Page 1

Data Gateway Interface

USER GUIDE

Description

The Atmel® Data Gateway Interface is a USB interface for handling the lowlevel transport of data to and from a target MCU. DGI is available on a

selection of tools and on-board debuggers, such as the Power Debugger

and the EDBG, as found on Xplained Pro.

DGI provides several interfaces utilizing the same API for configuration and

communication. Each interface implements an abstraction to a physical

communication interface, such as SPI and UART, or represents a service not

directly tied to a physical communication interface, such as the timestamp

interface.

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

Page 2

Table of Contents

Description.......................................................................................................................1

1. USB Communication................................................................................................. 3

2. Protocol......................................................................................................................4

2.1. DGI_CMD_SIGN_ON...................................................................................................................5

2.2. DGI_CMD_SIGN_OFF.................................................................................................................5

2.3. DGI_CMD_GET_VERSION......................................................................................................... 6

2.4. DGI_CMD_SET_MODE............................................................................................................... 6

2.5. DGI_CMD_TARGET_RESET.......................................................................................................7

2.6. DGI_CMD_INTERFACES_LIST...................................................................................................7

2.7. DGI_CMD_INTERFACES_ENABLE............................................................................................8

2.8. DGI_CMD_INTERFACES_SET_CONFIG................................................................................... 8

2.9. DGI_CMD_INTERFACES_GET_CONFIG...................................................................................9

2.10. DGI_CMD_INTERFACES_POLL_DATA......................................................................................9

2.11. DGI_CMD_INTERFACES_SEND_DATA................................................................................... 10

2.12. DGI_CMD_INTERFACES_STATUS...........................................................................................10

3. Interfaces.................................................................................................................12

3.1. Timestamp..................................................................................................................................12

3.1.1. Parsing.........................................................................................................................12

3.1.2. Configuration............................................................................................................... 14

3.2. GPIO...........................................................................................................................................14

3.2.1. Parsing.........................................................................................................................14

3.2.2. Configuration............................................................................................................... 14

3.3. SPI..............................................................................................................................................14

3.3.1. Parsing.........................................................................................................................15

3.3.2. Configuration............................................................................................................... 15

3.4. USART....................................................................................................................................... 15

3.4.1. Parsing.........................................................................................................................15

3.4.2. Configuration............................................................................................................... 15

3.5. I2C.............................................................................................................................................. 16

3.5.1. Parsing.........................................................................................................................16

3.5.2. Configuration............................................................................................................... 16

3.6. Power......................................................................................................................................... 16

3.6.1. Parsing.........................................................................................................................16

3.6.2. Configuration............................................................................................................... 18

4. Revision History.......................................................................................................21

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

2

Page 3

1. USB Communication

The DGI USB device consists of two endpoints; one OUT Bulk endpoint for sending commands from the

PC, and one IN Bulk endpoint for receiving responses. The endpoint size of both the IN and OUT

endpoint must be taken into account when communicating with the device. A completed packet is

recognized by the transfer having a length of less than the endpoint size. If a packet has a length which is

a multiple of the endpoint size, the last transfer must be a zero length transfer to complete the packet.

All communication is initiated by the host computer sending a command packet over the OUT endpoint.

All commands are given a response over the IN endpoint. Unrecognized commands will receive an error

response.

Commands can have a maximum length of 256 bytes. Responses to most commands are only a few

bytes. However, responses can be several thousand bytes when polling incoming data from the DGI

buffer.

The USB device is a custom implementation, not following any predefined USB classes, and will therefore

require the installation of a driver on most systems.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

