Features

• High-performance, Low-power 8/16-bit AVR XMEGA Microcontroller

• Non-volatile Program and Data Memories

– 16 KB - 128 KB of In-System Self-Programmable Flash

– 4 KB - 8 KB Boot Code Section with Independent Lock Bits

– 1 KB - 2 KB EEPROM

– 2 KB - 8 KB Internal SRAM

• Peripheral Features

– Four-channel DMA Controller with support for external requests

– Eight-channel Event System

– Five 16-bit Timer/Counters

Three Timer/Counters with 4 Output Compare or Input Capture channels

Two Timer/Counters with 2 Output Compare or Input Capture channels

High-Resolution Extensions on all Timer/Counters

Advanced Waveform Extension on one Timer/Counter

– Five USARTs

IrDA Extension on one USART

– Two Two-Wire Interfaces with dual address match (I

– Two SPIs (Serial Peripheral Interfaces) peripherals

– AES and DES Crypto Engine

– 16-bit Real Time Counter with Separate Oscillator

– One Twelve-channel, 12-bit, 2 Msps Analog to Digital Converter

– One Two-channel, 12-bit, 1 Msps Digital to Analog Converter

– Two Analog Comparators with Window compare function

– External Interrupts on all General Purpose I/O pins

– Programmable Watchdog Timer with Separate On-chip Ultra Low Power Oscillator

• Special Microcontroller Features

– Power-on Reset and Programmable Brown-out Detection

– Internal and External Clock Options with PLL

– Programmable Multi-level Interrupt Controller

– Sleep Modes: Idle, Power-down, Standby, Power-save, Extended Standby

– Advanced Programming, Test and Debugging Interfaces

PDI (Program and Debug Interface) for programming, test and debugging

• I/O and Packages

– 34 Programmable I/O Lines

– 44 - lead TQFP

– 44 - pad VQFN/QFN

– 49 - ball VFBGA

• Operating Voltage

– 1.6 – 3.6V

• Speed performance

– 0 – 12 MHz @ 1.6 – 3.6V

– 0 – 32 MHz @ 2.7 – 3.6V

2

C and SMBus compatible)

8/16-bit

XMEGA A4

Microcontroller

ATxmega128A4

ATxmega64A4

ATxmega32A4

ATxmega16A4

Preliminary

Typical Applications

• Industrial control • Climate control • Hand-held battery applications

• Factory automation • ZigBee • Power tools

• Building control • Motor control • HVAC

• Board control • Networking • Metering

• White Goods • Optical • Medical Applications

8069L–AVR–11/09

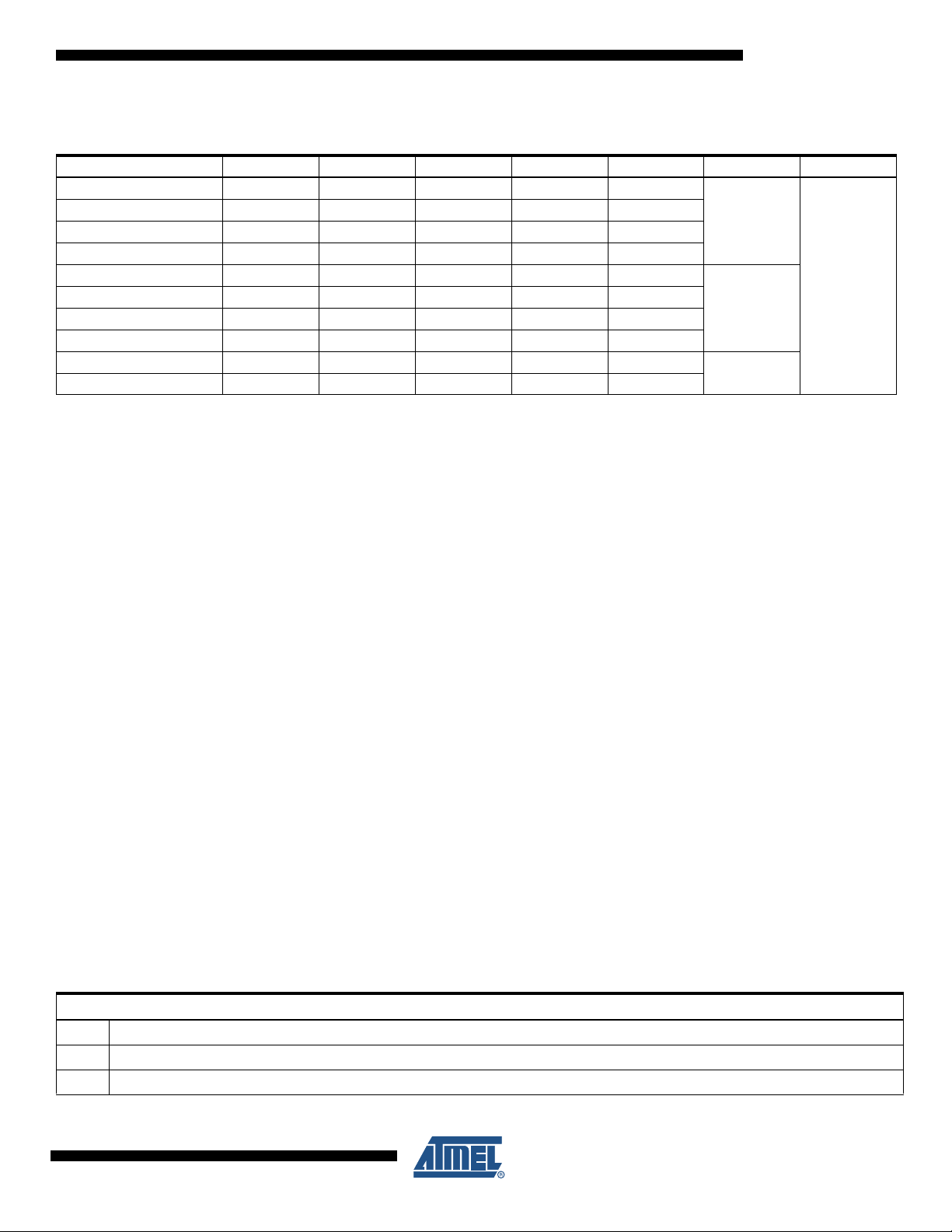

1. Ordering Information

XMEGA A4

Ordering Code Flash E

ATxmega128A4-AU 128 KB + 8 KB 2 KB 8 KB 32 1.6 - 3.6V

ATxmega64A4-AU 64 KB + 4 KB 2 KB 4 KB 32 1.6 - 3.6V

ATxmega32A4-AU 32 KB + 4 KB 1 KB 4 KB 32 1.6 - 3.6V

ATxmega16A4-AU 16 KB + 4 KB 1 KB 2 KB 32 1.6 - 3.6V

ATxmega128A4-MH 128 KB + 8 KB 2 KB 8 KB 32 1.6 - 3.6V

ATxmega64A4-MH 64 KB + 4 KB 2 KB 4 KB 32 1.6 - 3.6V

ATxmega32A4-MH 32 KB + 4 KB 1 KB 4 KB 32 1.6 - 3.6V

ATxmega16A4-MH 16 KB + 4 KB 1 KB 2 KB 32 1.6 - 3.6V

ATxmega32A4-CU 32 KB + 4K 1 KB 4 KB 32 1.6 - 3.6V

ATxmega16A4-CU 16 KB + 4 KB 1 KB 2 KB 32 1.6 - 3.6V

2

SRAM Speed (MHz) Power Supply Package

44A

44M1

49C2

(1)(2)(3)

Tem p

-40°C - 85°C

Notes: 1. This device can also be supplied in wafer form. Please contact your local Atmel sales office for detailed ordering information.

2. Pb-free packaging, complies to the European Directive for Restriction of Hazardous Substances (RoHS directive). Also

Halide free and fully Green.

3. For packaging information see ”Packaging information” on page 58.

Package Type

44A 44-Lead, 10 x 10 mm Body Size, 1.0 mm Body Thickness, 0.8 mm Lead Pitch, Thin Profile Plastic Quad Flat Package (TQFP)

44M1 44-Pad, 7x7x1 mm Body, Lead Pitch 0.50 mm, 5.20 mm Exposed Pad, Thermally Enhanced Plastic Very Thin Quad No Lead Package (VQFN)

49C2 49-Ball (7 x 7 Array), 0.65 mm Pitch, 5.0 x 5.0 x 1.0 mm, Very Thin, Fine-Pitch Ball Grid Array Package (VFBGA)

8069L–AVR–11/09

2

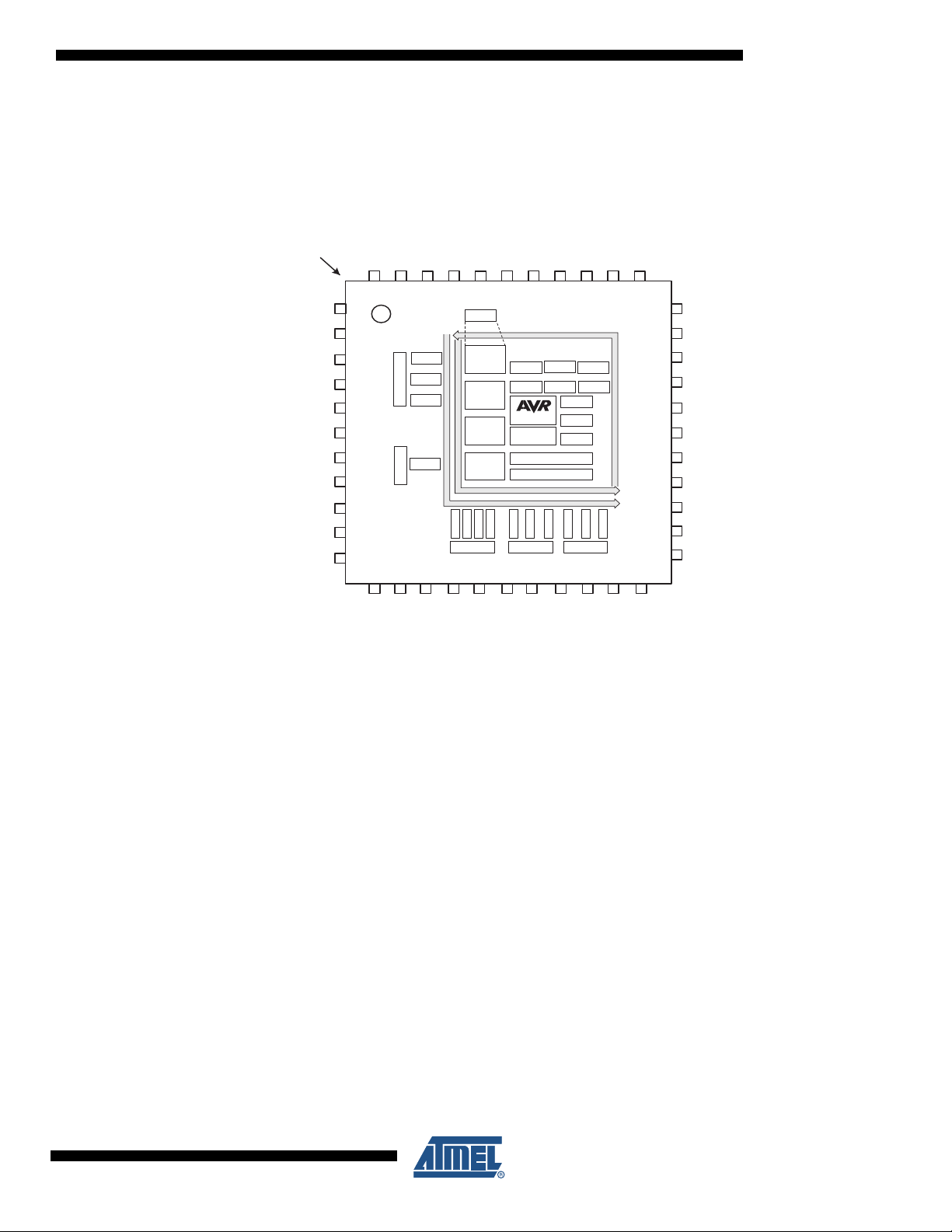

2. Pinout/Block Diagram

Figure 2-1. Bock Diagram and TQFP/QFN pinout

XMEGA A4

INDEX CORNER

PA 5

PA 6

PA 7

PB0

PB1

PB2

PB3

GND

VCC

PC0

PC1

PA 4

PA 3

PA 2

PA 1

PA 0

AVCC

GND

PR1

PR0

RESET/PDI_CLK

PDI_DATA

44

43

42

41

40

39

38

37

36

35

34

1

2

3

4

5

ADC A

A

AC A0

Port

A

AC A1

6

7

B

DAC B

Port

8

9

10

11

12

13

PC2

PC3

14

PC4

T/C0:1

Port C

15

PC5

Port R

OSC/CLK

Control

Power

Control

Reset

Control

Watchdog

USART0:1

TWI

DATA BU S

BOD POR

TEMP

CPU

DMA

Interrupt Controller

Event System ctrl

DATA BU S

EVENT ROUTING NETWORK

T/C0:1

SPI

USART0:1

Port D

16

17

PC6

PC7

VREF

RTC

OCD

FLASH

RAM

E2PROM

T/C0

SPI

USART0

Port E

18

19

20

PD0

VCC

GND

33

32

31

30

29

28

27

26

25

24

TWI

23

21

22

PD1

PD2

Note: For full details on pinout and pin functions refer to ”Pinout and Pin Functions” on page 49.

PE3

PE2

VCC

GND

PE1

PE0

PD7

PD6

PD5

PD4

PD3

8069L–AVR–11/09

3

Figure 2-2. VFBGA pinout

XMEGA A4

Top view

1 234567

A

B

C

D

E

F

G

Bottom view

7654321

A

B

C

D

E

F

G

Table 2-1. VFBGA pinout

123456

A PA3 AVCC GND PR1 PR0 PDI_DATA PE3

B

PA 4 PA1 PA 0 G ND

C PA5 PA2 PA6 PA7 GND PE1 GND

D PB1 PB2 PB3 PB0 GND PD7 PE0

E GND GND PC3 GND PD4 PD5 PD6

RESET/

PDI_CLK

PE2 VCC

F VCC PC0 PC4 PC6 PD0 PD1 PD3

G PC1 PC2 PC5 PC7 GND VCC PD2

8069L–AVR–11/09

4

3. Overview

XMEGA A4

The XMEGA™A4 is a family of low power, high performance and peripheral rich CMOS 8/16-bit

microcontrollers based on the AVR

instructions in a single clock cycle, the XMEGA A4 achieves throughputs approaching 1 Million

Instructions Per Second (MIPS) per MHz allowing the system designer to optimize power consumption versus processing speed.

