Page 1

Phase Control Circuit for Current Feedback

Description

The U2010B is designed as a phase-control circuit in

bipolar technology. It enables load-current detection and

has a soft-start function as well as reference voltage

Features

D

Full wave current sensing

D

Mains supply variation compensated

D

Programmable load-current limitation

with over- and high-load output

D

Variable soft-start

D

Voltage and current synchronization

D

Automatic retriggering switchable

D

Triggering pulse typical 125 mA

output. Motor control with load-current feedback and

overload protection are preferred applications.

D

Internal supply voltage monitoring

D

Current requirement v 3 mA

D

Temperature compensated reference voltage

Applications

D

Advanced motor control

D

Grinder

D

Drilling machine

U2010B

Package: DIP16, SO16

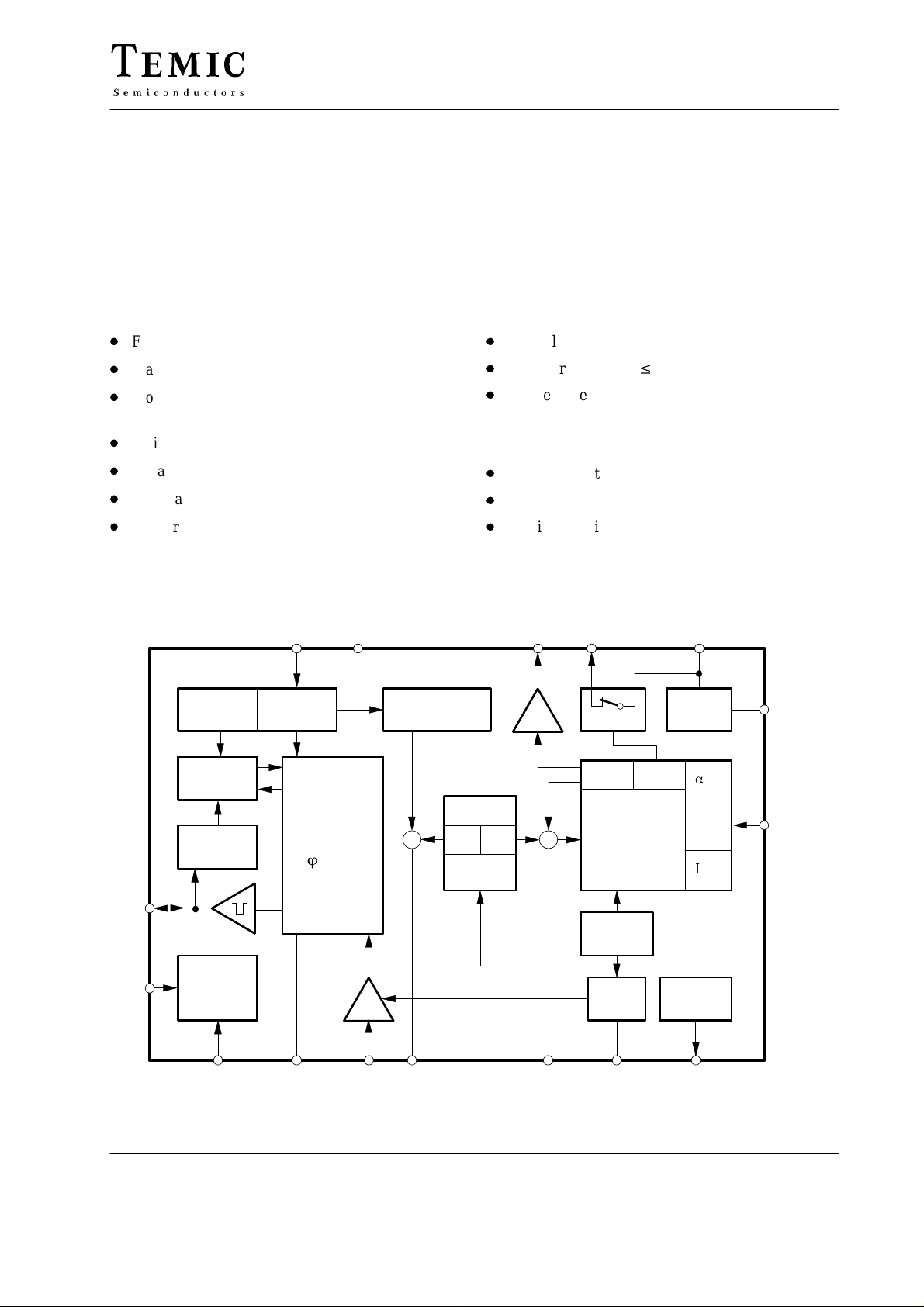

Block Diagram

96 11646

Limiting

detector

Automatic

retriggering

Current

detector

16

Pulse

output

Load

1

current

detector

15

Voltage

detector

control unit

Phase

ö

= f (V

Level

shift

14 13 12

Overload

Mains voltage

)

