Page 1

Introduction

This document contains the latest information about the AVR data book and the AVR

data sheets.

®

All references to the data book refers to the August 1999 version of the “AVR

MICROCONTROLLER DATA BOOK”.

All references to the A VR data she ets refer to the latest version of the AVR d ata

sheets on Atmel’s web page www.atmel.com

.

RISC

The data she ets on Atmel’s w eb pa ge are updated more frequen tly than the p rinted

data book. All known errors in each data sheet are corrected wh en a new v ersion is

released.

This document contains known errors that have not been corrected yet. All designers

using AVR microcontrollers should use this document together with the data sheets. It

is updated frequently, and should contain a complete list of all known documentation

errors at any given time.

Please note that this document only covers errors in the AVR documentation. For

errors in the AVR microcontrollers, see the errata sheet for each device.

If you find errors in the documentation that are not listed in this document, please

send an email to the AVR support line avr@atmel.com

.

Overview of data sheets

Part Number Data Sheet Revision

in the August 1999

AVR Data Book

AT90S1200 0838E-04/99 0838E-04/99

AT90S2313 0839E-04/99 0839E-04/99

AT90S/LS2323 and AT90S/LS2343 1004B-04/99 1004B-04/99

AT90S/LS2333 and AT90S/LS4443 1042D-04/99 1042D-04/99

AT90S4414/8515 0841E-04/99 0841E-04/99

AT90S/LS4434 and AT90S/LS8535 1041E-04/99 1041E-04/99

AT90C8534 1229A-04/99 1229A-04/99

ATtiny10/11/12 1006A-04/99 1006B-10/99

ATtiny15 1187A-06/99 1187B-11/99

ATtiny22/22L 1273A-04/99 1273A-04/99

ATmega161/161L 1228A-05/99 1228A-08/99

ATmega603/603L and ATmega103/103L 0945D-06/99 0945E-12/99

AVR Instruction Set 0856B-06/99 0856B-06/99

ATtiny28 N/A 1062B-10/99

Data Sheet Revision

on Atmel’s web site

www.atmel.com

8-Bit

Microcontroller

Data

Book Updates

and Changes

Rev. 12/99A

1

Page 2

AT90S1200

The latest data sheet on the web is rev. 0838E-04/99.

The data sheet in the printed data book is rev. 0838E-04/99.

Changes in the AT90S1200 Data Sheet:

Page: Change or Add:

2-3 In feature list under

I/O and packages,

replace “20-pin PDIP and SOIC” by “20-pin PDIP, SOIC and SSOP”.

2-20 Table 4: remove this note: “Not e: When ch anging the ISC01/ ISC00 bit s, INT0 must be disabl ed by cl earing its Int er-

rupt Enable bit in the GIMSK registe r. Otherwise an interrupt can occur when the bits are changed. ”

2-25 In the note for Table 6, add “To avoid unintenti onal MCU resets, the Watchdog Timer should be disabled or reset

before changing the Watchdog Timer Prescale Select.”

In the

EEPROM Read/Write Access

description,

change

“When the EEPROM is read or written, the CPU is

halted for two clock cycles before the next instruction is executed.” to “When the EEPROM is written, the CPU is

halted for two clock cycles before the next instruction is executed. When the EEPROM is read, the CPU is halted

for four clock cycles before the next instruction is executed.”

2-26 In the

Bit 0 - EERE: EEPROM Read Enable

description,

change

“When EERE has been set, the CPU i s halt ed f or

two clock cycles before the next instruction is executed.” to “When EERE has been set, the CPU is halted for four

clock cycles before the next instruction is executed.”

2-27 In the

Analog Comparator Control and Status Register

description, change the initial value of ACO from “0” to

“N/A”.

2-29 in the

2-33 in the

Port B Input Pins Address - PINB

Port D Input Pins Address - PIND

description, change the Initial Values from “Hi-Z” to “N/A”.

description, change the Initial Values of bits 0 to 6 from “Hi-Z” to “N/A”.

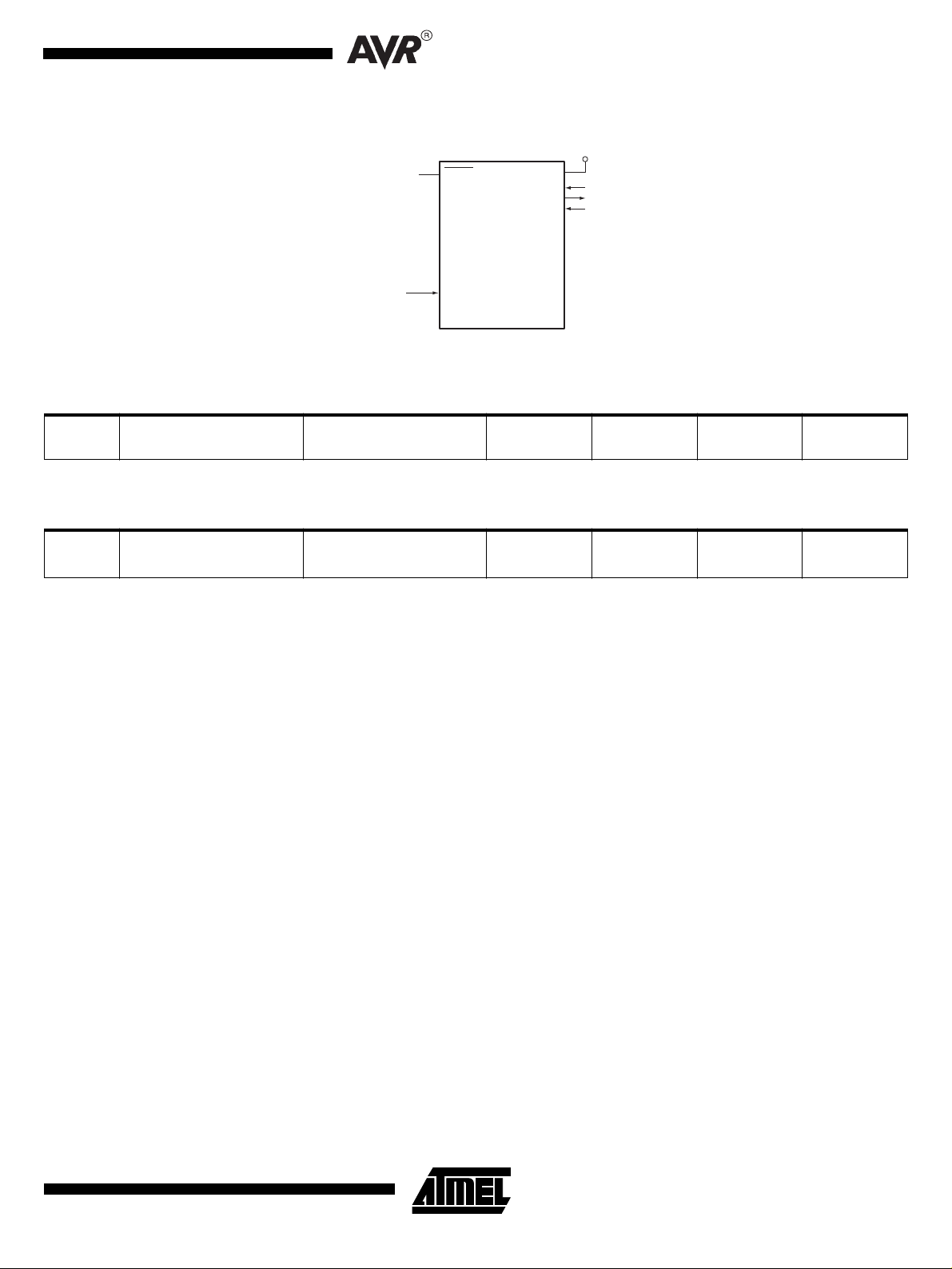

2-44 Replace figure 34 by the one below:

Figure

34 Serial Programming and Verify

VCC

PB7

PB6

PB5

2.7 - 6.0

SCK

MISO

MOSI

AT90S1200

GND

CLOCK INPUT

2

Data Book Updates and Changes

RESET

XTAL1

GND

Page 3

Data Book Updates and Changes

2-49: Replace the row bel ow in

V

ACIO

Analog Comparator

Input Offset Voltage

by:

V

ACIO

2-50 In first l ine of

Analog Comparator

Input Offset Voltage

Typical Characteristics

are not tested during manufacturing.”.

2-62 In

Register Summary

, replace “2-2-xx” by “2-xx”.

DC characteristics

VCC = 5V 40 mV

VCC = 5V

Vin = VCC /2

:

40 mV

, change “These data are characterized, but not tested.” to “These figures

3

Page 4

AT90S2313

The latest data sheet on the web is rev. 0839E-04/99.

The data sheet in the printed data book is rev. 0839E-04/99.

Changes in the AT90S2313 Data Sheet:

Page: Change or Add:

3-28 Table 5: remove this note: “Note: W hen changing th e ISC11/ISC10 bits, INT1 must be disable d by clea ring it s Inter -

rupt Enable bit in the GIMSK registe r. Otherwise an interrupt can occur when the bits are changed. ”

3-29 Table 6: remove this note: “Not e: When ch anging the ISC01/ ISC00 bit s, INT0 must be disabl ed by cl earing its Int er-

rupt Enable bit in the GIMSK registe r. Otherwise an interrupt can occur when the bits are changed. ”

3-38 On the top of the page, add paragraph “Note: If the compare register contains the TOP value and the prescaler is

not in use (CS12..CS10 = 001), the PWM output will not produce any pulse at all, because the up-counting and

down-counting values are reached simultaneously. When the prescaler is in use (CS12..CS10 ≠ 001 or 000), the

PWM output goes active when the counter reaches the TOP value, but the down-counting compare match is not

interpreted to be reached before the next time the counter reaches the TOP-value, making a one period PWM

pulse.”

3-39 In the note for Table 14, add “To avoid unintentional MCU resets, the Watchdog Timer should be disabled or reset

before changing the Watchdog Timer Prescale Select.”

In the

halted for two clock cycles before the next instruction is executed.” to “When the EEPROM is written, the CPU is

halted for two clock cycles before the next instruction is executed. When the EEPROM is read, the CPU is halted

for four clock cycles before the next instruction is executed.”

3-40 In the

EECR” to “4. Write a lo gical on e to the EEMWE bit in EECR (to be a ble to wr ite a l ogical one to the EEMWE bit, t he

EEWE bit must be written to zero in the same cycle).”

3-41 In the

two clock cycles before the next instruction is executed.” to “When EERE has been set, the CPU is halted for four

clock cycles before the next instruction is executed.”

3-47 In the

“N/A”.