The AVR CPU combines a rich instruction set with 32 general purpose working registers. All the

32 registers are directly connected to the Arithmetic Logic Unit (ALU), allowing two independent

registers to be accessed in one single instruction, executed in one clock cycle. The resulting

architecture is more code efficient while achieving throughputs many times faster than conventional single-accumulator or CISC based microcontrollers.

The XMEGA A4 devices provide the following features: In-System Programmable Flash with

Read-While-Write capabilities, Internal EEPROM and SRAM, four-channel DMA Controller,

eight-channel Event System, Programmable Multi-level Interrupt Controller, 34 general purpose

I/O lines, 16-bit Real Time Counter (RTC), five flexible 16-bit Timer/Counters with compare

modes and PWM, five USARTs, two Two Wire Serial Interfaces (TWIs), two Serial Peripheral

Interfaces (SPIs), AES and DES crypto engine, one Twelve-channel, 12-bit ADC with optional

differential input with programmable gain, one Two-channel 12-bit DAC, two analog comparators

with window mode, programmable Watchdog Timer with separate Internal Oscillator, accurate

internal oscillators with PLL and prescaler and programmable Brown-Out Detection.

The Program and Debug Interface (PDI), a fast 2-pin interface for programming and debugging,

is available.

®

enhanced RISC architecture. By executing powerful

The XMEGA A4 devices have five software selectable power saving modes. The Idle mode

stops the CPU while allowing the SRAM, DMA Controller, Event System, Interrupt Controller and

all peripherals to continue functioning. The Power-down mode saves the SRAM and register

contents but stops the oscillators, disabling all other functions until the next TWI or pin-change

interrupt, or Reset. In Power-save mode, the asynchronous Real Time Counter continues to run,

allowing the application to maintain a timer base while the rest of the device is sleeping. In

Standby mode, the Crystal/Resonator Oscillator is kept running while the rest of the device is

sleeping. This allows very fast start-up from external crystal combined with low power consumption. In Extended Standby mode, both the main Oscillator and the Asynchronous Timer continue

to run. To further reduce power consumption, the peripheral clock to each individual peripheral

can optionally be stopped in Active mode and in Idle sleep mode.

The device is manufactured using Atmel's high-density nonvolatile memory technology. The program Flash memory can be reprogrammed in-system through the PDI. A Bootloader running in

the device can use any interface to download the application program to the Flash memory. The

Bootloader software in the Boot Flash section will continue to run while the Application Flash

section is updated, providing true Read-While-Write operation. By combining an 8/16-bit RISC

CPU with In-System Self-Programmable Flash, the Atmel XMEGA A4 is a powerful microcontroller family that provides a highly flexible and cost effective solution for many embedded

applications.

The XMEGA A4 devices are supported with a full suite of program and system development

tools including: C compilers, macro assemblers, program debugger/simulators, programmers,

and evaluation kits.

8069L–AVR–11/09

5

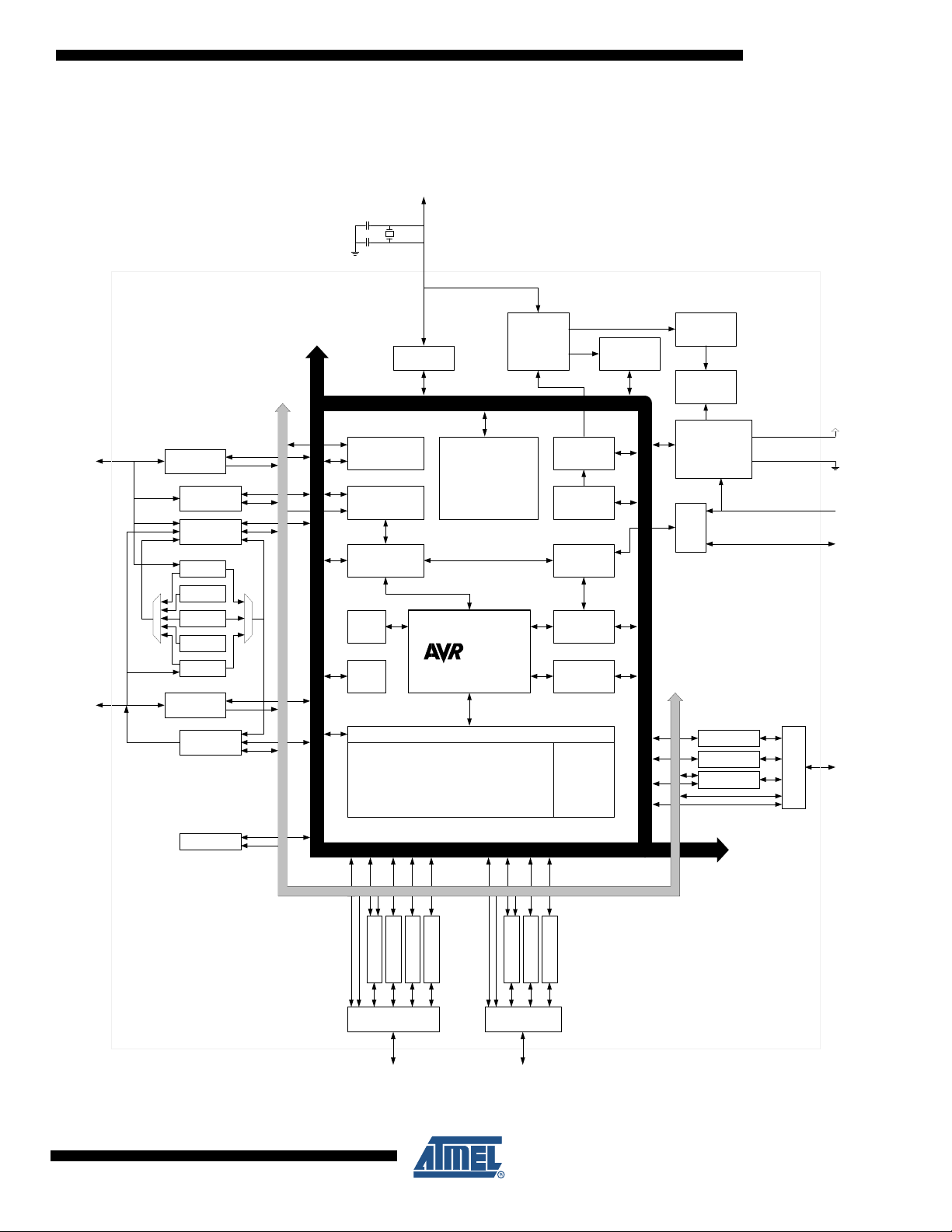

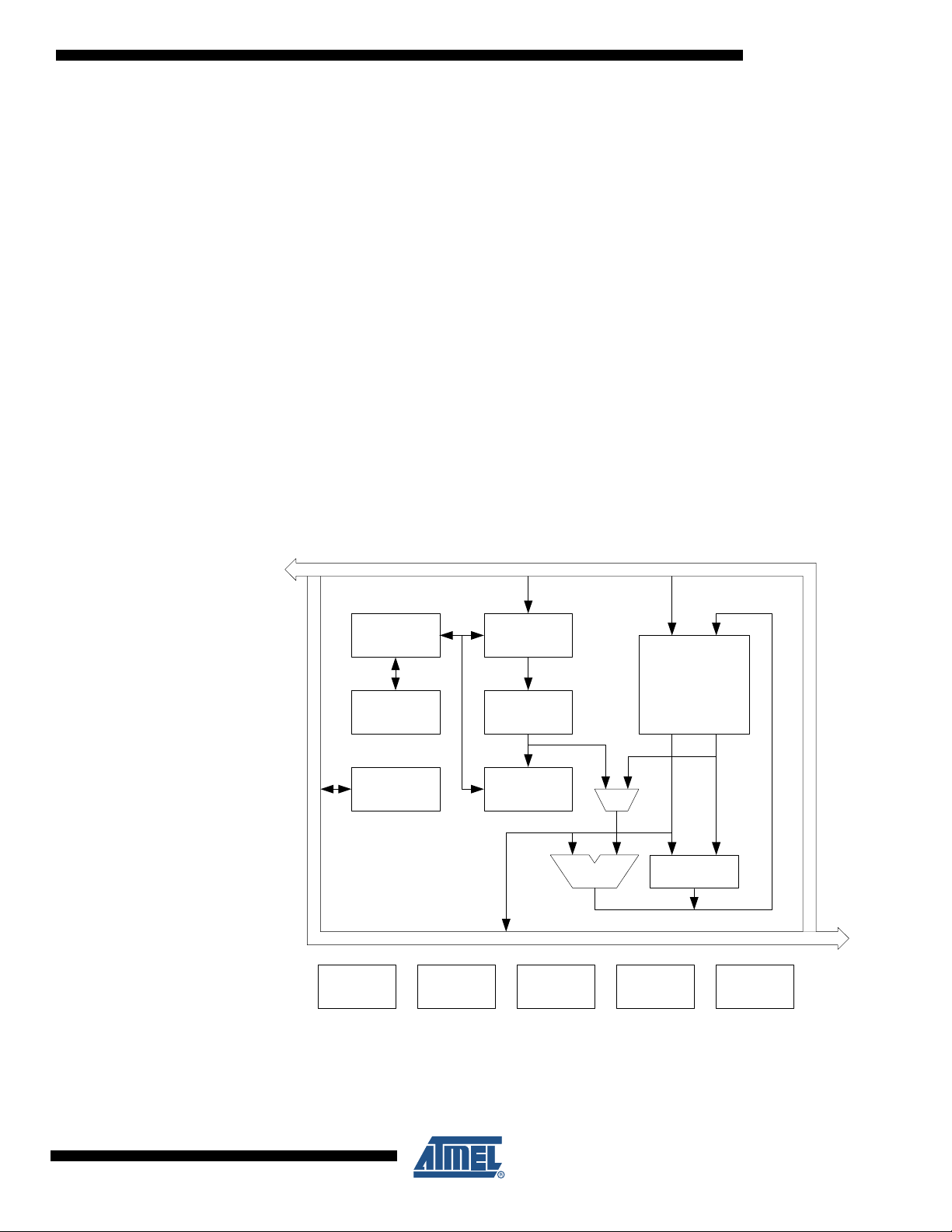

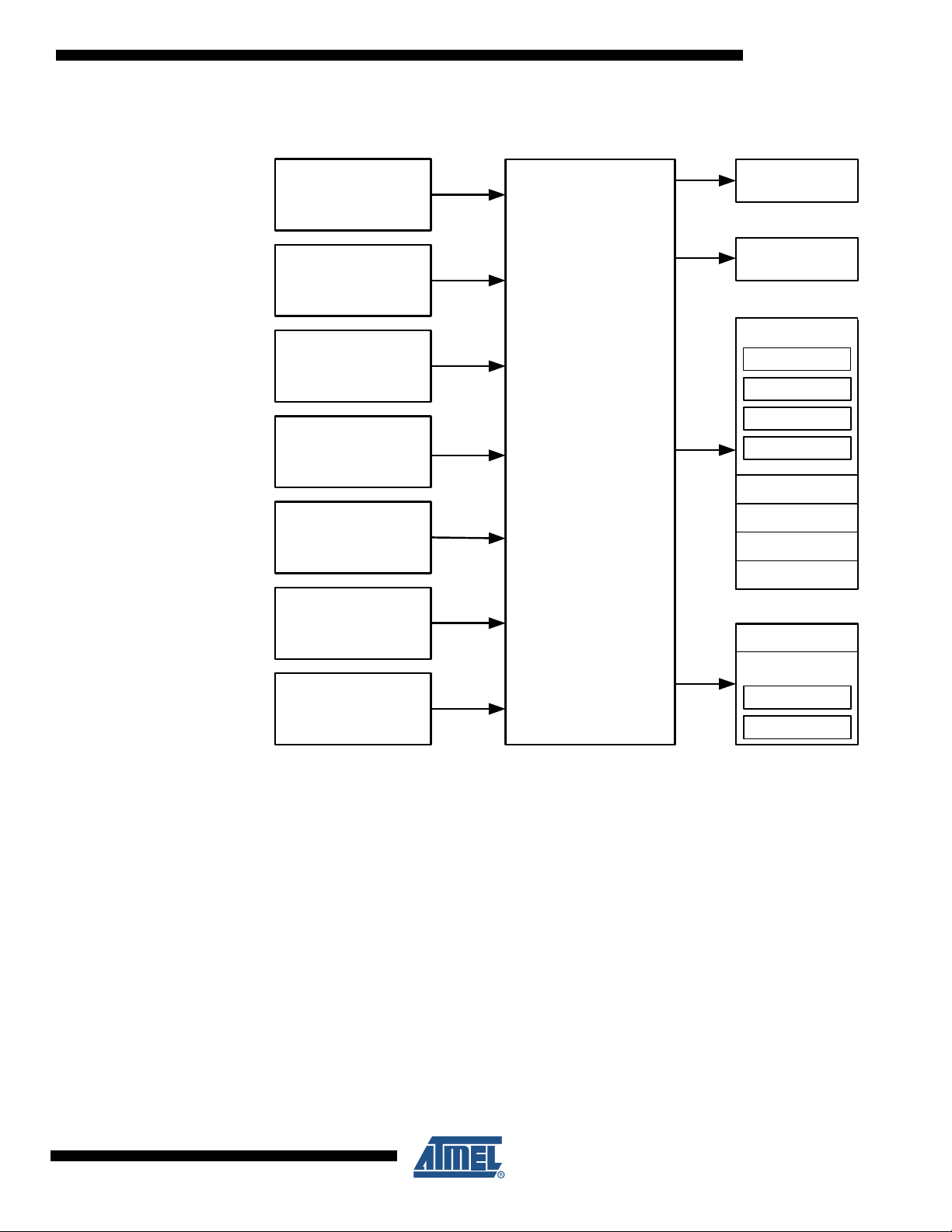

3.1 Block Diagram

PE[0..3]

PORT E (4)

TCE0

USARTE0

TWIE

Power

Supervision

POR/BOD &

RESET

PORT A (8)

PORT B (4)

DMA

Controller

BUS

Controller

SRAM

ADCA

ACA

DACB

OCD

PDI

CPU

PA[0..7]

Watchdog

Timer

Watchdog

Oscillator

Interrupt

Controller

DATA BUS

DATA BUS

Prog/Debug

Controller

VCC

GND

Oscillator

Circuits/

Clock

Generation

Oscillator

Control

Real Time

Counter

Event System

Controller

PDI_DATA

RESET/

PDI_CLK

Sleep

Controller

Flash EEPROM

NVM Controller

DES

AES

IRCOM

PORT C (8)

PC[0..7]

TCC0:1

USARTC0:1

TWIC

SPIC

PD[0..7]

PORT R (2)

XTAL1/

TOSC1

XTAL2/

TOSC2

PR[0..1]

PORT D (8)

TCD0:1

USARTD0:1

SPID

EVENT ROUTING NETWORK

PB[0..3]

Int. Ref.

