Page 1

Features

• Utilizes the AVR

• AVR - High-performance and Low-power RISC Architecture

– 118 Powerful Instructions - Most Single Clock Cycle Execution

– 32 x 8 General Purpose Working Registers

– Up to 8 MIPS Throughput at 8 MHz

• Data and Nonvolatile Program Memory

– 2K Bytes of In-System Programmable Flash

Endurance 1,000 Write/Erase Cycles

– 128 Bytes of internal SRAM

– 128 Bytes of In-System Programmab le EEPR OM

Endurance: 100,000 Write/Erase Cycles

– Programming Lock for Flash Program and EEPROM Data Security

• Peripheral Features

– One 8-bit Timer/Counter with Separate Prescaler

– Programmable Watchdog Timer with On-chip Oscillator

– SPI Serial Interface for In-System Programming

• Special Microcontroller Features

– Low-power Idle and Power Down Modes

– External and Internal Interrupt Sources

– Power-on Reset Circu it

– Selectable On-chip RC Oscillator

• Specifications

– Low-power, High-speed CMOS Process Technology

– Fully Static Operation

• Power Consumption at 4 MHz, 3V, 25°C

– Active: 2.4 mA

– Idle Mode: 0.5 mA

– Power Down Mode: <1 µA

• I/O and Packages

– 5 Programmable I/O Lines

– 8-pin PDIP and SOIC

• Operating Voltages

– 2.7 - 6.0V (ATtiny22L)

– 4.0 - 6.0V (ATtiny22)

• Speed Grades

– 0 - 4 MHz (ATtiny22L)

– 0 - 8 MHz (ATtiny22)

®

RISC Architecture

8-bit

Microcontr oller

with 2K Bytes of

In-System

Programmable

Flash

A Ttiny22

A Ttiny22L

Preliminary

Description

The ATtiny22/ L is a low-p ower CMO S 8 -bit micr ocon troll ers b ase d on the AV R RIS C

architecture. By executing powerful instructions in a single clock cycle, the ATtiny22/L

achieves throughputs approaching 1 MIPS per MHz allowing the system designer to

optimize power consumption versus processing speed.

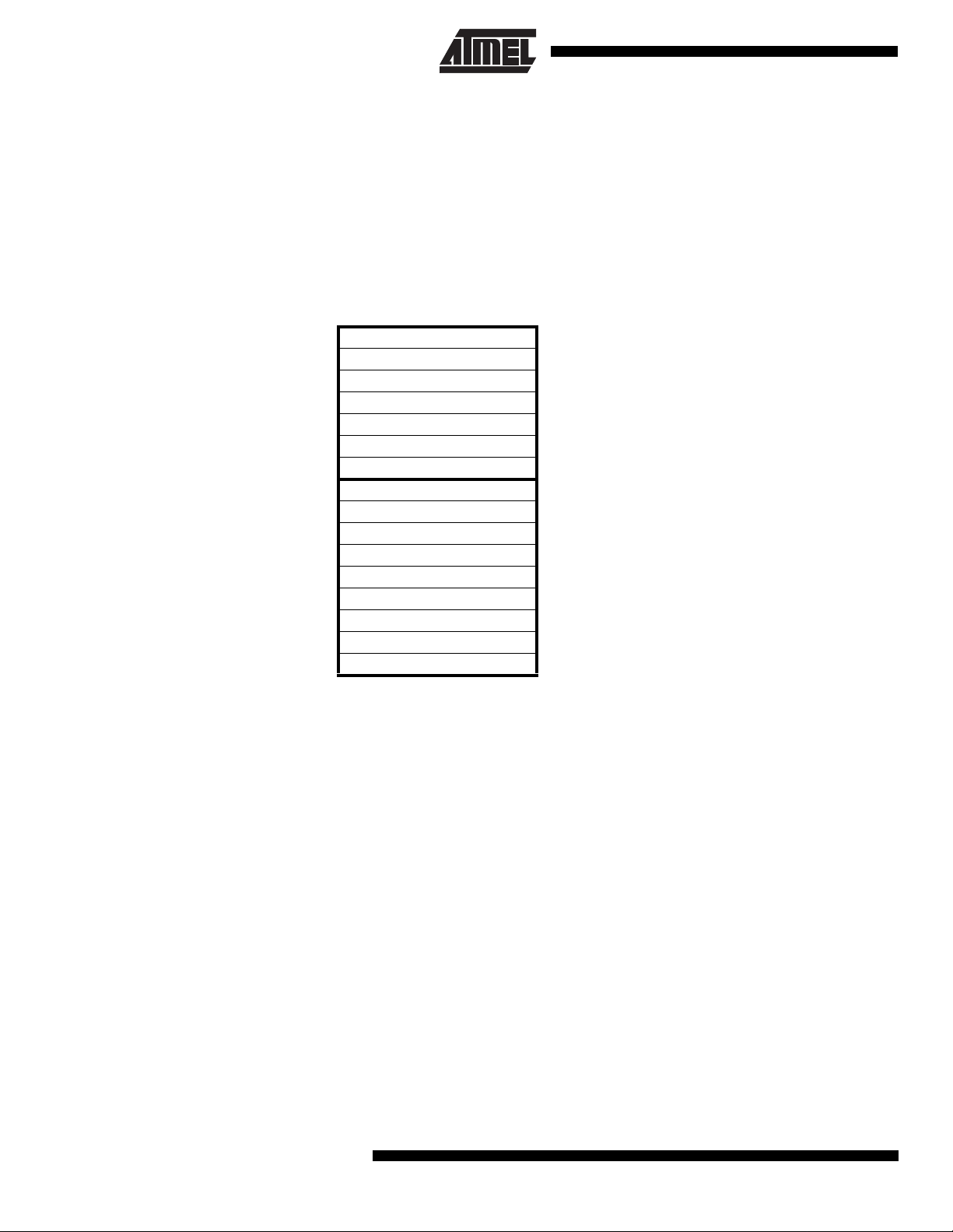

Pin Configuration

PDIP/SOIC

8

RESET

(CLOCK) PB3

PB4

GND

1

2

3

4

VCC

7

PB2 (SCK/T0)

6

PB1 (MISO/INT0)

5

PB0 (MOSI)

Rev. 1273A–04/99

1

Page 2

The AVR core combines a rich instruction set with 32 general purpose working registers. All the 32 registers are directly

connected to the Arithm etic Lo gic Unit (A LU), al lowing two ind ependen t regist ers to b e access ed in on e single inst ruction

executed in one clock cycle. The resulting architecture is more code efficient while achieving throughputs up to ten times

faster than conventional CISC microcontrollers.

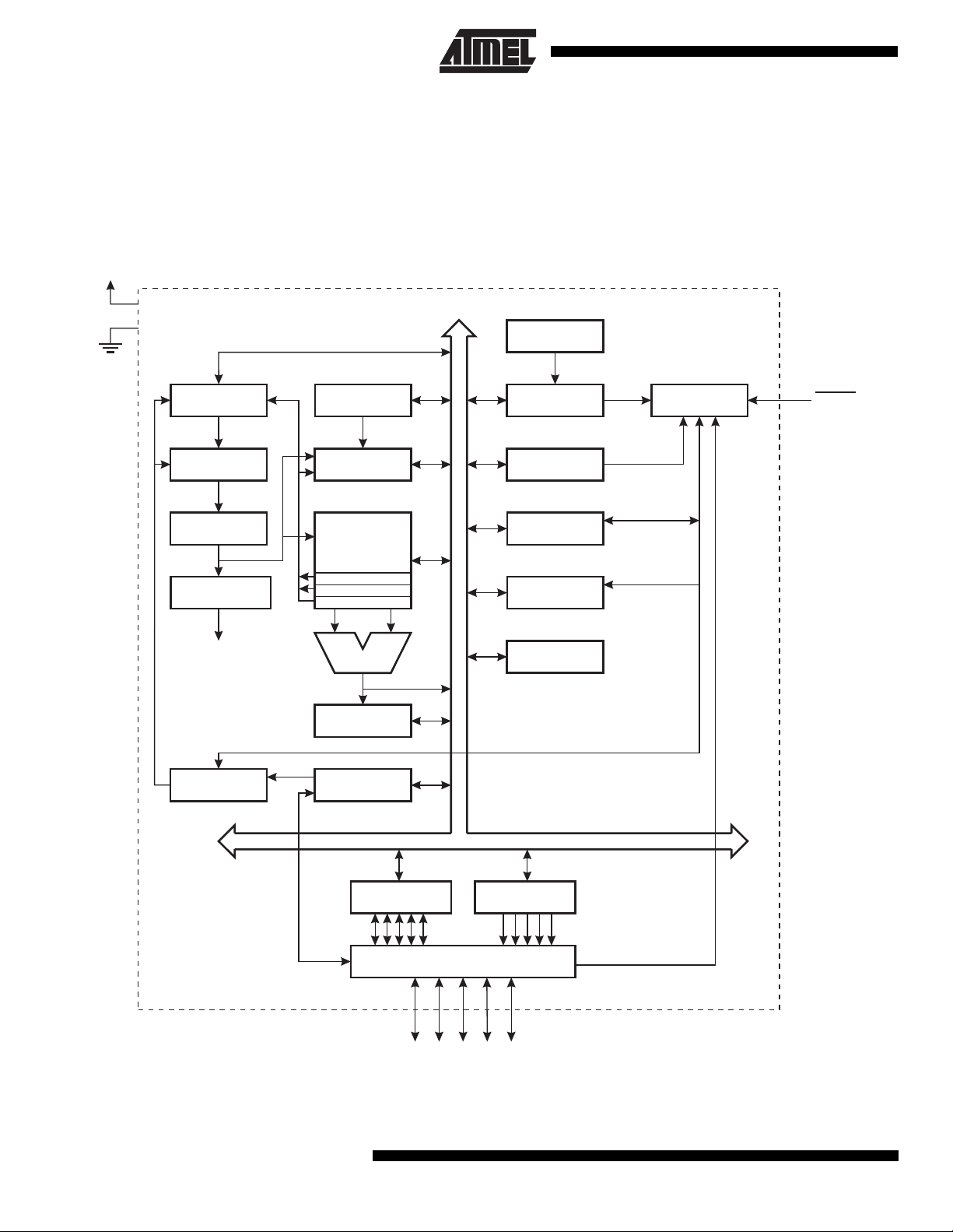

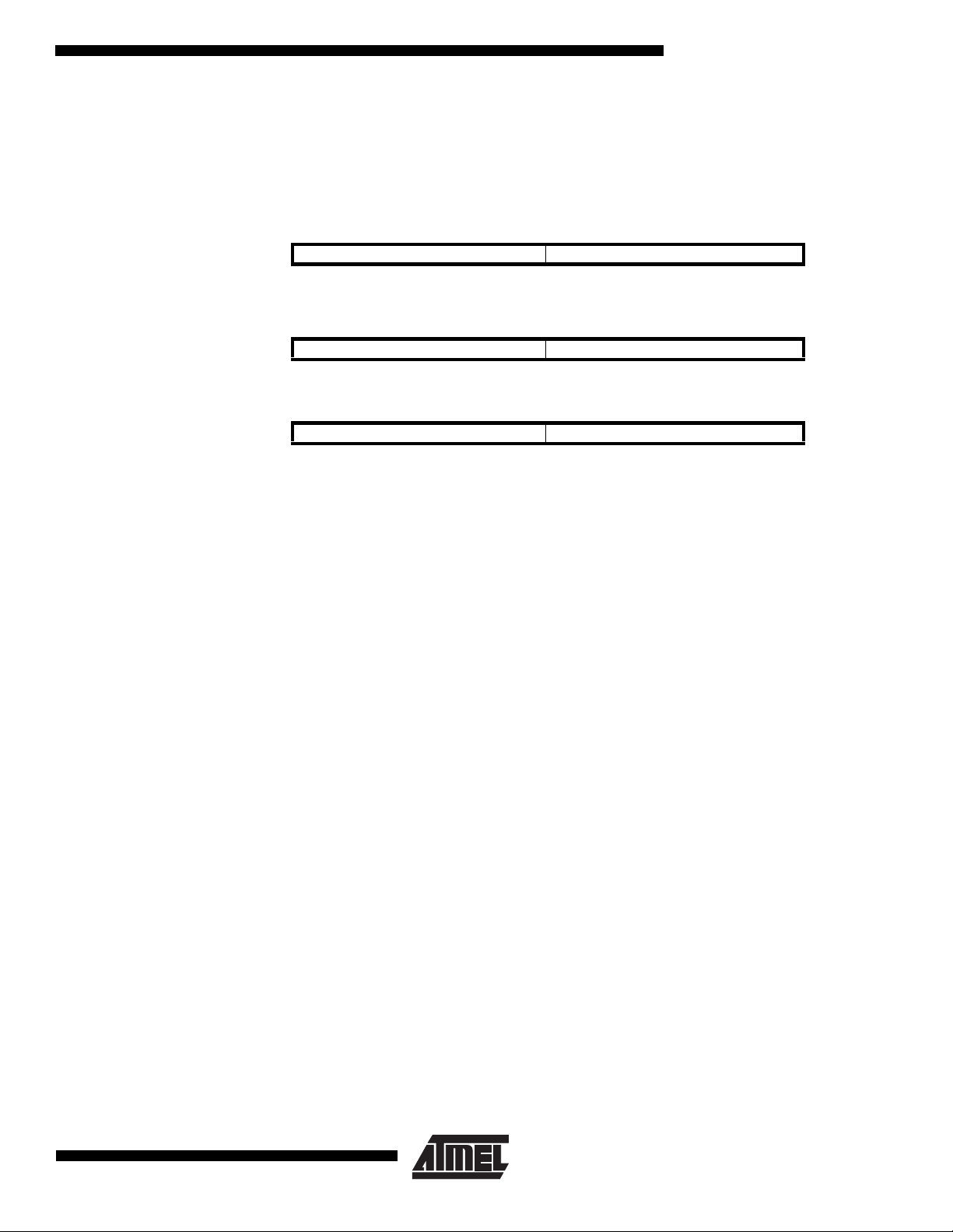

Block Diagram

Figure 1. The ATtiny22/L Block Diagram

VCC

8-BIT DATA BUS

INTERNAL

OSCILLATOR

GND

PROGRAM

COUNTER

PROGRAM

FLASH

INSTRUCTION

REGISTER

INSTRUCTION

DECODER

CONTROL

LINES

PROGRAMMING

LOGIC

STACK

POINTER

SRAM

GENERAL

PURPOSE

REGISTERS

X

Y

Z

ALU

STATUS

REGISTER

SPI

WATCHDOG

TIMER

MCU CONTROL

REGISTER

TIMER/

COUNTER

INTERRUPT

UNIT

EEPROM

TIMING AND

CONTROL

RESET

DATA REGISTER

PORTB

PORTB DRIVERS

PB0 - PB4

2

ATtiny22/22L

DATA DIR.

REG. PORTB

Page 3

ATtiny22/22L

The ATtiny22/L provides the following features: 2K bytes of In-System Programmable Flash, 128 bytes EEPROM,

128 bytes SRAM, five gen er al purpo se I/O l ine s, 32 g ene ral p ur pos e w or king r e gist ers , an 8- bit ti mer /counter, internal and

external interrupts , progr ammab le Wa tchdog Timer with i nternal osci llator, an S PI se rial p ort fo r Flash Memory downl oading and two softwa re selectable powe r saving modes. T he Idle Mode st ops the CPU while a llowing the SRAM,

timer/counters, SPI port and interrupt system to continue functioning. The power down mode saves the register contents

but freezes the oscillator, disabling all other chip functions until the next interrupt or hardware reset.

The device is manufactured using Atmel’s high density nonvolatile memory technology. The on-chip Flash allows the

program memory to be reprogrammed in-system through an SPI serial interface. By combining an 8-bit RISC CPU with ISP

Flash on a monolithic chip, the Atmel ATtiny22/L is a powerful microcontroller that provides a highly flexible and cost effective solution to many embedded control applications.

The ATtiny22/L AVR is supported with a full suite of program and system development tools including: C compilers, macro

assemblers, program debugger/simulators, in-circuit emulators, and evaluation kits.

Pin Descriptions ATtiny22/L

VCC

Supply voltage pin.

GND

Ground pin.

Port B (PB4..PB0)

Port B is a 5-bi t bi-dir ectional I /O port . Port pi ns can pr ovide in ternal p ull-up res istors (s elected fo r each bit). Wh en the

device is clocked from an external clock source, PB3 is used as the clock input. The port B pins are tri-stated when a reset

condition becomes active, even if the clock is not running.

RESET

Reset input. An exter na l res et is g ene ra ted by a l ow le vel o n th e RE SE T pin. Res et pulses lon ger than 50 ns will generate

a reset, even if the clock is not running. Shorter pulses are not guaranteed to generate a reset.

CLOCK

Clock signal input in external clock mode.