3-49 in the

3-54 in the

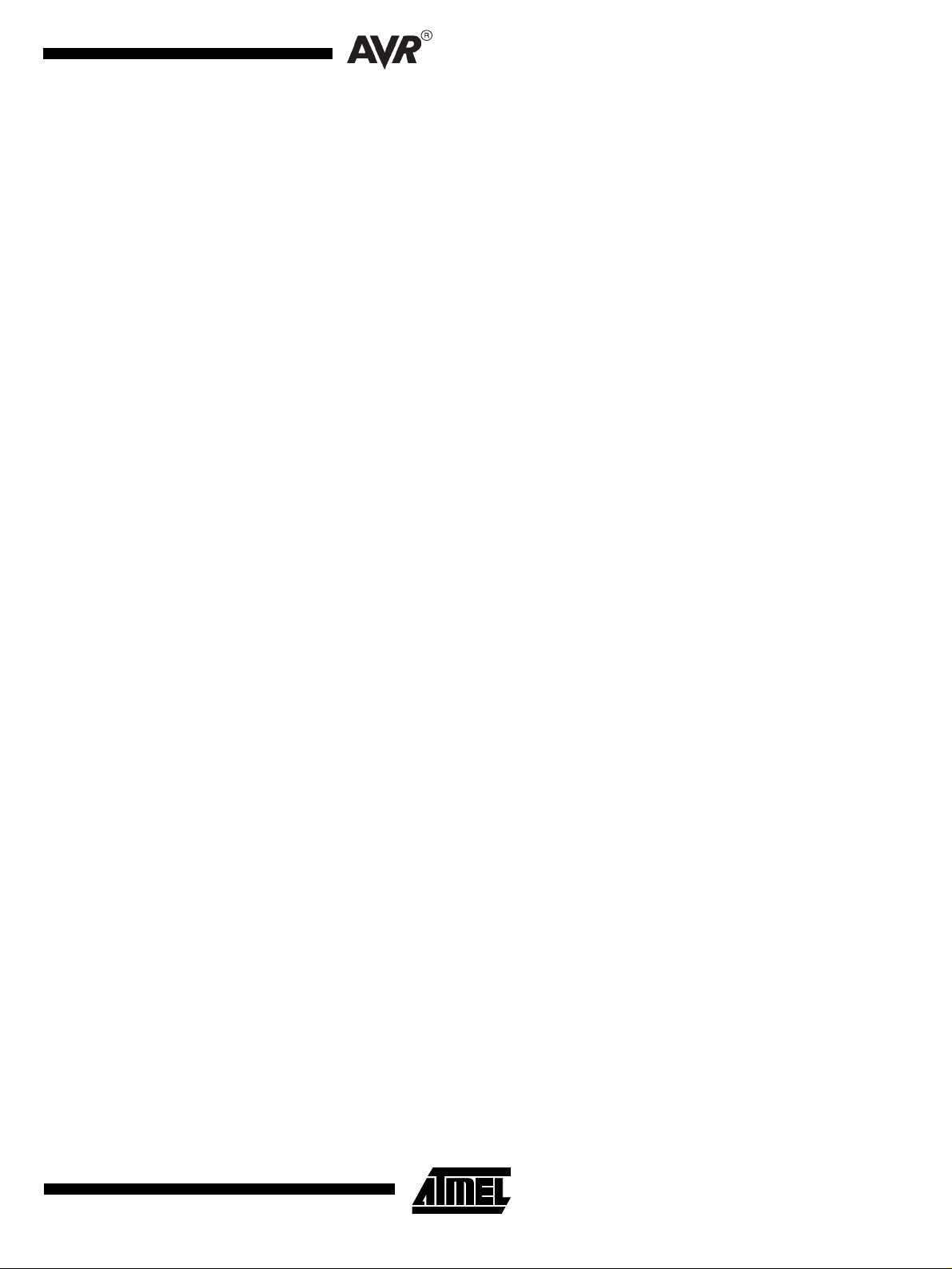

3-67 Replace figure 34 by the one below:

EEPROM Read/Write Access

Bit1 - EEWE: EEPROM Write Enable

Bit 0 - EERE: EEPROM Read Enable

Analog Comparator Control and Status Register

Port B Input Pins Address - PINB

Port D Input Pins Address - PIND

description,

description,

description, change the Initial Values from “Hi-Z” to “N/A”.

description, change the Initial Values of bits 0 to 6 from “Hi-Z” to “N/A”.

change

description,

“When the EEPROM is read or written, the CPU is

change

change

description, change the initial value of ACO from “0” to

“4. Write a logical one to the EEMWE bit in

“When EERE has been set, the CPU i s halt ed f or

4

Data Book Updates and Changes

Page 5

Data Book Updates and Changes

Figure

53 Serial Programming and Verify

3-72: Replace the row bel ow in

V

ACIO

Analog Comparator

Input Offset Voltage

by:

V

ACIO

Analog Comparator

Input Offset Voltage

GND

CLOCK INPUT

DC characteristics

AT90S2313

RESET

XTAL1

GND

:

VCC

PB7

PB6

PB5

2.7 - 6.0

SCK

MISO

MOSI

VCC = 5V 40 mV

VCC = 5V

Vin = VCC /2

40 mV

3-73 In first l ine of

are not tested during manufacturing.”.

3-84 In

Register Summary

Typical Characteristics

, replace “3-3-xx” and “3-3-3-xx” by “3-xx”.

, change “These data are characterized, but not tested.” to “These figures

5

Page 6

AT90S/LS2323 and AT90S/LS2343

The latest data sheet on the web is rev. 1004B-04/99.

The data sheet in the printed data book is rev. 1004B-04/99.

Changes in the AT90S/LS2323 and AT90S/LS2343 Data Sheet:

Page: Change or Add:

4-6 In the

4-7 In the

4-19 In Figure 20, add a box containin g “+1” as a n input to the summation operator.

4-25 In the first paragraph of

4-29 Table 9: remove this note: “Not e: When ch anging the ISC01/ ISC00 bit s, INT0 must be disabl ed by cl earing its Int er-

Pin Descriptions AT90S/LS2323

“Port B is a 3-bit bi-directional I/O port with internal pull-up resistors. The Port B output buffers can sink 20 mA. As

inputs, Port B pins that are externally pulled low, will source current if the pull -up resistors are activated.

Port B also serves the functions of various special features.

Port pins can provide internal pull-up resistors (selected for each bit). The port B pins are tri-stated when a reset

condition becomes acti ve.”

Pin Descriptions AT90S/LS2343

“Port B is a 5-bit bi-directional I/O port with internal pull-up resistors. The Port B output buffers can sink 20 mA. As

inputs, Port B pins that are externally pulled low, will source current if the pull -up resistors are activated.

Port B also serves the functions of various special features.

Port pins can provide internal pull-up resistors (selected for each bit). The port B pins are tri-stated when a reset

condition becomes acti ve.”

Watchdog Reset

pulse of 1 XTAL cycle duration.” by “When the Watchdog times out, it will generate a short reset pulse of 1 CPU

clock cycle duration.”

rupt Enable bit in the GIMSK registe r. Otherwise an interrupt can occur when the bits are changed. ”

replace the description for

replace the description for

, replace “When the Watchdog times out, it will generate a short reset

Port B (PB2..PB0)

Port B (PB4..PB0)

by

by

4-34 In the note for Table 11, add “To avoid unintenti onal MCU resets, the Watchdog Timer should be disabled or reset

before changing the Watchdog Timer Prescale Select.”

In

EEPROM Read/Write Access

two clock cycles before the next instruction is executed.” by “When the EEPROM is written, the CPU is halted for

two clock cycles before t he ne xt instruction is executed. When it is read, the CPU is halted for 4 clock cycles.”.

4-35 In the

EECR” to “4. Write a logica l one to the EEMWE bit i n EECR (to be able to wri te a logical one to the EEMWE bit, the

EEWE bit must be written to zero in the same cycle).”

In the

two clock cycles before the next instruction is executed.” to “When EERE has been set, the CPU is halted for four

clock cycles before the next instruction is executed.”

4-37 in the

6

Bit1 - EEWE: EEPROM Write Enable

Bit 0 - EERE: EEPROM Read Enable

Port B Input Pins Address - PINB

Data Book Updates and Changes

, replace the 6th line “When the EEPROM is read or written, the CPU is halted for

description, change “4. Write a logical one to the EEMWE bit in

description,

description, change the Initial Values of bits 0-4 from “Hi-Z” to “N/A”.

change

“When EERE has been set, the CPU i s halt ed f or

Page 7

Data Book Updates and Changes

4-38 Replace the secti on name “MISO - Port B, Bit 1” by “MISO/INT0 - Port B, Bit 1”

4-40 In

High-Voltage Serial Programming

“Power-up sequence: Apply 4.5 - 5.5V betwee n V

Then, if the RCEN Fuse is not programmed; Toggle XTAL1/PB3 at least 4 times with minimum 100ns pulse-width.

Set PB3 to “0”. Wait at least 100ns.

or if the RCEN Fuse is programmed; Set PB3 to “0”. Wait at least 4µs.

In both cases; Then apply 12V to RESET

any instructions.”

4-40 In

High-Voltage Serial Programming

4-42 In table 16, replace the entries

Read Fuse and

Lock bits

(AT90S/

LS2323)

Read Fuse and

Lock bits

(AT90S/

LS2343)

PB0

PB1

PB2

PB0

PB1

PB2

0_0000_0100_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_0000_0100_00

0_0100_1100_00

x_xxxx_xxxx_xx

by the entries (Note: Bit 7 in the 4’th and 5’th column for PB1 has been inverted compared to the origi nal data

book)

, replace item 1. by

and wait at least 100 ns before changing PB0. Wait 8 µs before giving

, replace in item 5 “Set PB5 to “1”.” by “Set RESET

0_0000_0000_00

0_0110_1000_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1000_00

x_xxxx_xxxx_xx

and GND. Set RESET and PB0 to “0” and wait at least 100 ns.

CC

to “0”.”

0_0000_0000_00

0_0110_1100_00

S

xx_xxFx_xx

1_2

0_0000_0000_00

0_0110_1100_00

S

xx_xxRx_xx

1_2

Reading

Fuse/Lock bit is programmed.

Reading

Fuse/Lock bit is programmed.

, S, F =’ 0’ means the

1, 2

, S, R =’ 0’ means the

1, 2

Read Fuse and

Lock bits

(AT90S/

LS2323)

Read Fuse and

Lock bits

(AT90S/

LS2343)

PB0

PB1

PB2

PB0

PB1

PB2

0_0000_0100_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_0000_0100_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0111_1000_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0111_1000_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0111_1100_00

S

xx_xxFx_xx

1_2

0_0000_0000_00

0_0111_1100_00

S

xx_xxRx_xx

1_2

Reading

Fuse/Lock bit is programmed.

Reading

Fuse/Lock bit is programmed.

, S, F =’ 0’ means the

1, 2

, S, R =’ 0’ means the

1, 2

4-43 In figure 35, remove “CLOCK INPUT”, “XTAL1/PB3” and the arrow connecting them.

4-49 In first l ine of

Typical Characteristics

, change “These data are characterized, but not tested.” to “These figures

are not tested during manufacturing.”.

4-59 In Register Summary, replace all “4-page” by “page”. In addition, for TIMSK; replace ”page 4 -15” by “page 4-28”,

for TIFR; replace “page 4-16” by “page 4-28”, for MCUCR; replace “page 4-16” by “page 4-29”, for MCUSR;

replace “page 4-14” by “page 4-26”.