AREFA

AREFB

Tempref

VCC/10

Figure 3-1. XMEGA A4 Block Diagram

XMEGA A4

8069L–AVR–11/09

6

4. Resources

A comprehensive set of development tools, application notes and datasheets are available for

download on http://www.atmel.com/avr.

4.1 Recommended reading

• XMEGA A Manual

• XMEGA A Application Notes

This device data sheet only contains part specific information and a short description of each

peripheral and module. The XMEGA A Manual describes the modules and peripherals in depth.

The XMEGA A application notes contain example code and show applied use of the modules

and peripherals.

The XMEGA A Manual and Application Notes are available from http://www.atmel.com/avr.

5. Disclaimer

For devices that are not available yet, typical values contained in this datasheet are based on

simulations and characterization of other AVR XMEGA microcontrollers manufactured on the

same process technology. Min. and Max values will be available after the device is

characterized.

XMEGA A4

8069L–AVR–11/09

7

6. AVR CPU

Flash

Program

Memory

Instruction

Decode

Program

Counter

OCD

32 x 8 General

Purpose

Registers

ALU

Multiplier/

DES

Instruction

Register

STATUS/

CONTROL

Peripheral

Module 1

Peripheral

Module 2

EEPROM PMICSRAM

DATA BUS

DATA BUS

6.1 Features

6.2 Overview

XMEGA A4

• 8/16-bit high performance AVR RISC Architecture

– 138 instructions

– Hardware multiplier

• 32x8-bit registers directly connected to the ALU

• Stack in RAM

• Stack Pointer accessible in I/O memory space

• Direct addressing of up to 16M Bytes of program and data memory

• True 16/24-bit access to 16/24-bit I/O registers

• Support for 8-, 16- and 32-bit Arithmetic

• Configuration Change Protection of system critical features

The XMEGA A4 uses the 8/16-bit AVR CPU. The main function of the CPU is program execution. The CPU must therefore be able to access memories, perform calculations and control

peripherals. Interrupt handling is described in a separate section. Figure 6-1 on page 8 shows

the CPU block diagram.

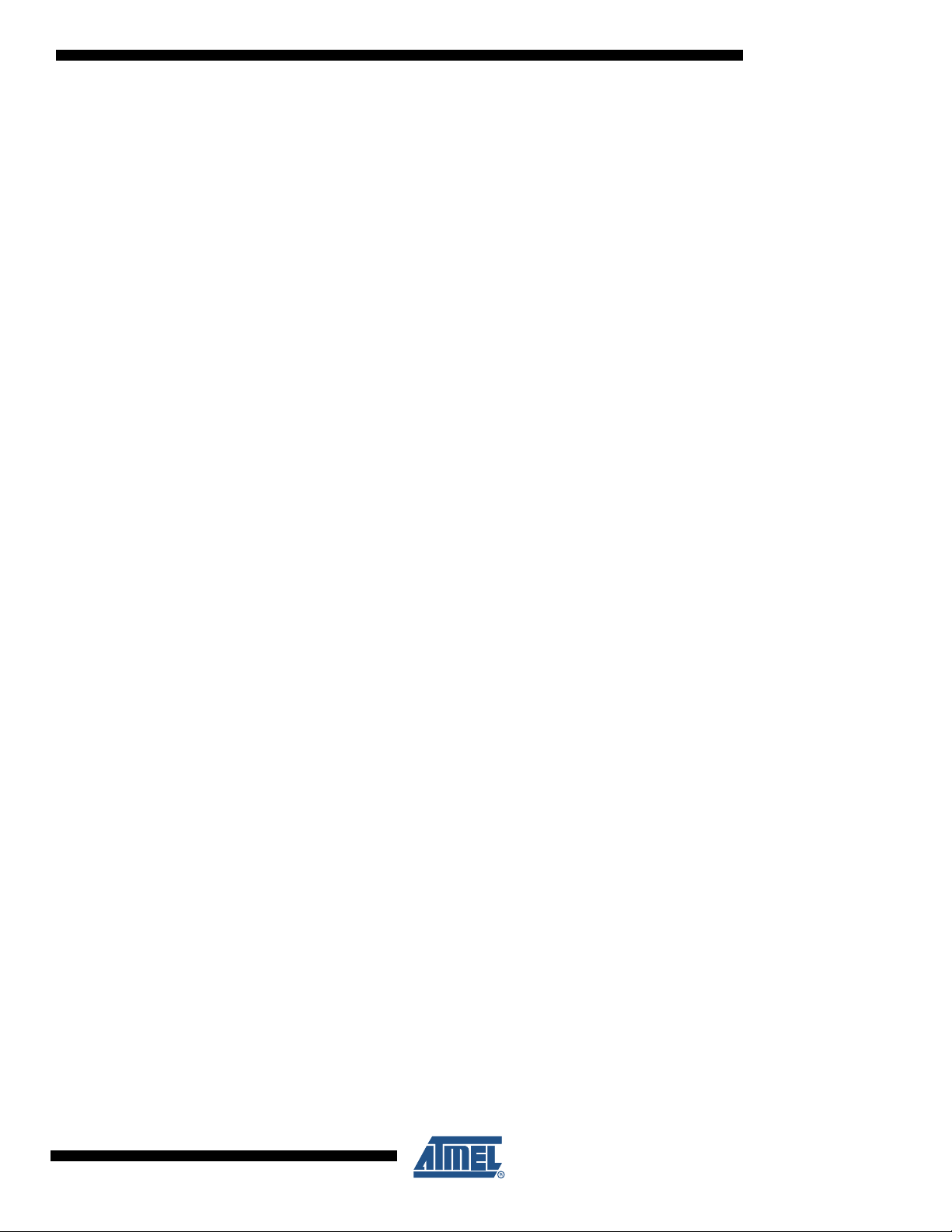

Figure 6-1. CPU block diagram

8069L–AVR–11/09

The AVR uses a Harvard architecture - with separate memories and buses for program and

data. Instructions in the program memory are executed with a single level pipeline. While one

instruction is being executed, the next instruction is pre-fetched from the program memory. This

8

concept enables instructions to be executed in every clock cycle. The program memory is InSystem Re-programmable Flash memory.

6.3 Register File

The fast-access Register File contains 32 x 8-bit general purpose working registers with single

clock cycle access time. This allows single-cycle Arithmetic Logic Unit (ALU) operation. In a typical ALU cycle, the operation is performed on two Register File operands, and the result is stored

back in the Register File.

Six of the 32 registers can be used as three 16-bit address register pointers for data space

addressing - enabling efficient address calculations. One of these address pointers can also be

used as an address pointer for look up tables in Flash program memory.

6.4 ALU - Arithmetic Logic Unit

The high performance Arithmetic Logic Unit (ALU) supports arithmetic and logic operations

between registers or between a constant and a register. Single register operations can also be

executed. Within a single clock cycle, arithmetic operations between general purpose registers

or between a register and an immediate are executed. After an arithmetic or logic operation, the

Status Register is updated to reflect information about the result of the operation.

XMEGA A4

6.5 Program Flow

The ALU operations are divided into three main categories – arithmetic, logical, and bit-functions. Both 8- and 16-bit arithmetic is supported, and the instruction set allows for efficient

implementation of 32-bit arithmetic. The ALU also provides a powerful multiplier supporting both

signed and unsigned multiplication and fractional format.

When the device is powered on, the CPU starts to execute instructions from the lowest address

in the Flash Program Memory ‘0’. The Program Counter (PC) addresses the next instruction to

be fetched. After a reset, the PC is set to location ‘0’.

Program flow is provided by conditional and unconditional jump and call instructions, capable of

addressing the whole address space directly. Most AVR instructions use a 16-bit word format,

while a limited number uses a 32-bit format.

During interrupts and subroutine calls, the return address PC is stored on the Stack. The Stack

is effectively allocated in the general data SRAM, and consequently the Stack size is only limited

by the total SRAM size and the usage of the SRAM. After reset the Stack Pointer (SP) points to

the highest address in the internal SRAM. The SP is read/write accessible in the I/O memory

space, enabling easy implementation of multiple stacks or stack areas. The data SRAM can

easily be accessed through the five different addressing modes supported in the AVR CPU.

8069L–AVR–11/09

9

7. Memories

7.1 Features

7.2 Overview

XMEGA A4

• Flash Program Memory

– One linear address space

– In-System Programmable

– Self-Programming and Bootloader support

– Application Section for application code

– Application Table Section for application code or data storage

– Boot Section for application code or bootloader code

– Separate lock bits and protection for all sections

– Built in fast CRC check of a selectable flash program memory section

• Data Memory

– One linear address space

– Single cycle access from CPU

– SRAM

– EEPROM

Byte and page accessible

Optional memory mapping for direct load and store

– I/O Memory

Configuration and Status registers for all peripherals and modules

16 bit-accessible General Purpose Register for global variables or flags

– Bus arbitration

Safe and deterministic handling of CPU and DMA Controller priority

– Separate buses for SRAM, EEPROM, I/O Memory and External Memory access

Simultaneous bus access for CPU and DMA Controller

• Production Signature Row Memory for factory programmed data

Device ID for each microcontroller device type

Serial number for each device

Oscillator calibration bytes

ADC, DAC and temperature sensor calibration data

• User Signature Row

One flash page in size

Can be read and written from software

Content is kept after chip erase

8069L–AVR–11/09

The AVR architecture has two main memory spaces, the Program Memory and the Data Memory. In addition, the XMEGA A4 features an EEPROM Memory for non-volatile data storage. All

three memory spaces are linear and require no paging. The available memory size configurations are shown in ”Ordering Information” on page 2. In addition each device has a Flash

memory signature row for calibration data, device identification, serial number etc.

Non-volatile memory spaces can be locked for further write or read/write operations. This prevents unrestricted access to the application software.

10

7.3 In-System Programmable Flash Program Memory

The XMEGA A4 devices contain On-chip In-System Programmable Flash memory for program

storage, see Figure 7-1 on page 11. Since all AVR instructions are 16- or 32-bits wide, each

Flash address location is 16 bits.

The Program Flash memory space is divided into Application and Boot sections. Both sections

have dedicated Lock Bits for setting restrictions on write or read/write operations. The Store Program Memory (SPM) instruction must reside in the Boot Section when used to write to the Flash

memory.

A third section inside the Application section is referred to as the Application Table section which

has separate Lock bits for storage of write or read/write protection. The Application Table section can be used for storing non-volatile data or application software.

Figure 7-1. Flash Program Memory (Hexadecimal address)

Word Address

XMEGA A4

0

EFFF / 77FF / 37FF / 17FF

F000 / 7800 / 3800 / 1800

FFFF / 7FFF / 3FFF / 1FFF

10000 / 8000 / 4000 / 2000

10FFF / 87FF / 47FF / 27FF

Application Section

(128 KB/64 KB/32 KB/16 KB)

...

Application Table Section

(4 KB/4 KB/4 KB/4 KB)

Boot Section

(8 KB/4 KB/4 KB/4 KB)

The Application Table Section and Boot Section can also be used for general application

software.

8069L–AVR–11/09

11

XMEGA A4

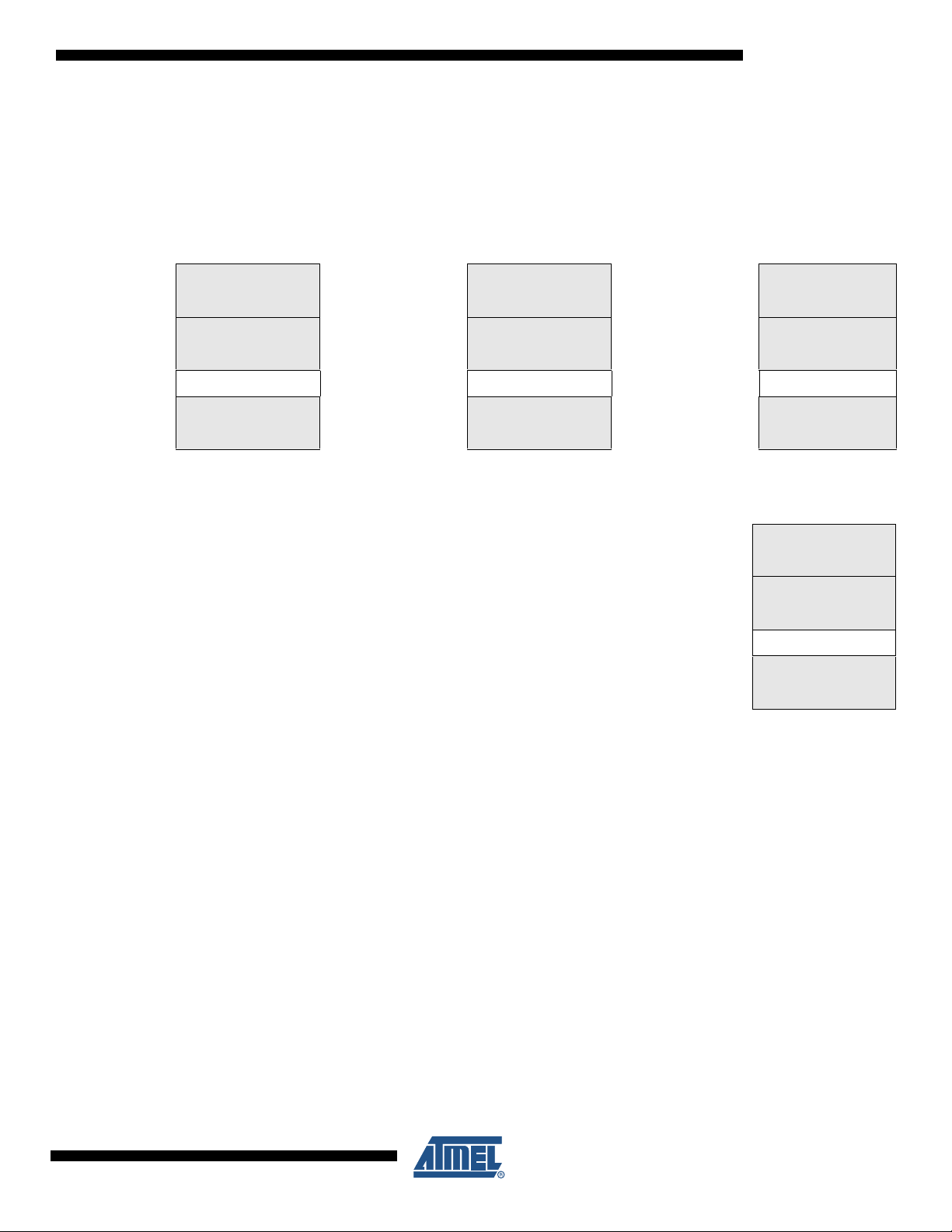

7.4 Data Memory

The Data Memory consist of the I/O Memory, EEPROM and SRAM memories, all within one linear address space, see Figure 7-2 on page 12. To simplify development, the memory map for all

devices in the family is identical and with empty, reserved memory space for smaller devices.