4

compensation

Output

–

12

Full wave

rectifier

High load

+

monitoring

100% 70%

Programmable

overload

protection

Voltage

Soft

start

11

Supply

voltage

a

max

Auto–

start

I

max

Reference

voltage

10

GND

A

B

9

C

2

3 5 67 8

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

4

Figure 1. Block diagram

1 (12)

Page 2

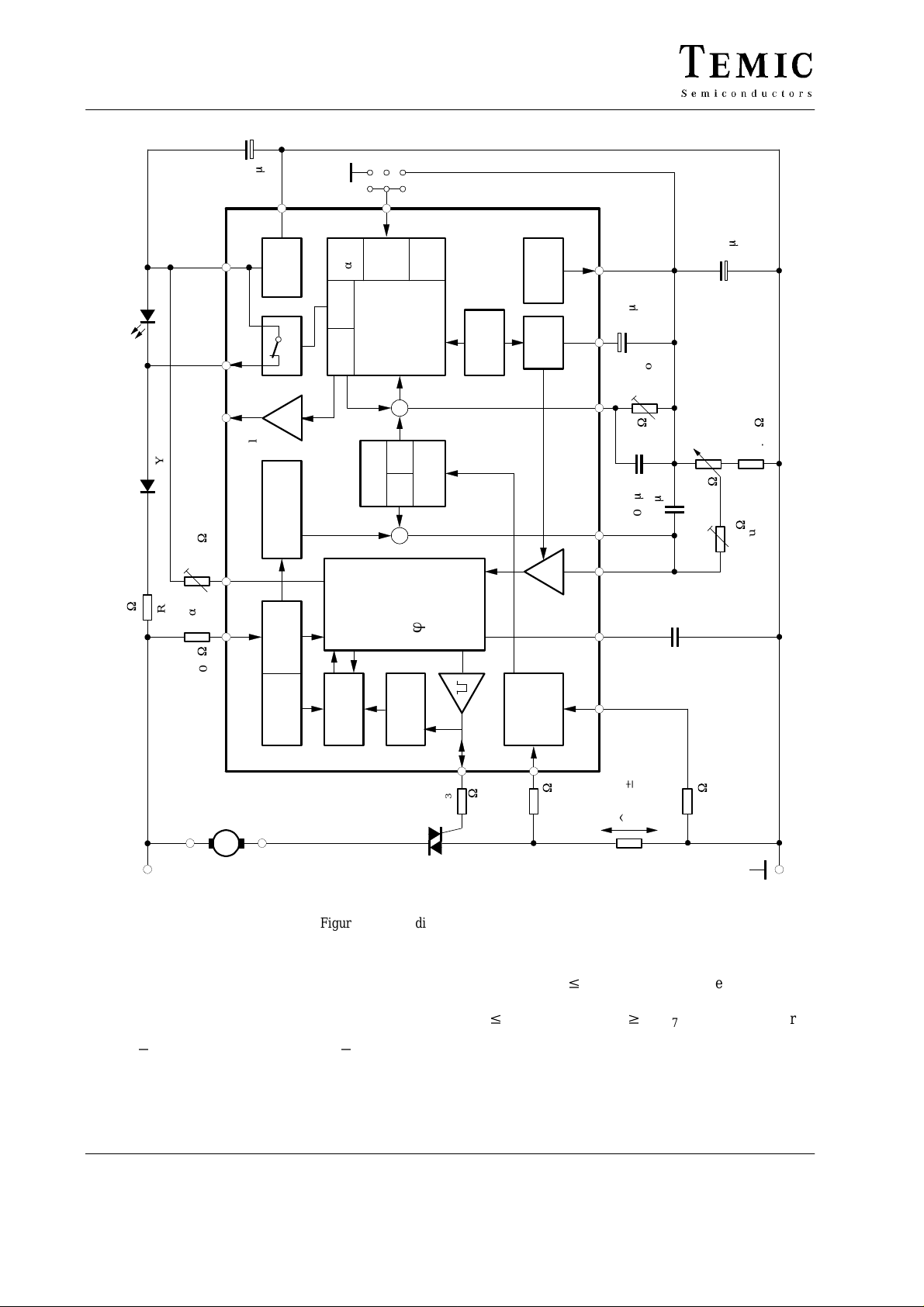

U2010B

C

1

m

22 F

Mode

B

C

A

1

S

3

D

1

D

/2 W

W

18 k

LED

BYT51K

8

R

1

R

a

2

R

W

470 k

max

W

330 k

10

GND

S

V

Overload

14 13 12 11

15

Supply

voltage

High load

compensation

Mains voltage

Voltage

detector

detector

Limiting

9

B

A

max

a

100% 70%

Output

Automatic

retriggering

C

max

I

Auto–

start

overload

protection

Programmable

+

2

rectifier

1

Full wave

–

)

