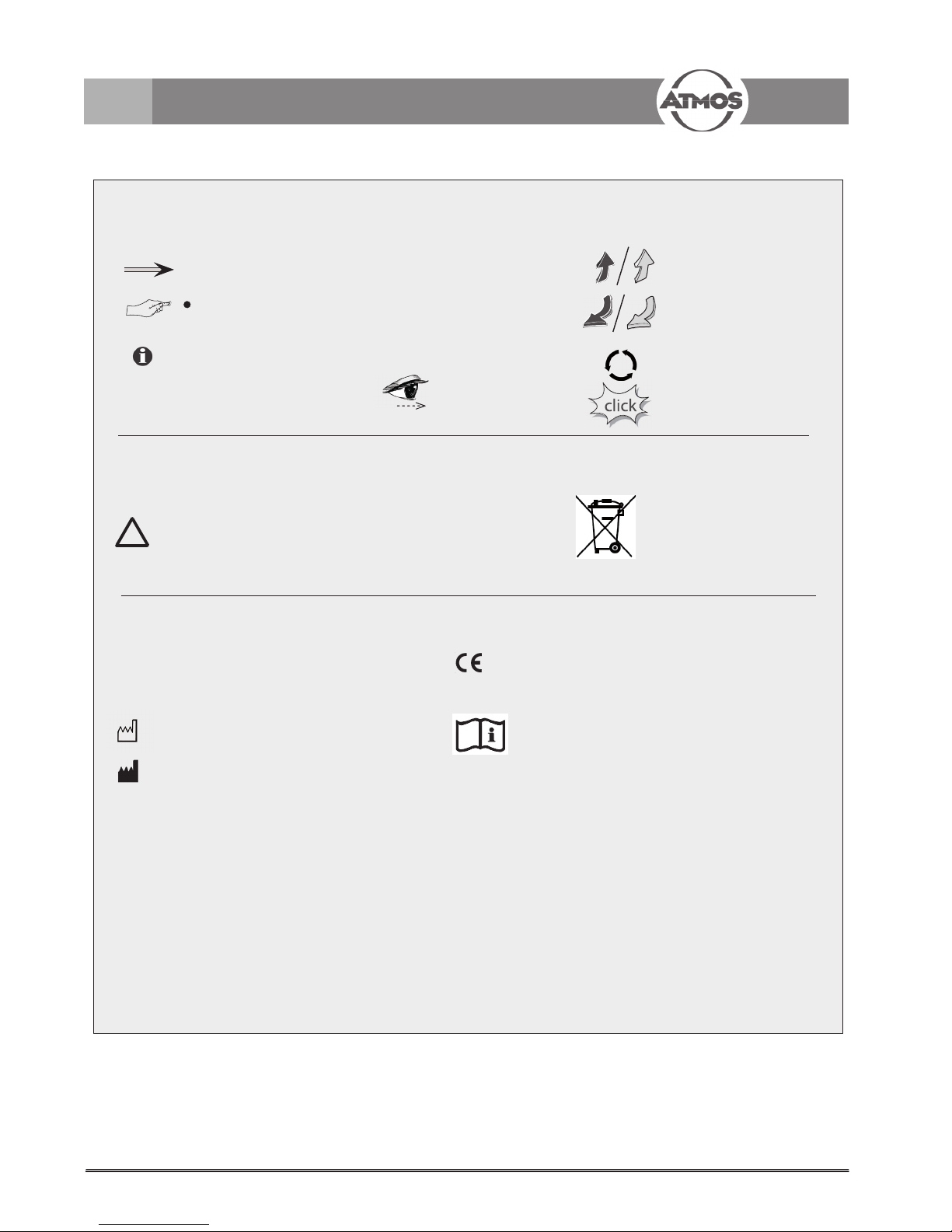

6

!

■

●

→

click

click

Pictures contained in this manual

Warning,

especial diligent notice!

Important notes

Symbols of the ATMOS Aqua clean

Serial number

Order number

Creation date

The CE sign shows that this

product meets the appropriate

requirements of the EC Directive

93/42 EEC.

REF

SN

Please observe operating instructions!

Proper disposal

Manufacturer

1.6 Explanation of pictures and symbols

1.0 Introduction

Short cuts / symbols contained in this manual

Please press where

the dot indicates

Subnumeration

Numeration

General information

Follow the arrows

whilst proceeding,

sequence

Replace

Check

Please read,

important information

Move, plug ... in this

direction

Engage, check correct

fi t

Turn, shift ... in this

direction

Page 7

7

2.0 For your Safety

Danger to the

device

● Do not allow any liquid to get into the unit. If

liquid has penetrated the unit, it may not be

operated again until it has been checked by

the customer service centre.

● The unit must be set up on a fi rm, level

surface.

● The main voltage specifi ed on the type plate must

match the power supply system.

● The unit may not be started:

• if cables or plugs are defective,

• if obvious defects might restrict safe

operation.

Prior to returning the device for repair to the

dealer you bought it, please clean it.

● Pay attention to the ambient conditions

described in chapter 1.5 Transport and

storage.

● Never plunge the unit into water, not even

when it is switched off.

● The device must be checked at regular inter-

vals regarding function and safety-relevant

damages, for example, wrap connection,

housing, etc.

● Never connect the unit to defective power

sockets or extension cables.

Avoid moisture on plug and switches.

● Prior to operation, please inspect the mains plug.

Only operate the device when the mains plug is

not damaged!

●

The unit, mains cable, accessories, connection

cables and hoses must be checked for damage

prior to starting up. Damaged cables and hoses

must be replaced immediately. Prior to use, check

the unit functions.

Danger of injury!

● Only persons instructed in medical use may

apply the ATMOS Aqua clean.

● The ATMOS Aqua clean may not be opera-

ted in splash water range and in explosion

hazardous areas.

General safety

information

• ATMOS cannot guarantee perfect functioning

neither will it be liable for damage to people or

property if:

• Any non-original ATMOS parts are used,

• the user instructions given in this manual are

not followed exactly or are disregarded,

• Assembly, resetting, alterations,extensions

and repairs are not carried out by people

authorised by ATMOS.

• there is any damage in transport due to

insuffi cient packing or due to residual water

in the device.

• Prior to starting up the ATMOS Aqua clean,

read these operating instructions carefully.

• The safety standard of the ATMOS Aqua clean

corresponds with recognized medical technical

regulations and the directives of the Medical

Devices Act.

• No warranty claims can be lodged for any da-

mage or malfunction which developed from the

use of third-party accessories or consumables.

• Only suitable for devices with a water

consumption of max. 550 ml/min and 2.2 bar

water pressure.

• The ATMOS Aqua clean may be operated only

in rooms used for medical purposes, but not

in areas subject to explosion hazards and in

oxygen rich environments.

● Always remove the plug from the wall socket

fi rst in order to disconnect the unit from the

mains. Only then may the connecting cable be

disconnected from the unit:

• before cleaning the unit,

• before leaving the room.

Never pull at the cable.

Never touch the plug or cable

with wet hands.

● Prior to any transport the water separation unit

must be fully emptied in order to prevent the

device from any damage.

● The device may not be exposed to frost neither

during transport, nor during storage.

● Close the main water tap at longer absence

(e.g. vacation) or unuse and switch off the

device.

!

● The device may not be operated without fi lter in

front of the water inlet.

● Do not lift the device at the cover.