Figure 7-2. Data Memory Map (Hexadecimal address)

Byte Address ATxmega64A4 Byte Address ATxmega32A4 Byte Address ATxmega16A4

1000

0

I/O Registers

(4 KB)

EEPROM

(1 KB)

0

FFF FFF FFF

1000

17FF 13FF 13FF

I/O Registers

(4 KB)

EEPROM

(2 KB)

RESERVED RESERVED RESERVED

1000

0

I/O Registers

(4 KB)

EEPROM

(1 KB)

2000

2FFF 2FFF 27FF

7.4.1 I/O Memory

Internal SRAM

(4 KB)

2000

Internal SRAM

(4 KB)

2000

Internal SRAM

(2 KB)

Byte Address ATxmega128A4

0

FFF

1000

17FF

2000

3FFF

I/O Registers

(4 KB)

EEPROM

(2 KB)

RESERVED

Internal SRAM

(8 KB)

All peripherals and modules are addressable through I/O memory locations in the data memory

space. All I/O memory locations can be accessed by the Load (LD/LDS/LDD) and Store

(ST/STS/STD) instructions, transferring data between the 32 general purpose registers in the

CPU and the I/O Memory.

The IN and OUT instructions can address I/O memory locations in the range 0x00 - 0x3F

directly.

I/O registers within the address range 0x00 - 0x1F are directly bit-accessible using the SBI and

CBI instructions. The value of single bits can be checked by using the SBIS and SBIC instructions on these registers.

The I/O memory address for all peripherals and modules in XMEGA A4 is shown in the ”Periph-

eral Module Address Map” on page 53.

7.4.2 SRAM Data Memory

The XMEGA A4 devices have internal SRAM memory for data storage.

8069L–AVR–11/09

12

7.4.3 EEPROM Data Memory

The XMEGA A4 devices have internal EEPROM memory for non-volatile data storage. It is

addressable either in a separate data space or it can be memory mapped into the normal data

memory space. The EEPROM memory supports both byte and page access.

7.5 Production Signature Row

The Production Signature Row is a separate memory section for factory programmed data. It

contains calibration data for functions such as oscillators and analog modules.

The production signature row also contains a device ID that identify each microcontroller device

type, and a serial number that is unique for each manufactured device. The device ID for the

available XMEGA A4 devices is shown in Table 7-1 on page 13. The serial number consist of

the production LOT number, wafer number, and wafer coordinates for the device.

The production signature row can not be written or erased, but it can be read from both application software and external programming.

Table 7-1. Device ID bytes for XMEGA A4 devices.

ATxmega16A4 41 94 1E

XMEGA A4

Device Device ID bytes

Byte 2 Byte 1 Byte 0

7.6 User Signature Row

The User Signature Row is a separate memory section that is fully accessible (read and write)

from application software and external programming. The user signature row is one flash page

in size, and is meant for static user parameter storage, such as calibration data, custom serial

numbers or identification numbers, random number seeds etc. This section is not erased by

Chip Erase commands that erase the Flash, and requires a dedicated erase command. This

ensures parameter storage during multiple program/erase session and on-chip debug sessions.

ATxmega32A4 41 95 1E

ATxmega64A4 46 96 1E

ATxmega128A4 46 97 1E

8069L–AVR–11/09

13

XMEGA A4

7.7 Flash and EEPROM Page Size

The Flash Program Memory and EEPROM data memory are organized in pages. The pages are

word accessible for the Flash and byte accessible for the EEPROM.

Table 7-2 on page 14 shows the Flash Program Memory organization. Flash write and erase

operations are performed on one page at a time, while reading the Flash is done one byte at a

time. For Flash access the Z-pointer (Z[m:n]) is used for addressing. The most significant bits in

the address (FPAGE) give the page number and the least significant address bits (FWORD)

give the word in the page.

Table 7-2. Number of words and Pages in the Flash.

Devices Flash Page Size FWORD FPAGE Application Boot

Size (words) Size No of Pages Size No of Pages

ATxmega16A4 16 KB + 4 KB 128 Z[6:0] Z[13:7] 16 KB 64 4 KB 16

ATxmega32A4 32 KB + 4 KB 128 Z[6:0] Z[14:7] 32 KB 128 4 KB 16

ATxmega64A4 64 KB + 4 KB 128 Z[6:0] Z[15:7] 64 KB 128 4 KB 16

ATxmega128A4 128 KB + 8 KB 256 Z[7:0] Z[16:8] 128 KB 256 8 KB 16

Table 7-3 on page 14 shows EEPROM memory organization for the XMEGA A4 devices.

EEPROM write and erase operations can be performed one page or one byte at a time, while

reading the EEPROM is done one byte at a time. For EEPROM access the NVM Address Register (ADDR[m:n]) is used for addressing. The most significant bits in the address (E2PAGE) give

the page number and the least significant address bits (E2BYTE) give the byte in the page.

Table 7-3. Number of Bytes and Pages in the EEPROM.

Devices EEPROM Page Size E2BYTE E2PAGE No of Pages

Size (Bytes)

ATxmega16A4 1 KB 32 ADDR[4:0] ADDR[10:5] 32

ATxmega32A4 1 KB 32 ADDR[4:0] ADDR[10:5] 32

ATxmega64A4 2 KB 32 ADDR[4:0] ADDR[10:5] 64

ATxmega128A4 2 KB 32 ADDR[4:0] ADDR[10:5] 64

8069L–AVR–11/09

14

8. DMAC - Direct Memory Access Controller

8.1 Features

• Allows High-speed data transfer

– From memory to peripheral

– From memory to memory

– From peripheral to memory

– From peripheral to peripheral

• 4 Channels

• From 1 byte and up to 16 M bytes transfers in a single transaction

• Multiple addressing modes for source and destination address

–Increment

– Decrement

– Static

• 1, 2, 4, or 8 bytes Burst Transfers

• Programmable priority between channels

8.2 Overview

The XMEGA A4 has a Direct Memory Access (DMA) Controller to move data between memories

and peripherals in the data space. The DMA controller uses the same data bus as the CPU to

transfer data.

XMEGA A4

It has 4 channels that can be configured independently. Each DMA channel can perform data

transfers in blocks of configurable size from 1 to 64K bytes. A repeat counter can be used to

repeat each block transfer for single transactions up to 16M bytes. Each DMA channel can be

configured to access the source and destination memory address with incrementing, decrementing or static addressing. The addressing is independent for source and destination address.

When the transaction is complete the original source and destination address can automatically

be reloaded to be ready for the next transaction.

The DMAC can access all the peripherals through their I/O memory registers, and the DMA may

be used for automatic transfer of data to/from communication modules, as well as automatic

data retrieval from ADC conversions, data transfer to DAC conversions, or data transfer to or

from port pins. A wide range of transfer triggers is available from the peripherals, Event System

and software. Each DMA channel has different transfer triggers.

To allow for continuous transfer, two channels can be interlinked so that the second takes over

the transfer when the first is finished and vice versa.

The DMA controller can read from memory mapped EEPROM, but it cannot write to the

EEPROM or access the Flash.

8069L–AVR–11/09

15

9. Event System

9.1 Features

9.2 Overview

• Inter-peripheral communication and signalling with minimum latency

• CPU and DMA independent operation

• 8 Event Channels allow for up to 8 signals to be routed at the same time

• Events can be generated by

– TImer/Counters (TCxn)

– Real Time Counter (RTC)

– Analog to Digital Converters (ADCx)

– Analog Comparators (ACx)

– Ports (PORTx)

– System Clock (Clk

– Software (CPU)

SYS

)

• Events can be used by

– TImer/Counters (TCxn)

– Analog to Digital Converters (ADCx)

– Digital to Analog Converters (DACx)

– Ports (PORTx)

– DMA Controller (DMAC)

– IR Communication Module (IRCOM)

• The same event can be used by multiple peripherals for synchronized timing

• Advanced Features

– Manual Event Generation from software (CPU)

– Quadrature Decoding

– Digital Filtering

• Functions in Active and Idle mode

XMEGA A4

8069L–AVR–11/09

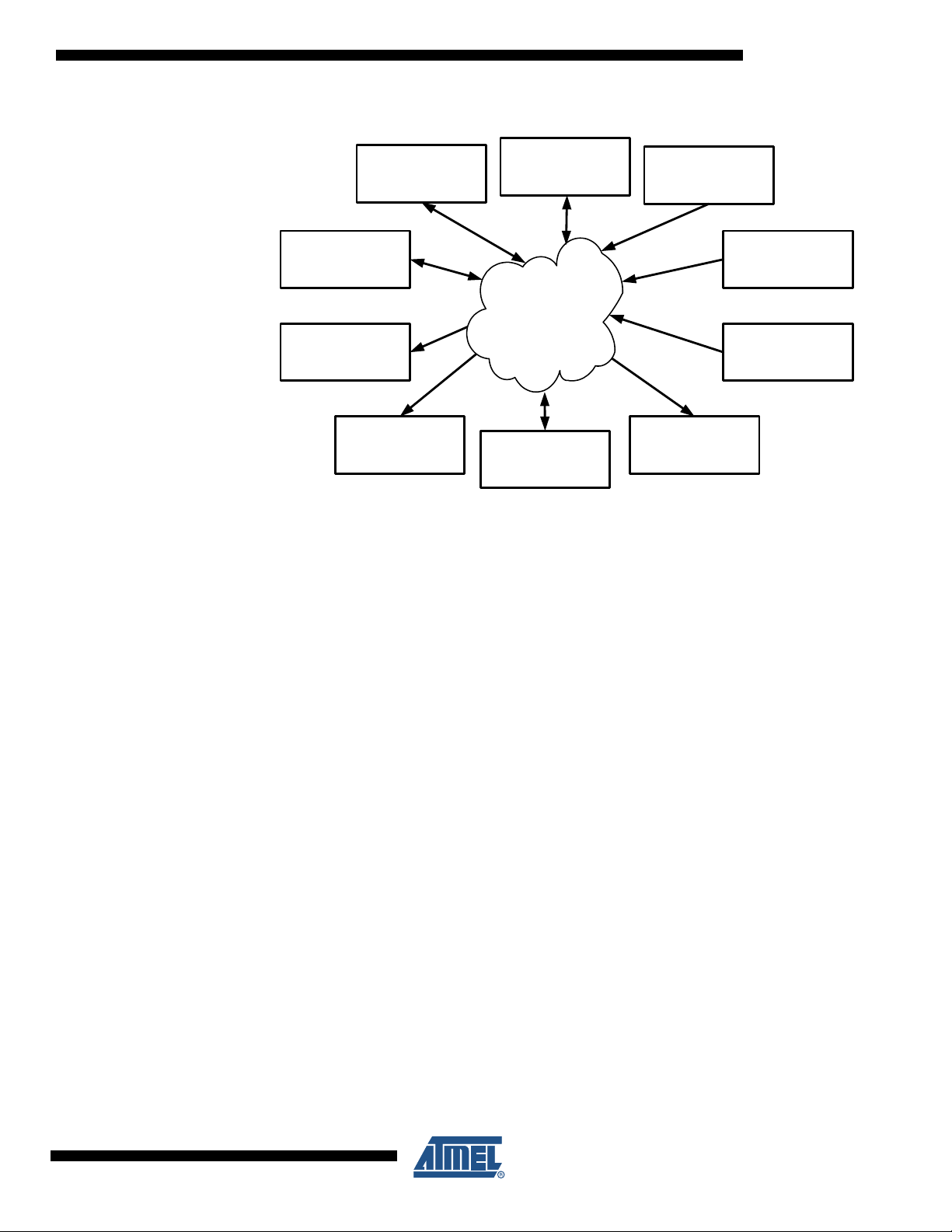

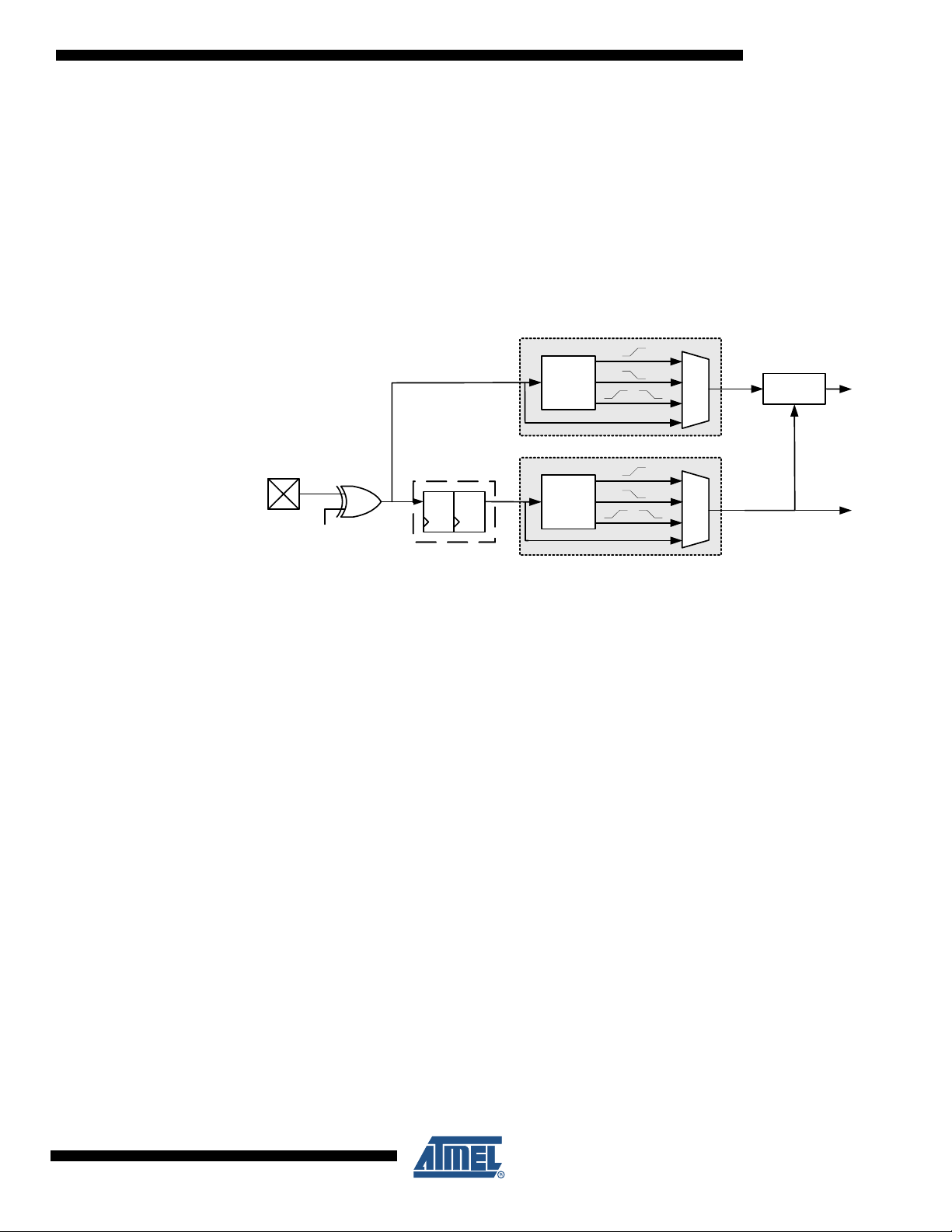

The Event System is a set of features for inter-peripheral communication. It enables the possibility for a change of state in one peripheral to automatically trigger actions in one or more

peripherals. Whose changes in a peripheral that will trigger actions in other peripherals are configurable by software. It is a simple, but powerful system as it allows for autonomous control of

peripherals without any use of interrupts, CPU or DMA resources.