4-60 In Instruction Set Summary under BRANCH INSTRUCTIONS, replace

CPSE Rd,Rr Compare, Skip if Equal if (Rd = Rr) PC

SBRC Rr, b Skip if Bit in Register Cleared if (Rr(b)=0) PC

SBRS Rr, b Skip if Bit in Register is Set if (Rr(b)=1) PC

SBIC P, b Skip if Bit in I/O Register Cleared if (P(b)=0) PC

SBIS P, b Skip if Bit in I/O Register is Set if (R(b)=1) PC

PC + 2 or 3 None 1 / 2

←

PC + 2 or 3 None 1 / 2

←

PC + 2 or 3 None 1 / 2

←

PC + 2 or 3 None 1 / 2

←

PC + 2 or 3 None 1 / 2

←

by

CPSE Rd,Rr Compare, Skip if Equal if (Rd = Rr) PC

SBRC Rr, b Skip if Bit in Register Cleared if (Rr(b)=0) PC

PC + 2 or 3 None 1 / 2 / 3

←

PC + 2 or 3 None 1 / 2 / 3

←

7

Page 8

SBRS Rr, b Skip if Bit in Register is Set if (Rr(b)=1) PC ← PC + 2 or 3 None 1 / 2 / 3

SBIC P, b Skip if Bit in I/O Register Cleared if (P(b)=0) PC

SBIS P, b Skip if Bit in I/O Register is Set if (R(b)=1) PC

PC + 2 or 3 None 1 / 2 / 3

←

PC + 2 or 3 None 1 / 2 / 3

←

8

Data Book Updates and Changes

Page 9

Data Book Updates and Changes

AT90S/LS2333 and AT90S/LS4433

The latest data sheet on the web is rev. 1042D-04/99.

The data sheet in the printed dat a b ook is rev. 1042D-04/99.

Changes in the AT90S/LS2333 and AT90S/LS4433 Data Sheet:

Page: Change or Add:

5-6 In “

5-15 In

5-28 Table 7: remove this note: “Note: When changing the ISC11/ISC10 bi ts, INT1 must be disabled by clearing its Inter-

5-34 In “

5-37 Before

5-39 In the note for Table 16, add “To avoid unintentional MCU resets, the Watchdog Timer should be disabled or reset

5-41 In the

Pin Descriptions

nected to Vcc via a low-pass filter.” to “This is the supply voltage for Port A and the A/D Convert er. If the ADC is not

used, this pin must be connected to Vcc. If the ADC is used, this pin should be connected to Vcc via a low-pass filter.”

Figure 20

rupt Enable bit in the GIMSK register. Otherwise an interrupt can occur when the bits are changed. ”

Table 8: remove this note: “Note: W hen changi ng the I SC01/ISC00 bi ts, I NT0 must be dis abled by cl ear ing it s Inter -

rupt Enable bit in the GIMSK register. Otherwise an interrupt can occur when the bits are changed. ”

Timer/Counter Control Register 1B - TCCR1B

set to divide by 8 from “...C-1 | C, 0, 0, 0, 0, 0, 0, 0, 0 | ...” to “...C-1 | C, 0, 0, 0, 0, 0, 0, 0 | ...”

use (CS12..CS10 = 001), the PWM output will not produce any pulse at all, because the up-counting and downcounting values are reached simultaneously. When the prescaler is in use (CS12..CS10 ≠ 001 or 000), the PWM

output goes active when the counter reaches the TOP value, but the down-counting compare match is not i nterpreted to be reached before the next time the counter reaches the TOP-value, making a one- period PWM pulse.”

before changing the Watchdog Timer Prescale Select.”

EECR” to “4. Write a logical one to the EEMWE bit i n EECR (to be able to writ e a logical one to the EEMWE bit , the

EEWE bit must be written to zero in the same cycle).”

, add a box containing “+1” as an input to the summation operator.

table 14

Bit1 - EEWE: EEPROM Write Enable

”,

, add paragraph “Note: If the compare register contains the TOP value and the prescaler is not in

, change “This is the supply vo ltage f or the A/D Conver ter. It should be externally con -

AVCC

”, bit3 -

description, change “4. Write a logical one to the EEMWE bit in

, change the count sequence when prescaler is

CTC1

5-47..50 In the

5-50 In last line, replace “UBRRH” by “UBRRHI”.

5-52 In “

5-59 In “

5-60 In

5-61 In the

5-66 In the

5-68 In the

5-80 In “

Analog Comparator Control and Status Register - ACSR

ADC Noise Canceling Techniques

Figure 49

Port B Input Pins Address - PINB

Port C Input Pins Address - PINC

Values “Q” to “0” (zero).

Port D Input Pins Address - PIND

Serial Downloading

description, replace “USR” by “UCSRA” and “UCR” by “UCSRB” everywhere.

UART

” item 3, replace “Figure 47” by “Fi gure 49”.

, replace the resistor by a 10 µH inductor. Change capacitor value from 10 nF to 100 nF.

description, change the Ini tial Values from “Hi-Z” to “N/A”.

description, change the Initial Values from “Hi-Z” to “N/A”. Change Initial

description, change the Ini tial Values from “Hi-Z” to “N/A”.

”, replace Figure 66 by the figu re below.

”, the initia l va l ue o f

ACO

is “N/A”.

9

Page 10

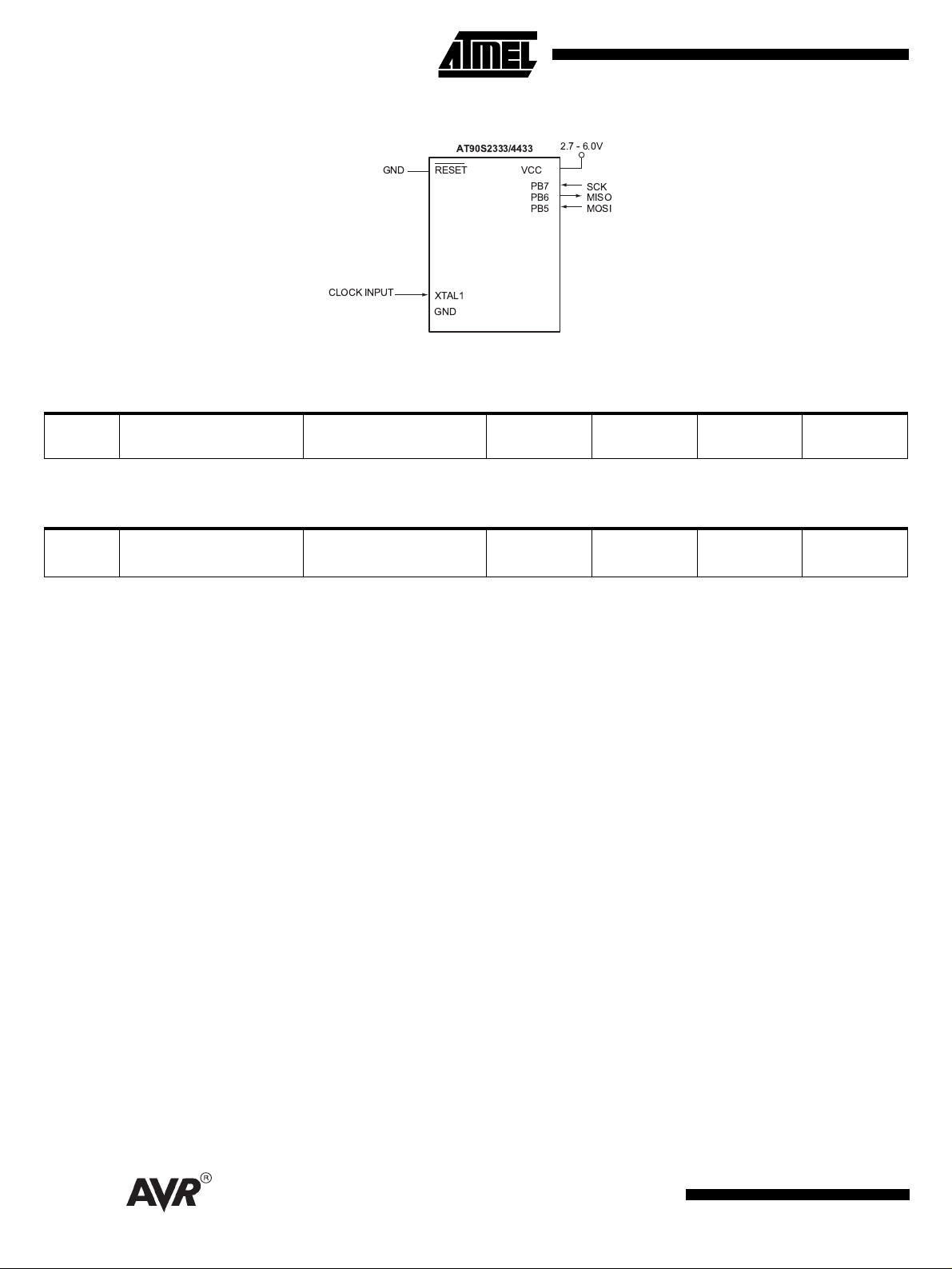

Figure 66. Serial Progr amming and Verify

GND

AT90S2333/4433

RESET

VCC

PB7

PB6

PB5

2.7 - 6.0V

SCK

MISO

MOSI

5-86 Replace the row below in

V

ACIO

Analog Comparator

Input Offset Voltage

by:

V

ACIO

5-86 In “

5-88 In first line of

Analog Comparator

Input Offset Voltage

DC Characteristics

Typical Characteristics

”, footnote 4, r eplace “IOL” by “IOH” everywhere.

are not tested during manufacturing.”.

CLOCK INPUT

DC characteristics

XTAL1

GND

:

VCC = 5V 40 mV

VCC = 5V

Vin = VCC /2

40 mV

, change “These data are characterized, but not tested.” to “These figures

10

Data Book Updates and Changes

Page 11

AT90S4414/8515

The latest data sheet on the web is rev. 0841E-04/99.

The data sheet in the printed dat a b ook is rev. 0841E-04/99.

Changes in the AT90S4414/8515 Data Sheet:

Page: Change or Add:

Data Book Updates and Changes

6-17 In

6-29 Table 6: remove this note: “Note: When changing the ISC11/ISC10 bi ts, INT1 must be disabled by clearing its Inter-

6-30 Table 7: remove this note: “Note: W hen changi ng the I SC01/ISC00 bi t s, INT0 must be dis able d by clear ing it s Inter -

6-39 Before

6-41 In the note for Table 15, add “To avoid unintentional MCU resets, the Watchdog Timer should be disabled or reset

6-42 In the

6-43 In the

Figure 19

rupt Enable bit in the GIMSK register. Otherwise an interrupt can occur when the bits are changed. ”

rupt Enable bit in the GIMSK register. Otherwise an interrupt can occur when the bits are changed. ”

use (CS12..CS10 = 001), the PWM output will not produce any pulse at all, because the up-counting and downcounting values are reached simultaneously. When the prescaler is in use (CS12..CS10 ≠ 001 or 000), the PWM

output goes active when the counter reaches the TOP value, but the down-counting compare match is not i nterpreted to be reached before the next time the counter reaches the TOP-value, making a one- period PWM pulse.”

before changing the Watchdog Timer Prescale Select.”

In the

halted for two clock cycles before the next instruction is executed.” to “When the EEPROM is written, the CPU is

halted for two clock cycles bef ore the next instruction is executed. When the EEPROM is read, the CPU is halted

for four clock cycles before the next instruction is executed.”

EECR” to “4. Write a log ica l one to t he EEMWE bit in EECR (t o be able t o writ e a logic al one to t he EEMWE bit , the

EEWE bit must be written to zero in the same cycle).”

two clock cycles before the next instruction is executed.” to “When EERE has been set, the CPU is halted for four

clock cycles before the next instructi on is executed.”