3

Page 4

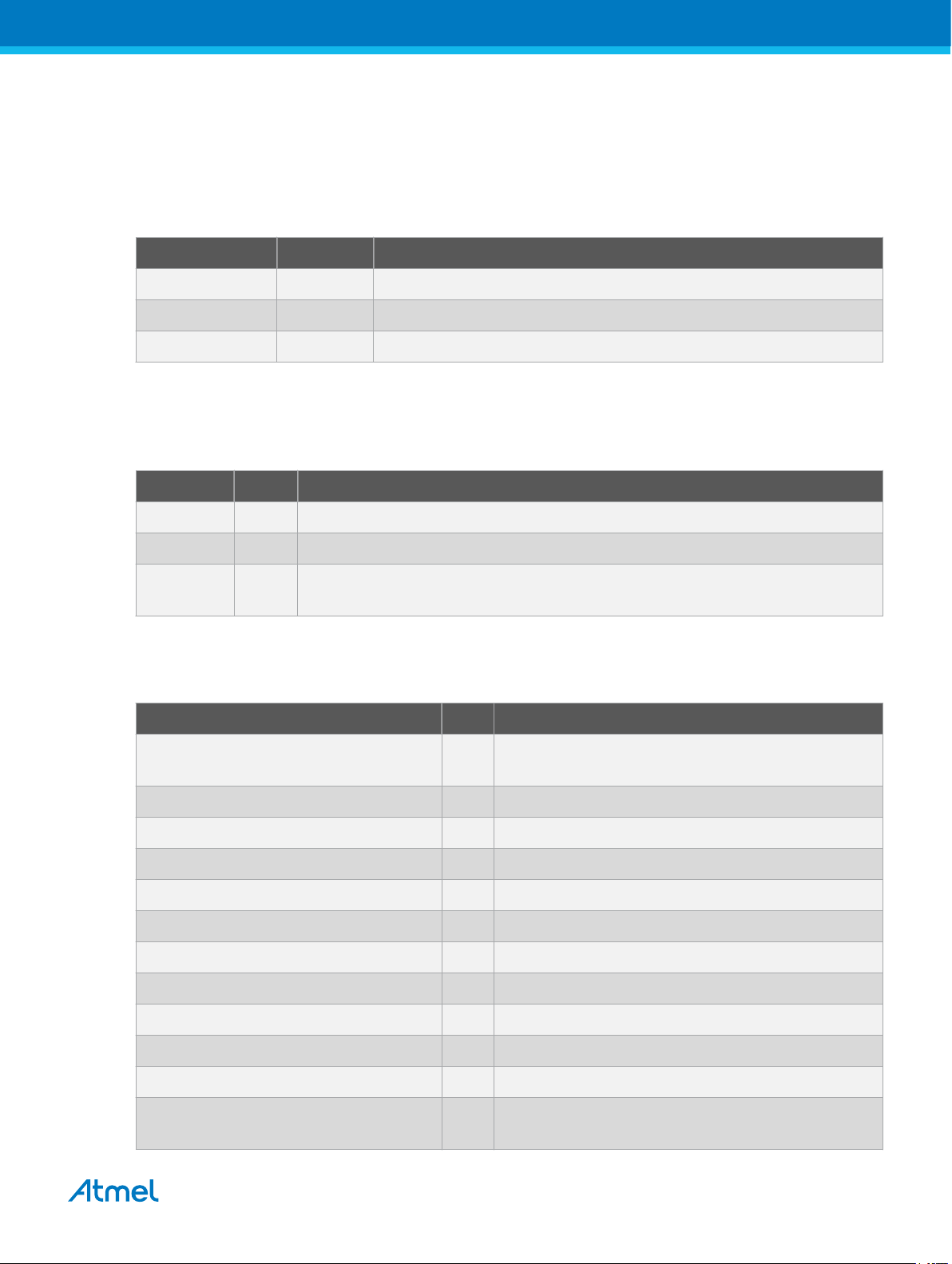

2. Protocol

All values in the protocol are big endian. Command packets consists of a command byte, a 2-byte length

and command-specific parameters. The length field only counts the bytes in parameters, and will be 0 for

commands without parameters.

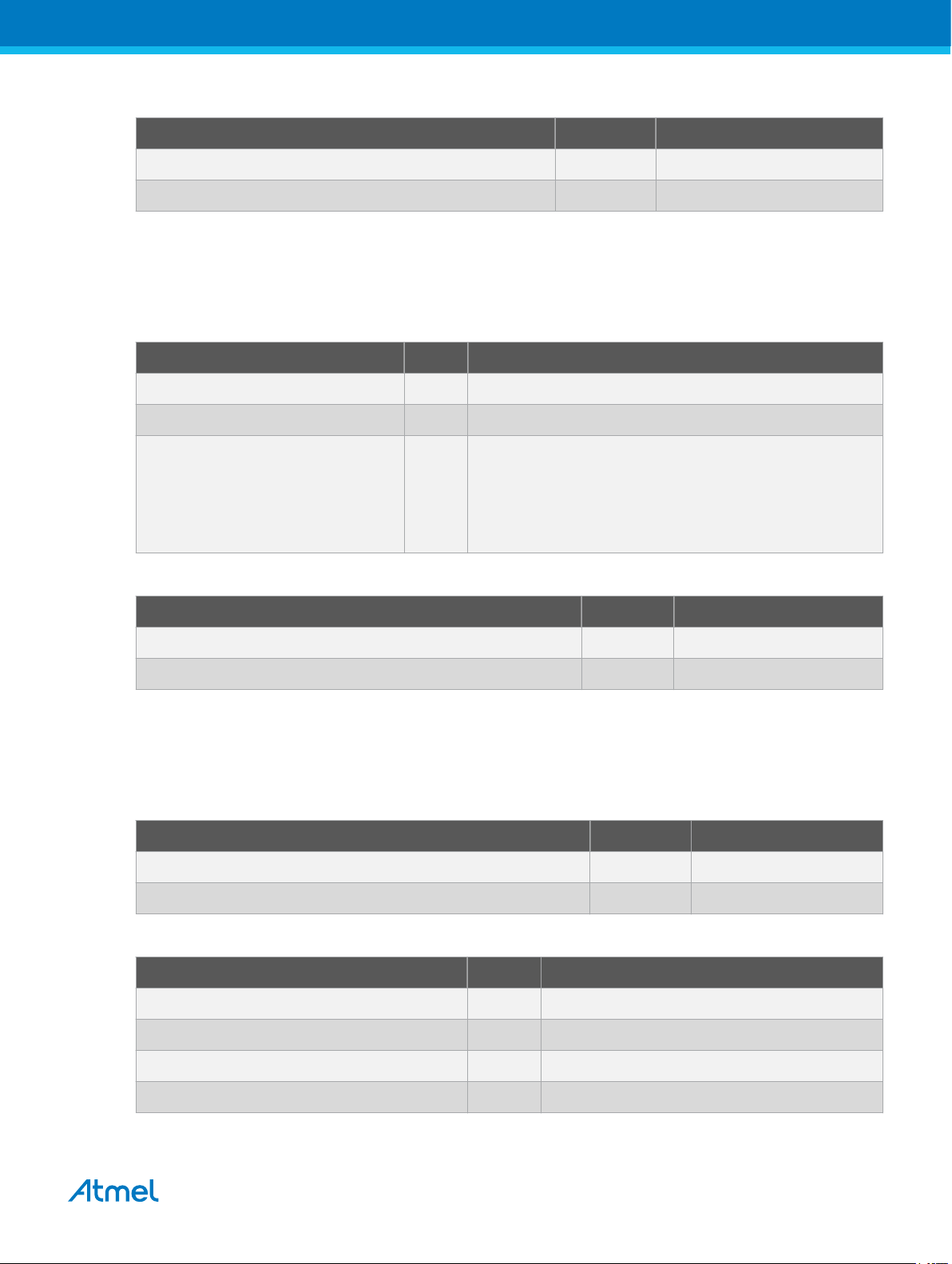

Table 2-1. Command Packet

Field Size Description

Command 1 Byte The identifier of the command to be executed.

Length 2 Bytes Amount of trailing data in parameters (n).

Parameters n Bytes Command-specific parameters.

All received packets are parsed, executed, and responded to by a response code. The response packet

consists of the received command byte, a status code, and parameters, depending on the command and

status code. Unknown commands will receive an error response.

Table 2-2. Response Packet

Field Size Description

Command 1 Byte The identifier of the command that was executed.

Status Code 1 Byte Response indicating the status of the executed command.

Parameters n Bytes Some status codes have parameters. The parsing of the parameters are

command-specific.