Clock Options

External Clock

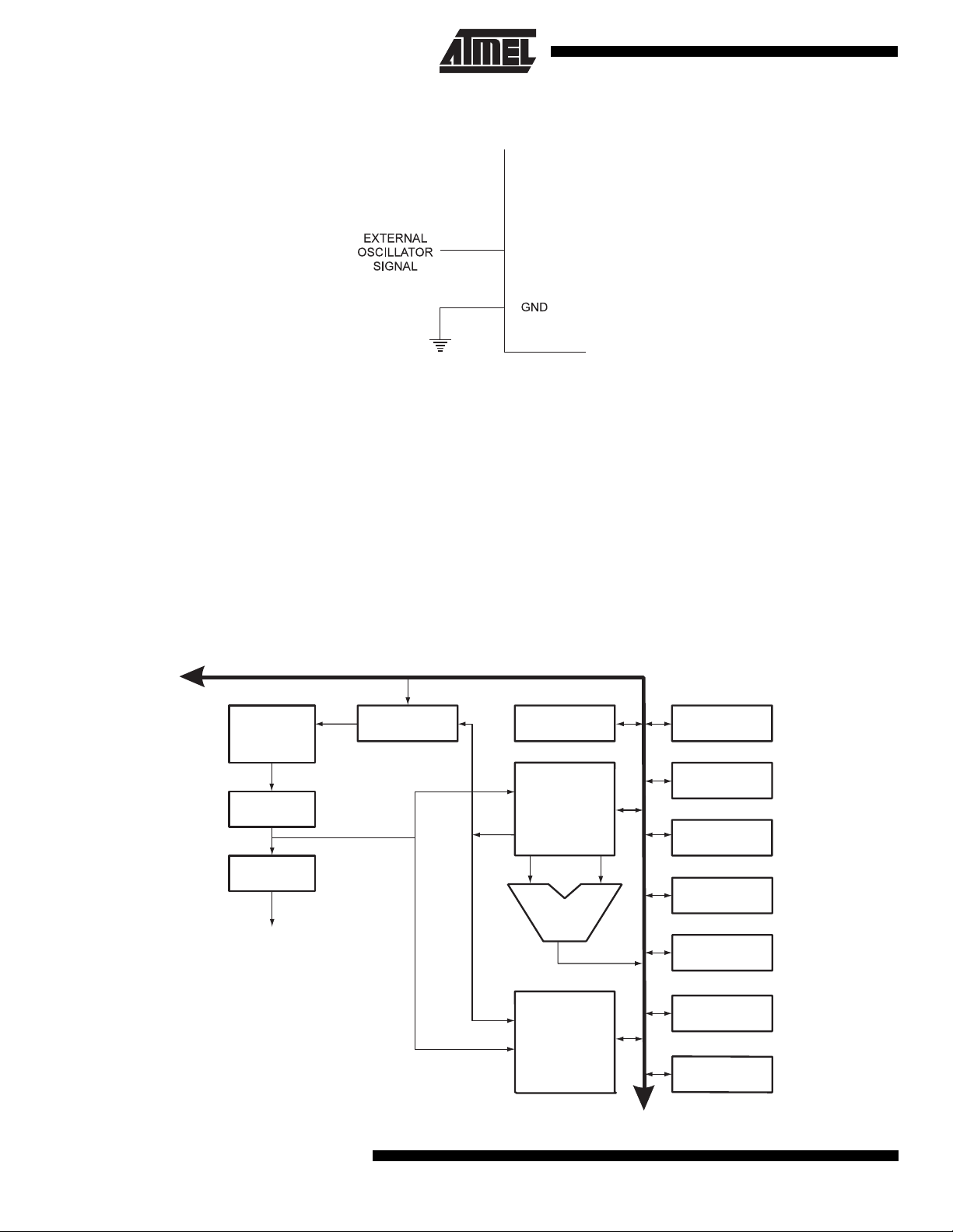

The ATtiny22/L can be clocked by an ext ernal cl ock sign al, as s hown in Figur e 2, or by the on -chip RC os cill ator. This RC

oscillator runs at a nomi nal frequ ency of 1 MHz (VCC = 5V). A fuse bit - RCEN - in the Fla sh memory selects the on -chip

RC oscillator as the clock source when programmed (“0”). The ATtiny22/L is shipped with this bit programmed.

3

Page 4

Figure 2. External Clock Drive Configuration

PB3

Architectural Overview

The fast-access register file concept contains 32 x 8-bit general purpose working registers with a single clock cycle access

time. This means that during one single clock cycle, one arithmetic logic unit (ALU) operation is executed. Two operands

are output from the registe r file, the operati on is executed, and the result is sto red back in the regi ster file in one cl ock

cycle.

Six of the 32 registers can be used as three 16-bit indirect address register pointers for Data Space addressing enabling

efficient address cal cula tions . One of th e thre e addres s poi nters i s also u sed as the a ddress pointer for the c onstan t table

look up function. These added function registers are the 16-bit X-register, Y-register and Z-register.

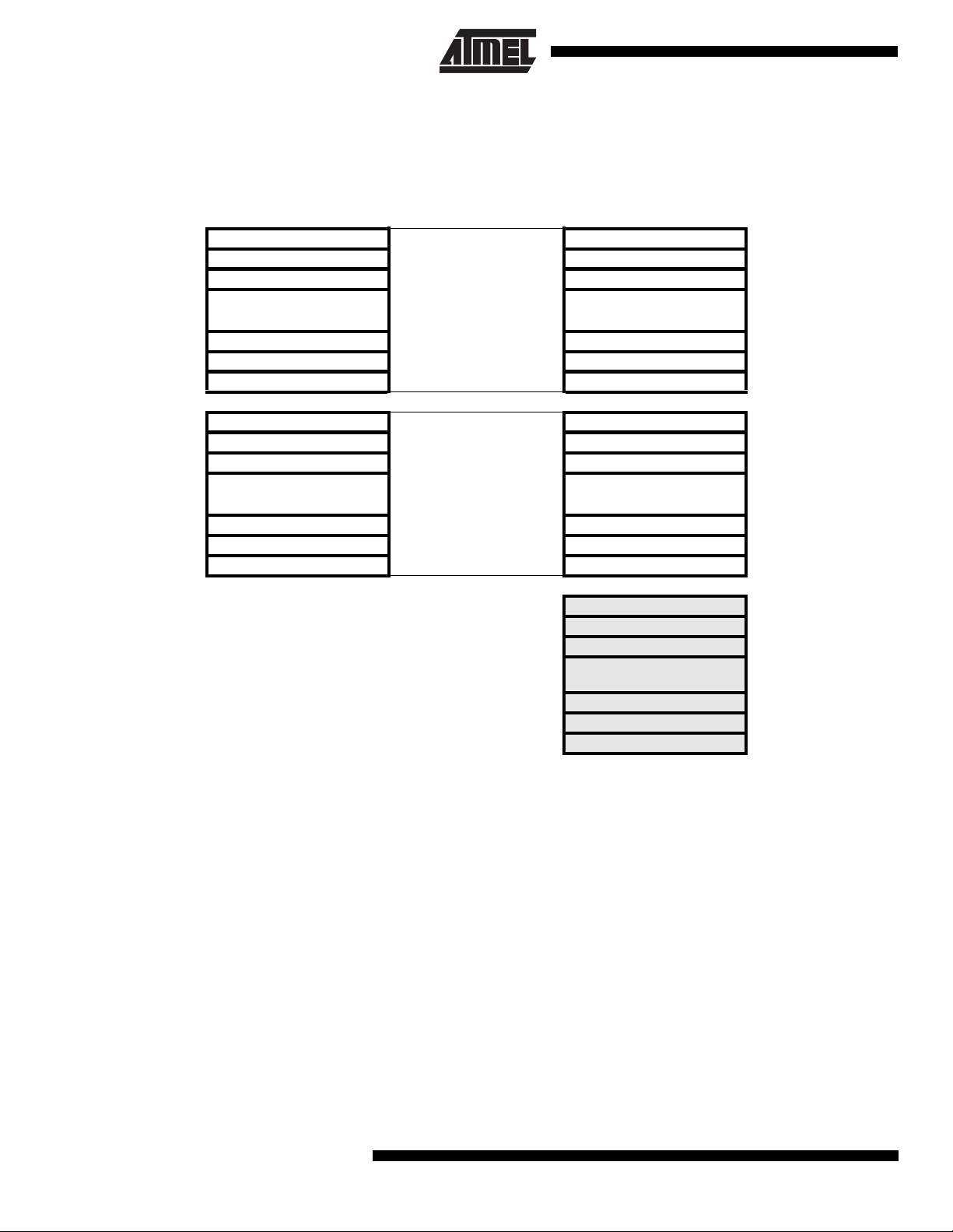

Figure 3. The ATtiny22/L AVR RISC Architecture

AVR

1K x 16

Program

Flash

Instruction

Register

Instruction

Decoder

Control Lines

Program

Counter

ATtiny22/L Architecture

Data Bus 8-bit

Status

and Test

32 x 8

General

Purpose

Registers

ALU

Direct Addressing

Indirect Addressing

128 x 8

Data

SRAM

Control

Registers

Interrupt

Unit

SPI

Unit

8-bit

Timer/Counter

Watchdog

Timer

I/O Lines

128 x 8

EEPROM

4

ATtiny22/22L

Page 5

ATtiny22/22L

The ALU supports arithmetic and logic functions between registers or between a constant and a register. Single register

operations are also executed in the ALU. Figure 3 shows the ATtiny22/L AVR RISC microcontroller architecture.

In addition to the register operation, the conventional memory addressing modes can be used on the register file as well.

This is enabled by the fact that the regi ster file is ass igned the 32 lowe rmost Data Sp ace addresse s ($00 - $1F), allowing

them to be accessed as though they were ordinary memory locations.

The I/O memory space contains 64 addresses for CPU peripheral functions as Control Registers, Timer/Counters,

A/D-converters, and oth er I/O func tions. The I/O memory can be ac cesse d directl y, or as th e Data Spa ce locati ons follo wing those of the register file, $20 - $5F.

The AVR has Harvard architecture - wi th separate memories a nd buses for pro gram and data. The p rogram memory is

accessed with a two stage pipeline. While one instruction is bei ng executed, the next instructio n is pre-fetched from the

program memory. This concept enables instructions to be executed in every clock cycle. The program memory is in-system

downloadable Flash memory.

With the relative jump and call instructions, the whole 1K address space is directly accessed. Most AVR instructions have a

single 16-bit word format. Every program memory address contains a 16- or 32-bit instruction.

During interrupts and subrouti ne calls, the return addres s program counter (PC) is sto red on the stack. The stack is

effectively allocated in the general da ta S RAM , a nd c onsequently the sta ck s iz e i s onl y li mi ted by the total SRAM size and

the usage of the SRAM. All user programs must initialize the SP in the reset routine (before subroutines or interrupts are

executed). The 8-bit stack pointer SP is read/write accessible in the I/O space.

The 128 bytes data SRAM + regist er file and I/O register s can be easily a ccessed thro ugh the five different ad dressing

modes supported in the AVR architecture.

The memory spaces in the AVR architecture are all linear and regular memory maps.

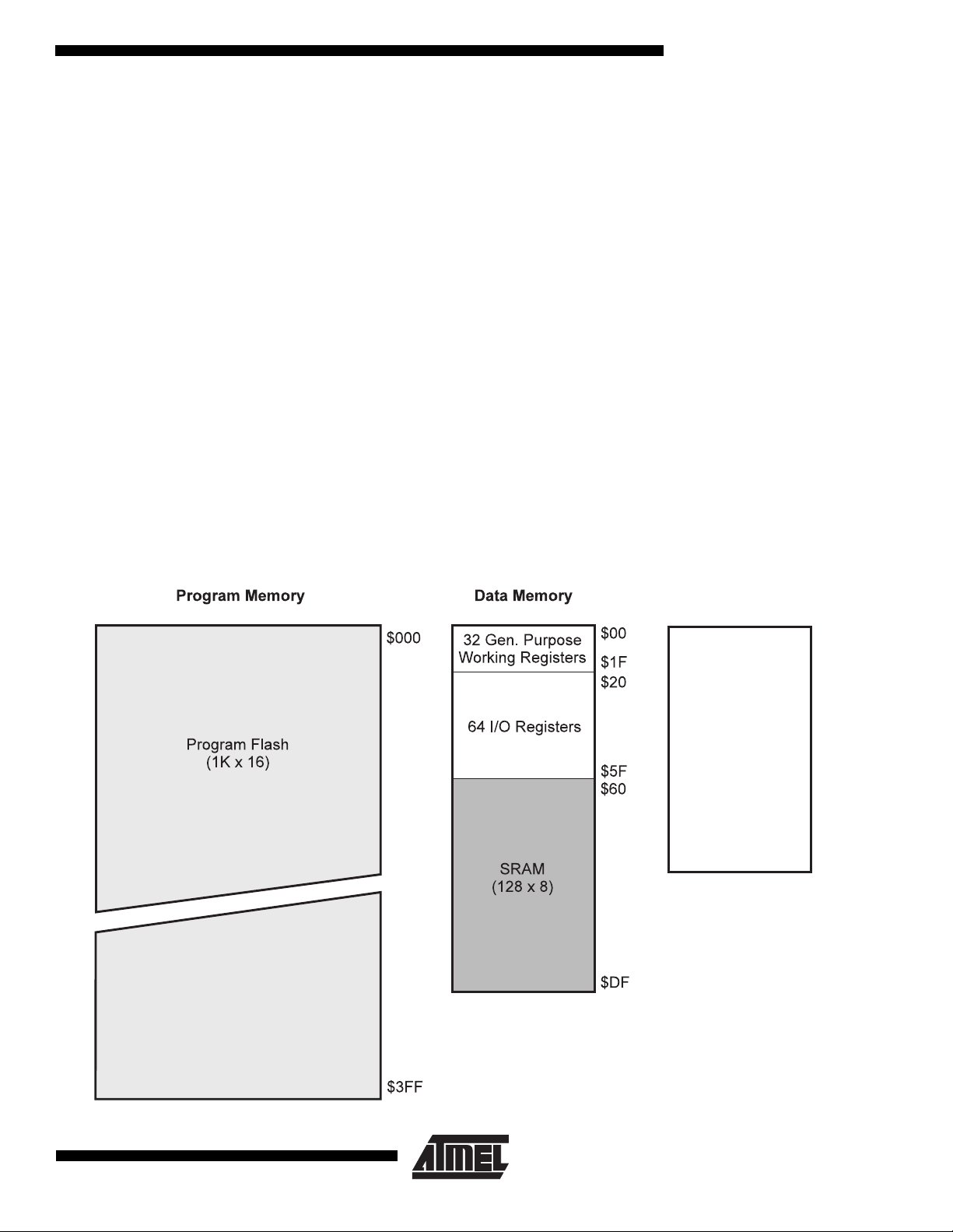

Figure 4. Memory Maps

EEPROM Data Memory

$000

EEPROM

(128 x 8)

$07F

5

Page 6

A flexible interrupt module has its control registers in the I/O space with an additional global interrupt enable bit in the status

register. All the different interrupts have a separate interrupt vector in the interrupt vector table at the beginning of the

program memory. T he different in terrupts ha ve priority in accordan ce with thei r interrupt ve ctor positi on. The lower the

interrupt vector address, the higher the priority.

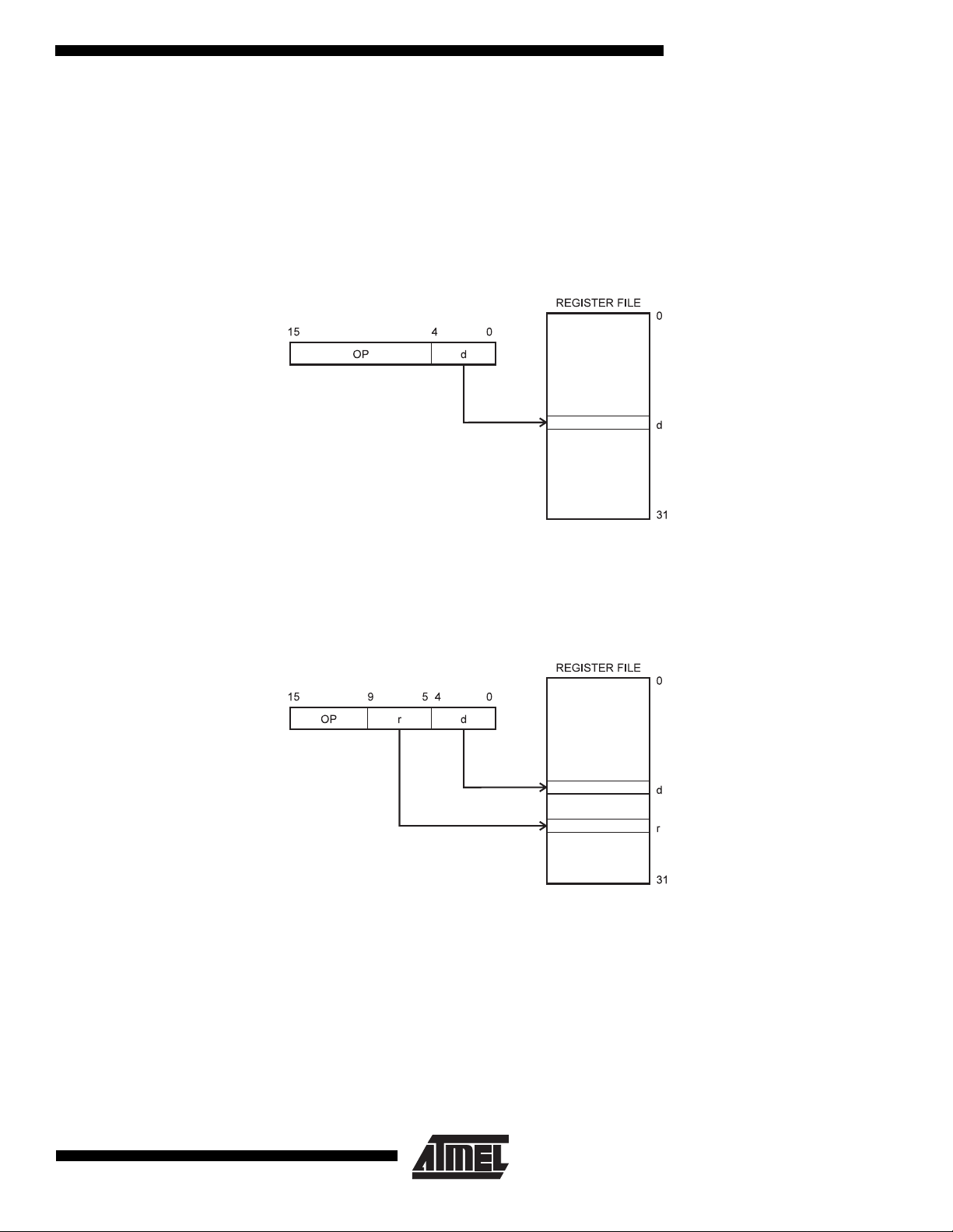

General Purpose Register File

Figure 5 shows the structure of the 32 general purpose registers in the CPU.

