Page 1

ATEVK525 Mass Storage Board for AVR

..............................................................................................

Hardware User Guide

Page 2

Section 1

Introduction ........................................................................................... 1-3

1.1 Overview ...................................................................................................1-3

1.2 ATEVK525 AVR Mass Storage Board Features .......................................1-4

Section 2

Using the ATEVK525............................................................................ 2-5

2.1 Getting started ..........................................................................................2-5

2.2 NAND Flash ..............................................................................................2-7

2.3 SD/MMC Card.........................................................................................2-11

2.4 LEDs .......................................................................................................2-12

2.5 Test Points ..............................................................................................2-12

2.6 Configuration Pads .................................................................................2-13

2.7 Solder Pads ............................................................................................2-14

Section 3

Software Implementation .................................................................... 3-15

3.1 Software packages .................................................................................3-15

3.2 Performances..........................................................................................3-17

3.3 Driver limitations......................................................................................3-18

3.4 Usage Notes ...........................................................................................3-19

3.5 Handling another NAND Flash device ....................................................3-19

Section 4

Troubleshooting Guide ....................................................................... 4-21

Section 5

Technical Specifications ..................................................................... 5-23

Section 6

Technical Support............................................................................... 6-24

Section 7

Complete Schematics......................................................................... 7-25

ATEVK525 Mass Storage Board for AVR User Guide 1

7740B–AVR–03/08

Page 3

1.1 Overview

Section 1

Introduction

Congratulations on acquiring the AVR® ATEVK525. This kit is an extension board

designed to enhance and demonstrate Mass Storage features in addition to the existing

development boards supporting the AT90USBxxx family.

This document describes the ATEVK525 dedicated to the AT90USBxxx <Generic

Product Name> microcontroller. This board is designed to allow an easy evaluation of

USB Mass Storage using demonstration software.

The ATEVK525 board has been designed to be plugged into the Atmel STK525 Starter

Kit Board in order to add Mass Storage capability to an existing development board, and

to combine them with other features (USB, RS232, Microphone..., but also all AVR

development tools), reducing the extension board complexity and cost.

This user guide acts as a general getting started guide as well as a complete technical

reference for advanced users.

ATEVK525 Mass Storage Board for AVR 1-3

7740B–AVR–03/08

Page 4

Introduction

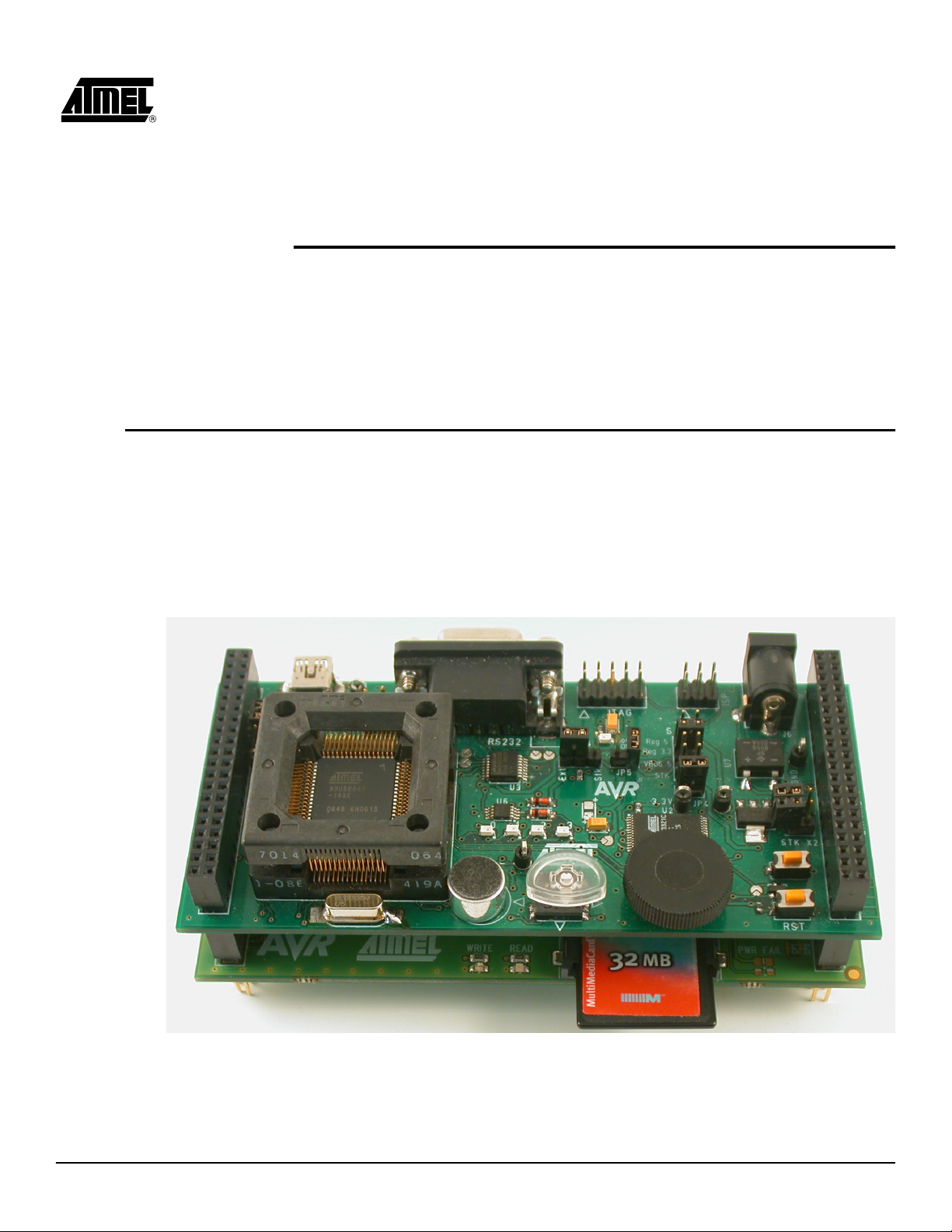

Figure 1-1 . ATEVK525

1.2 ATEVK525 AVR Mass Storage Board Features

The ATEVK525 provides the following features:

NAND Flash chip soldered (Micron MT29F2G08AACWP, 256 MBytes)

Reserved location additional NAND Flash chips module plug-in

Receptacle for SD and MMC memory cards

LED signalling for Read/Write operations

Power supply :

– 3.3V regulated from motherboard

– Additional overvoltage protection circuitry (optional) with failure indicator

Numerous access points for debug

1-4 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 5

2.1 Getting started

2.1.1 Plugging the board

Section 2

Using the ATEVK525

This chapter describes the board and all its features.

The ATEVK525 is an extension board that must be plugged on another microcontroller

hosting board, like STK525 (AT90USBxxx support), that provides supply voltage.

Figure 2-1 . Connecting the ATEVK525 under the STK525

Note: The

ATEVK525 Mass Storage Board for AVR 2-5

ATEVK525 can also be plugged onto the STK525, but in this configuration,

the user must take care to avoid contact between the board and either the

JTAG plug or the microcontroller ZIF socket.

7740B–AVR–03/08

Page 6

Using the ATEVK525

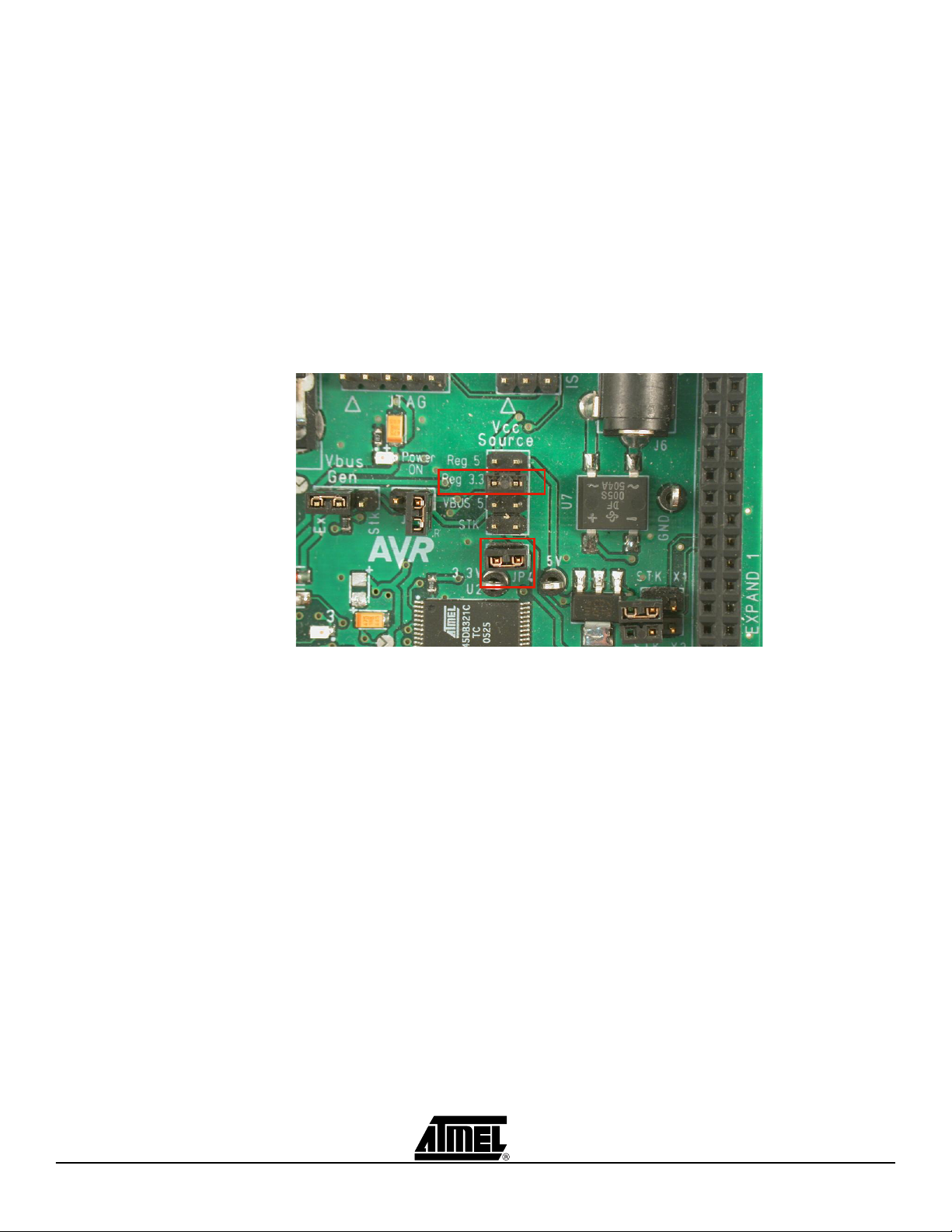

2.1.2 Power supply

The ATEVK525 must be powered with a voltage between 2.8 and 3.5V.

Before connecting or powering the boards, you must ensure the power supply

configuration on the motherboard.

The voltage must be set to 3.3V (microcontroller I/O levels), and this voltage must be

present on the VTG pins of the EXPAND connectors.

On the STK525, the configuration must be:

– JP4 closed (ties 3.3V to VTG pins)

– VCC SOURCE set to REG 3.3 mode (powers microcontroller I/O at 3.3V)

Figure 2-2 . Configuration to set on STK525

NAND Flash (MT29F2G08AACWP) current consumption is 1mA maximum in idle state,

and can reach 30mA (15mA typ.) during access operations (read/write/erase). For the

SD/MMC card consumption, please refer to your SD/MMC card datasheet.

2-6 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 7

2.1.3 Protection circuitry

Using the ATEVK525

The ATEVK525 includes an optional power supply protection circuit that prevents onboard resources from being damaged.

Figure 2-3 . Power protection circuit location

This supplement, if mounted, protects the storage devices from voltage above 3.5V. In

case of overvoltage detection, the power positive line of the extension board is not

connected to devices, and the LED “PWR_FAIL” is lit.

If the supplement is not mounted or needs to be disabled, the solder pad SP1 must be

soldered to connect power supply of the on-board resources (see photo above).

2.2 NAND Flash

2.2.1 Default device

The ATEVK525 comes with one NAND Flash chip soldered. At the time of writing, this

chip is the Micron MT29F2G08AACWP that features:

2 GBits (256 MBytes) organized as:

– 2048 blocks

– block size : 64 pages

– page size : 2112 bytes (2048 + 64 in spare zone)

Page program time of 300µs, Block erase time of 2ms

Copy-Back feature (enable cache transfers between blocks to speed up write

operation; no memory zone / address limitation)

The memory access is managed by the External Memory Interface hardware peripheral

of the AT90USBxxx microcontroller. Data and Address information share the same 8-bit

wide bus connected to the lowest bits of Memory Interface (A7-A0), while the Control

signals are connected to upper bits:

ATEVK525 Mass Storage Board for AVR 2-7

7740B–AVR–03/08

Page 8

Using the ATEVK525

1

1

13

13

NFCON1

NFCON2

Table 2-1 . NAND Flash pin assignment

NAND Flash Microcontroller Function

I/O[7:0] PORTA[7:0] (A7-A0) Data and Address bus

CLE PORTC0 (A8) Command Latch Enable

ALE PORTC1 (A9) Data Latch Enable

RE# PORTE1 (RD#) Read enable

WE# PORTE0 (WR#) Write enable

CE# PORTC2 (A10) Chip select (active low) (with on-board pull-up)

R/B# PORTC6 Ready / Busy# (pull-up must be enabled in micro)

Note: The ‘#’ character indicates that the corresponding signal is active low.

2.2.2 Additional devices

NAND Flash Module Description If another memory device is required for development or evaluation purpose, it is still

possible to install it on the ATEVK525 through an additional module as described below.

The board provides two SIP-13 receptacle footprints (2.54mm pitch). Users can solder a

receptacle on the board and then insert a NAND Flash module described below, or

directly solder the module.

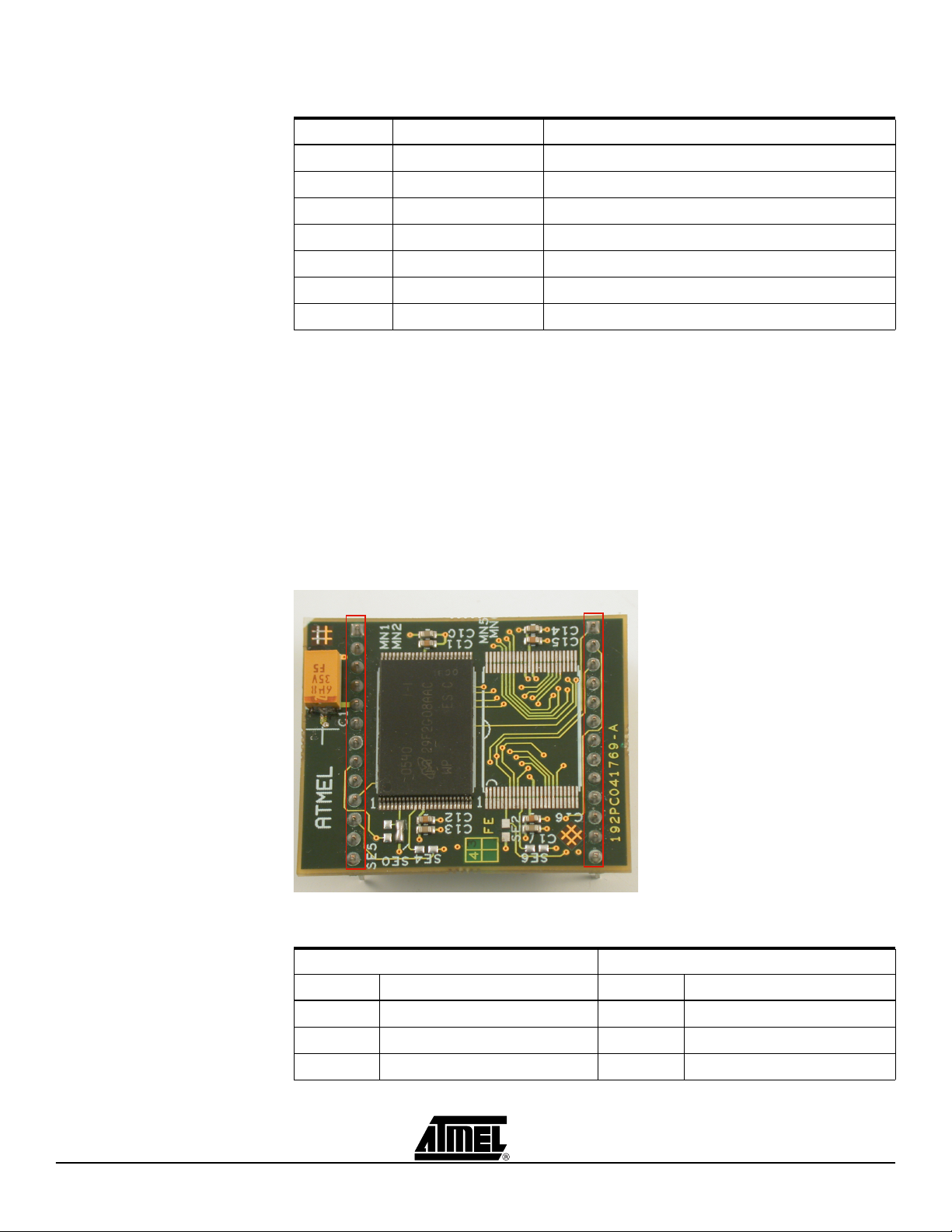

Figure 2-4 . NAND Flash module example

Table 2-2 . NAND Flash module pin-out description

Pin # Function Pin # Function

1 WP2# 1 WP3#

NFCON1 NFCON2

2 CE3# 2 R/B3#

3 CE2# 3 R/B2#

2-8 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 9

Using the ATEVK525

NFCON1 NFCON2

Pin # Function Pin # Function

4 WP0# 4 WP1#

5 VCC 5 D7

6 CLE 6 D6

7 ALE 7 D5

8 R/B1# 8 D4

9 CE0# 9 D3

10 R/B0# 10 D2

11 CE1# 11 D1

12 RE# 12 D0

13 WE# 13 GND

Refer to the CD-ROM documentation if you wish to create your own PCB board and

mount devices on this board (BOM and components placement).

Each module can receive up to four different devices, according to the following

placement :

Table 2-3 . NAND Flash devices placement

ATEVK525 Mass Storage Board for AVR 2-9

7740B–AVR–03/08

Page 10

Using the ATEVK525

See Note 1

NF Module Installation Figure 2-5 . NAND Flash module on the ATEVK525, plus MMC card

When using the NAND Flash module, the following pin assignments do not change :

Data/Address bus, CLE, ALE, RE#, WE#, WP# (Write Protect feature drives all the

chips at the same time). Other signal assignments are grouped in the following table.

Table 2-4 . NAND Flash module pin assignment

NAND Flash Microcontroller Function

CE0# PORTC2 (A10) Chip select for chip 0 (active low, on-board pull-up)

CE1# PORTC3 (A11) Chip select for chip 1 (active low, on-board pull-up)

CE2# PORTC4 (A12) Chip select for chip 2 (active low, on-board pull-up)

CE3# PORTC5 (A13) Chip select for chip 3 (active low, on-board pull-up)

R/B0# PORTC6 Ready / Busy# for chip 0 (pull-up to enable in micro)

R/B1# PORTC7 Ready / Busy# for chip 1 (pull-up to enable in micro)

R/B2# PORTD0 Ready / Busy# for chip 2 (pull-up to enable in micro)

R/B3# PORTD1 Ready / Busy# for chip 3 (pull-up to enable in micro)

Note: 1. When using the additional module, the resistor R10 must be unsoldered, else

the CE# lines of the NAND Flash soldered and the NAND Flash #0 of the module will be connected together (not applicable if NF #0 is not mounted on the

module)

2. When using the additional module, check that the configuration pads that enable

CTS/RTS lines on STK525 are not soldered, because these signals are also connected to the R/B#2 & 3. But if CTS/RTS lines are required, you cannot use the

R/B#2 & 3 signals, so disable the configuration pads CP1 & CP2 of the ATEVK525.

2-10 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 11

2.3 SD/MMC Card

Using the ATEVK525

The ATEVK525 includes a receptacle compatible with SD and MMC memory cards.

Figure 2-6 . SD card pinout (contact view)

Note: 1. The MMC card defined by specification v3.31 and earlier have only the pins #1 to #7

2. The MMC card defined by specification v4.0 and later (MMC Plus, Extra..) has 13

pins (increasing parallel data bus width)

Regardless of their differences, all SD/MMC cards have the following common points :

SPI mode: through a standard SPI bus, that method reduces the transfert speed, but

is easy to implement. The alternate access method is a parallel mode

Command set: cards have numerous commands that are common enough to

completely control the memory. Only the initialization process is different (but a

standard procedure automatically enables card identification and initialization). Be

aware of the card specification version (information contained in the CSD structure of

the card) before using advanced features (password protect, etc.).

Table 2-5 . SD/MMC card pin assignment in SPI mode

Pin # SD/MMC Card Function in SPI Mode AVR MCU

1 CS# Chip Select (active low) PORTB,0

2 DI SPI Master Out Slave In PORTB,2 (MOSI)

3 VSS Ground Gnd

4 VDD Supply Voltage Vcc

5 SCK SPI Clock PORTB,1 (SCK)

6 VSS Ground Gnd

7 DO SPI Master In Slave Out PORTB,3 (MISO)

ATEVK525 Mass Storage Board for AVR 2-11

7740B–AVR–03/08

Page 12

Using the ATEVK525

2.4 LEDs

Three LEDs are on the board:

– PWR_FAIL: orange LED that signals an overvoltage condition if the protection

circuit is mounted. This LED is optional.

– WRITE: red LED connected to PORTD7 of micro (also LED1 on STK525), that

may be driven by software when initiating a SCSI Write command

– READ: green LED connected to PORTD5 of micro (also LED3 on STK525),

that may be driven by software when initiating a SCSI Read command

Figure 2-7 . On-board SCSI signalling LEDs

2.5 Test Points

Several test points are included on the board to facilitate debug during development. All

the test points are circular pads with a silk-screen printing that indicates the

corresponding signal:

– VCC: power supply voltage (should be 3.3V), taken after the power protection

circuit

– GND: power supply ground

– SD_MISO: SD/MMC card MISO signal (card output)

– SD_MOSI: SD/MMC card MOSI signal (card input)

– SD_SCK: SD/MMC clock signal

– SD_CS: SD/MMC chip select signal (active low)

– NF_CLE: NAND Flash CLE signal

– NF_ALE: NAND Flash ALE signal

– NF_RE: NAND Flash RE# signal

– NF_WE: NAND Flash WE# signal

2-12 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 13

2.6 Configuration Pads

Cut Connection

WireDrop of solder

Using the ATEVK525

Configuration pads are used

default configuration is: connect.

2.6.1 Configuration Pads Listing

Table 2-6 . Configuration Pads

Config.

Pads

Reference

CP1 R/nB2

CP2 R/nB3

Note: See section 2.2.2 Additional devices for more details.

2.6.2 Configuration Pads - Disconnection

Figure 1. Configuration Pad - Disconnection

Related

Signals

to

disconnect/connect on-board peripherals or elements. Their

Function

Connect Ready/notBusy signal from NF#2 (third NF of the

optionnal module) to STK525

Connect Ready/notBusy signal from NF#3 (fourth NF of the

optionnal module) to STK525

2.6.3 Configuration Pads - Connection

Figure 2. Configuration Pad - Re-connection

ATEVK525 Mass Storage Board for AVR 2-13

7740B–AVR–03/08

Page 14

Using the ATEVK525

2.7 Solder Pads

2.7.1 Solder Pads Listing

Solder pads are used to

configuration is: disconnect. User may solder the pad to enable it.

disconnect/connect on-board peripherals or elements. Their default

Table 2-7 . Solder Pads

Solder.

Pads

Reference

SP1 VCC

Related

Signals

Function

This solder pad allows power protection circuit bypassing. If

this optional circuit is not mounted, this solder pad must be

soldered.

2-14 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 15

3.1 Software packages

Section 3

Software Implementation

This section contains information about the software package, its performance and

known limitations.

When you have connected the boards together and correctly checked their

configuration, you are invited to run one of the available demonstration packages:

USB Device External Multi Disk Drives. The board enumerates as a USB

composite Mass Storage device, and combines three external removable mass

storage media:

– MMC/SD memory card reader (depends on card used)

– NAND Flash 256MB (default, otherwise depends on chip used) disk

– DataFlash 8 MB disk

This package can be found on the CD-ROM provided with the kit.

USB Dual-Role Host / Device with FAT support and Shell

1. In Device mode (B-connector plugged), the package is identical to the first

package, that enumerates three hardware storage volumes through the

USB.

2. In Host mode (A-connector plugged), the application allows connecting one

USB mass storage device.

3. In both modes, the STK525 can be connected to a serial terminal (using

HyperTerminal on PC side for example), where the user can access a simple

command line interpreter (ushell) to perform file system access (FAT management included in software):

– 57600 bps

– 8 bits data, 1 bit stop, no parity

– no flow control

4. Navigation in the file system (on-board memories or USB Mass Storage

device connected to the USB Host interface) supports following commands:

– a:, b: ... (goto selected drive)

ATEVK525 Mass Storage Board for AVR 3-15

7740B–AVR–03/08

Page 16

Software Implementation

– cd dirname (change to specified directory)

– ls (list current directory content)

– touch filename (create an empty file)

– append filename (add text to the specified file)

– mark (bookmark current directory)

– cp filename (copy filename to bookmark)

– rm filename (erase file or empty directory)

– format drivename (format the drive)

– deltree drivename (delete recursively a directory)

– cat filename (display file content)

– cd.. (come back to previous directory)

– mount disk ( mount drive a, b...)

– mkdir filename (create a directory)

– disk (get number of drives and memory type associated)

– goto (goto bookmark)

– df (get free space information)

– rm* (delete all files in the directory)

– lsusb (get information about the connected device, in host mode only)

– suspend (suspend USB bus activity)

– resume (resume USB bus activity)

– reboot (reset the aplication)

This package is also included on the CD-ROM as a password protected archive. Please

refer to the CD-ROM documentation to know the procedure to follow to register and

access the source code.

Note: At first board start-up, the on-board memory chip need to be formatted by the Host oper-

ating system.

3-16 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 17

3.2 Performances

3.2.1 Benchmark

Software Implementation

Table 3-1 . Memory speed benchmark (8MHz clocked microcontroller

Memory

DataFlash AT45DB321 (page 512B) 200 35

AT45DB642 (page 1024B) 200 55

MMC/SD SD 1GB 80x 235 235

SD 256MB 215 155

MMC Plus 2GB Premium 235 170

MMC 32MB (old revision) 215 50

NAND Flash M29F2G008AAC (page 2KB, copyback) 1095 860

K9K2G08UOM (page 2KB, copyback disabled

HYF31DS512805 (page 512B, no copyback) 1110 590

Note: 1. The AVR micro controller cannot be clocked at 16MHz since this configuration

requires a 4.5V minimum power supply whereas NAND Flash or SD/MMC devices do

not withstand such a voltage level on I/Os. However, DataFlash are 5V-tolerant, and

speed measurements have been done independently of this evaluation board: for

45DB321, write speed is 40KB/sec and read speed is 300KB/sec. For 45DB642,

write speed is 80KB/sec and read speed is 300KB/sec.

2. In the K9K2G08UOM device, the COPYBACK instruction cannot be used in all the

memory plane, since it is efficient only between size-limited zones. This problem concern several other memorie devices.

(2)

) 1005 660

(1)

)

Speed (KBytes/sec)

Read Write

3.2.2 Direct limitations

The limitations on reading operations are:

– Dataflash: SPI bus frequency, internal read access speed

– SD/MMC: SPI bus frequency, internal read access speed

– NAND Flash: USB maximum data rate

The limitations on writing operations are:

– Dataflash: internal write access speed, page write duration & size, SPI bus

frequency

– SD/MMC: internal write access speed and duration, SPI bus frequency

– NAND Flash: memory internal writing structure (COPYBACK support or not,

page write and block erase duration, page size), USB maximum data rate

ATEVK525 Mass Storage Board for AVR 3-17

7740B–AVR–03/08

Page 18

Software Implementation

3.3 Driver limitations

3.3.1 DataFlash

3.3.2 SD/MMC

This is a mature driver that will not need to be substantially modified. This driver has

been tested with the AT45DB321 and AT45DB642. If you look at the code, you will

notice a special memory page management if 2 or 4 Dataflash devices are used on the

same bus.

In the case of 2 or 4 DataFlash sharing the same SPI bus (this is not the case here), the

driver can interlace the memory pages to enhance write speed. For contiguous sector

write operations, the driver switches to the next memory as soon as a page

programming operation has been started on the current memory. Inb this way, two or

four contiguous pages (2 KBytes or 512 Bytes according to the memory reference) are

allocated on different memories.

Like the DataFlash driver, no substantial modifications should be required. The SD and

MMC specification should remain backward compatible with the old releases, so that

this driver only exploits the basic functionalities of the specifications, in order to be

compatible even with old memories.

3.3.3 NAND Flash

However, several enhancements can be done to enhance operational timing (write,

read), particularly using multiple block read/write instructions in a “software way”, or by

implementing SD Bus operation, in a more “hardware way”.

The NAND Flash technology and the consumer request for continually faster and larger

devices conduce to numerous enhancements of memories structure, and thus memory

management drivers.

Limitations:

The COPYBACK feature is not address-dependent in the current driver version. This

means that the instruction is used by the driver to copy a page into another without

regards to the page addresses. But, due to higher capacities, more and more new

devices support COPYBACK on limited zones only: for example a COPYBACK

operation may only be possible between two blocks that share the same half-device

plane, or between odd or even blocks numbers. This may be due to internal structure

of memory (two memory planes, one over the other for example). So the

COPYBACK feature must be disabled in the driver for devices that impose

restrictions about it.

ECC (Error Correction Code) is not implemented in the driver. A basic ECC can

detect 2-bit error and correct 1-bit error per 256 or 512 bytes. However, such a

feature can still be added to the driver. The ECC implementation may result in a

compromise between data reliability and speed performance.

Another feature that should be implemented next is the Recovery option. This option

prevents user halts or disconnections during write operations from destroying the

memory File System structure, by recovering the data lost in the last write

3-18 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 19

3.4 Usage Notes

Software Implementation

operations.

Also, the support of more than one memory chip (facilitating memories interlacing) is

not yet integrated in the driver. That also concerns memories that are made of

several memory dies stacked (generaly memories of 4GBits and more).

Supported device list : supported devices are listed in the NH.F file of the driver.

Please read these notes carefully:

Once your file modifications (create, copy, delete) have been made on the Mass

Storage device, always eject the device properly. Under Windows O.S. you must

click on the corresponding button (near the clock) in the Windows task bar, to “Safely

remove hardware”. This will force the O.S. to flush all the write operations that are

needed to end the Mass Storage device access. If such an operation is not made, it

is possible that the last write operations are not completed, and since these

operation often concern the File Allocation Table, the device integrity can be

damaged.

When using the NAND Flash media as a storage device, when all the operations

seem to be completed (Windows safe eject, etc.), all the data to be written is inside

the NAND Flash driver. But there is a limitation that must been taken in account.

When a page (512B or 2BK) has to be updated in the memory, all the corresponding

blocks (each block contains 64 pages for example) is copied to a new free block, and

the required page is modified during the copy. To end this operation of block

translation, all the pages up to the modified one are programmed. But to precede an

optional contiguous write operation, the pages that end the block (the block tail) are

not yet programmed. They will be programmed if the next operation is a Read, or a

Write to a page that is not contained in the same block. So, before powering down

the Mass Storage board, the software cannot predict if the last BLOCK COPY TAIL

operation has been done. Thus the user must call the “void nf_usb_stop(void)”

function from “nf_mngt.c” file. In the current package, this function is automatically

called when USB Suspend or Disconnect condition is detected (that does not work in

Bus powered application).

3.5 Handling another NAND Flash device

If a new NAND Flash device must be supported, the user must use the NF MODULE

location on the board to plug a NAND Flash board on which the required device is

soldered.

Once the hardware modifications are done (R10 unsoldered), there are software

modifications to be done according to the NAND Flash device structure

“NF.H” file

– if your device is already included in the supported devices list, you have

nothing to do in this file.

– if your device is not included in the supported devices list, you must add it,

using the same description structure that other devices.

“CONF_NF.H” :

ATEVK525 Mass Storage Board for AVR 3-19

7740B–AVR–03/08

Page 20

Software Implementation

– if you want to use only one other memory reference, you must define the

memory name. For example, the board comes with the default configuration

#define NF_TYPE_MT29F2G08AACWP

– if you want to use different modules with different memory references, without

modifying the driver, you must enable to TRUE either

NF_AUTO_DETECT_2KB or NF_AUTO_DETECT_512B, according to the

page size of the memory.

3-20 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 21

Section 4

Troubleshooting Guide

Please refer to this guide before sending a request to AVR Technical Support. Main

problems should be solved here. This guide assumes that the board driver file provided

by Atmel is used.

Figure 4-1 . Troubleshooting Guide

Problem

ATEVK525 does not

work

NAND Flash device

(onboard chip only) does

not work

NAND Flash device

(additional module) does

not work

Reason or

Condition

Bad power supply

Board not correctly

mounted

Protection circuit

problem

Additional module is

mounted.

Chip select resistor

not mounted

Chip select resistor

still mounted

Module not correctly

mounted

Problem / Solution

Check the power supply source level

(3.3V) on VCC testpoint.

Check that the board has been mounted

in the correct sense.

If the board is over the STK525, check

that the ZIF socket is not perturbed by it.

Same thing for the JTAG plug if used.

If the PWR_FAIL LED is lighting ON

whereas the voltage you measure on

VCC is correct, bypass the protection

circuitry (solder SP1).

The onboard memory chip cannot be

accessed while the optional NAND Flash

module is mounted since two memories

will share their chip select signal.

Check that the R10 resistor is correctly

mounted, else the chip will never be

selected.

Check that the R10 resistor is not

mounted (else both onboard chip and

module chip are selected at the same

time)

Check if the module is correctly mounted.

Use preferentially a socket.

ATEVK525 Mass Storage Board for AVR 4-21

7740B–AVR–03/08

Page 22

Troubleshooting Guide

Problem

SD/MMC does not work

Reason or

Condition

Bad physical contact

Memory failure

Problem / Solution

Check the insertion direction. It can

sound stupid, but that can happen to

anybody...

Check that the connector is not too old.

Memories are not immortal...Check the

memory card with another memory

reader.

4-22 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 23

Section 5

Technical Specifications

System Unit

– Physical Dimensions ................................................. L=119 x W=56 x H=23 mm

– Weight ...........................................................................................................50 g

Operating Conditions

– Internal Voltage Supply ................................................................ 3.3V (+/-10%)

– External Voltage Supply ................................................ 3.3V (+/-10%) (100mA)

Features

– NAND Flash device............................................................ MT29F2G08AACWP

– MMC/SD receptacle

– Additional NAND Flash devices support

– Embedded signalling LEDs

– Optional power protection circuit

ATEVK525 Mass Storage Board for AVR 5-23

7740B–AVR–03/08

Page 24

Section 6

Technical Support

For Technical support, please contact avr@atmel.com. When requesting technical

support, please include the following information:

Which target AVR device is used (complete part number)

Target voltage and speed

Clock source and fuse setting of the AVR

Programming method (ISP, Parallel or specific Boot-Loader)

Hardware revisions of the AVR tools, found on the PCB

Version number of AVR Studio. This can be found in the AVR Studio help menu.

PC operating system and version/build

PC processor type and speed

A detailed description of the problem

ATEVK525 Mass Storage Board for AVR 6-24

7740B–AVR–03/08

Page 25

Section 7

Complete Schematics

On the next pages, the following documents of ATEVK525 are shown:

Complete schematics,

Assembly drawing,

Bill of materials.

Default configuration summary

ATEVK525 Mass Storage Board for AVR 7-25

7740B–AVR–03/08

Page 26

Complete Schematics

NC11NC22NC33NC44NC55NC6

6

R/B

7RE8CE9

NC710NC8

11

VCC1

12

VSS1

13

NC9

14

NC10

15

CLE

16

ALE

17WE18WP19

NC1120NC1221NC1322NC1423NC15

24

NC1625NC1726NC1827NC1928I/O029I/O130I/O231I/O332NC2033NC2134NC22

35

NC2948NC2847NC2746NC2645I/O744I/O643I/O542I/O441NC2540NC2439NC2338VCC237VSS2

36

48 PINS WSOP

x8 NAND FLASH

U3

MT29F2G08AACWP

VSRC

R1

47k

VCC

NF_nWP0NF_nWP0NF_nWP0NF_nWP0NF_nWP0NF_nWP0NF_nWP0NF_nWP0

NF_R/nB0NF_R/nB0NF_R/nB0NF_R/nB0NF_R/nB0NF_R/nB0NF_R/nB0NF_R/nB0NF_R/nB0NF_R/nB0NF_R/nB0NF_R/nB0

VSRCVSRC

PA5

PA0

PA4

PA6

PA3

PA7

PA2

PA1

1

TP7

NF_ALE

VSRC

1

TP10

GND

3

2

1

84

-

+

U1A

LM393/SO

OPTIONAL

Overvoltage

Protection

Circuit

Decoupling capacitor

must be near to IC

5

6

7

84

-

+

U1B

LM393/SO

Decoupling capacitor

must be near to IC

Decoupling capacitor

must be near to IC

R2 820

R3 820

Q1

Si2301

1TP2

SD_MISO

D1 HSMC-C170

WRITE

VSRC

D2 HSMG-C170

READ

VCC

SO

SCK

SI

1324567

SD/MMC

J5

nCS_mmc

SD/MMC CONNECTOR

VCC

Unsolder R8 and R10 resistor

if optional NAND Flash

module is mounted !