Page 8

8

1

2

3

1

2

3

Fig. 4

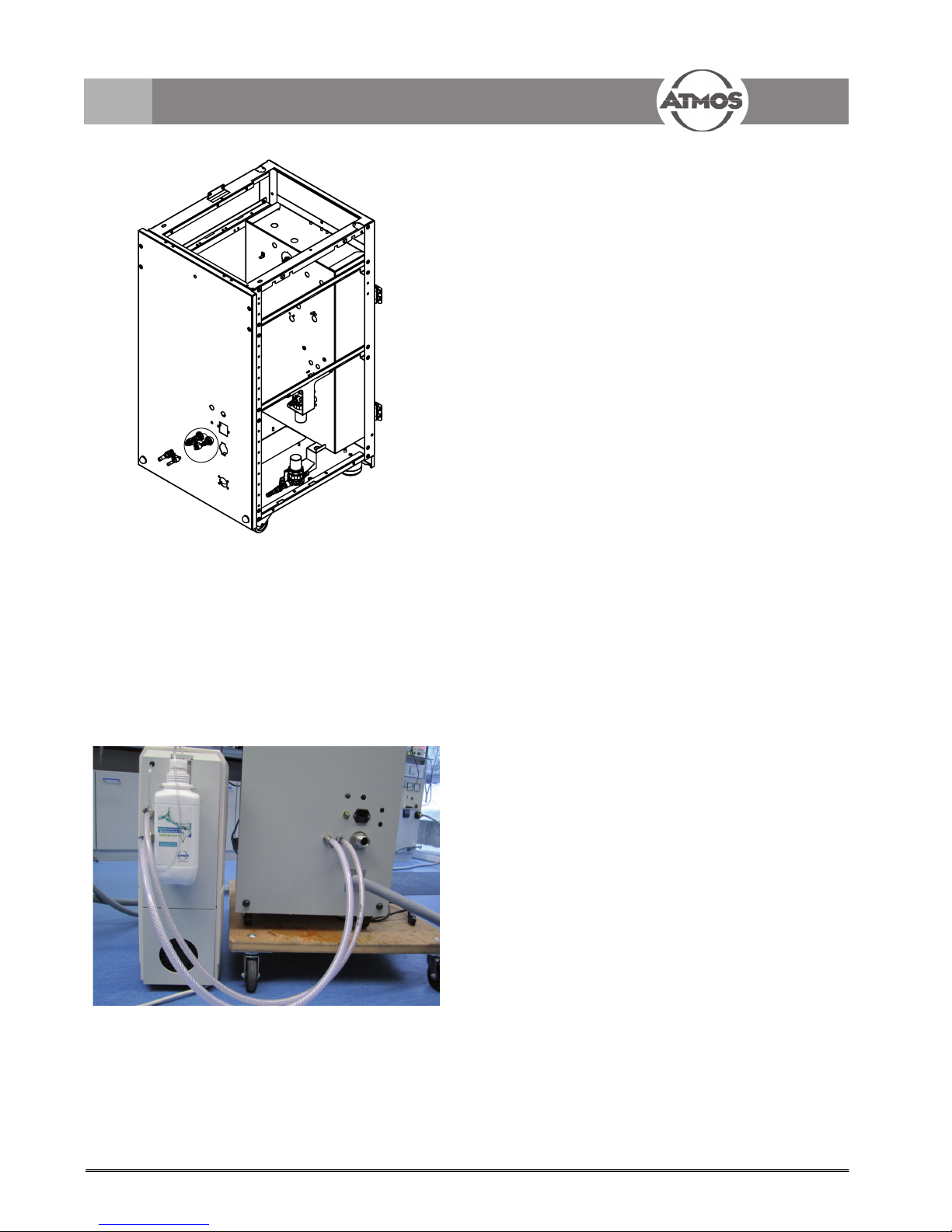

3.0 Setting up and starting

3.1 Installation in the auxiliary

housing

The device is mounted in a shapely housing next to the

treatment unit on a level and suffi ciently sustainable

surface.

Main switch:

It must be ensured that the power supply is

connected downstream of the main instrument /

practice switch.

Connect the device to a properly installed earthed contact

socket. Adhere to the connected load stated on the type

plate.

In case of unfi rm assembly, there is a danger of liquid

from the mixing container’s overfl ow spilling out and

activating the overfl ow sensor (see chapter 4.2).

Starting Sequence:

1. Open main water tap

2. Switch on ATMOS S 61 Servant

3. Switch on ATMOS Aqua clean

If error “F1” appears, switch the ATMOS S 61 Servant

off and on, until the error disappears.

3.2 Hose connections

Chemical bottle connection

PVC tubing

Ø internal = 2 mm

Ø outer = 4 mm

Connection to the water outlet

(supplying the instruments)

PVC tubing

Ø internal = 4 mm

Ø outer = 6 mm

Water connection (fresh water in drinking water

quality)

Permitted pressure at entry: 2-6 bar

PVC tubing (with KTW authorisation)

Ø internal = 6 mm

Ø outer = 8 mm

3.2.1 Initial connection of the

chemical bottle

Open the housing of the ATMOS Aqua clean and feed the

hose (Fig. 4) through the housing to the outside. Plug

the provided seal onto the bottle and insert the hose. Fix

the bottle in the provided support.

Fig. 3

1

Page 9

9

3.0 Setting up and starting

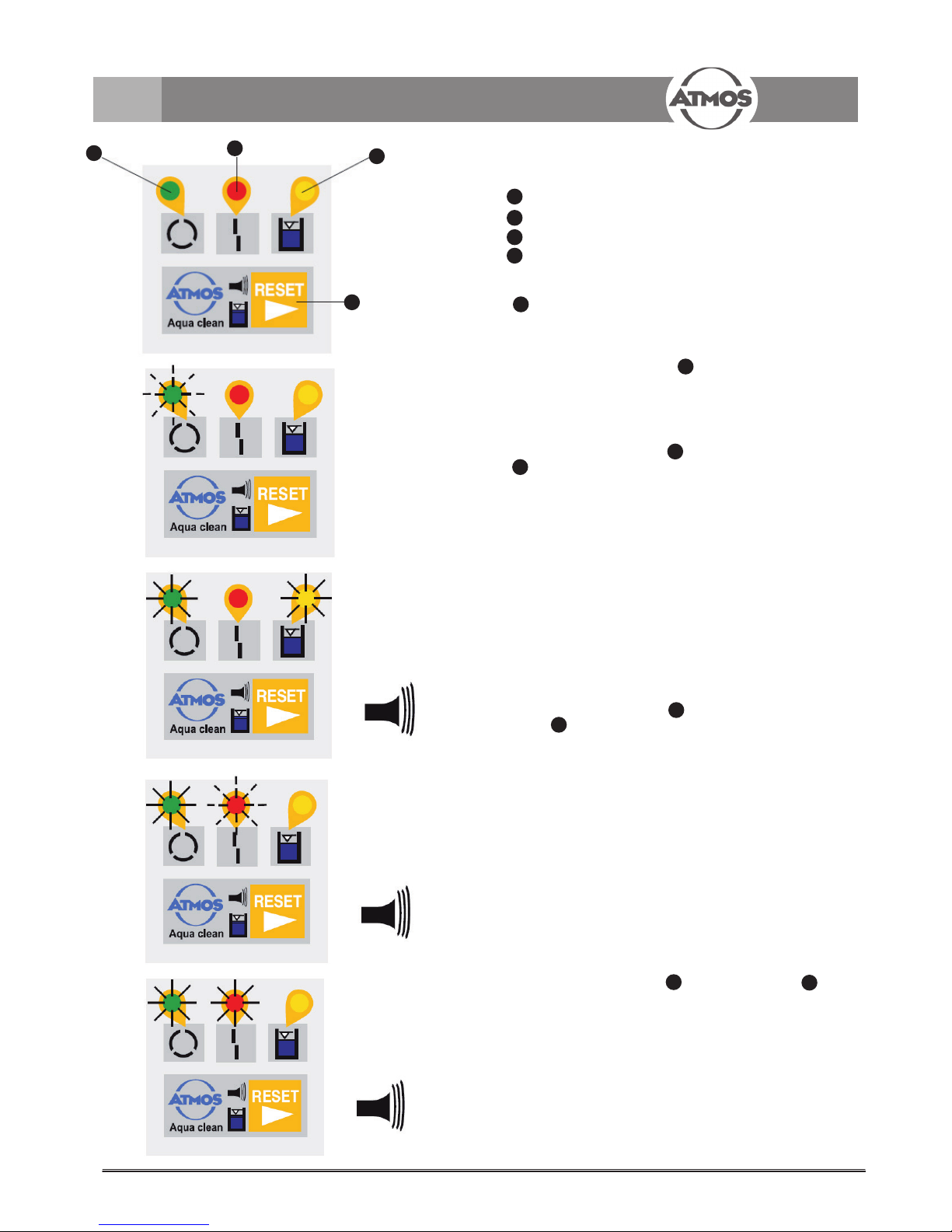

3.3 Explanation of the controls

Control light 1: Ready for use (green)

Control light 2: Fault (red)

Control light 3: Disinfectant sensor (yellow)

Alarm RESET button

Switch On/Checking routine: The green control signal

(Fig. 6) jitters:

During the system is switched on the ATMOS Aqua clean

automatically performs a checking routine. While this

procedure the control signal (Fig. 6) is blinking fast.