Figure 5. AVR CPU General Purpose Working Registers

7 0 Addr.

R0 $00

R1 $01

R2 $02

…

R13 $0D

General R14 $0E

Purpose R15 $0F

Working R16 $10

Registers R17 $11

…

R26 $1A X-register low byte

R27 $1B X-register high byte

R28 $1C Y-register low byte

R29 $1D Y-register high byte

R30 $1E Z-register low byte

R31 $1F Z-register high byte

All the register oper ating instruc tions in th e instruc tion set ha ve direc t and single c ycle acces s to all registers. The only

exception is the five constant arithmetic and logic instructions SBCI, SUBI, CPI, ANDI, ORI between a constant and a

register and the LDI instructi on for load immediate con stant data. These instructi ons apply to the second hal f of the registers in the register file - R16..R31. The general SBC, SUB, CP, AND, OR and all other operations between two registers or

on a single register apply to the entire register file.

As shown in Fig ure 5, e ach reg ister is al so a ssigned a da ta mem ory add ress , map ping t hem di rectly into the fir st 32 locations of the user Data Space. Although the register file is not physically implemented as SRAM locations, this memory

organization provides great flexibility in access of the registers, as the X, Y and Z registers can be set to index any register

in the file.

6

ATtiny22/22L

Page 7

ATtiny22/22L

X-Register, Y-Register, and Z-Register

The registers R26..R31 have some added functions to their general purpose usage. These registers are the address pointers for indirect addressing of the Data Space. The three indirect address registers X, Y and Z are defined as:

Figure 6. The X, Y, and Z Registers

15 0

X - register 7 0 7 0

R27 ($1B) R26 ($1A)

15 0

Y - register 7 0 7 0

R29 ($1D) R28 ($1C)

15 0

Z - register 7 0 7 0

R31 ($1F) R30 ($1E)

In the different addr essing modes these add ress reg isters have func tions as fix ed di splacem ent, au tomatic inc rement and

decrement (see the descriptions for the different instructions).

ALU - Arithmetic Logic Unit

The high-performa nce AV R ALU oper ates in di rect conn ectio n with all the 32 gener al purpos e working registe rs. Withi n a

single clock cy c le, ALU operations between regis ter s in th e r eg is ter fi le ar e exec uted . The A LU o per ati on s a re di v ided i nto

three main categories - arithmetic, logic and bit-functions

In-System Programmable Flash Program Memory

The ATtiny22/L contains 2K b ytes on- chip In- System Prog rammabl e Flash memor y for p rogram s torage. Sinc e all instruc tions are 16- or 32- bit words, the Flash is organiz ed as 1 K x 16. The Flash m emory has an enduranc e of at l east 1000

write/erase cycles.

The ATtiny22/L Program Counter PC is 10 bits wide, hence addressing the 1024 program memory addresses. See

page 38 for a detailed description on Flash data programming.

Constant tables must be allocated within the address 0-2K (see the LPM - Load Program Memory instruction description).

See page 9 for the different addressing modes.

EEPROM Data Memory

The ATtiny22/L contains 128 bytes of EEPROM data memory. It is organized as a separate data space, in which single

bytes can be read and written. The EEPROM has an endurance of at least 100,000 write/erase cycles. The access

between the EEPROM and the CPU is described on page 30 specifying the EEPROM address register, the EEPROM data

register, and the EEPROM control register.

For the SPI data downloading, see page 38 for a detailed description.

7

Page 8

SRAM Data Memory

The following figure shows how the ATtiny22/L Data Memory is organized:

Figure 7. SRAM Organization

Register File Data Address Space

R0 $00

R1 $01

R2 $02

……

R29 $1D

R30 $1E

R31 $1F

I/O Registers

$00 $20

$01 $21

$02 $22

……

$3D $5D

$3E $5E

$3F $5F

Internal SRAM

$60

$61

$62

…

$DD

$DE

$DF

The 224 Data Memory loca tions address the Regi ster file, I/O M emo ry and the data SRA M. The fi rst 96 loc ation s addres s

the Register File + I/O Memory, and the next 128 locations address the data SRAM.

The five different addressing modes for the data memory cover: Direct, Indirect with Displacement, Indirect, Indirect with

Pre-Decrement and Indirect with Post-Increment. In the register file, registers R26 to R31 feature the indirect addressing

pointer registers.

The Direct addressing reaches the entire data address space.

The Indirect with Displ acement mo de features 63 addres s locations reach from the base address gi ven by the Y and Z

register.

When using register indirect addressing modes with automatic pre-decrement and post-increment, the address registers X,

Y and Z are used and decremented and incremented.

The 32 general purpose working registers, 64 I/O registers and the 128 bytes of data SRAM in the ATtiny22/L are all

directly accessible through all these addressing modes.

8

ATtiny22/22L

Page 9

ATtiny22/22L

Program and Data Addressing Modes

The ATtiny22/L AVR RISC Microcon troller supports powerful and efficient addr essing modes for access to the program

memory (Flash) and dat a memor y. This s ection de scr ibes the d iffere nt addres sing modes su pporte d by th e AVR a rchitecture. In the figures, OP means the operation code part of the instruction word. To simplify, not all figures show the exact

location of the addressing bits.

Register Direct, Single Register Rd

Figure 8. Direct Single Register Addressing

The operand is contained in register d (Rd).

Register Direct, Two Registers Rd and Rr

Figure 9. Direct Register Addressing, Two Registers

Operands are contained in register r (Rr) and d (Rd). The result is stored in register d (Rd).

9

Page 10

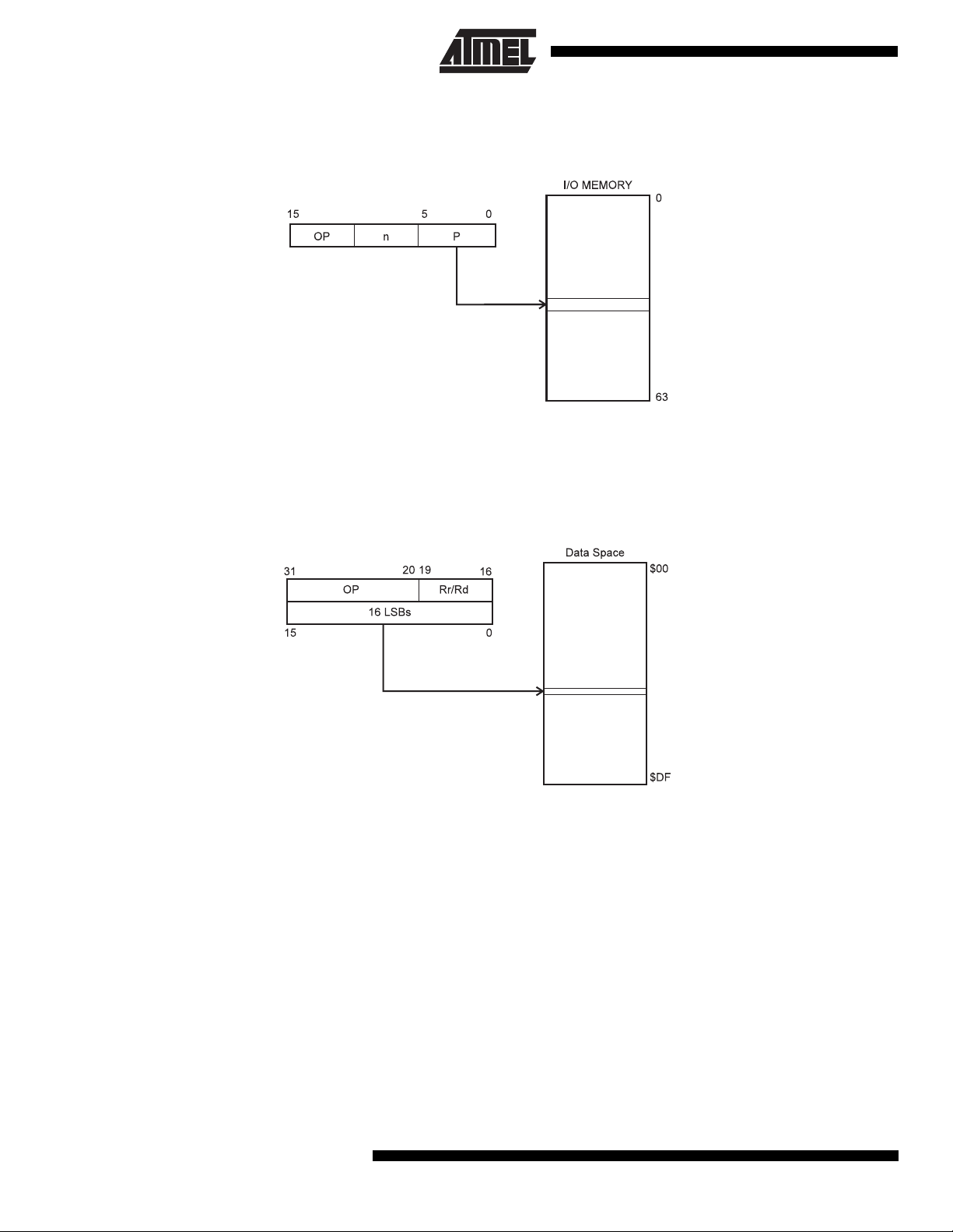

I/O Direct

Figure 10. I/O Direct Addressing

Operand address is contained in 6 bits of the instruction word. n is the destination or source register address.

Data Direct

Figure 11. Direct Data Addressing

A 16-bit Data Address is contained in the 16 LSBs of a two-word instr uction. Rd/Rr specify the de stination or source

register.

10

ATtiny22/22L

Page 11

ATtiny22/22L

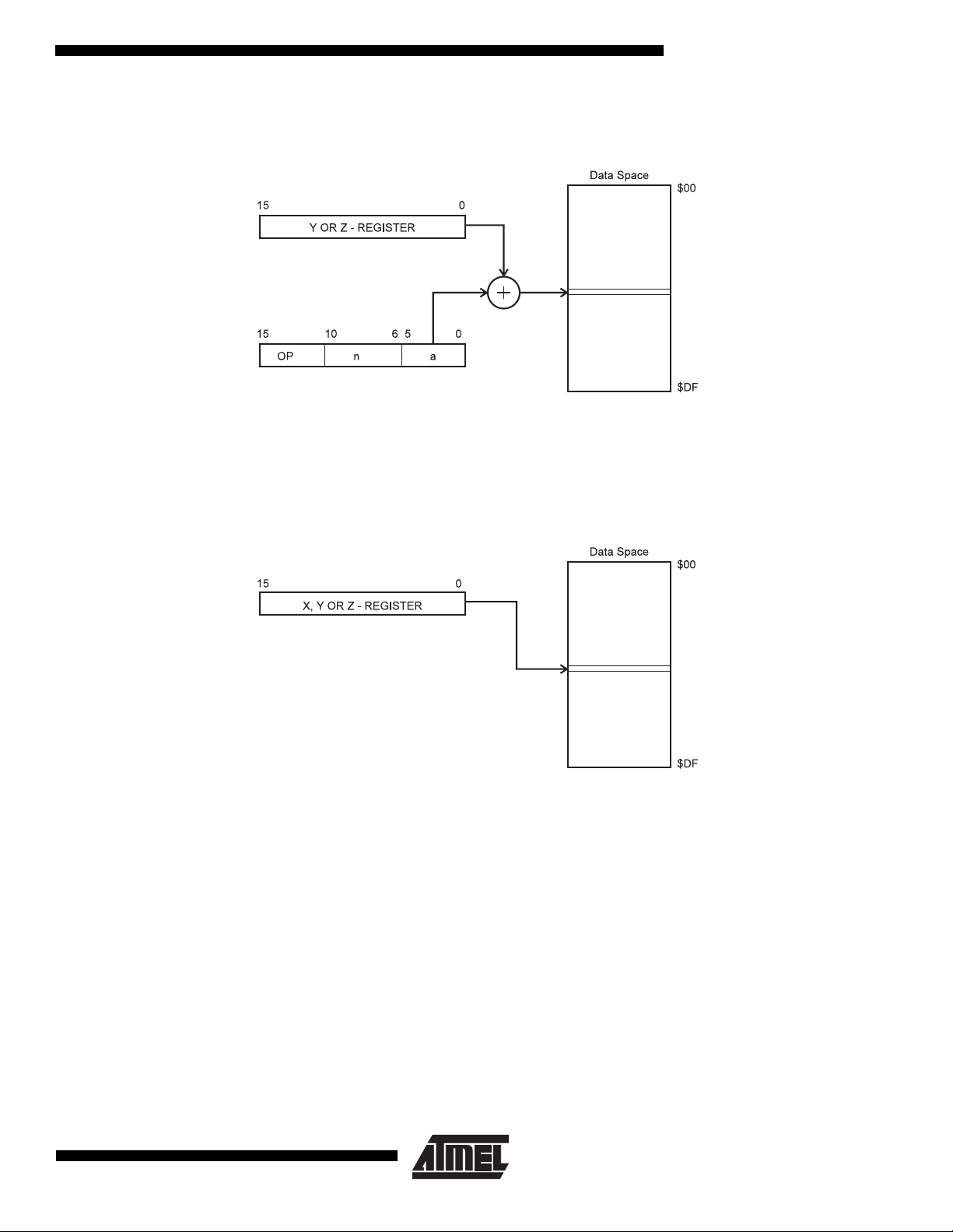

Data Indirect with Displacement Figure 12. Data Indirect with Displacement

Operand address is the result o f the Y or Z- register contents ad ded to the addre ss contained in 6 bits of the instruction

word.

Data Indirect

Figure 13. Data Indirect Addressing

Operand address is the contents of the X, Y or the Z-register.

11

Page 12

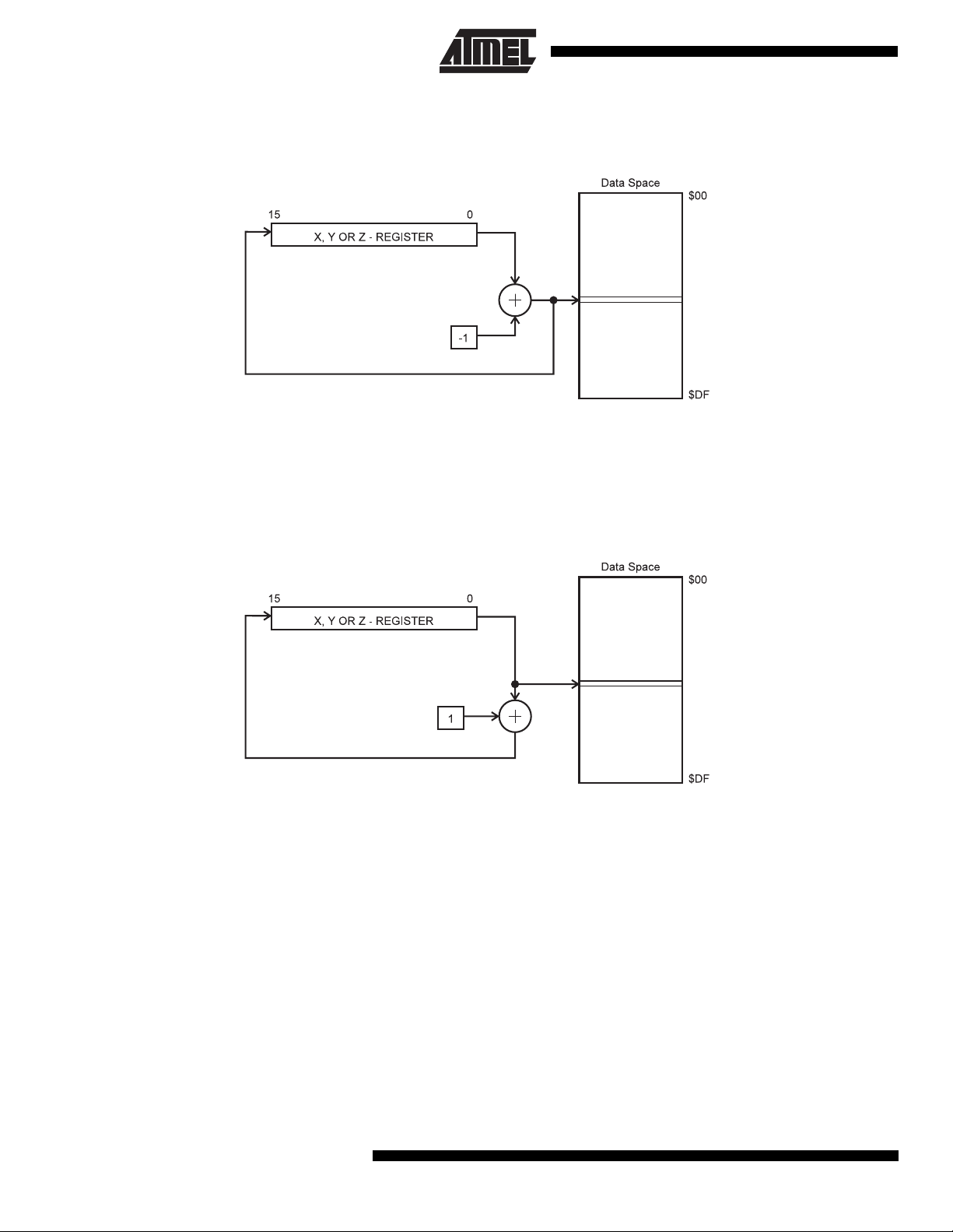

Data Indirect With Pre-Decrement

Figure 14. Data Indirect Addressing With Pre-Decrement

The X, Y or the Z-register is decremen ted be fore the oper ation. Operand ad dress is the decrem ented co ntents of the X, Y

or the Z-register.

