Page 1

查询ATF1516AS-10QC160供应商

Features

•

High Density, High Performance Electrically Erasable Complex

Programmable Logic Device

– 256 Macrocells

– 5 Product Terms per Macrocell, Expandable up to 40 per Macrocell

– 160, 192, 208-pins

– 10 ns Maximum Pin-to-Pin Delay

– Registered Operation Up To 100 MHz

– Enhanced Routing Resources

•

Flexible Logic Macrocell

– D/T/Latch Configurable Flip Flops

– Global and Individual Register Control Signals

– Global and Individual Output Enable

– Programmable Output Slew Rate

– Programmable Output Open Collector Option

– Maximum Logic utilization by burying a register within a COM output

•

Advanced Power Management Features

– Automatic 3 mA Stand-By for “L” Version (Max.)

– Pin-Controlled 4 mA Stand-By Mode (Typical)

– Programmable Pin-Keeper Inputs and I/Os

– Reduced-Power Feature Per Macrocell

•

Available in Commercial and Industrial Temperature Ranges

•

Available in 160-pin PQFP, 192 PGA and 208-pin RQFP Packages

•

Advanced EE Technology

– 100% Tested

– Completely Reprogrammable

– 100 Program/Erase Cycles

– 20 Year Data Retention

– 2000V ESD Protection

– 200 mA Latch-Up Immunity

•

JTAG Boundary-Scan Testing to IEEE Std. 1149.1-1990 and 1149.1a-1993 Supported

•

Fast In-System Programmability (ISP) via JTAG

•

PCI-compliant

•

3.3 or 5.0V I/O pins

•

Security Fuse Feature

High

Performance

EE-Based CPLD

ATF1516AS/L

Preliminary

Enhanced Features

•

Improved Connectivity (Additional Feedback Routing, Alternate Input Routing)

•

Output Enable Product Terms

•

D - Latch Mode

•

Combinatorial Output with Registered Feedback within any Macrocell

•

Three Global Clock Pins

•

ITD ( Input Transition Detection) Circuits on Global Clocks, Inputs and I/O

•

Fast Registered Input from Product Term

•

Programmable “Pin-Keeper” Option

•

VCC Power-Up Reset Option

•

Pull-Up Option on JTAG Pins TMS and TDI

•

Advanced Power Management Features

– Edge Controlled Power Down “L”