, add a box containing “+1” as an input to the summation operator.

table 14

EEPROM Read/Write Access

Bit1 - EEWE: EEPROM Write Enable description, change

Bit 0 - EERE: EEPROM Read Enable

, add paragraph “Note: If the compare register contains the TOP value and the prescaler is not in

description,

description,

change

“When the EEPROM is read or written, the CPU is

change

“When EERE has been set, the CPU i s halt ed fo r

“4. Write a logical one to the EEMWE bit in

6-54 In the

6-57 in the

6-59 in the

6-64 in the

6-66 in the

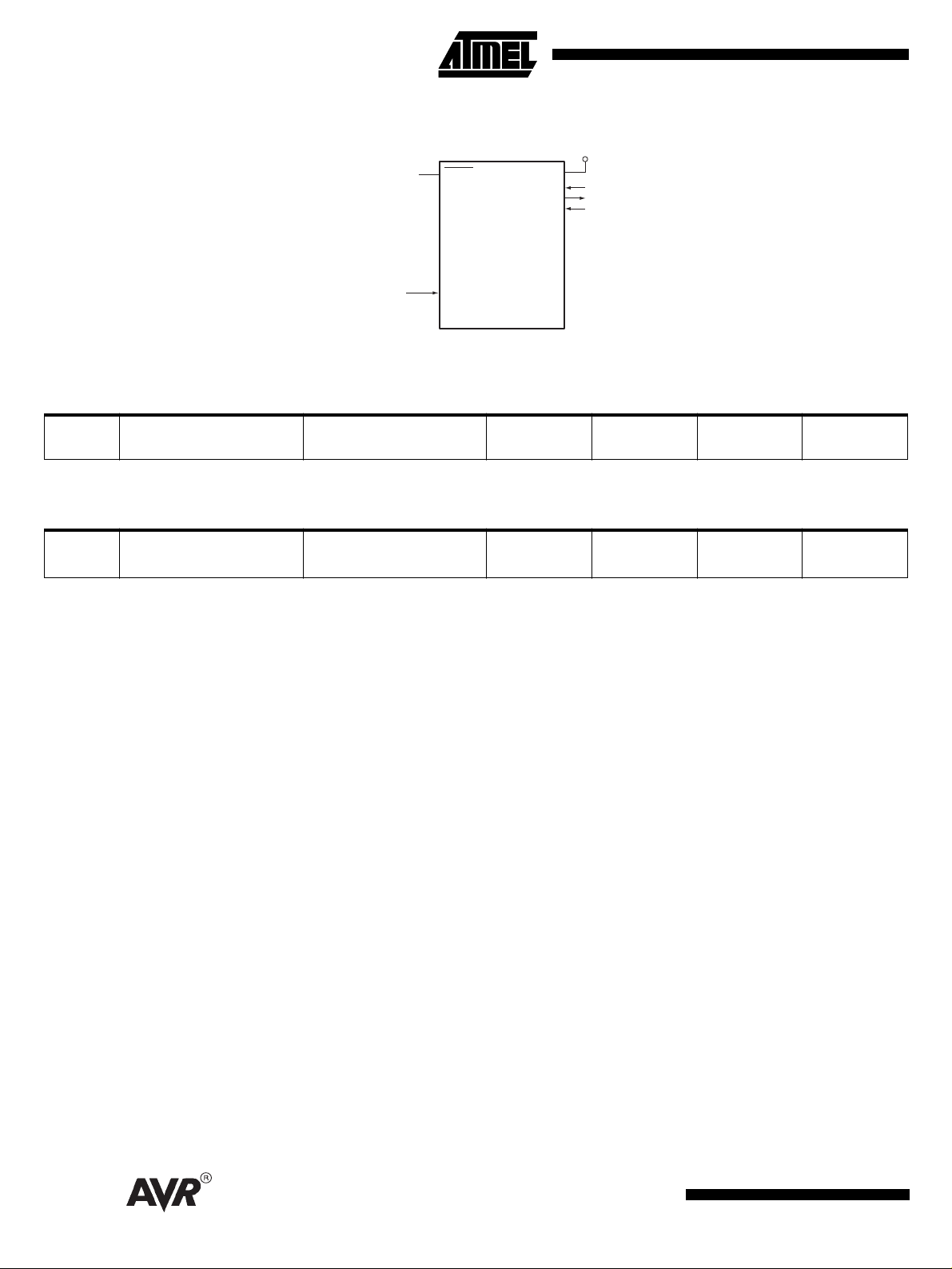

6-79 Replace

Analog Comparator Control and Status Register

“N/A”.

Port A Input Pins Address - PINA

Port B Input Pins Address - PINB

Port C Input Pins Address - PINC

Port D Input Pins Address - PIND

figure 64

description, change the ini tial value of ACO from “0” to

description, change the Initial Values from “Hi-Z” to “N/A”.

description, change the Initial Values from “Hi-Z” to “N/A”.

description, change the Initial Values from “Hi-Z” to “N/A”.

description, change the Initial Values from “Hi-Z” to “N/A”.

by the one below:

11

Page 12

Figure

64 Serial Programming and Verify

6-84: Replace the row below in

V

ACIO

Analog Comparator

Input Offset Voltage

by:

V

ACIO

6-88 In first line of

Analog Comparator

Input Offset Voltage

Typical Characteristics

are not tested during manufacturing.”.

GND

CLOCK INPUT

DC characteristics

AT90S4414/8515

RESET

XTAL1

GND

:

VCC

PB7

PB6

PB5

2.7 - 6.0

SCK

MISO

MOSI

VCC = 5V 40 mV

VCC = 5V

Vin = VCC /2

40 mV

, change “These data are characterized, but not tested.” to “These figures

6-98 In

Register Summary

, replace all “6-6-xx” by “6-xx”.

12

Data Book Updates and Changes

Page 13

Data Book Updates and Changes

AT90S/LS4434 and AT90S/LS8535

The latest data sheet on the web is rev. 1041E-04/99.

The data sheet in the printed dat a b ook is rev. 1041E-04/99.

Changes in the AT90S/LS4434 and AT90S/LS8535 Data Sheet:

Page: Change or Add:

7-6 In “

7-15 In

7-27 In “

7-29 Table 9: remove this note: “Note: When changing the ISC11/ISC10 bi ts, INT1 must be disabled by clearing its Inter-

7-30 In the

7-30 At the end of the

7-36 In “

Pin Descriptions

nected to Vcc via a low-pass filter.” to “This is the supply voltage for Port A and the A/D Convert er. If the ADC is not

used, this pin must be connected to Vcc. If the ADC is used, this pin should be connected to Vcc via a low-pass filter.”

Figure 19

Timer/Counter Inter rupt Flag Regi ster - TIFR

to “Bit 6 - TOV2: T imer /Counter2 Overflow Flag”.

rupt Enable bit in the GIMSK register. Otherwise an interrupt can occur when the bits are changed. ”

Table 10: remove this note: “Note: When changing the ISC01/ISC00 bits, INT0 must be disabled by clearing its

Interrupt Enable bit in the GIMSK register. Otherwise an interrupt can occur when the bits are changed.”

to “Note th at when a level triggered interrupt is use d for wake-up from power down, the low level must be held for a

time longer than the reset delay time- out period t

chronously, Power Down Mode is recom mended instead of Power Save Mode because the contents of the registers in the asynchronous timer should be considered undefined after wake up in Power Save Mode, even if AS2 is

0.”

Timer/Counter Control Register 1B - TCCR1B

set to divide by 8 from “...C-1 | C, 0, 0, 0, 0, 0, 0, 0, 0 | ...” to “...C-1 | C, 0, 0, 0, 0, 0, 0, 0 | ...”

, add a box containing “+1” as an input to the summation operator.

Power Down Mode

”,

Power Save Mode

, change “This is the supply vo ltage f or the A/D Conver ter. It should be externally con -

AVCC

section, replace paragraph 2 (“Note that if a level triggered interrupt... ...on page 7-98.”)

”, change heading “Bit 6 - T OV2: Timer/Counter0 Overflow Flag”

.”

TOUT

section, add the paragraph “If the asynchronous timer is NOT clocked asyn-

”, bit3 -

, change the count sequence when prescaler is

CTC1

7-39 Before

use (CS12..CS10 = 001), the PWM output will not produce any pulse at all, because the up-counting and downcounting values are reached simultaneously. When the prescaler is in use (CS12..CS10 ≠ 001 or 000), the PWM

output goes active when the counter reaches the TOP value, but the down-counting compare match is not i nterpreted to be reached before the next time the counter reaches the TOP-value, making a one- period PWM pulse.”

7-45 Replace last paragraph on page:

“When asynchronous operation is selected, the 32 kHz oscillator for Timer/Counter2 is always running, except in

power down mode. After a power up reset or wake-up from power down, the user should be aware of the fact that

this oscillator might take as long as one second to stabilize. Therefore, the content of all Timer/Counter2 regist ers

must be considered lost after a wake-up from power down, due to the unstable clock signal. The user is advised to

wait for at least one second before usi ng Timer/Counter2 after power-up or wake-up from power down.”

by

“When the asynchronous operation is selected, the 32kHZ oscillator for Timer/Counter2 is always running, except

in power down mode. After a power up reset or wake-up from power down, the user should be aware of the fact

that this osci llator might take as long as one second to stabilize. The user is advised to wait for at least one second

before using Timer/Counter2 after power-up or wake-up from power down. The contents of all Timer /Counter2 reg-

table 16

, add paragraph “Note: If the compare register contains the TOP value and the prescaler is not in

13

Page 14

isters must be co nsidered los t after a wake-up fr om power do wn due to un stab le c lock si gnal upon st art-u p, r egar dless of whether the oscillator is in use or a clock signal is applied to the TOSC pin.”

7-47 In the note for Table 22, add “To avoid unintentional MCU resets, the Watchdog Timer should be disabled or reset

before changing the Watchdog Timer Prescale Select.”

7-49 In the

EECR” to “4. Write a logica l one to the EEMWE bit i n EECR (to be able to wri te a logical one to the EEMWE bit, the

EEWE bit must be written to zero in the same cycle).”

In the

Bit 0 - EERE: EEPROM Read Enable

two clock cycles before the next instruction is executed.” to “When EERE has been set, the CPU is halted for four

clock cycles before the next instruction is executed.”

7-52 Change

Figure 40. SPI Transfer Format with CPHA = 1 and DORD = 0

7-60 In “

Analog Comparator Control and Status Register - ACSR

Bit1 - EEWE: EEPROM Write Enable description

Figure 40

description,

to the figure below.

change

, change “4. Write a logical one to the EEMWE bit in

“When EERE has been set, the CPU i s halt ed f or

”, the initial value of

ACO

is “N/A”.

7-67 In

Figure 50

7-69 In the

7-71 In the

7-76 In the

7-79 In the

7-91 In “

Serial Downloading

Figure 71. Serial Progr amming and Verify

, replace the resistor by a 10 µH inductor. Change capacitor value from 10 nF to 100 nF.

Port A Input Pins Address - PINA

Port B Input Pins Address - PINB

Port C Input Pins Address - PINC

Port D Input Pins Address - PIND

description, change the Initial Values from “Hi-Z” to “N/A” .

description, change the Initial Values from “Hi-Z” to “N/A” .

description, change the Initial Values from “Hi-Z” to “N/A” .

description, change the Initial Values from “Hi-Z” to “N/A” .