Data Indirect With Post-Increment

Figure 15. Data Indirect Addressing With Post-Increment

The X, Y or the Z-register is incremented after the operation. Operand address is the content of the X, Y or the Z-register

prior to incrementing.

12

ATtiny22/22L

Page 13

ATtiny22/22L

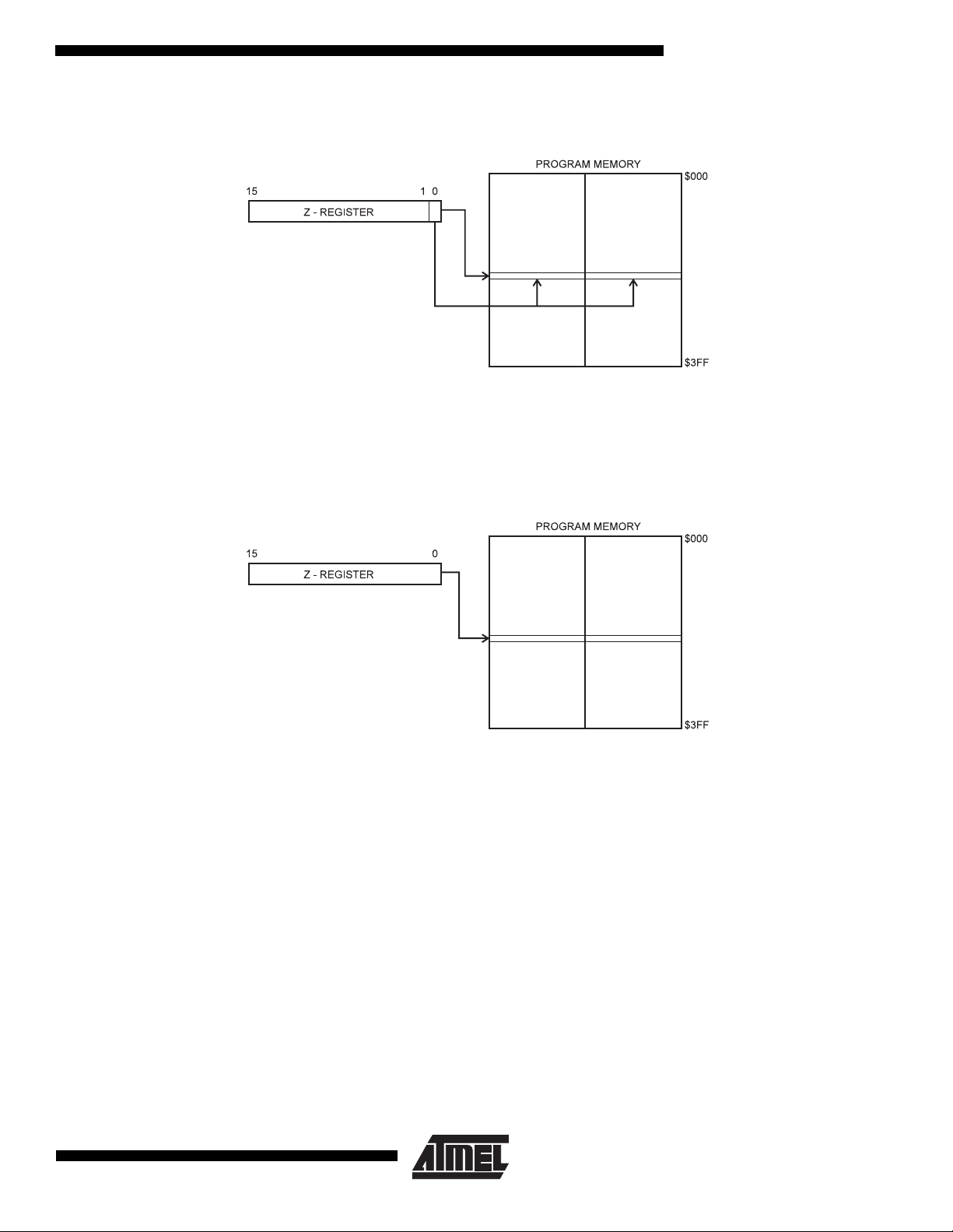

Constant Addressing Using the LPM Instruction

Figure 16. Code Memory Constant Addressing

Constant byte address i s sp ec ified by th e Z- regi st er c onte nts. The 15 MSBs select wor d add ress (0 - 1K ) , th e LSB s elec ts

low byte if cleared (LSB = 0) or high byte if set (LSB = 1).

Indirect Program Addressing, IJMP and ICALL

Figure 17. Indirect Program Memory Addressing

Program execution continues at address contained by the Z-register (i.e., the PC is loaded with the content of the

Z-register).

13

Page 14

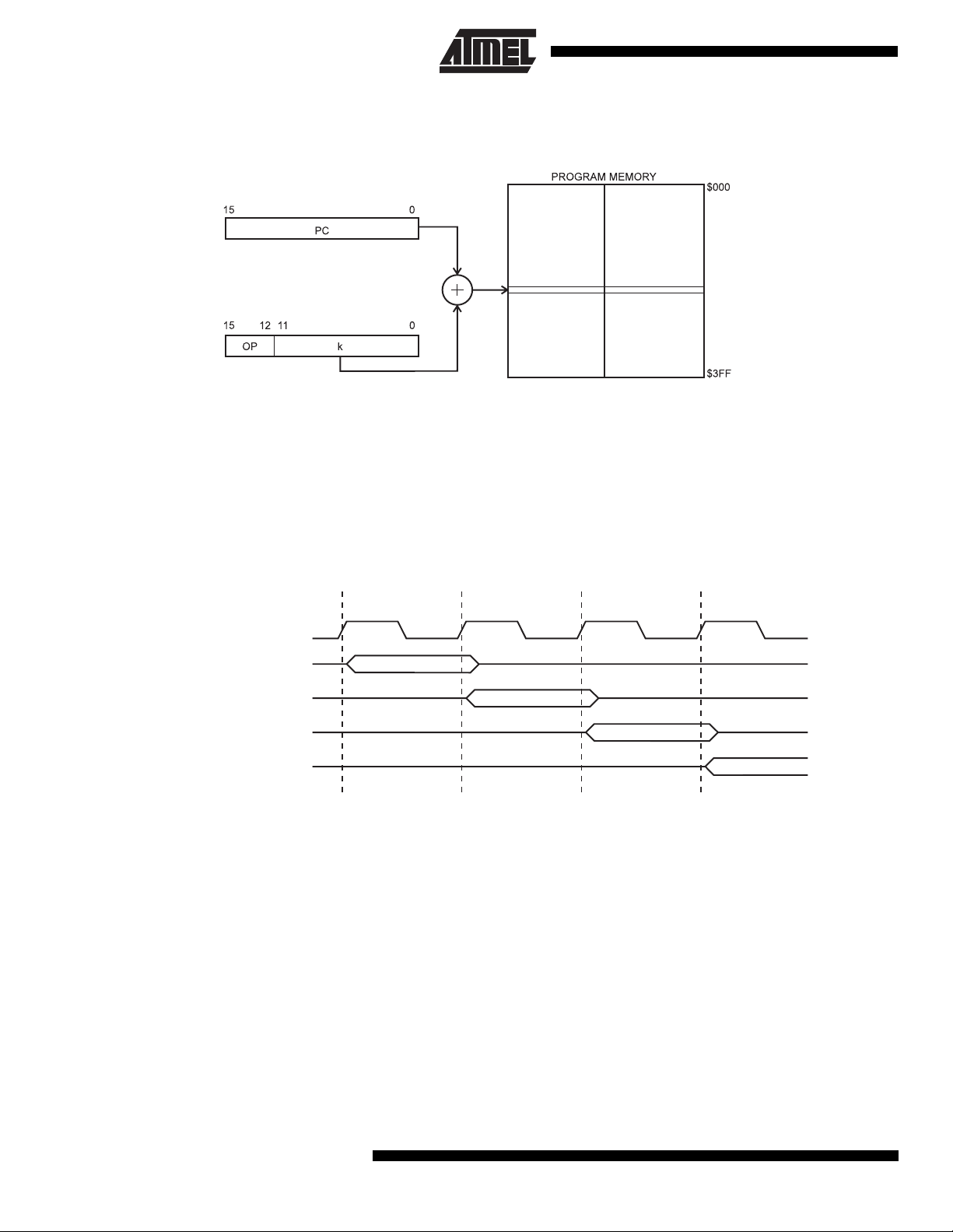

Relative Program Addressing, RJMP and RCALL

Figure 18. Relative Program Memory Addressing

Program execution continues at address PC + k + 1. The relative address k is -2048 to 2047.

Memory Access and Instruction Execution Timing

This section describes the general access timing concepts for instruction execution and internal memory access.

The AVR CPU is driven by the System Clock Ø, directly generated from the external clock signal applied to the CLOCK pin.

No internal clock division is used.

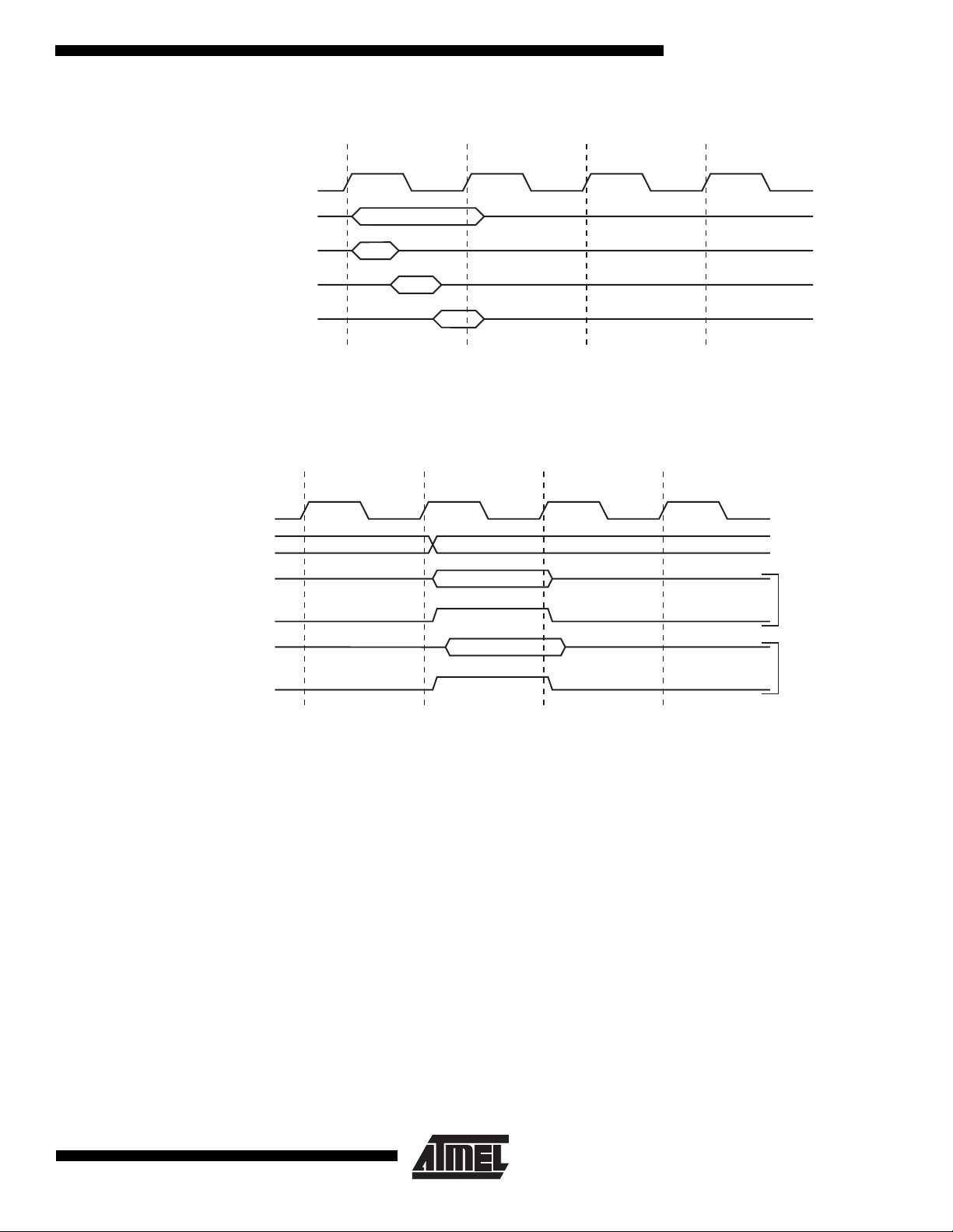

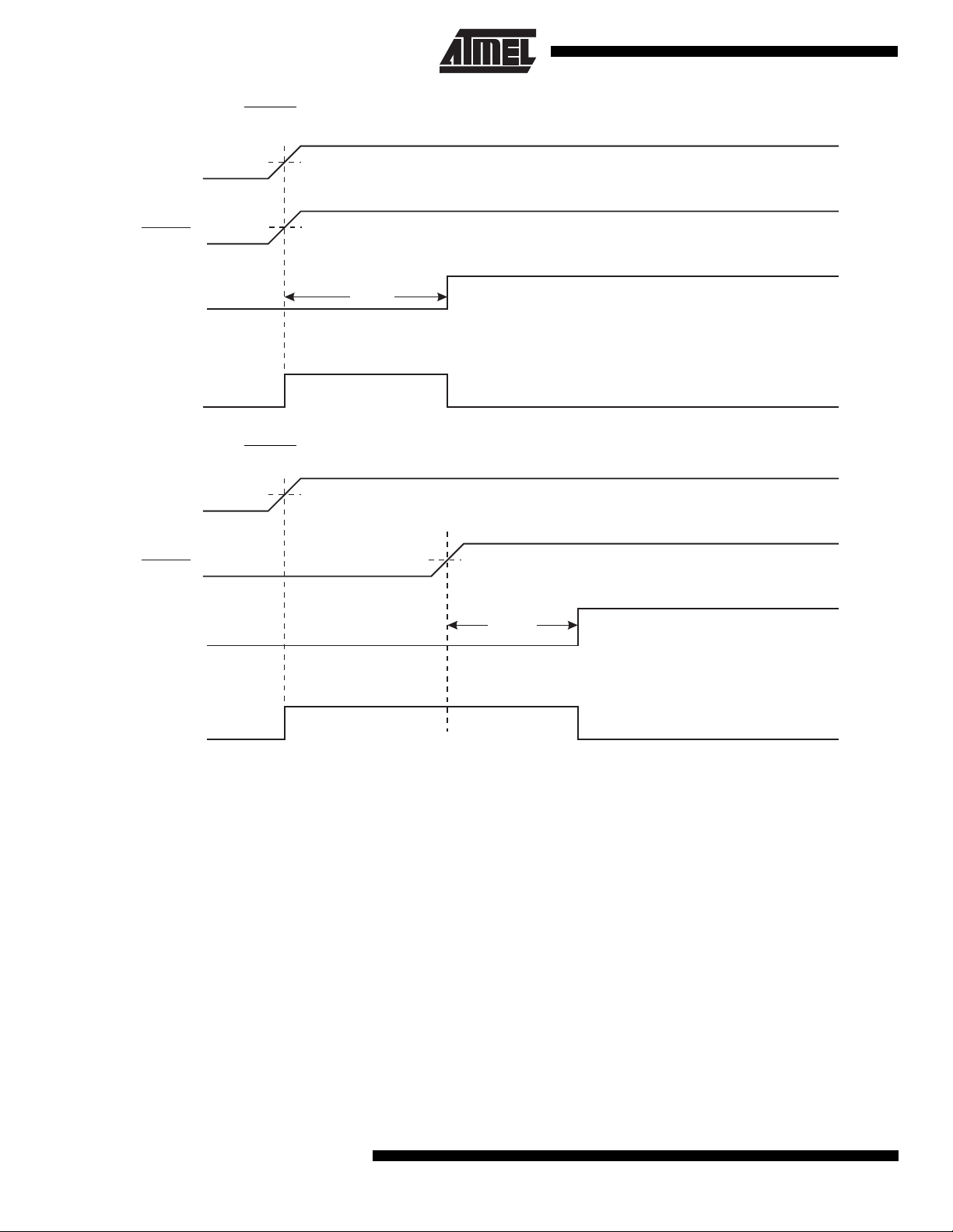

Figure 19. The Parallel Instruction Fetches and Instruction Executions

T1 T2 T3 T4

System Clock Ø

1st Instruction Fetch

1st Instruction Execute

2nd Instruction Fetch

2nd Instruction Execute

3rd Instruction Fetch

3rd Instruction Execute

4th Instruction Fetch

Figure 19 shows the parallel instruction fetches and instruction executions enabled by the Harvard architecture and the

fast-access register file concept. This is the basic pipelining concept to obtain up to 1 MIPS per MHz with the corresponding

unique results for functions per cost, functions per clocks, and functions per power-unit.