– Individual Macrocell Power Option

– Disable ITD on Global Clocks, Inputs and I/O

Rev. 0994A-A–01/98

1

Page 2

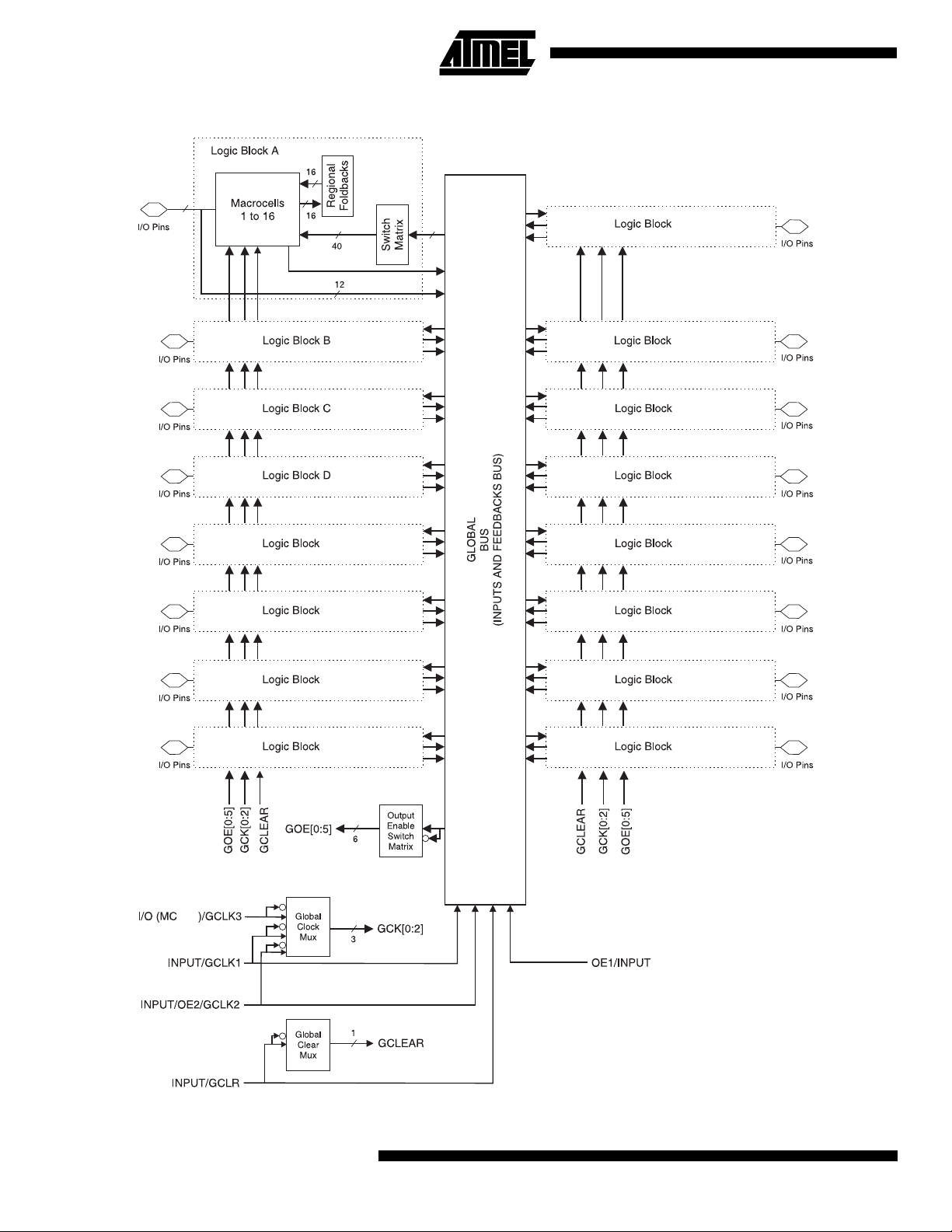

Block Diagram

6 to 12

P

O

N

M

256

E

F

G

H

L

K

J

I

2

ATF1516AS/L

Page 3

Description

The ATF1516AS is a high pe rforman ce, hig h densi ty Complex Programmable Logic Device (CPLD) which utilizes

Atmel’s proven el ectrical ly erasab le techno logy. W ith 256

logic macrocells and up to 164 inputs, it easily integrates

logic from several TTL, S SI, MSI, LSI and cl assic PLDs.

The ATF1516AS’s enhanced routing switch matrices

increase usable gate count, and incr ea se odds of successful pin-locked design modifications.

The ATF1516AS has up to 160 bi-directional I/O pins and 4

dedicated input pins, depending on the type of device package selected. Each dedicated pin can also serve as a global control signal; regi ster clock, r egister reset or output

enable. Each of these control signals can be selected for

use individually within each macrocell.

Each of the 256 mac rocells ge nerates a buried fe edback,

which goes to the gl obal bus . Each in put and I/O pin also

feeds into the global bus. The switch matrix in each logic

block then selects 40 individual signals from the global bus.

Each macrocell also generates a foldback logic term, which

goes to a regional bus. Casca de logi c between macro cells

in the ATF1516AS allows fa st, effici ent gen eration of complex logic func tions. The ATF15 16AS co ntains eigh t such