”, replace Figure 71 by the fig ure below.

VCC

PB7

PB6

PB5

2.7 - 6.0V

SCK

MISO

MOSI

CLOCK INPUT

GND

AT90S4434/8535

RESET

XTAL1

GND

14

Data Book Updates and Changes

Page 15

Data Book Updates and Changes

7-96 Replace the row bel ow in

V

ACIO

Analog Comparator

Input Offset Voltage

DC characteristics

VCC = 5V 40 mV

:

by:

V

ACIO

Analog Comparator

Input Offset Voltage

7-98 In first l ine of

Typical Characteristics

VCC = 5V

Vin = VCC /2

40 mV

, change “These data are characterized, but not tested.” to “These figures

are not tested during manufacturing.”.

7-109 In Register Summary, replace all “7-page” by “page”. In addition, replace “page 7-337-” by “page 7-33”, “page 7-

377-” by “page 7-37”, “page 7-387-” by “page 7-38”, “page 7-467-” by “page 7-46”, “page 7-487-” by “page 7-48”.

15

Page 16

AT90C8534

The latest data sheet on the web is rev. 1229A-04/99.

The data sheet in the printed data book is rev. 1229A-04/99.

Changes in the AT90C8534 Data Sheet:

Page: Change or Add:

8-5 In “

8-16 In Figure 19, add a box containin g “+1” as a n input to the summation operator.

8-26 At the end of the

8-31 In the

8-32 In the

Pin Descriptions

connected to Vcc via a low-pass filter.” to “This is the supply voltage for the A/D Converter. If the ADC is not used,

this pin must be connected to Vcc. If the ADC is used, this pin should be connect ed to Vcc via a low-pass filter.”

can occur. Therefore, it is recommended to first disable INT1 by clearing its Interrupt Enable bit in the GIMSK register. Then, the ISC1 bit can be changed. Finally, the INT1 interrupt flag should be cleared by writing a logical one

to its Interrupt Flag bi t in the GIFR register before the interrupt is re-enabled.”

At the end of the

can occur. Therefore, it is recommended to first disable INT0 by clearing its Interrupt Enable bit in the GIMSK register. Then, the ISC0 bit can be changed. Finally, the INT0 interrupt flag should be cleared by writing a logical one

to its Interrupt Flag bi t in the GIFR register before the interrupt is re-enabled.”

EEPROM Read/Write Access

halted for two clock cycles before the next instruction is executed.” to “When the EEPROM is written, the CPU is

halted for two clock cycles before the next instruction is executed. When the EEPROM is read, the CPU is halted

for four clock cycles before the next instruction is executed.”

Bit1 - EEWE: EEPROM Write Enable description

EECR” to “4. Write a logica l one to the EEMWE bit i n EECR (to be able to wri te a logical one to the EEMWE bit, the

EEWE bit must be written to zero in the same cycle).”

In the

Bit 0 - EERE: EEPROM Read Enable

two clock cycles before the next instruction is executed.” to “When EERE has been set, the CPU is halted for four

clock cycles before the next instruction is executed.”

”,

AV CC, change

Interrupt Sense Control 1

Interrupt Sense Control 0

“This is the supply voltage for the A/D Converter. It should be externally

description,

description,

description add this text: “When changing the ISC1 bit, an interrupt

description add this text: “When changing the ISC0 bit, an interrupt

change

“When the EEPROM is read or written, the CPU is

, change “4. Write a logical one to the EEMWE bit in

change

“When EERE has been set, the CPU i s halt ed f or

16

Data Book Updates and Changes

Page 17

Data Book Updates and Changes

ATtiny10/11/12

The latest data sheet on the web is rev. 1006B-10/99.

The data sheet in the printed dat a b ook is rev. 1006A-04/99.

Changes in the ATtiny10/11/12 Data Sheet on the web:

Page: Change or Add:

27 Table 13: remove this note: “Note: When changing the ISC01/ISC00 bits, INT0 must be disabled by clearing its

Interrupt Enable bit in the GIMSK register. Otherwise an interrupt can occur when the bits are changed.”

In the first paragraph of

“On wake-up from Power Down Mode on pin change, the two instructions following SLEEP are executed before

the pin change interrupt routine.

by

“On wake-up from Power Down Mode on pi n change, 2 i nstruc ti on cycle s are ex ecuted bef ore the pi n chang e inter -

rupt flag is updated. During these cycles, the processor executes instructions, but the interrupt condition is not

readable, and the interrupt routine has not started yet.

32 In the note for Table 16, add “To avoid unintentional MCU resets, the Watchdog Timer should be disabled or reset

33 In the last sentence of the first paragra ph, chan ge “When the EEPROM is read or writt en, the CPU is halted for two

clock cycles before the next instruction is executed.” to “When the EEPROM is written, the CPU is halted for two

clock cycles before the next instruction is executed. When the EEPROM is read, the CPU i s halted for four clock

cycles before the next instruction is executed.”

In the

EEPROM Control Register

34 In the

Bit 0 - EERE: EEPROM Read Enable

two clock cycles before the next instruction is executed.” to “When EERE has been set, the CPU is halted for four

clock cycles before the next instructi on is executed.”

Sleep modes for the ATtiny10/11

description, change the in itial value of EEWE from “0” to “X”.

description,

section, replace the sent ence

change

“When EERE has been set, the CPU i s halt ed fo r

Changes in the ATtiny10/11/12 section in the data book

Page: Change or Add:

9-3 In both

9-14 In Figure 12, add a box containing “+1” a s an input to the summation operator.

9-24 In the first line of the

In Figure 22, change “1 XTAL Cycle” to “1 CK Cycle”.

9-29 Table 13: remove this note: “Note: When changing the ISC01/ISC00 bits, INT0 must be disabled by clearing its

Interrupt Enable bit in the GIMSK register. Otherwise an interrupt can occur when the bits are changed.”

In the first paragraph of

Pin Configuration

figures, replace RESET with RESET

Watchdog Reset

Sleep modes for the ATtiny10/11

section, change “1 XTAL cycle” to “1 CK cycle”.

.

section, replace the sent ence

17

Page 18

“On wake-up from Power Down Mode on pin change, the two instructions following SLEEP are executed before

the pin change interrupt routine.

by

“On wake-up from Power Down Mode on pin chan ge, 2 i nstruc tion cy cle s are execut ed before the pi n change int er-

rupt flag is updated. During these cycles, the processor executes instructions, but the interrupt condition is not

readable, and the interrupt routine has not started yet.

9-34 In the note for Table 15, add “To avoid unintentional MCU resets, the Watchdog Timer should be disabled or reset

before changing the Watchdog Timer Prescale Select.”

In the first paragraph of

ATtiny12 Calibrated Internal RC Oscillator

section, add “For details on how to use the

pre-programmed calibration value, see the section ‘Calibrati on Byte in ATtiny12’ on page 9-42.

In the second paragraph, add “The calibrated oscillator is used to time EEPROM access. If EEPROM is written, do

not calibrate to m ore than 10% above the nominal frequency. Otherwise, the EEPROM write may fail. Table 1

shows the range for OSCCAL. Note that the Oscillator is intended for calibration to 1.0MHz, thus tuning to other

values is not guaranteed.

Table 1.

Internal RC Oscillator Frequency Range.

OSCCAL value Min. Frequency Max Frequency

$00 0.5MHz 1.0MHz

$7F 0.7MHz 1.5MHz

$FF 1.0MHz 2.0MHz

9-35 In the second line, change “The write access time is in the range of 2.5 - 4ms, depending on the V

time is in the range of 1.9 - 3.4ms, depending on the frequency of the calibrated RC oscillator.”

In the last sentence of the first paragra ph, chan ge “When the EEPROM is read or writt en, the CPU is halted for two

clock cycles before the next instruction is executed.” to “When the EEPROM is written, the CPU is halted for two

clock cycles before the next instruction is executed. When the EEPROM is read, the CPU is halted for four clock

cycles before the next instruction is executed.”

In the

EEPROM Control Register

9-36 In the 14th line, remove “(typically 2.5ms at V

description, change the initial value of EEWE from “0” to “X”.

= 5V or 4 ms at V

CC

= 2.7V)”

CC

.” to “The write access

CC

In the

Bit1 - EEWE: EEPROM Write Enable description

EECR” to “4. Write a logica l one to the EEMWE bit i n EECR (to be able to wri te a logical one to the EEMWE bit, the

EEWE bit must be written to zero in the same cycle).”

In the

Bit 0 - EERE: EEPROM Read Enable

two clock cycles before the next instruction is executed.” to “When EERE has been set, the CPU is halted for four

clock cycles before the next instruction is executed.”

9-37 In the

Analog Comparator Control and Status Register

“N/A”.

9-39 In the

Port B Input Pins Address - PINB

9-40 In the first li ne of section

Port B pins are connected to a p in ch ange detect or t hat can t rigger the pin ch ange i nterr upt. See ‘ Pin Change Int er rupt’ on page 9-28 for detai ls. In addition, Port B has the following alternate functi ons:”.

18

Data Book Updates and Changes

description,

description, change the Initial Value of bits 0-5 from “Hi-Z” to “N/A”.

Alternate Functions of Port B

, change “4. Write a logical one to the EEMWE bit in

change

“When EERE has been set, the CPU i s halt ed f or

description, change the initial value of ACO from “0” to

, change “The alternate pin functions of Port B are:” to “All

Page 19

Data Book Updates and Changes

9-42 In the section

Calibration Byte in ATtiny12

, add “At start-up, the user software must read this flash location and

write the value to the OSCCAL register.”

In the section

ATtiny10/11

, change “The +12V is used for programming enable only, and no current of significance is

drawn by this pin.” to “Only minor currents (<1mA) are drawn from the +12V pin during programming.”.

9-44 In Table 21, remove the entire first row. In the first cell of the second row, remove “(ATtiny12)”.

9-45 In the note on the bottom of the page, change “9, 6 = RSTISBL Fuse” to “9, 6 = RSTDISBL Fuse”.

9-46 In Table 22, remove the “t

WLWH_CE

“row.

In Figure 30, remove “CLOCK INPUT”, “PB3 (XTAL1)” and the arrow connecting them.

9-47 In the sixth line, change “Either an external clock is supplied at pin XTAL1 or a crystal needs to be connected

across pins XTAL1 and XTAL2” to “The device can be clocked by any clock option during Low-Voltage Serial Programming.”.

In the two last lines of the fir st paragraph, change “2 XTAL clock cycles” to “2 CK clock cycles” .

In the first entr y of the

Low-Voltage Serial Programming Algorithm

, change “If a crystal is not connected across

pins XTAL1 and XTAL2, apply a clock signal to the XTAL1 pin.” to “I n accordance with the setting of CKSEL fuses,

apply a crystal/resonator, external clock or RC network, or let the device run on the internal RC oscillator.”.

In the fifth entry, change the fir st “t

and t

WD_EEPROM

”.

WD_PROG

” to “t

WD_FLASH

or t

WD_EEPROM

”. Change the second “t

WD_PROG

” to “t

WD_FLASH

9-48 In the

“t

WD_PROG

Data Polling

” to “t

section, change the first “t

WD_EEPROM

”.

WD_PRO G

9-50 Replace Table 25 and Table 26 with these tables:

Symbol Minimum Wait Delay

t

WD_ERASE

Symbol Minimum Wait Delay

t

WD_FLASH

t

WD_EEPROM

9-52 In the

Symbol Parameter Condit ion Min Typ Max Units

I

CC

DC Characteristics

Power Supply Current

table, replace

Active 4MHz, V

Idle 4MHz, V

Power Down

3V, WDT enabled

Power Down

3V. WDT disabled

CC

(5)

(5)

” to “t

WD_FLA SH

or t

WD_EEPROM

”. Change the second and third

3.4 ms

1.7 ms

3.4 ms

= 3V 3.0 mA

CC

= 3V 1.0 1.2 mA

, V

=

, V

CC

CC

=

9.0 15

<1 2

µ

A

µ

A

19

Page 20

Symbol Parameter Condition Min Typ Max Units

Vacio

Iaclk

Tacpd

Analog Comp

Input Offset V

Analog Comp

Input leakage A

Analog Comp

Propagation Del.

VCC = 5V 40 mV

VCC = 5V

VIN = VCC/2

VCC = 2.7V

VCC = 4.0V

-50 50 nA

750

500

with

Symbol Parameter Condition Min Typ Max Units

Active 1MHz, V

(A Ttiny1 2V)

Active 2MHz, V

(ATtiny10/11L)

Active 4MHz, V

(ATtiny12L)

Active 6MHz, V

(A Ttiny1 0/11)

Active 8MHz, V

(ATtiny12)

Idle 1MHz, V

(AT tiny12V)

I

CC

Power Supply Current

Idle 2MHz, V

(ATtiny10/11L)

Idle 4MHz, V

(ATtiny12L)

CC

CC

CC

= 3V

CC

= 3V

CC

= 3V

CC

= 5V

CC

= 5V

CC

= 3V

= 3V

= 3V

TBD mA

TBD mA

3.0 mA

TBD mA

TBD mA

TBD mA

TBD mA

1.0 1.2 mA

ns

V

ACIO

I

ACLK

T

ACPD

Analog Comparator

Input Offset Voltage

Analog Comparator

Input Leakage Current

Analog Comparator

Propagation Delay

Idle 6MHz, V

CC

= 5V

(AT tiny10/11)

Idle 8MHz, V

CC

= 5V

(ATtiny12)

Power Down

(5)

, V

3V, WDT enabled

Power Down

(5)

, V

3V. WDT disabled

VCC = 5V

VIN = VCC/2

VCC = 5V

VIN = VCC/2

VCC = 2.7V

VCC = 4.0V

CC

CC

TBD mA

TBD mA

=

=

9.0 15

<1 2

µ

A

µ

A

40 mV

-50 50 nA

750

500

ns

20

Data Book Updates and Changes

Page 21

Data Book Updates and Changes

9-53 In the first table, change the title from “External Clock Drive” to “External Clock Dri ve ATtiny12” and add this table:

External Clock Drive ATtiny10/11

VCC = 2.7V to 4.0V VCC = 4.0V to 5.5V

Symbol Parameter

1/t

CLCL

t

CLCL

t

CHCX

t

CLCX

t

CLCH

t

CHCL

Oscillator Frequency 0206MHz

Clock Period 500 167 ns

High Time 200 67 ns

Low Time 200 67 ns

Rise Time 1.6 0.5

Fall Time 1.6 0.5

UnitsMin Max Min Max

s

µ

s

µ

9-54 In the first l ine, change “These data are characterized, but not tested.” to “These figures are not tested during manufactur-

ing.”.

9-72 In row 12 (MCUSR) of the table, change “WDTR” to “WDRF” and “BODR” to “BORF”.

21

Page 22

ATtiny15L

The latest data sheet on the web is rev. 1187B-11/99.

The data sheet in the printed data book is rev. 1187A-06/99.

Changes in the ATtiny15L Data Sheet on the web:

None.

Changes in the ATtiny15L section in the data book:

The data sheet for ATtiny15 has gone through serious imp rovements and corrections since the printi ng of the “AVR

RISC MICROCONTROLLER DATA BOOK AUGUST 1999”. The user is advised to download the complete new

ATtiny15 data sheet from the Web, since correcti ng the present data book would not give a user friendly result.

22

Data Book Updates and Changes

Page 23

Data Book Updates and Changes

ATtiny22/22L

The latest data sheet on the web is rev. 1273A-04/99.

The data sheet in the printed dat a b ook is rev. 1273A-04/99.

Changes in the ATtiny22/22L Data Sheet:

Generally: The external clock option does not exist in ATtiny22/L. Therefore, all references to the RCEN fuse and external

clock are wrong, and the part comes as ATtiny22L only, not ATtiny22.

Page: Change or Add:

All For all “ATtiny22/L” read “ATtiny22L”.

11-3 In the feature list, replace the following lines

•

Special Microcontroller Features

–...

– Selectable On-chip RC Oscillator

•

Power Consumption at 4 MHz, 3V, 25°C

– Active: 2.4 mA

– Idle Mode: 0.5 mA

– Power Down Mode: <1 µA

•

Operating Voltages

– 2.7 - 6.0V (ATtiny22L )

– 4.0 - 6.0V (ATtiny22)

•

Speed Grades

– 0 - 4 MHz (ATtiny22L)

– 0 - 8 MHz (ATtiny22)

by the following description;

•

Special Microcontroller Features

–...

– On-chip RC Oscillator

•

Power Consumption at 3V, 25°C

– Active: 1.5 mA

– Idle Mode: 100µA

– Power Down Mode: <1 µA

•

Operating Voltages

– 2.7 - 6.0V

•

Speed Grade

– Internal Oscillator ~1MHz@5.0V

11-3 Replace

Pin Configuration

by the figure shown below.

RESET

PB3

PB4

GND

1

2

3

4

8

7

6

5

VCC

PB2 (SCK/T0)

PB1 (MISO/INT0)

PB0 (MOSI)

23

Page 24

11-5 In the

“Port B is a 5-bit bi-directional I/O port with internal pull-up resistors. The Port B output buffers can sink 20 mA. As

inputs, Port B pins that are externally pulled low, will source current if the pull -up resistors are activated.

Port B also serves the functions of various special features.

Port pins can provide internal pull-up resistors (selected for each bit). The port B pins are tri-stated when a reset

condition becomes acti ve.”

Pin Descriptions ATtiny22/L

replace the descript ion for

Port B (PB4..PB0)

by

11-5 Remove the description “CLOCK” under

11-5 The whole section “

“

Clock Source

Clock options

Pin Descriptions ATtiny22/L.

“ including Figure 2 should be replaced by

The ATtiny22L is clocked by an on-chip RC oscillator. This RC oscillator runs at a nominal frequency

of 1 MHz (VCC = 5V).“

11-16 In Figur e 18, add a box containing “+1” as an input to the summation operator.

11-16 Replace second paragraph under

Memory Access and Instruction Execution Timing

, “The AV R C P U is drive n

by the System Clock Ø, directly generated from the external clock signal applied to the CLOCK pin.” by “The AVR

CPU is driven by the System Clock Ø, directly gener ated from the internal RC oscilla tor . “

11-21 In Power-On Reset, replace the first paragraph; ”The ATtiny22/L is designed for use in systems where it can oper-

ate from the internal RC oscillator or in applications where a clock signal is provided by an external clock source.

After V

by an external clock source, the clock must not be applied until V

has reached V

CC

, the device will start after the time t

POT

(see Figure 23). If the clock signal is provided

TOUT

has reached the minimum voltage defined for

CC

the applied frequency. “ by “The ATtiny22L is desig ned f or use in sys tems where i t can o perat e from th e inte rnal RC

oscillator. After V

has reached V

CC

, the device will start after the time t

POT

(see Figure 23).”

TOUT

11-23 In the first paragraph of Watchdog Reset, replace “When the Watchdog times out, it will generate a short reset

pulse of 1 CPU cycle duration.” by “When the Watchdog times out, it will generate a short reset pulse of 1 clock

cycle duration.”

11-27 Table 7: remove thi s no te: “Not e: When ch angi ng the ISC01/ISC00 bi ts, I NT0 must be disabl ed by cl earing its Int er -

rupt Enable bit in the GIMSK registe r. Otherwise an interrupt can occur when the bits are changed. ”

11-31 In the note for Table 9, add “To avoid unintentional MCU resets, the Watchdog Timer should be disabled or reset

before changing the Watchdog Timer Prescale Select.”

11-32 In line num ber 6, replace “When the EEPROM is read or written, the CPU is halted for two clock cycles before the

next instruction is executed.” by “When the EEPROM is written, the CPU is halted for two clock cycles before the

next instruction is executed. When it is read, the CPU is halted for 4 clock cycles.”.

11-33 In the

Bit1 - EEWE: EEPROM Write Enable description

, change “4. Write a logical one to the EEMWE bit in

EECR” to “4. Write a logica l one to the EEMWE bit i n EECR (to be able to wri te a logical one to the EEMWE bit, the

EEWE bit must be written to zero in the same cycle).”

In the

Bit 0 - EERE: EEPROM Read Enable

description,

change

“When EERE has been set, the CPU i s halt ed f or

two clock cycles before the next instruction is executed.” to “When EERE has been set, the CPU is halted for four

clock cycles before the next instruction is executed.”

11-34 In Table 10, remove the entry for PB3.

11-34 In the

Port B Input Pins Address - PINB

description, change the Initial Values of bits 0-4 from “Hi-Z” to “N/A”.

11-35 Remove sect ion, CLOCK - Port B, Bit 3.

24

Data Book Updates and Changes

Page 25

Data Book Updates and Changes

11-35 Replace the section name “MISO - Port B, Bit 1” by “MISO/INT0 - Port B, Bit 1”

11-36 In section Fuse Bits, replace the first sentence; “The ATtiny22/L has two Fuse bits, SPIEN and RCEN.” by “The

ATtiny22L has one Fuse bit, SPIEN.”, and re mov e the second bullet item which is a description of the RCEN fuse.

11-37 In Table 13, delete one of the rows saying

ATtiny22/L 2.7 - 6.0V 4.5 - 5.5V

11-37 In

11-37 In

High-Voltage Serial Programming Algorithm

between V

Apply 12V to RESET

and GND. Set RESET and PB0 to “0” and wait at least 100 ns. Set PB3 to “0”. Wait at least 4µs.

CC

and wait at least 100 ns before changing PB0. Wait 8 µs before giving any instructions.”

High-Voltage Serial Programming Algorithm

11-38 In Figure 31, r eplace “XTAL1/PB3” by “PB3”.

11-38 In table 14, replace the entries

Write Fuse bits PB0

PB1

PB2

Read Fuse and

Lock bits

PB0

PB1

PB2

0_0100_0000_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_0000_0100_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_11S1_111R_00

0_0010_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1000_00

x_xxxx_xxxx_xx

by the entries (Note: For Read Fuse and Lock bits; Bit 7 in the 4’th and 5’th column for PB1 have been inverted

compared to the origi nal data book.

Write Fuse bit PB0

PB1

PB2

Read Fuse and

Lock bits

PB0

PB1

PB2

0_0100_0000_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_0000_0100_00

0_0100_1100_00

x_xxxx_xxxx_xx

0_11S1_1110_00

0_0010_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0111_1000_00

x_xxxx_xxxx_xx

, replace item 1 by “Power-up sequence: Apply 4.5 - 5.5V

, replace in item 5 “Set PB5 to “1”.” by “Set RESET

0_0000_0000_00

0_0110_0100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1100_00

S

xx_xxRx_xx

1_2

0_0000_0000_00

0_0110_0100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0111_1100_00

S

xx_xx0x_xx

1_2

0_0000_0000_00

0_0110_1100_00

x_xxxx_xxxx_xx

0_0000_0000_00

0_0110_1100_00

x_xxxx_xxxx_xx

Wait

t

WLWH_PFB

Write Fuse bits cycle to finish. Set S,

= “0” to program, “1” to unprogram.

Reading 1, 2, S, R = “0” means the

Fuse/Lock bit is programmed.

Wait

t

WLWH_PFB

Write Fuse bit cycle to finish. Set S =

“0” to program, “1” to unprogram.

Reading 1, 2, S= “0” means the

Fuse/Lock bit is programmed.

to “0”.”

after Instr.3 for the

after Instr.3 for the

R

R

and delete the note “

= RCEN Fuse

“ to this table.

11-40 In figure 33, remove “CLOCK INPUT”, “XTAL1/PB3” and the arrow connecting them.

11-40 In last paragraph, replace “Either an external clock is applied to the XTAL1/PB3 pin or the device must be clocked

from the internal RC-oscillator.” by “The device is clocked from the internal RC-oscillator.”

11-41 In item “1. Power-up sequence”, replace “RESET” by “RESET

” (two occurrences) and delete “If the device is programmed for external clocking, apply a 0 to 8 MHz clock to the PB3 pin. If the internal RC oscillator is selected as

the clock source, no external cl ock source needs to be applied.”

11-43 In table 17, replace the entries

Read Lock and

Fuse Bits

Write RCEN Bit

0101 1000 xxxx xxxx xxxx xxxx

12

Sx xxxR

1010 1100 1011 111R xxxx xxxx xxxx xxxx

Read Lock and Fuse bits. ‘0’ =

programmed, ‘1’ = unprogrammed.

Write RCEN Fuse. Set bit R = ‘0’ to

program, ‘1’ to unprogram.

(1)

25

Page 26

by the entry (Remove the entry “Write RCEN Bit”):

Read Lock and

Fuse Bit

0101 1000 xxxx xxxx xxxx xxxx

and remove the notes “R = RCEN Fuse” and “When the state of the RCEN bit is changed, the device must be

power cycled for the changes to have any effect.”

11-44 Above Table 18, add “The per i od of th e i nternal RC oscil lator - t

11-45 In

I

CC

acteristics”, and delete the entries for 1/t

(VCC = 4.0 - 6.0V ),.

t

CLCL

DC Characteristics

Power Supply Current Active 4 MHz, VCC = 3V 3.0 mA

, replace the entries:

Idle 4 MHz, VCC = 3V 1.1 mA

Power Down 4 MHz

VCC = 3V WDT Enabled

Power Down 4 MHz

VCC = 3V WDT Disabled

CLCL(VCC

= 2.7 - 4.0V),

(2)

,

(2)

,

by the entries

12

Sx xxx0 Read Lock and Fuse bit. ‘0’ =

programmed, ‘1’ = unprogrammed.

is voltage depend ent as sho wn in “Typical char-

CLCL

(VCC = 2.7 - 4.0V),

t

CLCL

(VCC = 4.0 - 6.0V),

1/t

CLCL

25.0 µA

20.0 µA

I

CC

11-46 Remove the sections

11-46 In first line of

Power Supply Current Active, VCC = 3V 1.5 mA

Idle, VCC = 3V 100 µA

Power Down,

VCC = 3V WDT Enabled

Power Down,

VCC = 3V WDT Disabled

External Clock Drive Waveforms

Typical Characteristics

are not tested during manufacturing.”

and

External Clock Drive

, change “These data are characterized, but not tested.” to “These figures

.

25.0 µA

20.0

.

µA

11-46 For last sentence in second paragraph of the secti on Typical Characteristics, replace “The dominating factors are

the operating voltage and frequency“ by “The dominating factor is the operating voltage, as the frequency of

ATtiny22L is also a functi on of the operating voltage .

”

11-47 Remove Figure 37 and Figure 38

11-48 Remove Figure 40

11-49 Remove Figure 41

11-56 In Register Summ ary, replace all “11-page” by “page”. In addition, for TIMSK; replace ”page 11-15” by “page 11-

25”, for TIFR; replace “page 11-16” by “page 11-26”, for MCUCR; replace “page 11-16” by “page 11-26”, for

MCUSR; replace “page 11-14” by “page 11-24”

26

Data Book Updates and Changes

Page 27

Data Book Updates and Changes

11-56 In Register Summary, replace

$21 ($41) WDTCR - - -

by

$21 ($41) WDTCR

- - -

11-57 In Instruction Set Summary under BRANCH INSTRUCTIONS, replace

CPSE Rd,Rr Compare, Skip if Equal if (Rd = Rr) PC

SBRC Rr, b Skip if Bit in Register Cleared if (Rr(b)=0) PC

SBRS Rr, b Skip if Bit in Register is Set if (Rr(b)=1) PC

SBIC P, b Skip if Bit in I/O Register Cleared if (P(b)=0) PC

SBIS P, b Skip if Bit in I/O Register is Set if (R(b)=1) PC

by

CPSE Rd,Rr Compare, Skip if Equal if (Rd = Rr) PC

SBRC Rr, b Skip if Bit in Register Cleared if (Rr(b)=0) PC

SBRS Rr, b Skip if Bit in Register is Set if (Rr(b)=1) PC

SBIC P, b Skip if Bit in I/O Register Cleared if (P(b)=0) PC

SBIS P, b Skip if Bit in I/O Register is Set if (R(b)=1) PC

WDTO

WDTOE

WDE WDP2 WDP1 WDP0 Page 11-30

WDE WDP2 WDP1 WDP0 Page 11-30

PC + 2 or 3 None 1 / 2

←

PC + 2 or 3 None 1 / 2

←

PC + 2 or 3 None 1 / 2

←

PC + 2 or 3 None 1 / 2

←

PC + 2 or 3 None 1 / 2

←

PC + 2 or 3 None 1 / 2 / 3

←

PC + 2 or 3 None 1 / 2 / 3

←

PC + 2 or 3 None 1 / 2 / 3

←

PC + 2 or 3 None 1 / 2 / 3

←

PC + 2 or 3 None 1 / 2 / 3

←

11-59 Replace the

Ordering Information

“

Power Supply Speed (MHz) Ordering Code Package Operation Range

2.7 - 6.0V 4 ATtiny22L-4PC

ATtiny22L-4SC

ATtiny22L-4PI

ATtiny22L-4SI

4.0 - 6.0V 8 ATtiny22-8PC

ATtiny22-8SC

ATtiny22-8PI

ATtiny22-8SI

8P3

8S2

8P3

8S2

8P3

8S2

8P3

8S2

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Note: The speed grade refers to m a ximum clock rate when using an external clock drive. The internal RC oscillator has the same

nominal clock frequency for all speed grades.”

by the following

Ordering Information

“

Power Supply Speed (MHz) Ordering Code Package Operation Range

2.7 - 6.0V Internal Osc.

~1MHz@5.0V

ATtiny22L-1PC

ATtiny22L-1SC

ATtiny22L-1PI

ATtiny22L-1SI

8P3

8S2

8P3

8S2

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

“

27

Page 28

ATtiny28L /V

The latest data sheet on the web is rev. 1062B-10/99.

This data sheet is not in the printed data book.

Changes in the ATtinyL /V Data Sheet on the web:

None.

28

Data Book Updates and Changes

Page 29

ATmega161/161L

The latest data sheet on the web is rev. 1228A-08/99.

The data sheet in the printed dat a b ook is rev. 1228A-05/99.

Changes in the ATmega161/161L data sheet:

Page: Change or Add:

Data Book Updates and Changes

12-25 Add the following note below

table 2

: “note: if BOOTRST fuse is programmed, the reset vector is located on pro-

gram address $1e00, see table 38 on page 12-98 for details”.

Add this code example below the existing

code example

:

When the BOOTRST fuse is programmed, the most typical and general program setup for the Reset and Interrupt Vector

Addresses are:

Address Labels Code Comments

.org $002 ; Reset is located at $1e000

$002 jmp EXT_INT0 ; IRQ0 Handler

$004 jmp EXT_INT1 ; IRQ1 Handler

$006 jmp EXT_INT2 ; IRQ2 Handler

$008 jmp TIM2_COMP ; Timer2 Compare Handler

$00a jmp TIM2_OVF ; Timer2 Overflow Handler

$00c jmp TIM1_CAPT ; Timer1 Capture Handler

$00e jmp TIM1_COMPA ; Timer1 CompareA Handler

$010 jmp TIM1_COMPB ; Timer1 CompareB Handler

$012 jmp TIM1_OVF ; Timer1 Overflow Handler

$014 jmp TIM0_COMP ; Timer0 Compare Handler

$016 jmp TIM0_OVF ; Timer0 Overflow Handler

$018 jmp SPI_STC; ; SPI Transfer Complete Handler

$01a jmp UART_RXC0 ; UART0 RX Complete Handler

$01c jmp UART_RXC1 ; UART1 RX Complete Handler

$01e jmp UART_DRE0 ; UDR0 Empty Handler

$020 jmp UART_DRE1 ; UDR1 Empty Handler

$022 jmp UART_TXC0 ; UART0 TX Complete Handler

$024 jmp UART_TXC1 ; UART1 TX Complete Handler

$026 jmp EE_RDY ; EEPROM Ready Handler

$028 jmp ANA_COMP ; Analog Comparator Handler

;

$02a MAIN: ldi r16,high(RAMEND); Main program start

$02b out SPH,r16

$02c ldi r16,low(RAMEND)

$02d out SPL,r16

$02e <instr> xxx

;

.org $1e00

$1e00 jmp RESET ; Reset handler

… … … …

29

Page 30

12-35 Table 7: remove this note: “Note: W hen changing th e ISC11/ISC10 bits, INT1 must be disable d by clea ring it s Inter -

rupt Enable bit in the GIMSK registe r. Otherwise an interrupt can occur when the bits are changed. ”

Table 8: remove this note: “Note: W hen ch anging the ISC01/ ISC00 bit s, IN T0 must be dis abled by cl ear ing it s Inter -

rupt Enable bit in the GIMSK registe r. Otherwise an interrupt can occur when the bits are changed. ”

At the end of the

can occur. Therefore, it is recommended to first disable INT2 by clearing its Interrupt Enable bit in the GIMSK register. Then, the ISC2 bit can be changed. Finally, the INT2 interrupt flag should be cleared by writing a logical one

to its Interrupt Flag bi t in the GIFR register before the interrupt is re-enabled.”

12-36 At the end of the

chronously, Power Down Mode is recomm ended instead of Power Save Mode because the contents of the registers in the asynchronous timer should be considered undefined after wake up in Power Save Mode even if AS2 is

0.”

12-46

Replace

“When asynchronous operation is selected, the 32 kHz oscillator for Timer/Counter2 is always running, except in power down

mode. After a power up reset or wake-up from power down, the user should be aware of the fact that this oscillator might take

as long as one second to stabilize. Therefore, the content of all Timer/Counter2 registers must be considered lost after a wakeup from power down, due to the unstable clock signal. The user is advised to wait for at least one second before using

Timer/Counter2 after power-up or wake-up from power down.”

by

“When the asynchronous operation is select ed, the 32 kHZ oscillator for Timer/Counter2 is always running, except in power

down mode. After a power up reset or wake-up from power down, the user should be aware of the fact that this oscillator

might take as long as one second to stabilize. The user is advised to wait for at least one second before using Timer/Counter2

after power-up or wake-up from power down. The contents of all Timer/Counter2 registers must be considered lost after a

wake-up from power down due to unstable clock signal upon start-up, regardless of whether the oscillator is in use or a clock

signal is applied to the TOSC pin.”

last paragraph on page,

Interrupt Sense Control 2

Power Save Mode

section, add the paragraph “If the asynchronous timer is NOT clocked asyn-

description add this text: “When changing the ISC2 bit, an interrupt

12-55 In the note for Table 20, add “To avoid unintentional MCU resets, the Watchdog Timer should be disabled or reset

before changing the Watchdog Timer Prescale Select.”

12-56 In the

range of 2.5 - 4 ms, depending on the Vcc voltages” by “The write access time is in the range of 1.9 - 3.4 ms,

depending of the frequency of the RC oscil lator used to time the EEPROM access time. See table 21 for details.”

In the last sent ence of the

ten, the CPU is halted for two clock cycles before the next instruction is executed.” by “When the EEPROM is written, the CPU is halted for two clock cycles bef ore the next instruction is executed. When the EEPROM is read, the

CPU is halted for four clock cycles before the next instr uction is executed.”

In the

12-57 In the description of

Vcc = 5V or 4 ms at Vcc = 2.7V) has elapsed, “ by “When the write access t ime has elapsed, “

In the

EECR” to “4. Write a logica l one to the EEMWE bit i n EECR (to be able to wri te a logical one to the EEMWE bit, the

EEWE bit must be written to zero in the same cycle).”

Under “

and will not be subject to corruption.” by “Flash memory can not be updated by the CPU unless the boot loader

software supports wri ting t o the FLASH and the Boot Lock bi ts are conf igured so th at writ ing to the FLASH memory

from CPU is allowed. See Boot Loader Support on page 12-98 for details.”

EEPROM Read/Write Access

EEPROM Control Register

Bit1 - EEWE: EEPROM Write Enable description

Prevent EEPROM corruption

EEPROM Read/Write Access

bit 1 - EEWE

description,

description, change the initial value of EEWE from “0” to “X”.

: EEPROM write Enable, replace “When the write access time (typical ly 2.5 ms at

”, note 3

replace

replace

the second sentence “The write access time is in the

description,

, change “4. Write a logical one to the EEMWE bit in

the text: “Flash m emory can not be updated by the CPU,

replace

“When the EEPROM is read or writ-

30

Data Book Updates and Changes

Page 31

Add the text and table below to the EEPROM Read/Write section:

“An RC-oscillator is used to time EEPROM write access. In table 21 is the typical programming time listed for

EEPROM access from CPU.”

Table 21:

Data Book Updates and Changes

Symbol

EEPROM

write (from

CPU)

Note: See “Typical characteristics” to find typical RC-osc. frequency.

12-72 In the

Number of RCosc. cycles

2048 2.0ms 3.4ms

Min programming time Max programming time

Analog Comparator Control and Status Register

“N/A”. Also change Read/Wr it e status of AINBG from “R” to “R/W”.

12-79 In the

12-81 In the

12-87 In the

12-89 In the

12-94 In the

Port A Input Pins Address - PINA

Port B Input Pins Address - PINB

Port C Input Pins Address - PINC

Port D Input Pins Address - PIND

Port E Input Pins Address - PINE

description, change the Ini tial Values from “Hi-Z” to “N/A”.

description, change the Ini tial Values from “Hi-Z” to “N/A”.

description, change the Ini tial Values from “Hi-Z” to “N/A”.

description, change the Ini tial Values from “Hi-Z” to “N/A”.

description, change the Initial Values from “Hi-Z” to “N/A”.

12-98 Replace table 36 by:

BLB0 mode BL B02 BLB01 Protection

111

210

No restrictions for SPM, LPM accessing the Application section

SPM is not allowed to write to the Application section

description, change the ini tial value of ACO from “0” to

300

401

SPM is not allowed to write to the Application section, and LPM executing from the Boot

Loader section is not allowed to read from the Application section

LPM executing from the Boot Loader section is not allowed to read from the Application

section

12-98 Replace table 37 by:

BLB1 mode BL B12 BLB11 Protection

111

210

300

401

12-99 In the section describi ng

No restrictions for SPM, LPM accessing the Boot Loader section

SPM is not allowed to write to the Boot Loader section

SPM is not allowed to write to the Boot Loader section, and LPM executing from the

Application section is not allowed to read from the Boot Loader section

LPM executing from the Application section is not allowed to read from the Boot Loader

section

“Self-programming the Flash

during page write” by “The CPU is halted both during page erase and during page write and the SPMEN bit in the

SPMCR register will be auto-cleared. For future compatibility, however, it is recommended that the user software

verifies that the SPMEN bit is cleared before starting a new page-erase, page-write, or writing the lock-bits com-

”,

replace

“The CPU is halted both during page erase and

31

Page 32

mand. See code example below. It is essential that the page address used in both the page erase and page write

operation is addressing the same page.”

12-99 Add this t ext to the bottom of the

“Perform a page write”

the Z pointer will point to the first word in the successive page. ”

Code example:

Wait: in r16,SPMCR ; read SPMCR register

sbrc r16,SPMEN ; Wait for SPMEN to be cleared (in dicates that previous write operation is com pleted)

rjmp Wait ; if not cleared, keep waiting

ldi r16,(1<<PGWRT) + (1<<SPMEN) ; The previous writing is completed, set up for next erase

out SPMCR,r16 ; output to register

spm ; start the erase operation

12-102 Replace table 39 by:

Memory Lock Bits Protection Type

LB mode LB1 LB2

1 1 1 No memory lock features enabled

201

300

BLB0 mode BLB02 BLB01

111

210

Further programming of the Flash and EEPROM is disabled in parallel and serial programming mode. The

Fuse bits are locked in both serial and parallel programming mode.

Further programming and verification of the Flash and EEPROM is disabled in parallel and serial

programming mode. The Fuse bits are locked in both serial and parallel programming mode.

No restrictions for SPM, LPM accessing the Application section

SPM is not allowed to write to the Application section

sub-section: “When a page wri te operat ion is completed ,

(1)

(1)

300

401

BLB1 mode BLB12 BLB11

111

210

300

401

SPM is not allowed to write to the Application section, and LPM executing from the Boot Loader

section is not allowed to read from the Application section

LPM executing from the Boot Loader section is not allowed to read from the Application section

No restrictions for SPM, LPM accessing the Boot Loader section

SPM is not allowed to write to the Boot Loader section

SPM is not allowed to write to the Boot Loader section, and LPM executing from the Application

section is not allowed to read from the Boot Loader section

LPM executing from the Application section is not allowed to read from the Boot Loader section

12-111 Replace the following parameters in

t

WLRH

t

WLRH_CE

t

WLRH_FLASH

WR Low to RDY/BSY High 1 1.7 ms

WR Low to RDY/BSY High for Chip Erase 16 28 ms

WR Low to RDY/BSY High for Write Flash 8 14 ms

table 44

by these values:

32

Data Book Updates and Changes

Page 33

Data Book Updates and Changes

g

12-113 Replace

Symbol Minimum Wait Delay

t

WD_FLASH

t

WD_EEPROM

table 45

by:

and add this table:

46 Minimum wait delay after a chip erase command

Table

Symbol Minimum Wait Delay

t

WD_ERASE

12-114 Replace the row “Write Fuse Bits” in table 46 by

Write Fuse Bits

12-116: Replace the row bel ow in

1010 1100 101x xxxx xxxx xxxx 1D1B A987

DC characteristics

:

14 ms

3.4 ms

28 ms

Set bits D - A, 9 - 7 = ’0’ to program,

‘1’ to unprogram

V

ACIO

Analog Comparator

Input Offset Voltage

VCC = 5V 40 mV

by:

V

ACIO

Analog Comparator

Input Offset Voltage

VCC = 5V

Vin = VCC /2

40 mV

12-123 Add this text: “The characterization data is not tested during manufacturing.”.

12-129 In

$39 ($59) TIMSK TOIE1 OCIE1A OCIE1B TOIE2 TICIE1 OCIE2 TOIE 0 OCIE0 page 12-32

$38 ($58) TIFR TOV1 OCF1A OCF1B TOV2 ICF1 OCFI2 TOV 0 OCIF0 pa

12-129 In

Register summary

Register summary

, replace the rows TIMSK and TIFR by

, replace “12-12-xx” by “12-xx”.

e 12-33

33

Page 34

ATmega603/603/L and ATmega103/103L

The latest data sheet on the web is rev. 0945E-12/99.

The data sheet in the printed data book is rev. 0945D-06/99.

Changes in the ATmega103/103L data sheet on the web

None.

Changes in the ATmega103/103L section in the data book

Page: Change or Add:

13-5 Some text and symbols are outside the visible figure frame. The complete figure is given below .

Figure 1. The ATmega603/103 Block Diagram

VCC

GND

AVCC

AGND

AREF

PORTF BUFFERS

ANALOG MUX ADC

PROGRAM

COUNTER

PORTA DRIVER/BUFFERS

DATAREGISTER

PORTA

STACK

POINTER

PA0 - PA7PF0 - PF7

DATADIR.

REG. PORTA

INTERNAL

OSCILLATOR

WATCHDOG

8-BIT DATA BUS

TIMER

PC0 - PC7

PORTC DRIVERS

DATAREGISTER

PORTC

OSCILLATOR

OSCILLATOR

XTAL1

XTAL1

TOSC2

34

ANALOG

COMPARATOR

TIMING AND

CONTROL

DATAREGISTER

PORTD

PORTD DRIVER/BUFFERS

DATAREGISTER

+

-

PORTE

PROGRAM

FLASH

INSTRUCTION

REGISTER

INSTRUCTION

DECODER

CONTROL

LINES

DATADIR.

REG. PORTE

SRAM

GENERAL

PURPOSE

REGISTERS

X

Y

Z

ALU

STATUS

REGISTER

SPI

DATAREGISTER

PORTB

MCU CONTROL

REGISTER

TIMER/

COUNTERS

INTERRUPT

UNIT

EEPROM

PROGRAMMING

LOGIC

UART

DATADIR.

REG. PORTB

PORTB DRIVER/BUFFERSPORTE DRIVER/BUFFERS

PB0 - PB7PE0 - PE7

Data Book Updates and Changes

PD0 - PD7

DATADIR.

REG. PORTD

TOSC1

RESET

ALE

WR

RD

PEN

VCC

GND

Page 35

Data Book Updates and Changes

13-7 Replace descrip tion of AVCC, “This is the supply voltage to th e A/D Converter. It should be exte rnally connected to

V

via a low-pass filter. See page 13-68 for details on operation of the ADC“ by “Supply voltage for PortF, includ-

CC

ing ADC. The pin must be connected to Vcc when not used for the ADC. See

on page 13-78 for details when usin g the ADC“

ADC Noise Canceling Techniques

13-7 In description of PEN