If an error occurs the unit is not activated and the error is

shown at the controls (see below). After successful checking routine, control signal 1 illuminates constant and the

unit is ready for operation.

The green control signal and the yellow signal

(Fig. 7) are illuminated and an alarm tone

sounds.

Cause: Disinfectant sensor indicates, that the processing

water is not being sterilised!

Action: Change the chemical bottle (see chapter 4.2.1)!

If the chemical bottle cannot be changed immediately,

the RESET button must be pressed to deactivate the

continuous alarm tone. The unit remains functional, and

does not interrupt the work. However, a short signal tone

still sounds periodically. If this error was only produced

by an air bubble, it will expire within the next trial by itself.

However, no decontamination takes place until the empty

chemical bottle is replaced with a full one (see chapter

4.2.1).

The green control signal is illuminated and the red

signal jitters and an alarm tone sounds (Fig. 8).

Cause: Level monitor in the mixing container is soiled

or there is no water supply!

Action: First of all, check if the main water tap resp. water

feed line is opened! Clean or replace the mixing container

probe (see chapter 4.2).

Consequence: All valves and the pump are switched off.

The alarm tone can be switched off by the RESET button.

After solving the problem the ATMOS Aqua clean can only

be activated again by switching the unit off and on.

The green control signal and the red signal

are illuminated and an alarm tone sounds (Fig. 9).

Cause: Defective double membrane pump or overfl ow!

Action: Clean the overfl ow sensor. Check the double

membrane pump and the electronic control system (see

chapter 4.2).

Consequence: All valves and the pump are switched off.

The alarm tone can be switched off by the RESET button.

After solving the problem the ATMOS Aqua clean can only

be activated again by switching the unit off and on.

1

2

3

4

4

1

1

3

1

2

1

2

1

2

3

4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Page 10

10

3.4 Connection conditions for

ATMOS S 61 Servant

3.0 Setting up and starting

Scope of supply for option REF 530.2120.0

Article description REF Quantity

ATMOS Aqua clean 530.21210 1

Hose clamp 061.0060.0 2

Hose clamp 061.0061.0 2

Hose barb 8/8 Legris 000.0974.0 3

Hose barb 6/5 Legris 000.0988.0 2

Fabric tube 6x3; 1 m 005.0091.0 1

Fabric tube 8x3; 1 m 005.0020.0 1

Bottle support 1

Seal 1

ATMOS Green & Clean WK 534.3110.0 1

Starting Sequence:

1. Open main water tap

2. Switch on ATMOS S 61 Servant

3. Switch on ATMOS Aqua clean

If error “F1” appears, switch the ATMOS S 61 Servant

off and on, until the error disappears.

Fig. 10

Fig. 11

Page 11

11

3.5 Connection conditions

for irrigation and stimulation

devices

(Variotherm / Hygrotherm)

For operating an irrigation and stimulation device

the product, REF 502.1200.0, is required

Scope of supply:

Article description REF QTY

ATMOS Aqua clean 530.2121.0 1

Hose connection Vario-Aqua 502.1201.0 1

Hose connection HWA-Aqua 502.1202.0 1

Bottle support 1

Seal 1

ATMOS Green & Clean WK 534.3110.0 1

Starting Sequence:

1. Open main water tap

2. Switch on irrigation and stimulation device

3. Switch on ATMOS Aqua clean

If error “F1” appears, switch the irrigation and stimulation device off and on, until the error disappears.

3.0 Setting up and starting

Chemical bottle connection

PVC tubing

Ø internal = 2 mm

Ø outer = 4 mm

Connection to the water outlet

(supplying the instruments)

PVC tubing

Ø internal = 4 mm

Ø outer = 6 mm

Water connection (fresh water in drinking water

quality)

Permitted pressure at entry: 2-6 bar

PVC tubing (with KTW authorisation)

Ø internal = 6 mm

Ø outer = 8 mm

1

2

3

1

2

3

Fig. 12

Fig. 13. Connection to diagnostic device

Fig. 14. Water connection

Page 12

12

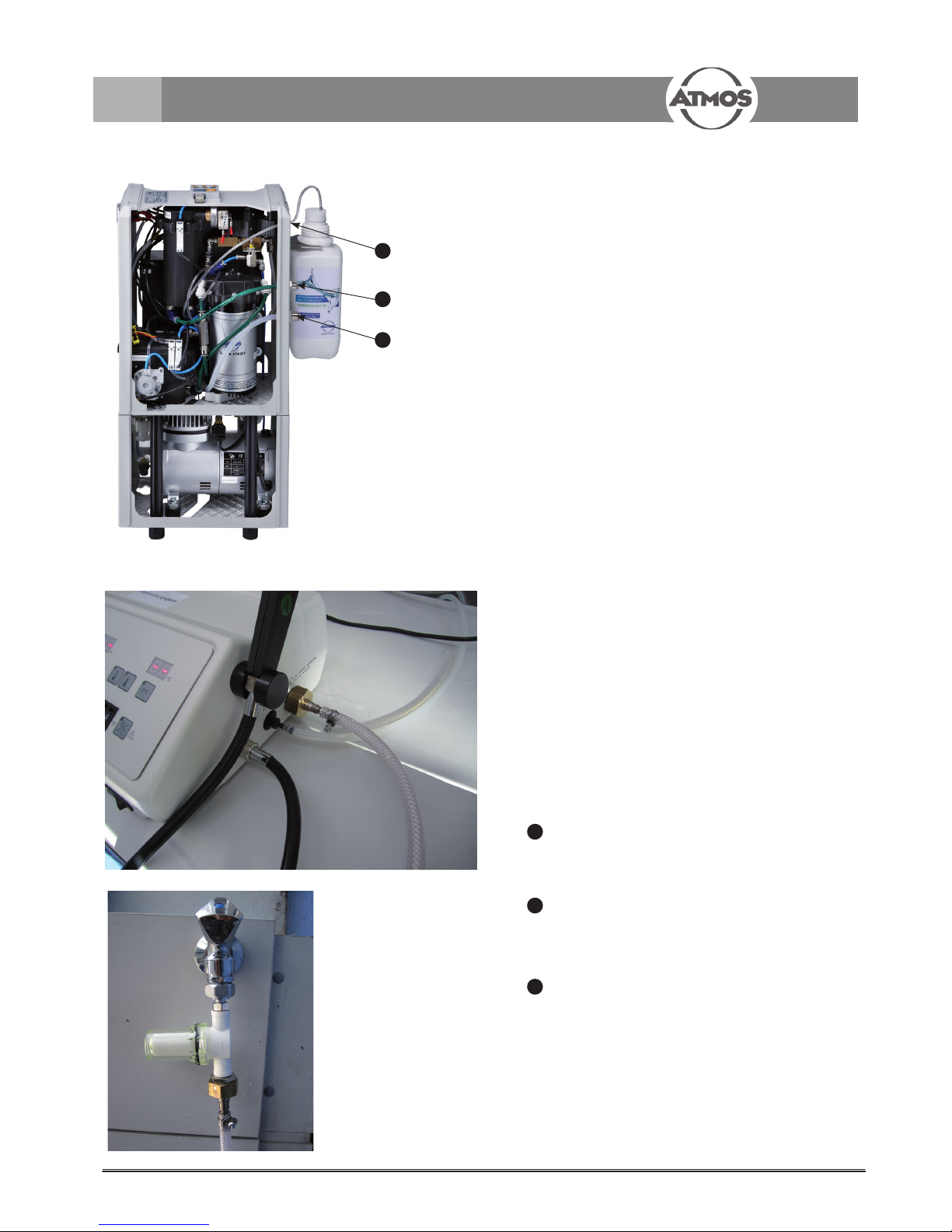

4.0 Cleaning and disinfection

4.1 Disinfectant /

Changing the chemical bottle

4.1.1 Disinfectant

(REF 534.3110.0)

For disinfection a 2% hydrogen peroxide solution with

added silver, ATMOS Green & Clean WK, is used. Hydrogen peroxide-based concentrates are particularly suitable

for reducing micro-organism levels in the water supply

because of their potent bactericidal and fungicidal action.

Hydrogen peroxide also show an outstanding ratio of

potential risk to disinfectant effi cacy, and present no risk

for the patient.

During each disinfecting operation in the ATMOS Aqua

clean system, a specifi ed amount of disinfected solution is

added to the 150 ml of water in the mixing container. This

provides the concentration of 0.0235% required for broadspectrum disinfection.