ATF1516AS/L

logic chains, each capable of creating sum term logic with a

fan in of up to 40 product terms

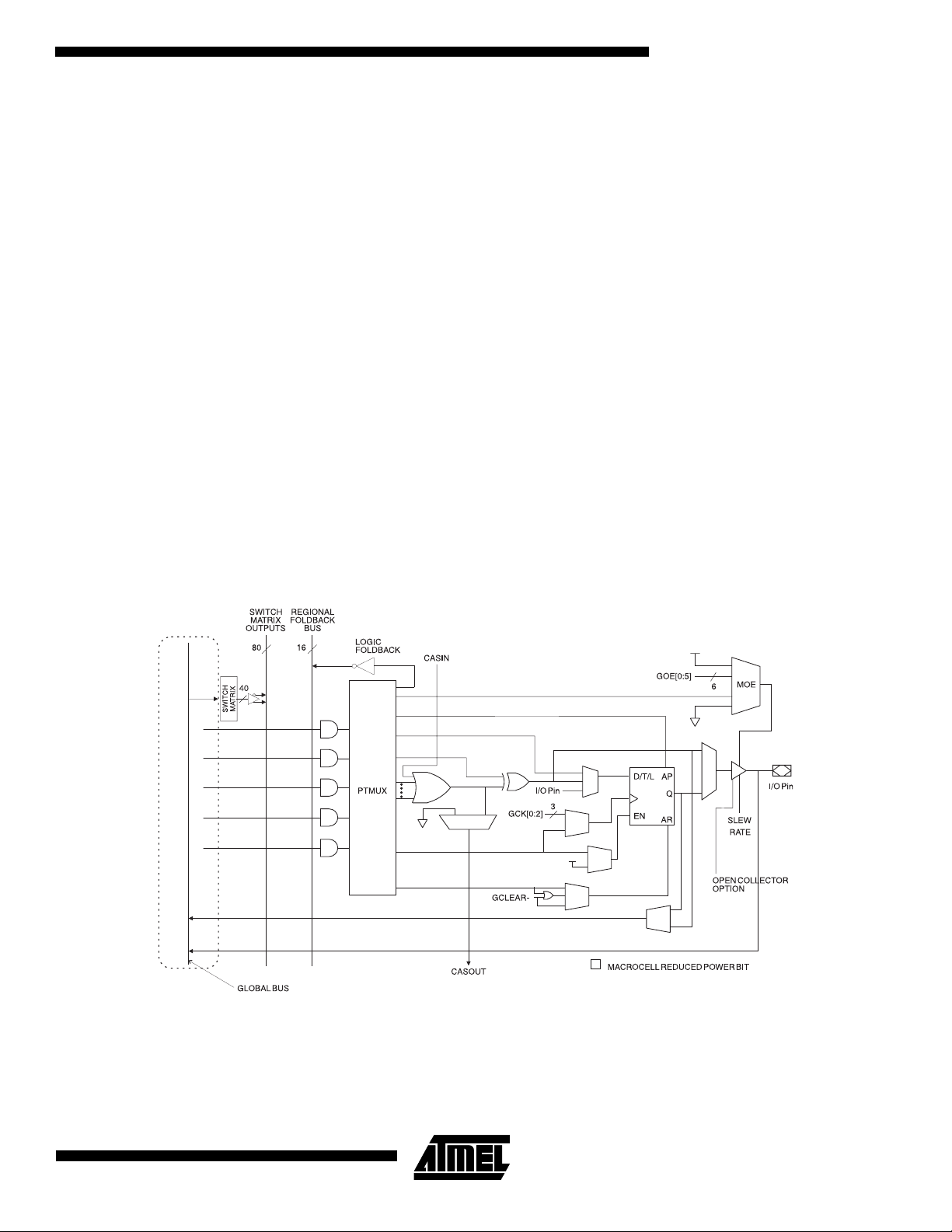

The ATF1516AS macrocel l, shown in F igure 1, is flexible

enough to support hi gh ly complex logic function s ope ratin g

at high speed. The macrocell consists of five sections:

product ter ms and product term select multiplexer;

OR/XOR/CASCADE logic; a flip-flop; output selec t and

enable; and logic array inputs.

Unused Macroc ell s are auto ma ticall y d isa bled by the compiler to decrease power consumption. A Security Fuse,

when programmed, protects the contents of the

ATF1516AS. Two bytes (16 bits) of User Signature are

accessible to the user for purposes such as storing project

name, part number, revision or date. The User Signature is

accessible regardless of the state of the Security Fuse.