14

ATtiny22/22L

Page 15

ATtiny22/22L

Figure 20. Single Cycle ALU Operation

T1 T2 T3 T4

System Clock Ø

Total Execution Time

Register Operands Fetch

ALU Operation Execute

Result Write Back

Figure 20 shows the internal tim ing con ce pt for the re gis ter fil e. In a si ngle cl oc k cy cle an ALU oper at ion using two r egi ste r

operands is executed, and the result is stored back to the destination register.

Figure 21. On-Chip Data SRAM Access Cycles

T1 T2 T3 T4

System Clock Ø

Address

Data

WR

Data

RD

Prev. Address

Address

The internal data SRAM access is performed in two System Clock cycles as described in Figure 21.

Read Write

15

Page 16

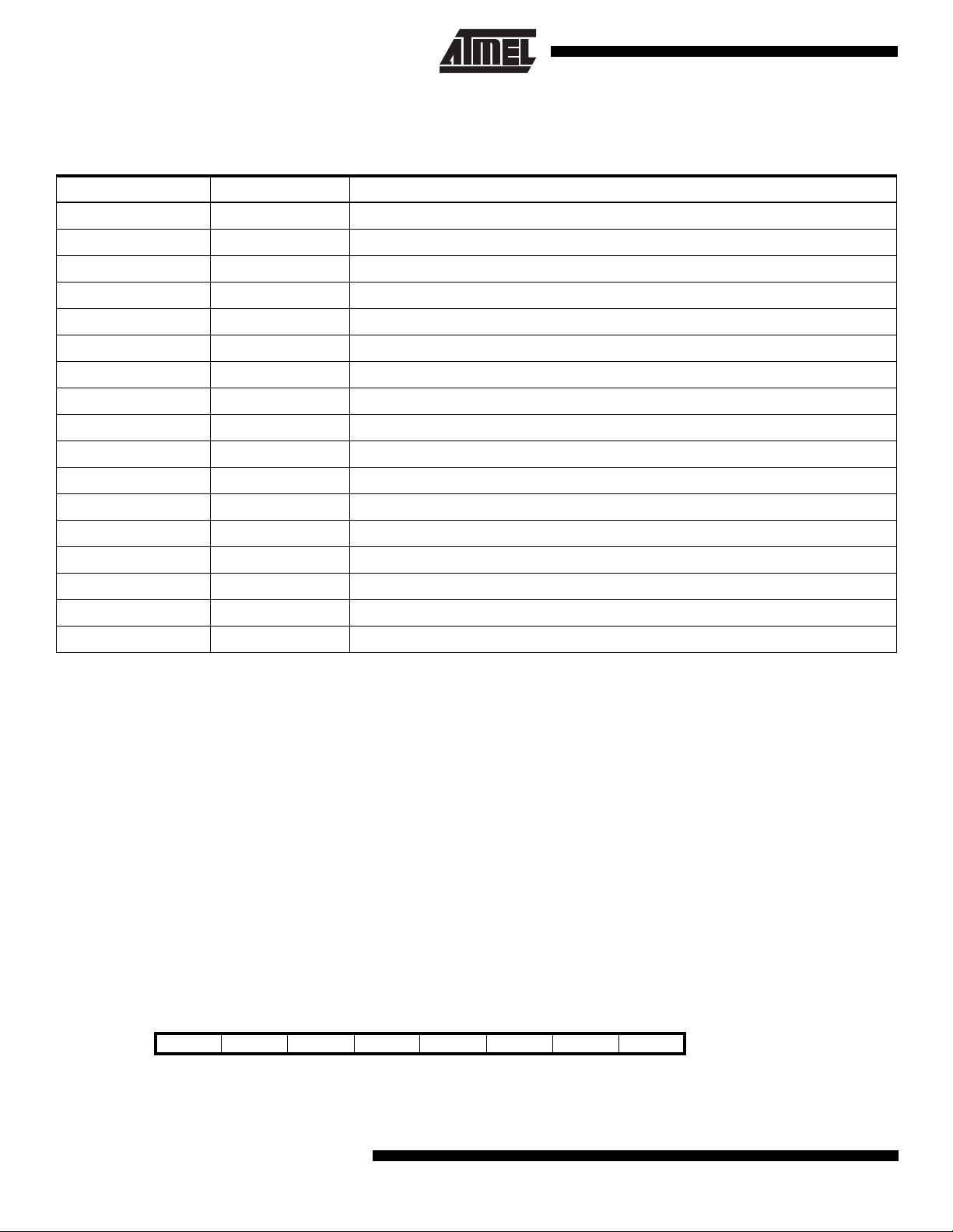

I/O Memory

The I/O space definition of the ATtiny22/L is shown in the following table:

Table 1. ATtiny22/L I/O Space

Address Hex Name Function

$3F ($5F) SREG Status REGister

$3D ($5D) SPL Stack Pointer Low

$3B ($5B) GIMSK General Interrupt MaSK register

$3A ($5A) GIFR General Interrupt Flag Register

$39 ($59) TIMSK Timer/Counter Interrupt MaSK register

$38 ($58) TIFR Timer/Counter Interrupt Flag register

$35 ($55) MCUCR MCU Control Register

$34 ($54) MCUSR MCU Status Register

$33 ($53) TCCR0 Timer/Counter 0 Control Register

$32 ($52) TCNT0 Timer/Counter 0 (8-bit)

$21 ($41) WDTCR Watchdog Timer Control Register

$1E ($3E) EEAR EEPROM Address Register

$1D ($3D) EEDR EEPROM Data Register

$1C ($3C) EECR EEPROM Control Register

$18 ($38) PORTB Data Register, Port B

$17 ($37) DDRB Data Direction Register, Port B

$16 ($36) PINB Input Pins, Port B

Note: Reserved and unused locations are not shown in the table.

All the different ATtiny22/L I/O and peripherals are placed in the I/O space. The different I/O locations are accessed by the

IN and OUT instructio ns transferring data between the 32 ge neral purpose working register s and the I/O space. I/O

registers withi n the add ress ra nge $00 - $1F a re direc tly bit -accessi ble usi ng the S BI and C BI ins tructio ns. In t hese

registers, the value of single bits can be checked by using the SBIS and SBIC instructions. Refer to the instruction set

chapter for more details. When using the I/O specific commands IN, OUT the I/O addresses $00 - $3F must be used. When

addressing I/O registers as SRAM, $20 must be added to this address. All I/O register addresses throughout this document

are shown with the SRAM address in parentheses.

For compatibility with fu tur e dev ices , r eser v ed bi ts sh oul d be writte n to z er o if accessed. Reserved I/O m emo ry a ddr ess es

should never be written.

Some of the status flags are cleared by writing a logical one to them. Note that the CBI and SBI instructions will operate on

all bits in the I/O reg ister, wr iting a o ne back int o any f lag r ead as set, th us clea ring the flag. The CBI and SBI i nstruc tion s

work with registers $00 to $1F only.

The different I/O and peripherals control registers are explained in the following sections.

Status Register - SREG

The AVR status register - SREG - at I/O space location $3F ($5F) is defined as:

Bit 76543210

$3F ($5F) I T H S V N Z C SREG

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

16

ATtiny22/22L

Page 17

ATtiny22/22L

• Bit 7 - I: Global Interrupt Enable

The global interrup t ena ble b it mu st b e se t (on e) for the interr upts to be enab led. The i ndivi dual interru pt enable contr ol i s

then performed in sep arate contr ol regis ters. If the glo bal interr upt enabl e register is cleared ( zero), non e of the interr upts

are enabled inde pendent of the indi vidua l interrup t enable setting s. The I-bi t is clear ed by hard ware aft er an inter rupt has

occurred, and is set by the RETI instruction to enable subsequent interrupts.

Bit 6 - T: Bit Copy Storage

•

The bit copy instructions BLD (Bit LoaD) and BST (Bit STore) use the T bit as source and destination for the operated bit. A

bit from a register in the regi s ter fil e c an be cop ie d in to T by the B ST in st ructi on, and a bit in T can be copied into a bit in a

register in the register file by the BLD instruction.

Bit 5 - H: Half Carry Flag

•

The half carry flag H indicates a half carry in some arithmetic operations. See the Instruction Set Description for detailed

information.

Bit 4 - S: Sign Bit, S = N ⊕ V

•

The S-bit is always an exclusive or between the negative flag N and the two’s complement overflow flag V. See the Instruc-

tion Set Description for detailed information.

Bit 3 - V: Two’s Complement Overflow Flag

•

The two’s complement overflow flag V supports two’s complement arithmetics. See the Instruction Set Description for

detailed information.

Bit 2 - N: Negative Flag

•

The negative flag N indicates a negative result from an arithmetical or logical operation. See the Instruction Set Description

for detailed information.

Bit 1 - Z: Zero Flag

•

The zero flag Z indicates a zero result from an arithmetical or logical operation. See the Instruction Set Description for

detailed information.

Bit 0 - C: Carry Flag

•

The carry flag C indicates a carry in an arithmetical or logical operation. See the Instruction S et Description for detailed

information.

Note that the status register is not automatically stored when entering an interrupt routine and restored when returning from

an interrupt routine. This must be handled by software.

Stack Pointer - SPL

An 8-bit register at I/O address $3 D ($5D) forms th e stack poin ter of the ATtin y22/L. 8 bits are us ed to address the

128 bytes of SRAM in locations $60 - $DF.

Bit 76543210

$3D ($5D) SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0 SPL

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

The Stack Pointer points to the data SRA M stack area where the Su broutin e and Interru pt Stacks are lo cated. Thi s Stack

space in the data SRAM must be de fined by the program bef ore any subroutine calls are executed or interr upts are

enabled. The stack pointer must be set to point above $60. The Stack Pointer is decremented by one when data is pushed

onto the Stack with the PUSH instruction, and it is decremented by two when an address is pushed onto the Stack with

subroutine calls and interrupts. The Stack Pointer is incremented by one when data is popped from the Stack with the POP

instruction, and it is incremented b y two when an address is popped from the Stack with return fro m subroutine RET or

return from interrupt RETI.

17

Page 18

Reset and Interrupt Handling

The ATtiny22/L provides two interrupt sources. These interrupts and the separate reset vector, each have a separate

program vector in the progr am me mor y s pac e. Bo th int er rupts ar e assi gn ed individual enable bit s whic h mus t be se t ( one )

together with the I-bit in the status register in order to enable the interrupt.

The lowest addresses in the program memor y space are automatical ly defined as the Reset and Interrupt vector s. The

complete list of ve ctors is shown i n Table 2 . The li st also determines th e prior ity levels of the in terrupts . The lower the

address the higher is the priority level. RESET has the highest priority, next is INT0 - the External Interrupt Request 0, etc.

Table 2. Reset and Inte rru pt Vectors

Vector No. Program Address Source Interrupt Definition

1 $000 RESET Hardware Pin, Power-on Reset and Watchdog Reset

2 $001 INT0 External Interrupt Request 0

3 $002 TIMER0, OVF0 Timer/Counter0 Overflow

The most typical program setup for the Reset and Interrupt Vector Addresses are:

Address Labels Code Comments

$000 rjmp RESET ; Reset Handler

$001 rjmp EXT_INT0 ; IRQ0 Handler

$002 rjmp TIM_OVF0 ; Timer0 Overflow Handler;

$003 MAIN: ldi r16, low(RAMEND) ; Main program start

out SPL, r16

<instr> xxx

… … … …

Reset Sources

The ATtiny22/L provides three sources of reset:

• Power-On Reset. The MCU is reset when the supply voltage is below the power-on reset threshold (V

• External Reset. The MCU is reset when a low level is present on the RESET

pin for more than 50 ns.

POT

).

• Watchdog Reset. The MCU is reset when the Watchdog timer period expires and the Watchdog is enabled.

During reset, all I/O registers are set to their initial values, and the program starts execution from address $000. The

instruction placed in addre ss $000 must be an RJMP - relative j ump - instructio n to the reset handli ng routine. If the

program never enables an inte r rupt s ou rce, the interrupt vecto rs a re no t us ed , an d reg ular program code can be p la ced at

these locations. The circuit diagram in Figure 22 shows the reset logic. Table 3 defines the timing and electrical parameters

of the reset circuitry.

18

ATtiny22/22L

Page 19

Figure 22. Reset Logic

ATtiny22/22L

VCC

RESET

Power-On Reset

Circuit

100 - 500K

Reset Circuit

Watchdog

Timer

On-Chip

RC-Oscillator

POR

14-Stage Ripple Counter

Q0 Q13Q3

COUNTER RESET

QS

R

Q

INTERNAL

RESET

The ATtiny22/L has a fixed startup time.

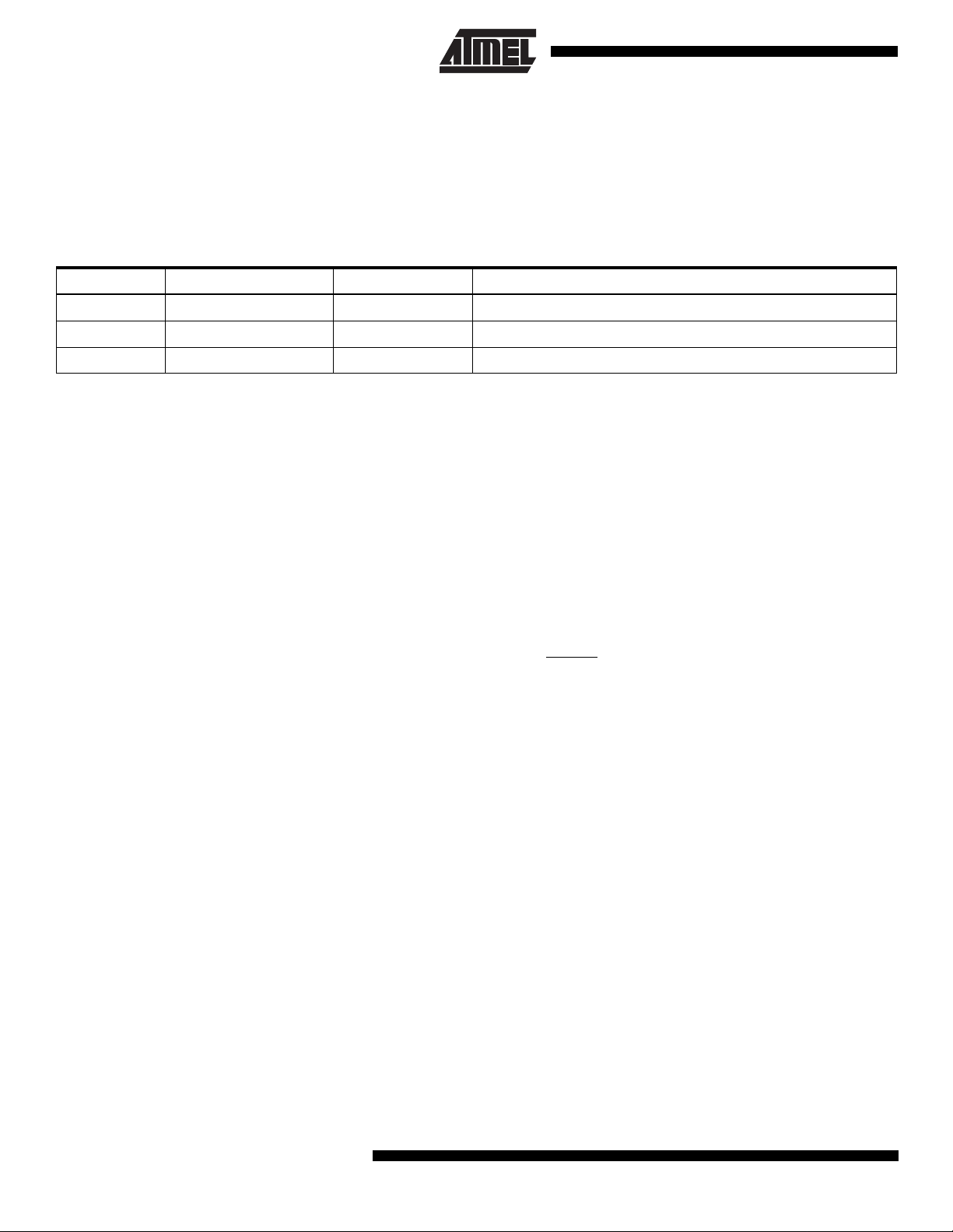

Table 3. Reset Characteristics (V

Symbol Parameter Min Typ Max Units

(1)

V

POT

V

RST

t

TOUT

Notes: 1. The Power-On Reset will not work unless the supply voltage has been below V

Power-On Reset Threshold Voltage, rising 1.0 1.4 1.8 V

Power-On Reset Threshold Voltage, falling 0.4 0.6 0.8 V

RESET Pin Threshold Voltage 0.6 V

Reset Delay Time-Out Period ATtiny22/L 11 16 21 µs

= 5.0V)

CC

CC

(falling).

