Datasheet TS68020VF16, TS68020MRB-C25, TS68020MRB-C20, TS68020MRB-C16, TS68020MR25 Datasheet (ATMEL)

...

1

Features

• Object Code Compatible with Earlier TS68000 Microprocessors

• Addressing Mode Extensions for Enhanced Support of High Level Languages

• New Bit Field Data Type Accelerates Bit-oriented Application, i.e. Video Graphics

• Fast on-chip Instruction Cache Speed Instructions and Improves Bus Bandwidth

• Co-processor Interface to Companion 32-bit Peripherals: TS68881 and TS68882

Floating Point Co-processors

• Pipelined Architecture with High Degree of Internal Parallelism Allowing Multiple

Instructions to be Executed Concurrently

• High Performance Asynchronous Bus in Non-multiplexed and Full 32 Bits

• Dynamic Bus Sizing Efficiently Supports 8-, 16-, 32-bit Memories and Peripherals

• Full Support of Virtual Memory and Virtual Machine

• Sixteen 32-bit General-purpose Data and Address Registers

• Two 32-bit Supervisor Stack Pointers and 5 Special Purpose Control Registers

• 18 Addressing Modes and 7 Data Types

• 4-Gbyte Direct Addressing Range

• Processor Speed: 16.67 MHz - 20 MHz - 25 MHz

• Power Supply: 5.0 V

DC

± 10%

Description

The TS68020 is the first full 32-bit implementation of the TS68000 family of microprocessors. Using HCMOS technology, the TS68020 is implemented with 32-bit registers

and data paths, 32-bit addresses, a rich instruction set, and versatile addressing

modes.

Screening/Quality

This product is manufactured in full compliance with either:

• MIL-STD-883 (class B)

• DESC 5962 - 860320

• or according to Atmel standards

See “Ordering Information” on page 43.

Pin connection: see page 3.

Rsuffix

PGA 114

Ceramic Pin Grid Array

Fsuffix

CQFP 132

Ceramic Quad Flat Pack

HCMOS 32-bit

Virtual Memory

Microprocessor

TS68020

Rev. 2115A–HIREL–07/0 2

2

TS68020

2115A–HIREL–07/02

Introduction The TS68020 is a high-performance 32-bit microprocessor. It is the first microprocessor

to have evolved from a 16-bit machine to a full 32-bit machine that provides 32-bit

address and data buses as well as 32-bit internal structures. Many techniques were utilized to improve performance and at the same time maintain compatibility with other

processors of the TS68000 Family. Among the improvements are new addressing

modes which better support high-level language structures, an expanded instruction set

which provides 32-bit operations for the limited cases not supported by the TS68000

and several new instructions which support new data types. For special-purpose applications when a general-purpose processor alone is not adequate, a co-processor

interface is provided.

The TS68020 is a high-performance microprocessor implemented in HCMOS, low

power, small geometry process. This process allows CMOS and HMOS (high density

NMOS) gates to be combined on the same device. CMOS structures are used where

speed and low power is required, and HMOS structures are used where minimum silicon area is desired. This technology enables the TS68020 to be very fast while

consuming less power (less than 1.5 watts) and still have a reasonably small die size. It

utilizes about 190.000 transistors, 103.000 of which are actually implemented. The

package is a pin-grid array (PGA) with 114 pins, arranged 13 pins on a side with a

depopulated center and 132 pins ceramic quad flat pack.

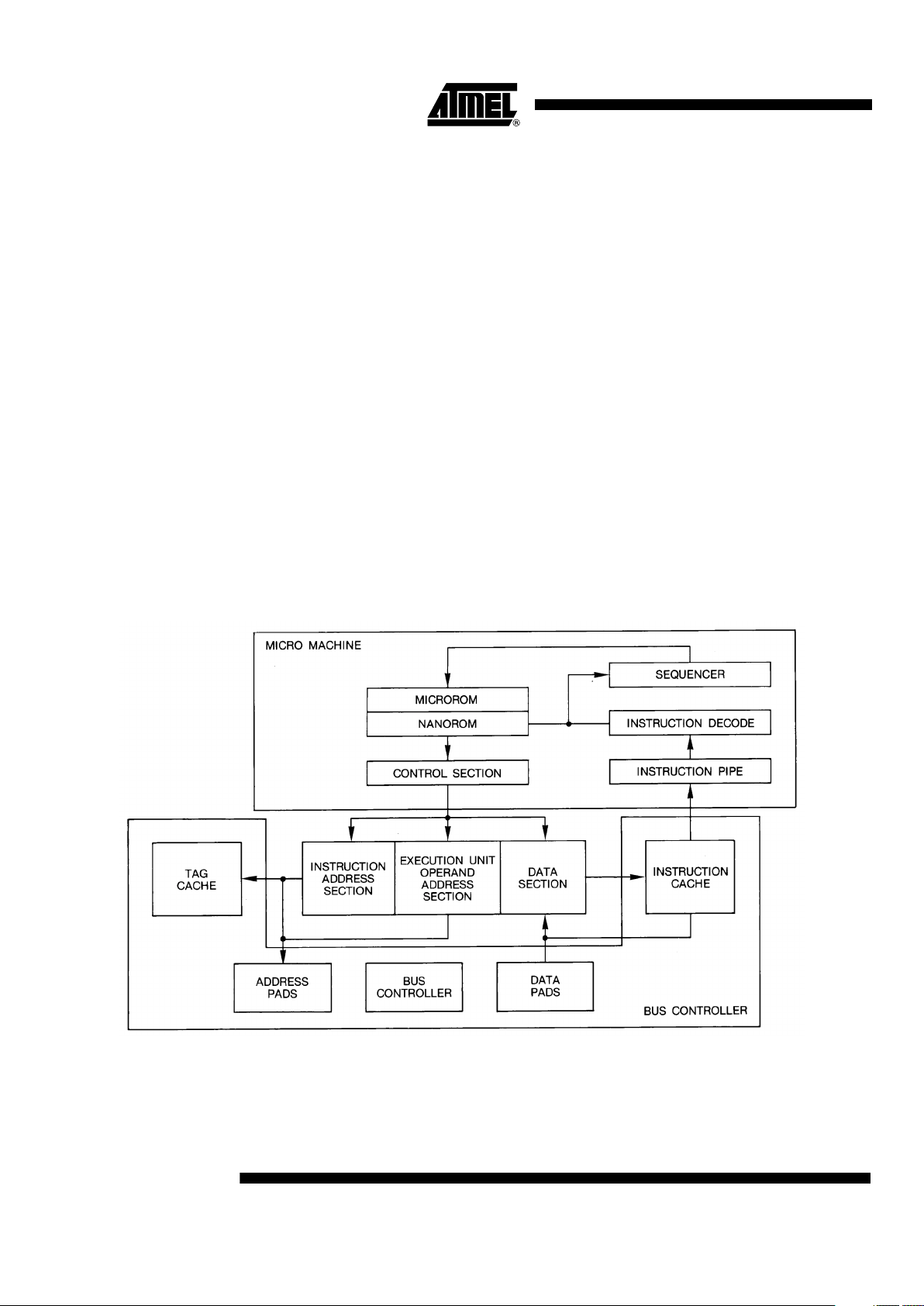

Figure 1 is a block diagram of the TS68020. The processor can be divided into two main

sections: the bus controller and the micromachine. This division reflects the autonomy

with which the sections operate.

Figure 1. TS68020 Block Diagram

The bus controller consists of the address and data pads and multiplexers required to

support dynamic bus sizing, a macro bus controller which schedules the bus cycles on

the basis of priority with two state machines (one to control the bus cycles for operated

accesses and the other to control the bus cycles for instruction accesses), and the

instruction cache with its associated control.

3

TS68020

2115A–HIREL–07/02

The micromachine consists of an execution unit, nanorom and microrom storage, an

instruction decoder, an instruction pipe, and associated control sections. The execution

unit consists of an address section, an operand address section, and a data section.

Microcode control is provided by a modified two-level store of microrom and nanorom.

Programmed logical arrays (PLAs) are used to provide instruction decode and sequencing information. The instruction pipe and other individual control sections provide the

secondary decode of instructions and generated the actual control signals that result in

the decoding and interpretation of nanorom and micorom information.

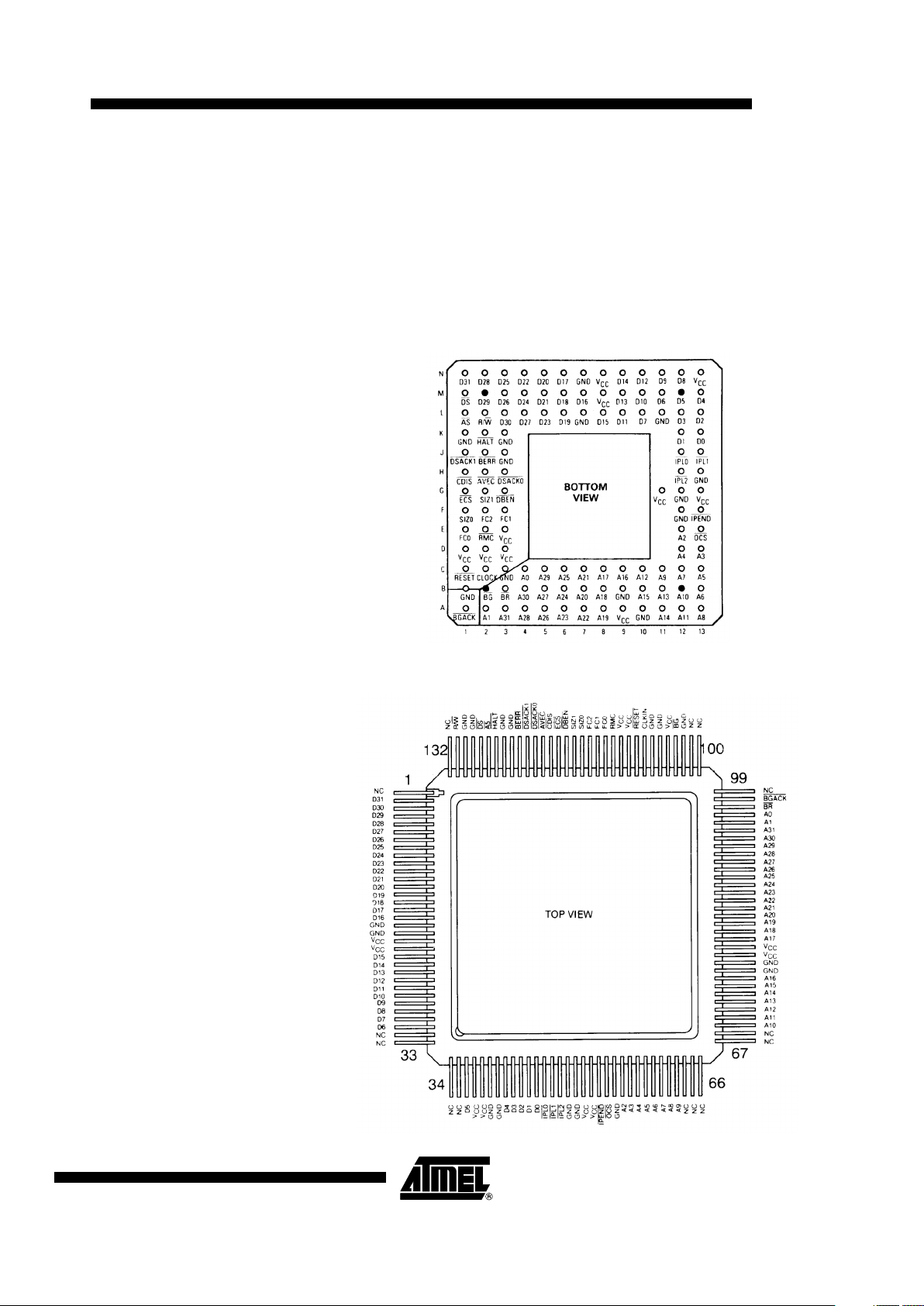

Figure 2. PGA Terminal Designation

Figure 3. CQFP Terminal Designation

4

TS68020

2115A–HIREL–07/02

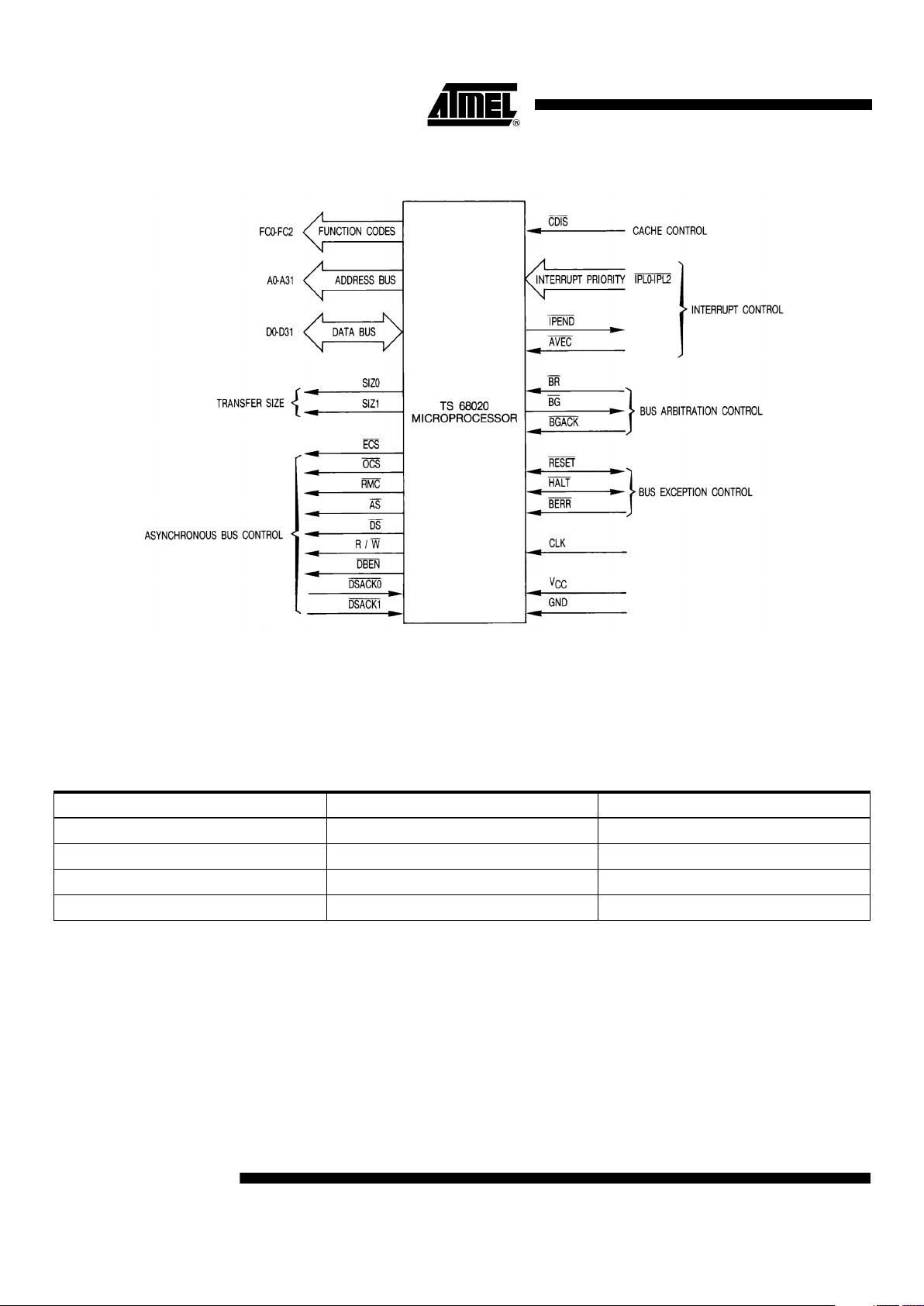

Figure 4. Functional Signal Groups

Signal Description Figure 4 illustrates the functional signal groups and Table 1 lists the signals and their

function.

The V

CC

and GND pins are separated into four groups to provide individual power supply connections for the address bus buffers, data bus buffers, and all other output

buffers and internal logic.

Group V

CC

GND

Address Bus A9, D3 A10, B9,C3, F12

Data Bus M8, N8, N13 L7, L11, N7, K3

Logic D1, D2, E3, G11, G13 G12, H13, J3, K1

Clock — B1

5

TS68020

2115A–HIREL–07/02

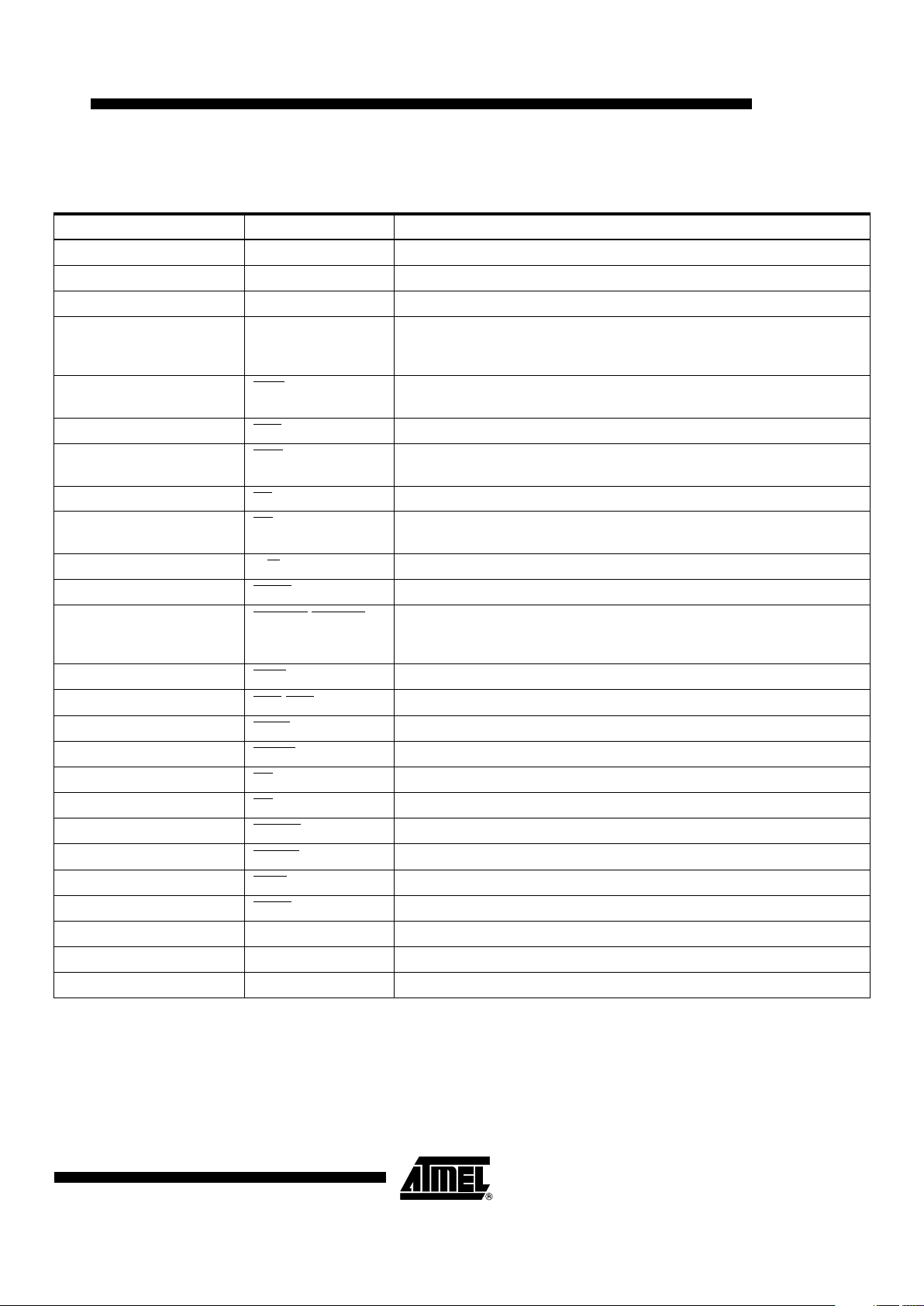

Table 1 . Signal Index

Signal Name Mnemonic Function

Address Bus A0-A31 32-bit Address Bus Used to address any of 4, 294, 967, 296 bytes.

Data Bus D0-D31 32-bit Data Bus Used to Transfer 8, 16, 24 or 32 bits of Data Per Bus Cycle.

Function Codes FC0-FC2 3-bit Function Case Used to Identify the Address Space of Each Bus Cycle.

Size SIZ0/SIZ1 Indicates the Number of Bytes Remaining to be Transferred for this Cycle.

These Signals, Together with A0 And A1, Define the Active Sections of the

Data Bus.

Read-Modify-Write Cycle RMC

Provides an Indicator that the Current Bus Cycle is Part of an Indivisiblereadmodify-write Operation.

External Cycle Start ECS

Provides an Indication that a Bus Cycle is Beginning.

Operand Cycle Start OCS

Identical Operation to that of ECS Except that OCS Is Asserted Only During

the First Bus Cycle of an Operand Transfer.

Address Strobe AS

Indicates that a Valid Address is on The Bus.

Data Strobe DS

Indicates that Valid Data is to be Placed on the Data Bus by an External

Device or has been Laced on the Data Bus by the TS68020.

Read/Write R/W

Defines the Bus Transfer as an MPU Read or Write.

Data Buffer Enable DBEN

Provides an Enable Signal for External Data Buffers.

Data Transfer and Size

Acknowledge

DSACK0

/DSACK1 Bus Response Signals that Indicate the Requested Data Transfer Operation

is Completed. In Addition, these Two Lines Indicate the Size of the External

Bus Port on a Cycle-by-cycle Basis.

Cache Disable CDIS

Dynamically Disables the On-chip Cache to Assist Emulator Support.

Interrupt Priority Level IPL0

-IPL2 Provides an Encoded Interrupt Level to the Processor.

Autovector AVEC

Requests an Autovector During an Interrupt Acknowledge Cycle.

Interrupt Pending IPEND

Indicates that an Interrupt is Pending.

Bus Request BR

Indicates that an External Device Requires Bus Mastership.

Bus Grant BG

Indicates that an External Device may Assume Bus Mastership.

Bus Grant Acknowledge BGACK

Indicates that an External Device has Assumed Bus Mastership.

Reset RESET

System Reset.

Halt HALT

Indicates that the Processor Should Suspend Bus Activity.

Bus Error BERR

Indicates an Invalid or Illegal Bus Operation is Being Attempted.

Clock CLK Clock Input to the Processor.

Power Supply V

CC

+5-volt ± 10% Power Supply.

Ground GND Ground Connection.

6

TS68020

2115A–HIREL–07/02

Detailed

Specifications

Scope

This drawing describes the specific requirements for the microprocessor 68020,

16.67 MHz, 20 MHz and 25 MHz, in compliance with the MIL-STD-883 class B.

Applicable

Documents

MIL-STD-883 • MIL-STD-883: Test Methods and Procedures for Electronics

• MIL-PRF-38535 appendix A: General Specifications for Microcircuits

• Desc Drawing 5962 - 860320xxx

Requirements

General The microcircuits are in accordance with the applicable document and as specified

herein.

Design and Construction

Terminal Connections Depending on the package, the terminal connections shall be as shown in Figure 2 and

Figure 3.

Lead Material and Finish Lead material and finish shall be any option of MIL-STD-1835.

Package The macrocircuits are packages in hermetically sealed ceramic packages which are

conform to case outlines of MIL-STD-1835 (when defined):

• 114-pin SQ.PGA UP PAE Outline

• 132-pin Ceramic Quad Flat Pack CQFP

The precise case outlines are described on Figure 23 and Figure 24.

7

TS68020

2115A–HIREL–07/02

Electrical Characteristics

Note: 1. Load network number 1 to 4 as specified (Table 7) gives the maximum loading of the relevant output.

Table 2 . Absolute Maximum Ratings

Symbol Parameter Test Conditions Min Max Unit

V

CC

Supply Voltage -0.3 +7.0 V

V

I

Input Voltage -0.5 +7.0 V

P

dmax

Max Power Dissipation

T

case

=-55°C2.0W

T

case

= +125°C1.9W

T

case

Operating Temperature

M Suffix -55 +125

°C

V Suffix -40 +85

°C

T

stg

Storage Temperature -55 +150 °C

T

leads

Lead Temperature Max 5 Sec. Soldering +270 °C

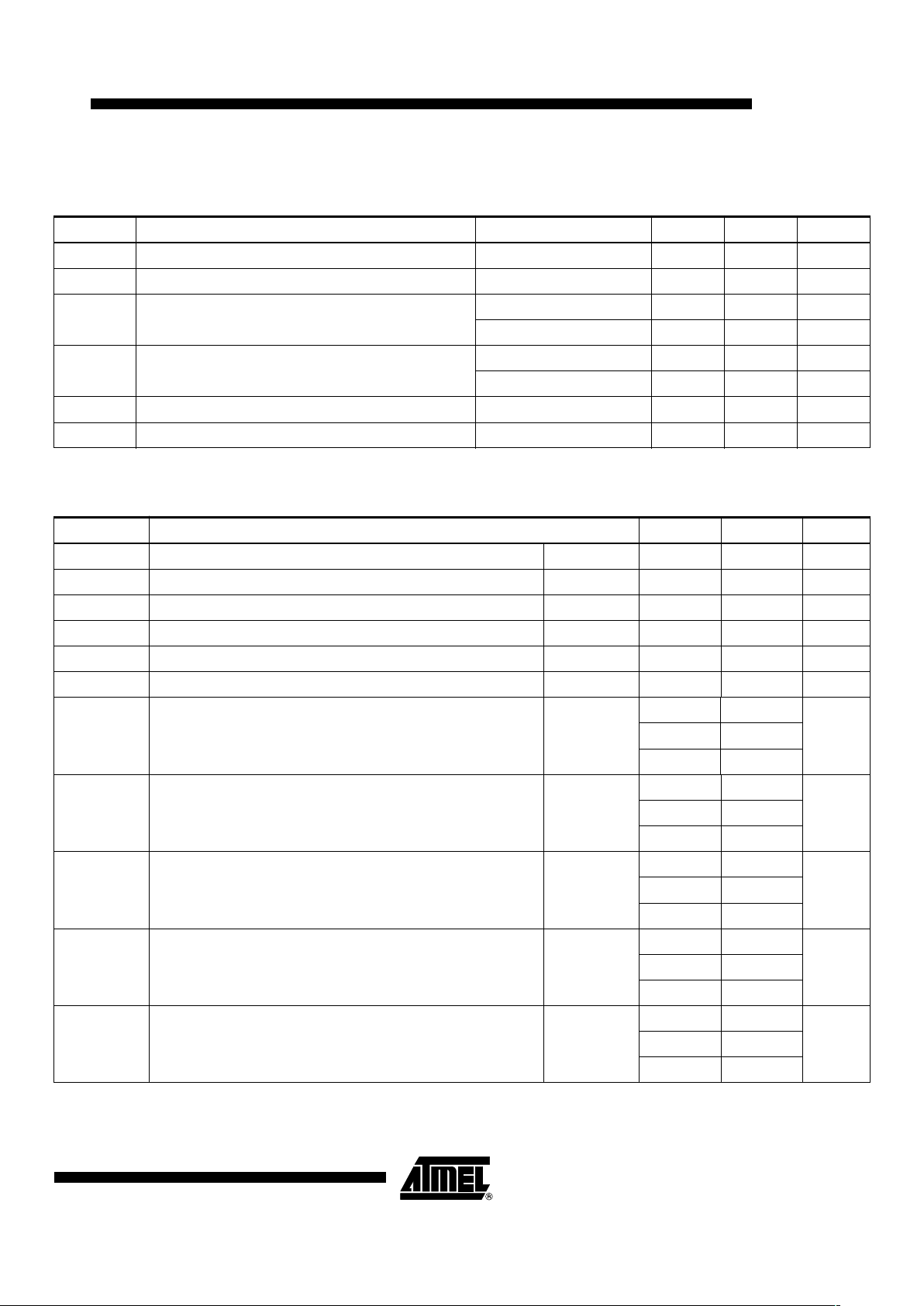

Table 3 . Recommended Condition of Use

Unless otherwise stated, all voltages are referenced to the reference terminal (see Table 1).

Symbol Parameter Min Max Unit

V

CC

Supply Voltage 4.5 5.5 V

V

IL

Low Level Input Voltage -0.3 0.5 V

V

IH

High Level Input Voltage 2.4 5.25 V

T

case

Operating Temperature -55 +125 °C

R

L

Value of Output Load Resistance

(1)

Ω

C

L

Output Loading Capacitance

(1)

pF

t

r

(c)–tf(c) Clock Rise Time (See Figure 5)

68020-16 5

ns68020-20 5

68020-25 4

f

c

Clock Frequency (See Figure 5)

68020-16 8 16.67

MHz68020-20 12.5 20

68020-25 12.5 25

t

cyc

CycleTime(seeFigure5)

68020-16 60 125

ns68020-20 50 80

68020-25 40 80

t

W

(CL) Clock Pulse Width Low (See Figure 5)

68020-16 24 95

ns68020-20 20 54

68020-25 19 61

t

W

(CH) ClockPulseWidthHigh(SeeFigure5)

68020-16 24 95

ns68020-20 20 50

68020-25 19 61

8

TS68020

2115A–HIREL–07/02

This device contains protective circuitry against damage due to high static voltages or

electrical fields; however, it is advised that normal precautions be taken to avoid application of any voltages higher than maximum-rated voltages to this high-impedance circuit.

Reliability of operation is enhanced if unused inputs are tied to an appropriate logic voltage level (e.g., either GND or V

CC

).

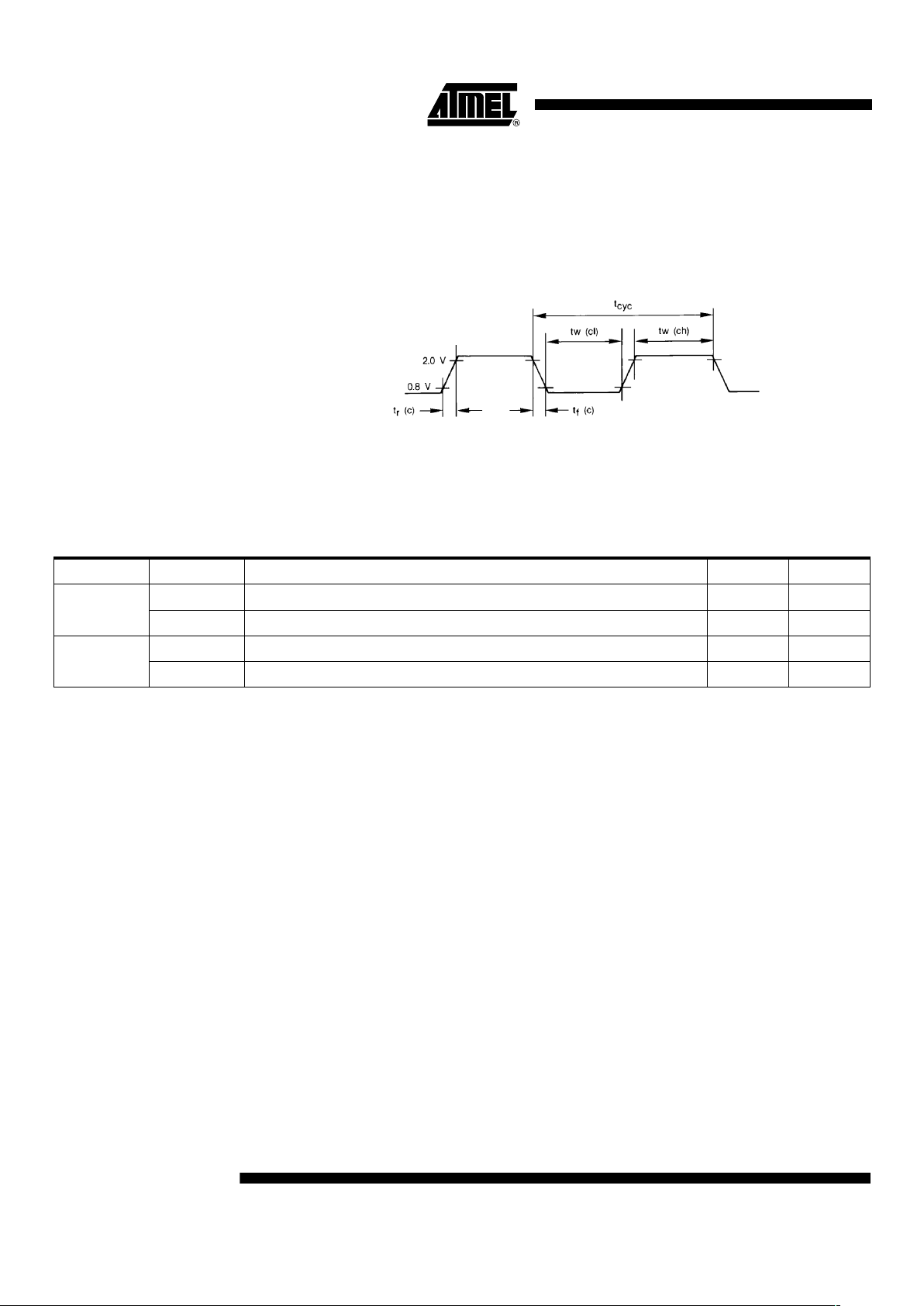

Figure 5. Clock Input Timing Diagram

Note: Timing measurements are referenced to and from a low voltage of 0.8V and a high volt-

age of 2.0V, unless otherwise noted. The voltage swing through this range should start

outside and pass through the range such that the rise or fall will be linear between 0.8V

and 2.0V.

Power Considerations The average chip-junction temperature, T

J,

in °C can be obtained from:

T

J=TA

+(PD· θJA)(1)

T

A

= Ambient Temperature, °C

θ

JA

= Package Thermal Resistance, Junction-to-Ambient, °C/W

P

D=PINT+PI/O

P

INT=ICC·VCC

, Watts — Chip Internal Power

P

I/O

= Power Dissipation on Input and Output Pins — User Determined

For most applications P

I/O<PINT

and can be neglected.

An approximate relationship between P

D

and TJ(if P

I/O

is neglected) is:

P

D

=K+(TJ+ 273) (2)

Solving equations (1) and (2) for K gives:

K=P

D

·(TA+273)+θJA·P

D

2

(3)

where K is a constant pertaining to the particular part K can be determined from equation (3) by measuring P

D

(at equilibrium) for a known TA. Using this value of K, the

values of P

D

and TJcan be obtained by solving equations (1) and (2) iterativley for any

value of T

A

.

Table 4 . Thermal Characteristics at 25°C

Package Symbol Parameter Value Unit

PGA 114

θ

JA

Thermal Resistance - Ceramic Junction to Ambient 26 °C/W

θ

JC

Thermal Resistance - Ceramic Junction to Case 5 ° C/W

CQFP 132

θ

JA

Thermal Resistance - Ceramic Junction to Ambient 34 °C/W

θ

JC

Thermal Resistance - Ceramic Junction to Case 2 ° C/W

9

TS68020

2115A–HIREL–07/02

The total thermal resistance of a package (θJA) can be separated into two components,

θ

JC

and θCA, representing the barrier to heat flow from the semiconductor junction to the

package (case), surface (θ

JC

) and from the case to the outside ambient (θCA). These

terms are related by the equation:

θ

JA

= θJC= θ

CA

(4)

θ

JC

is device related and cannot be influenced by the user. However, θCAis user dependent and can be minimized by such thermal management techniques as heat sinks,

ambient air cooling and thermal convection. Thus, good thermal management on the

part of the user can significantly reduce θ

CA

so that θJAapproximately equals θJC. Substi-

tution of θ

JC

for θJAin equation (1) will result in a lower semiconductor junction

temperature.

Mechanical and

Environment

The microcircuits shall meet all mechanical environmental requirements of MIL-STD883 for class B devices.

Marking The document where are defined the marking are identified in the related reference doc-

uments. Each microcircuit are legible and permanently marked with the following

information as minimum:

• ATMEL Logo

• Manufacturer’s Part Number

• Class B Identification

• Date-code of Inspection Lot

• ESD Identifier if Available

• Country of Manufacturing

Quality Conformance

Inspection

DESC/MIL-STD-883 Is in accordance with MIL-M-38510 and method 5005 of MIL-STD-883. Group A and B

inspections are performed on each production lot. Group C and D inspections are performed on a periodical basis.

Electrical

Characteristics

General Requirements All static and dynamic electrical characteristics specified and the relevant measurement

conditions are given below.

(last issue on request to our marketing services).

Table 5: Static electrical characteristics for all electrical variants.

Table 6: Dynamic electrical characteristics for 68020-16 (16.67 MHz), 68020-20 (20

MHz) and 68020-25 (25 MHz).

For static characteristics, test methods refer to “Test Conditions Specific to the Device”

on page 14 hereafter of this specification (Table 7).

10

TS68020

2115A–HIREL–07/02

For dynamic characteristics (Table 6), test methods refer to IEC 748-2 method, where

existing.

Indication of “min.” or “max.” in the column “test temperature” means minimum or maximum operating temperature.

.

Table 5 . Static Characteristics. VCC=5.0VDC± 10%; GND = 0VDC;Tc= -55/+125°Cor-40/+85°C (Figure 4 to Figure 8)

Symbol Parameter Condition Min Max Units

I

CC

Maximum Supply Current VCC=5.5V

T

case

-55°Cto+25°C

333 mA

I

CC

Maximum Supply Current VCC=5.5V

T

case

=125°C

207 mA

V

IH

High Level Input Voltage VO= 0.5V or 2.5

V

CC

= 4.5V to 5.5V

2.0 V

CC

V

V

IL

Low Level Input Voltage VO= 0.5V or 2.4V

V

CC

= 4.5V to 5.5V

-0.5 0.8 V

V

OH

High Level Output Voltage

All Outputs

IOH= 400 µA 2.4 V

V

OL

Low Level Output Voltage

Outputs A0-A31, FC0-FC2, D0-D31, SIZ0-SIZ1, BG

IOL=3.2mA

Load Circuit as

Figure 8

R=1.22kΩ

0.5 V

V

OL

Low Level Output Voltage

Outputs AS

,DS,RMC,R/W, DBEN, IPEND

IOL=5.3mA

Load Circuit as

Figure 8

R=740Ω

0.5 V

V

OL

Low Level Output Voltage

Outputs ECS

,OCS

IOL=2.0mA

Load Circuit as

Figure 8

R=2kΩ

0.5 V

V

OL

Low Level Output Voltage

Outputs HALT

, RESET

IOL= 10.7 mA

Load Circuit as Figure 6

and Figure 7

0.5 V

|I

IN

| Input Leakage Current (High and Low State) -0.5V ≤ VIN≤ VCC(Max) 2.5 µA

|I

OHZ

| High level leakage current at three-state outputs

Outputs A0-A31, AS

, DBEN,DS, D0-D31, R/W, FC0-FC2,

RMC

,SIZ0-SIZ1

V

OH

=2.4V 2.5 µA

|I

OLZ

| Low Level Leakage Current at Three-state Outputs

Outputs A0-A31, AS

, DBEN,DS,D0-D31R/W, FC0-FC2, RMC,

SIZ0-SIZ1

V

OL

= 0.5V 2.5 µA

I

OS

Output Short-circuit Current

(Any Output)

VCC=5.5V

V

O

=0V

(Pulsed. Duration 1 ms

Duty Cycle 10:1)

200 mA

11

TS68020

2115A–HIREL–07/02

Dynamic (Switching)

Characteristics

The limits and values given in this section apply over the full case temperature range 55°C to +125°CandV

CC

in the range 4.5V to 5.5V VIL=0.5VandVIH=2.4V(Seealso

note 12 and 13). The INTERVAL numbers refer to the timing diagrams. See Figure 5,

Figure 9 and Figure 12.

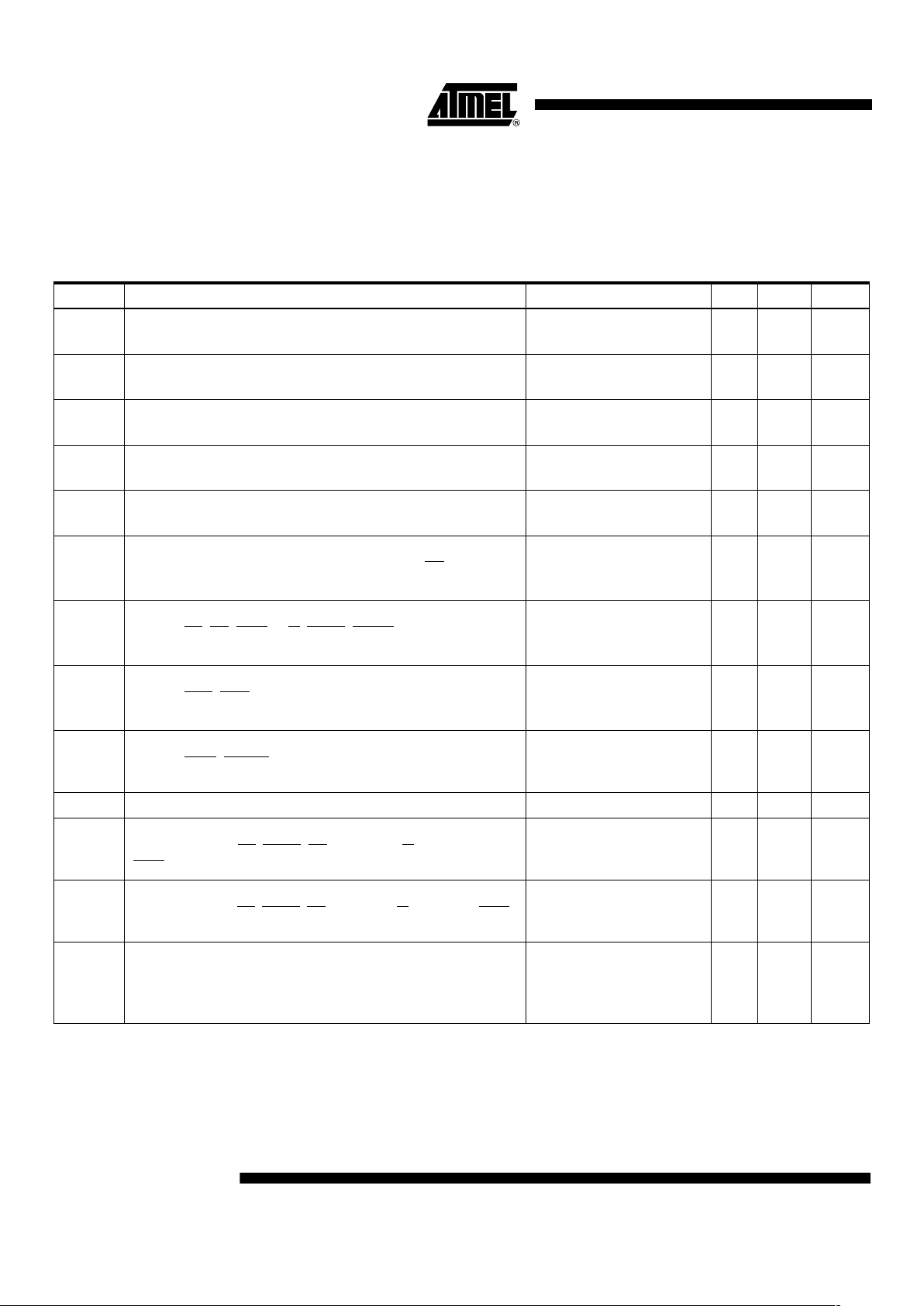

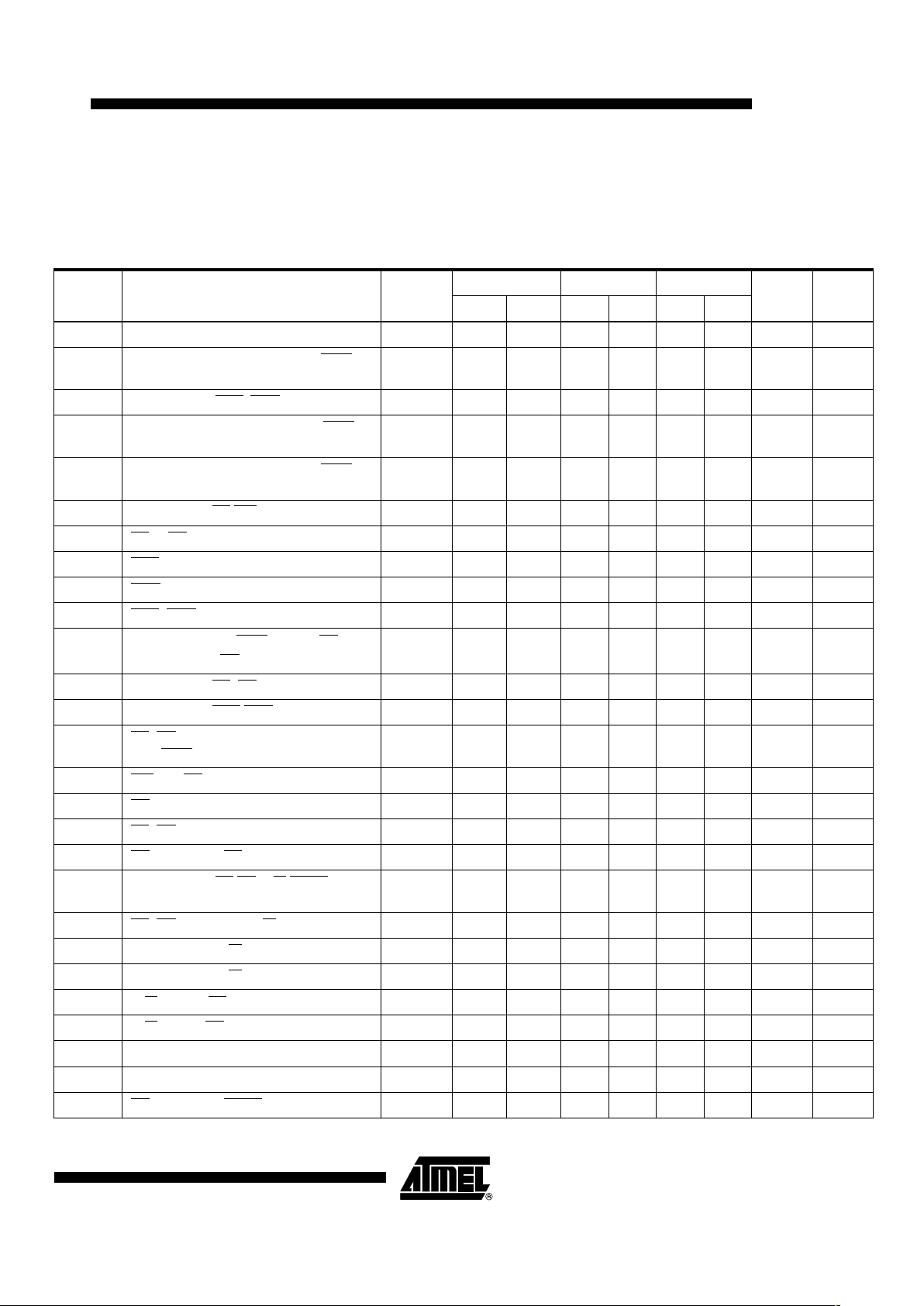

Table 6 . Dynamic Electrical Characteristics

Symbol Parameter

Interval

Number

68020-16 68020-20 68020-25

Unit NotesMin Max Min Max Min Max

t

CPW

Clock Pulse Width 2 , 3 24 95 20 54 19 61 ns

t

CHAV

Clock High to Address/FC/Size/RMC

Valid

6 0 30 025025 ns

t

CHEV

Clock High to ECS,OCSAsserted 6A 0 20015012ns

t

CHAZX

Clock High to Address/Data/FC/RMC/

Size High Impedance

7 0 60 050040 ns

(11)

t

CHAZn

Clock High to Address/FC/Size/RMC

Invalid

80 0 0 ns

t

CLSA

Clock Low to AS,DSAsserted 9 3 30 325318 ns

t

STSA

AS to DS Assertion (Read)(Skew) 9A -15 15 -10 10 -10 10 ns

(1)

t

ECSA

ECS Width Asserted 10 20 15 15 ns

t

OCSA

OCS Width Asserted 10A 20 15 15 ns

t

EOCSN

ECS,OCSWidth Negated 10B 15 10 5 ns

(11)

t

AVSA

Address/FC/Size/RMC ValidtoAS

Asserted (and DS Asserted, Read)

11 15 10 6 ns

(6)

t

CLSN

Clock Low to AS,DSNegated 12 0 30 0 25 0 15 ns

t

CLEN

Clock Low to ECS/OCS Negated 12A 0 30 0 25 0 15 ns

t

SNAI

AS,DS Negated to Address/FC/

Size/RMC

Invalid

13 15 10 10 ns

t

SWA

AS (and DS, Read) Width Asserted 14 100 85 70 ns

t

SWAW

DS Width Asserted, Write 14A 40 38 30 ns

t

SN

AS,DSWidth Negated 15 40 38 30 ns

(11)

t

SNSA

DS NegatedtoASAsserted 15A 35 30 25 ns

(8)

t

CSZ

Clock High to AS/DS/R/W/DBEN High

Impedance

16 60 50 40 ns

(11)

t

SNRN

AS,DS Negated to R/W High 17 15 10 10 ns

(6)

t

CHRH

Clock High to R/W High 18 0 30 0 25 0 20 ns

t

CHRL

Clock High to R/W Low 20 0 30 025020 ns

t

RAAA

R/W High to AS Asserted 21 15 10 5 ns

(6)

t

RASA

R/W Low to DS Asserted (Write) 22 75 60 50 ns

(6)

t

CHDO

Clock High to Data Out Valid 23 30 25 25 ns

t

SNDI

AS, DS Negated to Data Out Valid 25 15 10 5 ns

(6)

t

DNDBN

DS NegatedtoDBENNegated (Write) 25A 15 10 5 ns

(9)

12

TS68020

2115A–HIREL–07/02

t

DVS A

Data Out Valid to DS Asserted (Write)

26

26 15 10 5 ns

(6)

t

DICL

Data in Valid to Clock Low (Data Setup) 27 5 5 5 ns

t

BELCL

Late BERR/HALT Asserted to Clock

Low Setup Time

27A 20 15 10 ns

t

SNDN

AS,DS Negated to

DSACK

x/BERR/HALT/AVEC Negated

28 0 80065050ns

t

SNDI

DS Negated to Data On Invalid (Data in

Hold Time)

29 0 0 0 ns

(6)

t

SNDIZ

DS Negated to Data in High Impedance 29A 60 50 40 ns

t

DADI

DSACKx Asserted to Data In Valid 31 50 43 32

(2)(1 1)

t

DADV

DSACK Asserted to DSACKx Val id

(DSACK

Asserted Skew)

31A 15 10 10 ns

(3)(1 1)

t

HRrf

RESET Input Transition Time 32 1.5 1.5 1.5 Clks

t

CLBA

Clock Low to BG Asserted 33 0 30 0 25 0 20 ns

t

CLBN

Clock Low to BG Negated 34 0 30 0 25 0 20 ns

t

BRAGA

BR Asserted to BG Asserted (RMC Not

Asserted)

35 1.5 3.5 1.5 3.5 1.5 3.5 Clks

(11)

t

GAGN

BGACK Asserted to BG Negated 37 1.5 3.5 1.5 3.5 1.5 3.5 Clks

(11)

t

GABRN

BGACK Asserted to BR Negated 37A 0 1.5 0 1.5 0 1.5 Clks

(11)

t

GN

BG Width Negated 39 90 75 60 ns

(11)

t

GA

BG Width Asserted 39A 90 75 60 ns

t

CHDAR

Clock High to DBEN Asserted (Read) 40 0 30 0 25 0 20 ns

t

CLDNR

Clock Low to DBEN Negated (Read) 41 0 30 0 25 0 20 ns

t

CLDAW

Clock Low to DBEN Negated (Read) 42 0 30 0 25 0 20 ns

t

CHDNW

Clock High to DBEN Asserted (Read) 43 0 30 0 25 0 20 ns

t

RADA

R/W Low to DBEN Asserted (Write) 44 15 10 10 ns

(6)

t

DA

DBEN Width Asserted

READ

WRITE

45

60

120

50

100

40

80

ns

ns

(5)

(5)

t

RWA

R/W Width Asserted (Write or Read) 46 150 125 100 ns

t

AIST

Asynchronous Input Setup Time 47A 5 5 5 ns

(11)

t

AIHT

Asynchronous Input Hold Time 47B 15 15 10 ns

(11)

t

DABA

DSACKx Asserted to BERR/HALT

Asserted

48 30 20 18 ns

(4)(1 1)

t

DOCH

Data Out Hold from Clock High 53 0 0 0 ns

t

BNHN

BERR NegatedtoHALTNegated

(Rerun)

000ns

Table 6 . Dynamic Electrical Characteristics (Continued)

Symbol Parameter

Interval

Number

68020-16 68020-20 68020-25

Unit NotesMin Max Min Max Min Max

13

TS68020

2115A–HIREL–07/02

Notes: 1. This number can be reduced to 5 nanoseconds if the strobes have equal loads.

2. If the asynchronous setup time (= 47) requirements are satisfied, the DSACKx low to data setup time (= 31) and DSACKx

low to BERR low setup time (= 48) can be ignored. The data must only satisfy the data in to clock low setup time (= 27) for

the following clock cycle, BERR

must only satisfy the late BERR low to clock setup time (= 27) for the following clock cycle.

3. This parameter specifies the maximum allowable skew between DSACK0

to DSACK1 asserted or DSACK1 to DSACK0

asserted pattern = 47 must be met by DSACK0 and DSACK1.

4. In the absence of DSACKx

,BERRis an asynchronous input using the asynchronous input setup time (= 47).

5. DBEN

may stay asserted on consecutive write cycles.

6. Actual value depends on the clock input waveform.

7. This pattern indicates the minimum high time for ECS

and OCS in the event of an internal cache hit followed immediately by

a cache miss or operand cycle.

8. This specification guarantees operations with the 68881 co-processor, and defines a minimum time for DS negated to AS

asserted (= 13A). Without this parameter, incorrect interpretation of = 9A and = 15 would indicate that the 68020 does not

meet 68881 requirements.

9. This pattern allows the systems designer to guarantee data hold times on the output side of data buffers that have output

enable signals generated with DBEN

.

10. Guarantees that an alternate bus master has stopped driving the bus when the 68020 regains control of the bus after an

arbitration sequence.

11. Cannot be tested. Provided for system design purposes only.

12. T

case

=-55°C and +130°C in a Power off condition under Thermal soak for 4 minutes or until thermal equilibrium. Electrical

parameters are tested “instant on” 100 m sec. after power is applied.

13. All outputs unload except for load capacitance. Clock = fmax,

LOW: HALT

, RESET

HIGH: DSACK0,DSACK1, CDIS, IPL0-IPL2, DBEN, AVEC, BERR.

f Frequency of Operation 8.0 16.67 12.5 20.0 12.5 25 MHz

t

RADC

R/W Asserted to Data Bus Impedance

Change

55 30 25 20

(11)

t

HRPW

RESET Pulse Width (Reset Instruction) 56 512 512 512 Clks

(11)

t

BNHN

BERR NegatedtoHALTNegated

(Rerun)

57 0 0 0 ns

(11)

t

GANBD

BGACK Negated to Bus Driven 58 1 1 1 Clks

(10)(11)

t

GNBD

BG NegatedtoBusDriven 59 1 1 1 Clks

(10)(11)

Table 6 . Dynamic Electrical Characteristics (Continued)

Symbol Parameter

Interval

Number

68020-16 68020-20 68020-25

Unit NotesMin Max Min Max Min Max

14

TS68020

2115A–HIREL–07/02

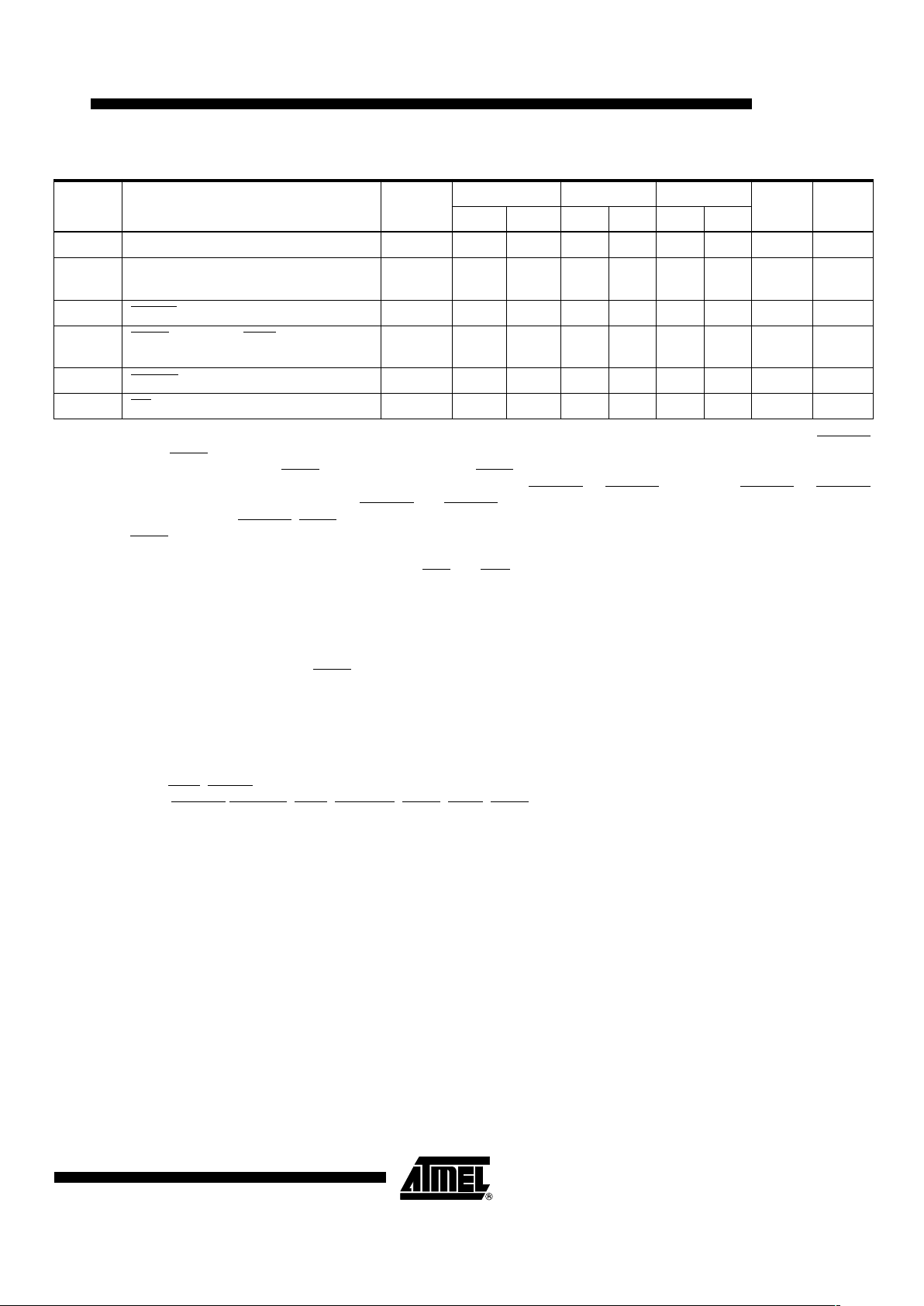

Test Conditions Specific

to the Device

Loading Network The applicable loading network shall be defined in column “Test conditions” of Table 6,

referring to the loading network number as shown in Figure 6, Figure 7, Figure 8 below.

Figure 6. RESET Test Loads

Figure 7. HALT Test Load

Figure 8. Test Load

Note: 1. Equivalent loading may be simulated by the tester.

Table 7 . Load Network

Load NBR Figure R R

L

C

L

Output Application

1 7 2 k 6.0 k 50 pF OCS

,ECS

2 7 1.22 k 6.0 k 130 pF A0-A31, D0-D31, BG, FC0-FC2, SIZ0-SIZ1

3 7 0.74 k 6.0 k 130 pF AS

,DS,R/W,RMC, DBEN, IPEND

15

TS68020

2115A–HIREL–07/02

Time Definitions The times specified in Table 6 as dynamic characteristics are defined in Figure 9 below,

by a reference number given the column “interval N°” of the tables together with the relevant figure number.

Figure 9. Read Cycle Timing Diagram

Note: Timing measurements are referenced to and from a low voltage of 0.8V and a high voltage of 2.0V, unless otherwise noted. The

voltage swing through this range should start outside and pass through the range such that the rise or fall will be linear between

0.8V and 2.0V.

16

TS68020

2115A–HIREL–07/02

Figure 10. Write Cycle Timing Diagram (Continued)

Note: Timing measurements are referenced to and from a low voltage of 0.8V and a high voltage of 2.0V, unless otherwise noted. The

voltage swing thorough this range should start outside and pass through the range such that the rise or fall will be linear

between 0.8V and 2.0V.

17

TS68020

2115A–HIREL–07/02

Figure 11. Bus Arbitration Timing Diagram

Note: Timing measurements are referenced to and from a low voltage of 0.8V and a high voltage of 2.0V, unless otherwise noted. The

voltage swing thorough this range should start outside and pass through the range such that the rise or fall will be linear

between 0.8V and 2.0V.

18

TS68020

2115A–HIREL–07/02

Input and Output Signals for

Dynamic Measurements

AC Electrical Specifications

Definitions

The AC specifications presented consist of output delays, input setup and hold times,

and signal skew times. All signals are specified relative to an appropriate edge of the

TS68020 clock input and, possibly, relative to one or more other signals.

The measurement of the AC specifications is defined by the waveforms in Figure 12. In

order to test the parameters guaranteed by Atmel, inputs must be driven to the voltage

levels specified in Figure 12. Outputs of the TS68020 are specified with minimum and/or

maximum limits, as appropriate, and are measured as shown. Inputs to the TS68020

are specified with minimum and, as appropriate, maximum setup and hold times, and

are measurement as shown. Finally, the measurements for signal-to-signal specification

are also shown.

Note that the testing levels used to verify conformance of the TS68020 to the AC specifications does not affect the guaranteed DC operation of the device as specified in the

DC electrical characteristics.

19

TS68020

2115A–HIREL–07/02

Figure 12. Drive Levels and Test Points for AC Specification

Legend:

A) Maximum Output Delay Specification

B) Minimum Output Hold Time

C) Minimum Input Setup Time Specification

D) Minimum Input Hold Time Specification

E) Signal Valid to Signal Valid Specification (Maximum or Minimum)

F) Signal Valid to Signal Invalid Specification (Maximum or Minimum)

Notes: 1. This output timing is applicable to all parameters specified relative to the rising edge of the clock.

2. This out put timing is applicable to all parameters specified relative to the falling edge of the clock.

3. This input timing is applicable to all parameters specified relative to the falling edge of the clock.

4. This input timing is applicable to all parameters specified relative to the falling edge of the clock.

5. This timing is applicable to all parameters specified relative to the assertion/negation of another signal.

20

TS68020

2115A–HIREL–07/02

Additional Information Additional information shall not be for any inspection purposes.

Power Consideration See Table 4.

Capacitance (Not for

Inspection Purposes

)

Capacitance Derating

Curves

Figure 13 to Figure 18 inclusive show the typical derating conditions which apply. The

capacitance includes any stray capacitance. The graphs may not be linear outside the

range shown.

Figure 13. Address Capacitance Derating Curve

Symbol Parameter Test Conditions Min Unit

C

in

Input Capacitance

V

in

=0VT

amb

=25°C

f=1MHz

20 pF

21

TS68020

2115A–HIREL–07/02

Figure 14. ECS and OCS Capacitance Derating Curve

Figure 15. R/W, FC, SIZ0-SIZ1, and RMC Capacitance Derating Curve

22

TS68020

2115A–HIREL–07/02

Figure 16. DS, AS, IPEND, and BG Capacitance Derating Curve

Figure 17. DBEN Capacitance Derating Curve

23

TS68020

2115A–HIREL–07/02

Figure 18. Data Capacitance Derating Curve

Functional

Description

Description of Registers As shown in the programming models (Figure 19 and Figure 20) the TS68020 has six-

teen 32-bit general-purpose registers, a 32-bit program counter, two 32-bit supervisor

stack pointers, a 16-bit status register, a 32-bit vector base register, two 3-bit alternate

function code registers, and two 32-bit cache handling (address and control) registers.

Registers D0-D7 are used as data registers for bit and bit field (1- to 32-bit), byte (8-bit),

long word (32-bit), and quad word (64-bit) operations. Registers A0-A6 and the user,

interrupt, and master stack pointers are address registers that may be used as software

stack pointers or base address registers. In addition, the address registers may be used

for word and long word operations. All of the 16 (D0-D7, A0-A7) registers may be used

as index registers.

The status register (Figure 21) contains the interrupt priority mask (three bits) as well as

the condition codes: extend (X), negated (N), zero (Z), overflow (V), and carry (C). Additional control bits indicate that the processor is in the trace mode (T1 or T0),

supervisor/user state (S), and master/interrupt state (M).

All microprocessors of the TS68000 Family support instruction tracing (via the T0 status

bit in the TS68020) where each instruction executed is followed by a trap to a userdefined trace routine. The TS68020 adds the capability to trace only the change of flow

instructions (branch, jump, subroutine call and return, etc.) using the T1 status bit.

These features are important for software program development and debug.

The vector base register is used to determine the runtime location of the exception vector table in memory, hence it supports multiple vector tables so each process or task can

properly manage exceptions independent of each other.

24

TS68020

2115A–HIREL–07/02

The TS68000 Family processors distinguish address spaces as supervisor / used and

program/data. These four combinations are specified by the function code pins

(FC0/FC1/FC2) during bus cycles, indication the particular address space. Using the

function codes, the memory sub-system can distinguish between authorized access

(supervisor mode is privileged access) and unauthorized access (user mode may not

have access to supervisor program or data areas). To support the full privileges of the

supervisor, the alternate function code registers allow the supervisor to specify an

access to user program or data areas by preloading the SFC/DFC registers

appropriately.

The cache registers (control — CACR, address — CAAR) allow software manipulation

of the on-chip instruction cache. Control and status accesses to the instruction cache

are provided by the cache control register (CACR), while the cache address register

(CAAR) holds the address for those cache control functions that require an address.

Figure 19. User Programming Model

25

TS68020

2115A–HIREL–07/02

Figure 20. Supervisor Programming Model Supplement

Figure 21. Status Register

Data Types and

Addressing Modes

Seven basic types are supported. These data types are:

•Bits

• Bits Flieds (String of consecutive bits, 1-32 bits long)

• BCD Digits (Packed: 2 digits/byte, Unpacked: 1 digit/byte)

• Byte Integers (8-bit)

• Word Integers (16-bit)

• Long Word Integers (32-bit)

• Quad Word Integers (64-bit)

In addition, operations on other data types, such as memory addresses, status word

data, etc...., are provided in the instruction set. The co-processor mechanism allows

direct support of floating-point data type with the TS68881 and TS68882 floating-point

co-processors, as well as specialized user-defined data types and functions.

26

TS68020

2115A–HIREL–07/02

The 18 addressing modes, shown in Table 8, include nine basic types:

• Register Direct

• Register Indirect

• Register Indirect with Index

• Memory Indirect

• Program Counter Indirect with Displacement

• Program Counter Indirect with Index

• Program Counter Memory Indirect

• Absolute

• Immediate

The register indirect addressing modes support postincrement, predecrement, offset,

and indexing. Programmers find these capabilities particularly useful for handling

advanced data structures common to sophisticated applications and high level languages. The program counter relative mode also has index and offset capabilities;

programmers find that this addressing mode is required to support position-independent

software. In addition to these addressing modes, the TS68020 provides data operand

sizing and scaling; these features provide performance enhancements to the

programmer.

.

Table 8 . TS68020 Addressing Modes

Addressing Modes Syntax

Register Direct

Data Register Direct

Address Register Direct

Dn

An

Register Indirect

Address Register Indirect

Address Register Indirect with Post Increment

Address Register Indirect with Predecrement

Address Register Indirect with Displacement

(An)

(An) +

–(An)

(d

16

An)

Register Indirect with Index

Address Register Indirect with Index (8-bit Displacement)

Address Register Indirect with Index (Base Displacement)

(d

8

,An,Xn)

(bd, An, Xn)

Memory Indirect

Memory Indirect Post-Indexed

Memory Indirect Pre-Indexed

([bd, An], Xn, od)

([bd, An, Xn], od)

Program Counter Indirect with Displacement (d

16

,PC)

Program Counter Indirect with Index

PC Indirect with Index (8-bit Displacement)

PC Indirect with Index (Base Displacement)

(d

8

,PC,Xn)

(bd, PC, Xn)

Program Counter Memory Indirect

PC Memory Indirect Post-Indexed

PC Memory Indirect Pre-Indexed

([bd, PC], Xn, od)

([bd, PC, Xn]), od)

27

TS68020

2115A–HIREL–07/02

Notes: 1. Dn = Data Register, D0-D7.

2. An = Address Register, A0-A7.

3. d

8,d16

= A twos-complement, or sign—extended displacement; added as part of the effective calculation; size is 8 (d8)or16

(d

16

) bits; when omitted assemblers use a value of zero.

4. Xn = Address or data register used as an index register; form is Xn, SIZE*SCALE, where SIZE is.W or.L (indicates index

register size) and SCALE is 1, 2, 4, or 8 (index register is multiplied by SCALE); use of SIZE and/or SCALE is optional.

5. bd = A two-complement base displacement; when present, size can be 16- or 32-bit.

6. od = Outer displacement, added as part of effective address calculation after any memory indirection; use is optional with a

sizeof16-or32-bit.

7. PC = Program Counter.

8. (data) = Immediate value of 8, 16 or 32 bits.

9. () = Effective Address.

10. [ ] = Use as indirect address to long word address.

Absolute

Absolute Short

Absolute Long

xxx.W

xxx.L

Immediate =data

Table 8 . TS68020 Addressing Modes (Continued)

Addressing Modes Syntax

28

TS68020

2115A–HIREL–07/02

Instruction Set Overview The TS68020 instruction set is shown in Table 9. Special emphasis has been given to

the instruction set’s support of structured high-level languages and sophisticated operating systems. Each instruction, with few exceptions, operates on bytes, words, and long

words and most instructions can use any of the 18 addressing modes. Many instruction

extensions have been made on the TS68020 to take advantage of the full 32-bit operation where, on the earlier 68000 Family members, only 8 and 16 bits values were used.

The TS68020 is upward source- and object-level code compatible with the family

because it supports all of the instructions that previous family members offer. Additional

instructions are now provided by the TS68020 in support of its advanced features.

Table 9 . Instruction Set

Mnemonic Description

ABCD

ADD

ADDA

ADDI

ADDQ

ADDX

AND

ANDI

ASL, ASR

Add Decimal with Extend

Add

Add Address

Add Immediate

Add Quick

AddwithExtend

Logical AND

Logical AND Immediate

Arithmetic Shift Left and Right

Bcc

BCHG

BCLR

BFCHG

BFCLR

BFEXTS

BFEXTU

BFFFO

BFINS

BFSET

BFTST

BKPT

BRA

BSET

BSR

BTST

Branch Conditionally

Test Bit and Change

Test Bit and Clear

Test Bit Field and Change

Test Bit Field and Clear

Signed Bit Field Extract

Unsigned Bit Field Extract

Bit Field Find First One

Bit Field Insert

Te st B it F ie ld a nd S et

Te st B it F ie ld

Breakpoint

Branch

Test Bit and Set

Branch to Subroutine

Te st B it

29

TS68020

2115A–HIREL–07/02

CALLM

CAS

CAS2

CHK

CHK2

CLR

CMP

CMPA

CMPI

CMPM

CMP2

Call Module

Compare and Swap Operands

Compare and Swap Dual Operands

Check Register Against Bound

Check Register Against Upper and Lower Bounds

Clear

Compare

Compare Address

Compare Immediate

Compare Memory to Memory

Compare Register Against Upper and Lower Bounds

DBcc

DIVS, DIVSL

DIVU, DIVUL

Test Condition, Decrement and Branch

Signed Divide

Unsigned Divide

EOR

EORI

EXG

EXT, EXTB

Logical Exclusive OR

Logical Exclusive OR Immediate

Exchange Registers

Sign Extend

ILLEGAL Take Illegal Instruction Tape

JMP

JSR

Jump

Jump to Subroutine

LEA

LINK

LSL, LSR

Load Effective Address

Link and Allocate

Logical Shift Left and Right

MOVE

MOVEA

MOVE CCR

MOVE SR

MOVE USP

MOVEC

MOVEM

MOVEP

MOVEQ

MOVES

MULS

MULU

Move

Move Address

Move Condition Code Register

Move Status Register

Move User Stack Pointer

Move Control Register

Move Multiple Registers

Move Peripheral

Move Quick

Move Alternate Address Space

Signed Multiply

Unsigned Multiply

NBCD

NEG

NEGX

NOP

NOT

Negate Decimal with Extend

Negate

Negate with Extend

No Operation

Logical Complement

Table 9 . Instruction Set (Continued)

Mnemonic Description

30

TS68020

2115A–HIREL–07/02

OR

ORI

Logical Inclusive OR

Logical Inclusive OR Immediate

PAC K

PEA

Pack BCD

Push Effective Address

RESET

ROL, ROR

ROXL, ROXR

RTD

RTE

RTM

RTR

RTS

Reset External Devices

Rotate Left and Right

Rotate with Extend Left and Right

Return and Deallocate

Return and Exception

Return from Module

Return and Restore Codes

Return from Subroutine

SBCD

Scc

STOP

SUB

SUBA

SUBI

SUBQ

SUBX

SWAP

Subtract Decimal with Extend

Set Conditionally

Stop

Subtract

Subtract Address

Subtract Immediate

Subtract Quick

Subtract with Extend

Swap Register Words

TA S

TRAP

TRAPcc

TRAPV

TST

Test Operand and Set

Tra p

Trap Conditionally

Trap on Overflow

Test Operand

UNLK

UNPK

Unlink

Unpack BCD

Co-processor Instructions

cpBCC

cpDBcc

cpGEN

cpRESTORE

cpSAVE

cpScc

cpTRAPcc

Branch Conditionally

Test Co-processor Condition, Decrement and Branch

Co-processor General Instruction

Restore Internal State of Co-processor

Save Internal State of Co-processor

Set Conditionally

Trap Conditionally

Table 9 . Instruction Set (Continued)

Mnemonic Description

31

TS68020

2115A–HIREL–07/02

Bit Field Operation The TS68020 supports variable length bit field operations up to 32-bit. A bit field may

start in any bit position and span any address boundary for the full length of the bit field,

up to the 32-bit maximum. The bit field insert (BFINS) inserts a value into a field. Bit field

extract unsigned (BFEXTU) and bit field extract signed (BFEXTS) extract an unsigned

or signed value from the field. BFFFO finds the first bit in a bit field that is set. To complement the TS68000 bit manipulation instruction, there are bit field change, clear, set

and test instructions (BFCHG, BFCLR, BFSET, BFTST). Using the on-chip barrel

shifter, the bit and bit field instructions are very fast and particularly useful in applications using packed bits and bit fields, such as graphics and communications.

Binary Coded Decimal (BCD)

Support

The TS68000 Family supports BCD operations including add, subtract, and negation.

The TS68020 adds the PACK and UNPACK operations for BCD conversions to and

from binary form as well as other conversions, e.g., ASCII and EBCDIC. The PACK

instruction reduces two bytes of data into a single byte while UNPACK reverses the

operation.

Bounds Checking Previous 68000 Family members offer variable bounds checking only on the upper limit

of the bound. The underlying assumption is that the lower bound is zero. This is

expanded on the TS68020 by providing two new instructions, CHK2 and CMP2. These

instructions allow checking and comparing of both the upper and lower bounds. These

instructions may be either signed or unsigned. The CMP2 instructions sets the condition

codes upon completion while the CHK2 instruction, in addition to setting the condition

codes, will take a system trap if either boundary condition is exceeded.

System Traps Three additions have been made to the system trap capabilities of the TS68020. The

current TRAPV (trap on overflow) instruction has been expanded to a TRAPcc format

where any condition code is allowed to be the trapping condition. And, the TRAPcc

instruction is expanded to optionally provide one or two additional words following the

trap instruction so user-specified information may be presented to the trap handler.

These additional words can be used when needed to provide simple error codes or

debug information for interactive runtime debugging or post-mortem program dumps.

Compilers may provide direction to run-time execution routines towards handling of specific conditions.

The breakpoint instruction, BKPT, is used to support the program breakpoint function for

debug monitors and real-time in-circuit or hardware emulators, and the operation will be

dependent on the actual system implementation. Execution of this instruction causes

the TS68020 to run a breakpoint acknowledge bus cycle, with a 3-bit breakpoint identifier placed on address lines A2, A3, and A4. This 3-bit identifier permits up to eight

breakpoints to be easily differentiated. The normal response to the TS68020 is an operation word (typically an instruction, originally replaced by the debugger with the

breakpoint instruction) placed on the data lines by external debugger hardware and the

breakpoint acknowledge cycle properly terminated. The TS68020 then executes this

operation word in place of the breakpoint instruction. The debugger hardware can count

the number of executions of each breakpoint and halt execution after a pre-determined

number of cycles.

32

TS68020

2115A–HIREL–07/02

Multi-processing To further support multi-processing with the TS68020, a compare and swap instruction,

CAS, has been added. This instruction makes use of the read-modify-write cycle to

compare two operands and swap a third operand pending the results of the compare. A

variant of this instruction, CAS2, performs similarly comparing dual operand pairs, and

updating two operands.

These multi-processing operations are useful when using common memory to share or

pass data between multiple processing elements. The read-modify-write cycle is an indivisible operand that allows reading and updating a “lock” operand used to control

access to the common memory elements. The CAS2 instruction is more powerful since

dual operands allow the “lock” to the checked and two values (i.e., both pointers in a

doubly-linked list) to be updated according to the lock’s status, all in a single operation.

Module Support The TS68020 includes support for modules with the call module (CALLM) and return

from module (RTM) instructions. The CALLM instruction references a module descriptor. This descriptor contains control information for entry into the associated module.

The CALLM instruction creates a module stack frame and stores the module state in

that frame. The RTM instruction recovers the previous module state from the stack

frame and returns to the calling module.

The module interface also provides a mechanism for finer resolution of access control

by external hardware. Although the TS68020 does not interrupt the access control information, it does communicate with external hardware when the access control is to be

changed, and relies on the external hardware to verify that the changes are legal.

CALLM and RTM, when used as subroutine calls and returns with proper descriptor formats, cause the TS68020 to perform the necessary actions to verify legitimate access to

modules.

Virtual Memory/Machine

Concepts

The full addressing range of the TS68020 is 4-Gbyte (4, 294, 967, 296). However, most

TS68020 systems implement a smaller physical memory. Nonetheless, by using virtual

memory techniques, the system can be made to appear to have a full 4-Gbyte of physical memory available to each user program. These techniques have been used for

many years in large mainframe computers and minicomputers. With the TS68020 (as

with the TS68010 and TS68012), virtual memory can be fully supported in microprocessor-based systems.

In a virtual memory system, a user program can be written as though it has a large

amount of memory available to it when actually only a smaller amount of memory is

physically present in the system. In a similar fashion, a system provides user programs

access to other devices that are not physically present in the system, such as tape

drives, disk drives, printers, or terminals. With proper software emulation, a physical

system can be made to appear to a user program as any other 68000 computer system

and the program may be given full access to all of the resources of that emulated system. Such an emulator system is called a virtual machine.

Virtual Memory The basic mechanism for supporting virtual memory is to provides a limited amount of

high-speed physical memory that can be accessed directly by the processor while maintaining of a much larger “virtual” memory on secondary storage devices such as large

capacity disk drives. When the processor attempts to access a location in the virtual

memory map that is not resident in the physical memory (referred to as a page fault), the

access to that location is temporarily suspended while the necessary data is fetched

from secondary storage and placed in physical memory; the suspended access is then

either restarted or continued.

33

TS68020

2115A–HIREL–07/02

The TS68020 uses instruction continuation to support virtual memory. In order for the

TS68020 to use instruction continuation, it stores its internal state on the supervisor

stack when a bus cycle is terminated with a bus error signal. It then loads the program

counter with the address of the virtual memory bus error handler from the exception vector table (entry number two) and resumes program execution to that new address. When

the bus error exception handler routine has completed execution, an RTE instruction is

executed which reloads the TS68020 with the internal state stored on the stack, reruns

the faulted bus cycle (when required), and continues the suspended instruction.

Instruction continuation is crucial to the support of virtual I/O devices in memorymapped input/output systems. Since the registers of a virtual device may be simulated

in the memory map, an access to such a register will cause a fault and the function of

theregistercanbeemulatedbysoftware.

Virtual Machine A typical use for a virtual machine system is the development of software, such as an

operating system, for a new machine also under development and not yet available for

programming use. In such a system, a governing operating system emulates the hardware of the prototype system and allows the new operating system to be executed and

debugged as though it were running on the new hardware. Since the new operating system is controlled by the governing operating system, it is executed at a lower privilege

level than the governing operating system. Thus, any attempts by the new operating

system to use virtual resources that are not physically present (and should be emulated)

are trapped to the governing system and handled by its software. In the TS68020, a virtual machine is fully supported by running the new operating system in the user mode.

The governing operating system executes in the supervisor mode and any attempt by

the new operating system to access supervisor resources or execute privileged instructions will cause a trap to the governing operating system.

Operand Transfer

Mechanism

Though the TS68020 has a full 32-bit data bus, it offers the ability to automatically and

dynamically downsize its bus to 8- or 16-bit if peripheral devices are unable to accommodate the entire 32-bit. This feature allows the programmer the ability to write code

that is not bus-width specific. For example, long word (32-bit) accesses to peripherals

may be used in the code, yet the TS68020 will transfer only the amount of data that the

peripheral can manage. This feature allows the peripheral to define its port size as 8-,

16-, or 32-bit wide and the TS68020 will dynamically size the data transfer accordingly,

using multiple bus cycles when necessary. Hence, programmers are not required to program for each device port size or know the specific port size before coding; hardware

designers have flexibility to choose implementations independent of software

prejudices.

This is accomplished through the use of the DSACK

pins and occurs on a cycle-by-cycle

basis. For example, if the processor is executing an instruction that requires the reading

of a long word operand, it will attempt to read 32-bit during the first bus cycle to a long

word address boundary. If the port responds that it is 32-bit wide, the TS68020 latches

all 32-bit of data and continues. If the port responds that it is 16-bit wide, the TS68020

latches 16 valid bits of data and runs another cycle to obtain the other 16-bit of data. An

8-bit port is handled similarly by with four bus read cycles. Each port is fixed in assignment to particular sections of the data bus.

Justification of data on the bus is handled automatically by dynamic bus sizing. When

reading 16-bit data from a 32-bit port, the data may appear on the top or bottom half of

the bus, depending on the address of the data. The TS68020 determines which portion

of the bus is needed to support the transfer and dynamically adjusts to read or write the

data on those data lines.

34

TS68020

2115A–HIREL–07/02

The TS68020 will always transfer the maximum amount of data on all bus cycles; i.e., it

always assumes the port is 32-bit wide when beginning the bus cycle. In addition, the

TS68020 has no restrictions concerning alignment of operands in memory; long word

operands need not be aligned on long word address boundaries. When misaligned data

requires multiple bus cycles, the TS68020 aligned data requires multiple bus cycles, the

TS68020 automatically runs the minimum number of bus cycles.

The Co-processor

Concept

The co-processor interface is a mechanism for extending the instruction set of the

TS68000 Family. Examples of these extensions are the addition of specialized data

operands for the existing data types or, for the case of the floating point, the inclusion of

new data types and operations for them as implemented by the TS68881 and TS68882

floating point co-processors.

The programmer’s model for the TS68000 Family of microprocessors is based on

sequential, non-concurrent instruction execution. This means each instruction is completely executed prior to the beginning of the next instruction. Hence, instructions do not

operate concurrently in the programmer’s model. Most microprocessors implement the

sequential model which greatly simplifies the programmer responsibilities since

sequencing control is automatic and discrete.

The TS68000 co-processor interface is designed to extend the programmer’s model and

it provides full support for the sequential, non-concurrent instruction execution model.

Hence, instruction execution by the co-processor is assumed to not overlap with instruction execution with the main microprocessor. Yet, the TS68000 co-processor interface

does allow concurrent operation when concurrency can be properly accommodated. For

example, the TS68881 or TS68882 floating-point co-processor will allow the TS68020 to

proceed executing instruction while the co-processor continues a floating-point operation, up to the point that the TS68020 sends another request to the co-processor.

Adhering to the sequential execution model, the request to the co-processor continues a

floating-point operation, up to the co-processor completes each TS68881 and TS68882

instruction before it starts the next, and the TS68020 is allowed to proceed as it can in a

concurrent fashion.

co-processors are divided into two types by their bus utilization characteristics. A coprocessor is a DMA co-processor if it can control the bus independent of the main processor. A co-processor is a non-DMA co-processor if it does not have the capability of

controlling the bus. Both co-processor types utilize the same protocol and main processor resources. Implementation of a co-processor as a DMA or non-DMA type is based

primarily on bus bandwidth of the co-processor, performance, and cost issues.

The communication protocol between the main processor and the co-processor necessary to execute a co-processor instruction is based on a group of co-processor interface

registers (Table 10) which are defined for the TS68000 Family co-processor interface.

The TS68020 hardware uses standard TS68000 asynchronous bus cycles to access the

registers. Thus, the co-processor doesn’t require a special bus hardware; the bus interface implemented by a co-processor for its interface register set must only satisfy the

TS68020 address, data, and control signal timing to guarantee proper communication

with the main processor. The TS68020 implements the communication protocol with all

co-processors in hardware (and microcode) and handles all operations automatically so

the programmer is only concerned with the instructions and data types provided by the

co-processor as extensions to the TS68020 instruction set and data types.

35

TS68020

2115A–HIREL–07/02

Other microprocessors in the TS68000 Family can operate any TS68000 co-processor

even though they may not have the hardware implementation of the co-processor interface as does the TS68020. Since the co-processor is operated through the coprocessor interface registers which are accessed via normal asynchronous bus cycles,

the co-processor may be used as a peripheral device. Software easily emulates the

communication protocol by addressing the co-processor interface registers appropriately and passing the necessary commands and operands required by the coprocessor.

The co-processor interface registers are implemented by the co-processor in addition to

those registers implemented as extensions to the TS68020 programmer’s model. For

example, the TS68881 implements the co-processor interface registers shown in Table

10 and the registers in the programming model, including eight 80-bit floating-point data

registers and three 32-bit control/status registers used by the TS68881 programmer.

Table 10. Co-processor Interface Registers

Register Function R/W

Response Requests Action from CPU R

Control CPU W

Save Initiate Save of Internal State R

Restore Initiate Restore of Internal State R/W

Operation Word Current Co-processor Instruction W

Command Word Co-processor Specific Command W

Condition Word Condition to be Evaluated W

Operand 32-bit Operand R/W

Register Select Specifies CPU Register or Mask R

Instruction Address Pointer to Co-processor Instruction R/W

Operand Address Pointer to Co-processor Operand R/W

Table 11. Co-processor Primitives

Processor Synchronization

Busy with Current Instruction

Proceed with Next Instruction, If No Trace

Service Interrupts and Re-query, If Trace Enable

Proceed with Execution, Condition True/False

Instruction Manipulation

Transfer Operation Word

Transfer Words from Instruction Stream

Exception Handling

Take Privilege Violation if S Bit Not Set

Take Pre-Instruction Exception

Take Mid-Instruction Exception

Take Post-Instruction Exception

36

TS68020

2115A–HIREL–07/02

Up to eight processors are supported in a single system with a system-unique co-processor identifier encoded in the co-processor instruction. When accessing a coprocessor, the TS68020 executes standard read and write bus cycle in CPU address

space, as encoded by the function codes, and places the co-processor identifier on the

address bus to be used by chip-select logic to select the particular co-processor. Since

standard bus cycle are used to access the co-processor, the co-processor may be

located according to system design requirements, whether it be located on the microprocessor local bus, on another board on the system bus, or any other place where the

chip-select and co-processor protocol using standard TS68000 bus cycles can be

supported.

Co-processor Protocol Interprocessor transfers are all initiated by the main processor during co-processor

instruction execution. During the processing of a co-processor instruction, the main processor transfers instruction information and data to the associated co-processor, and

receives data, requests, and status information from the co-processor. These transfers

are all based on the TS68000 bus cycles.

The typical co-processor protocol which the main processor follows is:

a) The main processor initiates the communications by writing command information to

a location in the co-processor interface.

b) The main processor reads the co-processor response to that information.

1) The response may indicate that the co-processor is busy, and the main processor

should again query the co-processor. This allows the main processor and co-processor to synchronize their concurrent operations.

2) The response may indicate some exception condition; the main processor

acknowledges the exception and begins exception processing.

3) The response may indicate that the co-processor needs the main processor to

perform some service such as transferring data to or from the co-processor. The coprocessor may also request that the main processor query the co-processor again

after the service is complete.

4) The response may indicate that the main processor is not needed for further processing of the instruction. The communication is terminated, and the main

processor is free to begin execution of the next instruction. At this point in the coprocessor protocol, as the main processor continues to execute the instruction

stream, the main processor may operate concurrently with the co-processor.

General Operand Transfer

Evaluate and Pass (Ea.)

Evaluate (Ea.) and Transfer Data

Write to Previously Evaluated (Ea.)

Take Address and Transfer Data

Transfer to/from Top of Stack

Register Transfer

Transfer CPU Register

Transfer CPU Control Register

Transfer Multiple CPU Registers

Transfer Multiple Co-processor Registers

Transfer CPU SR and/or ScanPC

Table 11. Co-processor Primitives (Continued)

37

TS68020

2115A–HIREL–07/02

When the main processor encounters the next co-processor instruction, the main processor queries the co-processor until the co-processor is ready; meanwhile, the main

processor can go on to service interrupts and do a context switch to execute other tasks,

for example.

Each co-processor instruction type has specific requirements based on this simplified

protocol. The co-processor interface may use as many extension words as requires to

implement a co-processor instruction.

Primitives/Response The response register is the means by which the co-processor communicates service

requests to the main processor. The content of the co-processor response register is a

primitive instruction to the main processor which is read during co-processor communication by the main processor. The main processor “executes” this primitive, thereby

providing the services requires by the co-processor. Table 11 summarizes the co-processor primitives that the TS68020 accepts.

Exceptions

Kinds of Exceptions Exception can be generated by either internal or external causes. The externally gener-

ated exceptions are the interrupts, the bus error, and reset requests. The interrupts are

requests from peripheral devices for processor action while the bus error and reset pins

are used for access control and processor restart. The internally generated exceptions

come from instructions, address errors, tracing, or breakpoints. The TRAP, TRAPcc,

TRAPV, cpTRAPcc, CHK, CHK2, and DIV instructions can all generate exceptions as

part of their execution. Tracing behaves like a very high priority, internally generated

interrupt whenever it is processed. The other internally generated exceptions are

caused by illegal instructions, instruction fetches from odd addresses, and privilege

violations.

Exception Processing

Sequence

Exception processing occurs in four steps. During the first step, an internal copy is made

of the status register. After the copy is made, the special processor state bits in the status register are changed. The S bit is set, putting the processor into supervisor privilege

state. Also, the T1 and T0 bits are negated, allowing the exception handler to execute

unhindered by tracing. For the reset and interrupt exceptions, the interrupt priority mask

is also updated.

In the second step, the vector number of the exception is determined. For interrupts, the

vector number is obtained by a processor read that is classified as an interrupt acknowledge cycle. For co-processor detected exceptions, the victor number is included in the

co-processor exception primitive response. For all other exceptions, internal logic provides the vector number. This vector number is then used to generate the address of the

exception vector.

The third step is to save the current processor status. The exception stack frame is created and filled on the supervisor stack. In order to minimize the amount of machine state

that is saved, various stack frame sizes are used to contain the processor state depending on the type of exception and where it occurred during instruction execution. If the

exception is an interrupt and the M bit is on, the M bit is forced off, and a short four word

exception stack frame is saved on the master stack which indicates that the exception is

saved on the interrupt stack. If the exception is a reset, the M bit is simply forced off, and

the reset vector is accessed.

38

TS68020

2115A–HIREL–07/02

The TS68020 provides an extension to the exception stacking process. If the M bit in the

status register is set, the master stack pointer (MSP) is used for all task related exceptions. When a non-task exception occurs (i.e., an interrupt), the M bit is cleared and the

interrupt stack pointer (ISP) is used. This feature allows all the task’s stack area to be

carried within a single processor control block and new tasks may be initiated by simply

reloading the master stack pointer and setting the M bit.

The fourth and last step of the exception processing is the same for all exceptions. The

exception vector offset is determined by multiplying the vector number by four. This offset is then added to the contents of the vector base register (VBR) to determine the

memory address of the exception vector. The new program counter value is fetched

from the exception vector. The instruction at the address given in the exception vector is

fetched, and the normal instruction decoding and execution is started.

On-chip Instruction

Cache

Studies have shown that typical programs spend most of their execution time in a few

main routines or tight loops. This phenomenon is known as locality of reference, and

has an impact on performance of the program. The TS68020 takes limited advantage of

this phenomenon in the form of its loop mode operation which allows certain instructions, when coupled with the DBcc instruction, to execute without the overhead of

instruction fetches. In effect, this is a three word cache. Although the cache hardware

has been supplied in a full range of computer systems for many years, technology now

allows this feature to be integrated into the microprocessor.

TS68020 Cache Goals There were two primary goals for the TS68020 microprocessor cache. The first design

goal was to reduce the processor external bus activity. In a given TS68000 system, the

TS68000 processor will use approximately 80 to 90 percent (for greater) of the available

bus bandwidth. This is due to its extremely efficient perfecting algorithm and the overall

speed of its internal architecture design. Thus, in an TS68000 system with more than

one bus master (such as a processor and DMA device) or in a multiprocessor system,

performance degradation can occur due to lack of available bus bandwidth. Therefore,

an important goal for an TS68020 on-chip cache was to provide a substantial increase

in the total available bus bandwidth.

The second primary design goal was to increase effective CPU throughput as larger

memory sizes or slower memories increased average access time. By placing a high

speed cache between the processor and the rest of the memory system, the effective

access time now becomes:

t

ACC

=h**t

CACHE

=(1-h)*t

ext

where t

ACC

is the effective system access time, t

CACHE

is the cache access time, t

ext

is

the access time of the rest of the system, and h is the hit ratio or the percentage of time

that the data is found in the cache. Thus, for a given system design, an TS68020 onchip cache provides a substantial CPU performance increase, or allows much slower

and less expensive memories to be used for the same processor performance.

The throughput increase in the TS68020 is gained in two ways. First, the TS68020

cache is accessed in two clock cycles versus the three cycles (minimum) required for an

external access. Any instruction fetch that is currently resident in the cache will provide

a 33% improvement over the corresponding external access.

39

TS68020

2115A–HIREL–07/02

Second, and probably the most important benefit of the cache, is that it allows instruction stream fetches and operand accesses to proceed in parallel. For example, if the

TS68020 requires both an instruction stream access and an operand access, and the

instruction is resident in the cache, the operand access will proceed unimpeded rather

than being queued behind the instruction fetch. Similarly, the TS68020 is fully capable of

executing several internal instructions (instructions that do not require the bus) while

completing an operand access for another instruction.

The TS68020 instruction cache is a 256-byte direct mapped cache organized as 64 long

word entries. Each cache entry consists of a tag field made up of the upper 24 address

bits, the FC2 (user/supervisor) value, one valid bit, and 32-bit of instruction data (Figure

22).

Figure 22. TS68020 On-chip Cache Organization

The TS68020 employs a 32-bit data bus and fetches instructions on long word address

boundaries. Hence, each 32-bit instruction fetch brings in two 16-bit instruction words

which are then written into the on-chip cache. When the cache is enabled, the subsequent prefetch will find the next 16-bit instruction word is already present in the cache

and the related bus cycle is saved. If the cache were not enabled, the subsequent

prefetch will find the bus controller still holds the full 32-bit and can satisfy the prefetch

and again save the related bus cycle. So, even when the on-chip instruction cache is not

enabled, the bus controller provides an instruction “cache hit” rate up to 50%.

40

TS68020

2115A–HIREL–07/02

Preparation for

Delivery

Certificate of Compliance Atmel offers a certificate of compliance with each shipment of parts, affirming the prod-

ucts are in compliance with MIL-STD-883 and guaranteeing the parameters are tested

at extreme temperatures for the entire temperature range.

Handling MOS devices must be handled with certain precautions to avoid damage due to accu-

mulation of static charge. Input protection devices have been designed in the chip to

minimize the effect of this static buildup. However, the following handling practices are

recommended:

a) Device should be handled on benches with conductive and grounded surface.

b) Ground test equipment, tools and operator

c) Do not handle devices by the leads.

d) Store devices in conductive foam or carriers.

e) Avoid use of plastic, rubber, or silk in MOS areas.

f) Maintain relative humidity above 50%, if practical.

41

TS68020

2115A–HIREL–07/02

Package Mechanical

Data

Figure 23. 114-lead - Ceramic Pin Grid Array

Figure 24. 132 Pins - Ceramic Quad Flat Pack

42

TS68020

2115A–HIREL–07/02

Mass PGA 114 - 6 grams typically

CQFP 132 - 14 grams typically

Terminal

Connections

114-lead - Ceramic Pin

Grid Array

See Figure 2.

132-lead - Ceramic Quad

Flat Pack

See Figure 3.

43

TS68020

2115A–HIREL–07/02

Ordering Information

Hi-REL Product

Commercial Atmel

Part-Number Norms Package

Temperature Range

T

c

(°C)

Frequency

(MHz) Drawing Number

TS68020MRB/C16 MIL-STD-883 PGA 114 -55/+125 16.67 -

TS68020MR1B/C16 MIL-STD-883 PGA 114/tin -55/+125 16.67 -

TS68020MRB/C20 MIL-STD-883 PGA 114 -55/+125 20 -

TS68020MR1B/C20 MIL-STD-883 PGA 114/tin -55/+125 20 -

TS68020MRB/C25 MIL-STD-883 PGA 114 -55/+125 25 -

TS68020MR1B/C25 MIL-STD-883 PGA 114/tin -55/+125 25 -

TS68020MFB/C16 MIL-STD-883 CQFP 132 -55/+125 16.67 -

TS68020MF1B/C16 MIL-STD-883 CQFP 132/tin -55/+125 16.67 -

TS68020MFB/C20 MIL-STD-883 CQFP 132 -55/+125 20 -

TS68020MF1B/C20 MIL-STD-883 CQFP 132/tin -55/+125 20 -

TS68020MFB/C25 MIL-STD-883 CQFP 132 -55/+125 25 -

TS68020MF1B/C25 MIL-STD-883 CQFP 132/tin -55/+125 25 -

TS68020DESC02XA DESC PGA 114/tin -55/+125 16.67 5962-8603202XA

TS68020DESC03XA DESC PGA 114/tin -55/+125 20 5962-8603203XA

TS68020DESC04XA DESC PGA 114/tin -55/+125 25 5962-8603204XA

TS68020DESC02XC DESC PGA 114 -55/+125 16.67 5962-8603202XC

TS68020DESC03XC DESC PGA 114 -55/+125 20 5962-8603203XC

TS68020DESC04XC DESC PGA 114 -55/+125 25 5962-8603204XC

TS68020DESC02YA DESC CQFP 132/tin -55/+125 16.67 5962-8603202YA

TS68020DESC03YA DESC CQFP 132/tin -55/+125 20 5962-8603203YA

TS68020DESC04YA DESC CQFP 132/tin -55/+125 25 5962-8603204YA

TS68020DESC02YC DESC CQFP 132 -55/+125 16.67 5962-8603202YC

TS68020DESC03YC DESC CQFP 132 -55/+125 20 5962-8603203YC

TS68020DESC04YC DESC CQFP 132 -55/+125 25 5962-8603204YC

Standard Product

Commercial Atmel

Part-Number Norms Package

Temperature Range

T

c

(°C)

Frequency

(MHz)

Drawing

Number

TS68020VR16 Internal Standard PGA 114 -40/+85 16.67 Internal