The ATF1516AS device is an In-System Programmable

(ISP) device. It uses the industry standard 4-pi n JTAG

interface (IEEE Std. 1149.1), and is fully compliant with

JTAG’s Boundary Scan Description Language (BSDL). ISP

allows the device to be programmed witho ut removing it

from the printed circuit board. In addition to simplifying the

manufacturing flow, ISP also allows design modifications to

be made in the field via software.

Figure 1.

ATF1516AS Macrocell

3

Page 4

Product Terms and Select MUX

Each ATF1516AS macrocell has five product terms. Each

product term recei ve s a s its inp u ts al l s ig nal s f ro m bo th th e

global bus and regional bus.

The product term select multip lexer ( PTMUX ) alloc ates th e

five product terms as needed to the macrocell logic gates

and control signals. The PTMUX programming is determined by the design c ompiler, which se lects the opt imum

macrocell configuration.

OR/XOR/CASCADE Logic

The ATF1516AS’s logic structure is designed to efficiently

support all types of logic. Within a single macrocell, all the

product terms can be routed to the OR gate, creating a 5input AND/OR sum term. With the addition of the CASIN

from neighboring macrocells, this can be expanded to as

many as 40 product terms with a very small additional

delay.

The macrocell’s XOR gate allows efficient implementation

of compare and arithmetic func tions. O ne input to th e XOR

comes from the OR sum term. The other XOR input can be

a product term or a fixed high or low level. For combinatorial outputs, the fi xed level input allow s polarit y selecti on.

For registered functions, the fixed levels allow DeMorgan

minimization of product terms. The XOR gate is also used

to emulate T- and JK-type flip-flops.

Flip Flop

The ATF1516AS’s flip flop has very flexible data and control functions. The data input can come from either the

XOR gate, from a se parate prod uct term or directly fr om

the I/O pin. Selecting the separate product term allows creation of a buried registered feedback within a combinatorial

output macrocell. (This feature is automatically implemented by the fitter so ftware). I n add ition to D , T, J K and

SR operation, the flip flop can also be configured as a flowthrough latch. In this mode, da ta passes th rough whe n the

clock is high and is latched when the clock is low.

The clock itself can eith er be th e Global CLK Si gnal ( GCK)

or an individual product term. The flip flop changes state on

the clock’s rising edge. When the GCK signal is used as

the clock, one of the macrocell product terms can be

selected as a clock enable. When the clock enable function

is active and the enable signal (product term) is low, all

clock edges are ignored. The flip flop’s asynchro nous re se t

signal (AR) can be either the Global Clear (G CLEAR), a

product term, or always o ff. AR can also be a logi c OR of

GCLEAR with a product term. The as ynchronous prese t

(AP) can be a product term or always off.

Output Select and Enable

The ATF1516AS macrocell output can be selected as registered or combinatorial. The buried feedback signal can be

either combinatorial or registered signal regardless of

whether the output is combinatorial or registered.

The output enable multiplexer (MOE) controls the output

enable signals . Any buffer ca n be perman ently enab led for

simple output operation. Buffers ca n also be permanently

disabled to allow use of the pin as an i nput. In this confi guration all the ma croce ll res our ces are still ava ilab le, i ncl uding the buried feedback, expan der and CASCADE logic .

The output enable for each macrocell can be selected as

either of the two dedicated OE input pins as an I/O pin configured as an input, or as an individual product term.

Global Bus/Switch Matrix

The global bus contains all input and I/O pin signals as well

as the buried fe edback signal from all 256 mac rocells.

The Switch Matrix in ea ch Logic Block receives as its

inputs all signals from the global bus. Under software control, up to 40 of these signals can be selected as inputs to

the Logic Block.

Foldback Bus

Each macrocell a lso generate s a foldbac k product ter m.