POT

V

Table 4. Reset Characteristics (VCC = 3.0V)

Symbol Parameter Min Typ Max Units

(1)

V

POT

V

RST

t

TOUT

Notes: 1. The Power-On Reset will not work unless the supply voltage has been below V

Power-On Reset Threshold Voltage, rising 1.0 1.4 1.8 V

Power-On Reset Threshold Voltage, falling 0 .4 0.6 0.8 V

RESET Pin Threshold Voltage 0. 6 V

CC

Reset Delay Time-Out Period ATtiny22/L 22 32 42 µs

(falling).

POT

V

Power-On Reset

The ATtiny22/L is designed for use in systems where it can operate from the internal RC oscillator or in applications where

a clock signal is prov id ed by an ex terna l c lo ck s ourc e. A fter V

has reached V

CC

, the device will start after the tim e t

POT

TOUT

(see Figure 23). If the clock sign al is provide d by an external clock so urce, the cloc k must not be applied un til VCC has

reached the minimum voltage defined for the applied frequency.

The start-up time t

is one watchdog cycl e. The frequ ency o f the w atchdog os cill ator is vol tage dep endent a s show n in

TOUT

“Typical character is tics ” on page 44.

19

Page 20

Figure 23. MCU Start-Up, RESET Tied to VCC.

V

V

POT

RST

t

TOUT

VCC

RESET

TIME-OUT

INTERNAL

RESET

Figure 24. MCU Start-Up, RESET

VCC

RESET

TIME-OUT

INTERNAL

RESET

Controlled Externally

V

POT

V

RST

t

TOUT

20

ATtiny22/22L

Page 21

ATtiny22/22L

External Reset

An external reset is generated by a low level on the RESET

if the clock is n ot runnin g. Shorter pulses a re not gu aranteed t o generate a rese t. When the applied signal r eaches the

Reset Threshold Voltage - V

- on its positive edge, the delay timer starts the MCU after the Time-out period t

RST

expired.

Figure 25. External Reset During Operation

pin. Reset pulses longer than 50 ns will generate a reset, even

has

TOUT

Watchdog Reset

When the Watchdog times out, it will generate a short reset pulse of 1 XTAL cycle duration. On the falling edge of this

pulse, the delay timer starts counting the Time-out period t

. Refer to page 28 for details on operation of the Watchdog.

TOUT

Figure 26. Watchdog Reset During Operation

21

Page 22

MCU Status Register - MCUSR

The MCU Status Register provides information on which reset source caused a MCU reset:

Bit 76543210

$34 ($54)------EXTRFPORFMCUSR

Read/WriteRRRRRRR/WR/W

Initial value 0 0 0 0 0 0 See bit description

Bit 7..2 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny22/L and always read as zero.

Bit 1 - EXTRF: External Reset Flag

•

After a power-on reset, this bit is undefined (X). It will be set by an external reset. A watchdog reset will leave this bit

unchanged.

Bit 0 - PORF: Power-On Reset Flag

•

This bit is set by a power-on reset. A watchdog reset or an external reset will leave this bit unchanged.

To summarize, the following table shows the value of these two bits after the three modes of reset.

Table 5. PORF and EXTRF Values after Reset

Reset Source PORF EXTRF

Power-On Reset 1 undefined

External Reset unchanged 1

Watchdog Reset unchanged unchanged

To make use of these bits to identify a reset condition, the user software should clear both the PORF and EXTRF bits as

early as possible in the program. Checking the PORF and EXTRF values is done before the bits are cleared. If the bit is

cleared before an external or watchdog reset occurs, the source of reset can be found by using the following truth table:

Table 6. Reset Sou rce Iden tifi c ation

PORF EXTRF Reset Source

0 0 Watchdog Reset

0 1 External Reset

1 0 Power-On Reset

1 1 Power-On Reset

Interrupt Handling

The ATtiny22/L has two 8-bit Interrupt Mask control register s; GIMSK - General Interrupt Mask register and TIMSK Timer/Counter Interrupt Mask register.

When an interrupt occurs, the Gl obal Interrupt Enable I-bit i s cleared (zero) and all inte rrupts are disabled. T he user

software can set (one) the I-bit to e nable n ested inter rupts. The I-bit is set ( one) when a Retur n from Inte rrupt i nstruct ion RETI - is executed.

When the Program Counter is vectored to the actual interrupt vector in order to execute the interrupt handling routine, hardware clears the corresponding flag that generated the interrupt. Some of the interrupt flags can also be cleared by writing a

logic one to the flag bit position(s) to be cleared.

If an interrupt condition occurs when the corresponding interrupt enable bit is cleared (zero), the interrupt flag will be set

and remembered until the interrupt is enabled, or the flag is cleared by software.

If one or more int errupt cond ition s oc cur when t he gl obal inter rup t enab le b it is cl eared (ze ro), th e co rre spondin g interr upt

flag(s) will be set and remembered until the global interrupt enable bit is set (one), and will be executed by order of priority.

Note that external level interrupt does not have a flag, and will only be remembered for as long as the interrupt condition is

active.

22

ATtiny22/22L

Page 23

ATtiny22/22L

Note that the status register is not automatically stored when entering an interrupt routine and restored when returning from

an interrupt routine. This must be handled by software.

General Interrupt Mask Register - GIMSK

Bit 7 6 5 4 3 2 1 0

$3B ($5B) - INT0 - - - - - - GIMSK

Read/Write R R/W R R R R R R

Initial value 0 0 0 0 0 0 0 0

Bit 7 - Res: Reserved Bit

•

This bit is a reserved bit in the ATtiny22/L and always reads as zero.

Bit 6 - INT0: External Interrupt Request 0 Enable

•

When the INT0 bit is set (one) and the I-bit in the Status Register (SREG) is set (one), the external pin interrupt is enabled.

The Interrupt Sense Control 0 bits 1/0 (ISC01 and ISC00) in the M CU gen eral Co ntrol Regi ster (MCUCR) defines wh ether

the external interrupt is activated on rising or falling edge of the INT0 pin or level sensed. Activity on the pin will cause an

interrupt request even if INT0 is configu red as an output. The corresp onding interrupt of Ex ternal Interrupt Request 0 is

executed from program memory address $001. See also “External Interrupts.”

Bits 5..0 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny22/L and always read as zero.

General Interrupt Flag Register - GIFR

Bit 7 6 5 4 3 2 1 0

$3A ($5A) - INTF0 - - - - - - GIFR

Read/Write R R/W R R R R R R

Initial value 0 0 0 0 0 0 0 0

Bit 7 - Res: Reserved Bit

•

This bit is a reserved bit in the ATtiny22/L and always reads as zero.

Bit 6 - INTF0: External Interrupt Flag0

•

When an event on the INT0 pin triggers an interrupt request, INTF0 becomes set (one). If the I-bit in SREG and the INT0 bit

in GIMSK are set (one), the MCU will jump to the interrupt vector at address $001. The flag is cleared when the interrupt

routine is executed. Alternatively, the flag can be cleared by writing a logical one to it.

Bits 5..0 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny22/L and always read as zero.

Timer/Counter Interrupt Mask Register - TIMSK

Bit 7 6 5 4 3 2 1 0

$39 ($59) - - - - - - TOIE0 - TIMSK

Read/Write R R R R R R R/W R

Initial value 0 0 0 0 0 0 0 0

Bit 7..2 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny22/L and always read zero.

Bit 1 - TOIE0: Timer/Counter0 Overflow Interrupt Enable

•

When the TOIE0 bit is set (one) and the I-bit in the Status Register is set (one), the Timer/Counter0 Overflow interrupt is

enabled. The corresponding interrupt (at vector $002) is executed if an overflow in Timer/Counter0 occurs, i.e., when the

Overflow Flag (Timer/Counter0) is set (one) in the Timer/Counter Interrupt Flag Register - TIFR.

Bit 0 - Res: Reserved Bit

•

This bit is a reserved bit in the ATtiny22/L and always reads as zero.

23

Page 24

Timer/Counter Interrupt FLAG Register - TIFR

Bit 7 6 5 4 3 2 1 0

$38 ($58) - - - - - - TOV0 - TIFR

Read/Write R R R R R R R/W R

Initial value 0 0 0 0 0 0 0 0

Bits 7..2 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny22/L and always read zero.

Bit 1 - TOV0: Timer/Counter0 Overflow Flag

•

The bit TOV0 is set (one) when an overflow occurs in Timer/Counter0. TOV0 is cleared by hardware when executing the

corresponding interrupt handling vector. Alternatively, TOV0 is cleared by writing a logical one to the flag. When the SREG

I-bit, and TOIE0 (Time r/Coun ter0 Ove rflow I nterrupt E nable), a nd TO V0 a re set (one), th e Tim er/Counter0 Overfl ow in terrupt is executed.

Bit 0 - Res: Reserved Bit

•

This bit is a reserved bit in the ATtiny22/L and always reads zero.

External Interrupt

The external interrupt is tr iggered by the INT0 pin. O bserve that, if en abled, the interr upt wil l trigger ev en if th e INT0 pin is

configured as an output. This featu re provides a way of gen erating a software int errupt. The exter nal interrupt can be triggered by a falling or r ising edg e or a l ow lev el . This i s set u p as i ndicated in the specificati on fo r the M CU Con tr ol R egi ste r

- MCUCR. When the ext ernal interr upt is en abled and is config ured a s level trigge red, t he inte rrupt will tri gger as long as

the pin is held low.

The external interrupt is set up as described in the specification for the MCU Control Register - MCUCR.

Interrupt Response Time

The interrupt ex ecution respon se for a ll the e nable d AVR i nterrupts is 4 c lock cycles minimum . 4 clock cycles after the

interrupt flag has been set, the program vector address for the actual interrupt handling routine is executed. During these 4

clock cycles, the Program Counter (2 bytes) is popped back from the Stack, the Stack Pointer is incremented by 2, and the

I flag in SREG is set. The vector is a relative jump to the interrupt routine, and this jump takes 2 clock cycles. If an interrupt

occurs during execution of a multi-cycle instruction, this instruction is completed before the interrupt is served.

A return from an interrupt handling routine (same as for a subroutine call routine) takes 4 clock cycles. During these 4 clock

cycles, the Program Counter (2 bytes) is popped back from the Stack, and the Stack Pointer is incremented by 2. When the

AVR exits from an interrupt, it will always return to the main program and execute one more instruction before any pending

interrupt is served.

MCU Control Register - MCUCR

The MCU Control Register contains control bits for general MCU functions.

Bit 76543210

$35 ($55) - - SE SM - - ISC01 ISC00 MCUCR

Read/Write R R R/W R/W R R R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7, 6 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny22/L and always read as zero.

Bit 5 - SE: Sleep Enable

•

The SE bit must be set (one) to make the MCU enter the sleep mode when the SLEEP instruction is executed. To avoid the

MCU entering the sleep mode unless it is the programmers purpose, it is recommended to set the Sleep Enable SE bit just

before the execution of the SLEEP instruction.

24

ATtiny22/22L

Page 25

ATtiny22/22L

• Bit 4 - SM: Sleep Mode

This bit selects between th e two avai lab le sleep modes. When SM is cleared (zer o), Idl e Mo de is se le cte d as Sle ep Mo de.

When SM is set (one), Power Down mode is selected as sleep mode. For details, refer to the section “Sleep Modes” on

page 25.

Bits 3, 2 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny22/L, and always read as zero.

Bits 1, 0 - ISC01, ISC00: Interrupt Sense Control 0 Bit 1 and Bit 0

•

The External Interrupt 0 is activated by the external pin INT0 if the SREG I-flag and the corresponding interrupt mask is set.

The level and edges on th e ex ternal INT0 pin that activat e the in terru pt a re define d in Table 7.

is sampled before det ecting edges. If ed ge or togg le interr upt is sele cted, pu lses that last l onger than one cloc k peri od will

generate an interru pt. Short er puls es ar e not gu aranteed to gene rate a n interr upt. If low lev el inter rupt is sel ected, the low

level must be held until the completion of the currently executing instruction to generate an interrupt.

Table 7. Interrupt 0 Sense Control

ISC01 ISC00 Description

0 0 The low level of INT0 generates an interrupt request.

01Reserved

1 0 The falling edge of INT0 generates an interrupt request.

The value on the INT01 pin

1 1 The rising edge of INT0 generates an interrupt request.

Note: When changing the ISC01/ISC00 bits, INT0 must be disabled by clearing its Interrupt Enable bit in the GIMSK Register. Other-

wise an interrupt can occur when the bits are changed.

Sleep Modes

To enter the sleep modes, the SE bit in MCUCR must be set (one) and a SLEEP instruction must be executed. If an

enabled interrupt occu rs whi le the M CU i s in a s l eep m ode , the MCU a w akes , ex ec ute s the in ter r upt ro utin e, a nd r es um es

execution from the instruction following SLEEP. The contents of the register file, SRAM and I/O memory are unaltered. If a

reset occurs during sleep mode, the MCU wakes up and executes from the Reset vector.

Idle Mode

When the SM bit is cleared (zero), the SLEEP instruction forces the MCU into the Idle Mode stopping the CPU but allowing

Timer/Counters, Watchdog and the interrupt system to continue operating. This enables the MCU to wake up from external

triggered interrupts as well as internal ones like Timer Overflow interrupt and watchdog reset.

Power Down Mode

When the SM bit is set (one), the SLEEP instruction forces the MCU into the Power Down Mode. In this mode, the

oscillator is stopped, while the external interrupts and the Watchdog (if enabled) continue operating. Only an external reset,

a watchdog reset (if enabled), or an external level interrupt on INT0 can wake up the MCU.

Note that if a level trigge red interrup t is used for wake-u p from Power Down Mod e, the changed level must be held for

some time to wake up the MCU. This makes the MCU less sensitive to noise. The changed level is sampled twice by the

watchdog oscillato r clock, and if the input has the requ ired level during this time , the MCU will wak e up. The period of the

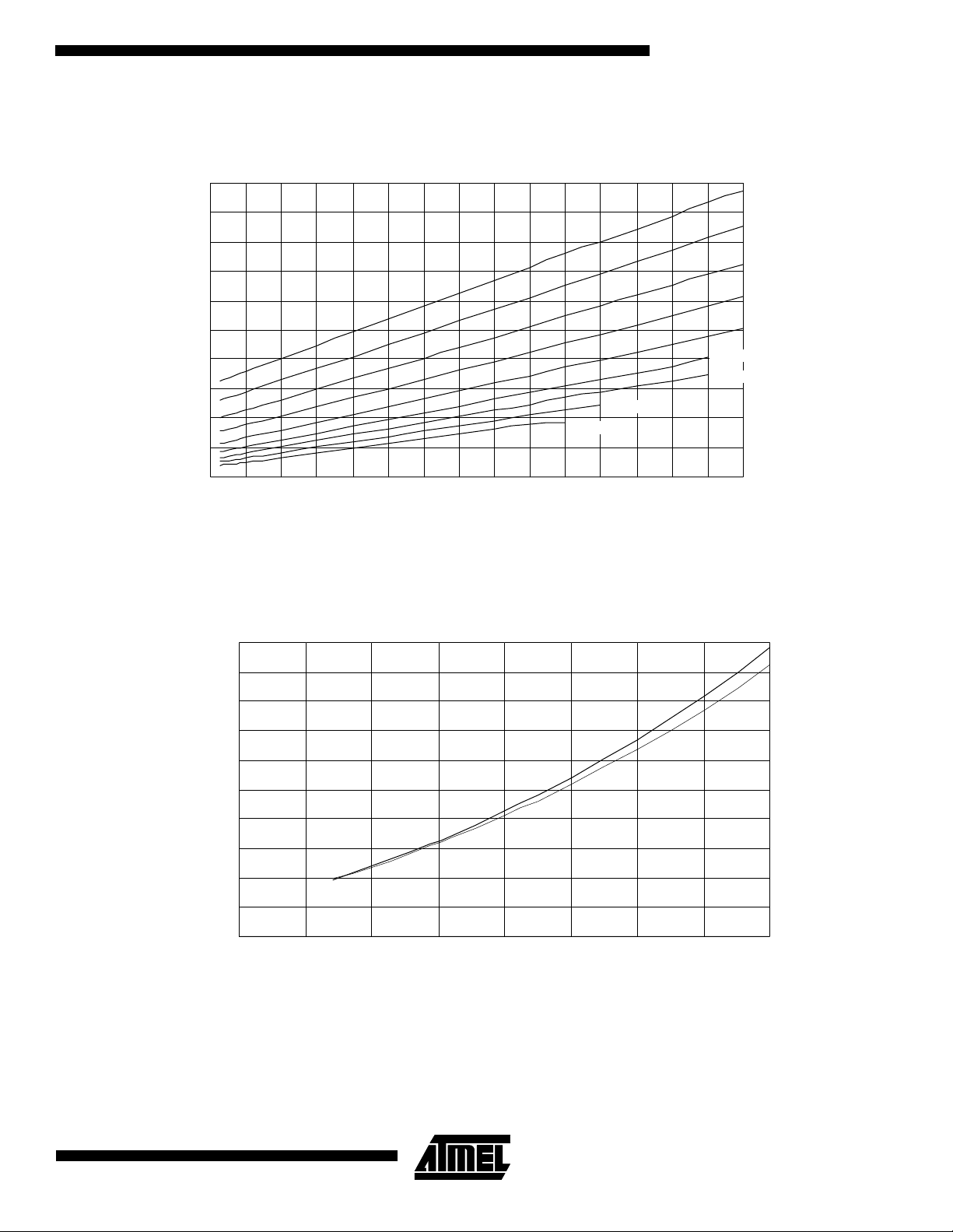

watchdog oscillator is 1 us (nominal) at 5.0V and 25C. The frequency of the watchdog oscillator is voltage dependent as

shown in section “Typical characteristics” on page 44.