4

= f (V

Phase

ö

control unit

Current

detector

Voltage

monitoring

Reference

Soft

Level

Load

current

96 11647

voltage

m

2

C

4.7 F

start

threshold

Overload

11

W

R

1 M

5

C

m

m

0.1 F

0.15 F

C

shift

3 5 67 8

24

detector

3

C

10 nF

1

P

4

7

C

Set point

W

50 k

10

R

m

1 F

W

R78.2 k

W

100 k

Load current

compensation

Load

230 V ~

TIC

226

Figure 2. Block diagram with external circuit

General Description

Mains Supply

The U2010B contains voltage limiting and can be

connected with the mains supply via D

voltage * between Pin 10 and Pin 11 * is smoothed

.

by C

1

2 (12)

and R1. Supply

1

16

W

3

R

180

In the case of V

1

W

4

R

3.3 k

v (70% of overload threshold voltage),

6

$

= 250 mV

(R6)

^

V

6

R

W

5

R

3.3 k

Pins 11 and 12 are connected internally whereby

v 1.2 V. When V6 w V

V

sat

flows across D

.

3

, the supply current

T70

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

Page 3

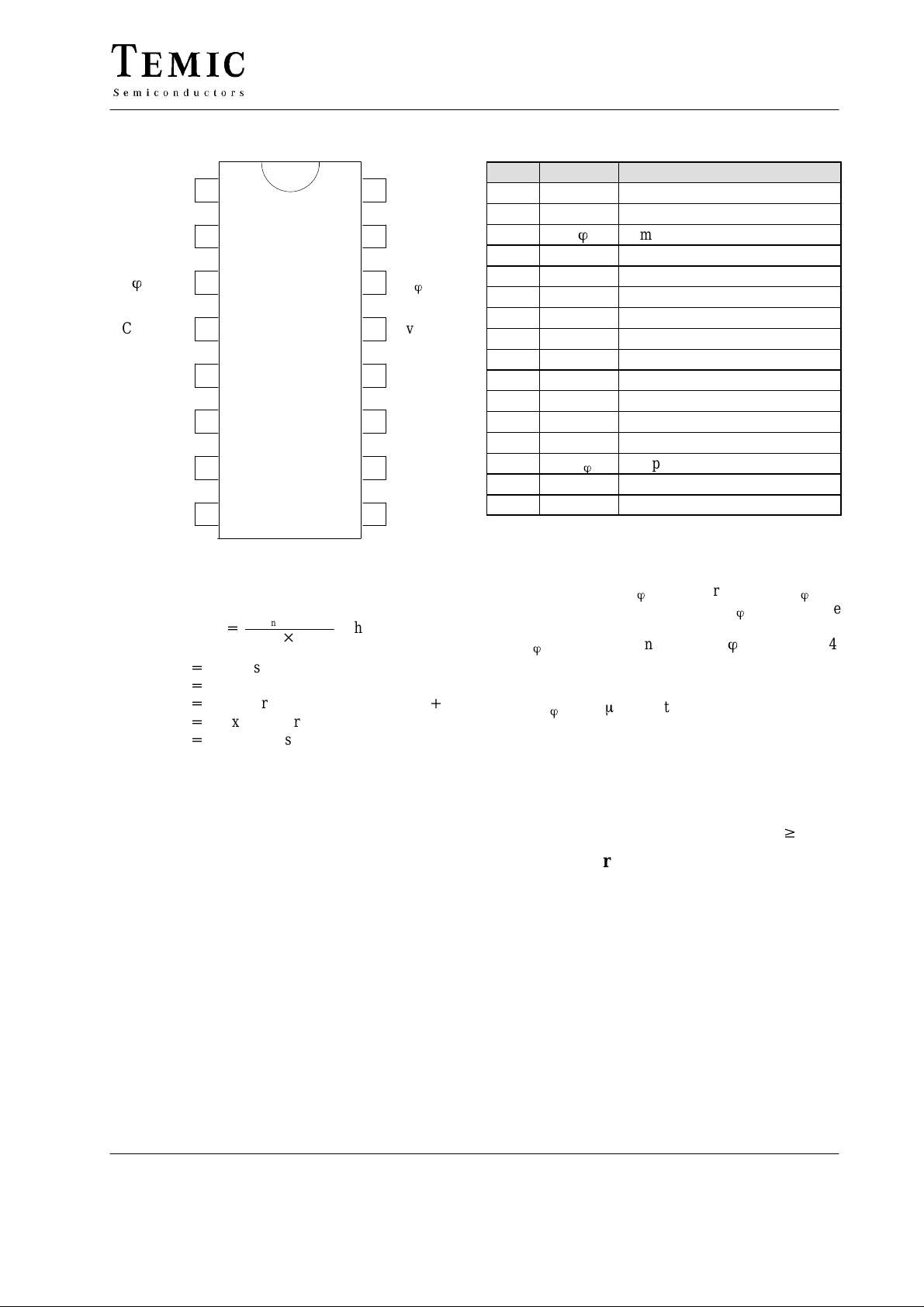

Pin Description

I

sense

I

sense

C

ö

Control

Comp.