This signal goes to the regional bus and is available to 16

macrocells. The foldback is an inverse polarity of one of the

macrocell’s product terms. T he 16 foldback te rms in eac h

region allows generation of hi gh fan -in su m ter ms (up to 21

product terms) with a small additional delay.

4

ATF1516AS/L

Page 5

ATF1516AS/L

Programmable Pin-Keeper Option

for Inputs and I/Os

The ATF1516AS offers the option of program ming all input

and I/O pins so that “pin keeper” circuits can be utilized.

When any pin is driven high or low and then subsequently

left floating, it will stay at that previous high or low leve l.

This circuitry preve nts unused input and I/O l ines from

floating to intermedi ate volta ge levels , which caus e unnecessary power consumption and system noise. The keeper

circuits eliminate the need for external pull-up resistors and

eliminate their DC power consumption.

Input Diagram

I/O Diagram

macrocells to be configured for maximum power savings.

This feature may be selected as a design option.

All ATF1516ASs also have an opti onal pow er down mode .

In this mode, current drops to below 10 mA. When the

power down opti on is select ed, eit her PD1 or PD2 pins (or

both) can be used to power down the part. The power down

option is selected in the design source fil e. When en abled,

the device goes into power down when either PD1 or PD2

is high. In the power down mod e, all inter nal logic signals

are latched and held, as are any enabled outputs.

All pin transitions are ignored until the PD pin is brought

low. When the power down feature is enabled, the PD1 or

PD2 pin cannot be used as a logic input or output. However, the pin’s macroc ell m ay still be u sed to g enera te buried foldback and cascade logic signals.

All Power-Down AC Character istic parameters are c omputed from external input or I/O pins, with Reduced Power

Bit turned on. For mac rocells in reduced-po wer mode

(Reduced power bit turned on), the reduced power adder,

tRPA, must be adde d to the AC p arameter s, w hich includ e

, t

the data paths t

Each output also has in divi dual sl ew rate contr ol. This may

be used to reduce system noise by slowing down o utputs

that do not need to operate at maximum speed. Outputs

default to slow switching, and may be specified as fas t

switching in the design file.

LAD

LAC

, tIC, t

ACL

, t

ACH

and t

SEXP

.

Design Software Support

ATF1516AS designs are supported by several third party

tools. Automated fitters allow logic synthesis using a variety

of high level description languages and formats.

Speed/Power Management

The ATF1516AS has several built-in speed and power

management features. The ATF1516A S contains circui try

that automatically puts the device into a low power standby mode when no logic trans itions are occ urring. This n ot

only reduces power consumption during inactive periods,

but also provide s a proportional po wer savings for m ost

applications running at system speeds below 50 MHz.

To further reduce power, each ATF1516AS macrocell has

a Reduced Power bit f eatu re . Thi s feat ure al lo ws in div id ual

Power Up Reset

The ATF1516AS has a power -up re set opt ion at t wo di fferent voltage trip levels when the device is being powered

down. Within the fitter, or during a conversion, if the

“power-reset” option is turned “on” (which is the default

option), the trip levels du ring power up or power down is at

2.8V. The user can change this default option from “on” to

“off” (within the fitter or specify it as a switch during conversion). When this is done, the voltage trip level during

power-down changes from 2.8V to 0.7V. This is to ensure a

robust operating enviro nme nt.

The registers in the ATF1516AS are designed to re se t du ring power up. At a poin t dela ye d slight ly fr om V

, all registers will be reset to the low state. The output

V

RST

state will depend on the polarity of the buffer.

This feature is critical for s tate machin e initi alizati on. How-

ever, due to the asynchronous nature of reset and the

uncertainty of h ow V

lowing conditions are required:

actually rises in the sys tem, the fo l-

CC

crossing

CC

5

Page 6

1. The V

2. After reset occurs, all input and feedback setup times

must be met before driving the clock pin high, and,

3. The clock must remain stable during T

rise must be monotonic,

CC

PR

.

Security Fuse Usage

A single fuse is provided to pre vent unauthorize d copying

of the ATF1516AS fuse patterns. Once programmed, fuse

verify is inhibited. However, User Signature and device ID

remains accessib le.