When waking up from Pow er D own M ode, there is a dela y fro m the wa ke-up con ditio n oc curs unti l the wak e-up b ecome s

effective. This allows the clock to restart and become stable after having been stopped. The wake-up period is equal to the

clock reset period, as shown in Table 3 and Table 4.

If the wake-up condition disappears before the MCU wakes up and starts to execute, e.g. a low level on is not held long

enough, the interrupt causing the wake-up will not be executed.

external

25

Page 26

Timer/Counter

The ATtiny22/L provides one general purpose 8- bit Timer/Counter - Timer/Counter0. The Timer/Counter has prescaling

selection from the 10-bit prescaling timer. The Timer/Counter can either be used as a timer with an internal clock timebase

or as a counter with an external pin connection that triggers the counting.

Timer/Counter Prescaler

Figure 27 shows the Timer/Co unter prescaler.

Figure 27. Timer/Counter0 Prescaler

CK

T0

CS00

CS01

CS02

10-BIT T/C PRESCALER

CK/8

0

TIMER/COUNTER0 CLOCK SOURCE

TCK0

CK/64

CK/256

CK/1024

The four different prescaled selections are: CK/8, CK/64, CK/256 and CK/1 024 where CK is the oscillator clock. CK,

external source and stop, can also be selected as clock sources.

8-Bit Timer/Counter0

Figure 28 shows the block diagram for Timer/Counter0.

The 8-bit Timer/Counter0 can s ele ct clock so urce f rom CK, pre scal ed CK , or an ex ter na l pin. In ad dition, it can be stopped

as described in the spe cific at ion for the Time r /Coun ter0 Control Register - TCCR0. The ov er flo w s tatus flag i s foun d in the

Timer/Counter Inte rrupt Fla g Register - TIFR. Control signals ar e found in th e Timer/Co unter0 Co ntrol Regi ster - TCC R0.

The interrupt enable/disable settings for Timer/Counter0 are found in the Timer/Counter Interrupt Mask Register - TIMSK.

When Timer/Counter0 is externally clocked, the external signal is synchronized with the oscillator frequency of the CPU. To

ensure proper sampling of the external clock, the minimum time between two external clock transitions must be at least one

internal CPU clock period. The external clock signal is sampled on the rising edge of the internal CPU clock.

The 8-bit Timer/Counter0 features both a high resolution and a high accuracy usage with the lower prescaling opportunities. Similarly, the high presc aling opportu nities mak e the Timer/Count er0 useful for lower speed func tions or exact timi ng

functions with infrequent actions.

26

ATtiny22/22L

Page 27

Figure 28. Timer/Counter 0 Block Diagram

ATtiny22/22L

T0

Timer/Counter0 Control Register - TCCR0

Bit 76 5 4 3 210

$33 ($53) - - - - - CS02 CS01 CS00 TCCR0

Read/Write R R R R R R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..3 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny22/L, and always read zero.

Bits 2,1,0 - CS02, CS01, CS00: Clock Select0, Bit 2,1 and 0

•

The Clock Select0 bits 2,1 and 0 define the prescaling source of Timer0.

Table 8. Clock 0 Prescale Se lect

CS02 CS01 CS00 Description

0 0 0 Stop, the Timer/Counter0 is stopped.

001CK

010CK/8

011CK/64

100CK/256

101CK/1024

1 1 0 External Pin T0, falling edge

1 1 1 External Pin T0, rising edge

27

Page 28

The Stop condition provides a Timer Enable/Disable function. The CK down divided modes are scaled directly from the CK

oscillator clock. If the external pin modes are used for Timer/Counter0, transitions on PB2/(T0) will clock the counter even if

the pin is configured as an output. This feature can give the user SW control of the counting.

Timer Counter 0 - TCNT0

Bit 76543210

$32 ($52) MSB LSB TCNT0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

The Timer/Counter0 is realized as an up-counter with read and write access. If the Timer/Counter0 is written and a clock

source is present, the Timer/Counter0 continues counting in the timer clock cycle following the write operation.

Watchdog Timer

The Watchdog Timer is clocked from a separate o n-chip oscillator. By controlli ng the Watchdog Timer prescale r, the

Watchdog reset interval can be adjusted a s shown in T able 9. See characterization data for typic al values at other V

levels. The WDR - Watchdog R eset - instructi on resets the Wa tchdog Ti mer. Ei ght differe nt clock cycle p eriods c an be

selected to determine the reset period. If the reset period expires without another Watchdog reset, the ATtiny22/L resets

and executes from the reset vector. For timing details on the Watchdog reset, refer to page 21.

To prevent unintentional disabling of the watchdog, a special turn -off sequence must be followed when the watchdog is

disabled. Refer to the description of the Watchdog Timer Control Register for details.

Figure 29. Watchdog Timer

Oscillator

CC

1 MHz at V

350 kHz at V

CC

CC

= 5V

= 3V

Watchdog Timer Control Register - WDTCR

Bit 76543210

$21 ($41) - - - WDTOE WDE WDP2 WDP1 WDP0 WDTCR

Read/Write R R R R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..5 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny22/L and will always read as zero.

28

ATtiny22/22L

Page 29

ATtiny22/22L

• Bit 4 - WDTOE: Watch Dog Turn-Off Enable

This bit must be se t ( on e) wh en the W D E bit is c le ared. O the r wis e, the wa tch dog wi ll n ot be di sa bl ed. O nce set, hardware

will clear this bit to zero after four clock cycles. Refer to the description of the WDE bit for a watchdog disable procedure.

Bit 3 - WDE: Watch Dog Enable

•

When the WDE is set (one) the Watchdog Timer is enabled, and if the WDE is cleared (zero) the Watchdog Timer function

is disabled. WDE can only be cleared if the WDTOE bit is set(one). To disable an enabled watchdog timer, the following

procedure must be followed:

1. In the same operation, write a logical one to WDTOE and WDE. A logical one must be written to WDE even though

it is set to one before the disable operation starts.

2. Within the next four clock cycles, write a logical 0 to WDE. This disables the watchdog.

Bits 2..0 - WDP2, WDP1, WDP0: Watchdog Timer Prescaler 1 and 0

•

The WDP2, WDP1 and WDP0 bits determine the Watchdog Timer prescaling when the Watchdog Timer is enabled. The

different prescaling values and their corresponding time-out periods are shown in Table 9.

Table 9. Watch Dog Timer Presca le Select

Number of WDT

WDP2 WDP1 WDP0

0 0 0 16K cycles 47 ms 15 ms

0 0 1 32K cycles 94 ms 30 ms

0 1 0 64K cycles 0.19 s 60 ms

0 1 1 128K cycles 0.38 s 0.12 s

1 0 0 256K cycles 0.75 s 0.24 s

1 0 1 512K cycles 1.5 s 0.49 s

1 1 0 1,024K cycles 3.0 s 0.97 s

1 1 1 2,048K cycles 6.0 s 1.9 s

Note: The frequency of the watchdog oscillator is voltage dependent as shown in the Electrical Characteristics section.

The WDR - Watchdog Reset - instruction should always be executed before the Watchdog Timer is enabled. This ensures that

the reset period will be in accordance with the Watchdog Timer prescale settings. If the Watchdog Timer is enabled without

reset, the watchdog timer may not start to count from zero.

Oscillator cycles

Typical time-out

at VCC = 3.0V

Typical time-out

at VCC = 5.0V

29

Page 30

EEPROM Read/Write Access

The EEPROM access registers are accessible in the I/O space.

The write access time is in the range of 2.5 - 4ms, depending on the V

user software detect when the next byte can be written.

In order to prevent unintentional EEPROM writes, a specific write procedure must be followed. Refer to the description of

the EEPROM Control Register for details on this.

When the EEPROM is read or written, the CPU is halted for two clock cycles before the next instruction is executed.

EEPROM Address Register - EEAR

Bit 76543210

$1E ($3E) - EEAR6 EEAR5 EEAR4 EEAR3 EEAR2 EEAR1 EEAR0 EEAR

Read/Write R R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bit 7 - Res: Reserved Bit

•

This bit is a reserved bit in the ATtiny22/L and will always read as zero.

Bit 6..0 - EEAR6..0: EEPROM Address

•

The EEPROM Address Register - EEAR6..0 - specifies the EEPROM address in the 128 bytes EEPROM space. The

EEPROM data bytes are addressed linearly between 0 and 127.

EEPROM Data Register - EEDR

Bit 76543210

$1D ($3D) MSB LSB EEDR

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

voltages. A self-timing function, however, lets the

CC

Bit 7..0 - EEDR7..0: EEPROM Data

•

For the EEPROM wri te ope ratio n, the EEDR regist er con tains the d ata to be wr itten to the EEPRO M in the addre ss g iven

by the EEAR register. For the EEPROM read operation, the EEDR contains the data read out from the EEPROM at the

address given by EEAR.

EEPROM Control Register - EECR

Bit 76543210

$1C ($3C) - - - - - EEMWE EEWE EERE EECR

Read/WriteRRRRRR/WR/WR/W

Initial value 0 0 0 0 0 0 0 0

Bit 7..3 - Res: Reserved Bits

•

These bits are reserved bits in the ATtiny22/L and will always read as zero.

Bit 2 - EEMWE: EEPROM Master Write Enable

•

The EEMWE bit determines whether setting EEWE to one causes the EEPROM to be written. When EEMWE is set(one)

setting EEWE will write data to the EEPROM at the selected address. If EEMWE is zero, setting EEWE will have no effect.

When EEMWE has been set (one ) by softwar e, hardwar e clears the bit to zer o after four cloc k cycles . See the des cripti on

of the EEWE bit for a EEPROM write procedure.

Bit 1 - EEWE: EEPROM Write Enable

•

The EEPROM Write Enable Signal EEWE is the write strobe to the EEPROM. When address and data are correctly set up,

the EEWE bit must be set to write the value into the EEPROM. The EEMWE bit must be set when the logical one is written

to EEWE, otherwise no EEPROM write takes place. The following procedure should be followed when writing the

EEPROM (the order of steps 2 and 3 is unessential):

30

ATtiny22/22L

Page 31

ATtiny22/22L

1. Wait until EEWE becomes zero

2. Write new EEPROM address to EEAR (optional)

3. Write new EEPROM data to EEDR (optional)

4. Write a logical one to the EEMWE bit in EECR

5. Within four clock cycles after setting EEMWE, write a logical one to EEWE

Caution: An interrupt between step 4 and step 5 will make the write cycle fail, since the EEPROM Master Write Enable will

time-out. If an interrupt routine accessing the EEPROM is interrupting another EEPROM access, the EEAR and EEDR register will be modified, causing the interrupted EEPROM access to fail. It is recommended to have the global interrupt flag

cleared during the 4 last s teps t o avoi d these probl ems. W hen th e write acce ss ti me (typi call y 2.5 m s at V

= 2.7V) has elapsed , the E EWE bit is c leared (zero) by har dware . The user softwa re can p oll this bit a nd wait for a

at V

CC

zero before writing the next byte. When EEWE has been set, the CPU is halted for two cycles before the next instruction is

executed.

Bit 0 - EERE: EEPROM Read Enable

•

The EEPROM Read Enable Signal EERE is the read strobe to the EEPROM. When the correct address is set up in the

EEAR register, the EERE bit must be set. When the EERE bit is cleared (zero) by hardware, requested data is found in the

EEDR register. The EEPROM read access takes one instruction and there is no need to poll the EERE bit. When EERE

has been set, the CPU is hal ted for two cyc les befor e the next in structio n is execut ed. The user should poll the EEWE bit

before starting the read operation. If a wri te operation is in progress whe n new data or addres s is written to th e EEPROM

I/O registers, the write operation will be interrupted, and the result is undefined.

= 5V or 4 ms

CC

Prevent EEPROM Corruption

During periods of low V

EEPROM to operate properly. These issues are the same as for board level systems using the EEPROM, and the same

design solutions sho uld be appli ed. An EEPROM dat a corrupti on can be ca used by two s ituat ions w hen the volta ge is too

low. First, a regular write sequence to the EEPROM requires a minimum voltage to operate correctly. Secondly, the CPU

itself can execute instructions incorrectly, if the supply voltage for executing instructions is too low.

EEPROM data corruption can easily be avoided by following these design recommendations (one is sufficient):

1. Keep the AVR RESET active (low) during periods of insufficient power supply voltage. This is best done by an external low V

Reset Protection circuit, often referred to as a Brown-Out Detector (BOD). Please refer to application

CC

note AVR 180 for design considerations regarding power-on reset and low voltage detection.

2. Keep the A VR core in P ower Down Sleep Mode during periods of low V

to decode and execute instructions, effectively protecting the EEPROM registers from unintentional writes.

3. Store constants in Flash memory if the ability to change memory contents from software is not required. Flash

memory can not be updated by the CPU, and will not be subject to corruption.

the EEPROM data can be corrup ted beca use the s upply vol tage is too low for the CPU and the

CC,

. This will prevent the CPU from attempting

CC

31

Page 32

I/O Port B

All AVR ports h ave true Read-Modify-Writ e f unc tio nal it y when u se d as ge ner al d igital I /O po r ts. Thi s means that the direc tion of one port pin can be changed without unintentionally changing the direction of any other pin with the SBI and CBI

instructions. The same applies for changing drive value (if configured as output) or enabling/disabling of pull-up resistors (if

configured as input).

Port B is a 5-bit bi-directional I/O port.

Three I/O memory address locations are allocated for Port B, one each for the Data Register - PORTB, $18 ($38), Data

Direction Register - DDRB, $17($37) and the Port B Input Pins - PINB, $16($36). The Port B Input Pins address is read

only, while the Data Register and the Data Direction Register are read/write.

All port pins have individually selectable pull-up resistors. The Port B output buffers can sink 20mA and thus drive LED displays directly. When pins PB0 to PB4 are used as inputs and are externally pulled low, they will source current if the

internal pull-up resistors are activated.

The Port B pins with alternate functions are shown in the following table:

Table 10. Port B Pins Alternate Functions

Port Pin Alternate Functions

PB0 MOSI (Data input line for memory downloading)

PB1

PB2

PB3 CLOCK (Clock input)

MISO (Data output line for memory uploading)

INT0 (External Interrupt0 Input)

SCK (Serial clock input for serial programming)

TO (Timer/Counter0 counter clock input)

When the pins are used for the alternate function the DDRB and PORTB register has to be set according to the alternate

function description.

Port B Data Register - PORTB

Bit 76543210

$18 ($38) - - - PORTB4 PORTB3 PORTB2 PORTB1 PORTB0 PORTB

Read/Write R R R R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Port B Data Direction Register - DDRB

Bit 76543210

$17 ($37) - - - DDB4 DDB3 DDB2 DDB1 DDB0 DDRB

Read/Write R R R R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Port B Input Pins Address - PINB

Bit 76543210

$16 ($36) - - - PINB4 PINB3 PINB2 PINB1 PINB0 PINB

Read/WriteRRRRRRRR

Initial value 0 0 0 Hi-Z Hi-Z H i-Z Hi-Z Hi-Z

The Port B Input Pins address - PINB - is not a register, and this address enables access to the physical value on each Port

B pin. When reading PORTB, the Port B Data Latch is read, and when reading PINB, the logical values present on the pins

are read.

32

ATtiny22/22L

Page 33

ATtiny22/22L

General Digital I/O

All pins in port B have equal functionality when used as digital I/O pins.

PBn, General I/O pin: The DDBn bi t in the D DRB r eg ist er s el ect s th e di rec tio n of t his pi n, i f DDB n i s set (one), PBn is con-

figured as an outpu t pi n. If DDBn is cleared (ze ro ), P Bn is configured as an input pi n. If P O RTBn is set (one) when the pin

configured a s a n in put p in, the M OS pull up resi stor is a ctiv ated . To sw itch th e pull u p resi stor off, the POR TBn h as to be

cleared (zero) or the pin has to be configured as an output pin. The port pins are tri-stated when a reset condition becomes

active, even if the clock is not running.

Table 11. DDBn Effects on Port B Pins

DDBn PORTBn I/O Pull up Comment

0 0 Input No Tri-state (Hi-Z)

0 1 Input Yes PBn will source current if ext. pulled low.

1 0 Output No Push-Pull Zero Output

1 1 Output No Push-Pull One Output

Alternate Functions of Port B

The alternate pin functions of Port B are:

CLOCK - Port B, Bit 3

Clock input: When the RCEN fu se is programm ed and the devic e runs from th e inter nal RC osci llato r, this pi n is a gen eral

I/O pin. When the RCEN Fuse is unprogrammed, an external clock source must be connected to CLOCK.

SCK/T0 - Port B, Bit 2

In serial programming mode, this bit serves as the serial clock input, SCK.