I

Load

C

soft

V

Ref

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

Output

V

Sync.

V

R

ö

Overload

High load

V

S

GND

Mode

U2010B

Pin Symbol Function

1 I

2 I

sense

sense

3 C

4 Control Control input

5 Comp. Compensation output

6 I

7 C

8 V

Load

soft

Ref

9 Mode Mode selection

10 GND Ground

11 V

12 High load High load indication

13 Overload Overload indication

14 V

15 V

R

Sync.

16 Output Trigger output

Load current sensing

Load current sensing

ö

Ramp voltage

Load current limitation

Soft start

Reference voltage

Supply voltage

S

Ramp current adjust

ö

Voltage synchronization

95 11406

Series resistance R1 can be calculated as follows:

V

–V

V

mains

V

Smax

I

tot

I

Smax

I

x

R

+

+

+

+

+

1max

mains

+

Mains supply voltage

Maximum supply voltage

Total current consumption = I

Maximum current consumption of the IC

Current consumption of the

2 I

Smax

tot

whereas

Smax

)I

x

external components

Voltage Monitoring

As the voltage is built up, uncontrolled output pulses are

avoided by internal voltage monitoring. Apart from that

all the latches in the circuit (phase control, load limit

regulation) are reset and the soft-start capacitor is short

circuited. This guarantees a specified start-up behavior

each time the supply voltage is switched on or after short

interruptions of the mains supply. Soft-start is initiated

after the supply voltage has been built up. This behavior

guarantees a gentle start-up for the motor and automatically ensures the optimum run-up time.

Phase Control

The function of the phase control is largely identical to the

well known IC family U211B. The phase angle of the

trigger pulse is derived by comparing the ramp voltage V

which is mains synchronized by the voltage detector with

the set value on the control input, Pin 4. The slope of the

ramp is determined by C

charging current can be varied using R

maximum phase angle, α

using R

(minimum current flow angle

ö

and its charging current Iö. The

ö

can also be adjusted by

max,

at Pin 14. The

ö

ö

) see figure 4.

min

When the potential on Pin 3 reaches the set point level of

Pin 4, a trigger pulse width, t

value of C

(tp = 9 ms/nF). At the same time, a latch is set

ö

, is determined from the

p

with the output pulse, as long as the automatic

retriggering has not been activated, then no more pulses

can be generated in that half cycle. Control input at Pin 4

(with respect to Pin 10) has an active range from

to –1 V. When V4 = V8, then the phase angle is at its

V

8

maximum, α

The minimum phase angle, α

i.e., the current flow angle is minimum.

max,

is set with V4 w –1 V.

min,

Automatic Retriggering

The current-detector circuit monitors the state of the triac

after triggering by measuring the voltage drop at the triac

gate. A current flow through the triac is recognized, when

the voltage drop exceeds a thres hold level of typ. 40 mV.

If the triac is quenched within the relevant half-wave after

triggering; for example owing to low load currents before

or after the zero crossing of current wave or; for commutator motors, owing to brush lifters. Then the automatic

retriggering circuit ensures immediate retriggering, if

necessary with a high repetition rate, t

3

remains reliably triggered.

, until the triac

pp/tp

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

3 (12)

Page 4

U2010B

Current Synchronization

Current synchronization fulfils two functions:

*

Monitoring the current flow after triggering.

In case the triac extinguishes again or it does not switch

on, automatic triggering is activated until the

triggering is successful.

*

Avoiding a triggering due to inductive load.

In the case of inductive load operation the current

synchronization ensures that in the new half wave no

pulse is enabled as long as there is a current available

which from the previous half-wave, which flows from

the opposite polarity to the actual supply voltage.

A special feature of the integrated circuit is the

realization of this current synchronization. The device

evaluates the voltage at the pulse output between gate and

reference electrode of the triac. This results in saving

separate current synchronization input with specified

series resistance.

Voltage Synchronization with Mains Voltage

Compensation

The voltage detector synchronizes the reference ramp

with the mains-supply voltage. At the same time, the

mains dependent input current at Pin 15 is shaped and

rectified internally. This current activates the automatic

retriggering and at the same time is available at Pin 5. By

suitable dimensioning, it is possible to attain the specified

compensation effect. Automatic retriggering and mains

voltage compensation are not activated until |V

increases to 8 V. Resistance, R

defines the width of

sync.

the zero voltage cross over pulse, synchronization

current, and hence the mains supply voltage

compensation current.

Mains

96 11648

– 10|

15

If the mains voltage compensation and the automatic

retriggering are not required, both functions can be

suppressed by limiting |V

| v 7 V (figure 3).

15 – 10

Load Current Compensation

The circuit continuously measures the load current as a

voltage drop at resistance R

. The evaluation and use of

6

both half waves results in a quick reaction to load current

change. Due to voltage at resistance R

, there is a

6

difference between both input currents at Pins 1 and 2.