Programming

ATF1516AS devices are In-System Programmable (ISP)

devices utilizing the 4-pin JTAG protocol. Thi s capability

eliminates packa ge h andl in g no rm all y requ ire d for pr ogra m

and facilitates rapid design iterations and field changes.

Atmel provides ISP hardware and software to allow programming of the ATF1516AS via the PC. ISP is perfomed

by using either a download c able, or a compar able board

tester or a simple microprocessor interface.

To facilitate ISP programmi ng by the Automated Test

Equipment (ATE) vendors. Serial Vector Format (SVF)

files can be created by Atmel provided Software utilities.

ATF1516AS devices can also be programmed using standard 3rd party programmers. With 3rd party programmer

the JTAG ISP port can be disabled thereby allowing 4 additional I/O pins to be used for logic.

Contact your local Atmel representativ es or Atmel PLD

applications for details.

ISP Programming Protection

The ATF1516AS ha s a special featur e which locks the

device and prevents the inputs and I/O from drivi ng if the

programming process is interrupted due to any reason. The

inputs and I/O default to high-Z state during such a condition. In addition the pin keep er option pres erves t he f ormer

state during device programming.

All ATF1516AS devices ar e initially s hipped in the er ased

state thereby making them ready to use for ISP.

Note: For more information refer to the “Desigining for In-Sys-

tem Programmability with Atmel CPLDs” application

note.

Timing Model

U

6

ATF1516AS/L

Page 7

ATF1516AS/L

Input Test W aveforms and

Measurement Levels

rR, tF = 1.5 ns typical

Power Down Mode

The ATF1516AS includes two pins for optional pin controlled power down feature. When this mode is enabled, the

PD pin acts as the power down pin. When the PD1 and

PD2 pin is high, the device supply current is reduced to

less than 3 mA. During power down, all outp ut data and

internal logic states are latched and held. Therefore, all

registered and co mbin atoria l output da ta remai n valid. Any

outputs which were in a Hi-Z state at the onset will remain

at Hi-Z. During power down, all input si gnals except th e

power down p in are block ed. Input an d I/O hold l atches

remain active to insure that pins do not float to indete rminate levels, further r educing system po wer. The power

down pin feature is enabled in the logic design file. Designs

using either power down pin may not use the PD pin logic

array input. However, all other PD pin as macrocell

resources may still be used, including the buried feedback

and foldback product term array inputs.

Output AC Test Loads:

(3.0V)*

(703 )*

(8060 )*

Note: *Numbers in parenthesis refer to 3.0V operating condi-

tions (preliminary).

7

Page 8

JTAG-BST Overview

The JTAG boundary-scan testing is controlled by the Test

Access Port (TAP) controller in the ATF1516AS. The

boundary-scan technique involves the inclusion of a shiftregister stage (conta ined in a b oun dary-sc an cell) ad jacen t

to each component so that signals at component boundaries can be controlle d and observed us ing scan testin g

principles. Each inp u t pin and I/O pin has its own boundary

scan cell (BSC) in order to support boundary scan testing.

The ATF1516AS does not currently include a Test Reset

(TRST) input pi n because th e TAP contr oller is aut omatically reset at power up. The six JTAG BST modes supported include: SAMPLE/PRELOAD, EXTEST, BYPASS,

IDCODE. BST on the ATF1516A S is implemented u sing

the Boundary Sc an Definiti on Langu age (BSD L) desc ribed

in the JTAG specification (IEEE Standard 1149.1). Any

third party tool that suppo rts the BS DL format can be used

to perform BST on the ATF1516AS.

The ATF1516A S also ha s the opti on of usi ng four JTA Gstandard I/O pins for in-system programming (ISP). The

ATF1516AS is programmable through the four JTAG pins

using programming compatible with the IEEE JTAG Standard 1149.1. Programming is performed by using 5V TTLlevel programming signals fr om the JTAG ISP inter face.

The JTAG feature is a progr am mab le opti on. If J TAG (BS T

or ISP) is not needed, then the four JTAG control pins are

available as I/O pins.

BSC Configuration Pins and

Macrocells (except JTAG TAP Pins)

Note: The ATF1516AS has pull-up option on TMS and TDI

pins. This feature is selected as a design option.

JTAG Boundary Scan Cell (BSC)

Testing

The ATF1516AS contains up to 160 I/O pins and 4 input

pins, depending on the device type and package ty pe

selected. Each input pi n and I/O pin has its own bounda ry

scan cell (BSC) in order to suppor t boundary sca n testing

as described in detail by IEEE Standard 1149.1. Typical

BSC consis ts of thre e capture registe rs or sca n regist ers

and up to two update registers. There are two types of

BSCs, one for input or I/O pin, and one for the macrocells.

The BSCs in the device are chain ed together through the

capture registers. Input to the capture register chain is fed

in from the TDI pin while the output is directed to the TDO

pin. Capture re gisters a re used to capture ac tive de vice

data signals, to shift data in and out of the device and to

load data into the update registers. Control signals are generated internally by the JTAG TAP controller. The BSC

configurati on for th e input and I/O pins a nd macr ocells are

shown below.

8

ATF1516AS/L

Page 9

BSC Configuration for Macrocell

ATF1516AS/L

Pin BSC

TDO

OEJ

Pin

0

1

DQ

Capture

DR

TDI

Clock

Shift

TDO

0

0

1

DQ

DQ

1

OUTJ

TDI

Shift

0

0

1

DQ

Capture

DR

DQ

Update

DR

1

Pin

Mode

Clock

Macrocell BSC

9

Page 10

PCI Compliance

The ATF1516AS also supports the growing need in the

industry to support the new Peripheral Component Interconnect (PCI) interface standard in PCI-based designs and

specifications . The PCI interfac e calls for high curre nt drivers which are much larger than the traditional TTL drivers.

PCI Voltage-to-Current Curv es for +5V

Signaling in Pull-Up Mode

point

Pull Up

-44

Current (mA)

Test Point

-178

VCC

2.4

1.4

Voltage

DC

drive point

AC drive

-2

PCI Voltage-to-Current Curves for +5V

Signaling in Pull-Down Mode

VCC

Voltage

2.2

DC

drive point

0.55

3.6

AC drive

point

Pull Down

95

Test Point

Current (mA)

380

10

ATF1516AS/L

Page 11

Ordering Information

t

PD

(ns)

t

CO1

(ns)

f

MAX

(MHz) Ordering Code Package Operation Range

ATF1516AS/L

10 5 125 ATF1516AS-10QC160

ATF1516AS-10UC192

ATF1516AS-10QHC208

15 8 100 ATF1516AS-15QC160

ATF1516AS-15UC192

ATF1516AS-15QHC208

15 8 100 ATF1516AS-15Q160

ATF1516AS-15UI192

ATF1516AS-15QHI208

20 12 83.3 ATF1516ASL-20QC160

ATF1516ASL-20UC192

ATF1516ASL-20QHC208

20 12 83.3 ATF1516ASL-20QI160

ATF1516ASL-20UI192

ATF1516ASL-20QHI208

25 15 70 ATF1516ASL-25QC160

ATF1516ASL-25UC192

ATF1516ASL-25QHC208

25 15 70 ATF1516ASL-25QI60

ATF1516ASL-25UI192

ATF1516ASL-25QHI208

160Q

192U

208QH

160Q

192U

208QH

160Q

192U

208QH

160Q

192U

208QH

160Q

192U

208QH

160Q

192U

208QH

160Q

192U

208QH

Commercial

(0°C to 70°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to +85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to +85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to +85°C)

160Q

192U

208QH

Package Type

160-Lead, Plastic Quad FlatPack (PQFP)

192-Lead, Plastic Grid Array (PGA)

208-Lead, Plastic Quad Flatpack with Heat Spreader (RQFP)

11

Loading...

Loading...