Below is a list of the supported commands and possible response codes. Refer to the following subsections for details.

Table 2-3. List of Commands

Name Value Description

DGI_CMD_SIGN_ON 0x00 Initializes DGI and returns a verification string. Must

be the first command called.

DGI_CMD_SIGN_OFF 0x01 Disconnects and stops all interfaces.

DGI_CMD_GET_VERSION 0x02 Returns the version of the DGI implementation.

DGI_CMD_SET_MODE 0x0A Sets the operating mode of DGI.

DGI_CMD_INTERFACES_LIST 0x08 Lists all available interface identifiers.

DGI_CMD_INTERFACES_ENABLE 0x10 Used to enable/disable interfaces.

DGI_CMD_INTERFACES_STATUS 0x11 Fetches the status for the interfaces.

DGI_CMD_INTERFACES_SET_CONFIG 0x12 Sets the configuration for the specified interface.

DGI_CMD_INTERFACES_GET_CONFIG 0x13 Gets the configuration for the specified interface.

DGI_CMD_INTERFACES_SEND_DATA 0x14 Sends data for transmission over specified interface.

DGI_CMD_INTERFACES_POLL_DATA 0x15 Returns the data buffer for the specified interface.

DGI_CMD_TARGET_RESET 0x20 Controls the state of the reset line of the target

device.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

4

Page 5

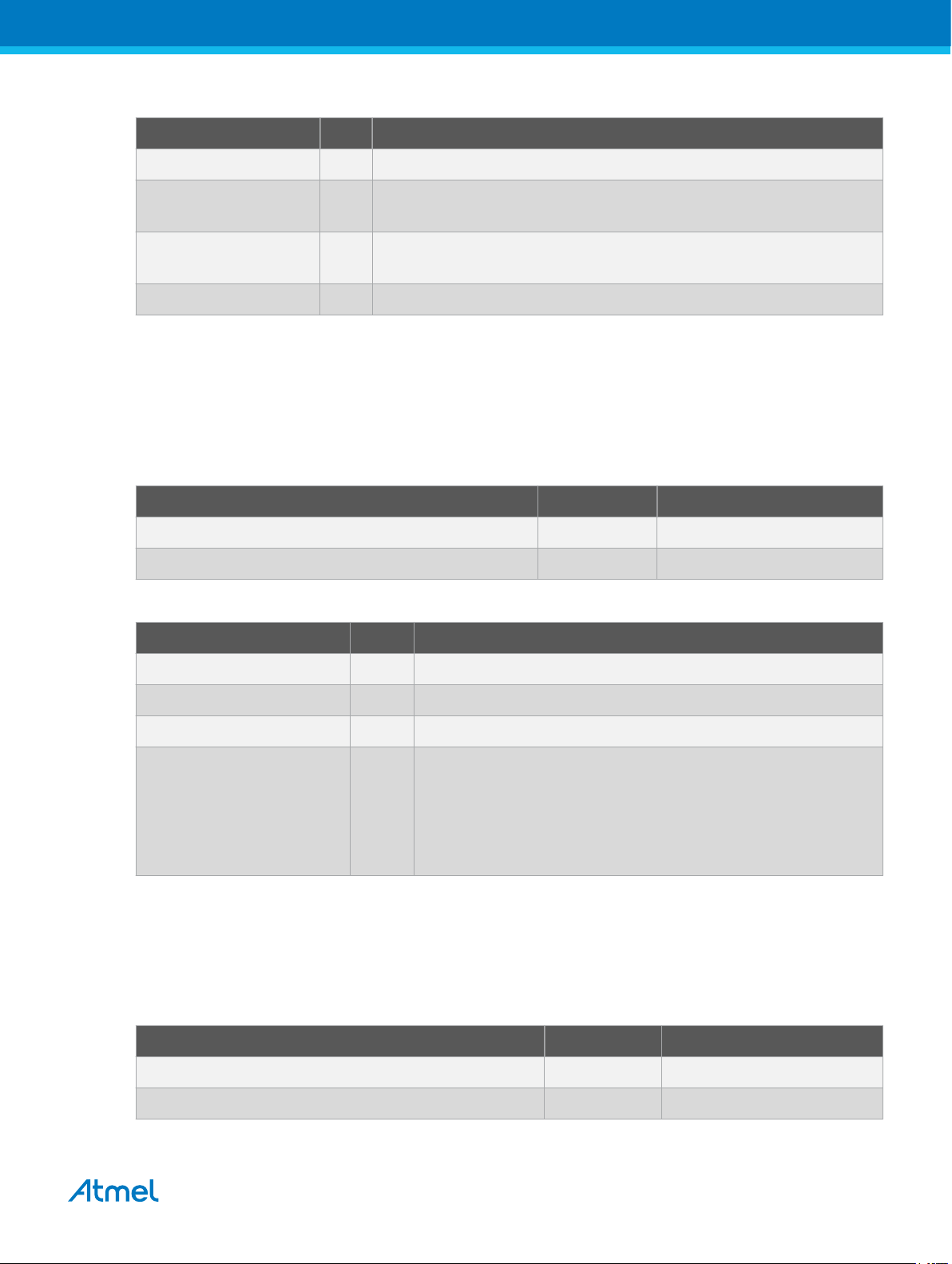

Table 2-4. List of Responses

Name Value Description

DGI_RESP_OK 0x80 Verifies that the command was executed correctly.

DGI_RESP_FAIL 0x99 An error occurred during execution of the command. Usually caused

DGI_RESP_DATA 0xA0 The command was executed correctly and returned data. The data is

DGI_RESP_UNKNOWN 0xFF The received command identifier is unknown.

2.1. DGI_CMD_SIGN_ON

The sign on command is always the very first command to be called. It will initialize all states, buffers, and

interfaces to a known starting point. A tool-specific string is returned as an acknowledgment of the sign

on.

Table 2-5. Command Packet

Field Size Description

DGI_CMD_SIGN_ON (0x00) 1 Byte Command ID.

by wrong usage of the protocol.

command-specific and must be parsed accordingly.

Length (0) 2 Bytes No parameters.