This difference controls the internal current source,

whose positive current values are available at Pins 5

and 6. The output current generated at Pin 5 contains the

difference from the load-current detection and from the

mains-voltage compensation (see figure 1).

The effective control voltage at Pin 4 is the final current

at Pin 5 together with the desired value network. An

increase of mains voltage causes the increase of control

angle α, an increase of load current results in a decrease

in the control angle. This avoiding a decrease in

revolution by increasing the load as well as the increase

of revolution by the increment of mains supply voltage.

Load Current Limitation

The total output load current is available at Pin 6. It

results in a voltage drop across R

of the load current reaches about 70% of the threshold

value (V

) i.e., ca. 4.35 V at Pin 6, it switches the high

T70

load comparator and opens the switch between Pins 11

and 12. By using an LED between these pins, (11 and 12)

a high load indication can be realized.

If the potential at Pin 6 increases to ca. 6.2 V (= V

it switches the overload comparator. The result is

programmable at Pin 9 (operation mode).

. When the potential

11

T100

),

4 (12)

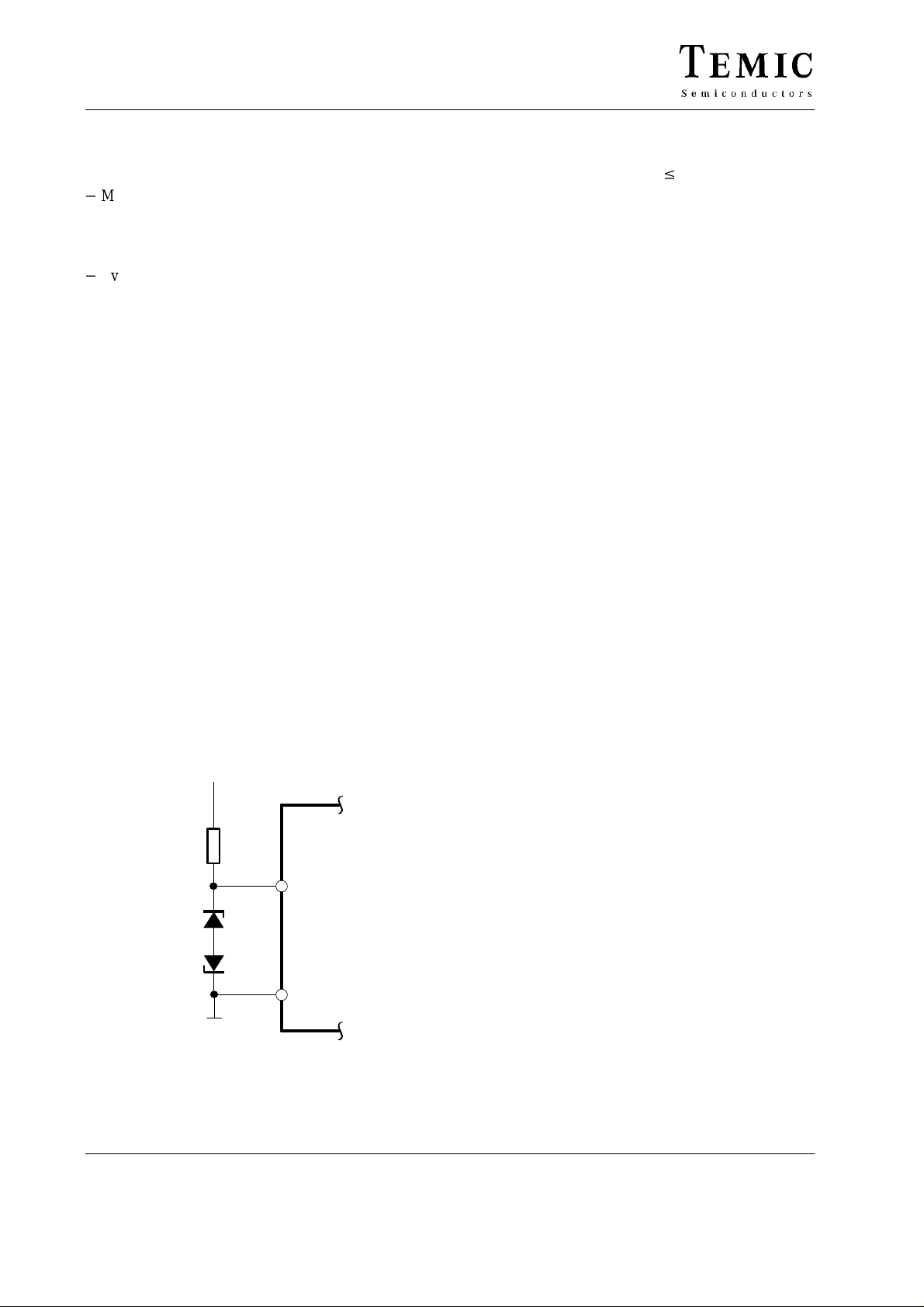

2x

BZX55

C6V2

R

2

15

U2010B

Mode selection:

a) α

(V9 = 0)

max

In this mode of operation, after V

threshold V

, Pin 13 switches to –V

T100

has reached the

6

(Pin 11) and

S

Pin 6 to GND (Pin 10). A soft-start capacitor is then

shorted and the control angle is switched to α

max

.

This position is maintained until the supply voltage

is switched off. The motor can be started again with

10

soft-start function when the power is switched on

again. As the overload condition switches Pin 13 to

Pin 11, it is possible to set in a smaller control angle,

, by connecting a further resistance between

α

max

Figure 3.

Pins 13 and 14.

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

Page 5

U2010B

b) Auto start (Pin 9 * open)

The circuit behaves as written under α

max

with the exception that Pin 6 is not connected to

GND. If the value of V

threshold value (V

decreases to 25% of the

6

), the circuit becomes active

T25

again with soft-start.

(V9 = 0),

c) I

max

When V

maximum value i.e. V

to Pin 8 (V

without soft-start capacitor discharging at Pin 7.

With this mode of operation, direct load current

control (I

shown in figure 18.

Absolute Maximum Ratings

Reference point Pin 10, unless otherwise specified

Parameters Symbol Value Unit

Sink current Pin 11 –I

t

v

10 m

s –i

Sync. currents Pin 15

v

10 m

t

s

Phase control

Control voltage Pins 4 and 8 –V

Input current Pin 4

Charging current Pin 14 – I

Soft-start

Input voltage Pins 7 and 8 –V

Pulse output

Input voltage Pin 16 +V

Reference voltage source

Output current Pin 8 I

t

v

10 m

s 30

Load current sensing

Input currents Pins 1 and 2

Input voltages Pins 5 and 6 – V

Overload output Pin 13 I

High-load output Pin 12

v

10 m

t

s

Storage temperature range T

Junction temperature range T

Ambient temperature range T

"

"

(V9 = V8)

S

s

I

syncV

i

syncV

I

"

I

I

max

ϕ

I

I

–V

I

0

"

I

i

i

L

I

L

stg

j

amb

has attained the overload threshold

6

) through the resistance R (= 2 kW)

Ref

) is possible. A recommended circuit is

max

= V

6

; Pin 13 is switched

T100

30 mA

100

5

mA

20

0 – V

500

8

V

m

A

0.5 mA

0 – V

2

V

11

8

V

V

10 mA

1 mA

0 – V

8

V

1 mA

30

mA

100

*

40 to )125

125

*

10 to )100

C

C

C

Thermal Resistance

Parameters Symbol Value Unit

Junction ambient DIP16

SO16 on p.c.

SO16 on ceramic

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

R

thJA

120

K/W

180

100

5 (12)

Page 6

U2010B

Electrical Characteristics

VS + –13 V, T

= 25°C, reference point Pin 10, unless otherwise specified

amb

Parameters Test Conditions / Pins Symbol Min. T yp. Max. Unit

Supply Pin 11

Supply voltage limitation –I

Current requirement –V

= 3.5 mA

S

= 30 mA

–I

S

S

= 13.0 V

(Pins 1, 2, 8 and 15 open)

Reference voltage source Pin 8

Reference voltage I

Temperature coefficient I

= 10 A

L

= 2.5 mA

I

L

= 2.5 mA

S

= 10 A

I

S

–V

TC

Voltage monitoring Pin 11

Turn-on threshold –V

Phase control – synchronization Pin 15

Input current V oltage sync.

Voltage limitation

"

I

= 2 mA

L

Input current Current sync. Pin 16

"

"

"

Reference ramp, figure 4

Charging current Pin 14 –I

Start voltage Pin 3 –V

Temperature coefficient of

start voltage

Pin 3 TC

Final voltage Pin 3 –V

Rϕ − reference voltage I

Temperature coefficient I

Pulse output current V

Output pulse width V

=

ϕ

ϕ

I

ϕ

C

Α Pins 14 and 11 V

=

Α Pin 14

=

Α

= – 1.2 V, figure 5, Pin 16 I

16

= V

S

limit,

= 3.3 nF, figure 6, Pin 16

3

TC

Automatic retriggering

Repetition rate I15 w 150 A t

Threshold voltage Pin 16

Soft start, figure 7 and 8 Pin 7

Starting current V

Final current V

= V

7

8

= –1V –I

7–10

Discharge current +I

Output current Pin 4 +I

Supply voltage compensation, figure 9 Pin 15

Transfer gain I15/ I

5

Pin 15/5

(Pins 1 and 2 open)

Output offset current V

Load current detection, R

1 =

(R6)

R

2

= V

= V5 = 0

15

= 3 k, V15 = 0, V

= V6 = V

5

figure 10

8,

Transfer gain I5/150 mV, I6/150 mV G

Output offset currents Pin 5, Pin 6 - 8 –I

Reference voltage I1, I2 = 100 A Pins 1 and 2 –V

Shunt voltage amplitude see figure 2

"

–V

–I

VRef

I

syncV

V

syncV

I

syncI

t

pp

"

–I

G

"

V

S

Ref

Son

ϕ

max

min

R

VR

0

p

V

0

0

0

0

i

I

I

0

Ref

(R6)

S

14.5

14.6

16.5

16.8

V

3.2 mA

8.6

8.4

8.9

8.8

–0.004

9.2

9.1

V

%/K

+0.006

11.3 12.3 V

0.15 2 mA

8.0 8.5 9.0 V

3 30

1 100

A

A

1.85 1.95 2.05 V

R

ϕ

0.96 1.02 1.10 V

ϕ

–0.003 %/K

(V8"

200 mV)

0.03

%/K

0.06

100 125 150 mA

30

3 5 7.5 t

I

20 60 mV

5 10 15

15 25 40

s

p

A

A

0.5 mA

0.2 2 mA

14 17 20

0

2

0.28 0.32 0.37

0 3 6

A/mV

A

A

300 400 mV

250 mV

6 (12)

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

Page 7

Load current limitation, Pin 6-8, figs. 11 to 14

High load switching Threshold V

T70

U2010B

UnitMax.Typ.Min.SymbolTest Conditions / PinsParameters

V

T70

4 4.35 4.7 V

Overload switching Threshold V

Restart switching Threshold V

T100

T25

V

T100

V

Input current Enquiry mode I

Output impedance Switching mode R

Programming input, figure 2, Pin 9

Input voltage - auto-start Pin 9 open –V

Input current V9 = 0 (

V

High load output, V

, figure 12, I12 = –3 mA, Pin 11-12

T70

Saturation voltages V

V

Overload output, V

, V9 = open or V9 = V10, fig. 13

T100

Leakage current V

V

Saturation voltages V

I

a

)

max

= V8 (I

9

6-8

v

6-8

w

6-8

v

= (V11+1)V Pin 13 I

13

6-8

w

= 10 mA Pins 11-13 V

13

V

V

V

V

max

T70

T70

T25

T100

)

,

–I

V

V

Output current, max. load V9 = V8, fig. 13 Pin 13 I

Leakage current V

V

6

T100

v

Pin 13 I

Output impedance Open collector

Saturation voltage V

V

V

6

T100

w

V

6-8

I

13

T100

w

= 10 mA Pin 13 V

Pin 13 R

,

13–8

T25

I

9

sat

lim

lkg

sat

13

lkg

5.8 6.2 6.6 V

1.25 1.55 1.85 V

i

0

9

9

2 4 8 k

3.8 4.3 4.7 V

5

5

0.5

7.0

10

10

0.75

7.4

1

20

20

1.0

7.8

0.5

mA

W

mA

V

mA

0.1 V

1 mA

4

0

2 4 8 k

mA

W

100 mV

250

10 nF

6.8 nF

4.7 nF 3.3 nF 2.2 nF

Rö ( kW )96 11797

33 nF

200

°

a

150

100

Phase angle ( )

50

0

0 200 400 600 800 1000

Figure 4.

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

C

/ t

ö

= 1.5 nF

GT

I ( mA )

95 10338

120

100

80

60

40

20

0

0 200 400 600 800

RGT ( W )

Figure 5.

Pulse Output

V

=–1.2V

GT

1000

7 (12)

Page 8

U2010B

m

p

t ( s )

95 10339

m

7

I ( A )

400

Output Pulse Width

D

t

/DCö=9ms/nF

p

300

200

100

0

01020

Cö = ( nF )

Figure 6.

50

Soft Start

V

=–13V

S

40

V

6=V8

30

Reference Point Pin 8

20

0

40

80

m

5

I ( A )

120

Mains Supply

Compensation

160

Pins 1 and 2 open

V

=–13V

s

30

200

–2 –1 0 1

95 10342

Reference Point

Pin 10

2

I15 ( mA )

Figure 9.

200

Load Current

Detection

V

160

6=VRef=V8

VS=–13V

V

=0V

15=V10

120

m

5

I ( A )

80

Reference Point

Pin 8

95 10340

7

V ( V )

95 10341

10

0

0 2.5 5.0 7.5

V7 ( V )

Figure 7.

12

10

1mF

8

2.2mF 4.7mF

6

4

2

0

02468

Reference Point Pin 8

Cö=10mF

Soft Start

V

=–13V

S

V

6=V8

t ( s )

Figure 8.

40

0

10

95 10343

–400 –200 0 200

V

( mV )

(R6)

400

Figure 10.

20

Load Current limitation:

Auto Start Operation

V

=–13V

16

S

Pin 9 open

Reference Points: V

=Pin 10, V6=Pin 8

13

12

13–10

–V ( V )

8

4

V

10

95 10344

02468

0

T25

V

T100

10

V

( V )

6–8

Figure 11.

8 (12)

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

Page 9

U2010B

11–12

V ( V )

95 10345

13–10

–V ( V )

10

High Load Output ( 70% )

I

=–3mA

12

8

6

4

Reference Point Pin 8

2

0

012 34

V6 ( V )

Figure 12.

12

Load Current limitation:

Current Control Operation

10

VS=–13V

8

V

9=V8

Reference Points:

V

=Pin 10

6

13

V

=Pin 8

6

4

V

T70

56

10

Power Dissipation at Series Resistance R

1

8

6

V

P ( W )

4

2

0

7

95 10348

010203040

R1 ( kW )

50

Figure 15.

10

Power Dissipation at Series Resistance

8

6

V

P ( W )

4

95 10346

13–10

V ( V )

95 10347

2

V

0

T100

02468

t ( s )

Figure 13.

20

Load Current limitation:

V

=–13V

S

16

V

9=V10

Reference Points: V13=Pin 10, V6=Pin 8

a

max

Operation

12

8

4

V

0

T100

02468

V

( V )

6–8

Figure 14.

2

0

10

95 10350

03 6 912

IS ( mA )

15

Figure 16.

100

80

W

60

1max

R (k )

40

20

0

10

95 10349

02468

Max. Series Resistance

V

=230V

X

M

IS ( mA )

10

Figure 17.

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

9 (12)

Page 10

U2010B

Application Circuit

1

m

C

3

D

1

D

/2 W

W

18 k

96 11649

LED

BYT51K

8

R

W

470 k

1

R

22 F

max

a

W

1 M

2

R

10

S

V

Overload

max

a

9

R

14 13 12 11

15

W

GND

Supply

voltage

High load

compensation

Mains voltage

Voltage

detector

A

100% 70%

max

a

B

C

A

1

S

9

B

Auto–

start

overload

Programmable

+

2

Output

1

–

Phase

control unit

C

max

I

protection

rectifier

Full wave

4

= f(V )

ö

12

W

R

BC308

220 k

T1

2

D

1N4148

voltage

Reference

m

2

C

4.7 F

Soft

Voltage

monitoring

start

11

R

threshold

Overload

W

1 M

5

C

m

m

0.1 F

0.15 F

shift

Level

3 5 67 8

3

C

1

P

4

C

10 nF

6

C

7

C

Set point

W

50 k

10

R

m

1 F

m

1 F

R

W

100 k

13

W

100 k

W

R78.2 k

Load current

compensation

230 V ~

10 (12)

330 k

24

Load

detector

Limiting

Automatic

retriggering

Current

detector

16

W

3

R

Load

TIC

226

180

L

current

detector

1

250 mV

W

4

R

3.3 k

"

=

(R6)

^

V

6

R

W

5

R

3.3 k

N

Figure 18.

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

Page 11

Dimensions in mm

Package: DIP16

U2010B

94 9128

Package: SO16

94 8875

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

11 (12)

Page 12

U2010B

Ozone Depleting Substances Policy Statement

It is the policy of TEMIC TELEFUNKEN microelectronic GmbH to

1. Meet all present and future national and international statutory requirements.

2. Regularly and continuously improve the performance of our products, processes, distribution and operating systems

with respect to their impact on the health and safety of our employees and the public, as well as their impact on

the environment.

It is particular concern to control or eliminate releases of those substances into the atmosphere which are known as

ozone depleting substances (ODSs).

The Montreal Protocol ( 1987) and its London Amendments (1990 ) intend to severely restrict the use of ODSs and

forbid their use within the next ten years. Various national and international initiatives are pressing for an earlier ban

on these substances.

TEMIC TELEFUNKEN microelectronic GmbH semiconductor division has been able to use its policy of

continuous improvements to eliminate the use of ODSs listed in the following documents.

1. Annex A, B and list of transitional substances of the Montreal Protocol and the London Amendments respectively

2. Class I and II ozone depleting substances in the Clean Air Act Amendments of 1990 by the Environmental

Protection Agency (EPA) in the USA

3. Council Decision 88/540/EEC and 91/690/EEC Annex A, B and C (transitional substances) respectively.

TEMIC can certify that our semiconductors are not manufactured with ozone depleting substances and do not contain

such substances.

We reserve the right to make changes to improve technical design and may do so without further notice.

Parameters can vary in different applications. All operating parameters must be validated for each customer

application by the customer. Should the buyer use TEMIC products for any unintended or unauthorized

application, the buyer shall indemnify TEMIC against all claims, costs, damages, and expenses, arising out of,

directly or indirectly, any claim of personal damage, injury or death associated with such unintended or

unauthorized use.

12 (12)

TEMIC TELEFUNKEN microelectronic GmbH, P.O.B. 3535, D-74025 Heilbronn, Germany

Telephone: 49 (0)7131 67 2831, Fax number: 49 (0)7131 67 2423

TELEFUNKEN Semiconductors

Rev . A1, 28-May-96

Loading...

Loading...