During normal operation, this pin can serve as the external counter clock input. See the timer/counter description for further

details. If externa l tim er/c ounter c lock ing is sele cted, activ ity on this pin will clock the c ounter eve n if i t is configu red as an

output.

MISO - Port B, Bit 1

In serial programming mode, this bit serves as the serial data output, MISO.

During normal operation, this pin can serve as the external interrupt0 input. See the interrupt description for details on how

to enable this interrupt. Note that activity on this pin will trigger the interrupt even if the pin is configured as an output.

MOSI - Port B, Bit 0

In serial programming mode, this pin serves as the serial data input, MOSI.

33

Page 34

Memory Programming

Program and Data Memory Lock Bits

The ATtiny22/L MCU provides two lock bits which can be left unprogrammed (“1”) or can be programmed (“0”) to obtain the

additional features listed in Table 12 . The Lock bits can only be erased with the Chip Erase operation.

Table 12. Lock Bit Protection Modes

Memory Lock Bits

Protection TypeMode LB1 LB2

1 1 1 No memory lock features enabled.

2 0 1 Further programming of the Flash and EEPROM is disabled.

3 0 0 Same as mode 2, and verify is also disabled.

Note: 1. In the H igh-vol tage Serial Progr amming mo de, further progra mming of the Fuse bits are als o disab led. Progr am the fuse bi ts

before programming the lock bits.

Fuse Bits

The ATtiny22/L has two Fuse bits, SPIEN and RCEN.

• When the SPIEN Fuse is programmed (“0”), Serial Program and Data Downloading is enabled. Default value is

programmed (“0”). This bit is not accessible in the Low-Voltage Serial Programming mode.

• When the RCEN Fuse is programmed (“0”), the internal RC oscillator is selected as the MCU clock source. Default value

is programmed (“0”). Changing the RCEN Fuse does not have effect until the next power-on reset.

The status of the Fuse bits is not affected by Chip Erase.

(1)

Signature Bytes

All Atmel micro control lers ha ve a three -byte signatur e code which ide ntifie s the de vice. T he thre e bytes re side in a sep arate address space.

(1)

For ATtiny22/L

1. $000: $1E (indicates manufactured by Atmel)

2. $001: $91 (indicates 2K bytes Flash memory)

3. $002: $06 (Indicates ATtiny22/L when signature byte $001 is $91.)

Note: 1. When both lock bits are programmed (Lock mode 3), the signature bytes can not be read in the Low-voltage Serial mode.

they are:

Reading the signature bytes will return: $00, $01 and $02.

Programming the Flash and EEPROM

Atmel’s ATtiny22/L offers 2K bytes of in-system programmable Flash Program memory and 128 bytes of EEPROM Data

memory.

The ATtiny22/L is shipped with the on-chip Flas h Program and EEPROM Data memory arrays in the erased state

(i.e., contents = $FF) and ready to be programmed.

The device supports a High-voltage (12V) Serial Programming mode and a Low-voltage Serial Programming mode. The

+12V is used for programm ing enable on ly, and no current of significanc e is drawn by thi s pin. The Low-volt age Serial

Programming mode provides a convenient way to download Program and Data into the device inside the user’s system.

The Program and EEPROM memory arrays in the ATtiny22/L are programmed byte-by-byte in either programming modes.

For the EEPROM, an auto-era se cycle is provided within the self-timed wri te instruction in the Low-vo ltage Serial

Programming mode.

During programming, the supply voltage must be in accordance with Table 13.

34

ATtiny22/22L

Page 35

ATtiny22/22L

Table 13. Supply Voltage During Programming

Part Low-voltage Serial Programming High-voltage Serial Prog ramm ing

ATtiny22/L 2.7 - 6.0 V 4.5 - 5.5V

ATtiny22/L 2.7 - 6.0 V 4.5 - 5.5V

High-Voltage Serial Programming

This section describes how to program and verify Flash Program memory, EEPROM Data memory, Lock bits and Fuse bits

in the ATtiny22/L.

Figure 30. High-Voltage Serial Programming

11.5 - 12.5V 4.5 - 5.5V

ATtiny22/L

SERIAL CLOCK INPUT

RESET

XTAL1/PB3

GND

VCC

PB2

PB1

PB0

SERIAL DATA OUTPUT

SERIAL INSTR. INPUT

SERIAL DATA INPUT

High-Voltage Serial Programming Algorithm

To program and verify the ATtiny22/L in the high-voltage serial programming mode, the following sequence is

recommended (See instruction formats in Table 14):

1. Power-up sequence: Apply 4.5 - 5.5V between V

and GND. Set PB5 and PB0 to “0” and wait at least 100 ns.

CC

Toggle PB3 at least 4 times with minimum 100 ns pulse-width. Set PB3 to “0”. Wait at least 100 ns. Apply 12V to

PB5 and wait at least 100 ns before changing PB0. Wait 8 µs before giving any instructions.

2. The Flash array is programmed one byte at a time by supplying first the address, then the low and high data byte.

The write instruction is self-timed, wait until the PB2 (RDY/BSY

) pin goes high.

3. The EEPROM array is programmed one byte at a time by supplying first the address, then the data byte. The write

instruction is self-timed, wait until the PB2 (RDY/BSY

) pin goes high.

4. Any memory location can be verified by using the Read instruction which returns the contents at the selected

address at serial output PB2.

5. Power-off sequence:Set PB3 to “0”.

Set PB5 to “1”.

Turn V

power off.

CC

When writing or readi ng se rial data to the dev ic e, data is clo ck ed on the risi ng edg e of the serial clock, see Figure 31, Figure 32 and Table 15 for details.

35

Page 36

Figure 31. High-Voltage Serial Programming Waveforms

SERIAL DATA INPUT

PB0

SERIAL INSTR. INPUT

PB1

SERIAL DATA OUTPUT

PB2

SERIAL CLOCK INPUT

XTAL1/PB3

MSB

MSB

MSB LSB

012345678910

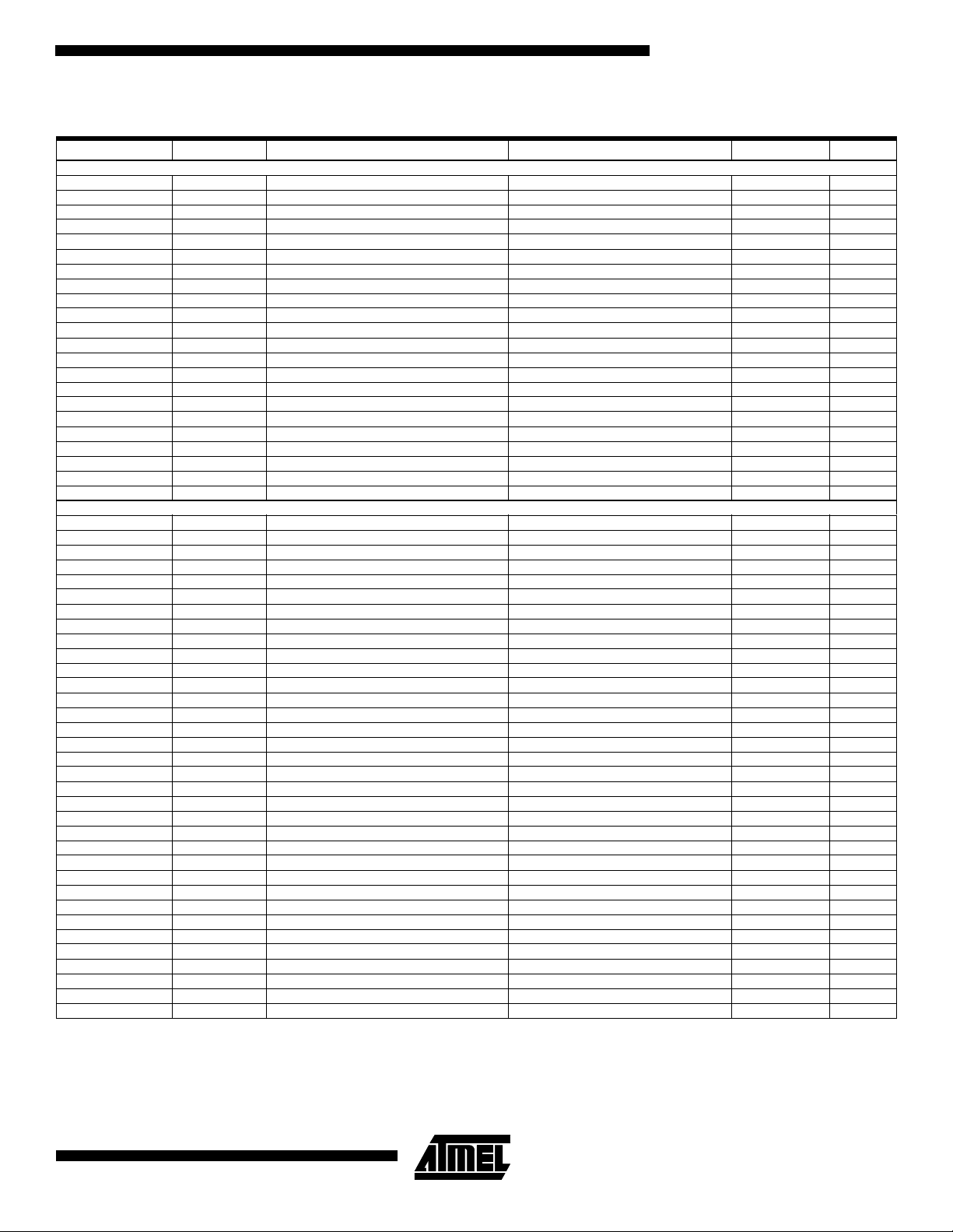

Table 14. High-Voltage Serial Programming Instruction Set

Instruction Format

Instruction

Chip Erase PB0

PB1

PB2

Write Flash

High and Low

Address

Write Flash Low

byte

Write Flash

High byte

Read Flash

High and Low

Address

Read Flash

Low byte

Read Flash

High byte

Write EEPROM

Low Address

Write EEPROM

byte

Read EEPROM

Low Address

PB0

PB1

PB2

PB0

PB1

PB2

PB0

PB1

PB2

PB0

PB1

PB2

PB0

PB1

PB2

PB0

PB1

PB2

PB0

PB1

PB2

PB0

PB1

PB2

PB0

PB1

PB2

0_1000_0000_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_0001_0000_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_ i i i i_i i i i _00

0_0010_1100_00

x_xxxx_xxxx_xx

0_ i i i i_i i i i _00

0_0010_1100_00

x_xxxx_xxxx_xx

0_0000_0010_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1000_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0111_1000_00

x_xxxx_xxxx_xx

0_0001_0001_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_ i i i i_i i i i _00

0_0010_1100_00

x_xxxx_xxxx_xx

0_0000_0011_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_0100_00

x_xxxx_xxxx_xx

0_0000_00aa_00

0_0001_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_0100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0111_0100_00

x_xxxx_xxxx_xx

0_0000_00aa_00

0_0001_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1100_00

o_oooo_ooox_xx

0_0000_0000_00

0_0111_1100_00

o_oooo_ooox_xx

0_0bbb_bbbb_00

0_0000_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_0100_00

x_xxxx_xxxx_xx

0_0bbb_bbbb_00

0_0000_1100_00

x_xxxx_xxxx_xx

0_bbbb_bbbb_00

0_bbbb_bbbb_00

0_0000_0000_00

0_0110_1100_00

x_xxxx_xxxx_xx

0_0000_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1100_00

0_0000_0000_00

0_0000_0000_00

0_0111_1100_00

0_0000_0000_00

0_0000_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1100_00

0_0000_0000_00

LSB

LSB

0_0000_0000_00

0_0100_1100_00

x_xxxx_xxxx_xx

Operation RemarksInstr.1 Instr.2 Instr.3 Instr.4

Wait

t

WLWH_CE

Chip Erase cycle to finish.

Repeat Instr.2 for a new 256 byte

page. Repeat Instr.3 for each new

address.

Wait after Instr.3 until PB2 goes

high. Repeat Instr.1, Instr. 2 and

Instr.3 for each new address.

Wait after Instr.3 until PB2 goes

high. Repeat Instr.1, Instr. 2 and

Instr.3 for each new address.

Repeat Instr.2 and Instr.3 for each

new address.

Repeat Instr.1 and Instr.2 for each

new address.

Repeat Instr.1 and Instr.2 for each

new address.

Repeat Instr.2 for each new

address.

Wait after Instr.3 until PB2 goes

high

Repeat Instr.2 for each new

address.

after Instr.3 for the

36

ATtiny22/22L

Page 37

Table 14. High-Voltage Serial Programming Instruction Set (Continued)

Instruction Format

ATtiny22/22L

Instruction

Read EEPROM

byte

Write Fuse bits

Write Lock bits PB0

Read Fuse and

Lock bits

Read Signature

Bytes

PB0

PB1

PB2

PB0

PB1

PB2

PB1

PB2

PB0

PB1

PB2

PB0

PB1

PB2

0_0000_0000_00

0_0110_1000_00

x_xxxx_xxxx_xx

0_0100_0000_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_0010_0000_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_0000_0100_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_0000_1000_00

0_0100_1100_00

x_xxxx_xxxx_xx

Note: a = address high bits

b = address low bits

i = data in

o = data out

x = don’t care

1

= Lock Bit1

2

= Lock Bit2

R = RCEN Fuse

S = SPIEN Fuse

0_0000_0000_00

0_0110_1100_00

o_oooo_ooox_xx

0_11S1_111R_00

0_0010_1100_00

x_xxxx_xxxx_xx

21

0_1111_1

0_0010_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1000_00

x_xxxx_xxxx_xx

0_0000_00bb_00

0_0000_1100_00

x_xxxx_xxxx_xx

1_00

0_0000_0000_00

0_0110_0100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_0100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1100_00

1_2

Sxx_xxRx_xx

0_0000_0000_00

0_0110_1000_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1100_00

0_0000_0000_00

0_0000_0000_00

0_0110_1100_00

o_oooo_ooox_xx

Operation RemarksInstr.1 Instr.2 Instr.3 Instr.4

Repeat Instr.2 for each new

address

Wait

t

WLWH_PFB

Write Fuse bits cycle to finish. Set

S,R = “0” to program, “1” to

unprogram.

Wait after Instr.4 until PB2 goes

high. Write

the Lock bit.

Reading

Fuse/Lock bit is programmed.

Repeat Instr.2 - Instr.4 for each

Signature byte address

after Instr.3 for the

2, 1

= “0” to program

1, 2

, S, R = “0” means the

High-Voltage Serial Programming Characteristics

Figure 32. High-Voltage Serial Programming Timing

SDI (PB0), SII (PB1)

t

IVSH

SCI (PB3)

SDO (PB2)

t

SHSL

t

SHOV

t

SHIX

t

SLSH

37

Page 38

Table 15. High-Voltage Serial Programming Characteristics

T

= 25°C ± 10%, VCC = 5.0V ± 10% (Unless otherwise noted)

A

Symbol Parameter Min Typ Max Units

t

SHSL

t

SLSH

t

IVSH

SCI (PB3) Pulse Width High 100 ns

SCI (PB3) Pulse Width Low 100 ns

SDI (PB0), SII (PB1) Valid to SCI (PB3)

High

50 ns

t

SHIX

t

SHOV

t

WLWH_CE

t

WLWH_PFB

SDI (PB0), SII (PB1) Hold after SCI

(PB3) High

SCI (PB3) High to SDO (PB2) Valid 10 16 32 ns

Wait after Instr.3 for Chip Erase 5 10 15 ms

Wait after Instr.3 for Write Fuse Bits 1.0 1.5 1.8 ms

50 ns

Low-Voltage Serial Downloading

Both the Program and Data memory arrays can be programmed using the serial SPI bus while RESET is pulled to GND.

The serial interface co nsists of pin s SCK, MOSI (input ) and MISO (outpu t), see Figure 33. After RESET

Programming Enable instruction needs to be executed first before program/erase instructions can be executed.

Figure 33. Low-voltage Serial Programming and Verify

GND

CLOCK INPUT

ATtiny22/L

RESET

XTAL1/PB3

GND

VCC

PB2

PB1

PB0

2.7 - 6.0V

SCK

MISO

MOSI

is set low, the

For the EEPROM, an auto-erase cycle is provided within the self-timed write instruction and there is no need to first execute the Chip Erase instruction. The Chip Erase instruction turns the content of every memory location in both the Program

and EEPROM arrays into $FF.

The Program and EEPROM memory arrays have separate address spaces, $0000 to $03FF for Flash Program memory

and $000 to $07F for EEPROM Data memory.

Either an external clock is applied to the XTAL1/PB3 pin or the device must be clocked from the internal RC-oscillator. The

minimum low and high periods for the serial clock (SCK) input are defined as follows:

Low: > 2 MCU clock cycles

High: > 2 MCU clock cycles

38

ATtiny22/22L

Page 39

ATtiny22/22L

Low-Voltage Serial Programming Algorithm

When writing serial data to the ATtiny22/L, data is clocked on the rising edge of SCK.

When reading data from the ATtiny22/L, data is clocked on the falling edge of SCK. See Figure 34, Figure 35 and Table 18

for timing details.

To program and ver ify the ATtiny2 2/L in the Low- Voltage Ser ial Program ming mode, th e following sequence is recom-

mended (see four byte instruction formats in Table 17 ):

1. Power-up sequence: