Table of Contents

Section 1

Introduction...........................................................................................1-1

1.1 Device Support .................................. ....... ...... ....... ...... ....... ......................1-1

Section 2

Getting Started......................................................................................2-1

2.1 Unpacking the System..............................................................................2-1

2.2 System Requirements...............................................................................2-1

Section 3

Connecting the System.........................................................................3-1

Section 4

Hardware Description...........................................................................4-1

4.1 Jumpers, Links and their Functions ..........................................................4-2

4.2 External Connections................................................................................4-2

Section 5

Installing the Software ..........................................................................5-1

5.1 Windows 95 ..............................................................................................5-1

5.2 Windows 3.1 .............................................................................................5-1

Section 6

How to Use the Software......................................................................6-1

6.1 Projects.....................................................................................................6-1

6.2 Files ..........................................................................................................6-1

Section 7

Programming Using the Board ...................... .... ..... ..... .........................7-1

7.1 Device Orientation ............................. .............................................. ...... ...7-1

7.2 Voltage Selection......................................................................................7-1

7.3 Power and Lead Connections...................................................................7-2

Section 8

Brown-Out Detector..............................................................................8-1

Section 9

Board Applications................................................................................9-1

9.1 Using Switches and LEDs.........................................................................9-1

9.2 Using External Connections......................................................................9-1

i

Table of Contents

9.2.1 Misc. Header ......................................................................................9-2

9.3 Using Analog Functions ............................................................................9-2

9.3.1 Analog Port: Marked on Board ...........................................................9-2

9.3.2 Using Internal Reference....................................................................9-2

9.3.3 Using External Reference...................................................................9-3

9.4 Using External RAM..................................................................................9-3

9.4.1 RAM Recommendations.....................................................................9-3

9.4.2 RAM Socket Pin Layout......................................................................9-3

9.4.3 Address Latch................. ....... ...... .............................................. ...... ...9-3

9.5 Using LCD Connections............................................................................9-3

9.6 Using RS232.............................................................................................9-4

9.7 Programming In-System ...........................................................................9-4

9.8 ISP Header Layout....................................................................................9-5

9.9 Interface Using Resistors..........................................................................9-5

9.10 Using an Analogue Multiplexer IC.............................................................9-5

9.10.1 Using Real Time Clock.......................................................................9-6

ii

Section 1

Introduction

Welcome to the megaAVR™ Starter Kit.

This system incorporates an applications board and in-system programming hardware

key for programming AVR

README.TXT file included with the software for installation information.

®

devices in your application. Be sure to check the

1.1 Device Support

The system software currently has support for the following devices.

■

ATmega603

■

ATmega603L

■

ATmega103

■

ATmega103L

Software upgrades for new devices will be available in the AVR section of the Atmel

website, which is located at http://www.atmel.com.

megaAVR™ Starter Kit Manual 1-1

Introduction

1-2 megaAVR™ Starter Kit Manual

Section 2

Getting Started

2.1 Unpacking the System

2.2 System Requirements

Contents of box:

■

Evaluation Board

■

Disk set consisting of AVR ISP software and STK300 Application Builder

■

In-System Programming (ISP) Dongle

■

ISP Ribbon Cable

The minimum hardware and software requirements are:

■

80386 Processor or Above

■

1MB Ram

■

1MB Free Hard Disk Space

■

Windows 3.1 or Windows 95

megaAVR™ Starter Kit Manual 2-1

Getting Started

2-2 megaAVR™ Starter Kit Manual

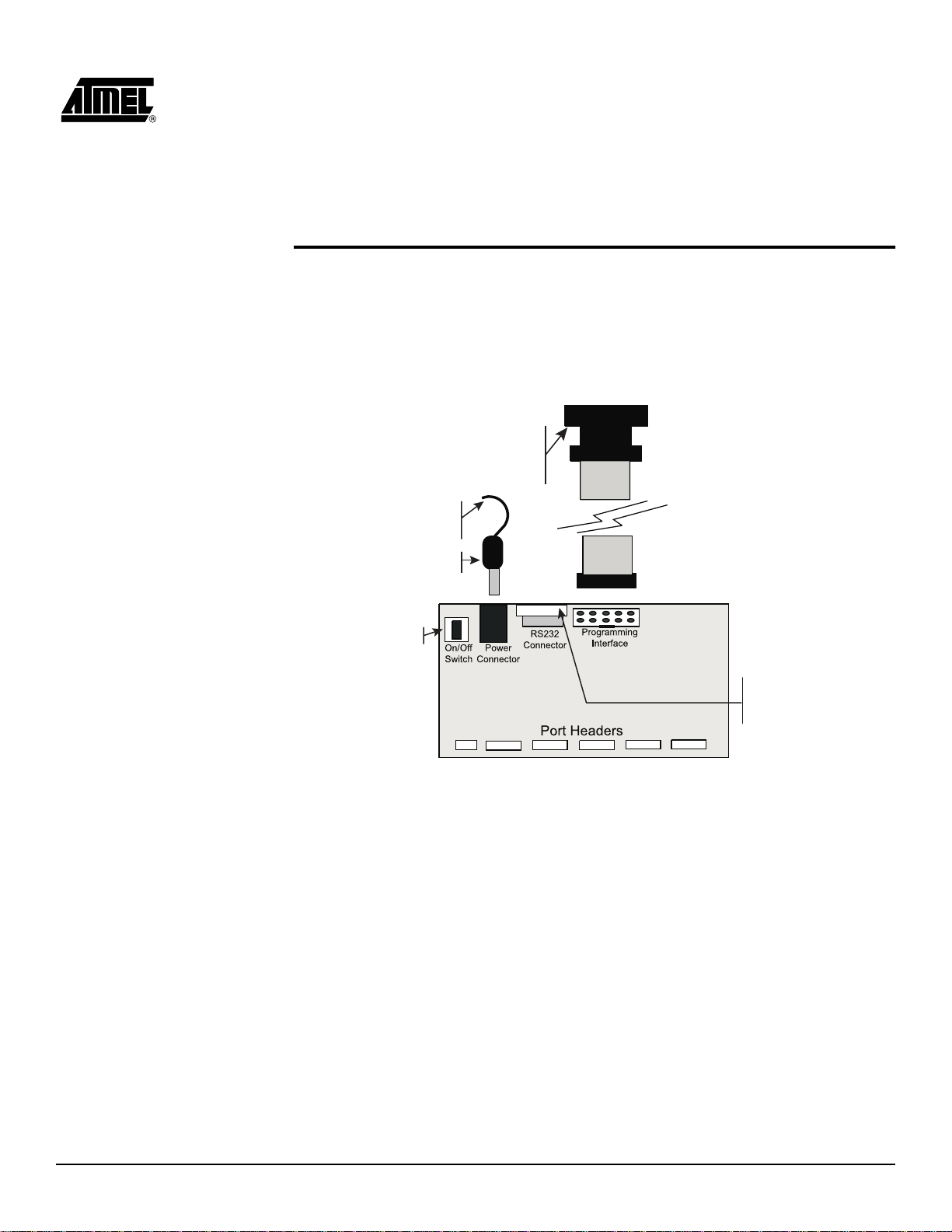

Section 3

PLUG HEADER ON LEAD

INTO PROGRAMMING

INTERFACE - KEY WAY

GIVES ORIENTATION

CONNECT LEAD

SUPPLIED TO DONGLE

AND INSERT IN

PC PRINTER PORT

POWER SUPPLY

9 - 15V DC

7 - 12V AC

ON-OFF SWITCH

RS 232 CONNECTOR

NOT USED FOR

PROGRAMMING

POWER CONNECTOR

5.5/2.1 BARREL

Connecting the System

megaAVR™ Starter Kit Manual 3-1

A Power Supply is required with a standard 2.1mm barrel connector . It can be AC 7 12V or DC 9 - 15V . The conne ctor is inse rted into the power con nection socket as

shown, above.

The programming lead supplied is fitted into the Dongle case and the other end is

inserted into the programming interface on the board as shown.

The Dongle case i s co nnect ed to one o f the prin ter ports o n the PC. I f this is not LPT1,

then you will need to change t he printer port se tting in the so ftware—see s oftware section for details.

Connecting the System

3-2 megaAVR™ Starter Kit Manual

Hardware Description

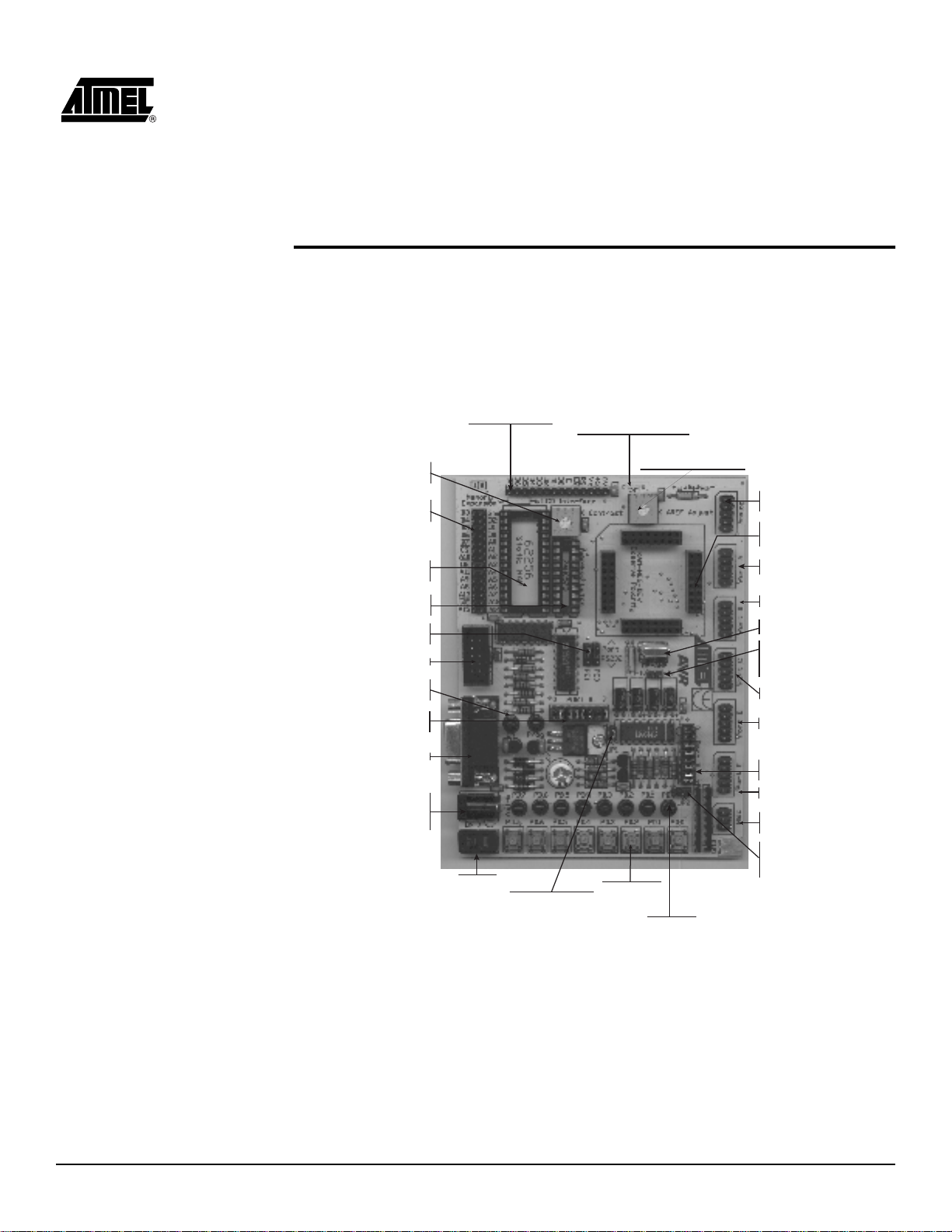

LCD CONNECTOR

ANALOG REFERENCE

VOLTAGE ADJUSTMENT

PLUG IN MEGA

BOARD HERE

ANALOG I/P

PORT A DIGITAL

4 MHz CRYSTAL

PORT B HEADER

PORT C HEADER

PORT D JUMPERS

DISABLE SWITCHES

PORT D HEADER

MISC. HEADER

FOR NON-PORT PINS

JP2 - JUMPER

FOR BROWN-OUT

AT 2.9V OR 4.5V

8 LEDS ON

PORT B

8 SWITCHES

ON PORT D

JP1 JUMPER FOR

3.3 OR 5V VCC SELECT

ON-OFF

SWITCH

POWER INPUT

9-15V DC

OR 7-12 AC

RS232

PORT B JUMPERS

DISABLE LEDS

POWER ON AND

PROG LIGHTS

SELECTOR

FOR RS232

ISP INTERFACE

ADDRESS LATCH

IC FOR RAM

EXTERNAL

SRAM SOCKET

EXTERNAL

MEMORY EXPANSION

LCD CONTRAST

ADJUSTMENT

LK1 - CUT FOR A/D

EXTERNAL REFERENCE

O/P PINS FOR -VE

SUPPL Y T O

OPAMP ETC.

PORT E HEADER

The main features of the board are shown in the diagram below.

Section 4

megaAVR™ Starter Kit Manual 4-1

Note:

There are a number of jumpers on the board which are used to select different

operations and voltages. The default jumper settings are for programming operations at 5V JP1 Closed, with brown-out also set to 5V JP2 Open.

To carry out other operations, some jumpers may have to be removed—refer to

the relevant section for details. A full list of the jumpers and links are given in the

following table.

Hardware Description

4.1 Jumpers, Links and their Functions

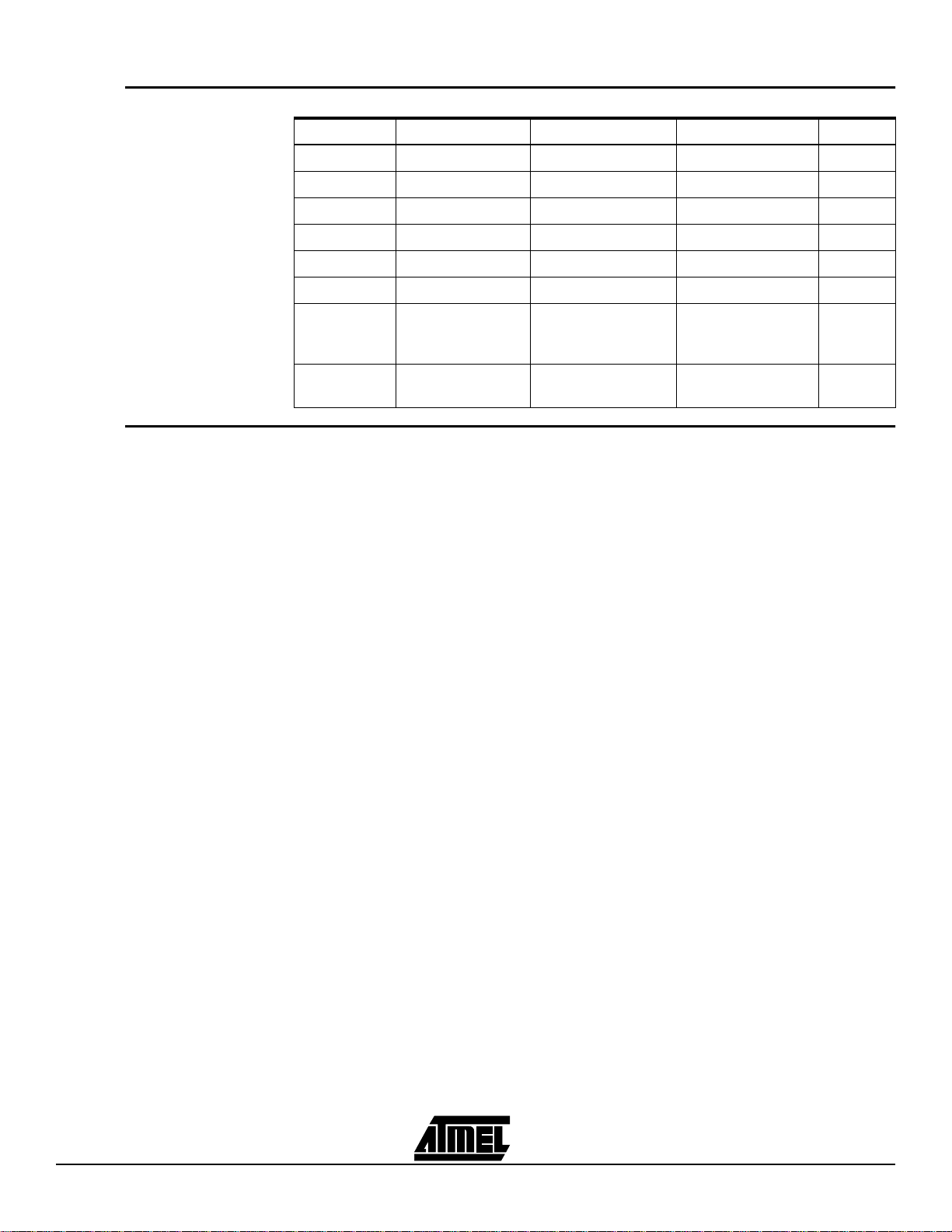

Jumper Function Open Closed Default

JP1 V oltage select 5V 3.3V Open

JP2 Brown-out select 2.9V 4.5V Closed

PE0 RS232 RXD Port E.0 RXD Port E.0

PE1 RS232 TXD Port E.1 TXD Port E.1

Port B LEDs LEDs Disabled LEDs Enabled Closed

Port D Switches Switches Disabled Switches Enabled Closed

4.2 External Connections

LK1 Analog

Reference

CUT Under

Board

LCD Contrast If Cut, add

If LK1 cut, then

EXTERNAL REF

from header

extra resistor

ONBOARD POT Closed

Contrast Pot Closed

All Ports are brought out to edge of board on to headers. Each header has a VCC and

Ground pin for power supply to external circuits. Port F is the Analog input port and is on

the header marked “Analog”. There is an ex tra six-pin header for miscellaneous fun ctions—Read, Write, ALE, Reset, Ground and VCC.

See sections “Using External Connections” on page 9-1 and “Using Analog Functions”

on page 9-2 for details.

4-2 megaAVR™ Starter Kit Manual

Section 5

Installing the Software

5.1 Windows 95

5.2 Windows 3.1

To install the software, insert the supplied dis k or CD-RO M i nto yo ur co mpu ter and per form the following steps:

1. Click on the “Start” button.

2. Select “Settings”.

3. Select “Control Panel”.

4. Choose “Add/Remove Programs”.

5. Click the “Install” button.

6. Follow On-Screen prompts.

The software will then be installed onto your computer and an Icon will be added to your

start menu.

Choose “RUN” from Program Manager, and enter A:\SETUP.EXE as the filename.

Press the “OK” button and the software installation program will begin.

The software will the n b e i ns tal led on to you r c omp uter a nd an Ico n a nd Pr og ra m Gr ou p

will be added to Program Manager.

Note:

In the unlikely event that you have any problems installing the software or suspect that

you have faulty media, please contact the Atmel Starter Kit hotline:

Telephone Number:

Fax Number:

Email:

On some PCs, especially laptops, programming problems may occur if the

BIOS Parallel Port settings are set to EPP Version 1.7. If programming problems do happen, ensure that the Parallel Port settings in your BIOS are set to

EPP V1.9 not V1.7. This applies to both Windows 95 and Windows 3.1 based

PCs.

(44) 1970 621 049

(44) 1970 621 040

stk300_support@atmel.com

megaAVR™ Starter Kit Manual 5-1

Installing the Software

5-2 megaAVR™ Starter Kit Manual

Section 6

How to Use the Software

The software is fully context sensitive. This means that pressing F1 at any time will bring

up help information about the current option that you have selected.

Please note that the toolbar icons referred to in the text have ToolTip’s, so if you want to

know the function of any particular butto n, hold your mouse p ointer over the button i n

question and its function will be displayed.

■

Starting a Project

■

In-System Programming (ISP)

■

Hardware Requirements

■

Projects

■

Data Files

■

Editing Data

6.1 Project s

6.2 Files

If you have used a high-end professional development system, you will be familiar with

the project concept. Essentially, this is a collection of details and data which are managed by the program on your behalf. In the AVR, you have both Program Memory and

non volatile Data Memory (EEPROM), with various security and device options. The

project manager keep s thi s information together for y ou so y ou don't hav e to remember

and reload all the various files every time you use the programmer.

The project manager will all ow you to store inform ation like the project nam e and the

project identifier. It also has a small notepad for you to store comments about the

project.

Before you can start a programming session, you must either open an existing project or

start a new project. You can op en a pr oject, or create a new on e, by e ither goi ng to th e

Project menu and selecting “New” or “Open”, or by using the “New Project” or “Open

Project” buttons on the toolbar.

Once a project is open, you can load the files that you need to program into the device.

Files may be loaded by either using the “Load” command in the File menu or by using

the “Open” icon on the toolbar.

The program will automatically decode your files whether they are in Intel Hex format,

Atmel Generic , Binar y o r Motor ola S rec ord . The file y ou c hoose wil l be loaded into the

window, then it is displayed on the top of the desktop. Therefore, if y ou have the

EEPROM Data Memory window on top, it will load the data into that window.

megaAVR™ Starter Kit Manual 6-1

How to Use the Software

6-2 megaAVR™ Starter Kit Manual

Section 7

Programming Using the Board

7.1 Device Orientation

7.2 Voltage Selection

Before programming a devi ce using the prog ramming modul e, the device adap ter must

be inserted c orrec tly int o the pr ogramm ing un it. The a dapter itsel f has a c orner cut-off ,

which locates pin 1 of the device and matches the marking on the main uni t. This

adapter should be prefitted, bu t can be replaced if th e device programming life is

exceeded—refer to your supplier to obtain a new device adapter.

The orientation of the devi ce is vitall y i mportan t. If yo u put it in the wr ong way then you

may damage the device. DO NOT PLUG A DEVICE ADAPTER IN WITH THE POWER

SWITCHED ON or you ma y d ama ge i t. S imil arly , n eve r remov e t he d ev ice adapter with

the power on.

Jumper JP1 is used to select either 3.3V or 5V programming.

For V

For V

Jumper JP2 is used to set Brown-Out detector voltage.

For Brown-Out = 4.5V, insert jumper JP2 - jumper closed

For Brown-Out = 2.9V, remove jumper JP2 - jumper open

This should be set to the same voltage as V

to 4.5V, then the device will be held in reset and will NOT program. See “Brown-Out

Detector” on page 8-1 for more details.

= 5V, remove jumper JP1 - jumper open

CC

= 3.3V, insert JP1 - jumper closed

CC

. If VCC is set to 3.3V and Brown-Out is set

CC

JP1

JP2

megaAVR™ Starter Kit Manual 7-1

Programming Using the Board

7.3 Power and Lead Connections

The 10-way programm ing le ad is in se rt ed in the box header—the k ey- way en su re s correct orientation. The computer con nections are s hown in “Conne cting the System ” on

page 3-1.

The power supply 9-15V DC or 7-12V AC is plugged into the power connector 5.5/2.1

Barrel.

The Power On/Off switch is located next to the power connector. Insert the device

adapter before switching the power on. The power on LED should light when the power

is correctly applied.

Your hardware is now ready for programming. Refer to “How to Use the Software” on

page 6-1 for details of programming operations. A programming LED indicates programming is happening.

7-2 megaAVR™ Starter Kit Manual

Section 8

Brown-Out Detector

The brown-out detector cir cuit is used to detect vol tage drops . If a sh ort gli tch occ urs in

the power, this circuit ensures that the processor resets properly rather than operating

randomly.

The brown-out detector mu st be set to the sam e voltage a s the circuit voltage, V

3.3V or 5V. For 3.3V operati on , ju mpe r J P2 mus t b e r emo ve d ( jumper op en) an d for 5V

operation it must be closed.

Voltage Operating Voltage Hysteresis

5 Volts 4.5 Volts 200 mV

3.3 Volts 2.9 Volts 200 mV

These values are approximate and may vary with temperature and other factors.

CC

—

megaAVR™ Starter Kit Manual 8-1

Brown-Out Detector

8-2 megaAVR™ Starter Kit Manual

Section 9

Board Applications

9.1 Using Switches and LEDs

9.2 Using External Connections

The LEDs are connected through a 1K resistor network to Port B.

The switches are connected to Port D.

The switches an d LE Ds can be di sco nnecte d, if requir ed. To use them, ens ure that th e

jumpers labeled “Port B” and “Port D” are closed. The board is also marked with the port

pin connection for each switch and LED.

The ports must be correctly set in software as input or output. This is accomplished by

setting the direction control r egister s to 0 for i nput and 1 for output. Ty pica l set-up c ode

would be:

ldi r16,$ff ;move immediate into temporary store register

out DDRB,r16 ;set direction register to ones for output -

LEDs

out PORTB,r16 ;switch all the LEDs on

ldi r16,$00 ;move immediate into temporary store register

out DDRD,r16 ;set direction register to zeros for input

Switches

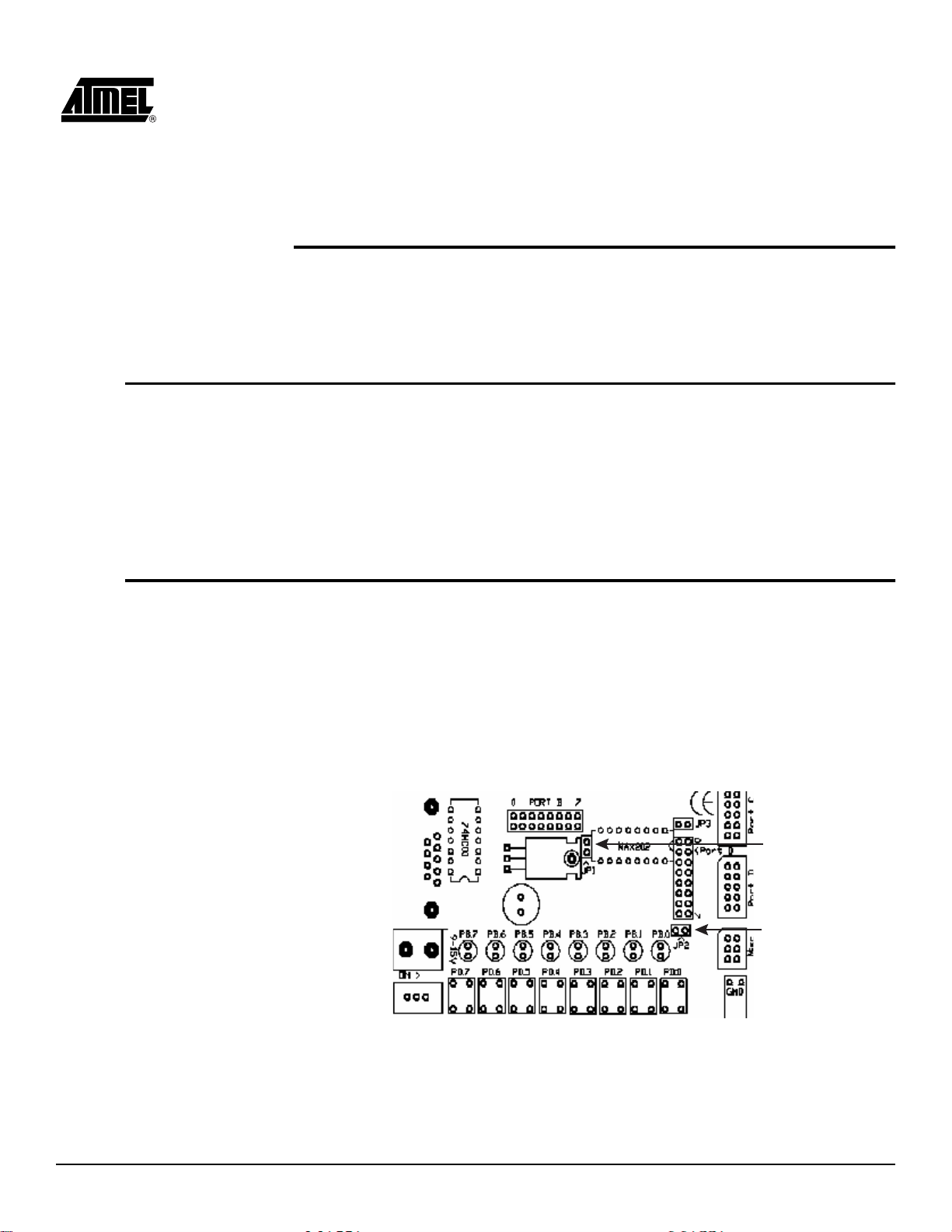

All the ports are brought out to headers on the edge of the boar d. In additi on to the port

pins, each header has a connection for ground and V

this voltage, V

and the brown-out detector will operate.

Note:

If your circuit is to draw significant current (>150 mA) then a heat sink will be

required on the on-board regulator—LM317. This device is rated at 1.5 amps

but it does need a heat sink to supply this current. If your circuit will draw more

than 1 amp, you may need a separate power supply. The ports on the device

are connected to the headers marked Port A, Port B, Port C, Port D, Port E and

Analog, Port F. The layout of all the headers is the same and is shown in the following diagram.

, will be either 3.3V or 5V depending on the setti ng of jumper 1, JP1,

CC

to supply external circuits. Note

CC

megaAVR™ Starter Kit Manual 9-1

Board Applications

CUT CORNER

SHOWN ON BOARD

FOR ORIENTATION

BIT 0 OF PORT.

SAME FOR ALL PORTS

BIT 7 OF PORT.

SAME FOR ALL PORTS

9.2.1 Misc. Header

9.3 Using Analog Functions

EXTRA CONNECTION

FOR GROUND

EXTRA CONNECTION

FOR V

CC

The last header labeled “Misc.” has con nections to processor pins other tha n the

port pins.

CUT OUT MARKED

ON BOARD

FOR ORIENTATION

READ

RD

WRITE

WR

EXTRA CONNECTION

FOR GROUND

EXTRA CONNECTION

FOR V

CC

If external operat ions do not wan t pull-up s on the port pin , both the swit ches and the

LEDs can be disconnected from the processor. To isolate the LEDs, remove the jumper

set labeled “Port B”, and to isolate the switches, remove the jumper set labeled “Port D”.

The A/D converters use the head er labele d “A nal og ” for the A/D in puts on Po rt F, whic h

is input only. A +10V to -10V supply is provided on the connector marked “Op-Amp” next

to the crystal. A lead from this connector can be used for an external amp lifier for th e

A/D inputs. The layout of the Analog header is shown below.

9.3.1 Analog Port: Marked on Board

ADC0 - ADC7 CONNECTED

CUT OUT MARKED

ON BOARD

FOR ORIENTATION

TO PORT FPF0 - PF7

The A/D converters can use either the on-boar d (Internal) Voltage Reference or an

external Voltage Reference.

9.3.2 Using Internal Reference

To use the internal, on-boa rd Vo ltage Re ference, the pot m arked “ AREF” is used to set

the voltage lev el. The vo ltage le vel can be measur ed with a D VM connec ted to the

9-2 megaAVR™ Starter Kit Manual

Board Applications

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

A14

A12

A7

A6

A5

A4

A3

A2

A1

A0

I/O0

I/O1

I/O2

VSS

VCC

WE

A13

A8

A9

A11

OE

A10

CS

I/O7

I/O6

I/O5

I/O4

I/O3

header pins labeled “A nal og Ref” and “Analog Gnd” in the pr evio us dia gr am o r fro m th e

two holes marked Meter + and -.

9.3.3 Using External Reference

9.4 Using External RAM

9.4.1 RAM Recommendations

9.4.2 RAM Socket Pin Layout

To use the A/D converters with an external Voltag e Reference, the li nk marked “LK1”

must be cut. The voltage is applied to the pins marked “Analog Ref” and “Analog Gnd”

on the Analog header—see previous diagram.

The ATmega103 can be used with external SRAM. A socket is provided for a 28-pin

RAM chip and for an address latch chip. These are next to the device adapter at the top

of the board. There is also a he ader for furt her mem ory expan sion, whi ch is conn ected

through the address latc h. The pin functi ons are marked on the board, includi ng chip

select (CS).

A low power 62256 SRAM is suggested with an access time of 70 nS. If a very fast RAM

is required, the crys tal frequ ency may nee d to be incre ased. If a muc h slower SRAM is

used, the SRAM Wait State bit must be enabled in user software–—see data book. The

layout of the 28-pin RAM socket is shown below, and any RAM with this pin-out could

be used.

9.4.3 Address Latch

The board connections ar e for a 74HC573 device. This dev ice will ope rate reliab ly with

the 4 MHz cr ystal su pplied but i f a faster crystal is ins erted, a f aster ver sion of th is

device may be required—74AHC573 or 74FHC573. Note that this option will alter the

EMC characteristics of the board and the CE mark will no longer be valid

without retesting.

9.5 Using LCD Connections

megaAVR™ Starter Kit Manual 9-3

The header marked LCD interf ace is for a standard 2 x 16 LCD. The c onnections are

shown on the board and in the following table.

Connection Name Function

0V Ground

+5 V

Vo Contrast

RS Register Select- A14

Wr Not Write

EEnable

D0 Data Bit 0

- must be 5V

CC

Board Applications

Connection Name Function

D1 Data Bit 1

D2 Data Bit 2

D3 Data Bit 3

D4 Data Bit 4

D5 Data Bit 5

D6 Data Bit 6

D7 Data Bit 7

The board is designed for use with a LCD with a Hitachi driver chip built-in, with a contrast pin voltage of 0 to 5 Volts. The pot next to the LCD connector is used for contrast

adjustment.

If you use a different LCD driver, it may have a different voltage contrast range. In order

to accommodate this, add a resistor to the board (shown on board) and cut track on

underside of board—marked cut.

This board is not designed for use with back lit LCD modules , so the extra c onnections

needed are not included and the power supply will not supply the current required.

The LCD must be driven in Memory Mappe d Mode as Read and Wri te are descite pins

on the Mega parts—see data sheet. If the crystal has been changed to a faster crystal

frequency, memory mapped operations will not work.

9.6 Using RS232

9.7 Programming InSystem

The connection supplied is a 9-way female D-type, so a straight-through lead is

required, not a null-modem cable.

The Jumpers in the middle of the board, marked PE0 and PE1 must be set to RS232,

not Port or RXD and TXD will be disabled.

As this board has a 4 MHz crystal , the percentage error on the Baud Rate will be

between 0.2 and 7.8%. Replacing the crystal with a 3.6846 MHz or 4.608 MHz crystal

will reduce this error to zero but may have EMC implications.

A standard (straight-through) lead is required, NOT a null-modem cable.

Devices can be programmed in your circuit rather than on the board.

For In-System Programming , ISP, the 10- conduc tor ribbon cable is co nnecte d to a dual

row 10-pin 0.1" pitch header on your circuit.

You will need to use either a multiplexer chip, such as a 4053, or wire directly to the pins

of the device. Without a multipl exer chip , Serial Co mmunications and SPI por t will b e

unusable.

In addition, the syste m 5 Volts an d Ground nee ds to be connec ted to the pr ogrammin g

lead.

DO NOT EXCEED 5 VOLTS ± 5% (4.75V TO 5.25V). YOU MAY DAMAGE YOUR

COMPUTER. THIS WARNING APPLIES TO ANY ISP SYSTEM.

9-4 megaAVR™ Starter Kit Manual

9.8 ISP Header Layout

9.9 Interface Using Resistors

Board Applications

KEY WAY

OPTIONAL PROGRAM

INDICATOR CICRUIT

PROGRAMMING HEADER MISO IS CALLED PDO AND

MOSI IS PDI ON MEGA

DEVICES - PORT E BITS 0 AND 1

NOT PINS ON PORT B.

9.10 Using an Analogue Multiplexer IC

USER

CIRCUIT

Typical resistor values would be 1K. This circuit is fine if ports PB7, PE0 and PE1 are

used as inputs in your circuit and no communication is required. If Outputs are needed

or RS232 connections , especiall y higher than a few mill iamps, th en the multipl exed circuit is preferable.

TO ISP

CONNECTOR

TO USER

CIRCUIT

The multiplexer select can be driven from the LED connection on the programming lead,

as can a low power LED with its cathode connected to the LED connection via a suitable

resistor. 1KΩ is fine. If you use this connectio, then the output will be low 0 during programming and a 1 at all other times. Note that it will float if the programmer is not active,

i.e., the software is not running, so you may need to use a pull-up resistor.

megaAVR™ Starter Kit Manual 9-5

Board Applications

9.10.1 Using Real Time Clock

Note:

A 32.768 kHz crystal is connected to TOSC1 and TOSC2 pins—Pin 18 and Pin 19. This

can be used to generate a 1 second pulse—see data book for details.

All the pins except ground will float if the programmer is not active. The device

may then be programmed in the normal way.

9-6 megaAVR™ Starter Kit Manual

Board Applications

Lights and Switches

VCC

P-RESET

VCC

10K

Resnet

Active 0 on LEDs

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

EXT RESET

RESET

R12

10K

Q2

BC182

123

R14

1M

R11

10K

Q1

BC182

123

MEGA Pin 3 ( PE1)

MEGA Pin 11 (SCK

MEGA Pin 2 ( PE0)

4

15

X14Y

Z

X012X113Y02Y11Z05Z13INH6A11B10C

U2

1K

1K

R13

R16

PORT B Bit 1

9

4053

PORT PIN

PE1

RS 232

PORT PIN

PE0

RS 232RST + BROWNOUT

Brow nout Detector Circuit

C7

5V Brownout

LCD Interface

100nF

MOSI (ISP)

SCK (ISP)

R9

11K

R10

18K

Data 7

Data 6

Data 5

Data 4

Data 3

Data 2

Data 1

Data 0

Enable

R/W

Reg Sel

Cont

+5V

GND

MOSI (ISP)

PB0

Pro gramming Interface

+5

14

13

12

11

10

9

8

7

6

5

4

3

2

1

100R

+5

LED Enable ( ISP)

1 2

3 4

5 6

7 8

9 10

ISP LED

ISP RST

ISP MOSI

HEADER 5X2

ISP SCK

3

+5

1K

R2

ISP MISO

BRIDGE

BC212

1

2

1K

R1

RST (ISP)

External Power Source

(DC or AC)

S1

SW SPST

-+

R8

43K

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

HEADER 8X2

PB0

PB1

PB2

PB3

PB4

PB5

PB6

PB7

VCC

PD0

10K

Resnet

PD3

PD4

PD2

PD1

PD7

PD5

PD6

Active 0 on Switches

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

HEADER 8X2

PD0

PD1

PD2

PD3

PD4

PD5

PD6

PD7

C19

100nF

VCC

C18

100nF

C17

100nF

C16

100nF

C15

100nF

C14

100nF

C13

100nF

VREF

C20

VR1

10K

VCC

Analogue Reference Decoupling Capacitors

100nF

AGND

P9

594837261

+5V+5V

16

15

RS232 Circuit

Vcc

C1+1V+2C1-3C2+4C2-5V-6T2OUT7R2IN

U4

-10V

+10V

GND

14

13

T1OUT

C10

+

C9

+

C12

+

C11

+

R1IN

12

10uF

10uF

10uF

10uF

11

R1OUT

T2IN10T1IN

9

8

R2OUT

RS232

MAX202CPE

TXD

RXD

EN

U3C

9

R3

10K

+5

C8

11

U3D

LCD Timing Ciruit

12

A15

8

74HC00

10

33pF

74HC00

13

BAT85

D2

CS

3

U3A

74HC00

1

2

2

VOUT

6 R15

U3B

74HC00

4

5

WR

RD

REG1

LM317T

3

VIN

VCC

REG2

ADJ

1

R6

240R

C3

220uF

1

VOUT

GND

2

VIN

LM78L05ACH

3

C4

470nF

+5

C6

100nf

R5

39R

R4

680R

R7

820R

3V3

C5

470nF

GND GND AGND

9-7 megaAVR™ Starter Kit Manual

Board Applications

megaAVR™ Starter Kit Manual 9-8

Board Applications

9-9 megaAVR™ Starter Kit Manual

Atmel Headquarters Atmel Operations

Corporate Headquarters

2325 Orchard Parkway

San Jose, CA 95131

TEL (408) 441- 0311

FAX (408) 487-2600

Europe

Atmel U.K., Ltd.

Coliseum Business Centre

Riverside Way

Camberley, Surrey GU15 3YL

England

TEL (44) 1276-686677

FAX (44) 1276-686697

Asia

Atmel Asia, Ltd.

Room 1219

Chinachem Golden Plaza

77 Mody Road

Tsimshatsui East

Kowloon, Hong Kong

TEL (852) 27219778

FAX (852) 27221369

Japan

Atmel Japan K.K.

Tonetsu Shinkawa Bldg., 9F

1-24-8 Shinka wa

Chuo-ku, Tokyo 104-0033

Japan

TEL (81) 3-3523-3551

FAX (81) 3-3523-7581

Atmel Colorado Springs

1150 E. Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906

TEL (719) 576-3300

FAX (719) 540-1759

Atmel Rousset

Zone Indu strie lle

13106 Rousset Cedex, France

TEL (33) 4 42 53 60 00

FAX (33) 4 42 53 60 01

Fax-on-Demand

North America:

1-(800) 292-8635

International:

1-(408) 441-0732

e-mail

literature@atmel.com

Web Site

http://www.atmel.com

BBS

1-(408) 436-4309

© Atmel Corporation 1998.

Atmel Corporation makes no warranty for the use of its products, other than those expressly contained in the Company’s standard warranty which is detailed in Atmel’s Terms and Conditions located on the Company’s web site. The Company assumes no responsibility for

any errors which may appear in this document, reserves the right to change devices or specifications detailed herein at any time without

notice, and does not make any commitment to update the information contained herein. No licenses to patents or other intellectual property of Atmel are granted by the Company in connection with the sale of Atmel products, expressly or by implication. Atmel’s products are

not authorized for use as critical components in life support devices or systems.

Marks bearing ® and/or ™ are registered trademarks and trademarks of Atmel Corporation.

Terms and product names in this document may be trademarks of others.

Printed on recycled paper.

1149A–02/99/2M

Loading...

Loading...