Page 1

Features

®

• AVR

• Data and Nonvolatile Program Memories

• Peripheral Features

• Special Microcontroller Features

• Power Consumption at 4 MHz, 3V, 20°C

• I/O and Packages

• Operating Voltages

• Speed Grades:

– High-performance and Low-power RISC Architecture

– 118 Powerful Instructions – Most Single Clock Cycle Execution

– 32 x 8 General-purpose Working Registers

– Up to 8 MIPS Throughput at 8 MHz

– 4K/8K Bytes of In-System Programmable Flash

SPI Serial Interface for In-System Programming

Endurance: 1,000 Write/Erase Cycles

– 256/512 Bytes EEPROM

Endurance: 100,000 Write/Erase Cycles

– 256/512 Bytes Internal SRAM

– Programming Lock for Software Security

– 8-channel, 10-bit ADC

– Programmable UART

– Master/Slave SPI Serial Interface

– Two 8-bit Timer/Counters with Separate Prescaler and Compare Mode

– One 16-bit Timer/Counter with Separate Prescaler, Compare and

Capture Modes and Dual 8-, 9- or 10-bit PWM

– Programmable Watchdog Timer with On-chip Oscillator

– On-chip Analog Comparator

– Power-on Reset Circuit

– Real-time Clock (RTC) with Separate Oscillator and Counter Mode

– External and Internal Interrupt Sources

– Three Sleep Modes: Idle, Power Save and Power-down

– Active: 6.4 mA

– Idle Mode: 1.9 mA

– Power-down Mode: <1 µA

– 32 Programmable I/O Lines

– 40-pin PDIP, 44-pin PLCC and 44-pin TQFP

–V

: 4.0 - 6.0V AT90S4434/AT90S8535

CC

: 2.7 - 6.0V AT90LS4434/AT90LS8535

–V

CC

– 0 - 8 MHz AT90S4434/AT90S8535

– 0 - 4 MHz AT90LS4434/AT90LS8535

8-bit

Microcontroller

with 4K/8K

Bytes In-System

Programmable

Flash

AT90S4434

AT90LS4434

AT90S8535

AT90LS8535

Preliminary

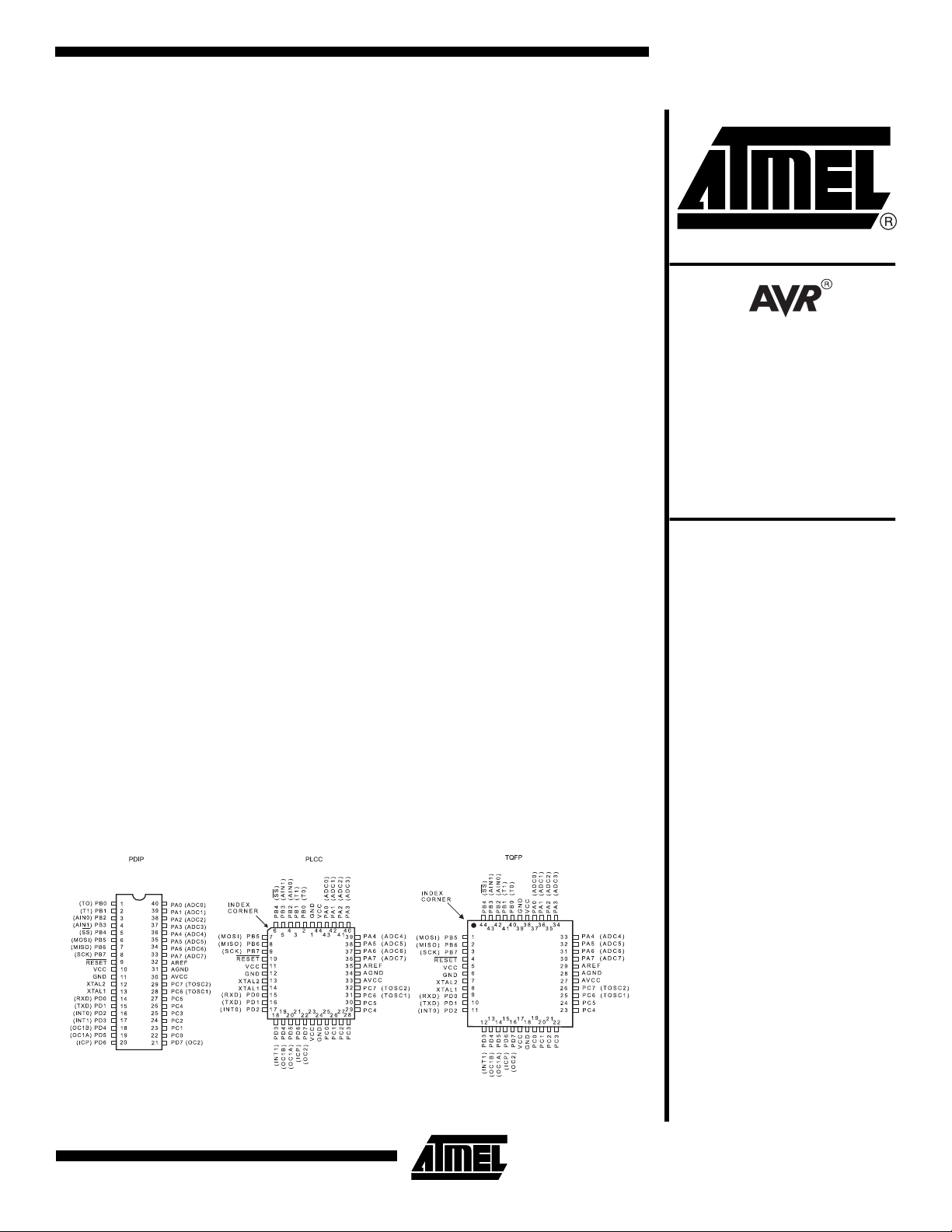

Pin Configurations

Rev. 1041F–10/00

1

Page 2

Description

The AT90S4434/8535 is a low-power CMOS 8-bit microcontroller based on the AVR RISC architecture. By executing powerful instructions in a single clock cycle, the AT90S4434/8535 achieves throughputs approaching 1 MIPS per MHz allowing

the system designer to optimize power consumption versus processing speed.

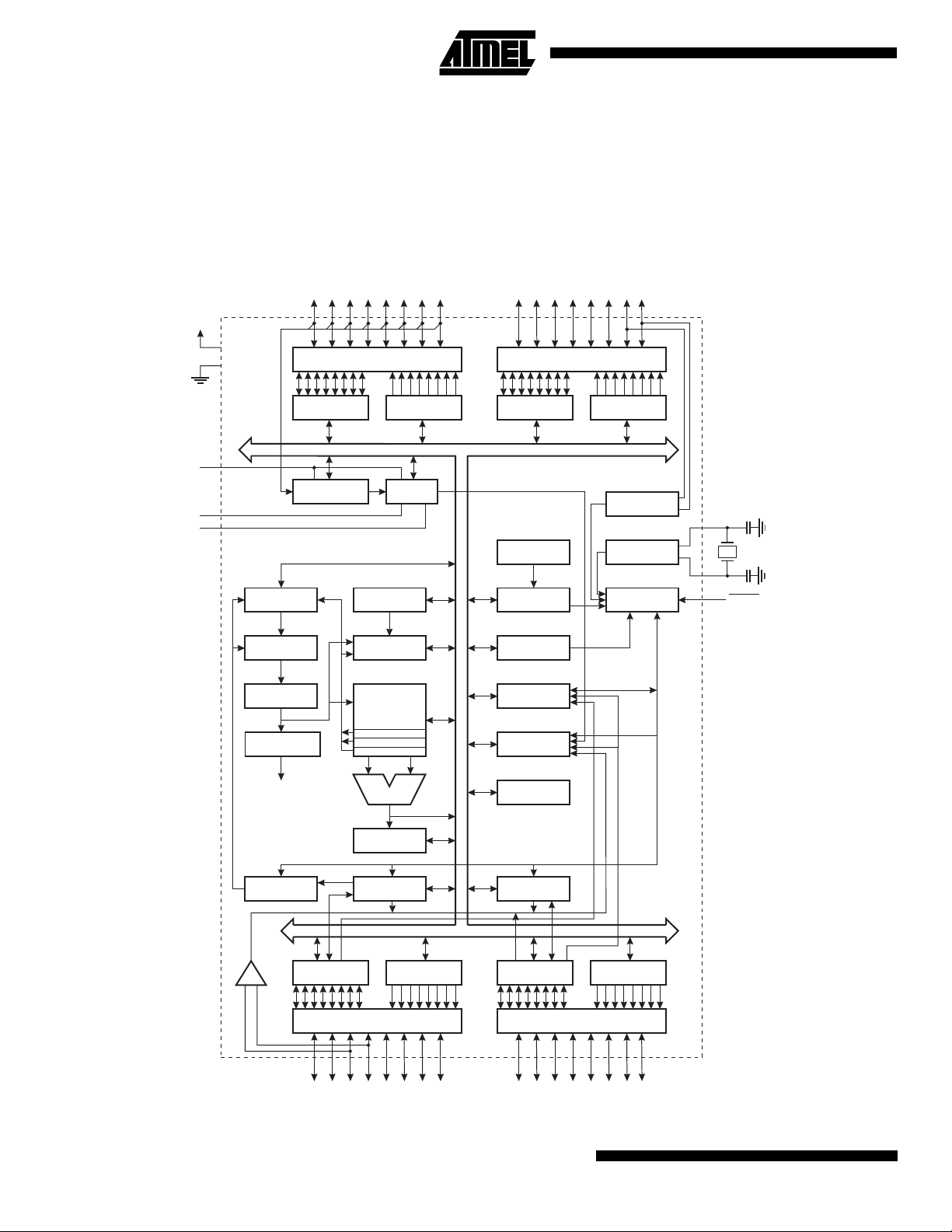

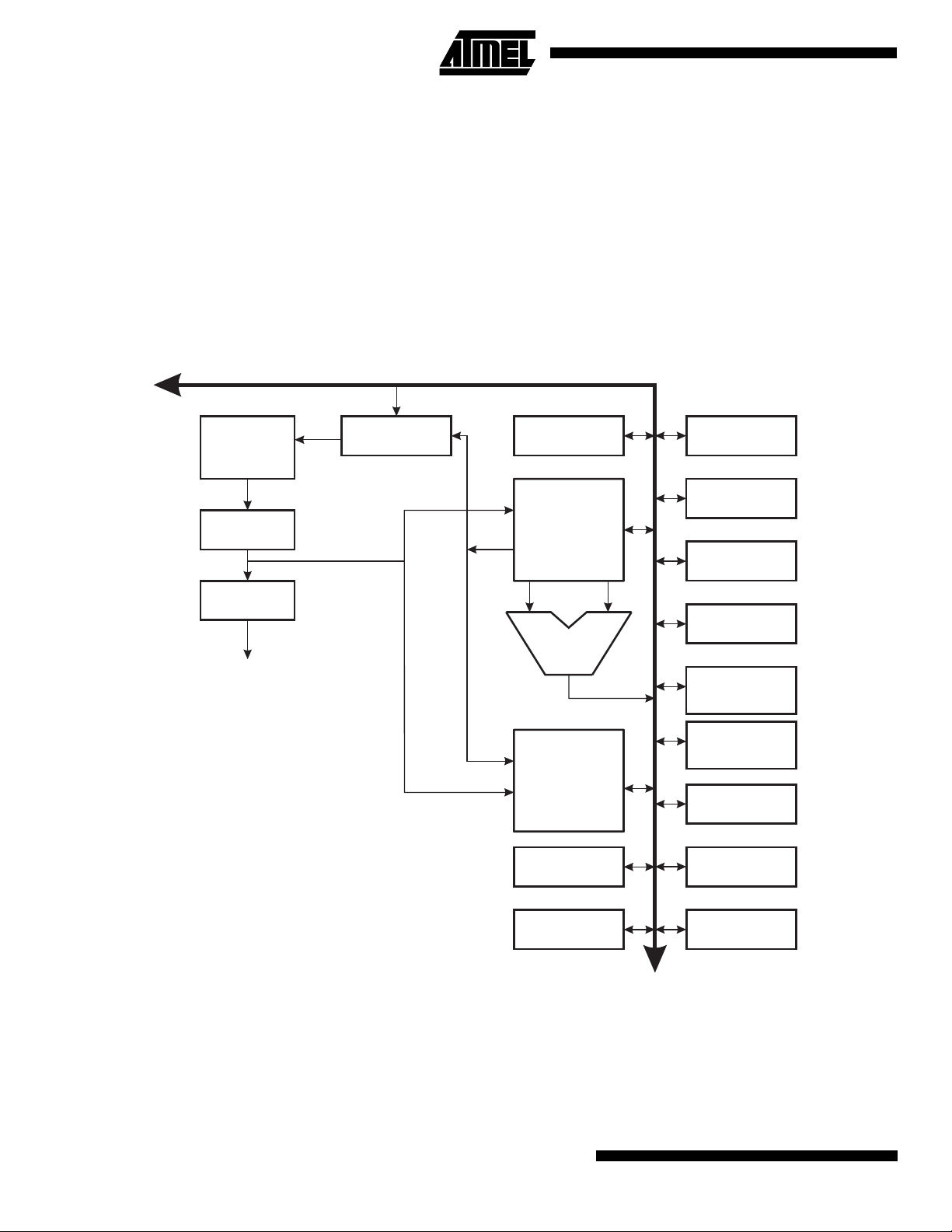

Block Diagram

Figure 1. The AT90S4434/8535 Block Diagram

PA0 - PA7

VCC

PC0 - PC7

GND

AVCC

AGND

AREF

DATA REGISTER

PROGRAM

COUNTER

PROGRAM

FLASH

INSTRUCTION

REGISTER

INSTRUCTION

DECODER

CONTROL

LINES

PORTA DRIVERS

DATA DIR.

PORTA

ANALOG MUX ADC

REG. PORTA

STACK

POINTER

SRAM

GENERAL

PURPOSE

REGISTERS

X

Y

Z

ALU

8-BIT DATA BUS

PORTC DRIVERS

DATA REGISTER

PORTC

INTERNAL

OSCILLATOR

WATCHDOG

TIMER

MCU CONTROL

REGISTER

TIMER/

COUNTERS

INTERRUPT

UNIT

EEPROM

DATA DIR.

REG. PORTC

OSCILLATOR

OSCILLATOR

TIMING AND

CONTROL

XTAL1

XTAL2

RESET

STATUS

REGISTER

PROGRAMMING

LOGIC

DATA REGISTER

ARATOR

ANALOG

COMP

PORTB

+

-

2

AT90S/LS4434 and AT90S/LS8535

SPI

REG. PORTB

PORTB DRIVERS

PB0 - PB7

DATA DIR.

UART

DATA REGISTER

PORTD

PORTD DRIVERS

PD0 - PD7

DATA DIR.

REG. PORTD

Page 3

AT90S/LS4434 and AT90S/LS8535

The AVR core combines a rich instruction set with 32 general-purpose working registers. All the 32 registers are directly

connected to the Arithmetic Logic Unit (ALU), allowing two independent registers to be accessed in one single instruction

executed in one clock cycle. The resulting architecture is more code efficient while achieving throughputs up to ten times

faster than conventional CISC microcontrollers.

The AT90S4434/8535 provides the following features: 4K/8K bytes of In-System Programmable Flash, 256/512 bytes

EEPROM, 256/512 bytes SRAM, 32 general-purpose I/O lines, 32 general-purpose working registers, Real-time Clock

(RTC), three flexible timer/counters with compare modes, internal and external interrupts, a programmable serial UART,

8-channel, 10-bit ADC, programmable Watchdog Timer with internal oscillator, an SPI serial port and three softwareselectable power-saving modes. The Idle Mode stops the CPU while allowing the SRAM, timer/counters, SPI port and

interrupt system to continue functioning. The Power-down Mode saves the register contents but freezes the oscillator, disabling all other chip functions until the next interrupt or hardware reset. In Power Save Mode, the timer oscillator continues

to run, allowing the user to maintain a timer base while the rest of the device is sleeping.

The device is manufactured using Atmel’s high-density nonvolatile memory technology. The on-chip ISP Flash allows the

program memory to be reprogrammed in-system through an SPI serial interface or by a conventional nonvolatile memory

programmer. By combining an 8-bit RISC CPU with In-System Programmable Flash on a monolithic chip, the Atmel

AT90S4434/8535 is a powerful microcontroller that provides a highly flexible and cost effective solution to many embedded

control applications.

The AT90S4434/8535 AVR is supported with a full suite of program and system development tools including: C compilers,

macro assemblers, program debugger/simulators, in-circuit emulators and evaluation kits.

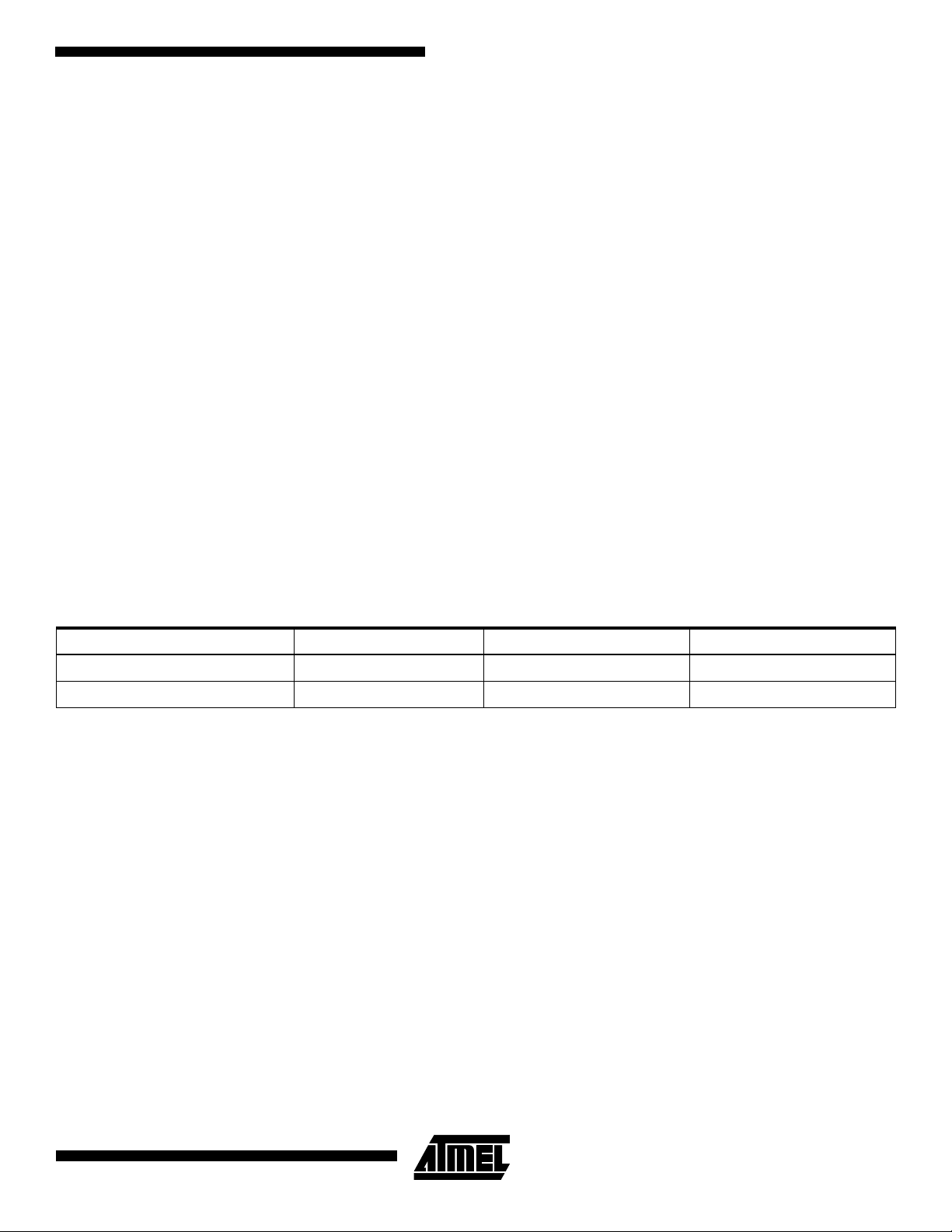

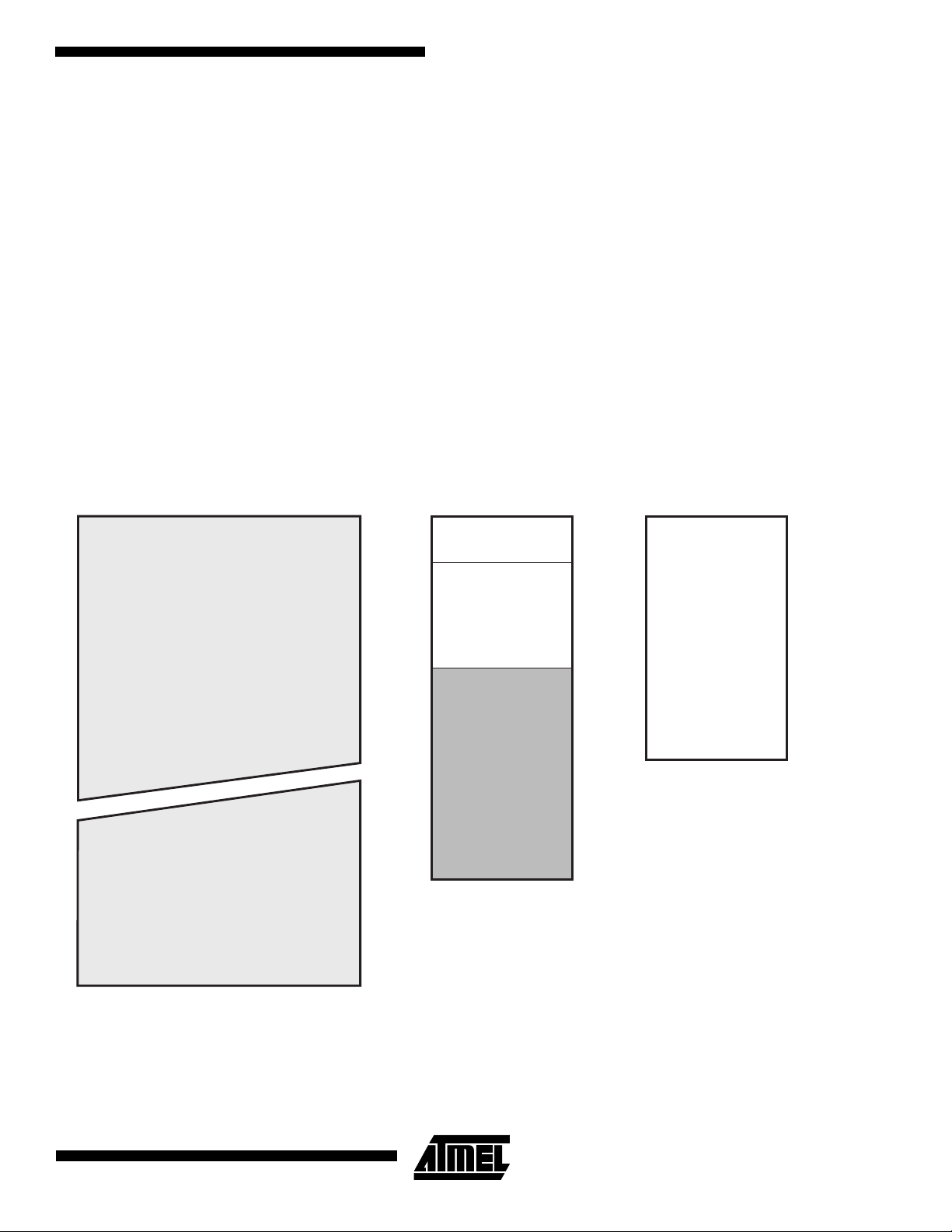

Comparison between AT90S4434 and AT90S8535

The AT90S4434 has 4K bytes of In-System Programmable Flash, 256 bytes of EEPROM and 256 bytes of internal SRAM.

The AT90S8535 has 8K bytes of In-System Programmable Flash, 512 bytes of EEPROM and 512 bytes of internal SRAM.

Table 1 summarizes the different memory sizes for the two devices.

Table 1. Memory Size Summary

Part Flash EEPROM SRAM

AT90S4434 4K bytes 256 bytes 256 bytes

AT90S8535 8K bytes 512 bytes 512 bytes

Pin Descriptions

VCC

Digital supply voltage

GND

Digital ground

Port A (PA7..PA0)

Port A is an 8-bit bi-directional I/O port. Port pins can provide internal pull-up resistors (selected for each bit). The Port A

output buffers can sink 20 mA and can drive LED displays directly. When pins PA0 to PA7 are used as inputs and are

externally pulled low, they will source current if the internal pull-up resistors are activated.

Port A also serves as the analog inputs to the A/D Converter.

The Port A pins are tri-stated when a reset condition becomes active, even if the clock is not running.

Port B (PB7..PB0)

Port B is an 8-bit bi-directional I/O port with internal pull-up resistors. The Port B output buffers can sink 20 mA. As inputs,

Port B pins that are externally pulled low will source current if the pull-up resistors are activated. Port B also serves the

functions of various special features of the AT90S4434/8535 as listed on page 71.

3

Page 4

The Port B pins are tri-stated when a reset condition becomes active, even if the clock is not running.

Port C (PC7..PC0)

Port C is an 8-bit bi-directional I/O port with internal pull-up resistors. The Port C output buffers can sink 20 mA. As inputs,

Port C pins that are externally pulled low will source current if the pull-up resistors are activated. Two Port C pins can alternatively be used as oscillator for Timer/Counter2.

The Port C pins are tri-stated when a reset condition becomes active, even if the clock is not running.

Port D (PD7..PD0)

Port D is an 8-bit bi-directional I/O port with internal pull-up resistors. The Port D output buffers can sink 20 mA. As inputs,

Port D pins that are externally pulled low will source current if the pull-up resistors are activated.

Port D also serves the functions of various special features of the AT90S4434/8535 as listed on page 79.

The Port D pins are tri-stated when a reset condition becomes active, even if the clock is not running.

RESET

Reset input. An external reset is generated by a low level on the RESET pin. Reset pulses longer than 50 ns will generate

a reset, even if the clock is not running. Shorter pulses are not guaranteed to generate a reset.

XTAL1

Input to the inverting oscillator amplifier and input to the internal clock operating circuit.

XTAL2

Output from the inverting oscillator amplifier.

AVCC

This is the supply voltage pin for Port A and the A/D Converter. If the ADC is not used, this pin must be connected to VCC.

If the ADC is used, this pin must be connected to VCC via a low-pass filter. See page 61 for details on operation of the

ADC.

AREF

This is the analog reference input for the A/D Converter. For ADC operations, a voltage in the range 2V to AV

applied to this pin.

AGND

Analog ground. If the board has a separate analog ground plane, this pin should be connected to this ground plane. Otherwise, connect to GND.

must be

CC

4

AT90S/LS4434 and AT90S/LS8535

Page 5

AT90S/LS4434 and AT90S/LS8535

Clock Options

Crystal Oscillator

XTAL1 and XTAL2 are input and output, respectively, of an inverting amplifier which can be configured for use as an

on-chip oscillator, as shown in Figure 2. Either a quartz crystal or a ceramic resonator may be used.

Figure 2. Oscillator Connections

MAX 1 HC BUFFER

HC

C2

C1

Note: When using the MCU Oscillator as a clock for an external device, an HC buffer should be connected as indicated in the figure.

External Clock

To drive the device from an external clock source, XTAL2 should be left unconnected while XTAL1 is driven as shown in

Figure 3.

Figure 3. External Clock Drive Configuration

XTAL2

XTAL1

GND

Timer Oscillator

For the Timer Oscillator pins, PC6(TOSC1) and PC7(TOSC2), the crystal is connected directly between the pins. No external capacitors are needed. The oscillator is optimized for use with a 32,768 Hz watch crystal. An external clock signal

applied to TOSC1 goes through the same amplifier having a bandwidth of 256 kHz. The external clock signal should therefore be in the interval 0 Hz - 256 kHz.

5

Page 6

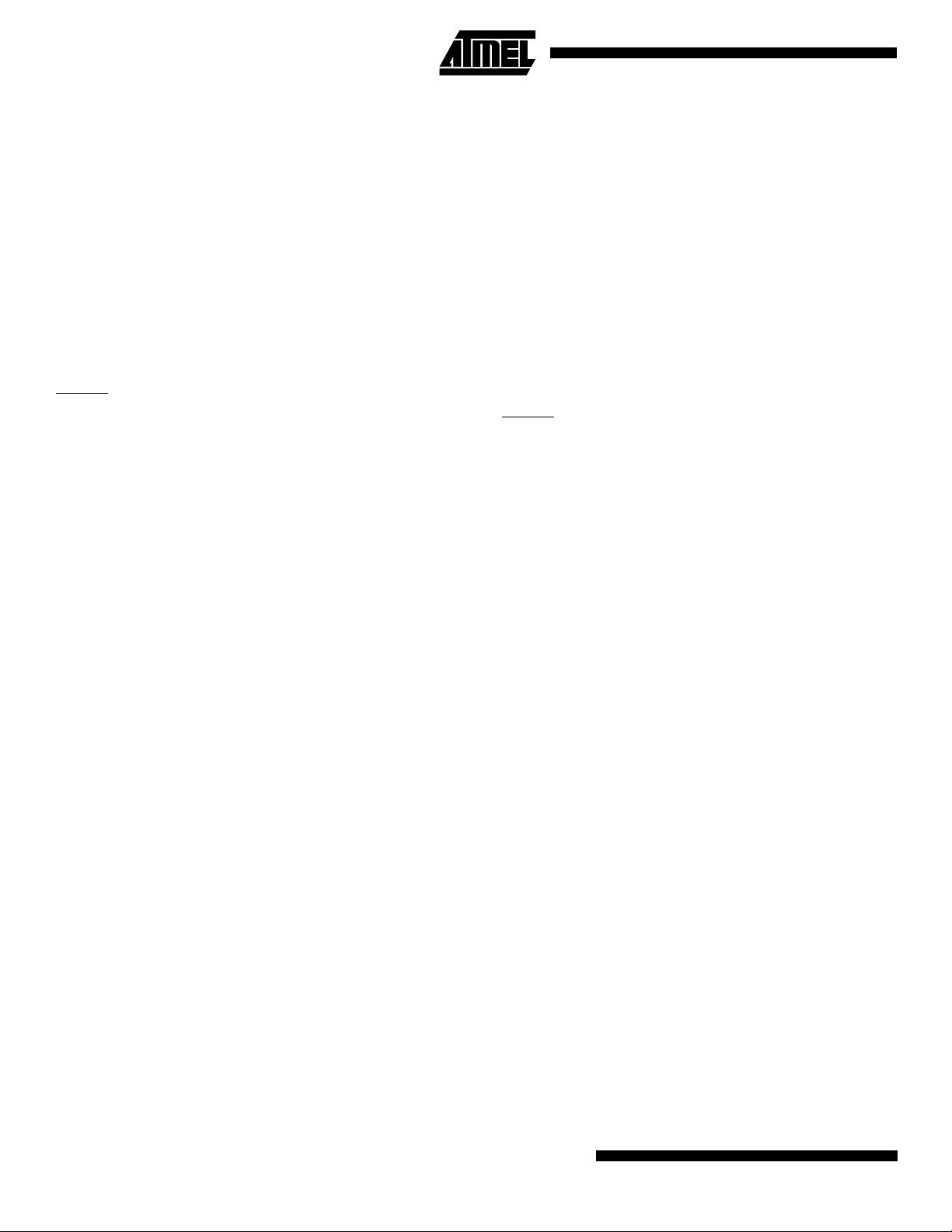

Architectural Overview

The fast-access register file concept contains 32 x 8-bit general-purpose working registers with a single clock cycle access

time. This means that during one single clock cycle, one Arithmetic Logic Unit (ALU) operation is executed. Two operands

are output from the register file, the operation is executed and the result is stored back in the register file – in one clock

cycle.

Six of the 32 registers can be used as three 16-bit indirect address register pointers for Data Space addressing, enabling

efficient address calculations. One of the three address pointers is also used as the address pointer for the constant table

look-up function. These added function registers are the 16-bit X-register, Y-register and Z-register.

Figure 4. The AT90S4434/8535 AVR RISC Architecture

AVR

2K/4K X 16

Program

Memory

Instruction

Register

Instruction

Decoder

Control Lines

AT90S4434/8535 Architecture

Data Bus 8-bit

Program

Counter

Direct Addressing

Indirect Addressing

Status

and Control

32 x 8

General

Purpose

Registrers

ALU

256/512 x 8

Data

SRAM

Interrupt

Unit

SPI

Unit

Serial

UART

8-bit

Timer/Counter

16-bit

Timer/Counter

with PWM

8-bit

Timer/Counter

with PWM

Watchdog

Timer

256/512 x 8

EEPROM

32

I/O Lines

Analog to Digital

Converter

Analog

Comparator

The ALU supports arithmetic and logic functions between registers or between a constant and a register. Single register

operations are also executed in the ALU. Figure 4 shows the AT90S4434/8535 AVR RISC microcontroller architecture.

In addition to the register operation, the conventional memory addressing modes can be used on the register file as well.

This is enabled by the fact that the register file is assigned the 32 lowermost Data Space addresses ($00 - $1F), allowing

them to be accessed as though they were ordinary memory locations.

6

AT90S/LS4434 and AT90S/LS8535

Page 7

AT90S/LS4434 and AT90S/LS8535

The I/O memory space contains 64 addresses for CPU peripheral functions as Control Registers, Timer/Counters, A/D

converters and other I/O functions. The I/O memory can be accessed directly or as the Data Space locations following

those of the register file, $20 - $5F.

The AVR uses a Harvard architecture concept – with separate memories and buses for program and data. The program

memory is executed with a two-stage pipeline. While one instruction is being executed, the next instruction is pre-fetched

from the program memory. This concept enables instructions to be executed in every clock cycle. The program memory is

in-system downloadable Flash memory.

With the relative jump and call instructions, the whole 2K/4K address space is directly accessed. Most AVR instructions

have a single 16-bit word format. Every program memory address contains a 16- or 32-bit instruction.

During interrupts and subroutine calls, the return address Program Counter (PC) is stored on the stack. The stack is effectively allocated in the general data SRAM and consequently, the stack size is only limited by the total SRAM size and the

usage of the SRAM. All user programs must initialize the SP in the reset routine (before subroutines or interrupts are

executed). The 9/10-bit stack pointer (SP) is read/write-accessible in the I/O space.

The 256/512 bytes data SRAM can be easily accessed through the five different addressing modes supported in the AVR

architecture.

The memory spaces in the AVR architecture are all linear and regular memory maps.

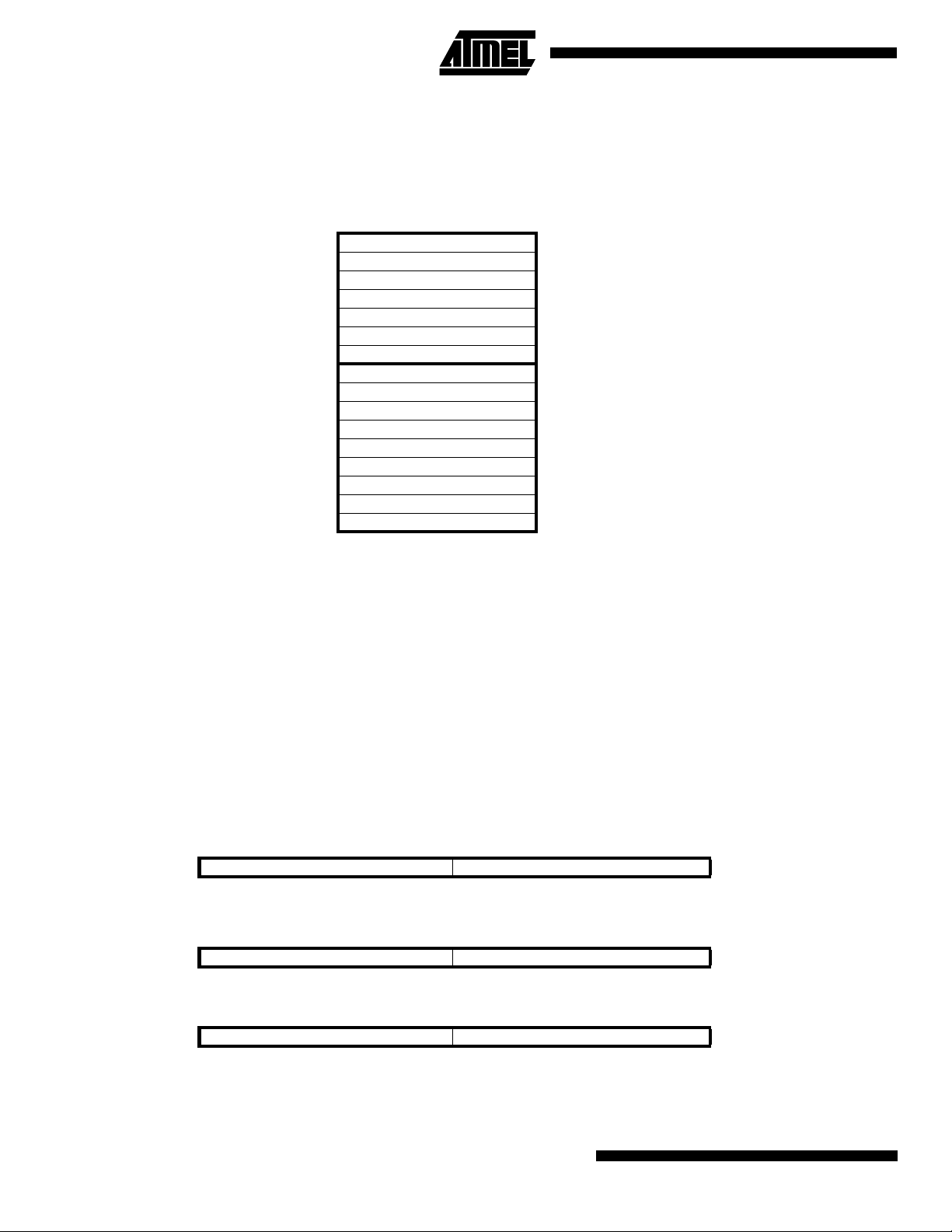

Figure 5. Memory Maps

Program Flash

(2K/4K x 16)

$000

Data MemoryProgram Memory

32 Gen. Purpose

Working Registers

64 I/O Registers

Internal SRAM

(256/512 x 8)

$0000

$001F

$0020

$005F

$0060

$015F/$025F

Data Memory

$000

EEPROM

(256/512 x 8)

$0FF/$1FF

$7FF/$FFF

A flexible interrupt module has its control registers in the I/O space with an additional global interrupt enable bit in the status

register. All the different interrupts have a separate interrupt vector in the interrupt vector table at the beginning of the program memory. The different interrupts have priority in accordance with their interrupt vector position. The lower the

interrupt vector address, the higher the priority.

7

Page 8

General-purpose Register File

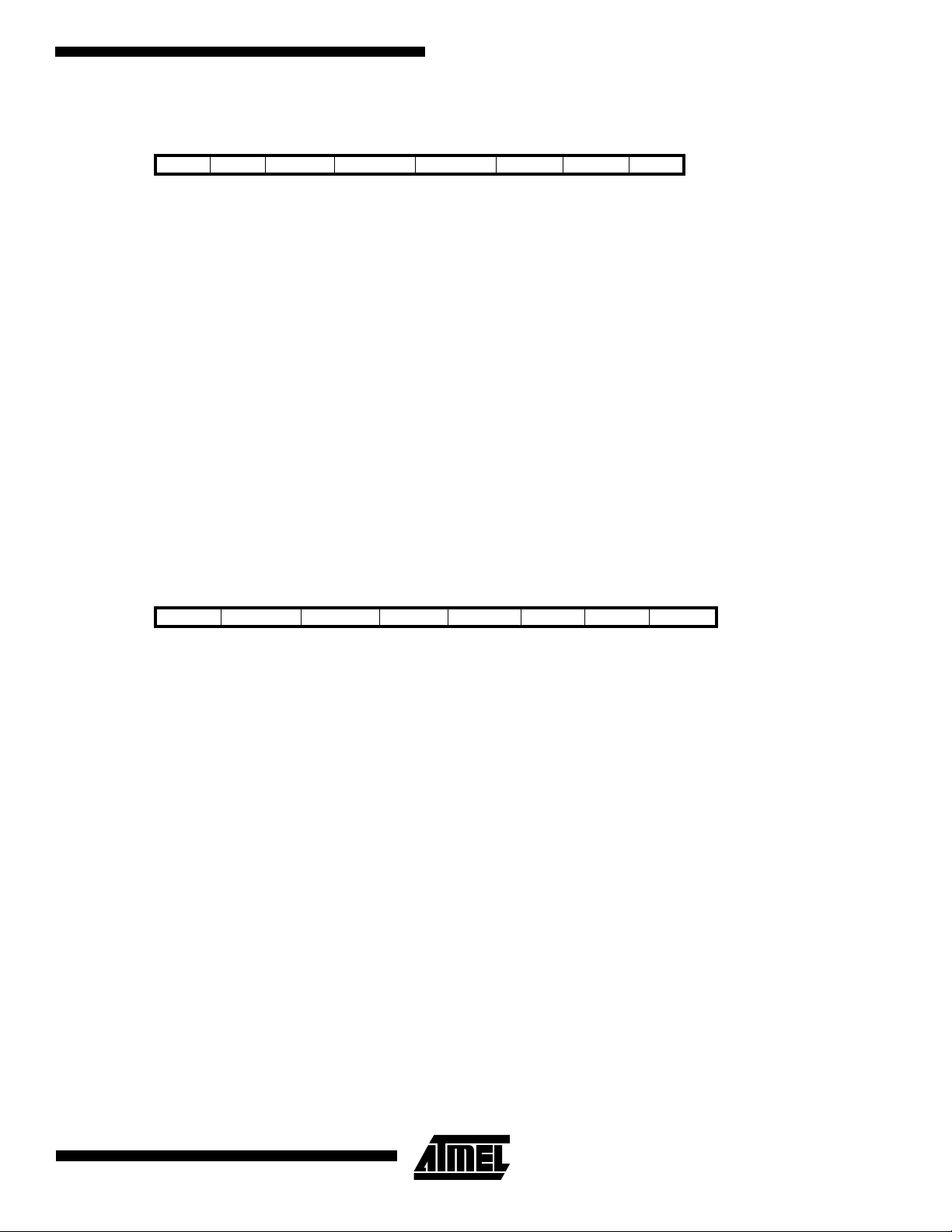

Figure 6 shows the structure of the 32 general-purpose working registers in the CPU.

Figure 6. AVR CPU General-purpose Working Registers

70Addr.

R0 $00

R1 $01

R2 $02

…

R13 $0D

General R14 $0E

Purpose R15 $0F

Working R16 $10

Registers R17 $11

…

R26 $1A X-register low byte

R27 $1B X-register high byte

R28 $1C Y-register low byte

R29 $1D Y-register high byte

R30 $1E Z-register low byte

R31 $1F Z-register high byte

All the register operating instructions in the instruction set have direct and single-cycle access to all registers. The only

exception is the five constant arithmetic and logic instructions SBCI, SUBI, CPI, ANDI and ORI between a constant and a

register and the LDI instruction for load immediate constant data. These instructions apply to the second half of the registers in the register file (R16..R31). The general SBC, SUB, CP, AND and OR and all other operations between two

registers or on a single register apply to the entire register file.

As shown in Figure 6, each register is also assigned a data memory address, mapping them directly into the first 32 locations of the user Data Space. Although not being physically implemented as SRAM locations, this memory organization

provides great flexibility in access of the registers, as the X, Y and Z registers can be set to index any register in the file.

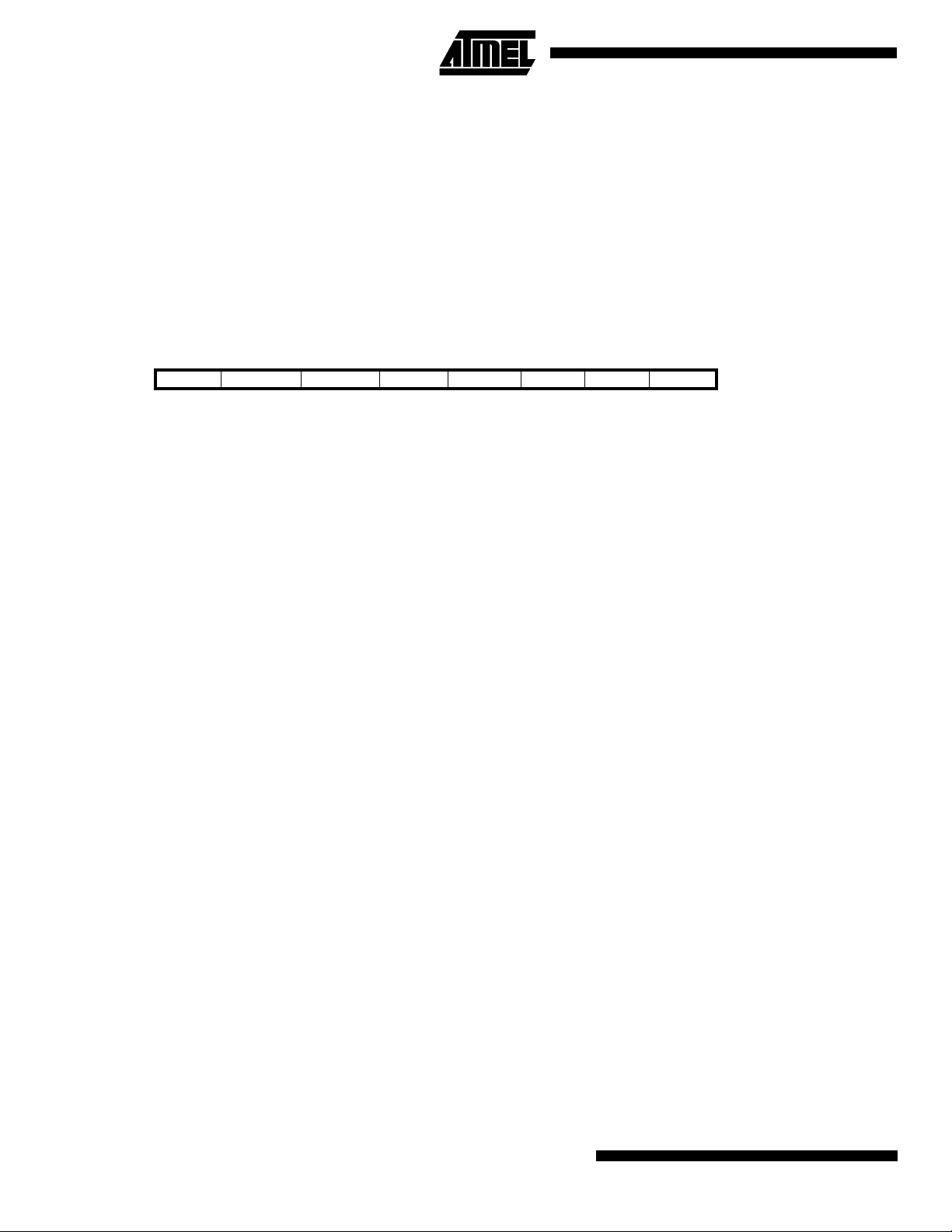

X-register, Y-register and Z-register

The registers R26..R31 have some added functions to their general-purpose usage. These registers are address pointers

for indirect addressing of the Data Space. The three indirect address registers, X, Y and Z, are defined in Figure 7.

Figure 7. X-, Y- and Z-registers

15 0

X-register 7 0 7 0

R27 ($1B) R26 ($1A)

15 0

Y-register 7 0 7 0

R29 ($1D) R28 ($1C)

15 0

Z-register 7 0 7 0

R31 ($1F) R30 ($1E)

In the different addressing modes, these address registers have functions as fixed displacement, automatic increment and

decrement (see the descriptions for the different instructions).

8

AT90S/LS4434 and AT90S/LS8535

Page 9

AT90S/LS4434 and AT90S/LS8535

ALU – Arithmetic Logic Unit

The high-performance AVR ALU operates in direct connection with all the 32 general-purpose working registers. Within a

single clock cycle, ALU operations between registers in the register file are executed. The ALU operations are divided into

three main categories: arithmetic, logical and bit functions.

In-System Programmable Flash Program Memory

The AT90S4434/8535 contains 4K/8K bytes on-chip, In-System Programmable Flash memory for program storage. Since

all instructions are 16- or 32-bit words, the Flash is organized as 2K/4K x 16. The Flash memory has an endurance of at

least 1000 write/erase cycles. The AT90S4434/8535 Program Counter (PC) is 11/12 bits wide, thus addressing the

2048/4096 program memory addresses.

See page 93 for a detailed description on Flash data downloading.

See page 10 for the different program memory addressing modes.

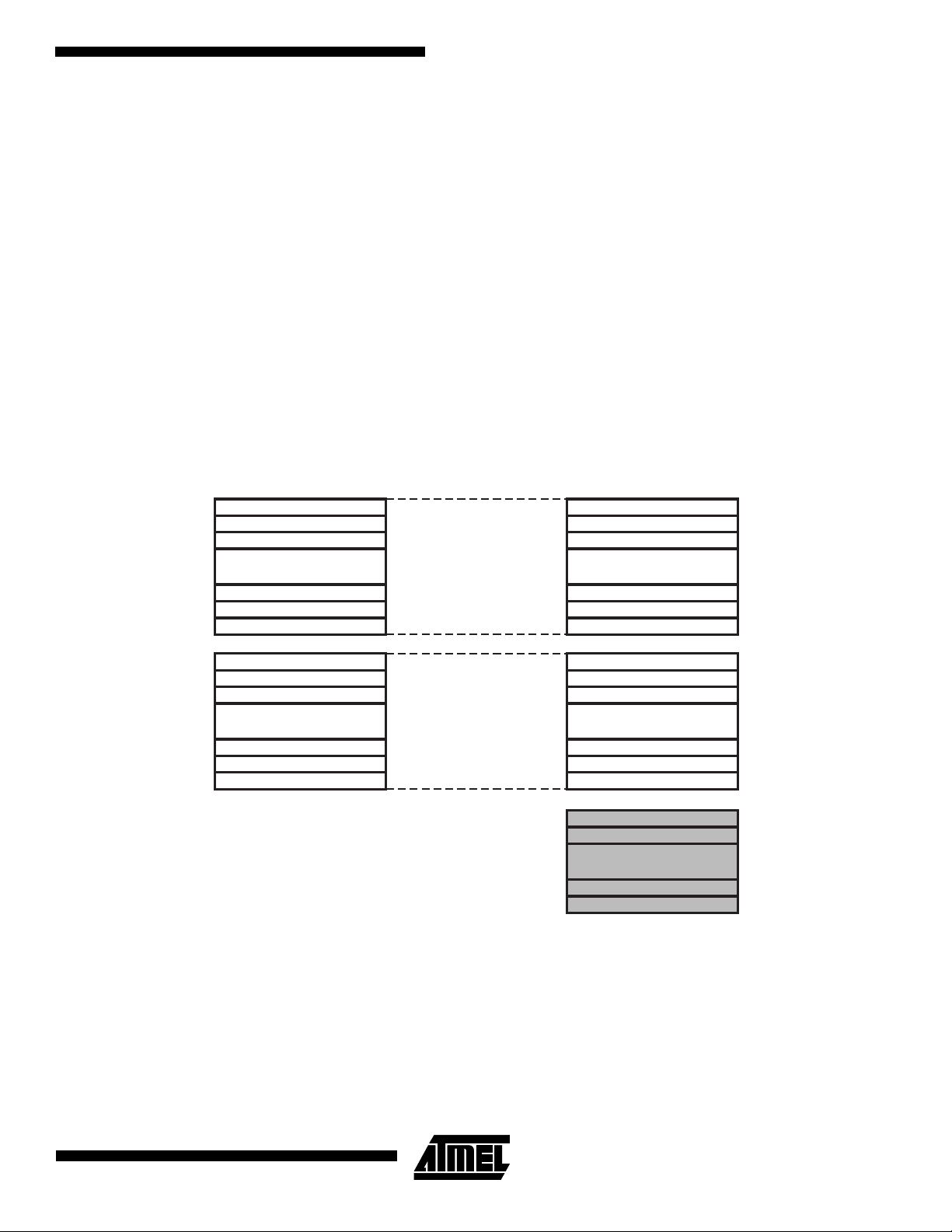

SRAM Data Memory

Figure 8 shows how the AT90S4434/8535 SRAM memory is organized.

Figure 8. SRAM Organization

Register File

R0

R1

R2

...

R29

R30

R31

I/O Registers

$00

$01

$02

...

$3D

$3E

$3F

Data Address Space

$0000

$0001

$0002

...

$001D

$001E

$001F

$0020

$0021

$0022

...

$005D

$005E

$005F

Internal SRAM

$0060

$0061

...

$015E/$025E

$015F/$025F

The lower 352/608 data memory locations address the Register file, the I/O memory and the internal data SRAM. The first

96 locations address the Register file + I/O memory, and the next 256/512 locations address the internal data SRAM.

The five different addressing modes for the data memory cover: Direct, Indirect with Displacement, Indirect, Indirect with

Pre-decrement and Indirect with Post-increment. In the register file, registers R26 to R31 feature the indirect addressing

pointer registers.

The direct addressing reaches the entire data space.

The Indirect with Displacement mode features 63 address locations reached from the base address given by the Y- or

Z-registers.

9

Page 10

When using register indirect addressing modes with automatic pre-decrement and post-increment, the address registers X,

Y and Z are decremented and incremented.

The 32 general-purpose working registers, 64 I/O registers and the 256/512 bytes of internal data SRAM in the

AT90S4434/8535 are all accessible through all these addressing modes.

See the next section for a detailed description of the different addressing modes.

Program and Data Addressing Modes

The AT90S4434/8535 AVR RISC microcontroller supports powerful and efficient addressing modes for access to the program memory (Flash) and data memory (SRAM, register file and I/O memory). This section describes the different

addressing modes supported by the AVR architecture. In the figures, OP means the operation code part of the instruction

word. To simplify, not all figures show the exact location of the addressing bits.

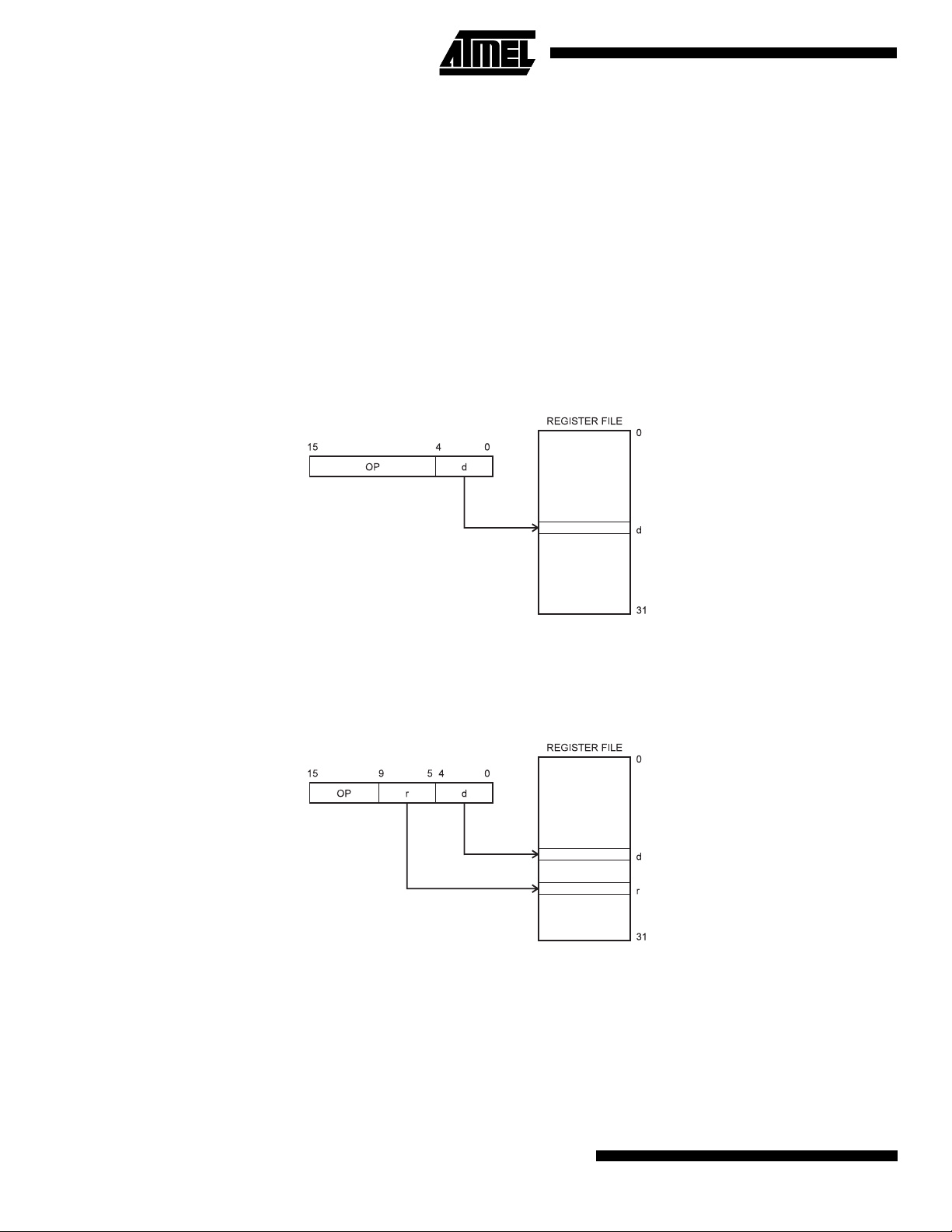

Register Direct, Single Register Rd

Figure 9. Direct Single Register Addressing

The operand is contained in register d (Rd).

Register Direct, Two Registers Rd And Rr

Figure 10. Direct Register Addressing, Two Registers

Operands are contained in register r (Rr) and d (Rd). The result is stored in register d (Rd).

10

AT90S/LS4434 and AT90S/LS8535

Page 11

AT90S/LS4434 and AT90S/LS8535

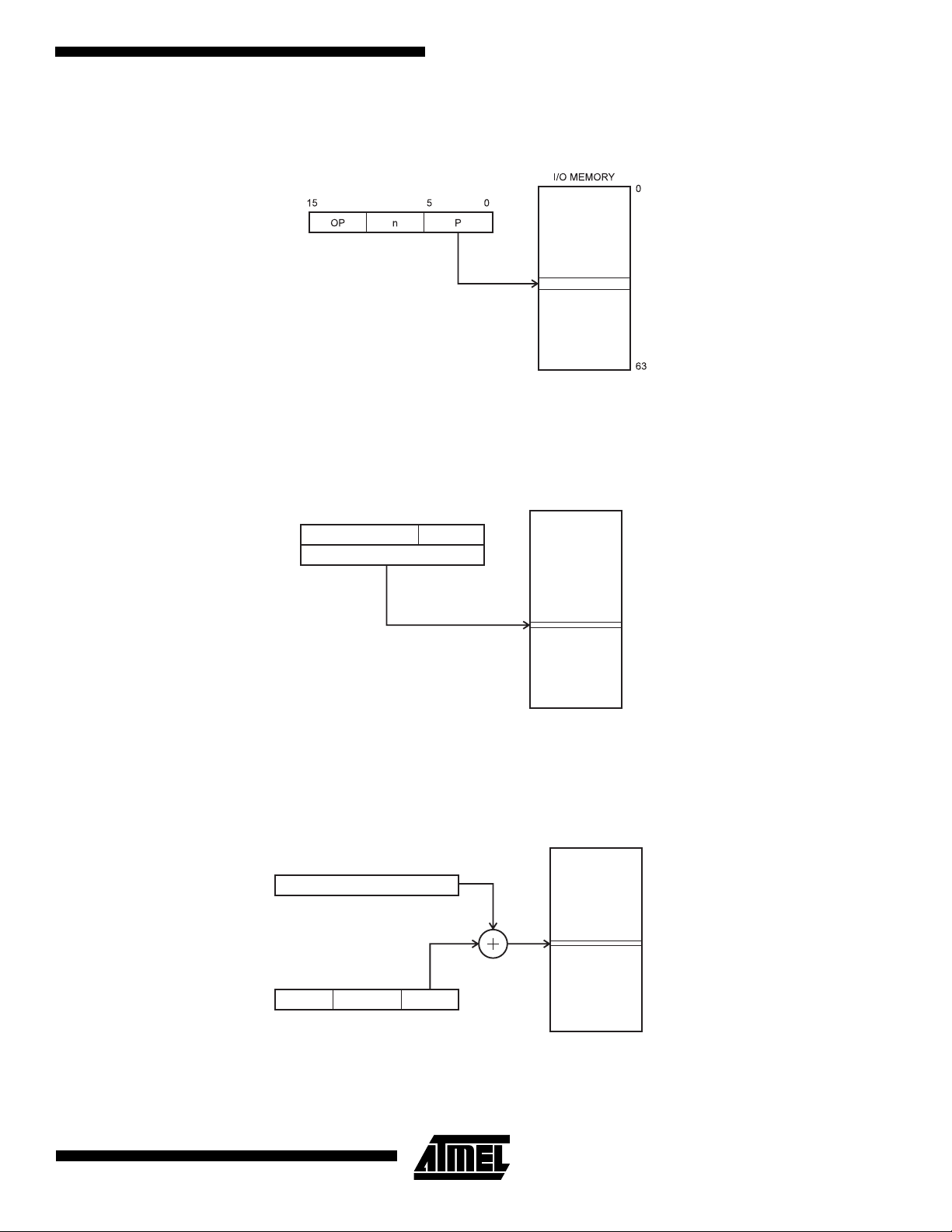

I/O Direct

Figure 11. I/O Direct Addressing

Operand address is contained in six bits of the instruction word. n is the destination or source register address.

Data Direct

Figure 12. Direct Data Addressing

16 LSBs

20 19

16

31

OP Rr/Rd

15 0

Data Space

$0000

$015F/

$025F

A 16-bit data address is contained in the 16 LSBs of a 2-word instruction. Rd/Rr specify the destination or source register.

Data Indirect with Displacement

Figure 13. Data Indirect with Displacement

15

15

OP an

Data Space

0

Y OR Z - REGISTER

05610

$0000

$015F/

025F

Operand address is the result of the Y- or Z-register contents added to the address contained in six bits of the instruction

word.

11

Page 12

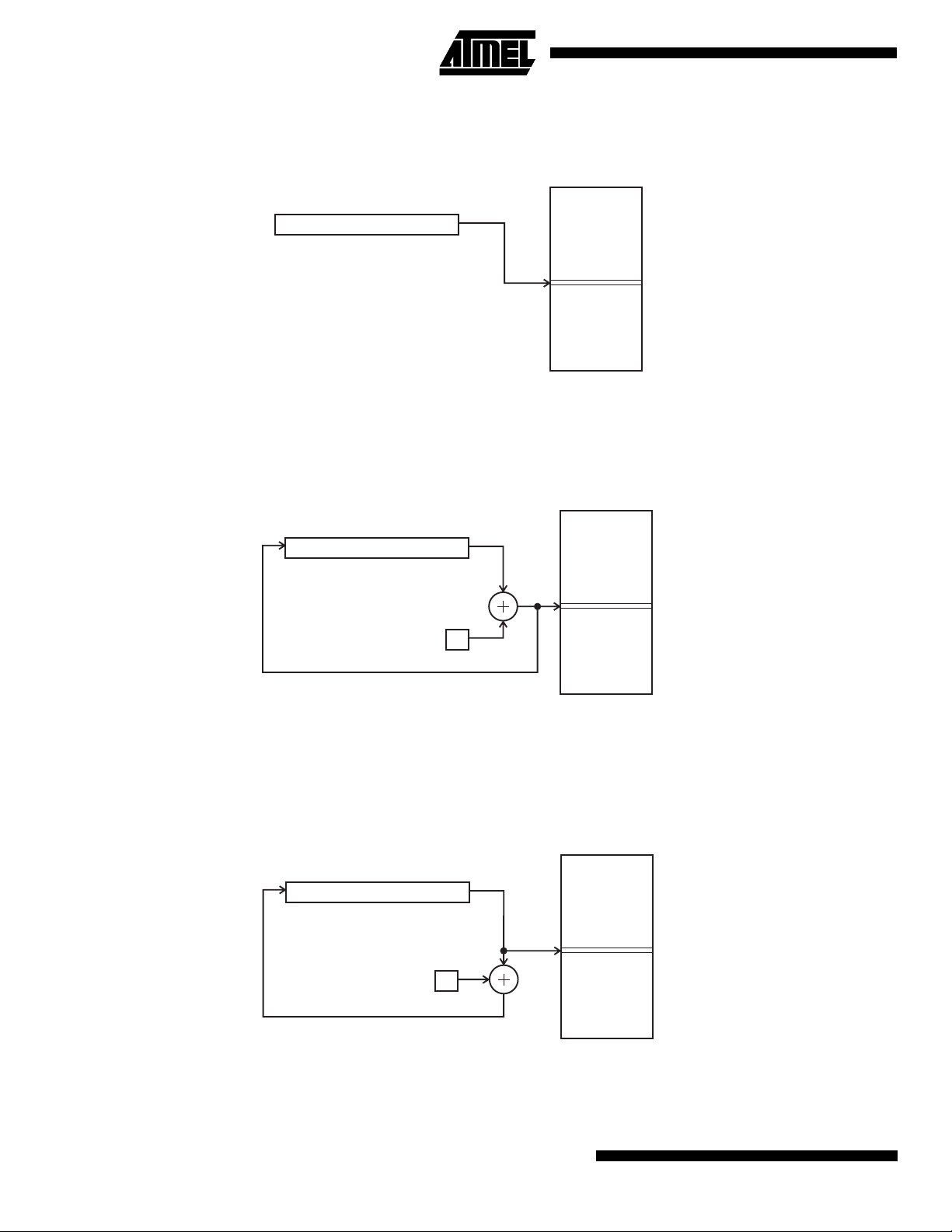

Data Indirect

/

Figure 14. Data Indirect Addressing

015

X, Y OR Z - REGISTER

Operand address is the contents of the X-, Y- or the Z-register.

Data Indirect with Pre-decrement

Figure 15. Data Indirect Addressing with Pre-decrement

015

X, Y OR Z - REGISTER

Data Space

Data Space

$0000

$015F/

$025F

$0000

-1

$015F/

$025F

The X-, Y- or the Z-register is decremented before the operation. Operand address is the decremented contents of the X-,

Y- or the Z-register.

Data Indirect with Post-increment

Figure 16. Data Indirect Addressing with Post-increment

Data Space

015

X, Y OR Z - REGISTER

1

$0000

$015F

$025F

The X-, Y- or the Z-register is incremented after the operation. Operand address is the content of the X-, Y- or the Z-register

prior to incrementing.

12

AT90S/LS4434 and AT90S/LS8535

Page 13

AT90S/LS4434 and AT90S/LS8535

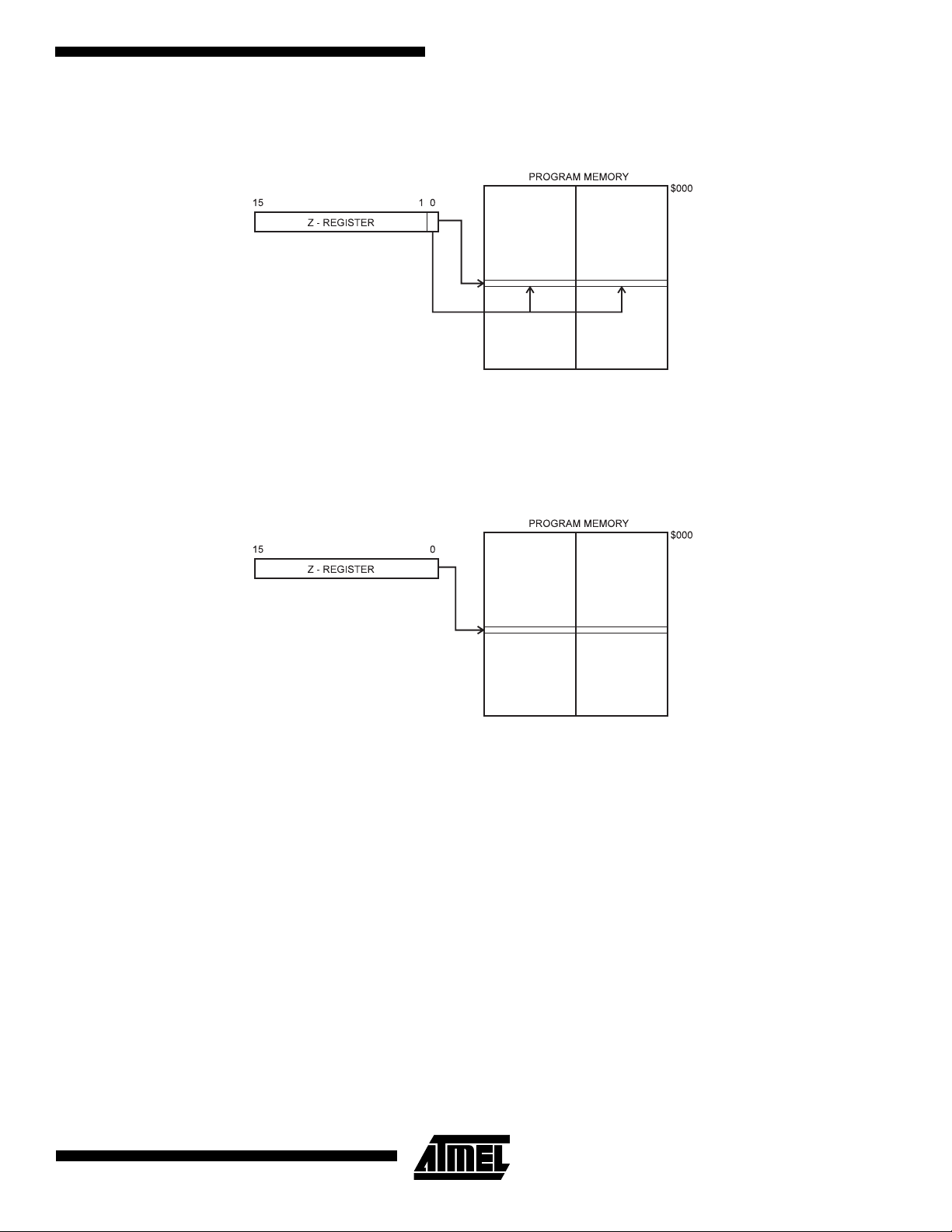

Constant Addressing Using the LPM Instruction

Figure 17. Code Memory Constant Addressing

$7FF/

$FFF

Constant byte address is specified by the Z-register contents. The 15 MSBs select word address (0 - 2K/4K), the LSB

selects low byte if cleared (LSB = 0) or high byte if set (LSB = 1).

Indirect Program Addressing, IJMP and ICALL

Figure 18. Indirect Program Memory Addressing

$7FF/

$FFF

Program execution continues at address contained by the Z-register (i.e., the PC is loaded with the contents of the

Z-register).

13

Page 14

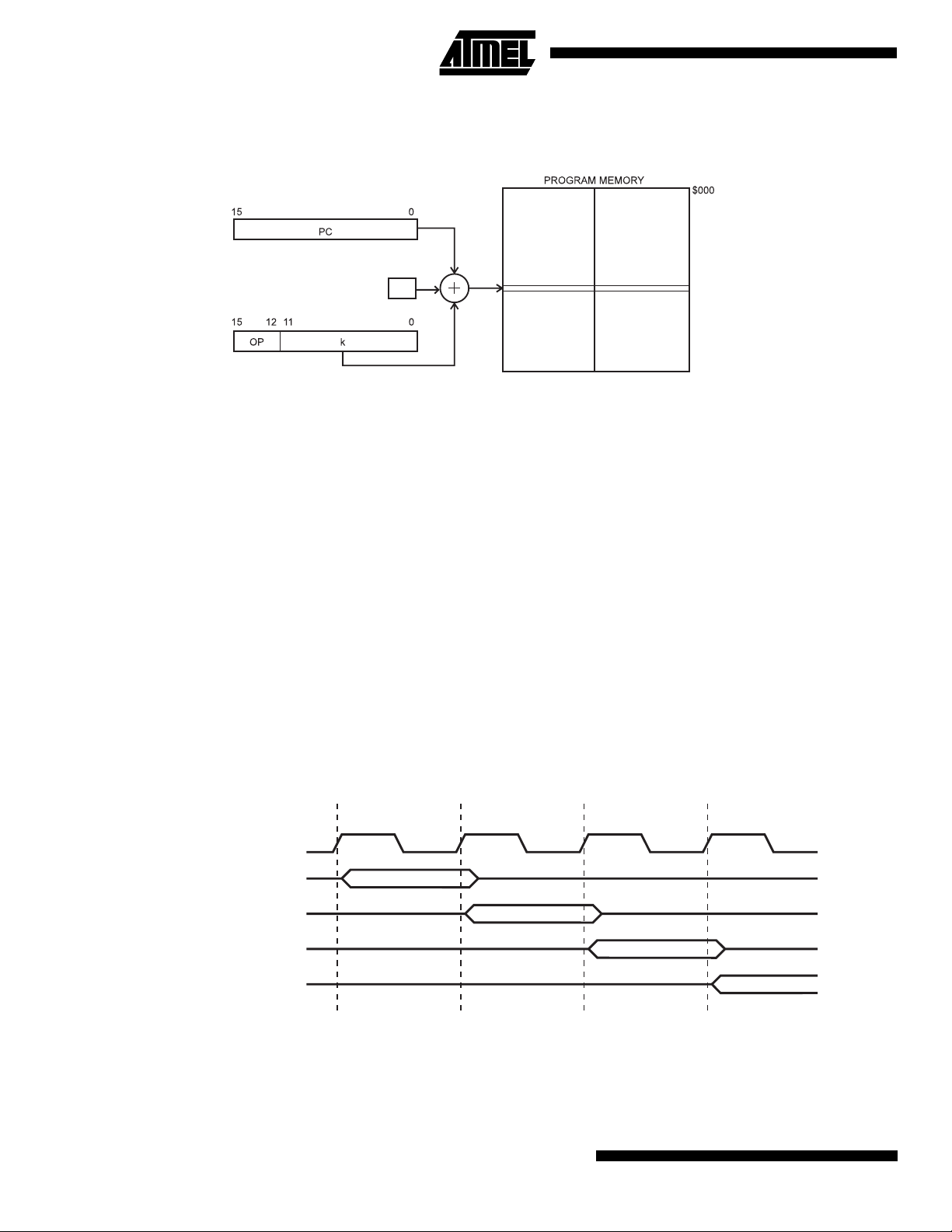

Relative Program Addressing, RJMP and RCALL

Figure 19. Relative Program Memory Addressing

+1

$7FF/

$FFF

Program execution continues at address PC + k + 1. The relative address k is from -2048 to 2047.

EEPROM Data Memory

The AT90S4434/8535 contains 256/512 bytes of data EEPROM memory. It is organized as a separate data space, in

which single bytes can be read and written. The EEPROM has an endurance of at least 100,000 write/erase cycles. The

access between the EEPROM and the CPU is described on page 48 specifying the EEPROM address registers, the

EEPROM data register and the EEPROM control register.

For the SPI data downloading, see page 93 for a detailed description.

Memory Access Times and Instruction Execution Timing

This section describes the general access timing concepts for instruction execution and internal memory access.

The AVR CPU is driven by the System Clock Ø, directly generated from the external clock crystal for the chip. No internal

clock division is used.

Figure 20 shows the parallel instruction fetches and instruction executions enabled by the Harvard architecture and the

fast-access register file concept. This is the basic pipelining concept to obtain up to 1 MIPS per MHz with the corresponding

unique results for functions per cost, functions per clocks and functions per power-unit.

Figure 20. The Parallel Instruction Fetches and Instruction Executions

T1 T2 T3 T4

System Clock Ø

1st Instruction Fetch

1st Instruction Execute

2nd Instruction Fetch

2nd Instruction Execute

3rd Instruction Fetch

3rd Instruction Execute

4th Instruction Fetch

Figure 21 shows the internal timing concept for the register file. In a single clock cycle an ALU operation using two register

operands is executed and the result is stored back to the destination register.

14

AT90S/LS4434 and AT90S/LS8535

Page 15

AT90S/LS4434 and AT90S/LS8535

Figure 21. Single Cycle ALU Operation

T1 T2 T3 T4

System Clock Ø

Total Execution Time

Register Operands Fetch

ALU Operation Execute

Result Write Back

The internal data SRAM access is performed in two System Clock cycles as described in Figure 22.

Figure 22. On-chip Data SRAM Access Cycles

T1 T2 T3 T4

System Clock Ø

Address

Data

WR

Data

RD

Prev. Address

Address

Write

Read

15

Page 16

I/O Memory

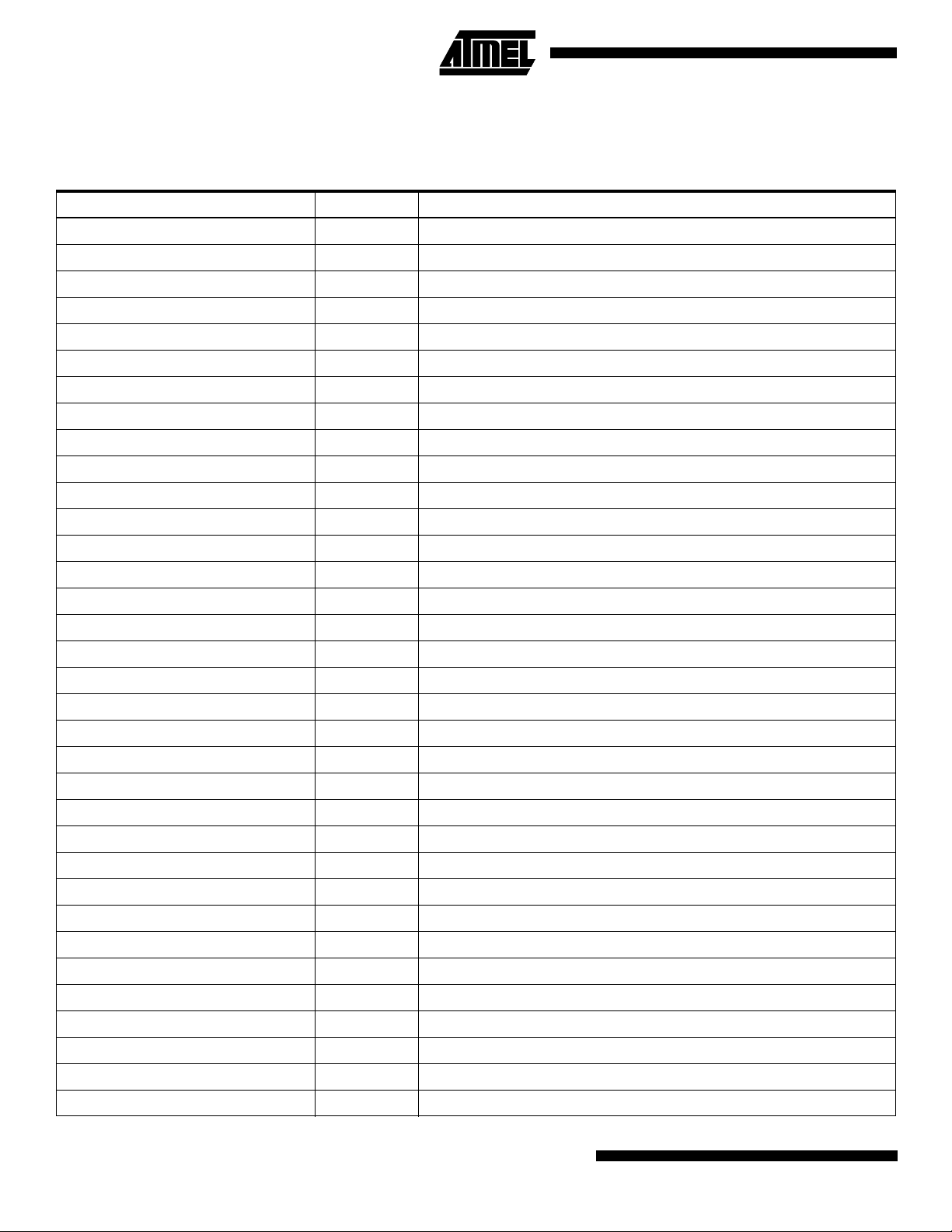

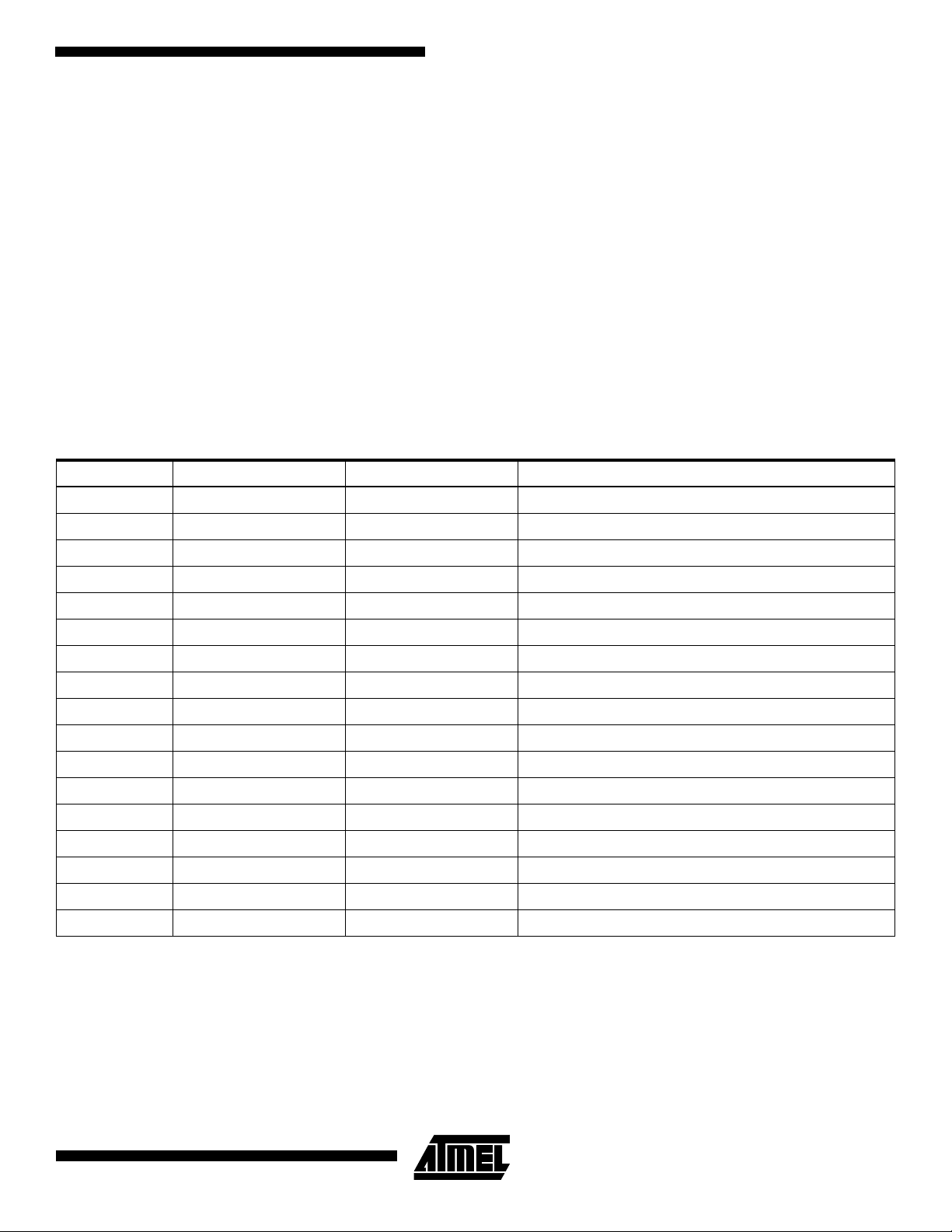

The I/O space definition of the AT90S4434/8535 is shown in Table 2.

Table 2. AT90S4434/8535 I/O Space

I/O Address (SRAM Address) Name Function

$3F ($5F) SREG Status REGister

$3E ($5E) SPH Stack Pointer High

$3D ($5D) SPL Stack Pointer Low

$3B ($5B) GIMSK General Interrupt MaSK register

$3A ($5A) GIFR General Interrupt Flag Register

$39 ($59) TIMSK Timer/Counter Interrupt MaSK register

$38 ($58) TIFR Timer/Counter Interrupt Flag register

$35 ($55) MCUCR MCU general Control Register

$34 ($45) MCUSR MCU general Status Register

$33 ($53) TCCR0 Timer/Counter0 Control Register

$32 ($52) TCNT0 Timer/Counter0 (8-bit)

$2F ($4F) TCCR1A Timer/Counter1 Control Register A

$2E ($4E) TCCR1B Timer/Counter1 Control Register B

$2D ($4D) TCNT1H Timer/Counter1 High Byte

$2C ($4C) TCNT1L Timer/Counter1 Low Byte

$2B ($4B) OCR1AH Timer/Counter1 Output Compare Register A High Byte

$2A ($4A) OCR1AL Timer/Counter1 Output Compare Register A Low Byte

$29 ($49) OCR1BH Timer/Counter1 Output Compare Register B High Byte

$28 ($48) OCR1BL Timer/Counter1 Output Compare Register B Low Byte

$27 ($47) ICR1H T/C 1 Input Capture Register High Byte

$26 ($46) ICR1L T/C 1 Input Capture Register Low Byte

$25 ($45) TCCR2 Timer/Counter2 Control Register

$24 ($44) TCNT2 Timer/Counter2 (8-bit)

$23 ($43) OCR2 Timer/Counter2 Output Compare Register

$22 ($42) ASSR Asynchronous Mode Status Register

$21 ($41) WDTCR Watchdog Timer Control Register

$1F ($3E) EEARH EEPROM Address Register High Byte

$1E ($3E) EEARL EEPROM Address Register Low Byte

$1D ($3D) EEDR EEPROM Data Register

$1C ($3C) EECR EEPROM Control Register

$1B ($3B) PORTA Data Register, Port A

$1A ($3A) DDRA Data Direction Register, Port A

16

$19 ($39) PINA Input Pins, Port A

$18 ($38) PORTB Data Register, Port B

AT90S/LS4434 and AT90S/LS8535

Page 17

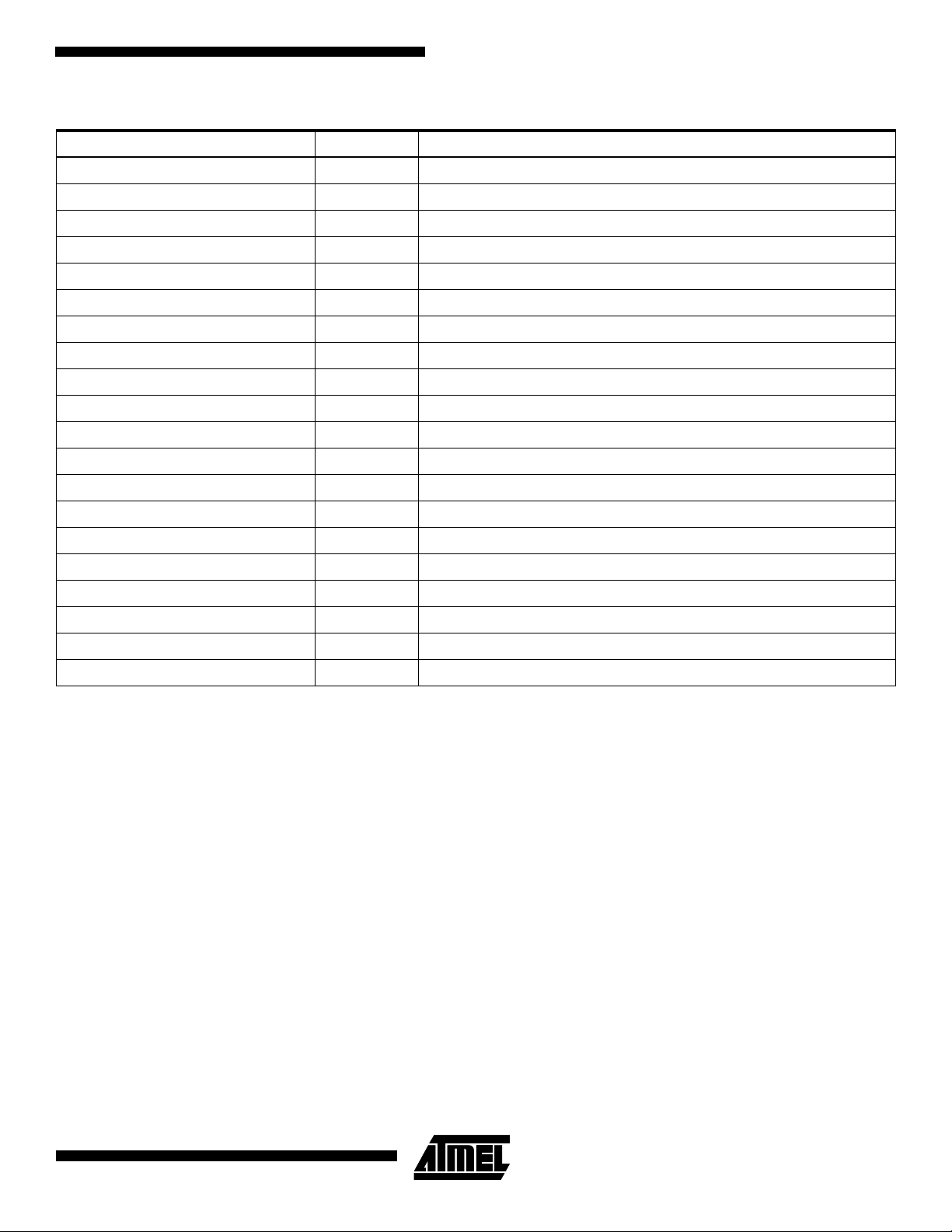

Table 2. AT90S4434/8535 I/O Space (Continued)

I/O Address (SRAM Address) Name Function

$17 ($37) DDRB Data Direction Register, Port B

$16 ($36) PINB Input Pins, Port B

$15 ($35) PORTC Data Register, Port C

$14 ($34) DDRC Data Direction Register, Port C

$13 ($33) PINC Input Pins, Port C

$12 ($32) PORTD Data Register, Port D

$11 ($31) DDRD Data Direction Register, Port D

$10 ($30) PIND Input Pins, Port D

$0F ($2F) SPDR SPI I/O Data Register

$0E ($2E) SPSR SPI Status Register

$0D ($2D) SPCR SPI Control Register

$0C ($2C) UDR UART I/O Data Register

$0B ($2B) USR UART Status Register

$0A ($2A) UCR UART Control Register

AT90S/LS4434 and AT90S/LS8535

$09 ($29) UBRR UART Baud Rate Register

$08 ($28) ACSR Analog Comparator Control and Status Register

$07 ($27) ADMUX ADC Multiplexer Select Register

$06 ($26) ADCSR ADC Control and Status Register

$05 ($25) ADCH ADC Data Register High

$04 ($24) ADCL ADC Data Register Low

Note: Reserved and unused locations are not shown in the table.

All AT90S4434/8535 I/Os and peripherals are placed in the I/O space. The I/O locations are accessed by the IN and OUT

instructions transferring data between the 32 general-purpose working registers and the I/O space. I/O registers within the

address range $00 - $1F are directly bit-accessible using the SBI and CBI instructions. In these registers, the value of

single bits can be checked by using the SBIS and SBIC instructions. Refer to the instruction set section for more details.

When using the I/O specific commands IN and OUT, the I/O addresses $00 - $3F must be used. When addressing I/O registers as SRAM, $20 must be added to these addresses. All I/O register addresses throughout this document are shown

with the SRAM address in parentheses.

For compatibility with future devices, reserved bits should be written to zero if accessed. Reserved I/O memory addresses

should never be written.

Some of the status flags are cleared by writing a logical “1” to them. Note that the CBI and SBI instructions will operate on

all bits in the I/O register, writing a “1” back into any flag read as set, thus clearing the flag. The CBI and SBI instructions

work with registers $00 to $1F only.

The I/O and peripherals control registers are explained in the following sections.

17

Page 18

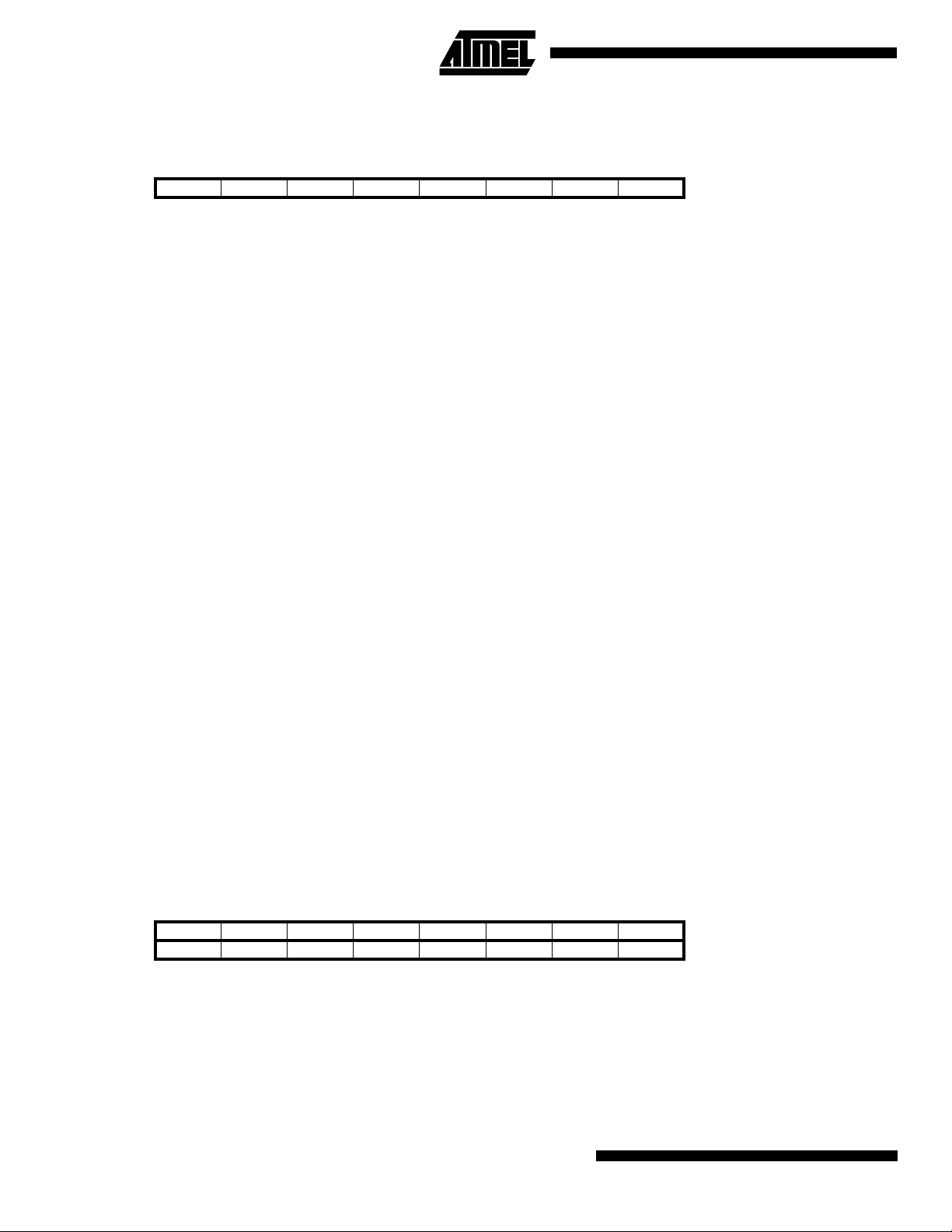

Status Register – SREG

The AVR Status Register (SREG) at I/O space location $3F ($5F) is defined as:

Bit 76543210

$3F ($5F) I T H S V N Z C SREG

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bit 7 – I: Global Interrupt Enable

•

The global interrupt enable bit must be set (one) for the interrupts to be enabled. The individual interrupt enable control is

then performed in separate control registers. If the global interrupt enable register is cleared (zero), none of the interrupts

are enabled independent of the individual interrupt enable settings. The I-bit is cleared by hardware after an interrupt has

occurred and is set by the RETI instruction to enable subsequent interrupts.

Bit 6 – T: Bit Copy Storage

•

The bit copy instructions BLD (Bit LoaD) and BST (Bit STore) use the T-bit as source and destination for the operated bit. A

bit from a register in the register file can be copied into T by the BST instruction and a bit in T can be copied into a bit in a

register in the register file by the BLD instruction.

Bit 5 – H: Half-carry Flag

•

The half-carry flag H indicates a half-carry in some arithmetic operations. See the Instruction Set description for detailed

information.

Bit 4 – S: Sign Bit, S = N⊄⊕ V

•

The S-bit is always an exclusive or between the negative flag N and the two’s complement overflow flag V. See the Instruction Set description for detailed information.

•

Bit 3 – V: Two’s Complement Overflow Flag

The two’s complement overflow flag V supports two’s complement arithmetics. See the Instruction Set description for

detailed information.

Bit 2 – N: Negative Flag

•

The negative flag N indicates a negative result from an arithmetical or logical operation. See the Instruction Set description

for detailed information.

Bit 1 – Z: Zero Flag

•

The zero flag Z indicates a zero result from an arithmetical or logic operation. See the Instruction Set description for

detailed information.

•

Bit 0 – C: Carry Flag

The carry flag C indicates a carry in an arithmetical or logical operation. See the Instruction Set description for detailed

information.

Note that the Status Register is not automatically stored when entering an interrupt routine and restored when returning

from an interrupt routine. This must be handled by software.

Stack Pointer – SP

The AT90S4434/8535 Stack Pointer is implemented as two 8-bit registers in the I/O space locations $3E ($5E) and $3D

($5D). As the AT90S4434/8535 data memory has $15F/$25F locations, 9/10 bits are used.

Bit 151413121110 9 8

$3E ($5E) ––––––SP9 SP8 SPH

$3D ($5D) SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0 SPL

76543210

Read/Write R R R R R R R/W R/W

R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

00000000

18

AT90S/LS4434 and AT90S/LS8535

Page 19

AT90S/LS4434 and AT90S/LS8535

The Stack Pointer points to the data SRAM stack area where the Subroutine and Interrupt stacks are located. This stack

space in the data SRAM must be defined by the program before any subroutine calls are executed or interrupts are

enabled. The Stack Pointer must be set to point above $60. The Stack Pointer is decremented by 1 when data is pushed

onto the stack with the PUSH instruction and it is decremented by 2 when an address is pushed onto the stack with subroutine calls and interrupts. The Stack Pointer is incremented by 1 when data is popped from the stack with the POP

instruction and it is incremented by 2 when an address is popped from the stack with return from subroutine RET or return

from interrupt RETI.

Reset and Interrupt Handling

The AT90S4434/8535 provides 16 different interrupt sources. These interrupts and the separate reset vector each have a

separate program vector in the program memory space. All interrupts are assigned individual enable bits that must be set

(one) together with the I-bit in the Status Register in order to enable the interrupt.

The lowest addresses in the program memory space are automatically defined as the Reset and Interrupt vectors. The

complete list of vectors is shown in Table 3. The list also determines the priority levels of the different interrupts. The lower

the address, the higher the priority level. RESET has the highest priority, and next is INT0 (the External Interrupt Request

0), etc.

Table 3. Reset and Interrupt Vectors

Vector No. Program Address Source Interrupt Definition

1 $000 RESET Hardware Pin, Power-on Reset and Watchdog Reset

2 $001 INT0 External Interrupt Request 0

3 $002 INT1 External Interrupt Request 1

4 $003 TIMER2 COMP Timer/Counter2 Compare Match

5 $004 TIMER2 OVF Timer/Counter2 Overflow

6 $005 TIMER1 CAPT Timer/Counter1 Capture Event

7 $006 TIMER1 COMPA Timer/Counter1 Compare Match A

8 $007 TIMER1 COMPB Timer/Counter1 Compare Match B

9 $008 TIMER1 OVF Timer/Counter1 Overflow

10 $009 TIMER0 OVF Timer/Counter0 Overflow

11 $00A SPI, STC SPI Serial Transfer Complete

12 $00B UART, RX UART, Rx Complete

13 $00C UART, UDRE UART Data Register Empty

14 $00D UART, TX UART, Tx Complete

15 $00E ADC ADC Conversion Complete

16 $00F EE_RDY EEPROM Ready

17 $010 ANA_COMP Analog Comparator

19

Page 20

The most typical and general program setup for the Reset and Interrupt vector addresses are:

Address Labels Code Comments

$000 rjmp RESET ; Reset Handler

$001 rjmp EXT_INT0 ; IRQ0 Handler

$002 rjmp EXT_INT1 ; IRQ1 Handler

$003 rjmp TIM2_COMP ; Timer2 Compare Handler

$004 rjmp TIM2_OVF ; Timer2 Overflow Handler

$005 rjmp TIM1_CAPT ; Timer1 Capture Handler

$006 rjmp TIM1_COMPA ; Timer1 CompareA Handler

$007 rjmp TIM1_COMPB ; Timer1 CompareB Handler

$008 rjmp TIM1_OVF ; Timer1 Overflow Handler

$009 rjmp TIM0_OVF ; Timer0 Overflow Handler

$00a rjmp SPI_STC; ; SPI Transfer Complete Handler

$00b rjmp UART_RXC ; UART RX Complete Handler

$00c rjmp UART_DRE ; UDR Empty Handler

$00d rjmp UART_TXC ; UART TX Complete Handler

$00e rjmp ADC ; ADC Conversion Complete Interrupt Handler

$00f rjmp EE_RDY ; EEPROM Ready Handler

$010 rjmp ANA_COMP ; Analog Comparator Handler

$011 MAIN: ldi r16, high(RAMEND); Main program start

$012 out SPH,r16

$013 ldi r16, low(RAMEND);

$014 out SPL,r16

$015 <instr> xxx

…………

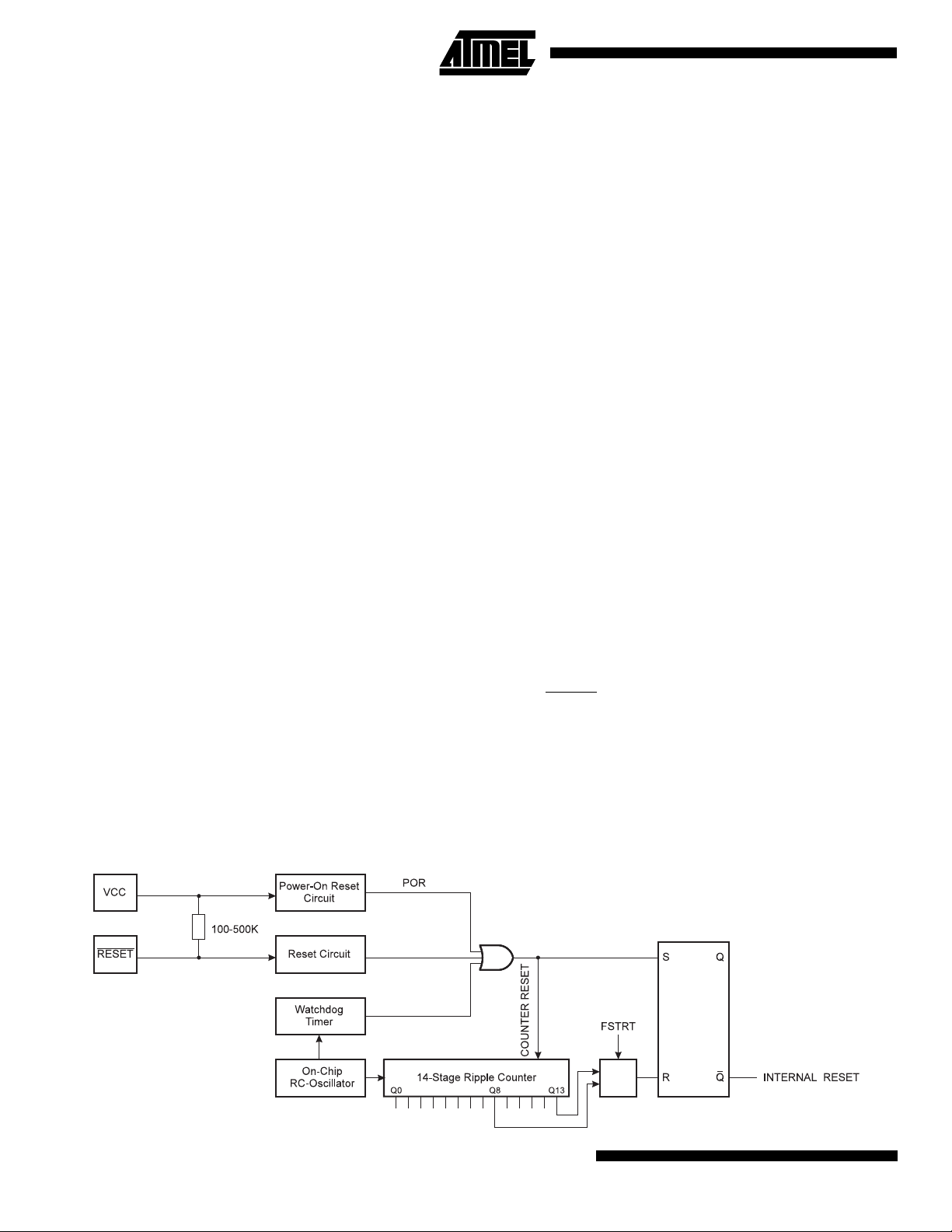

Reset Sources

The AT90S4434/8535 has three sources of reset:

• Power-on Reset. The MCU is reset when the supply voltage is below the Power-on Reset threshold (V

POT

).

• External Reset. The MCU is reset when a low level is present on the RESET pin for more than 50 ns.

• Watchdog Reset. The MCU is reset when the Watchdog timer period expires and the Watchdog is enabled.

During reset, all I/O registers are set to their initial values and the program starts execution from address $000. The instruction placed in address $000 must be an RJMP (relative jump) instruction to the reset handling routine. If the program never

enables an interrupt source, the interrupt vectors are not used and regular program code can be placed at these locations.

The circuit diagram in Figure 23 shows the reset logic. Table 4 defines the timing and electrical parameters of the reset

circuitry.

Figure 23. Reset Logic

20

AT90S/LS4434 and AT90S/LS8535

Page 21

AT90S/LS4434 and AT90S/LS8535

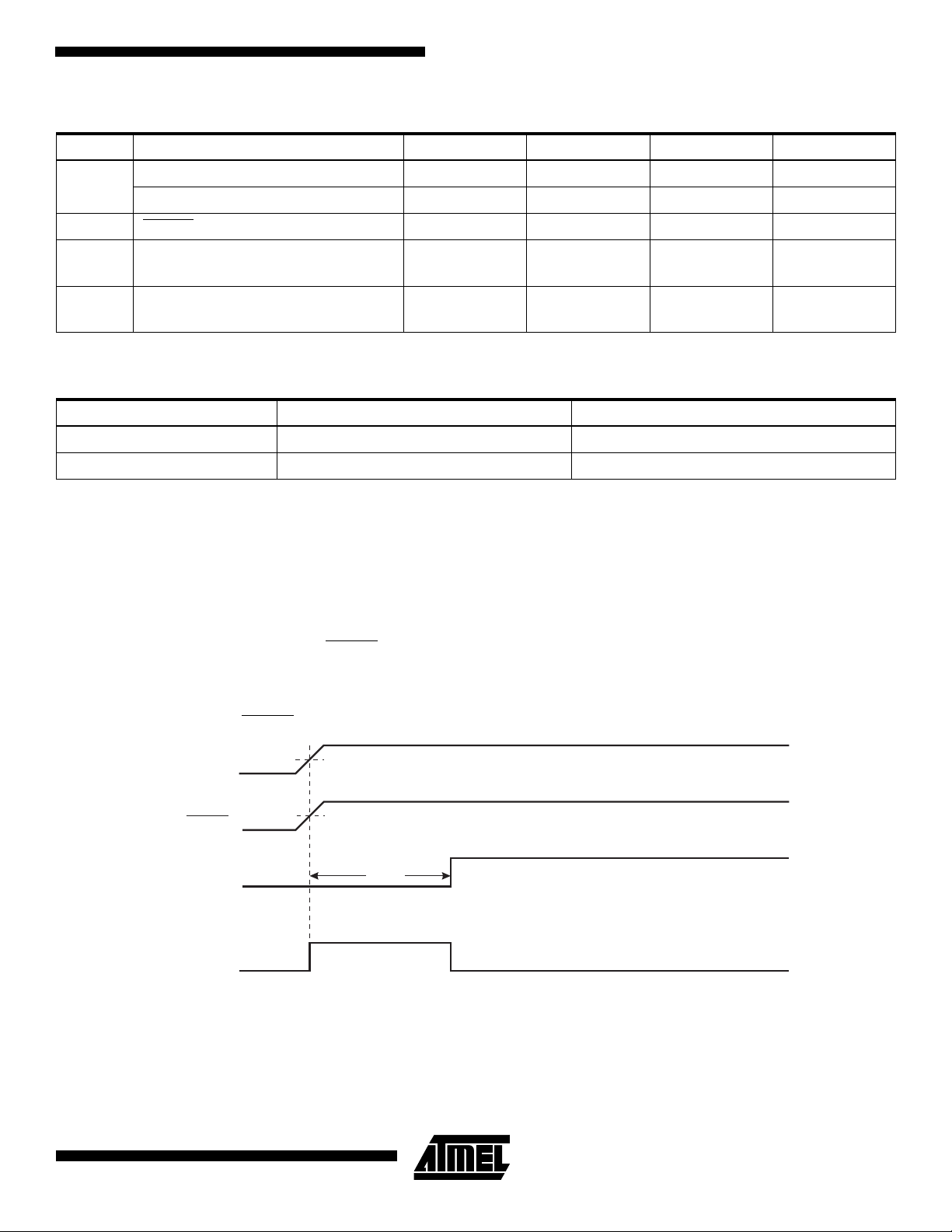

Table 4. Reset Characteristics (V

= 5.0V)

CC

Symbol Parameter Min Typ Max Units

(1)

V

POT

V

RST

t

TOUT

t

TOUT

Note: 1. The Power-on Reset will not work unless the supply voltage has been below V

Power-on Reset Threshold (rising) 1.0 1.4 1.8 V

Power-on Reset Threshold (falling) 0.4 0.6 0.8 V

RESET Pin Threshold Voltage 0.6 V

Reset Delay Time-out Period

FSTRT Unprogrammed

Reset Delay Time-out Period

FSTRT Programmed

11.0 16.0 21.0 ms

1.0 1.1 1.2 ms

CC

POT

(falling).

V

Table 5. Number of Watchdog Oscillator Cycles

FSTRT Time-out at VCC = 5V Number of WDT Cycles

Programmed 1.1 ms 1K

Unprogrammed 16.0 ms 16K

Power-on Reset

A Power-on Reset (POR) circuit ensures that the device is reset from power-on. As shown in Figure 23, an internal timer

clocked from the Watchdog Timer oscillator prevents the MCU from starting until after a certain period after V

reached the Power-on Threshold voltage (V

), regardless of the VCC rise time (see Figure 24).

POT

CC

has

The user can select the start-up time according to typical oscillator start-up time. The number of WDT oscillator cycles is

shown in Table 5. The frequency of the Watchdog oscillator is voltage-dependent as shown in “Typical Characteristics” on

page 100.

If the built-in start-up delay is sufficient, RESET

ing the pin low for a period after V

has been applied, the Power-on Reset period can be extended. Refer to Figure 25 for

CC

can be connected to VCC directly or via an external pull-up resistor. By hold-

a timing example of this.

Figure 24. MCU Start-up, RESET

VCC

RESET

TIME-OUT

INTERNAL

RESET

Tied to VCC.

V

POT

V

RST

t

TOUT

21

Page 22

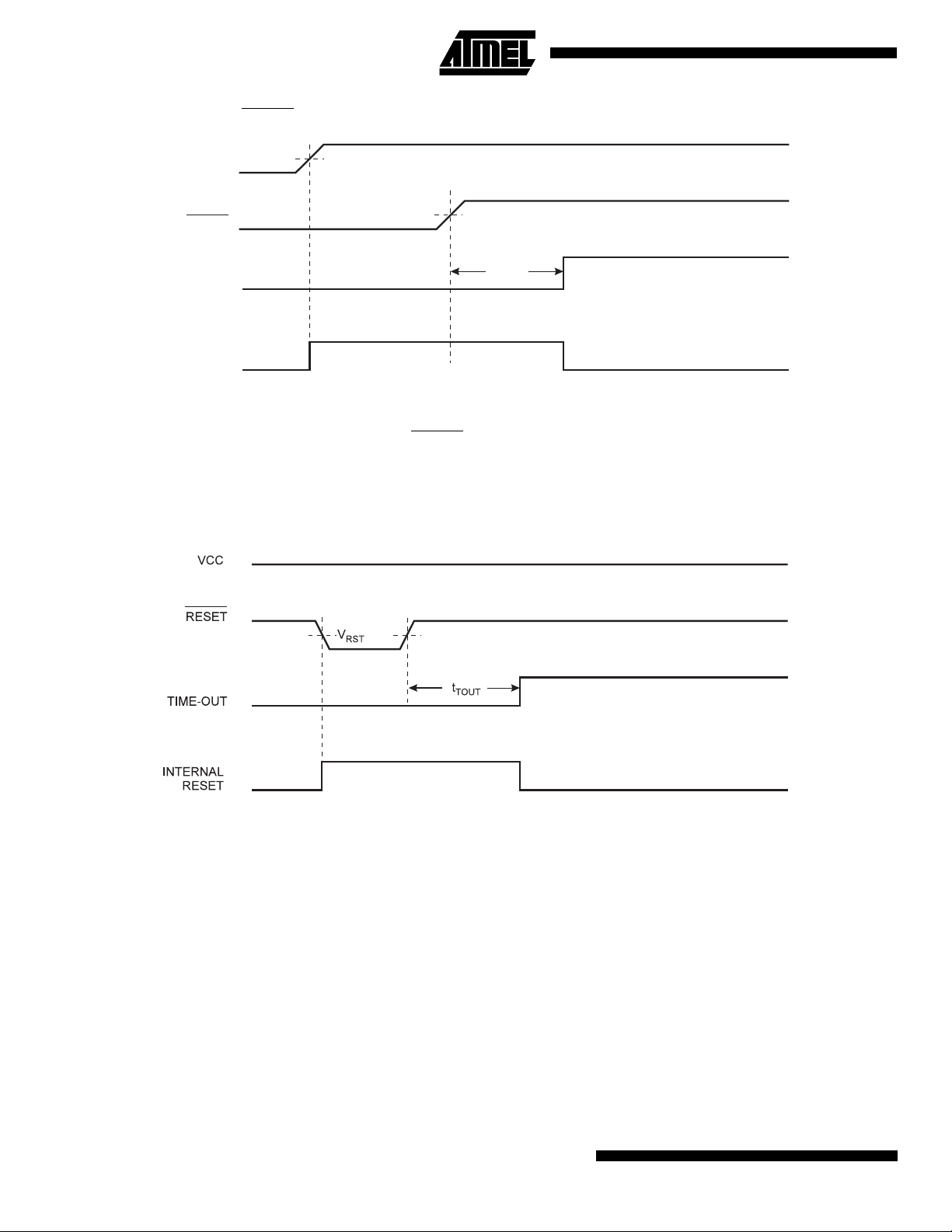

Figure 25. MCU Start-up, RESET

VCC

RESET

TIME-OUT

INTERNAL

RESET

Controlled Externally

V

POT

V

RST

t

TOUT

External Reset

An external reset is generated by a low level on the RESET

pin. Reset pulses longer than 50 ns will generate a reset, even

if the clock is not running. Shorter pulses are not guaranteed to generate a reset. When the applied signal reaches the

Reset Threshold Voltage (V

) on its positive edge, the delay timer starts the MCU after the Time-out period t

RST

TOUT

has

expired.

Figure 26. External Reset during Operation

22

AT90S/LS4434 and AT90S/LS8535

Page 23

AT90S/LS4434 and AT90S/LS8535

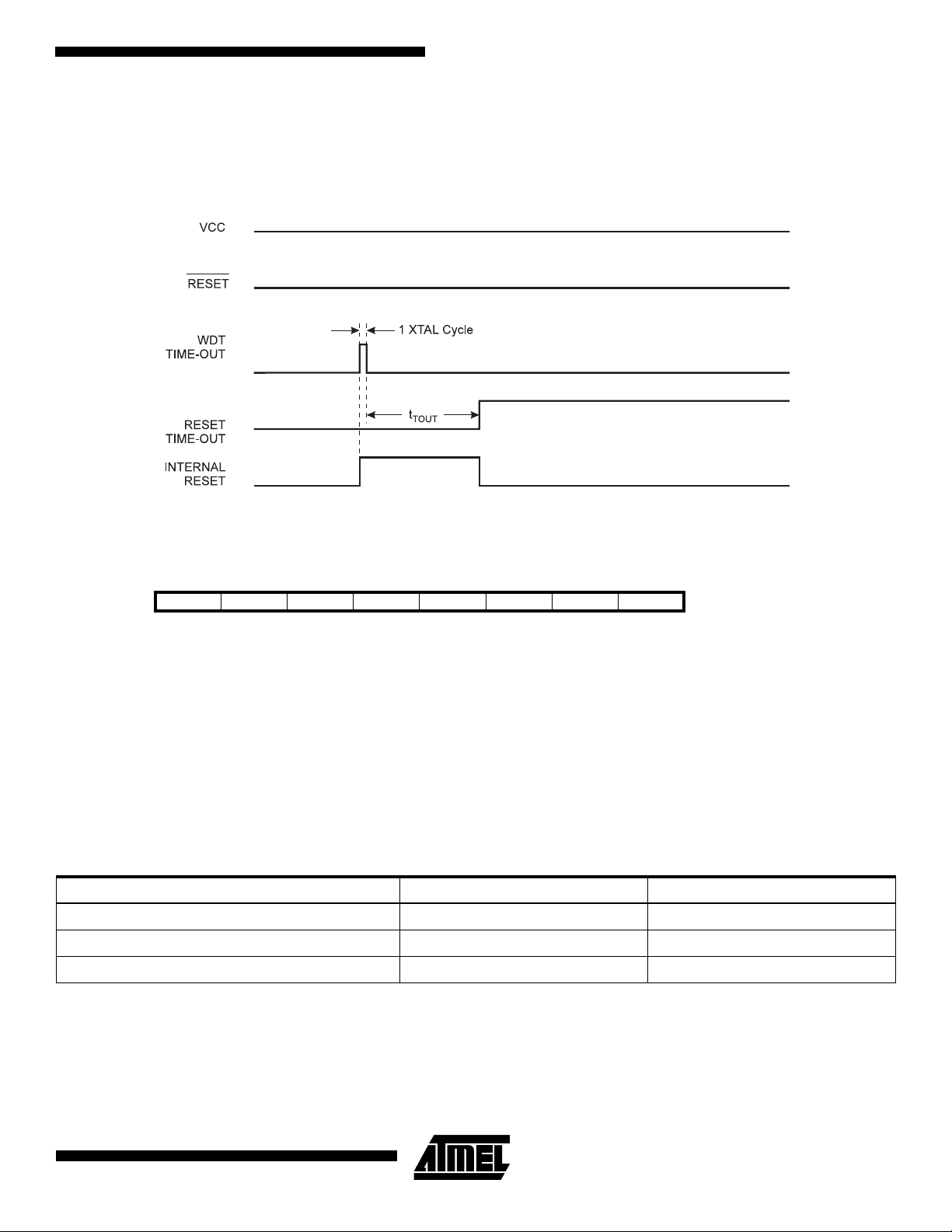

Watchdog Reset

When the Watchdog times out, it will generate a short reset pulse of 1 XTAL cycle duration. On the falling edge of this

pulse, the delay timer starts counting the Time-out period t

Figure 27. Watchdog Reset during Operation

. Refer to page 45 for details on operation of the Watchdog.

TOUT

MCU Status Register – MCUSR

The MCU Status Register provides information on which reset source caused an MCU reset.

Bit 76543210

$34 ($54) ––––––EXTRF PORF MCUSR

Read/Write R R R R R R R/W R/W

Initial value 0 0 0 0 0 0 See bit description

•

Bits 7..2 – Res: Reserved Bits

These bits are reserved bits in the AT90S4434/8535 and always read as zero.

Bit 1 – EXTRF: External Reset Flag

•

After a power-on reset, this bit is undefined (X). It can only be set by an External Reset. A Watchdog Reset will leave this bit

unchanged. The bit is reset by writing a logical “1” to the bit.

Bit 0 – PORF: Power-on Reset Flag

•

This bit is only set by a Power-on Reset. A Watchdog Reset or an External Reset will leave this bit unchanged. The bit is

reset by writing a logical “1” to the bit.

To summarize, Table 6 shows the value of these two bits after the three modes of reset.

Table 6. PORF and EXTRF Values after Reset

Reset Source EXTRF PORF

Power-on Reset undefined 1

External Reset 1 unchanged

Watchdog Reset unchanged unchanged

To make use of these bits to identify a reset condition, the user software should clear both the PORF and EXTRF bits as

early as possible in the program. Checking the PORF and EXTRF values is done before the bits are cleared. If the bit is

cleared before an External or Watchdog Reset occurs, the source of reset can be found by using Table 7.

23

Page 24

Table 7. Reset Source Identification

EXTRF PORF Reset Source

0 0 Watchdog Reset

0 1 Power-on Reset

1 0 External Reset

1 1 Power-on Reset

Interrupt Handling

The AT90S4434/8535 has two 8-bit interrupt mask control registers: GIMSK (General Interrupt Mask register) and TIMSK

(Timer/Counter Interrupt Mask register).

When an interrupt occurs, the Global Interrupt Enable I-bit is cleared (zero) and all interrupts are disabled. The user software can set (one) the I-bit to enable nested interrupts. The I-bit is set (one) when a Return from Interrupt instruction (RETI)

is executed.

When the Program Counter is vectored to the actual interrupt vector in order to execute the interrupt handling routine, hardware clears the corresponding flag that generated the interrupt. Some of the interrupt flags can also be cleared by writing a

logical “1” to the flag bit position(s) to be cleared. If an interrupt condition occurs when the corresponding interrupt enable

bit is cleared (zero), the interrupt flag will be set and remembered until the interrupt is enabled or the flag is cleared by

software.

If one or more interrupt conditions occur when the global interrupt enable bit is cleared (zero), the corresponding interrupt

flag(s) will be set and remembered until the global interrupt enable bit is set (one) and will be executed by order of priority.

Note that external level interrupt does not have a flag and will only be remembered for as long as the interrupt condition is

active.

Note that the Status Register is not automatically stored when entering an interrupt routine and restored when returning

from an interrupt routine. This must be handled by software.

General Interrupt Mask Register – GIMSK

Bit 7 6 5 4 3 2 1 0

$3B ($5B) INT1 INT0 –– ––––GIMSK

Read/Write R/W R/W R R R R R R

Initial value 0 0 0 0 0 0 0 0

Bit 7 – INT1: External Interrupt Request 1 Enable

•

When the INT1 bit is set (one) and the I-bit in the Status Register (SREG) is set (one), the external pin interrupt is enabled.

The Interrupt Sense Control1 bits 1/0 (ISC11 and ISC10) in the MCU general Control Register (MCUCR) define whether

the external interrupt is activated on rising or falling edge of the INT1 pin or level sensed. Activity on the pin will cause an

interrupt request even if INT1 is configured as an output. The corresponding interrupt of External Interrupt Request 1 is

executed from program memory address $002. See also “External Interrupts.”

Bit 6 – INT0: External Interrupt Request 0 Enable

•

When the INT0 bit is set (one) and the I-bit in the Status Register (SREG) is set (one), the external pin interrupt is enabled.

The Interrupt Sense Control0 bits 1/0 (ISC01 and ISC00) in the MCU general Control Register (MCUCR) define whether

the external interrupt is activated on rising or falling edge of the INT0 pin or level sensed. Activity on the pin will cause an

interrupt request even if INT0 is configured as an output. The corresponding interrupt of External Interrupt Request 0 is

executed from program memory address $001. See also “External Interrupts.”

Bits 5.0 – Res: Reserved Bits

•

These bits are reserved bits in the AT90S4434/8535 and always read as zero.

24

AT90S/LS4434 and AT90S/LS8535

Page 25

AT90S/LS4434 and AT90S/LS8535

General Interrupt Flag Register – GIFR

Bit 7 6 5 4 3 2 1 0

$3A ($5A) INTF1 INTF0 –– ––––GIFR

Read/Write R/W R/W R R R R R R

Initial value 0 0 0 0 0 0 0 0

Bit 7 – INTF1: External Interrupt Flag1

•

When an edge or logical change on the INT1 pin trigger an interrupt request, INTF1 becomes set (one). This flag is always

cleared (0) when the pin is configured for low-level interrupts, as the state of a low-level interrupt can be determined by

reading the PIN register.

If the I-bit in SREG and the INT1 bit in GIMSK are set (one), the MCU will jump to the interrupt address $002. For edge and

logic change interrupts, this flag is cleared when the interrupt routine is executed. Alternatively, the flag can be cleared by

writing a logical “1” to it.

Bit 6 – INTF0: External Interrupt Flag0

•

When an edge or logical change on the INT0 pin trigger an interrupt request, INTF0 becomes set (one). This flag is always

cleared (0) when the pin is configured for low-level interrupts, as the state of a low-level interrupt can be determined by

reading the PIN register.

If the I-bit in SREG and the INT0 bit in GIMSK are set (one), the MCU will jump to the interrupt address $001. For edge and

logic change interrupts, this flag is cleared when the interrupt routine is executed. Alternatively, the flag can be cleared by

writing a logical “1” to it.

Bits 5..0 – Res: Reserved Bits

•

These bits are reserved bits in the AT90S4434/8535 and always read as zero.

Timer/Counter Interrupt Mask Register – TIMSK

Bit 7 6 5 4 3 2 1 0

$39 ($59) OCIE2 TOIE2 TICIE1 OCIE1A OCIE1B TOIE1 – TOIE0 TIMSK

Read/Write R/W R/W R/W R/W R/W R/W R R/W

Initial value 0 0 0 0 0 0 0 0

Bit 7 – OCIE2: Timer/Counter2 Output Compare Match Interrupt Enable

•

When the OCIE2 bit is set (one) and the I-bit in the Status Register is set (one), the Timer/Counter2 Compare Match interrupt is enabled. The corresponding interrupt (at vector $003) is executed if a compare match in Timer/Counter2 occurs (i.e.,

when the OCF2 bit is set in the Timer/Counter Interrupt Flag Register [TIFR]).

Bit 6 – TOIE2: Timer/Counter2 Overflow Interrupt Enable

•

When the TOIE2 bit is set (one) and the I-bit in the Status Register is set (one), the Timer/Counter2 Overflow interrupt is

enabled. The corresponding interrupt (at vector $004) is executed if an overflow in Timer/Counter2 occurs (i.e., when the

TOV2 bit is set in the Timer/Counter Interrupt Flag Register [TIFR]).

Bit 5 – TICIE1: Timer/Counter1 Input Capture Interrupt Enable

•

When the TICIE1 bit is set (one) and the I-bit in the Status Register is set (one), the Timer/Counter1 Input Capture Event

Interrupt is enabled. The corresponding interrupt (at vector $005) is executed if a capture-triggering event occurs on pin 20,

PD6 (ICP) (i.e., when the ICF1 bit is set in the Timer/Counter Interrupt Flag Register [TIFR]).

Bit 4 – OCE1A: Timer/Counter1 Output CompareA Match Interrupt Enable

•

When the OCIE1A bit is set (one) and the I-bit in the Status Register is set (one), the Timer/Counter1 CompareA Match

interrupt is enabled. The corresponding interrupt (at vector $006) is executed if a CompareA match in Timer/Counter1

occurs (i.e., when the OCF1A bit is set in the Timer/Counter Interrupt Flag Register [TIFR]).

Bit 3 – OCIE1B: Timer/Counter1 Output CompareB Match Interrupt Enable

•

When the OCIE1B bit is set (one) and the I-bit in the Status Register is set (one), the Timer/Counter1 CompareB Match

interrupt is enabled. The corresponding interrupt (at vector $007) is executed if a CompareB match in Timer/Counter1

occurs (i.e., when the OCF1B bit is set in the Timer/Counter Interrupt Flag Register [TIFR]).

25

Page 26

Bit 2 – TOIE1: Timer/Counter1 Overflow Interrupt Enable

•

When the TOIE1 bit is set (one) and the I-bit in the Status Register is set (one), the Timer/Counter1 Overflow Interrupt is

enabled. The corresponding interrupt (at vector $008) is executed if an overflow in Timer/Counter1 occurs (i.e., when the

TOV1 bit is set in the Timer/Counter Interrupt Flag Register [TIFR]).

Bit 1 – Res: Reserved Bit

•

This bit is a reserved bit in the AT90S4434/8535 and always reads zero.

Bit 0 – TOIE0: Timer/Counter0 Overflow Interrupt Enable

•

When the TOIE0 bit is set (one) and the I-bit in the Status Register is set (one), the Timer/Counter0 Overflow Interrupt is

enabled. The corresponding interrupt (at vector $009) is executed if an overflow in Timer/Counter0 occurs (i.e., when the

TOV0 bit is set in the Timer/Counter Interrupt Flag Register [TIFR]).

Timer/Counter Interrupt Flag Register – TIFR

Bit 7 6 5 4 3 2 1 0

$38 ($58) OCF2 TOV2 ICF1 OCF1A OCF1B TOV1 – TOV0 TIFR

Read/Write R/W R/W R/W R/W R/W R/W R R/W

Initial value 0 0 0 0 0 0 0 0

Bit 7 – OCF2: Output Compare Flag 2

•

The OCF2 bit is set (one) when compare match occurs between the Timer/Counter2 and the data in OCR2 (Output Compare Register2). OCF2 is cleared by hardware when executing the corresponding interrupt handling vector. Alternatively,

OCF2 is cleared by writing a logical “1” to the flag. When the I-bit in SREG and OCIE2 (Timer/Counter2 Compare Match

Interrupt Enable) and the OCF2 are set (one), the Timer/Counter2 Compare Match Interrupt is executed.

Bit 6 – TOV2: Timer/Counter2 Overflow Flag

•

The TOV2 bit is set (one) when an overflow occurs in Timer/Counter2. TOV2 is cleared by hardware when executing the

corresponding interrupt handling vector. Alternatively, TOV2 is cleared by writing a logical “1” to the flag. When the SREG

I-bit and TOIE2 (Timer/Counter2 Overflow Interrupt Enable) and TOV2 are set (one), the Timer/Counter2 Overflow Interrupt is executed. In PWM mode, this bit is set when Timer/Counter2 advances from $00.

Bit 5 – ICF1: Input Capture Flag 1

•

The ICF1 bit is set (one) to flag an input capture event, indicating that the Timer/Counter1 value has been transferred to the

Input Capture Register (ICR1). ICF1 is cleared by hardware when executing the corresponding interrupt handling vector.

Alternatively, ICF1 is cleared by writing a logical “1” to the flag. When the SREG I-bit and TICIE1 (Timer/Counter1 Input

Capture Interrupt Enable) and ICF1 are set (one), the Timer/Counter1 Capture Interrupt is executed.

Bit 4 – OCF1A: Output Compare Flag 1A

•

The OCF1A bit is set (one) when compare match occurs between the Timer/Counter1 and the data in OCR1A (Output

Compare Register 1A). OCF1A is cleared by hardware when executing the corresponding interrupt handling vector. Alternatively, OCF1A is cleared by writing a logical “1” to the flag. When the I-bit in SREG and OCIE1A (Timer/Counter1

Compare Match InterruptA Enable) and the OCF1A are set (one), the Timer/Counter1 Compare A Match Interrupt is

executed.

Bit 3 – OCF1B: Output Compare Flag 1B

•

The OCF1B bit is set (one) when compare match occurs between the Timer/Counter1 and the data in OCR1B (Output

Compare Register 1B). OCF1B is cleared by hardware when executing the corresponding interrupt handling vector. Alternatively, OCF1B is cleared by writing a logical “1” to the flag. When the I-bit in SREG and OCIE1B (Timer/Counter1

Compare Match InterruptB Enable) and the OCF1B are set (one), the Timer/Counter1 Compare Match B Interrupt is

executed.

Bit 2 – TOV1: Timer/Counter1 Overflow Flag

•

The TOV1 is set (one) when an overflow occurs in Timer/Counter1. TOV1 is cleared by hardware when executing the corresponding interrupt handling vector. Alternatively, TOV1 is cleared by writing a logical “1” to the flag. When the I-bit in

SREG and TOIE1 (Timer/Counter1 Overflow Interrupt Enable) and TOV1 are set (one), the Timer/Counter1 Overflow Interrupt is executed. In PWM mode, this bit is set when Timer/Counter1 advances from $0000.

Bit 1 – Res: Reserved Bit

•

This bit is a reserved bit in the AT90S4434/8535 and always reads zero.

26

AT90S/LS4434 and AT90S/LS8535

Page 27

AT90S/LS4434 and AT90S/LS8535

Bit 0 – TOV0: Timer/Counter0 Overflow Flag

•

The bit TOV0 is set (one) when an overflow occurs in Timer/Counter0. TOV0 is cleared by hardware when executing the

corresponding interrupt handling vector. Alternatively, TOV0 is cleared by writing a logical “1” to the flag. When the SREG

I-bit and TOIE0 (Timer/Counter0 Overflow Interrupt Enable) and TOV0 are set (one), the Timer/Counter0 Overflow Interrupt is executed.

External Interrupts

The external interrupts are triggered by the INT1 and INT0 pins. Observe that, if enabled, the interrupts will trigger even if

the INT0/INT1 pins are configured as outputs. This feature provides a way of generating a software interrupt. The external

interrupts can be triggered by a falling or rising edge or a low level. This is set up as indicated in the specification for the

MCU Control Register (MCUCR). When the external interrupt is enabled and is configured as level-triggered, the interrupt

will trigger as long as the pin is held low.

The external interrupts are set up as described in the specification for the MCU Control Register (MCUCR).

Interrupt Response Time

The interrupt execution response for all the enabled AVR interrupts is four clock cycles minimum. Four clock cycles after

the interrupt flag has been set, the program vector address for the actual interrupt handling routine is executed. During this

4-clock-cycle period, the Program Counter (2 bytes) is pushed onto the stack and the Stack Pointer is decremented by 2.

The vector is normally a relative jump to the interrupt routine and this jump takes two clock cycles. If an interrupt occurs

during execution of a multi-cycle instruction, this instruction is completed before the interrupt is served.

A return from an interrupt handling routine (same as for a subroutine call routine) takes four clock cycles. During these four

clock cycles, the Program Counter (2 bytes) is popped back from the stack, the Stack Pointer is incremented by 2 and the

I-flag in SREG is set. When the AVR exits from an interrupt, it will always return to the main program and execute one more

instruction before any pending interrupt is served.

MCU Control Register – MCUCR

The MCU Control Register contains control bits for general MCU functions.

Bit 76543210

$35 ($55) – SE SM1 SM0 ISC11 ISC10 ISC01 ISC00 MCUCR

Read/Write R R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bit 7 – Res: Reserved Bit

•

This bit is a reserved bit in the AT90S4434/8535 and always reads zero.

Bit 6 – SE: Sleep Enable

•

The SE bit must be set (one) to make the MCU enter the Sleep Mode when the SLEEP instruction is executed. To avoid

the MCU entering the Sleep Mode unless it is the programmer’s purpose, it is recommended to set the Sleep Enable (SE)

bit just before the execution of the SLEEP instruction.

Bits 5, 4 – SM1/SM0: Sleep Mode Select Bits 1 and 0

•

These bits select between the three available sleep modes as shown in Table 8.

Table 8. Sleep Mode Select

SM1 SM0 Sleep Mode

00Idle

01Reserved

1 0 Power-down

11Power Save

27

Page 28

Bits 3, 2 – ISC11, ISC10: Interrupt Sense Control 1 Bits 1 and 0

•

The External Interrupt 1 is activated by the external pin INT1 if the SREG I-flag and the corresponding interrupt mask in the

GIMSK is set. The level and edges on the external INT1 pin that activate the interrupt are defined in Table 9.

Table 9. Interrupt 1 Sense Control

ISC11 ISC10 Description

0 0 The low level of INT1 generates an interrupt request.

01Reserved

1 0 The falling edge of INT1 generates an interrupt request.

1 1 The rising edge of INT1 generates an interrupt request.

The value on the INT pin is sampled before detecting edges. If edge interrupt is selected, pulses that last longer than one

CPU clock period will generate an interrupt. Shorter pulses are not guaranteed to generate an interrupt. If low-level interrupt is selected, the low level must be held until the completion of the currently executing instruction to generate an

interrupt. If enabled, a level-triggered interrupt will generate an interrupt request as long as the pin is held low.

Bit 1, 0 – ISC01, ISC00: Interrupt Sense Control 0 Bits 1 and 0

•

The External Interrupt 0 is activated by the external pin INT0 if the SREG I-flag and the corresponding interrupt mask is set.

The level and edges on the external INT0 pin that activate the interrupt are defined in Table 10.

Table 10. Interrupt 0 Sense Control

ISC01 ISC00 Description

0 0 The low level of INT0 generates an interrupt request.

01Reserved

1 0 The falling edge of INT0 generates an interrupt request.

1 1 The rising edge of INT0 generates an interrupt request.

The value on the INT pin is sampled before detecting edges. If edge interrupt is selected, pulses that last longer than one

CPU clock period will generate an interrupt. Shorter pulses are not guaranteed to generate an interrupt. If low-level interrupt is selected, the low level must be held until the completion of the currently executing instruction to generate an

interrupt. If enabled, a level-triggered interrupt will generate an interrupt request as long as the pin is held low.

Sleep Modes

To enter any of the three sleep modes, the SE bit in MCUCR must be set (one) and a SLEEP instruction must be executed.

The SM0 and SM1 bits in the MCUCR register select which sleep mode (Idle, Power-down or Power Save) will be activated

by the SLEEP instruction. See Table 8.

If an enabled interrupt occurs while the MCU is in a sleep mode, the MCU wakes up, executes the interrupt routine and

resumes execution from the instruction following SLEEP. The contents of the register file, SRAM and I/O memory are

unaltered. If a reset occurs during Sleep Mode, the MCU wakes up and executes from the Reset vector.

Idle Mode

When the SM1/SM0 bits are set to 00, the SLEEP instruction makes the MCU enter the Idle Mode, stopping the CPU but

allowing SPI, UARTs, Analog Comparator, ADC, Timer/Counters, Watchdog and the interrupt system to continue operating. This enables the MCU to wake up from external triggered interrupts as well as internal ones like the Timer Overflow

and UART Receive Complete interrupts. If wake-up from the Analog Comparator Interrupt is not required, the Analog Comparator can be powered down by setting the ACD-bit in the Analog Comparator Control and Status Register (ACSR). This

will reduce power consumption in Idle Mode. When the MCU wakes up from Idle Mode, the CPU starts program execution

immediately.

28

AT90S/LS4434 and AT90S/LS8535

Page 29

AT90S/LS4434 and AT90S/LS8535

Power-down Mode

When the SM1/SM0 bits are set to 10, the SLEEP instruction makes the MCU enter the Power-down Mode. In this mode,

the external oscillator is stopped while the external interrupts and the Watchdog (if enabled) continue operating. Only an

external reset, a Watchdog reset (if enabled) or an external level interrupt can wake up the MCU.

Note that when a level-triggered interrupt is used for wake-up from power-down, the low level must be held for a time

longer than the reset delay Time-out period t

When waking up from Power-down Mode, a delay from the wake-up condition occurs until the wake-up becomes effective.

This allows the clock to restart and become stable after having been stopped. The wake-up period is equal to the reset

period, as shown in Table 4 on page 21.

If the wake-up condition disappears before the MCU wakes up and starts to execute, e.g., a low-level on is not held long

enough, the interrupt causing the wake-up will not be executed.

Power Save Mode

When the SM1/SM0 bits are 11, the SLEEP instruction makes the MCU enter the Power Save Mode. This mode is identical

to Power-down, with one exception: If Timer/Counter2 is clocked asynchronously, i.e., the AS2 bit in ASSR is set,

Timer/Counter2 will run during sleep. In addition to the power-down wake-up sources, the device can also wake up from

either a Timer Overflow or Output Compare event from Timer/Counter2 if the corresponding Timer/Counter2 interrupt

enable bits are set in TIMSK and the global interrupt enable bit in SREG is set.

When waking up from Power Save Mode by an external interrupt, two instruction cycles are executed before the interrupt

flags are updated. When waking up by the asynchronous timer, three instruction cycles are executed before the flags are

updated. During these cycles, the processor executes instructions, but the interrupt condition is not readable and the interrupt routine has not started yet.

When waking up from Power Save Mode by an asynchronous timer interrupt, the part will wake up even if global interrupts

are disabled.

If the asynchronous timer is not clocked asynchronously, Power-down Mode is recommended instead of Power Save Mode

because the contents of the registers in the asynchronous timer should be considered undefined after wake-up in Power

Save Mode, even if AS2 is 0.

TOUT

.

29

Page 30

Timer/Counters

The AT90S4434/8535 provides three general-purpose Timer/Counters – two 8-bit T/Cs and one 16-bit T/C.

Timer/Counter2 can optionally be asynchronously clocked from an external oscillator. This oscillator is optimized for use

with a 32.768 kHz watch crystal, enabling use of Timer/Counter2 as a Real-time Clock (RTC). Timer/Counters 0 and 1

have individual prescaling selection from the same 10-bit prescaling timer. Timer/Counter2 has its own prescaler. These

Timer/Counters can either be used as a timer with an internal clock time base or as a counter with an external pin connection that triggers the counting.

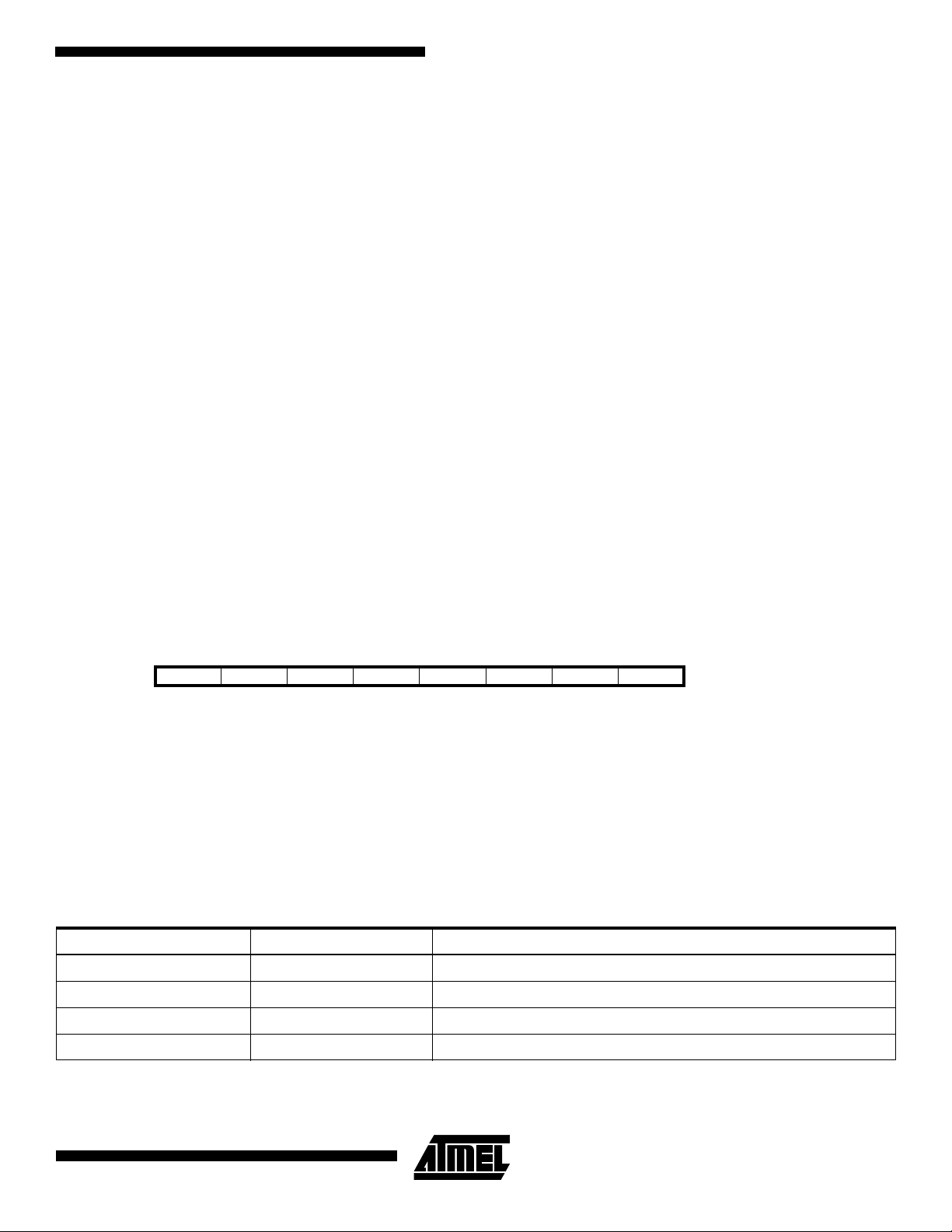

Timer/Counter Prescalers

Figure 28. Prescaler for Timer/Counter0 and 1

TCK1

TCK0

For Timer/Counters 0 and 1, the four different prescaled selections are: CK/8, CK/64, CK/256 and CK/1024, where CK is

the oscillator clock. For the two Timer/Counters 0 and 1, CK, external source and stop can also be selected as clock

sources.

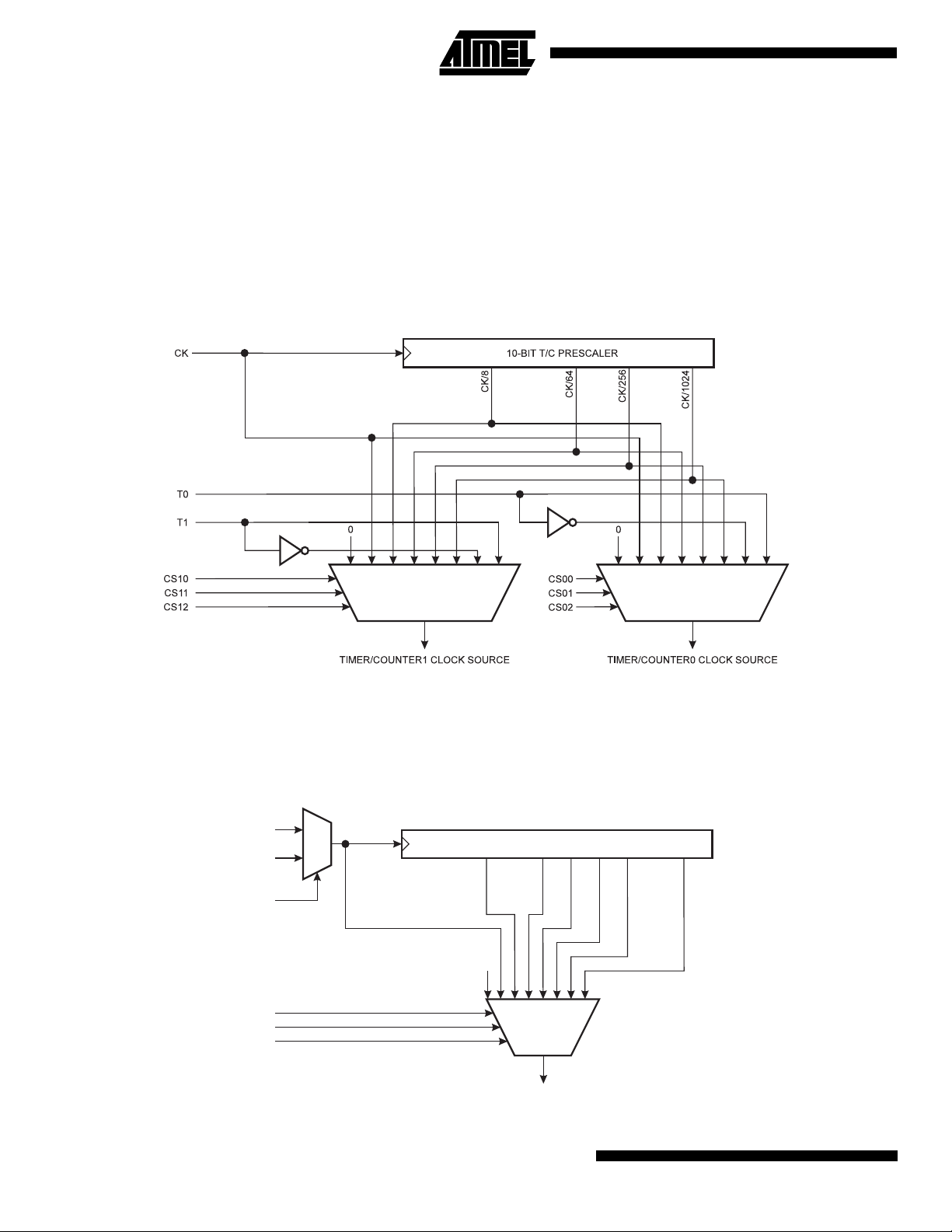

Figure 29. Timer/Counter2 Prescaler

CK

TOSC1

AS2

CS20

CS21

CS22

PCK2

10-BIT T/C PRESCALER

PCK2/8

0

TIMER/COUNTER2 CLOCK SOURCE

PCK2

PCK2/32

PCK2/64

PCK2/128

PCK2/256

PCK2/1024

30

AT90S/LS4434 and AT90S/LS8535

Page 31

AT90S/LS4434 and AT90S/LS8535

The clock source for Timer/Counter2 prescaler is named PCK2. PCK2 is by default connected to the main system clock

(CK). By setting the AS2 bit in ASSR, Timer/Counter2 prescaler is asynchronously clocked from the PC6(TOSC1) pin. This

enables use of Timer/Counter2 as a Real-time Clock (RTC). When AS2 is set, pins PC6(TOSC1) and PC7(TOSC2) are

disconnected from Port C. A crystal can then be connected between the PC6(TOSC1) and PC7(TOSC2) pins to serve as

an independent clock source for Timer/Counter2. The oscillator is optimized for use with a 32.768 kHz crystal. Alternatively,

an external clock signal can be applied to PC6(TOSC1). The frequency of this clock must be lower than one fourth of the

CPU clock and not higher than 256 kHz.

8-bit Timer/Counter0

Figure 30 shows the block diagram for Timer/Counter0.

The 8-bit Timer/Counter0 can select clock source from CK, prescaled CK or an external pin. In addition, it can be stopped

as described in the specification for the Timer/Counter0 Control Register (TCCR0). The overflow status flag is found in the

Timer/Counter Interrupt Flag Register (TIFR). Control signals are found in the Timer/Counter0 Control Register (TCCR0).

The interrupt enable/disable settings for Timer/Counter0 are found in the Timer/Counter Interrupt Mask Register (TIMSK).

When Timer/Counter0 is externally clocked, the external signal is synchronized with the oscillator frequency of the CPU. To

assure proper sampling of the external clock, the minimum time between two external clock transitions must be at least one

internal CPU clock period. The external clock signal is sampled on the rising edge of the internal CPU clock.

The 8-bit Timer/Counter0 features both a high-resolution and a high-accuracy usage with the lower prescaling opportunities. Similarly, the high prescaling opportunities make the Timer/Counter0 useful for lower speed functions or exact timing

functions with infrequent actions.

Figure 30. Timer/Counter0 Block Diagram

OCIE1A

OCIE1B

TOIE1

TICIE1

TOIE2

TA BUS

8-BIT DA

OCIE2

TIMER INT. MASK

REGISTER (TIMSK)

TIMER/COUNTER0

(TCNT0)

TOIE0

07

T/C0 OVER-

FLOW IRQ

TIMER INT. FLAG

REGISTER (TIFR)

TOV2

OCF2

T/C CLK SOURCE

ICF1

OCF1B

OCF1A

TOV1

TOV0

T/C0 CONTROL

REGISTER (TCCR0)

CONTROL

LOGIC

CS02

CS01

CS00

CK

T0

31

Page 32

Timer/Counter0 Control Register – TCCR0

Bit 7 6 5 4 3 2 1 0

$33 ($53) –– – – –CS02 CS01 CS00 TCCR0

Read/Write R R R R R R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..3 – Res: Reserved Bits

•

These bits are reserved bits in the AT90S4434/8535 and always read zero.

•

Bits 2, 1, 0 – CS02, CS01, CS00: Clock Select0, Bits 2, 1 and 0

The Clock Select0 bits 2,1 and 0 define the prescaling source of Timer/Counter0.

Table 11. Clock 0 Prescale Select

CS02 CS01 CS00 Description

0 0 0 Stop, Timer/Counter0 is stopped.

00 1CK

01 0CK/8

01 1CK/64

10 0CK/256

1 0 1 CK/1024

1 1 0 External Pin T0, falling edge

1 1 1 External Pin T0, rising edge

The Stop condition provides a Timer Enable/Disable function. The prescaled CK modes are scaled directly from the CK

oscillator clock. If the external pin modes are used, the corresponding setup must be performed in the actual Data Direction

Control Register (cleared to zero gives an input pin).

Timer Counter 0 – TCNT0

Bit 76543210

$32 ($52) MSB LSB TCNT0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

The Timer/Counter0 is realized as an up-counter with read and write access. If the Timer/Counter0 is written and a clock

source is present, the Timer/Counter0 continues counting in the clock cycle following the write operation.

32

AT90S/LS4434 and AT90S/LS8535

Page 33

16-bit Timer/Counter1

K

Figure 31 shows the block diagram for Timer/Counter1.

Figure 31. Timer/Counter1 Block Diagram

T/C1 OVER-

FLOW IRQ

OCIE2

TOIE2

TICIE1

OCIE1B

TA BU S

8-BIT DA

OCIE1A

TIMER INT. MASK

REGISTER (TIMSK)

15

T/C1 INPUT CAPTURE REGISTER (ICR1)

15

T/C1 COMPARE

MATCHA IRQ

TOIE1

TOIE0

TIMER/COUNTER1 (TCNT1)

8

7

8

7

ICF1

OCF2

TOV2

TIMER INT. FLAG

REGISTER (TIFR)

ICF1

OCF1B

OCF1B

AT90S/LS4434 and AT90S/LS8535

T/C1 COMPARE

MATCHB IRQ

OCF1A

TOV1

OCF1A

TOV1

CAPTURE

TRIGGER

CAPTURE IRQ

TOV0

REGISTER A (TCCR1A)

COM1A1

0

T/C CLEAR

0

T/C CLOCK SOURCE

UP/DOWN

T/C1 INPUT

T/C1 CONTROL

COM1B1

COM1A0

COM1B0

PWM11

PWM10

CONTROL

LOGIC

T/C1 CONTROL

REGISTER B (TCCR1B)

CS11

CS12

CTC1

ICNC1

ICES1

CS10

C

T1

8

8

15

15

TIMER/COUNTER1 OUTPUT COMPARE REGISTER A

7

16 BIT COMPARATOR

8

7

15

0

15

0

TIMER/COUNTER1 OUTPUT COMPARE REGISTER B

7

16 BIT COMPARATOR

8

7

0

0

The 16-bit Timer/Counter1 can select clock source from CK, prescaled CK or an external pin. In addition, it can be stopped

as described in the specification for the Timer/Counter1 Control Registers (TCCR1A and TCCR1B). The different status

flags (Overflow, Compare Match and Capture Event) and control signals are found in the Timer/Counter1 Control Registers

(TCCR1A and TCCR1B). The interrupt enable/disable settings for Timer/Counter1 are found in the Timer/Counter Interrupt

Mask Register (TIMSK).

When Timer/Counter1 is externally clocked, the external signal is synchronized with the oscillator frequency of the CPU. To

assure proper sampling of the external clock, the minimum time between two external clock transitions must be at least one

internal CPU clock period. The external clock signal is sampled on the rising edge of the internal CPU clock.

The 16-bit Timer/Counter1 features both a high-resolution and a high-accuracy usage with the lower prescaling opportunities. Similarly, the high prescaling opportunities makes the Timer/Counter1 useful for lower speed functions or exact timing

functions with infrequent actions.

The Timer/Counter1 supports two Output Compare functions using the Output Compare Register 1A and B (OCR1A and

OCR1B) as the data sources to be compared to the Timer/Counter1 contents. The Output Compare functions include

optional clearing of the counter on compareA match and actions on the Output Compare pins on both compare matches.

Timer/Counter1 can also be used as an 8-, 9- or 10-bit Pulse Width Modulator. In this mode the counter and the

OCR1A/OCR1B registers serve as a dual glitch-free stand-alone PWM with centered pulses. Refer to page 38 for a

detailed description of this function.

The Input Capture function of Timer/Counter1 provides a capture of the Timer/Counter1 contents to the Input Capture Register (ICR1), triggered by an external event on the Input Capture Pin (ICP). The actual capture event settings are defined by

the Timer/Counter1 Control Register (TCCR1B). In addition, the Analog Comparator can be set to trigger the input capture.

Refer to “Analog Comparator” on page 60 for details on this. The ICP pin logic is shown in Figure 32.

33

Page 34

Figure 32. ICP Pin Schematic Diagram

If the Noise Canceler function is enabled, the actual trigger condition for the capture event is monitored over four samples

and all four must be equal to activate the capture flag. The input pin signal is sampled at XTAL clock frequency.

Timer/Counter1 Control Register A – TCCR1A

Bit 7 6 5 4 3 2 1 0

$2F ($4F) COM1A1 COM1A0 COM1B1 COM1B0 ––PWM11 PWM10 TCCR1A

Read/Write R/W R/W R/W R/W R R R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7, 6 – COM1A1, COM1A0: Compare Output Mode1A, Bits 1 and 0

•

The COM1A1 and COM1A0 control bits determine any output pin action following a compare match in Timer/Counter1.

Any output pin actions affect pin OC1A (Output CompareA pin 1). This is an alternative function to an I/O port and the corresponding direction control bit must be set (one) to control an output pin. The control configuration is shown in Table 12.

Bits 5, 4 – COM1B1, COM1B0: Compare Output Mode1B, Bits 1 and 0

•

The COM1B1 and COM1B0 control bits determine any output pin action following a compare match in Timer/Counter1.

Any output pin actions affect pin OC1B (Output CompareB). This is an alternative function to an I/O port and the corresponding direction control bit must be set (one) to control an output pin. The control configuration is given in Table 12.

Table 12. Compare 1 Mode Select

COM1X1 COM1X0 Description

0 0 Timer/Counter1 disconnected from output pin OC1X

0 1 Toggle the OC1X output line.

1 0 Clear the OC1X output line (to zero).

1 1 Set the OC1X output line (to one).

Note: X = A or B.

In PWM mode, these bits have a different function. Refer to Table 16 for a detailed description. When changing the

COM1X1/COM1X0 bits, Output Compare Interrupt 1 must be disabled by clearing their Interrupt Enable bits in the TIMSK

Register. Otherwise an interrupt can occur when the bits are changed.

Bits 3..2 – Res: Reserved Bits

•

These bits are reserved bits in the AT90S4434/8535 and always read zero.

•

Bits 1..0 – PWM11, PWM10: Pulse Width Modulator Select Bits

These bits select PWM operation of Timer/Counter1 as specified in Table 13. This mode is described on page 38.

34

AT90S/LS4434 and AT90S/LS8535

Page 35

AT90S/LS4434 and AT90S/LS8535

Table 13. PWM Mode Select

PWM11 PWM10 Description

0 0 PWM operation of Timer/Counter1 is disabled

0 1 Timer/Counter1 is an 8-bit PWM

1 0 Timer/Counter1 is a 9-bit PWM

1 1 Timer/Counter1 is a 10-bit PWM

Timer/Counter1 Control Register B – TCCR1B

Bit 7 6 5 4 3 2 1 0

$2E ($4E) ICNC1 ICES1 ––CTC1 CS12 CS11 CS10 TCCR1B

Read/Write R/W R/W R R R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bit 7 – ICNC1: Input Capture1 Noise Canceler (4 CKs)

•

When the ICNC1 bit is cleared (zero), the Input Capture Trigger Noise Canceler function is disabled. The input capture is

triggered at the first rising/falling edge sampled on the ICP (input capture pin) as specified. When the ICNC1 bit is set (one),

four successive samples are measured on the ICP (input capture pin), and all samples must be high/low according to the

input capture trigger specification in the ICES1 bit. The actual sampling frequency is XTAL clock frequency.

Bit 6 – ICES1: Input Capture1 Edge Select

•

While the ICES1 bit is cleared (zero), the Timer/Counter1 contents are transferred to the Input Capture Register (ICR1) on

the falling edge of the input capture pin (ICP). While the ICES1 bit is set (one), the Timer/Counter1 contents are transferred

to the Input Capture Register (ICR1) on the rising edge of the input capture pin (ICP).

Bits 5, 4 – Res: Reserved Bits

•

These bits are reserved bits in the AT90S4434/8535 and always read zero.

Bit 3 – CTC1: Clear Timer/Counter1 on Compare Match

•

When the CTC1 control bit is set (one), the Timer/Counter1 is reset to $0000 in the clock cycle after a compareA match. If

the CTC1 control bit is cleared, Timer/Counter1 continues counting and is unaffected by a compare match. Since the compare match is detected in the CPU clock cycle following the match, this function will behave differently when a prescaling

higher than 1 is used for the timer. When a prescaling of 1 is used and the compareA register is set to C, the timer will count

as follows if CTC1 is set:

... | C-2 | C-1 | C | 0 | 1 |...

When the prescaler is set to divide by 8, the timer will count like this:

... | C-2, C-2, C-2, C-2, C-2, C-2, C-2, C-2 | C-1, C-1, C-1, C-1, C-1, C-1, C-1, C-1 | C, 0, 0, 0, 0, 0, 0, 0 |1,1,1,1,1,1,1,1|...

In PWM mode, this bit has no effect.

Bits 2, 1, 0 – CS12, CS11, CS10: Clock Select1, Bits 2, 1 and 0

•