Table 2-6. Response Packet

Field Size Description

DGI_CMD_SIGN_ON (0x00) 1 Byte Command ID.

DGI_RESP_DATA (0xA0) 1 Byte Response code.

Length 2 Bytes Length, n, of the acknowledgment string.

String n Bytes Acknowledgment string.

2.2. DGI_CMD_SIGN_OFF

The sign off command is the last command to be called. It will de-initialize all states, buffers, and

interfaces.

Table 2-7. Command Packet

• EDBG = "EDBG Data Gateway Interface"

• Power Debugger = "Powerdebugger Data Gateway

Interface"

• Atmel-ICE = "Atmel-ICE Data Gateway Interface"

Field Size Description

DGI_CMD_SIGN_OFF (0x01) 1 Byte Command ID.

Length (0) 2 Bytes No parameters.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

5

Page 6

Table 2-8. Response Packet

Field Size Description

DGI_CMD_SIGN_OFF (0x01) 1 Byte Command ID.

DGI_RESP_OK (0x80) 1 Byte Response code.

2.3. DGI_CMD_GET_VERSION

This command gets the version number of the DGI implementation. The latest version at the time of

writing is 3.1.

Table 2-9. Command Packet

Field Size Description

DGI_CMD_GET_VERSION (0x02) 1 Byte Command ID.

Length (0) 2 Bytes No parameters.

Table 2-10. Response Packet

Field Size Description

DGI_CMD_GET_VERSION (0x02) 1 Byte Command ID.

DGI_RESP_DATA (0xA0) 1 Byte Response code.

Major version 1 Byte Incremented only for big breaking changes.

Minor version 1 Byte Incremented for each change relevant to the protocol.

2.4. DGI_CMD_SET_MODE

This command changes the operating mode of certain aspects of the DGI mechanisms and protocol.

Affected commands will have details in the command specific sections.

Table 2-11. Command Packet

Field Size Description

DGI_CMD_SET_MODE (0x0A) 1 Byte Command ID.

Length (1) 2 Bytes

Mode 1 Byte Each bit corresponds to a specific setting. Default value is 0.

• Bit 2

0: Use 2 byte length for poll response.

1: Use 4 byte length for poll response.

• Bit 0

0: Poll response does not include overflow indicator.

1: Add buffer overflow indicator to poll response.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

6

Page 7

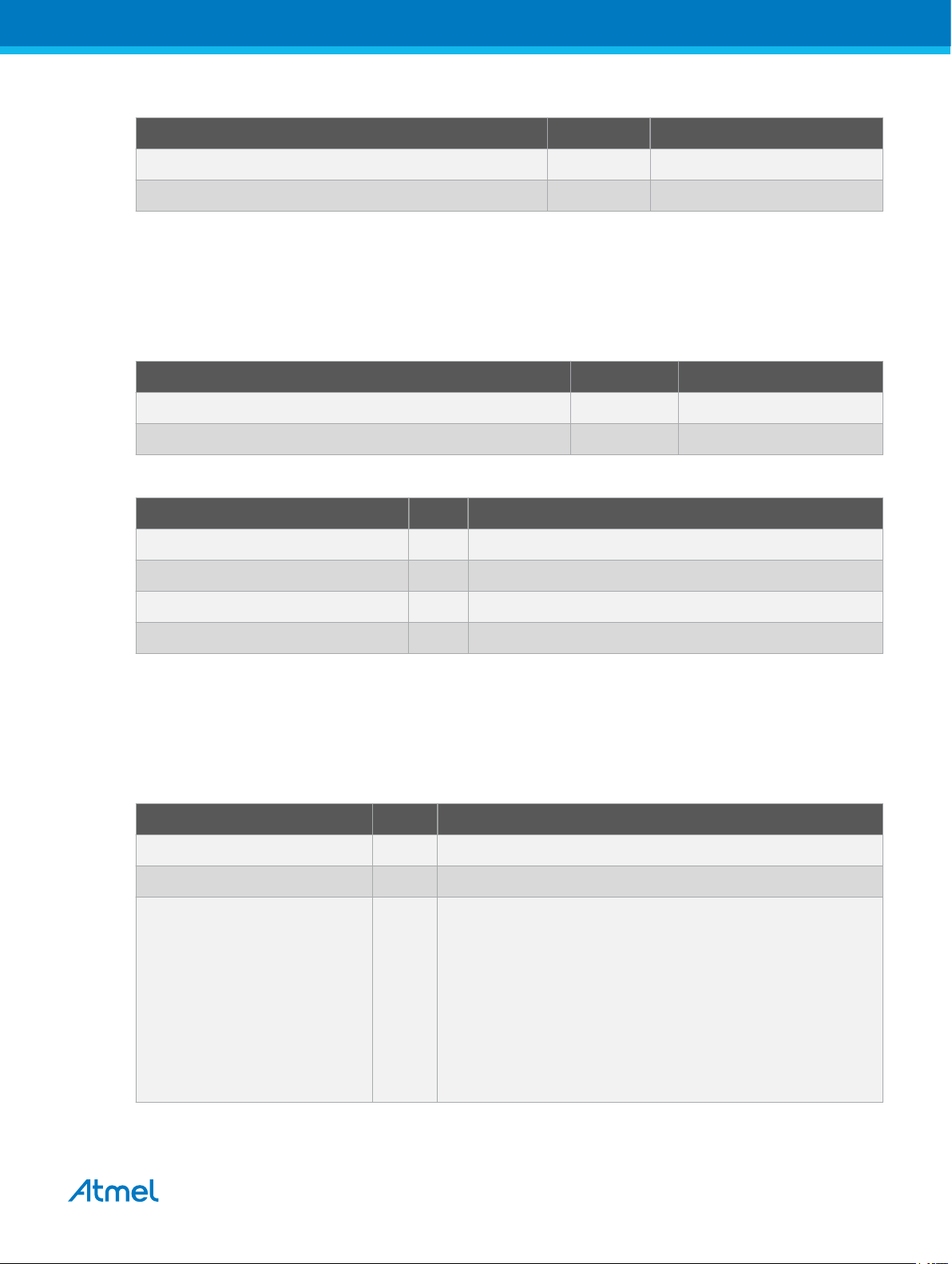

Table 2-12. Response Packet

Field Size Description

DGI_CMD_SET_MODE (0x0A) 1 Byte Command ID.

DGI_RESP_OK (0x80) 1 Byte Response code.

2.5. DGI_CMD_TARGET_RESET

This command sets the state of the reset line.

Table 2-13. Command Packet

Field Size Description

DGI_CMD_TARGET_RESET (0x20) 1 Byte Command ID.

Length (1) 2 Bytes

Reset state 1 Byte • Bit 0

0: Not asserted (released, pulled high by external

pull-up).

1: Asserted (pulled low).

Table 2-14. Response Packet

Field Size Description

DGI_CMD_TARGET_RESET (0x20) 1 Byte Command ID.

DGI_RESP_OK (0x80) 1 Byte Response code.

2.6. DGI_CMD_INTERFACES_LIST

This command is used to discover the available interfaces on the tool. It will receive a list of all interfaces.

Table 2-15. Command Packet

Field Size Description

DGI_CMD_INTERFACES_LIST (0x08) 1 Byte Command ID.

Length (0) 2 Bytes No parameters.

Table 2-16. Response Packet

Field Size Description

DGI_CMD_INTERFACES_LIST (0x08) 1 Byte Command ID.

DGI_RESP_DATA (0x80) 1 Byte Response code.

Count (n) 1 Byte Number of interfaces in following list.

Interface list n Bytes List of identifiers for available interfaces.

Related Links

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

7

Page 8

Interfaces on page 12

2.7. DGI_CMD_INTERFACES_ENABLE

This command controls the off/on state of the interfaces. A list of multiple interface states can be passed.

The return code will stop execution and return a failure response for the first interface failing status

update.

Table 2-17. Command Packet

Field Size Description

DGI_CMD_INTERFACES_ENABLE (0x10) 1 Byte Command ID.

Length (n×2) 2 Bytes

Interface ID 1 Byte Identifier of interface.

State to set Possible values are:

Table 2-18. Response Packet

• 0: Off.

• 1: On.

• 2: On, timestamped.

Field Size Description

DGI_CMD_INTERFACES_ENABLE (0x10) 1 Byte Command ID.

DGI_RESP_OK (0x80) 1 Byte Response code.

Related Links

Timestamp on page 12

2.8. DGI_CMD_INTERFACES_SET_CONFIG

This command sets the configuration of an interface. See the interface specific section for details.

Table 2-19. Command Packet

Field Size Description

DGI_CMD_INTERFACES_SET_CONFIG (0x12) 1 Byte Command ID.

Length (1+6×n) 2 Bytes

Interface ID 1 Byte Identifier of interface to set configuration for.

Config ID 2 Bytes Identifier of configuration parameter to set.

Config value 4 Bytes Value of configuration parameter. Repeated

Repeated n times.

n times.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

8

Page 9

Table 2-20. Response Packet

Field Size Description

DGI_CMD_INTERFACES_SET_CONFIG (0x12) 1 Byte Command ID.

DGI_RESP_OK (0x80) 1 Byte Response code.

2.9. DGI_CMD_INTERFACES_GET_CONFIG

This command gets the configuration of an interface. See the interface specific section for details.

Table 2-21. Command Packet

Field Size Description

DGI_CMD_INTERFACES_GET_CONFIG (0x13) 1 Byte Command ID.

Length (1) 2 Bytes

Interface ID 1 Byte Identifier of interface to set configuration for.

Table 2-22. Response Packet

Field Size Description

DGI_CMD_INTERFACES_GET_CONFIG (0x13) 1 Byte Command ID.

DGI_RESP_DATA (0xA0) 1 Byte Response code.

Length 2 Bytes Length, n, of configuration.

Config ID 2 Bytes Identifier of configuration parameter to set.

Config value 4 Bytes Value of configuration parameter. Repeated

2.10. DGI_CMD_INTERFACES_POLL_DATA

This command polls data from the receive buffer of an interface. It needs to be called often to avoid

overflow conditions in the device buffers. Only call this command for interfaces that are on and does not

have timestamping enabled. Data for interfaces using timestamped mode can be polled from the

timestamp interface. See the timestamp section for details. The mode set command affects the response

of this command.

Table 2-23. Command Packet

Field Size Description

DGI_CMD_INTERFACES_POLL_DATA (0x15) 1 Byte Command ID.

Length (1) 2 Bytes

Repeated n times.

n times.

Interface ID 1 Byte Identifier of interface to poll data from.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

9

Page 10

Table 2-24. Response Packet

Field Size Description

DGI_CMD_INTERFACES_POLL_DATA

(0x15)

DGI_RESP_DATA (0xA0) 1 Byte Response code.

Length (n) 2/4 Bytes

Overflow indicator* 0/4 Bytes A non-zero value means an

Data n Bytes Raw data that has been received

Related Links

Timestamp on page 12

2.11. DGI_CMD_INTERFACES_SEND_DATA

This command sends data over the specified interface. The interface must be enabled first. Data is

buffered and will be sent to the master at the clock speed determined by the configuration, or at the

speed determined by the master of the physical interface (as for SPI, I2C, and USART). The command

will return true as long as the data buffer is free. If there is pending data in the send buffer already, this

command will return a failure.

Table 2-25. Command Packet

1 Byte Command ID.

Amount of data received

depending on

mode set

overflow has occurred. Only

available if specifically set by a set

mode command. Not included in

the length field even if enabled.

from the interface.

Field Size Description

DGI_CMD_INTERFACES_SEND_DATA (0x14) 1 Byte Command ID.

Length (1+n) 2 Bytes n is limited to 250 bytes.

Interface ID 1 Byte Identifier of interface to send data to.

Data n Bytes Data to send over interface.

Table 2-26. Response Packet

Field Size Description

DGI_CMD_INTERFACES_SEND_DATA (0x14) 1 Byte Command ID.

DGI_RESP_OK (0x80) 1 Byte Response code.

2.12. DGI_CMD_INTERFACES_STATUS

This command gets the status of all available subscriptions.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

10

Page 11

Table 2-27. Command Packet

Field Size Description

DGI_CMD_INTERFACES_STATUS (0x11) 1 Byte Command ID.

Length (0) 2 Bytes

Table 2-28. Response Packet

Field Size Description

DGI_CMD_INTERFACES_STATUS (0x11) 1 Byte Command ID.

DGI_RESP_DATA (0xA0) 1 Byte Response code.

Interface ID 1 Byte Identifier for interface. This byte is repeated for each

interface.

Status 1 Byte Status of interface.

• Bit 0: Started.

• Bit 1: Timestamped mode.

• Bit 2: Overflow occurred.

This byte is repeated for each interface.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

11

Page 12

3. Interfaces

All functionality of DGI is centered around the implemented interfaces. All interfaces uses the same USB

protocol, but every interface has it's own configuration parameters and handling of communication. For

details refer to the interface-specific sections. Note that not all interfaces are available on all boards

implementing the DGI device. The available interfaces can be read through the USB protocol.

Table 3-1. List of Interfaces

Name Identifier Description

Timestamp 0x00 Service interface which appends timestamps to all received events

SPI 0x20 Communicates directly over SPI in slave mode.

USART 0x21 Communicates directly over USART in slave mode.

I2C 0x22 Communicates directly over I2C in slave mode.

GPIO 0x30 Monitors and controls the state of GPIO pins.

on associated interfaces.

Power 0x40 (data) and 0x41

Reserved 0xFF Special identifier used to indicate no interface.

Related Links

DGI_CMD_INTERFACES_LIST on page 7

3.1. Timestamp

The data returned over the timestamp interface is a sequential stream of timestamped packets of data

belonging to the interfaces that has timestamping enabled. The first byte in each packet is the interface

identifier and will decide how the rest of the packet must be parsed.

The timestamp is relying on a 16-bit timer, which is sampled and embedded into each packet. The timer

tick frequency can be read from the timestamp configuration. It is in the area of about half a microsecond.

When the timer overflows, a packet will be embedded in the stream to indicate this event. Note that if a

data packet is being embedded as the timer overflows, an overflow packet will not be embedded. Instead

it will be indicated in the header of the data packet.

All timestamped packets are generated from module interrupts within the DGI device, which can not be

interrupted by the timer overflow interrupt. This means that there is a possibility that the timer has

overflowed before the timer was sampled and embedded. To be able to keep the timestamp in sync and

accurate for such events the packets are also embedding the timer overflow bit. This bit is sampled after

the timer itself, and can potentially be set even if the sampled timer value was in sync.

(sync events)

Receives data and sync events from attached power measurement

co-processors.

3.1.1. Parsing

The timestamp data is a buffer containing data from several interfaces in the order they were received.

Each entry has the format as shown below.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

12

Page 13

Table 3-2. Data Format

Field Size Description

Interface ID 1 Byte Identifies the interface this entry is related to.

Interface specific data n Bytes The length and interpretation of data is specific to the interface ID.

To handle the timestamp properly declare a variable to accumulate the ticks as the timer overflows

(hereby denoted by Tc). The timestamp of an entry (hereby denoted by T) is the sum of Tc and the

timestamp tag of the entry (hereby denoted by Tt). Note that T is a value of ticks since sampling was

started. The length of a tick can be found in the configuration section. While iterating the data coming

from the timestamp interface, resolve the interface ID and handle the timestamp and interpretation of the

data according to the details in the following sections.

Timestamp [0x00]

An entry with the timestamp interface ID is embedded for every overflow of the 16-bit timer. Tc should be

incremented by 216 = 65536. The data section of this entry contains a counter that is incremented once

for each entry of this type.

Table 3-3. Timestamp Specific Data

Field Size Description

Counter 1 Byte Incremented for each entry of this type.

SPI [0x20], USART [0x21], I2C [0x22], GPIO [0x30]

For each character received over SPI, I2C, USART, or a change on the GPIO lines an entry is made in the

timestamp buffer. The entry contains a sample of the 16-bit timer (Tt) which must be added to Tc to get T.

It also contains a timer overflow flag which requires special consideration. If this byte is non-zero it means

that the timer has overflowed during handling the current entry, and Tt must be examined to decide if it

happened before or after the timestamp was sampled. If Tt is less than 256 or so, the overflow happened

prior to sampling and Tc must be incremented by 216 prior to calculating T. In the other case, Tt is greater

than 256, Tc is incremented by 216 after T has been calculated. The overflow flag is cleared after this, so

no entry with the timestamp ID will be embedded in the stream for this overflow.

Table 3-4. Specific Data

Field Size Description

Timestamp 2 Byte The 16-bit timer value.

Timer overflow flag 1 Byte If this is non-zero the timer has overflowed during the handling of this entry.

Data 1 Byte The received data.

Power sync [0x41]

An entry of this type is embedded for every 1000 samples, and gives the timestamp of the n×1000th

sample in the power stream. In this context, n denotes the count of entry occurrences of this type since

the power interface was started. The structure of this entry is the same as described above for SPI,

USART, etc. The data field contains a counter which is incremented for each entry of this type.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

13

Page 14

Table 3-5. Specific data

Field Size Description

Timestamp 2 Byte The 16-bit timer value.

Timer overflow flag 1 Byte If this is non-zero the timer has overflowed during the handling of this entry.

Counter 1 Byte Incremented for each packet.

3.1.2. Configuration

The timestamp configuration contains the timer tick frequency (denoted by fT) and prescaler (denoted by

p). These values can be used to calculate a timestamp in seconds (denoted by t) from the tick count

(denoted by T) by the formula =

Table 3-6. Configuration Parameters

Field ID Description

Prescaler 0 Prescaler, p, of the tick duration.

Frequency 1 Frequency, fT, of the timer module.

.

3.2. GPIO

The GPIO interface consists of four lines available, which can be individually set to input or output

through the configuration interface. This interface can only be used in timestamp mode. Input lines are

monitored and will trigger an entry to be added to the timestamp buffer on each change. Output lines can

be controlled through the send data command.

3.2.1. Parsing

Each received data byte corresponds to an input pattern on the GPIO pins. If a bit is 1 it means that the

corresponding GPIO pin is high, a 0 means a low level.

3.2.2. Configuration

The GPIO configuration controls the direction of the pins.

Table 3-7. Configuration Parameters

Field ID Description

Input pins 0 Setting a bit to 1 means the pin is monitored.

Output pins 1 Setting a bit to 1 means the pin is set to output and can be controlled by the send

command.

3.3. SPI

The SPI interface is used for serial transfer of data. It operates in slave mode, and requires the master to

initiate all communication. Whenever the SPI master does a transfer a character is added in the incoming

buffer and a character is sent from the SPI send buffer. If no data is availabe in the send buffer it will send

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

14

Page 15

0xFF as an idle character. This must be taken into consideration in the protocol to be able to distinguish

idle characters from real data.

To avoid the risk of getting out of synchronization with the SPI transfer and starting receiving data in the

middle of a character, the configuration allows for forcing the interface to wait for the chip select line to

toggle before starting.

3.3.1. Parsing

The data received over the SPI interface is the raw data. No special handling is required.

3.3.2. Configuration

The SPI configuration controls the mode of transfer used.

Table 3-8. Configuration Parameters

Field ID Description

Character length 0 The number of bits in one character (5-8).

SPI mode 1 Sets the transfer mode used for SPI:

• 0: Clock idle low, sample on rising edge

• 1: Clock idle low, sample on falling edge

• 2: Clock idle high, sample on falling edge

• 3: Clock idle high, sample on rising edge

Force CS sync 2 Setting this parameter will make the SPI interface wait for a chip select toggle

3.4. USART

The USART interface is used for serial transmission of data. It can operate in both synchronous and

asynchronous modes. In synchronous mode the USART works in slave mode and the clock line must be

supplied from an external master.

3.4.1. Parsing

The data received over the USART interface is the raw data. No special handling is required.

3.4.2. Configuration

The configuration sets the transfer parameters of the USART.

Table 3-9. Configuration Parameters

Field ID Description

Baud rate 0 The transfer speed of the interface in asynchronous mode.

Character length 1 The number of bits of data in each character (5-8).

before starting SPI transfers.

Parity type 2 The type of parity bit; 0 = Even, 1 = Odd, 2 = Space, 3 = Mark, 4 = None

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

15

Page 16

Field ID Description

Stop bits 3 Count of stop bits used; 0 = 1 bit, 1 = 1.5 bits, 2 = 2 bits

Synchronous mode 4 If this is non-zero synchronous mode will be used. Otherwise asynchronous

3.5. I2C

The I2C interface is used to transfer data serially. It operates in slave mode and must therefore have a

master connected to control the data flow.

Data is transmitted from the master by addressing the slave with the write flag. Then data can be sent

byte by byte to the slave device.

To support transferring data from the PC to the I2C master, the master has to poll the slave device

regularly by sending the address with the read flag. The first byte read indicates the count of bytes of data

waiting. If it is non-zero there is waiting data, and this data must be read out byte by byte in the same

operation (no stop or repeated start).

3.5.1. Parsing

The data received over the I2C interface is the raw data. No special handling is required.

3.5.2. Configuration

mode is used.

The I2C configuration sets the operation parameters of the interface.

Table 3-10. Configuration Parameters

Field ID Description

Speed 0 The expected operation speed of the interface in Hertz helps the slave device adjust the

Address 1 Address of the slave device.

3.6. Power

The power interface is used to transfer power measurements and related data. It relies on a coprocessor

that does the power measurements and transmits a stream of formatted data.

There are currently two flavors of the power measurement coprocessor, which are referred to as the XAM

and the PAM. XAM is used on Xplained Pro boards that is embedding power measurement capabilities.

PAM is used on the Power Debugger and offers a greater feature set. Look in the documentation for the

Xplained Pro and Power Debugger for more details about the feature sets.

3.6.1. Parsing

The data coming from the power interface is a stream of packets of variable length. The upper 2 bits of

the first byte of each packet describes the type and decides the rest of the interpretation. Below is a table

of valid packet types.

timings. Up to 400kHz is supported.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

16

Page 17

Table 3-11. Packet Types

Type ID (upper 2 bits) Description

Primary sample 0b10 3-byte packet of A channel current sample.

Auxiliary sample 0b00 2-byte packet of B channel current sample and A and B channel

voltage sample.

Notification 0b11 Notification packet for special events.

Reserver 0b01

Notification

The notification packet is 1 byte long in total. It provides a way to give notifications about events.

Table 3-12. Notification Interpretation

Field Bit position Description

ID 7:6 Set to 0b11 for this packet.

Extended 5 Reserved for future use.

Type 4 If 0, data field contains an event, otherwise it's a sample rate.

Data 3:0 Type of event or sample rate

Table 3-13. Events

Event Value Description

Sync tick 0 This event is embedded in the stream after every 1000 samples for PAM.

Primary sample

The primary sample packet contains a sample of the A channel current. It holds information about the

range of the current sample, which must be used to index the correct calibration values.

Table 3-14. Primary Sample Interpretation

Field Bit position Description

ID 23:22 Set to 0b10 for this packet.

Range 21:20 For XAM the range field is used as an index for the calibration to be used.

For PAM, 0 means low range, 1 means high range and 2 means invalid

sample and the previous value should be used instead.

Sample rate 19:16 The sample rate can be ignored as this is constant for the current

implementation. For XAM it is 16kHz. For PAM it is 62.5kHz.

Sample 15:0 The raw value of the sample is used together with the calibration data to

calculate the actual current value.

Auxiliary sample

The auxiliary sample packet transmits A- and B-channel voltage and B-channel current. It is currently only

used for PAM. Whenever such a packet is received it should be timestamped with the same timestamp as

the latest primary packet.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

17

Page 18

Table 3-15. Auxiliary Sample Interpretation

Field Bit position Description

ID 15:14 Set to 0b00 for this packet.

Channel 13:12 0 = B Current, 1 = B Voltage, 2 = A Voltage.