The indication of a change in a peripheral is referred to as an event, and is usually the same as

the interrupt conditions for that peripheral. Events are passed between peripherals using a dedicated routing network called the Event Routing Network. Figure 9-1 on page 17 shows a basic

block diagram of the Event System with the Event Routing Network and the peripherals to which

it is connected. This highly flexible system can be used for simple routing of signals, pin functions or for sequencing of events.

The maximum latency is two CPU clock cycles from when an event is generated in one peripheral, until the actions are triggered in one or more other peripherals.

The Event System is functional in both Active and Idle modes.

16

Figure 9-1. Event System Block Diagram

ADCx

DACx

Event Routing

Network

PORTx

CPU

ACx

RTC

T/Cxn

DMACIRCOM

ClkSYS

XMEGA A4

The Event Routing Network can directly connect together ADCs, DACs, Analog Comparators

(ACx), I/O ports (PORTx), the Real-time Counter (RTC), Timer/Counters (T/C) and the IR Communication Module (IRCOM). Events can also be generated from software (CPU).

All events from all peripherals are always routed into the Event Routing Network. This consist of

eight multiplexers where each can be configured in software to select which event to be routed

into that event channel. All eight event channels are connected to the peripherals that can use

events, and each of these peripherals can be configured to use events from one or more event

channels to automatically trigger a software selectable action.

8069L–AVR–11/09

17

10. System Clock and Clock options

10.1 Features

• Fast start-up time

• Safe run-time clock switching

• Internal Oscillators:

– 32 MHz run-time calibrated RC oscillator

– 2 MHz run-time calibrated RC oscillator

– 32.768 kHz calibrated RC oscillator

– 32 kHz Ultra Low Power (ULP) oscillator with 1 kHz ouput

• External clock options

– 0.4 - 16 MHz Crystal Oscillator

– 32 kHz Crystal Oscillator

– External clock

• PLL with internal and external clock options with 1 to 31x multiplication

• Clock Prescalers with 1 to 2048x division

• Fast peripheral clock running at 2 and 4 times the CPU clock speed

• Automatic Run-Time Calibration of internal oscillators

• Crystal Oscillator failure detection

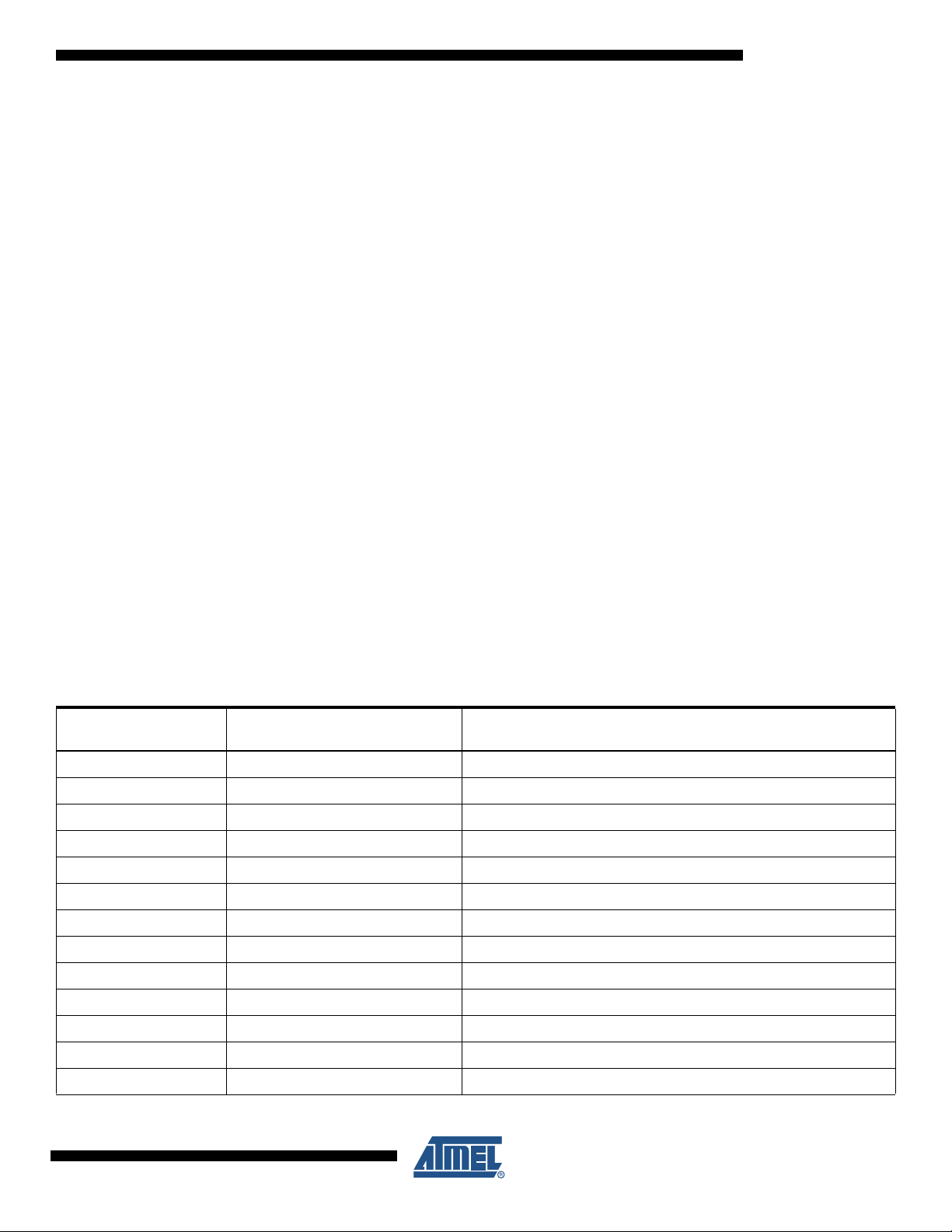

10.2 Overview

XMEGA A4

XMEGA A4 has an advanced clock system, supporting a large number of clock sources. It incorporates both integrated oscillators, external crystal oscillators and resonators. A high frequency

Phase Locked Loop (PLL) and clock prescalers can be controlled from software to generate a

wide range of clock frequencies from the clock source input.

It is possible to switch between clock sources from software during run-time. After reset the

device will always start up running from the 2 Mhz internal oscillator.

A calibration feature is available, and can be used for automatic run-time calibration of the internal 2 MHz and 32 MHz oscillators. This reduce frequency drift over voltage and temperature.

A Crystal Oscillator Failure Monitor can be enabled to issue a Non-Maskable Interrupt and

switch to internal oscillator if the external oscillator fails. Figure 10-1 on page 19 shows the principal clock system in XMEGA A4.

8069L–AVR–11/09

18

Figure 10-1. Clock system overview

32 MHz

Run-time Calibrated

Internal Oscillator

32 kHz ULP

Internal Oscillator

32.768 kHz

Calibrated Internal

Oscillator

32.768 KHz

Crystal Oscillator

0.4 - 16 MHz

Crystal Oscillator

2 MHz

Run-Time Calibrated

Internal Oscillator

External

Clock Input

CLOCK CONTROL

UNIT

with PLL and

Prescaler

WDT/BOD

clk

ULP

RTC

clk

RTC

EVSYS

PERIPHERALS

ADC

DAC

PORTS

...

clk

PER

DMA

INTERRUPT

RAM

NVM MEMORY

FLASH

EEPROM

CPU

clk

CPU

XMEGA A4

10.3 Clock Options

10.3.1 32 kHz Ultra Low Power Internal Oscillator

Each clock source is briefly described in the following sub-sections.

The 32 kHz Ultra Low Power (ULP) Internal Oscillator is a very low power consumption clock

source. It is used for the Watchdog Timer, Brown-Out Detection and as an asynchronous clock

source for the Real Time Counter. This oscillator cannot be used as the system clock source,

and it cannot be directly controlled from software.

10.3.2 32.768 kHz Calibrated Internal Oscillator

The 32.768 kHz Calibrated Internal Oscillator is a high accuracy clock source that can be used

as the system clock source or as an asynchronous clock source for the Real Time Counter. It is

calibrated during production to provide a default frequency which is close to its nominal

frequency.

8069L–AVR–11/09

19

10.3.3 32.768 kHz Crystal Oscillator

The 32.768 kHz Crystal Oscillator is a low power driver for an external watch crystal. It can be

used as system clock source or as asynchronous clock source for the Real Time Counter.

10.3.4 0.4 - 16 MHz Crystal Oscillator

The 0.4 - 16 MHz Crystal Oscillator is a driver intended for driving both external resonators and

crystals ranging from 400 kHz to 16 MHz.

10.3.5 2 MHz Run-time Calibrated Internal Oscillator

The 2 MHz Run-time Calibrated Internal Oscillator is a high frequency oscillator. It is calibrated

during production to provide a default frequency which is close to its nominal frequency. The

oscillator can use the 32 kHz Calibrated Internal Oscillator or the 32 kHz Crystal Oscillator as a

source for calibrating the frequency run-time to compensate for temperature and voltage drift

hereby optimizing the accuracy of the oscillator.

10.3.6 32 MHz Run-time Calibrated Internal Oscillator

The 32 MHz Run-time Calibrated Internal Oscillator is a high frequency oscillator. It is calibrated

during production to provide a default frequency which is close to its nominal frequency. The

oscillator can use the 32 kHz Calibrated Internal Oscillator or the 32 kHz Crystal Oscillator as a

source for calibrating the frequency run-time to compensate for temperature and voltage drift

hereby optimizing the accuracy of the oscillator.

XMEGA A4

10.3.7 External Clock input

The external clock input gives the possibility to connect a clock from an external source.

10.3.8 PLL with Multiplication factor 1 - 31x

The PLL provides the possibility of multiplying a frequency by any number from 1 to 31. In combination with the prescalers, this gives a wide range of output frequencies from all clock sources.

8069L–AVR–11/09

20

11. Power Management and Sleep Modes

11.1 Features

• 5 sleep modes

–Idle

– Power-down

–Power-save

–Standby

– Extended standby

• Power Reduction registers to disable clocks to unused peripherals

11.2 Overview

The XMEGA A4 provides various sleep modes tailored to reduce power consumption to a minimum. All sleep modes are available and can be entered from Active mode. In Active mode the

CPU is executing application code. The application code decides when and what sleep mode to

enter. Interrupts from enabled peripherals and all enabled reset sources can restore the microcontroller from sleep to Active mode.

In addition, Power Reduction registers provide a method to stop the clock to individual peripherals from software. When this is done, the current state of the peripheral is frozen and there is no

power consumption from that peripheral. This reduces the power consumption in Active mode

and Idle sleep mode.

XMEGA A4

11.3 Sleep Modes

11.3.1 Idle Mode

In Idle mode the CPU and Non-Volatile Memory are stopped, but all peripherals including the

Interrupt Controller, Event System and DMA Controller are kept running. Interrupt requests from

all enabled interrupts will wake the device.

11.3.2 Power-down Mode

In Power-down mode all system clock sources, and the asynchronous Real Time Counter (RTC)

clock source, are stopped. This allows operation of asynchronous modules only. The only interrupts that can wake up the MCU are the Two Wire Interface address match interrupts, and

asynchronous port interrupts, e.g pin change.

11.3.3 Power-save Mode

Power-save mode is identical to Power-down, with one exception: If the RTC is enabled, it will

keep running during sleep and the device can also wake up from RTC interrupts.

11.3.4 Standby Mode

Standby mode is identical to Power-down with the exception that all enabled system clock

sources are kept running, while the CPU, Peripheral and RTC clocks are stopped. This reduces

the wake-up time when external crystals or resonators are used.

8069L–AVR–11/09

21

11.3.5 Extended Standby Mode

Extended Standby mode is identical to Power-save mode with the exception that all enabled

system clock sources are kept running while the CPU and Peripheral clocks are stopped. This

reduces the wake-up time when external crystals or resonators are used.

XMEGA A4

8069L–AVR–11/09

22

12. System Control and Reset

12.1 Features

• Multiple reset sources for safe operation and device reset

– Power-On Reset

– External Reset

– Watchdog Reset

The Watchdog Timer runs from separate, dedicated oscillator

– Brown-Out Reset

Accurate, programmable Brown-Out levels

– PDI reset

– Software reset

• Asynchronous reset

– No running clock in the device is required for reset

• Reset status register

12.2 Resetting the AVR

During reset, all I/O registers are set to their initial values. The SRAM content is not reset. Application execution starts from the Reset Vector. The instruction placed at the Reset Vector should

be an Absolute Jump (JMP) instruction to the reset handling routine. By default the Reset Vector

address is the lowest Flash program memory address, ‘0’, but it is possible to move the Reset

Vector to the first address in the Boot Section.

XMEGA A4

The I/O ports of the AVR are immediately tri-stated when a reset source goes active.

The reset functionality is asynchronous, so no running clock is required to reset the device.

After the device is reset, the reset source can be determined by the application by reading the

Reset Status Register.

12.3 Reset Sources

12.3.1 Power-On Reset

The MCU is reset when the supply voltage VCC is below the Power-on Reset threshold voltage.

12.3.2 External Reset

The MCU is reset when a low level is present on the RESET pin.

12.3.3 Watchdog Reset

The MCU is reset when the Watchdog Timer period expires and the Watchdog Reset is enabled.

The Watchdog Timer runs from a dedicated oscillator independent of the System Clock. For

more details see ”WDT - Watchdog Timer” on page 24.

12.3.4 Brown-Out Reset

The MCU is reset when the supply voltage VCC is below the Brown-Out Reset threshold voltage

and the Brown-out Detector is enabled. The Brown-out threshold voltage is programmable.

8069L–AVR–11/09

23

12.3.5 PDI reset

The MCU can be reset through the Program and Debug Interface (PDI).

12.3.6 Software reset

The MCU can be reset by the CPU writing to a special I/O register through a timed sequence.

13. WDT - Watchdog Timer

13.1 Features

• 11 selectable timeout periods, from 8 ms to 8s.

• Two operation modes

– Standard mode

– Window mode

• Runs from the 1 kHz output of the 32 kHz Ultra Low Power oscillator

• Configuration lock to prevent unwanted changes

13.2 Overview

XMEGA A4

The XMEGA A4 has a Watchdog Timer (WDT). The WDT will run continuously when turned on

and if the Watchdog Timer is not reset within a software configurable time-out period, the microcontroller will be reset. The Watchdog Reset (WDR) instruction must be run by software to reset

the WDT, and prevent microcontroller reset.

The WDT has a Window mode. In this mode the WDR instruction must be run within a specified

period called a window. Application software can set the minimum and maximum limits for this

window. If the WDR instruction is not executed inside the window limits, the microcontroller will

be reset.

A protection mechanism using a timed write sequence is implemented in order to prevent

unwanted enabling, disabling or change of WDT settings.

For maximum safety, the WDT also has an Always-on mode. This mode is enabled by programming a fuse. In Always-on mode, application software can not disable the WDT.

8069L–AVR–11/09

24

14. PMIC - Programmable Multi-level Interrupt Controller

14.1 Features

• Separate interrupt vector for each interrupt

• Short, predictable interrupt response time

• Programmable Multi-level Interrupt Controller

– 3 programmable interrupt levels

– Selectable priority scheme within low level interrupts (round-robin or fixed)

– Non-Maskable Interrupts (NMI)

• Interrupt vectors can be moved to the start of the Boot Section

14.2 Overview

XMEGA A4 has a Programmable Multi-level Interrupt Controller (PMIC). All peripherals can

define three different priority levels for interrupts; high, medium or low. Medium level interrupts

may interrupt low level interrupt service routines. High level interrupts may interrupt both lowand medium level interrupt service routines. Low level interrupts have an optional round robin

scheme to make sure all interrupts are serviced within a certain amount of time.

The built in oscillator failure detection mechanism can issue a Non-Maskable Interrupt (NMI).

XMEGA A4

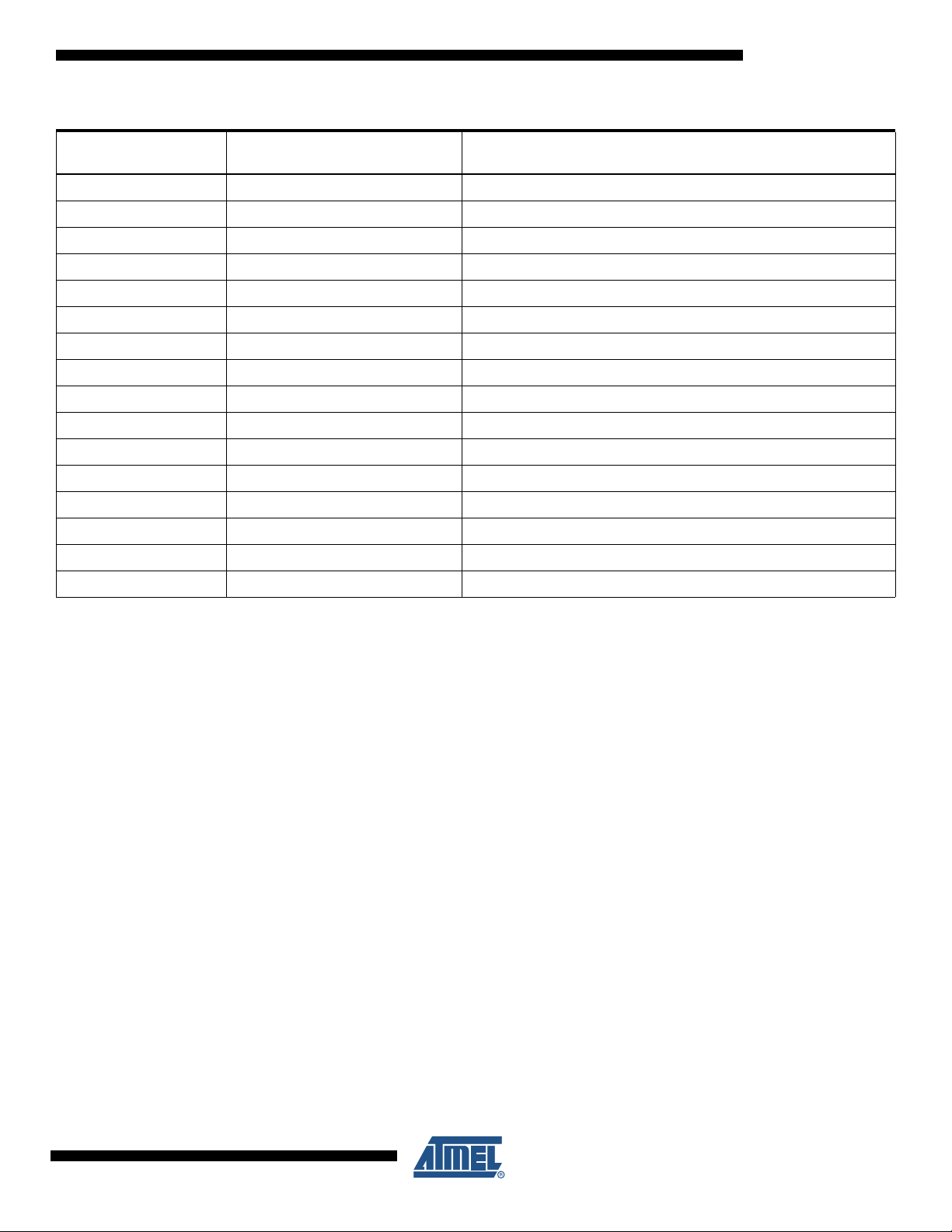

14.3 Interrupt vectors

When an interrupt is serviced, the program counter will jump to the interrupt vector address. The

interrupt vector is the sum of the peripheral’s base interrupt address and the offset address for

specific interrupts in each peripheral. The base addresses for the XMEGA A4 devices are shown

in Table 14-1. Offset addresses for each interrupt available in the peripheral are described for

each peripheral in the XMEGA A manual. For peripherals or modules that have only one interrupt, the interrupt vector is shown in Table 14-1. The program address is the word address.

Table 14-1. Reset and Interrupt Vectors

Program Address

(Base Address) Source Interrupt Description

0x000 RESET

0x002 OSCF_INT_vect Crystal Oscillator Failure Interrupt vector (NMI)

0x004 PORTC_INT_base Port C Interrupt base

0x008 PORTR_INT_base Port R Interrupt base

0x00C DMA_INT_base DMA Controller Interrupt base

0x014 RTC_INT_base Real Time Counter Interrupt base

0x018 TWIC_INT_base Two-Wire Interface on Port C Interrupt base

0x01C TCC0_INT_base Timer/Counter 0 on port C Interrupt base

0x028 TCC1_INT_base Timer/Counter 1 on port C Interrupt base

0x030 SPIC_INT_vect SPI on port C Interrupt vector

0x032 USARTC0_INT_base USART 0 on port C Interrupt base

0x038 USARTC1_INT_base USART 1 on port C Interrupt base

0x03E AES_INT_vect AES Interrupt vector

8069L–AVR–11/09

25

Table 14-1. Reset and Interrupt Vectors (Continued)

Program Address

(Base Address) Source Interrupt Description

0x040 NVM_INT_base Non-Volatile Memory Interrupt base

0x044 PORTB_INT_base Port B Interrupt base

0x056 PORTE_INT_base Port E Interrupt base

0x05A TWIE_INT_base Two-Wire Interface on Port E Interrupt base

0x05E TCE0_INT_base Timer/Counter 0 on port E Interrupt base

0x06A TCE1_INT_base Timer/Counter 1 on port E Interrupt base

0x074 USARTE0_INT_base USART 0 on port E Interrupt base

0x080 PORTD_INT_base Port D Interrupt base

0x084 PORTA_INT_base Port A Interrupt base

0x088 ACA_INT_base Analog Comparator on Port A Interrupt base

0x08E ADCA_INT_base Analog to Digital Converter on Port A Interrupt base

0x09A TCD0_INT_base Timer/Counter 0 on port D Interrupt base

0x0A6 TCD1_INT_base Timer/Counter 1 on port D Interrupt base

0x0AE SPID_INT_vector SPI on port D Interrupt vector

0x0B0 USARTD0_INT_base USART 0 on port D Interrupt base

XMEGA A4

0x0B6 USARTD1_INT_base USART 1 on port D Interrupt base

8069L–AVR–11/09

26

15. I/O Ports

15.1 Features

15.2 Overview

XMEGA A4

• Selectable input and output configuration for each pin individually

• Flexible pin configuration through dedicated Pin Configuration Register

• Synchronous and/or asynchronous input sensing with port interrupts and events

– Sense both edges

– Sense rising edges

– Sense falling edges

– Sense low level

• Asynchronous wake-up from all input sensing configurations

• Two port interrupts with flexible pin masking

• Highly configurable output driver and pull settings:

– Totem-pole

– Pull-up/-down

– Wired-AND

– Wired-OR

– Bus-keeper

– Inverted I/O

• Optional Slew rate control

• Configuration of multiple pins in a single operation

• Read-Modify-Write (RMW) support

• Toggle/clear/set registers for Output and Direction registers

• Clock output on port pin

• Event Channel 7 output on port pin

• Mapping of port registers (virtual ports) into bit accessible I/O memory space

The XMEGA A4 devices have flexible General Purpose I/O Ports. A port consists of up to 8 pins,

ranging from pin 0 to pin 7. The ports implement several functions, including synchronous/asynchronous input sensing, pin change interrupts and configurable output settings. All functions are

individual per pin, but several pins may be configured in a single operation.

15.3 I/O configuration

All port pins (Pn) have programmable output configuration. In addition, all port pins have an

inverted I/O function. For an input, this means inverting the signal between the port pin and the

pin register. For an output, this means inverting the output signal between the port register and

the port pin. The inverted I/O function can be used also when the pin is used for alternate

functions.

8069L–AVR–11/09

27

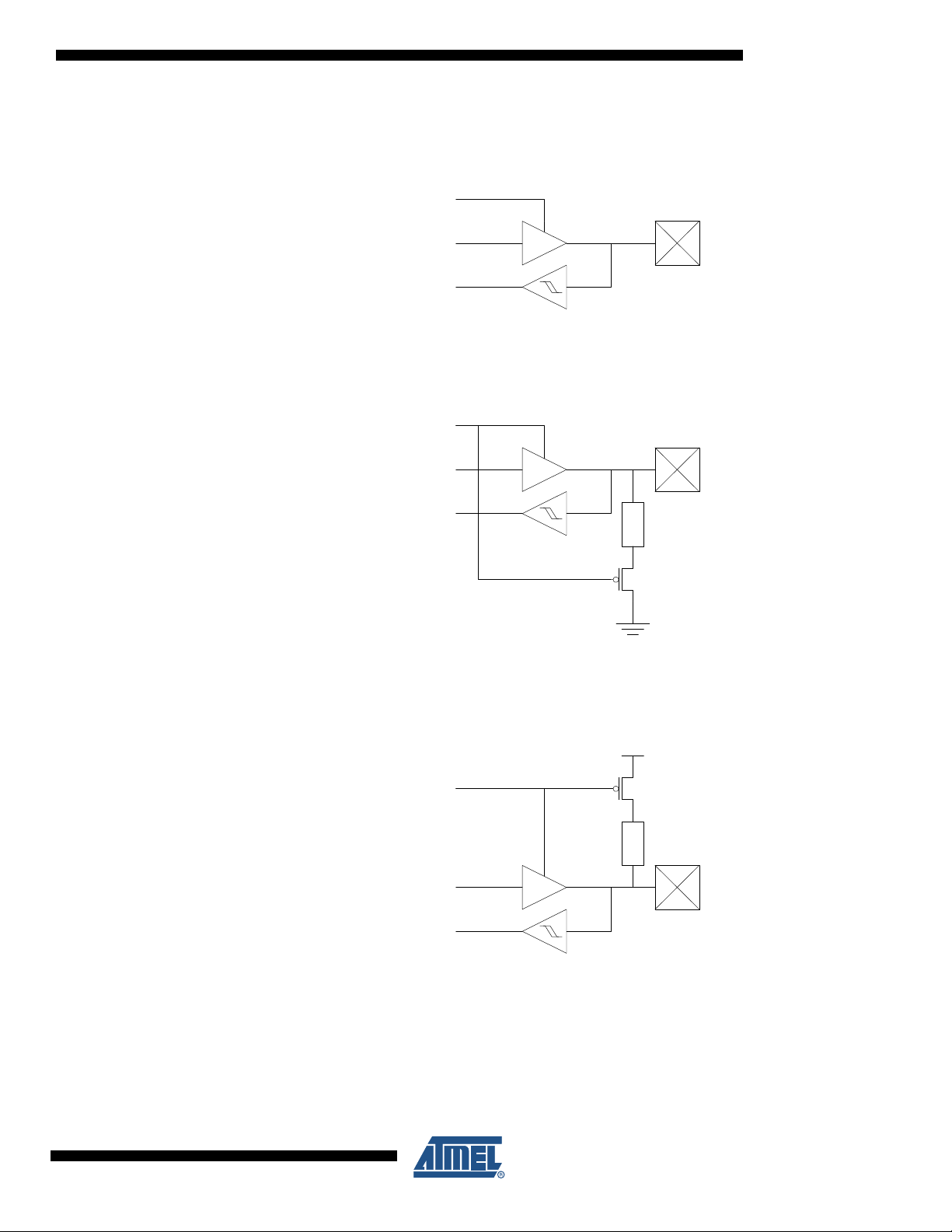

15.3.1 Push-pull

INn

OUTn

DIRn

Pn

INn

OUTn

DIRn

Pn

INn

OUTn

DIRn

Pn

15.3.2 Pull-down

XMEGA A4

Figure 15-1. I/O configuration - Totem-pole

Figure 15-2. I/O configuration - Totem-pole with pull-down (on input)

15.3.3 Pull-up

15.3.4 Bus-keeper

Figure 15-3. I/O configuration - Totem-pole with pull-up (on input)

The bus-keeper’s weak output produces the same logical level as the last output level. It acts as

a pull-up if the last level was ‘1’, and pull-down if the last level was ‘0’.

8069L–AVR–11/09

28

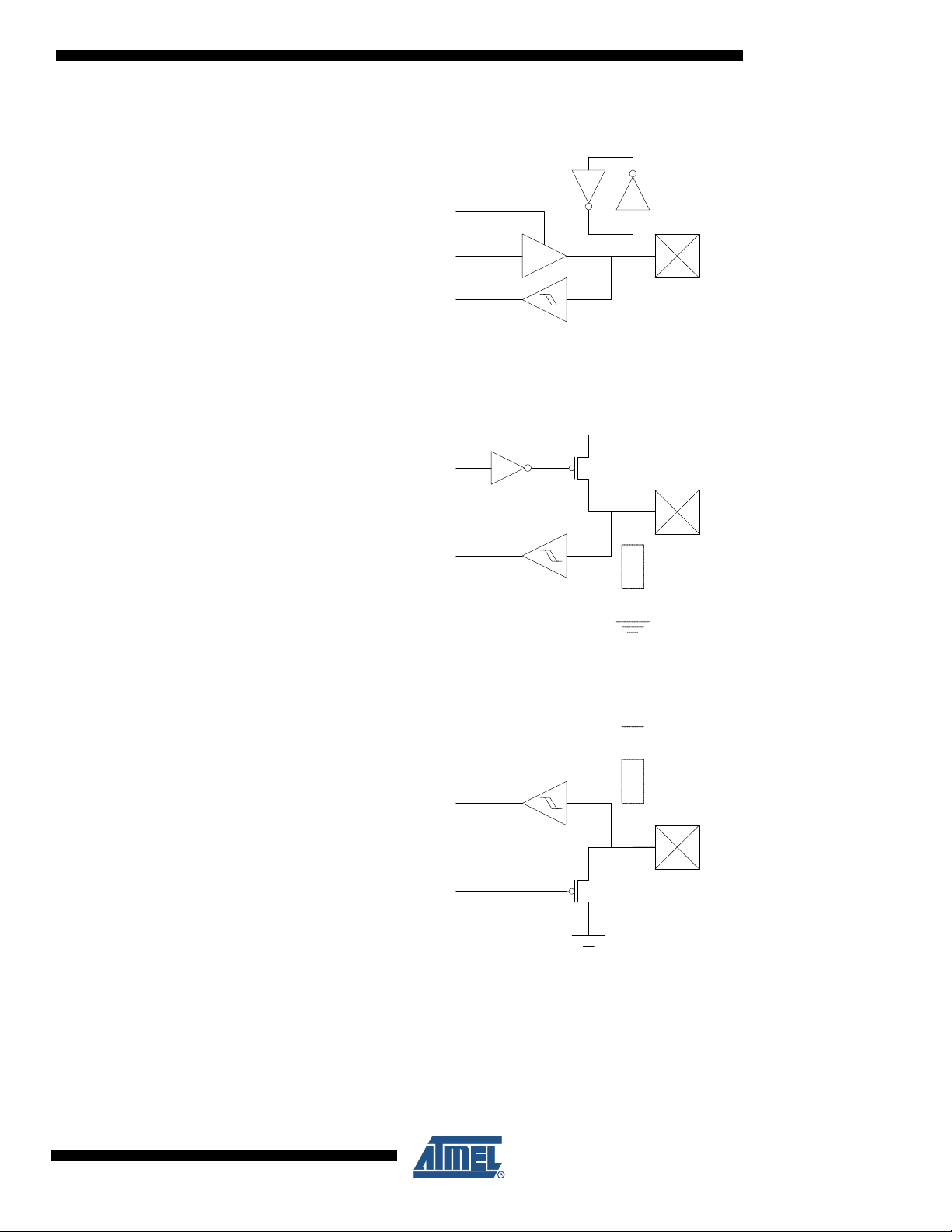

15.3.5 Others

INn

OUTn

DIRn

Pn

INn

OUTn

Pn

INn

OUTn

Pn

XMEGA A4

Figure 15-4. I/O configuration - Totem-pole with bus-keeper

Figure 15-5. Output configuration - Wired-OR with optional pull-down

8069L–AVR–11/09

Figure 15-6. I/O configuration - Wired-AND with optional pull-up

29

15.4 Input sensing

INVERTED I/O

Interrupt

Control

IREQ

Event

Pn

D

Q

R

D

Q

R

Synchronizer

INn

EDGE

DETECT

Asynchronous sensing

Synchronous sensing

EDGE

DETECT

XMEGA A4

• Sense both edges

• Sense rising edges

• Sense falling edges

• Sense low level

Input sensing is synchronous or asynchronous depending on the enabled clock for the ports,

and the configuration is shown in Figure 15-7 on page 30.

Figure 15-7. Input sensing system overview

When a pin is configured with inverted I/O, the pin value is inverted before the input sensing.

15.5 Port Interrupt

Each port has two interrupts with separate priority and interrupt vector. All pins on the port can

be individually selected as source for each of the interrupts. The interrupts are then triggered

according to the input sense configuration for each pin configured as source for the interrupt.

15.6 Alternate Port Functions

In addition to the input/output functions on all port pins, most pins have alternate functions. This

means that other modules or peripherals connected to the port can use the port pins for their

functions, such as communication or pulse-width modulation. ”Pinout and Pin Functions” on

page 49 shows which modules on peripherals that enable alternate functions on a pin, and

which alternate function is available on a pin.

8069L–AVR–11/09

30

16. T/C - 16-bit Timer/Counter

16.1 Features

• Five 16-bit Timer/Counters

– Three Timer/Counters of type 0

– Two Timer/Counters of type 1

• Three Compare or Capture (CC) Channels in Timer/Counter 0

• Two Compare or Capture (CC) Channels in Timer/Counter 1

• Double Buffered Timer Period Setting

• Double Buffered Compare or Capture Channels

• Waveform Generation:

– Single Slope Pulse Width Modulation

– Dual Slope Pulse Width Modulation

– Frequency Generation

• Input Capture:

– Input Capture with Noise Cancelling

– Frequency capture

– Pulse width capture

– 32-bit input capture

• Event Counter with Direction Control

• Timer Overflow and Timer Error Interrupts and Events

• One Compare Match or Capture Interrupt and Event per CC Channel

• Supports DMA Operation

• Hi-Resolution Extension (Hi-Res)

• Advanced Waveform Extension (AWEX)

XMEGA A4

16.2 Overview

XMEGA A4 has five Timer/Counters, three Timer/Counter 0 and two Timer/Counter 1. The difference between them is that Timer/Counter 0 has four Compare/Capture channels, while

Timer/Counter 1 has two Compare/Capture channels.

The Timer/Counters (T/C) are 16-bit and can count any clock, event or external input in the

microcontroller. A programmable prescaler is available to get a useful T/C resolution. Updates of

Timer and Compare registers are double buffered to ensure glitch free operation. Single slope

PWM, dual slope PWM and frequency generation waveforms can be generated using the Compare Channels.

Through the Event System, any input pin or event in the microcontroller can be used to trigger

input capture, hence no dedicated pins are required for this. The input capture has a noise canceller to avoid incorrect capture of the T/C, and can be used to do frequency and pulse width

measurements.

A wide range of interrupt or event sources are available, including T/C Overflow, Compare

match and Capture for each Compare/Capture channel in the T/C.

PORTC and PORTD each has one Timer/Counter 0 and one Timer/Counter1. PORTE has one

Timer/Conter0. Notation of these are TCC0 (Time/Counter C0), TCC1, TCD0, TCD1 and TCE0,

respectively.

8069L–AVR–11/09

31

XMEGA A4

AWeX

Compare/Capture Channel D

Compare/Capture Channel C

Compare/Capture Channel B

Compare/Capture Channel A

Waveform

Generation

Buffer

Comparator

Hi-Res

Fault

Protection

Capture

Control

Base Counter

Counter

Control Logic

Timer Period

Prescaler

DTI

Dead-Time

Insertion

Pattern

Generation

clk

PER4

PORT

Event

System

clk

PER

Timer/Counter

Figure 16-1. Overview of a Timer/Counter and closely related peripherals

The Hi-Resolution Extension can be enabled to increase the waveform generation resolution by

2 bits (4x). This is available for all Timer/Counters. See ”Hi-Res - High Resolution Extension” on

page 34 for more details.

The Advanced Waveform Extension can be enabled to provide extra and more advanced feature for the Timer/Counter. This is only available for Timer/Counter 0. See ”AWEX - Advanced

Waveform Extension” on page 33 for more details.

8069L–AVR–11/09

32

17. AWEX - Advanced Waveform Extension

17.1 Features

• Output with complementary output from each Capture channel

• Four Dead Time Insertion (DTI) Units, one for each Capture channel

• 8-bit DTI Resolution

• Separate High and Low Side Dead-Time Setting

• Double Buffered Dead-Time

• Event Controlled Fault Protection

• Single Channel Multiple Output Operation (for BLDC motor control)

• Double Buffered Pattern Generation

17.2 Overview

The Advanced Waveform Extension (AWEX) provides extra features to the Timer/Counter in

Waveform Generation (WG) modes. The AWEX enables easy and safe implementation of for

example, advanced motor control (AC, BLDC, SR, and Stepper) and power control applications.

Any WG output from a Timer/Counter 0 is split into a complimentary pair of outputs when any

AWEX feature is enabled. These output pairs go through a Dead-Time Insertion (DTI) unit that

enables generation of the non-inverted Low Side (LS) and inverted High Side (HS) of the WG

output with dead time insertion between LS and HS switching. The DTI output will override the

normal port value according to the port override setting. Optionally the final output can be

inverted by using the invert I/O setting for the port pin.

XMEGA A4

The Pattern Generation unit can be used to generate a synchronized bit pattern on the port it is

connected to. In addition, the waveform generator output from Compare Channel A can be distributed to, and override all port pins. W hen the Pattern Generator unit is enabled, the DTI unit is

bypassed.

The Fault Protection unit is connected to the Event System. This enables any event to trigger a

fault condition that will disable the AWEX output. Several event channels can be used to trigger

fault on several different conditions.

The AWEX is available for TCC0. The notation of this is AWEXC.

8069L–AVR–11/09

33

18. Hi-Res - High Resolution Extension

18.1 Features

• Increases Waveform Generator resolution by 2-bits (4x)

• Supports Frequency, single- and dual-slope PWM operation

• Supports the AWEX when this is enabled and used for the same Timer/Counter

18.2 Overview

The Hi-Resolution (Hi-Res) Extension is able to increase the resolution of the waveform generation output by a factor of 4. When enabled for a Timer/Counter, the Fast Peripheral clock running

at four times the CPU clock speed will be as input to the Timer/Counter.

The High Resolution Extension can also be used when an AWEX is enabled and used with a

Timer/Counter.

XMEGA A4 devices have three Hi-Res Extensions that each can be enabled for each

Timer/Counters pair on PORTC, PORTD and PORTE. The notation of these are HIRESC,

HIRESD and HIRESE, respectively.

XMEGA A4

8069L–AVR–11/09

34

19. RTC - 16-bit Real-Time Counter

10-bit

prescaler

Counter

Period

Compare

=

=

Overflow

Compare Match

1 kHz

32 kHz

19.1 Features

• 16-bit Timer

• Flexible Tick resolution ranging from 1 Hz to 32.768 kHz

• One Compare register

• One Period register

• Clear timer on Overflow or Compare Match

• Overflow or Compare Match event and interrupt generation

19.2 Overview

The XMEGA A4 includes a 16-bit Real-time Counter (RTC). The RTC can be clocked from an

accurate 32.768 kHz Crystal Oscillator, the 32.768 kHz Calibrated Internal Oscillator, or from the

32 kHz Ultra Low Power Internal Oscillator. The RTC includes both a Period and a Compare

register. For details, see Figure 19-1.

A wide range of Resolution and Time-out periods can be configured using the RTC. With a maximum resolution of 30.5 µs, time-out periods range up to 2000 seconds. With a resolution of 1

second, the maximum time-out period is over 18 hours (65536 seconds).

XMEGA A4

Figure 19-1. Real Time Counter overview

8069L–AVR–11/09

35

20. TWI - Two-Wire Interface

20.1 Features

• Two Identical TWI peripherals

• Simple yet Powerful and Flexible Communication Interface

• Both Master and Slave Operation Supported

• Device can Operate as Transmitter or Receiver

• 7-bit Address Space Allows up to 128 Different Slave Addresses

• Multi-master Arbitration Support

• Up to 400 kHz Data Transfer Speed

• Slew-rate Limited Output Drivers

• Noise Suppression Circuitry Rejects Spikes on Bus Lines

• Fully Programmable Slave Address with General Call Support

• Address Recognition Causes Wake-up when in Sleep Mode

2

• I

C and System Management Bus (SMBus) compatible

20.2 Overview

The Two-Wire Interface (TWI) is a bi-directional wired-AND bus with only two lines, the clock

(SCL) line and the data (SDA) line. The protocol makes it possible to interconnect up to 128 individually addressable devices. Since it is a multi-master bus, one or more devices capable of

taking control of the bus can be connected.

XMEGA A4

The only external hardware needed to implement the bus is a single pull-up resistor for each of

the TWI bus lines. Mechanisms for resolving bus contention are inherent in the TWI protocol.

PORTC and PORTE each has one TWI. Notation of these peripherals are TWIC and TWIE,

respectively.

8069L–AVR–11/09

36

21. SPI - Serial Peripheral Interface

21.1 Features

• Two Identical SPI peripherals

• Full-duplex, Three-wire Synchronous Data Transfer

• Master or Slave Operation

• LSB First or MSB First Data Transfer

• Seven Programmable Bit Rates

• End of Transmission Interrupt Flag

• Write Collision Flag Protection

• Wake-up from Idle Mode

• Double Speed (CK/2) Master SPI Mode

21.2 Overview

The Serial Peripheral Interface (SPI) allows high-speed full-duplex, synchronous data transfer

between different devices. Devices can communicate using a master-slave scheme, and data is

transferred both to and from the devices simultaneously.

PORTC and PORTD each has one SPI. Notation of these peripherals are SPIC and SPID,

respectively.

XMEGA A4

8069L–AVR–11/09

37

22. USART

22.1 Features

22.2 Overview

XMEGA A4

• Five Identical USART peripherals

• Full Duplex Operation (Independent Serial Receive and Transmit Registers)

• Asynchronous or Synchronous Operation

• Master or Slave Clocked Synchronous Operation

• High-resolution Arithmetic Baud Rate Generator

• Supports Serial Frames with 5, 6, 7, 8, or 9 Data Bits and 1 or 2 Stop Bits

• Odd or Even Parity Generation and Parity Check Supported by Hardware

• Data OverRun Detection

• Framing Error Detection

• Noise Filtering Includes False Start Bit Detection and Digital Low Pass Filter

• Three Separate Interrupts on TX Complete, TX Data Register Empty and RX Complete

• Multi-processor Communication Mode

• Double Speed Asynchronous Communication Mode

• Master SPI mode for SPI communication

• IrDA support through the IRCOM module

The Universal Synchronous and Asynchronous serial Receiver and Transmitter (USART) is a

highly flexible serial communication module. The USART supports full duplex communication,

and both asynchronous and clocked synchronous operation. The USART can also be set in

Master SPI mode to be used for SPI communication.

Communication is frame based, and the frame format can be customized to support a wide

range of standards. The USART is buffered in both direction, enabling continued data transmission without any delay between frames. There are separate interrupt vectors for receive and

transmit complete, enabling fully interrupt driven communication. Frame error and buffer overflow are detected in hardware and indicated with separate status flags. Even or odd parity

generation and parity check can also be enabled.

One USART can use the IRCOM module to support IrDA 1.4 physical compliant pulse modulation and demodulation for baud rates up to 115.2 kbps.

PORTC and PORTD each has two USARTs. PORTE has one USART. Notation of these peripherals are USARTC0, USARTC1, USARTD0, USARTD1 and USARTE0, respectively.

8069L–AVR–11/09

38

23. IRCOM - IR Communication Module

23.1 Features

• Pulse modulation/demodulation for infrared communication

• Compatible to IrDA 1.4 physical for baud rates up to 115.2 kbps

• Selectable pulse modulation scheme

– 3/16 of baud rate period

– Fixed pulse period, 8-bit programmable

– Pulse modulation disabled

• Built in filtering

• Can be connected to and used by one USART at a time

23.2 Overview

XMEGA contains an Infrared Communication Module (IRCOM) for IrDA communication with

baud rates up to 115.2 kbps. This supports three modulation schemes: 3/16 of baud rate period,

fixed programmable pulse time based on the Peripheral Clock speed, or pulse modulation disabled. There is one IRCOM available which can be connected to any USART to enable infrared

pulse coding/decoding for that USART.

XMEGA A4

8069L–AVR–11/09

39

24. Crypto Engine

24.1 Features

24.2 Overview

XMEGA A4

• Data Encryption Standard (DES) CPU instruction

• Advanced Encryption Standard (AES) Crypto module

• DES Instruction

– Encryption and Decryption

– Single-cycle DES instruction

– Encryption/Decryption in 16 clock cycles per 8-byte block

• AES Crypto Module

– Encryption and Decryption

– Support 128-bit keys

– Support XOR data load mode to the State memory for Cipher Block Chaining

– Encryption/Decryption in 375 clock cycles per 16-byte block

The Advanced Encryption Standard (AES) and Data Encryption Standard (DES) are two commonly used encryption standards. These are supported through an AES peripheral module and

a DES CPU instruction. All communication interfaces and the CPU can optionally use AES and

DES encrypted communication and data storage.

DES is supported by a DES instruction in the AVR XMEGA CPU. The 8-byte key and 8-byte

data blocks must be loaded into the Register file, and then DES must be executed 16 times to

encrypt/decrypt the data block.

The AES Crypto Module encrypts and decrypts 128-bit data blocks with the use of a 128-bit key.

The key and data must be loaded into the key and state memory in the module before encryption/decryption is started. It takes 375 peripheral clock cycles before the encryption/decryption is

done and decrypted/encrypted data can be read out, and an optional interrupt can be generated.

The AES Crypto Module also has DMA support with transfer triggers when encryption/decryption is done and optional auto-start of encryption/decryption when the state memory is fully

loaded.

8069L–AVR–11/09

40

25. ADC - 12-bit Analog to Digital Converter

25.1 Features

• One ADC with 12-bit resolution

• 2 Msps sample rate

• Signed and Unsigned conversions

• 4 result registers with individual input channel control

• 12 single ended inputs

• 8x4 differential inputs

• 4 internal inputs:

– Integrated Temperature Sensor

– DAC Output

– VCC voltage divided by 10

– Bandgap voltage

• Software selectable gain of 2, 4, 8, 16, 32 or 64

• Selectable accuracy of 8- or 12-bit.

• Internal or External Reference selection

• Event triggered conversion for accurate timing

• DMA transfer of conversion results

• Interrupt/Event on compare result

25.2 Overview

XMEGA A4

XMEGA A4 devices have one Analog to Digital Converter (ADC), see Figure 25-1 on page 42.

The ADC converts analog voltages to digital values. The ADC has 12-bit resolution and is capable of converting up to 2 million samples per second. The input selection is flexible, and both

single-ended and differential measurements can be done. For differential measurements an

optional gain stage is available to increase the dynamic range. In addition several internal signal

inputs are available. The ADC can provide both signed and unsigned results.

This is a pipeline ADC. A pipeline ADC consists of several consecutive stages, where each

stage convert one part of the result. The pipeline design enables high sample rate at low clock

speeds, and remove limitations on samples speed versus propagation delay. This also means

that a new analog voltage can be sampled and a new ADC measurement started while other

ADC measurements are ongoing.

ADC measurements can either be started by application software or an incoming event from

another peripheral in the device. Four different result registers with individual input selection

(MUX selection) are provided to make it easier for the application to keep track of the data. Each

result register and MUX selection pair is referred to as an ADC Channel. It is possible to use

DMA to move ADC results directly to memory or peripherals when conversions are done.

Both internal and external analog reference voltages can be used. An accurate internal 1.0V

reference is available.

An integrated temperature sensor is available and the output from this can be measured with the

ADC. The output from the DAC, VCC/10 and the Bandgap voltage can also be measured by the

ADC.

8069L–AVR–11/09

41

Figure 25-1. ADC overview

ADC

Channel A

Register

Channel B

Register

Channel C

Register

Channel D

Register

Pin inputsPin inputs

1-64 X

Internal inputs

Channel A MUX selection

Channel B MUX selection

Channel C MUX selection

Channel D MUX selection

Event

Trigger

Configuration

Reference selection

XMEGA A4

Each ADC has four MUX selection registers with a corresponding result register. This means

that four channels can be sampled within 1.5 µs without any intervention by the application other

than starting the conversion. The results will be available in the result registers.

The ADC may be configured for 8- or 12-bit resolution, reducing the minimum conversion time

(propagation delay) from 3.5 µs for 12-bit to 2.5 µs for 8-bit resolution.

ADC conversion results are provided left- or right adjusted with optional ‘1’ or ‘0’ padding. This

eases calculation when the result is represented as a signed integer (signed 16-bit number).

PORTA has one ADC. Notation of this peripheral is ADCA.

8069L–AVR–11/09

42

26. DAC - 12-bit Digital to Analog Converter

DAC

Channel A

Register

Channel B

Register

Event

Trigger

Configuration

Reference selection

Channel A

Channel B

26.1 Features

• One DAC with 12-bit resolution

• Up to 1 Msps conversion rate

• Flexible conversion range

• Multiple trigger sources

• 1 continuous output or 2 Sample and Hold (S/H) outputs

• Built-in offset and gain calibration

• High drive capabilities

• Low Power Mode

26.2 Overview

The XMEGA A4 devices feature one 12-bit, 1 Msps DAC with built-in offset and gain calibration,

see Figure 26-1 on page 43.

A DAC converts a digital value into an analog signal. The DAC may use an internal 1.1 voltage

as the upper limit for conversion, but it is also possible to use the supply voltage or any applied

voltage in-between. The external reference input is shared with the ADC reference input.

XMEGA A4

Figure 26-1. DAC overview

The DAC has one continuous output with high drive capabilities for both resistive and capacitive

loads. It is also possible to split the continuous time channel into two Sample and Hold (S/H)

channels, each with separate data conversion registers.

A DAC conversion may be started from the application software by writing the data conversion

registers. The DAC can also be configured to do conversions triggered by the Event System to

have regular timing, independent of the application software. DMA may be used for transferring

data from memory locations to DAC data registers.

The DAC has a built-in calibration system to reduce offset and gain error when loading with a

calibration value from software.

8069L–AVR–11/09

PORTB has one DAC. Notation of this peripheral is DACB.

43

27. AC - Analog Comparator

27.1 Features

• Two Analog Comparators

• Selectable Power vs. Speed

• Selectable hysteresis

– 0, 20 mV, 50 mV

• Analog Comparator output available on pin

• Flexible Input Selection

– All pins on the port

– Output from the DAC

– Bandgap reference voltage.

– Voltage scaler that can perform a 64-level scaling of the internal VCC voltage.

• Interrupt and event generation on

– Rising edge

– Falling edge

–Toggle

• Window function interrupt and event generation on

– Signal above window

– Signal inside window

– Signal below window

27.2 Overview

XMEGA A4

XMEGA A4 features two Analog Comparators (AC). An Analog Comparator compares two voltages, and the output indicates which input is largest. The Analog Comparator may be configured

to give interrupt requests and/or events upon several different combinations of input change.

Both hysteresis and propagation delays may be adjusted in order to find the optimal operation

for each application.

A wide range of input selection is available, both external pins and several internal signals can

be used.

The Analog Comparators are always grouped in pairs (AC0 and AC1) on each analog port. They

have identical behavior but separate control registers.

Optionally, the state of the comparator is directly available on a pin.

PORTA has one AC pair. Notation of this peripheral is ACA.

8069L–AVR–11/09

44

Figure 27-1. Analog comparator overview

AC0

+

-

Pin inputs

Internal inputs

Pin inputs

Internal inputs

VCC scaled

Interrupt

sensitivity

control

Interrupts

AC1

+

-

Pin inputs

Internal inputs

Pin inputs

Internal inputs

VCC scaled

Events

Pin 0 output

XMEGA A4

8069L–AVR–11/09

45

27.3 Input Selection

AC0

+

-

AC1

+

-

Input signal

Upper limit of window

Lower limit of window

Interrupt

sensitivity

control

Interrupts

Events

The Analog comparators have a very flexible input selection and the two comparators grouped

in a pair may be used to realize a window function. One pair of analog comparators is shown in

Figure 27-1 on page 45.

•

Input selection from pin

• Internal signals available on positive analog comparator inputs

• Internal signals available on negative analog comparator inputs

27.4 Window Function

The window function is realized by connecting the external inputs of the two analog comparators

in a pair as shown in Figure 27-2.

XMEGA A4

– Pin 0, 1, 2, 3, 4, 5, 6 selectable to positive input of analog comparator

– Pin 0, 1, 3, 5, 7 selectable to negative input of analog comparator

– Output from 12-bit DAC

– 64-level scaler of the VCC, available on negative analog comparator input

– Bandgap voltage reference

– Output from 12-bit DAC

Figure 27-2. Analog comparator window function

8069L–AVR–11/09

46

28. OCD - On-chip Debug

28.1 Features

• Complete Program Flow Control

– Go, Stop, Reset, Step into, Step over, Step out, Run-to-Cursor

• Debugging on C and high-level language source code level

• Debugging on Assembler and disassembler level

• 1 dedicated program address or source level breakpoint for AVR Studio / debugger

• 4 Hardware Breakpoints

• Unlimited Number of User Program Breakpoints

• Unlimited Number of User Data Breakpoints, with break on:

– Data location read, write or both read and write

– Data location content equal or not equal to a value

– Data location content is greater or less than a value

– Data location content is within or outside a range

– Bits of a data location are equal or not equal to a value

• Non-Intrusive Operation

– No hardware or software resources in the device are used

• High Speed Operation

– No limitation on debug/programming clock frequency versus system clock frequency

28.2 Overview

XMEGA A4

The XMEGA A4 has a powerful On-Chip Debug (OCD) system that - in combination with Atmel’s

development tools - provides all the necessary functions to debug an application. It has support

for program and data breakpoints, and can debug an application from C and high level language

source code level, as well as assembler and disassembler level. It has full Non-Intrusive Operation and no hardware or software resources in the device are used. The ODC system is

accessed through an external debugging tool which connects to the PDI physical interface.

Refer to ”Program and Debug Interfaces” on page 48.

8069L–AVR–11/09

47

29. Program and Debug Interfaces

29.1 Features

• PDI - Program and Debug Interface (Atmel proprietary 2-pin interface)

• Access to the OCD system

• Programming of Flash, EEPROM, Fuses and Lock Bits

29.2 Overview

The programming and debug facilities are accessed through PDI physical interface. The PDI

physical interface uses one dedicated pin together with the Reset pin, and no general purpose

pins are used.

29.3 PDI - Program and Debug Interface

The PDI is an Atmel proprietary protocol for communication between the microcontroller and

Atmel’s development tools.

XMEGA A4

8069L–AVR–11/09

48

30. Pinout and Pin Functions

The pinout of XMEGA A4 is shown in ”Pinout/Block Diagram” on page 3. In addition to general

I/O functionality, each pin may have several functions. This will depend on which peripheral is

enabled and connected to the actual pin. Only one of the alternate pin functions can be used at

time.

30.1 Alternate Pin Functions Description

The tables below shows the notation for all pin functions available and describe their functions.

30.1.1 Operation/Power Supply

VCC Digital supply voltage

AVCC Analog supply voltage

GND Ground

30.1.2 Port Interrupt functions

SYNC Port pin with full synchronous and limited asynchronous interrupt function

ASYNC Port pin with full synchronous and full asynchronous interrupt function

XMEGA A4

30.1.3 Analog functions

ACn Analog Comparator input pin n

AC0OUT Analog Comparator 0 Output

ADCn Analog to Digital Converter input pin n

DACn Digital to Analog Converter output pin n