If the ATMOS Green & Clean WK bottle is completely

empty, an error message appears on the external indicator, stating that no more disinfectant solution can be

withdrawn. The empty bottle should be detached from the

fi tting tube on the ATMOS Aqua clean and replaced with a

new one.

Please note that only ATMOS Green & Clean WK

provides the concentration required for broadspectrum

disinfection.

The use of chemicals other than from ATMOS may damage

the ATMOS Aqua clean as well as other devices which are

connected.

Safety precautions: Keep out of the reach of children. In

case of contact with the eyes, rinse thoroughly with water.

In case of skin contact, wash with water. Store ATMOS

Green & Clean WK at room temperature (or +5°C to

max. +30°C) and preferably protected from light!

Composition: hydrogen peroxide, silver and less than 0.1%

stabilisers, water.

For any further information, please see the safety

data sheet!

4.1.2 Changing the chemical bottle

Remove the chemical bottle from the unit (Fig. 16) . Pull gently

to remove the screw top and the attached tube which

extends into the bottle (Fig. 17) .

Remove the screw top from the new bottle of chemical, insert

the tube into it and screw back onto the bottle (Fig. 18).

Replace the bottle into the holder.

Fig. 15

Fig. 16

Fig. 17 Fig. 18

Page 13

13

4.0 Cleaning and disinfection

4.2 Care and cleaning

Additional programs:

Automatic emptying: For emptying the unit during operation the RESET button has to be held down for

approx. 8 sec. (control signal jitters) until a second

acoustic signal is activated. Then the green control

signal 1 jitters slowly. Supply container and pressure

container are empty if no more water comes out of the

unit. Now, the ATMOS Aqua clean can either be switched

off or the normal operation can be activated by holding

down the RESET button for another 8 sec.

Intensive decontamination: To increase the concentration of the chemicals as required, the intensive decontamination can be activated by holding down the RESET

button (control signal jitters) for approx.

4 sec. until the fi rst acoustic signal is activated. While

this procedure is taking place control signal jitters

and signal is illuminated. Afterwards the handle must

be oprated. With the next chemical dosing operation will

be delivered 3 doses of chemical, followed by 2 doses

each in the next 4 dosing operations. No chemical will be

added to the completing dosing in order that the normal

concentration is ensured with fi nalisation of the intensive

decontamination. Control signal 3 expires after the intensive decontamination and a short acoustic signal is activated. The ATMOS Aqua clean returns into normal operation.

Intensive decontamination is always recommended prior

to longer idle times like weekend or holiday and after treatment of patients with suspicion of HIV, HBV or HCV.

Remove water level probe from the mixing container

and clean or replace.

● Switch off main switch.

● Carefully pull probe up and out.

● Clean or replace probe. Check the electronic control

system.

● Replace the probe in the mixing container.

● Switch on main switch.

Check overfl ow sensor at the mixing container.

● Switch off main switch.

● Clean/dry overfl ow sensor . Check electrical

connections of the electronic control system

(see page 22).

● Check double membrane pump and the electronic

control system.

● Switch on main switch.

If this error exists further on, the double membrane is

probably broken, whereby the double membrane pump

(module 5) has to be replaced!

Surface disinfection

Please use ATMOS Green & Clean SK for the daily

surface disinfection .

1

2

3

4

4

1

1

1

1

2

3

4

1

2

Fig. 19

Fig. 20

Page 14

14

5.0 Maintenance

• Annual service inspection for the ATMOS Aqua clean with

service kit (service interval is also dependent on water

hardness!) This service contains a complete function

control of the device, exchange of the input fi lter (Fig.

21), test (if required exchange) of the water dosing valves

(Fig. 22) and magnetic valves , the water non-return

valve (Fig 22) as well as the tubes (Fig 22). Additionally, also an inspection (and if required cleaning) of the

mixing container (Fig. 22) and its probes needs to be

carried out.

• The safety-related checks acc. to IEC 62353 must be

performed at least every 12 months.

• ATMOS cannot guarantee perfect functioning neither will

it be liable for damage to people or property if:

• any non-original ATMOS parts are used,

• the user instructions given in this manual are not

followed exactly or are disregarded,

• assembly, resetting, alterations, extensions and

repairs are not carried out by people authorised by

ATMOS.

• No warranty rights shall exist in the event of damage or

failure caused by the use of non-ATMOS accessories or

non-ATMOS consumables.

• Check hoses and connections on any leakages at regular

intervals.

• Prior to sending in the device for repair it must be fully

emptied.

• For an extensive fi nal inspection of the device during

repair, please include all accessories into the delivery.

5.1 Regular inspections

• Functional and tidiness inspections are required after any

work at the ATMOS Aqua clean. Safety-related inspections are to be performed along with the inspection of the

connected treatment unit or at least once a year (acc. to

BGVA3). Furthermore the control and safety functions

must be checked.

1

1

2

3

4

5

Fig. 21

Fig. 22

1

1

2

3

4

5

Page 15

15

6.1 Retrofi tting at ATMOS S 61 Servant

For retrofi tting at the ATMOS S 61 Servant the product,

REF 530.2120.N is required.

Scope of supply:

Article description REF QTY

ATMOS Aqua clean 530.2121.0 1 piece

Hose clip 061.0060.0 2 pieces

Hose clip 061.0061.0 2 pieces

Pressure reducer, mini 502.0955.0 1 piece

Lock nut M4 052.0024.0 2 pieces

Hexagon head screw

DIN 933 - M4 x 12 051.0297.0 2 piece

Disk DIN 125 - A 4,3 053.0001.0 4 pieces

Bulkhead connector

straight Rd8 Legris 000.0978.0 1 piece

Bulkhead connector

straight Rd6 Legris 000.0980.0 1 piece

Screw in union

straight Rd4/1/8“ Legris 000.0977.0 2 pieces

Screw in union

straight Rd8/1/8“ Legris 000.0976.0 1 piece

Hose barb 8/8 Legris 000.0974.0 3 pieces

Screw in union

straight Rd6/1/8“ Legris 000.0975.0 1 piece

Hose barb 6/5 Legris 000.0988.0 2 pieces

Screw in union

L Rd8/1/8“ Legris 000.0981.0 1 piece

Mounting plate 530.2122.0 1 piece

Valve mounting angle 530.2123.0 1 piece

Disk 22 x 16 x 1 053.0113.0 2 pieces

Disk 22 x 18 x 1 053.0114.0 2 pieces

Hose quick connector

T 4-4-4 000.0513.0 1 piece

Bottle support 1 piece

Seal 1 piece

ATMOS Green & Clean WK 534.3110.0 1 bottle

Hose RD.I. 6,0 x 3,0 000.0091.0 1000 mm

Hose RD.I. 8,0 x 3,0 005.0020.0 1000 mm

Hose, Rilsan RD.A. 8,0 005.0025.0 240 mm

Hose, Rilsan RD.A. 6,0 005.0173.0 200 mm

Hose, Rilsan RD.A.4,0 005.0026.0 450 mm

Hose, Rilsan RD.A.4,0 005.0026.0 250 mm

Hose, Rilsan RD.A.4,0 005.0026.0 680 mm

6.0 Retrofi tting

1

2

3

4

5

6

7

8

9

10

17

16

15

14

13

12

11

18

19

Page 16

16

6.0 Retrofi tting

180

30

591

X

18 mit Schälbohrer bohren

16 mit Schälbohrer bohren

X

1 : 1

18

7

8

17

9

9

12

3

1

11

16

15

19

2

13

10

11

14

Fig. 23

A

B

A Assemble the mounting plate and build it in.

B Exchange existing plate against mounting plate .

15

16

Please drill the required holes into ther rear part of the housing as per the drawing.

Starting Sequence:

1. Open main water tap

2. Switch on ATMOS S 61 Servant

3. Switch on ATMOS Aqua clean

If error “F1” appears, switch the ATMOS S 61 Servant

off and on, until the error disappears.

diam. 18 mm, drill with hole cutter

diam. 16 mm, drill with hole cutter

4

5

6

Page 17

17

6.0 Retrofi tting

6.1.1 Tubing

Article description REF Length

Hose RD.I. 6,0 x 3,0 000.0091.0 1000 mm

Hose RD.I. 8,0 x 3,0 005.0020.0 1000 mm

Hose, Rilsan RD.A. 8,0 005.0025.0 240 mm

Hose, Rilsan RD.A. 6,0 005.0173.0 200 mm

Hose, Rilsan RD.A.4,0 005.0026.0 450 mm

Hose, Rilsan RD.A.4,0 005.0026.0 250 mm

Hose, Rilsan RD.A.4,0 005.0026.0 680 mm

Hose, Rilsan RD.A.8,0 005.0025.0 130 mm

1

2

3

4

5

6

7

1

2

3

4

5

6

7

Fig 24

8

8

water connection

non-return valve

Page 18

18

6.1.2 Retrofi tting of a delay PCB

● Drilling of the holes for the fi xing bolts. Place the PCB on the carrier

plate and mark the drillings. Afterwards drill the holes with a 3.5 mm

drill.

● Screw the 4 bolts M3x10 including washer and locknut.

● Tighten the PCB with 4 lens head screws 3x5.

● Fix the connecting cable (REF 530.2124.0) as per the drawing.

● Connect the existing Aquastop to the PCB, REF 011.1314.0.

6.0 Retrofi tting

Fig. 25

Fig 26

Page 19

19

6.0 Retrofi tting

6.1.3 Delayed switching circuit for Aquastop

011.1314.0

GND

V+

230V

12V =

12V

PCB for 230V switching

230V

Control PCB

ST1

011.1307.0

Aquastop Verzögerung

Delay for Aquastop switching

spülbeh

sekretbeh

reserve

Steuerplatine

Control PCB

530.1149.0

S5c

S5

530.2124.0

+12V

GND

Page 20

20

6.0 Retrofi tting

6.1.4 Water connections

Aquastop

Wasserzulauf

Water Inlet

Aquaclean

530.2121.0

Eingang

Inlet

Ausgang

Outlet

Schlauchschelle

Hose Clamp

061.0060.0

Gewebeschlauch 8 mm

Fabric-Reinforced Hose 8mm

005.0091.0

Gewebeschlauch 6 mm

Fabric-Reinforced Hose 6mm

005.0020.0

Schlauchtülle 8mm

Spout 8mm

000.0974.0

Schlauchtülle 6mm

Spout 6 mm

000.0988.0

Schottverschraubung 6/6

Bulkhead connector 6/6

000.0980.0

Schottverschraubung 8/8

Bulkhead connector 8/8

000.0978.0

Ursprünglich am T-Stück

Originally on T-Connector

Druckerhöhung auf 3,5 bar

Pressure elevation to 3.5 bar

Schlauch RILSAN 8mm

Hose RILSAN 8mm

005.0025.0

Schlauch RILSAN 8mm

Hose RILSAN 8mm

005.0025.0

Schlauchverbinder L 8-8

Hose Connector L 8-8

000.0252.0

Ohrspülmodul

Ear Irrigation Module

Manometer

Schlauch RILSAN 6mm

Hose RISAN 6mm

005.0173.0

Schlauchverbinder 1/8”/6

Hose Connector 1/8”/6

000.0975.0

Schlauchverbinder 1/8”/4

Hose Connector 1/8”/4

Schlauch RILSAN 4mm

Hose RILSAN 4mm

005.0026.0

Druckminderer

Pressure Reducer

502.0955.0

2 bar2 bar

Bereits vorhanden

Already existing

Neue zu installierende Teile

New parts to be assembled

Befüllung Schlauchspülbehälter

Refilling of hose rinsing container

Page 21

21

6.2 Retrofi tting at

ATMOS Servant 5 / 5 C

For retrofi tting at the ATMOS Servant 5 / 5 C

the article, REF 510.2150.0, is required.

Scope of supply:

Article description REF Qty.

ATMOS Aqua clean 530.2121.0 1 piece

Hose clip 061.0060.0 4 pieces

Pressure reducer, mini 502.0955.0 1 piece

Bulk head connector

straight Rd8 000.0978.0 1 piece

Bulk head connector

straight Rd6 000.0980.0 1 piece

Screw in union

straight Rd4/1/8“ 000.0977.0 1 piece

Screw in union

straight Rd 6/1/8“ 000.0975.0 1 piece

Hose barb 8/8 000.0974.0 2 pieces

Hose barb 6/5 000.0988.0 2 pieces

Disk 22 x 16 x 1 053.0113.0 2 pieces

Disk 22 x 18 x 1 053.0114.0 2 pieces

Hose quick connector

T RD8-8-8 000.0253.0 1 piece

Hose quick connector

L RD8-8 000.0252.0 1 piece

Hose Rd.I. 6,0 x 3,0 005.0091.0 1000 mm

Hose Rd.I. 8,0 x 3,0 005.0020.0 1000 mm

Hose, Rilsan Rd.A.4,0 005.0026.0 1000 mm

Hose, Rilsan Rd.A.6,0 005.0173.0 200 mm

Hose, Rilsan Rd.A.8,0 005.0025.0 1000 mm

Bottle support 1 piece

Seal 1 piece

ATMOS Green & Clean WK 534.3110.0 1 bottle

6.2.1 Drilling

Note:

When drilling the holes for the screwed connection (water

in- / outlet into and out of the ATMOS Servant 5 housing)

it is important to consider the equipment of the ATMOS

Servant 5 which needs to be retrofi tted.

Here we can only provide some general information and

recommendations because of the many different version

currently in use.

6.0 Retrofi tting

3

4

1

2

3

4

5

6

7

8

9

10

17

16

15

14

13

12

11

Fig. 28

Starting Sequence:

1. Open main water tap

2. Switch on ATMOS Servant 5 / 5 C

3. Switch on ATMOS Aqua clean

If error “F1” appears, switch the ATMOS Servant 5/5 C

off and on, until the error disappears.

Fig. 27

Page 22

22

6.0 Retrofi tting

11

10

3

1

7

12

5

2

6

9

4

8

1

Fig. 29

Fig. 30

6.2.2 Tubing

6.2.3 Add-on kit

heating module

existing new

Page 23

23

6.0 Retrofi tting

6.2.4 Delayed switching circuit for Aquastop until 2005

011.1314.0

GND

V+

230V

12V =

Inline Cable Fuse

T 1A slow

Schwammschalter

Sponge Switch

bl

br

bl

br

bl

br

12V

PCB for 230V switching

230V

Control PCB

ST6/ST8/ST9

ST1

ST2

KL1

Steuerplatine Servant 5

Control PCB Servant 5

510.0040.0

011.1307.0

Aquastop Verzögerung

Delay for Aquastop switching PCB

Verzögerungsschaltung für Aquastop Servant 5 bis Bj. 2005

Delayed switching circuit for Aquastop on Servant 5 until 2005

Ursprünglicher Anschluß Aquastop.

Original Aqustop connection

ST15

ST11

Vorhandenes Kabel Stirnlampenhaken

Existing cable for headlamp suspension

510.2152.0

S5c

S5

510.2153.0

+12V

GND

Page 24

24

6.0 Retrofi tting

6.2.4.1 Delayed switching circuit for Aquastop from 2006

011.1314.0

GND

V+

230V

12V =

12V

PCB for 230V switching

230V

Control PCB

ST1

011.1307.0

Aquastop Verzögerung

Delay for Aquastop switching

Verzögerungsschaltung für Aquastop

Delayed switching circuit for Aquastop on

Servant 5 from 2006 / Servant 5c / Systema II

Saughandgriff

Suction Handle

Drucklufthandgriff

Pressed Air Handle

Beckenspülung

Bowl rinsing

Pegelschalter

Level Switch

Schalter Schlauchspülbehälter

Microswitch Hose Rinsing Bottle

Ohrspülmodul

Ear Irrigation Module

Fallrohrelektroden

Drain Pipe Electrodes

Füllstandselektroden Sekretbehälter

Level Electrods Secretion Jar

Taster Spiegelschnellerwärmer

Push Button Mirror Quick Heater

Sicherheitsschalter Abdeckklappe

Cover switch

Steuerplatine

Control PCB

Servant 5c / Systema II

506.6100.0

Ursprünglicher Anschluß Aquastop

Original Aqustop connection

+

Ursprüngliches Kabel vom Ohrspülmodul

Original cable from ear irrigation module

510.2152.0

S5c

S5

510.2153.0

+12V

GND

Page 25

25

6.0 Retrofi tting

6.2.5 Water connections until 2005

Spülung Ohrspülschale

Basin Rinsing

Befüllung Spülbehälter

Rinsing bottle refilling

AQUACLEAN

530.2121.0

Gewebeschlauch 8mm

Fabric-Reinforced Hose 8mm

005.0091.0

Gewebeschlauch 6mm

Fabric-Reinforced Hose 6mm

005.0091.0

Schlauchtülle 8mm

Spout 8mm

000.0974.0

Schlauchtülle 6mm

Spout 6 mm

000.0988.0

Schlauchschelle

Hose clamp

061.0060.0

Schottverschraubung 6/6

Bulkhead connector 6/6

000.0980.0

Schottverschraubung 8/8

Bulkhead connector 8/8

000.0978.0

Ventilblock

Valve Block

Aquastop

Wasserfilter

Water Filter

502.0890.0

Schlauch RILSAN 8mm

Hose RILSAN 8mm

005.0025.0

Schlauch RILSAN 8mm

Hose RILSAN 8mm

005.0025.0

Druckminderer

Pressure reducer

Schlauch RILSAN 6mm

Hose RILSAN 6mm

005.0173.0

Schlauchschnellverbinder I 1/8”/6

Hose Quick Connector I 1/8”/6

Anschluß Zulauf Heizblock Ohrspülung

Inlet connectot heating block ear irrigation

Wasserdruck

Water pressure

Wasserzulauf

Water Inlet

Eingang

Inlet AQUACLEAN

8 mm

Ausgang

Outlet AQUACLEAB

6 mm

This branchwas connected at the pressure reducer before

Dieser Zweig war vorher mit dem Druckminderer verbunden

Wasseranschluß Servant 5 bis BJ 2005

Water connections Servant 5 until 2005

Die Veränderungen sind rot gekennzeichnet

The modifications are marked with red colour

2 bar

Page 26

26

6.0 Retrofi tting

6.2.5.1 Water connections from 2006

Aquastop

Wasserzulauf

Water Inlet

Aquaclean 530.2121.0

Ohrspülmodul

Ear Irrigation Module

Bereits vorhanden

Already existing

Neue zu installierende Teile

New parts to be assembled

Eingang

Inlet

Ausgang

Outlet

Wasserfilter

Water Filter

Vorhandener Druckminderer

Existing Pressure Reducer

Anschlußleiste Magnetventile

Valve bank

Manometer

Schlauchschelle

Hose Clamp

061.0060.0

Gewebeschlauch 8 mm

Fabric-Reinforced Hose 8mm

005.0091.0

Gewebeschlauch 6 mm

Fabric-Reinforced Hose 6mm

005.0020.0

Schlauchtülle 8mm

Spout 8mm

000.0974.0

Schlauchtülle 6mm

Spout 6 mm

000.0988.0

Schottverschraubung 6/6

Bulkhead connector 6/6

000.0980.0

Schottverschraubung 8/8

Bulkhead connector 8/8

000.0978.0

Druckminderer

Pressure Reducer

502.0955.0

Schlauch RILSAN 6mm

Hose RISAN 6mm

005.0173.0

Schlauchverbinder 1/8”/6

Hose Connector 1/8”/6

000.0975.0

Schlauch RILSAN 4mm

Hose RILSAN 4mm

005.0026.0

Schlauchverbinder 1/8”/4

Hose Connector 1/8”/4

Schlauch RILSAN 8mm

Hose RILSAN 8mm

005.0025.0

Schlauch RILSAN 8mm

Hose RILSAN 8mm

005.0025.0

Schlauch RILSAN 8mm

Hose RILSAN 8mm

005.0025.0

Schlauchverbinder L 8-8

Hose Connector L 8-8

000.0252.0

Schlauchverbinder T 8-8-8

Hose Connector T 8-8-8

000.0253.0

Anschluß Wasser / Water Circuit

Servant 5c / Systema II / Servant 5 ab 2006

2 bar

Page 27

27

7.0 Troubleshooting

Prior to dispatch, the ATMOS Aqua clean was subjected to an extensive functional test. If, nevertheless, a failure should

appear, you may possibly clear it yourself if you follow these notes:

Error Possible reason Troubleshooting

Device/pump does not

start up

– Loose power plug – Check connection to supply socket

– No mains voltage – Check inbuilding fuse

– Check whether power plug on

the unit is loose

– Defective fuse at the power input – Exchange fuse

8.0 Accessories and Spare Parts

Article description REF

ATMOS Green & Clean WK 534.3110.0

Service kit 069.0260.0

Page 28

28

9.0 Technical information

9.1 Structure

To ensure that it meets the most stringent in-service

requirements, the ATMOS Aqua clean consists of several

modules:

Module 1 - Electronic control system.

Module 2 - Pressure container; this generates the

water pressure. In addition to the container, this

module contains a magnetic valve, a pressure-sensitive

switch and a non-return valve.

Module 3 - Membrane pump; includes pump and

non-return valve.

Module 4 - Mixing container; here, water is mixed

with the disinfectant (after the cascade section).

This module includes the container, fi lling and

overfl ow sensor, 2 magnetic valves and the disinfectant

sensor.

Module 5 - Double membrane pump and membrane

break sensor.

Module 6 - Water unit; consists of a fl ow rate limiter

and dosing valves.

Module 7 - Compressed air unit; this is a pressure

regulator.

Module 8 - Auxiliary installation housing; consists

of housing, fi xing plate, main water tap with fi lter

(100 μm), compressed-air service module, transformer

and main switch.

Fig. 31, module 1

Fig. 32, module 2

Fig. 33, module 3

Fig. 34, module 4 and 5

Fig. 35, module 6

Fig. 36, module 7 Fig. 37, module 8

module 5

Page 29

29

9.0 Technical

9.2 Electrical connections, circuit board

Overfl ow sensor (yellow)

Pressure-sensitive switch (red)

Mixing container probe (yellow/red/black)

Disinfectant sensor (green)

Level monitor in the pressure container (blue)

Air cushion valve on the pressure container (black) MV4

External display

Chemical valve (black) MV3

Water safety valve 5 (brown)

Pump motor connection

Membrane breaking (yellow)

Power supply plug 24 V AC (orange)

Water dosing valve 1 (brown)

Compressed air valve (black) MV2

Main fuse 3,15 A T

When replacing the fuses, always use the same

type!

9.3 Wiring diagram

see Fig. 39.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

!

Fig. 38

Fig. 39

Page 30

30

Issue of technical data: 21.09.2010

10.0 Technical specifi cations

Voltage: 230 V AC (add-on device)

Frequency: 50/60 Hz

Maximum power consumption: 0.8 A

Permitted water pressure: 2-6 bar

Operating pressure (water): 2.2 bar

Operating pressure (air): 4 bar

Maximum water fl ow rate: 550 ml/min

Water quality: drinking water

Disinfectant: ATMOS Green & Clean WK

Hydrogen peroxide, 2% solution

Mixing ratio: 1:85 standard setting

1:42 intensive decontamination

Working solution: 235 ppm

Overall dimensions: (H x W x D): 550 x 265 x 160 mm

Fig. 40

Page 31

31

11.0 Disposal

● The ATMOS Aqua clean does not contain any hazardous materials.

● The housing is recyclable.

● Device and accessories must be decontaminated prior to disposal.

● Please take care on a careful separation of the different materials.

● Please observe national disposal regulations (e.g. waste incineration).

Disposal within the EC

The device described above is a high-quality medical product with a long service life. After its life cycle it must

be disposed of professional. According to the EC directives (WEEE and RoHS) the device may not be disposed of in

domestic waste. Please observe existing national laws and rules for disposal of old devices.

Disposal within the Federal Republic of Germany

In the Federal Republic of Germany the law for electrical devices (ElektroG) rules the disposal of electrical devices.

In order to guarantee a proper disposal of your old device, please either pass on your old device to your specialised dealer

or send it directly to ATMOS MedizinTechnik for a professional disposal.

Prior to disposal the device surface must be disinfected.

Page 32

32

12.0 Notes on EMC

12.1 Guidelines and Manufacturer‘s Declaration - Emissions

The ATMOS Aqua clean is intended for use in the electromagnetic environment specifi ed below.

The customer or user of the ATMOS Aqua clean should ensure that it is used in such an environment.

■ Medical electrical equipment is subject to special precautions with regard to EMC and must be installed acc.

to following EMC notes.

■ Portable and mobile HF communication facilities can influence medical electrical equipment.

■ The use of other accessories, other converters and cables than stated may lead to an increased emission

or a reduced interference immunity of the equipment or system.

Emissions Test Compliance Electromagnetic Environment - Guidance

RF Emissions

CISPR 11

Group 1 The ATMOS Aqua clean uses RF energy only for

its internal function. Therefore, its RF emissions are

very low and are not likely to cause any interference

in nearby electronic equipment.

RF Emissions

CISPR 11

Class B

The ATMOS Aqua clean is suitable for use in all establishments, including domestic, and those directly

connected to the public low-voltage power supply

network that supplies buildings used for domestic

purposes.

Harmonics IEC 61000-3-2 Class A

Flicker

IEC 61000-3-3

Compliance

12.2 Guidelines and Manufacturer‘s Declaration - Immunity for

ATMOS Aqua clean

The ATMOS Aqua clean is intended for use in the electromagnetic environment specifi ed below. The customer or

user of the ATMOS Aqua clean should ensure that it is used in such an environment.

Immunity Test

IEC 60601Test Level

Compliance Level

Electromagnetic Environment - Guidance

ESD

IEC 61000-4-2

± 6 kV Contact

± 8 kV Air

± 6 kV Contact

± 8 kV Air

Floors should be wood, concrete,

or ceramics tile. If fl oors are syn-

thetic, the relative humidity should

be at least 30%.

EFT

IEC 61000-4-4

± 2 kV Mains

± 1 kV I/Os

± 2 kV Mains

not applicable

Mains power quality should be that

of a typical commercial or hospital

environment.

Surges

IEC 61000-4-5

± 1 kV

asymmetric

± 2 kV

symmetric

± 2 kV

asymmetric

± 2 kV

symmetric

Mains power quality should be that

of a typical commercial or hospital

environment.

Power Frequency

50/60 Hz

Magnetic fi eld

IEC 61000-4-8

3 A/m not applicable Power frequency magnetic fi elds

should be that of a typical commercial or hospital environment.

The device may not be used directly next to other devices or piled up with other devices.

If operation next to or piled with other devices is necessary, please watch the device to check its intended

operation in this arrangement.

Page 33

33

Immunity Test

IEC 60601Test Level

Compliance Level

Electromagnetic

Environment - Guidance

Voltage Dips / Dropout

IEC 61000-4-11

< 5 % UT

(> 95 % Dip of the UT)

for 0.5 Cycle

40 % U

T

(60% Dip of the UT)

for 5 Cycles

70% U

T

(30 % Dip of the UT)

for 25 Cycles

< 5 % UT

(>95 % Dip of the U

T

)

for 5 s

< 5 % UT

(> 95 % Dip of the UT)

for 0.5 Cycle

40 % U

T

(60% Dip of the UT)

for 5 Cycles

70% U

T

(30 % Dip of the UT)

for 25 Cycles

< 5 % UT

(>95 % Dip of the U

T

)

for 5 s

Mains power quality should be

that of a typical commercial or

hospital environment. If the user of

the ATMOS Aqua clean demands

continued function even in case of

interruptions of the energy supply,

it is recommended to supply the

ATMOS Aqua clean from an

uninterruptible current supply or a

battery.

NOTE U

T

is the mains alternating current prior to application of the test levels.

12.0 Notes on EMC

12.3 Guidelines and Manufacturer´s Declaration - Immunity

The ATMOS Aqua clean is intended for use in the electromagnetic environment specifi ed below. The customer or

user of the ATMOS Aqua clean should ensure that it is used in such an environment.

Immunity Test

IEC 60601Test Level

Compliance Level

Electromagnetic Environment Guidance

Conducted RF

IEC 61000-4-6

3 V

eff

150 kHz to 80 MHz

3 V

Portable and mobile communications

equipment should be separated from the

ATMOS Aqua clean incl. the cables by no

less than the distances calculated/listed

below.

Recommended distances:

d = 3,5/3√ P

d = 3,5/3√ P for 80 MHz up to 800 MHz

d = 7/3√ P for 800 MHz up to 2,5 GHz

where „P“ is the max. power in watts (W)

and D is the recommended separation

distance in meters (m).

Field strengths from fi xed transmitters, as

determined by an electromagnetic site (a)

survey, should be less than the compliance level (b).

Interference may occur in the vicinity of

equipment containing following symbol

Radiated RF

IEC 61000-4-3

3 V/m

80 MHz to 2.5 GHz 3 V/m

Page 34

34

12.4 Recommended separations between portable and mobile RF Communications

equipment and the ATMOS Aqua clean

Recommended separations between portable and mobile RF Communications

equipment and the ATMOS Aqua clean

The ATMOS Aqua clean is intended for use in electromagnetic environment in which radiated disturbances are

controlled. The customer or user of the ATMOS Aqua clean can help prevent electromagnetic interference by

maintaining a minimum distance between portable and mobile RF Communications equipment and the ATMOS

Aqua clean as recommended below, according to the maximum output power of the communications equipment.

Separation distance, depending on transmit-frequency m

Nominal output of the

transmitter

W

150 kHz up to 80 MHz

d = 3,5/3√ P

80 MHz up to 800 MHz

d = 3,5/3 √ P

800 MHz up to 2,5 GHz

d = 7/3 √ P

0,01 0,12 0,12 0,24

0,1 0,37 0,37 0,74

1 1,2 1,2 2,4

10 3,69 3,69 7,38

100 11,66 11,66 23,32

For transmitters for which the maximum nominal output is not indicated in the above table, the recommended

separation distance d in meters (m) can be determined using the equation belonging to the respective column

whereas P is the maximum nominal output of the transmitter in watts (W) acc. to manufacturer´s specifi cation.

NOTE 1 With 80 MHz and 800 MHz the higher frequency range applies.

NOTE 2 These guidelines might not be applicable in any case. The propagation of electromagnetic sizes is

infl uenced by absorptions and refl ections of buildings, objects and people.

NOTE 1 With 80 MHz and 800 MHz the higher frequency range applies.

NOTE 2 These guidelines might not be applicable in any case. The propagation of electromagnetic sizes is

infl uenced by absorptions and refl ections of buildings, objects and people.

a The fi eld strength of stationary transmitters, such as base stations of cellular phones and mobile terrain radio

equipment, amateur radio transmitters, cbm broadcast and TV stations cannot be predestined exactly.

To determine the electromagnetic environment in regard to stationary transmitters, a study of the location is to

be considered. If the measured fi eld strength at the location where the ATMOS Aqua clean is used exceeds

the above compliance level, the ATMOS Aqua clean is to be observed to verify the intended use.

If abnormal performance characteristics are noted, additional measures might be necessary, e. g. a changed

arrangement or another location for the device.

b Within the frequency range of 150 kHz to 80 MHz the fi eld strength is to be below 3 V/m.

12.0 Notes on EMC

Page 35

35

For your notes

Page 36

MedizinTechnik

This document is copyrighted. Duplication, translations, microlming and savings on electronic systems, particularly for commercialpurposes

are illegal without prior agreement of the manufacturer. All compiled data are based on manufacturers instructions. All logos,

product names and designations used in this document are property of the respective manufacturer.

We do not take over any warranty and liability in the case of missing inscriptions. Subject to modications and amendments.

1. General:

Our General Standard Terms and Conditions apply exclusively. Client’s

terms and conditions which are contrary to or deviate from our General

Standard Terms and Conditions are not recognised unless their validity

is explicitly confirmed in writing. Our General Standard Terms and

Conditions also apply even if we deliver to clients without reservation,

in the knowledge of the client’s contrary terms and conditions. Our

General Standard Terms and Conditions also apply to all future business

with that client.

2. Proposal - Order Confirmation

Our proposals are subject to change without notice unless otherwise

stated in our order confirmation. Each order is only accepted by us

following our written order confirmation.

3. Orders

Every order requires an exact description of all of our product’s details.

We assume no liability for errors and damage caused by inaccurate or

incomplete ordering details.

4. Prices

Unless otherwise stated in the order confirmation, our prices in the

order confirmation are ex factory prices and exclude packaging and

value added tax. Packaging is charged separately at cost price in the

invoice. Value added tax is charged separately in the invoice according

to the legal rate on the invoice date. We reserve the right to change

prices appropriately should price reductions or increases, especially

due to wage settlements, changes in the price of materials or currency

fluctuations, be incurred. Proof of such changes will be provided for the

client on request.

5. Payment Conditions - Balancing

Unless otherwise stated in the order confirmation, our invoices

are payable with a 3% discount within 10 days (except for repair and

assembly services) or within 21 days from the invoice date net cash;

money receipts is decisive for complying with this term. We are entitled

to charge interest after the due date at a rate 2% above the relevant

basic interest rate of the German Federal Bank. Should the client have

payment arrears, we are entitled to charge interest on arrears at a rate

5% above the relevant basic interest rate of the German Federal Bank.

Should we be able to prove higher damages due to arrears, we are also

entitled to claim these. The client only has the right to balance invoices

against its own claims should such claims be confirmed in a court of

law or recognised by us. The client does not have the right of retention

due to disputed counterclaims.

6. Delivery Periods

Fulfilment of our delivery duties requires the punctual and proper

fulfilment of the client’s duties. The right to defense on the grounds of an

unfulfilled contract is reserved.Should the client default in accepting the

goods delivery or breach other cooperation duties, we are entitled either

to withdraw from the contract or claim compensation for any increased

costs incurred up to that time without setting a further deadline. The right

to make further claims is reserved. Furthermore, in such cases, the risk

of coin-cidental destruction or a coincidental deterioration in the quality

of the delivered goods is transferred to the client in the case of default

in accepting such goods or payment arrears. Acts of God or stoppages

(due to insufficient supplies of material, industrial disputes etc.) entitle

us either to demand an appropriate extension of delivery periods or to

partly or entirely dissolve the delivery contract. This does not give the

client the right to claim damages. We have fulfilled delivery periods if the

delivery goods have left our factory or the client has been informed of

the goods’ readiness for delivery within such delivery periods. Delivery

periods stipulated by the client are not recognisedby us unless they

form part of our order confirmation. We adhere to legal terms and

conditions in cases where, as a result of an undue delay in the delivery

for which we are liable, the client is entitled to claim that his interests

in a continued fulfilment of the contract have ceased. We also adhere

to legal terms and conditions should a delay in delivery be caused by

deliberate or grossly negligent action by us or our representatives for

which we are responsible. We are also responsible for such actions by

our representatives or agents. Should the delivery delay not be caused

by our deliberate infringement of contractual duties for which we are

responsible, our liability is limited to damage which is regarded as typical

for that case. We are liable according to the legal terms and conditions if

and in so far as the delivery delay for which we are responsible is caused

by an infringement of a substantial contractual duty. In such cases, our

liability is also limited to damage which is regardedas typical for that

case. Should the delivery delay be caused by a culpable infringement

of non-substantial contractual duties, our client is also entitled to claim

a one-off damage compen-sation worth 3 percentage points of the

delivery value of the goods for each week’s delay, up to a maximum

which is no higher than 15 percentage points of the delivery value of

the goods

7. Delivery - Familiarisation

In the case of the delivery of devices for the medico-technical industry

which require assembly and/or familiarisation for the final customer using

specialist trade personnel (such as Ear, Nose and Throat Apparatus and

Suction Units), we reserve the right to deliver the goods exclusively to

the relevant specialist traders. Should the trader not carry out assembly

and/or familiarisation for the final customer, this is carried out by us. In

such cases, we reserve the right to charge the client for the additionally

created costs. Our specialist traders operate a recording system so

that, if necessary, our products can be traced to the final customer. The

specialist trader undertakes to immediately report to us all events and

risks which must be reported in connection with our products.

8. Passage of Risk - Packaging

Unless otherwise stated in our order confirmation, delivery is agreed

ex factory. The risk of the goods’ damage or loss is therefore transferred

to the client as soon as the goods leave the factory or the client is in

default of acceptance of the goods. This also applies to cases where we

confirm prepaid carriage. Transport packaging and all other packaging

according to the packaging regulations is not returnable. Our client is

responsible for disposing the packaging at its own cost. Our deliveries are

insured by us at the client’s expense unless explicitly otherwise agreed.

No insurance is arranged in the case of goods which are collected by

our clients. In the case of transport damage, claims are only handled if

the client receives confirmation of any damage, reduced weight or loss

by the shipping company before accepting the delivery.

9. Warranty

The client is responsible for examining the delivered goods

immediately after receiving them to determine any eventual deficiencies

or delivery errors, and to report these immediately. Should the client

fulfil this examining and reporting responsibility, and should payment

conditions be fulfilled, we shall be liable to the client within the scope

of legal regulations. Our period of warranty shall in all cases be two

years. Our client can make use of the warranty as follows, so long as

he can provide first buyer proof (in the form of an invoice or delivery

note) and provided that the product still has the original, unchanged

serial number:

a. We choose whether to fulfil our guarantee by providing repair

services free of charge - either on the client’s premises or in our factory

- or replacing the product. We can also provide these guarantee

services through an authorised company;

b. Should a product be returned to us, the client agrees to send

the product in its original or similar packaging, offering the same

protection as the original packaging, to our address or any address

notified by us.

c. Our guarantee ceases to apply if changes of any kind have been

made to our product, unless such changes have been made by us

or a company authorised by us, or have been previously agreed

upon in writing by us. Our guarantee also ceases to apply if third

parties have carried out repairs to our products or replaced parts

thereof. This applies regardless of the fact whether these measures

individually or collectively led to a deficiency of the product;

d. We accept no responsibility for damage defects caused by

- operational wear and tear;

- incorrect installation or incorrect or insufficient maintenance;

- incorrect operation of the product (in contradiction to the operating instructions

delivered with the product); - improper use or operating faults; -

inappropriate or negligent handling and care, especially with respect

to dirt, lime, suction of fluids, inappropriate cleaning and sterilisation;

- using accessories and/or replacementpartswhich are not explicitly

approved;

- incorrect assembly and/or initial operation by the client or third

parties; - the client’s negligence in handling the product; - unacceptable

operating conditions, such as humidity, temperatures, the power supply,

vibrations.

- accidents, acts of God, especially lightening, water, fire, public

unrest and insufficient ventilation. We are not liable for damage to

other objects apart from our product itself, except in thecase of any

deliberate or grossly negligent actions by us or our representatives or

agents. Should no deliberate breach of contract be claimed, our liability

is limited to damage which is regarded as typical for tthat case. This

also applies in the case of our culpable infringement of substantial

contractual duties The indispensable conditions of German Liability

Law remain unaffected thereby.

- For second-hand equipment, the period of warranty shall be reduced

to a period of twelve months.

10. Reservation of Ownership

We retain ownership of our goods until the receipt of all payments

arising from the business relationship, including all demands arising

from installation orders, subsequent orders, repairs, accessory deliveries

and replacement orders. Should we have agreed upon payment on the

basis of cheque and bill transactions, the ownership reservation applies

until the cheque received byus has been paid in, and does not expire

through our credit upon receiving the client’s cheque. In the case of

a breach of contract by the client, especially payment arrears, we are

entitled to repossess our goods. Repossession of our goods repre-sents

a withdrawal from the contract, unless explicitly declared in writing by

us. We have the right to utilise the product after its repossession, whilst

the income form such use is balanced against the client’s arrears, after

deducting appropriate utilisation costs.The client is responsible for

handling the goods with care. Should maintenance and inspection work

be necessary, the client must carry these out punctually at his own cost.

Our client is entitled to sell the goods he has bought from us in a proper

sale transaction. However, he must immediately assign all outstanding

claims to the value of the final invoice sum (including value added tax)

of our claims to his customers or third parties. The client is entitled to

collect this claim even after such assignment. Our right to collect the

claim ourselves remains unaffected thereby.We undertake to release

the securities to which we are entitled if requested to do so by the

client should the realisable value of the our securities be more than 10

percentage points higher than the outstanding claims. We reserve the

right to choose the securities to be released.

11. Plans and Illustrations

We retain ownership of and copyrights to all plans, illustrations,

calculations and other documents which are attached to our proposals.

The client must receive explicit written permission before passing these

on to third parties. Imitating our legally patented products is forbidden

and will be prosecuted.

12. Jurisdiction and Place of Performance

Our central office is the place of performance for all disputes in

connection with these General Standard Terms and Conditions and

the contracts closed with clients under them. This jurisdiction excludes

other jurisdiction relating to persons or subject-matter. Furthermore, our

client is not entitled to bring charges against us in another court should

he file counter-charges, carry out counterbalancing or declare retention.

We, however, are entitled to bring charges against our client at their

general place of jurisdiction or at another relevant court recognised by

German or foreign law.Unless otherwise stated in the order confirmation,

our central office is the place of performance.

Lenzkirch, September 2008

ATMOS MedizinTechnik GmbH & Co. KG

79853 Lenzkirch/Germany

ATMOS General terms and conditions

Loading...

Loading...