Sample 11:0 For voltage data divide the raw value by -200 to get the measured voltage. For

3.6.2. Configuration

The power configuration consists of a generic section that can be used to control the power measurement

and related functionality. There is also a section that is specific to the type of power coprocessor used.

The specific section contains the calibration that is required to interpret the incoming data and get the

correct output values.

Table 3-16. Generic Configuration Parameters

Field ID Description

Type 0 Type of coprocessor for power measurement.

current data use the calibration values.

• XAM = 0x10

• PAM = 0x11

Channel 1 Setting a bit to 1 will activate the related channel; bit 0=A, bit 1=B.

Calibrate 2 For XAM, any write will trigger calibration. For PAM, the value will decide the type of

calibration performed; 2 = Reset to factory, 3 = A channel, 4 = B channel.

Lock range 3 For PAM, setting to 1 will lock the A channel in high range. For XAM, not

implemented.

Output voltage 4 For PAM, sets the output voltage of the target supply to the given value in mV. For

XAM, not implemented.

XAM

The XAM coprocessor calibration start at parameter ID 10. It consists of four blocks of configuration

parameters, one for each supported range. The blocks has the structure as described in the table below.

Note that 'N' refers to the range index.

Table 3-17. XAM Range Calibration Parameters

Field ID Type Description

Token N×12 + 10 uint16 The lower byte contains the id of the range on the form 0xnn (n =

N+1). Note that the sample field in the data packet uses 0indexing, where this field uses 1-indexing. The upper byte

identifies the state of the calibration:

• 0 = Uncalibrated

• 1 = Factory calibrated

• 2 = User calibrated

Offset

correction

N×12 + 13 uint16 Subtract this value from the raw value to correct offset error.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

18

Page 19

Field ID Type Description

Float gain

N×12 + 14 float Multiply the offset corrected raw value with this gain correction.

correction

µA Resolution N×12 + 20 float Resolution in µA. Factor to multiply the corrected raw value with to

get the current in µA.

PAM

The PAM coprocessor, having a wider range, has a more complex model for calibration. To read the PAM

calibration it is necessary to read the entire block of parameter values from 10 to 175 into a buffer. The

buffer can then be parsed into the following sections:

The 32-byte header:

Table 3-18. PAM Calibration Header

Field Offset Type Description

Format 0 uint8 Calibration format version. Set to 2 for this version.

Data invalidation 1 uint8 Is set to zero to indicate successful calibration

Local A-channel

calibration

2 int16 Contains an averaged offset value for the high range of channel

A, as used internally by the PAM.

User calibration flag 4 uint8 Indicates whether the calibration data is the result of a factory

( 0 ) or user ( 1 ) calibration.

The 512-byte A-Channel calibration parameters:

The 'N' parameter represents the eight voltage ranges on the PAM, as determined by this formula:

= 1.6 +

Table 3-19. PAM CHA Calibration Parameters

. Use the calibration point that is closest to the actual voltage reported by the tool.

1.8

Field Offset Type Description

Format 0 uint8

Data invalidation 1 uint8 Is set to zero to indicate successful calibration

High range calibration

data

Low range calibration

data

N×60 + 8 see below Contains the calibration data for voltage N for the high

range of the A-channel as described below.

N×60 + 22 see below Contains the calibration data for voltage N for the low

range of the A-channel as described below.

For each calibration voltage, the PAM A-channel calibration data contains a two-segment linearization for

each range. The top segment of the low range and the low segment of the high range use the same

calibration currents and helps ensure a good transition between the ranges.

Table 3-20. PAM CHA Calibration Data

Field Offset Type Description

High level offset 0 int16

High level gain 2 float

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

19

Page 20

Field Offset Type Description

Crosspoint 6 int16 The cross-point indicates the raw data value where the high and low

segment meet.

Low level offset 8 int16

Low level gain 10 float

The B-Channel calibration data is contained in the remainder of the calibration:

The 'N' parameter represents the eight voltage ranges on the PAM.

Table 3-21. PAM CHB Calibration Parameters

Field Offset Type Description

Format 0 uint8

Data invalidation 1 uint8 Is set to zero to indicate successful calibration

Offset N×14 + 2 int16

Gain N×14 + 4 float

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

20

Page 21

4. Revision History

Doc Rev. Date Comments

32223A 09/2016 Initial document release.

Atmel Data Gateway Interface [USER GUIDE]

Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

21

Page 22

Atmel Corporation 1600 Technology Drive, San Jose, CA 95110 USA T: (+1)(408) 441.0311 F: (+1)(408) 436.4200 | www.atmel.com

©

2016 Atmel Corporation. / Rev.: Atmel-32223A-Data-Gateway-Interface_User Guide-09/2016

Atmel®, Atmel logo and combinations thereof, Enabling Unlimited Possibilities®, and others are registered trademarks or trademarks of Atmel Corporation in U.S. and

other countries. Other terms and product names may be trademarks of others.

DISCLAIMER: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN THE ATMEL TERMS AND

CONDITIONS OF SALES LOCATED ON THE ATMEL WEBSITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED

OR STATUTORY WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT,

CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS AND PROFITS, BUSINESS

INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no representations or warranties with respect to the accuracy or completeness of the contents of this

document and reserves the right to make changes to specifications and products descriptions at any time without notice. Atmel does not make any commitment to

update the information contained herein. Unless specifically provided otherwise, Atmel products are not suitable for, and shall not be used in, automotive

applications. Atmel products are not intended, authorized, or warranted for use as components in applications intended to support or sustain life.

SAFETY-CRITICAL, MILITARY, AND AUTOMOTIVE APPLICATIONS DISCLAIMER: Atmel products are not designed for and will not be used in connection with any

applications where the failure of such products would reasonably be expected to result in significant personal injury or death (“Safety-Critical Applications”) without

an Atmel officer's specific written consent. Safety-Critical Applications include, without limitation, life support devices and systems, equipment or systems for the

operation of nuclear facilities and weapons systems. Atmel products are not designed nor intended for use in military or aerospace applications or environments

unless specifically designated by Atmel as military-grade. Atmel products are not designed nor intended for use in automotive applications unless specifically

designated by Atmel as automotive-grade.

Loading...

Loading...