NF_nRENF_nRENF_nRENF_nRE

NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1NF_R/nB1

NF_nCE1

R8

0

NF_nWENF_nWENF_nWENF_nWENF_nWENF_nWENF_nWENF_nWE

R4

150k

VCC

10 nF

C3

PA0

NF_D2

1nF

C4

PA3

NF_D3

PA2

PA4

NF_D4

NF_D5

PA5

PA7

PA6

SO

NF_D7

PA1

1TP3

SD_SCK

PA3

SCK

NF_nWP3

NF_nWENF_nWE

PA5

CP2

NF_nWP1

R9

75k

PA7

SI

NF_nRE

PC[7..0]

PC3

PC7

CP1

PC1

PC6

PC0

NF_nCE0

PC2

1

TP9

NF_RE

PC0PC0

VCC

PA0

R5

47k

NF_nCE2

PC4NF_D0

NF_D1

PA1

PC5

PA2

R6

10k

PC3

PC2

NF_nCE3

PA4

PA6

NF_D6

PC4

PC5

PC1

NF_R/nB2

R11

47k

PA[7..0]

PC7

PC6

NF_R/nB3

VCC

1TP4

SD_MOSI

GND

1

GND

2

AUXI1

3

AUXO1

4

DATA7

5

DATA6

6

DATA5

7

DATA4

8

DATA3

9

DATA0

10

DATA1

11

DATA9

12

SI

13

SO

14

SCK

15

CS

16

XT1

17

XT2

18

VTG

19

VTG

20

GND

21

GND

22

PB7

23

PB6

24

PB5

25

PB4

26

PB3

27

PB2

28

PB1

29

PB0

30

PD7

31

PD6

32

PD5

33

PD4

34

PD3

35

PD2

36

PD1

37

PD0

38

GND

39

GND

40

CON 2x20J1

EXP. CON 1

R7

47k

10 nF

C6

1nF

C5

GND

1

GND

2

AUXI0

3

AUXO0

4

CT7

5

CT6

6

CT5

7

CT4

8

CT3

9

CT2

10

CT1

11

BSEL2

12

(n.c.)

13

REF

14

NRST

15

PE2

16

PE1

17

PE0

18

GND

19

GND

20

VTG

21

VTG

22

PC7

23

PC6

24

PC5

25

PC4

26

PC3

27

PC2

28

PC1

29

PC0

30

PA7

31

PA6

32

PA5

33

PA4

34

PA3

35

PA2

36

PA1

37

PA0

38

GND

39

GND

40

CON 2x20J3

EXP. CON 0

SP1

123456789

101112

13

J4-NF_CON#2

NF MODULE

12345678910111213

J2-NF_CON#1

NF MODULE

VCC

NF_CLE

C2

4,7µF

R10

0

D3

HSML-C170

PWR FAIL

1TP5

SD_CS

1

TP6

NF_CLE

NF_ALE

NF_nWP2

R12

820

VSRC

SO

2 1

U2

LM385-1,2/SOT23

C8

4,7µF

SCK

1

TP1

VCC

10 nF

C7

nCS_mmc

SI

C1

1µF

1

TP8

NF_WE

VSRC

nCS_mmc

Figure 7-1 . Schematics, 1 of 1

7-26 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 27

Figure 7-2 . Assembly Drawing, 1 of 1(component side view)

Complete Schematics

ATEVK525 Mass Storage Board for AVR 7-27

7740B–AVR–03/08

Page 28

Complete Schematics

Table 7-1 . Bill of Materials

Qtty

1 C1 1µF Tantalum 1µF 16V capacitor SMD 3216

2 C2, C8 4.7µF Tantalum 4.7µF 16V capacitor SMD 3216

3 C3, C6, C7 10nF Ceramic multi-layer 10nF capacitor SMD 0805

2 C4, C5 1nF Ceramic multi-layer 1nF capacitor SMD 0805

1 D1 HSMC-C170 Red LED “WRITE” SMD 0805

1 D2 HSMG-C170 Green LED “READ” SMD 0805

1 D3 HSML-C170 Orange LED “PWR_FAIL” SMD 0805

2 J1, J3 M20-6102005 PC104 2x20-pin through-hole female press-fit stackable

1 J5 FPS009-3001 Yamaichi SD/MMC Connector with manual eject See DS

2 J2, J4 SIP13, 2.54mm pitch, socket for NAND Flash module 2.54mm pitch

2 CP1, CP2 Configuration Pad Enabled by default. Can be disabled cutting it. N/A

1 SP1 Solder Pad Disabled by default. Can be enabled with a solder drop. N/A

10 TP1-TP10 Test Point Solder or touch the testpoint with a probe Circular pad

2 R1, R11 47 KOhms Resistor 0.1W 1% 47 KOhms SMD 0805

2 R5, R7 47 KOhms Resistor 0.1W 1% 47 KOhms SMD 0805

2 R2, R3 820 Ohms Resistor 0.1W 1% 820 Ohms SMD 0805

1 R12 820 Ohms Resistor 0.1W 1% 820 Ohms SMD 0805

1 R4 150 KOhms Resistor 0.1W 1% 150 KOhms SMD 0805

1 R6 10 KOhms Resistor 0.1W 1% 10 KOhms SMD 0805

2 R8, R10 0 Ohms Resistor 0 Ohms (strap) SMD 0805

1 R9 75 KOhms Resistor 0.1W 1% 75KOhms SMD 0805

1 U1 LM393M Double comparator, open collector output SO-8

1 U2 LM385M3-1.2 Voltage reference 1.235V SOT-23

1 U3 MT29F2G008AACWP 256Mx8bits NAND Flash memory TSSOP-48

1 Q1 Si2301BDS P-Channel low Vgs & Rds(on) FET transistor SOT-23

Schematic

Reference

Part Reference Description Case

CAPACITORS

DIODES

CONNECTORS

2.54mm pitch

connector

CONFIGURATION

RESISTORS

INTEGRATED CIRCUITS

Note: The rows with grey background color specify that the corresponding component is not

mounted by default (power protection circuit, NAND Flash socket...)

7-28 ATEVK525 Mass Storage Board for AVR

7740B–AVR–03/08

Page 29

7.0.1 Default Configuration - Summary

Table 7-2 . Default Configuration summary

Name Ref. Function State

PWR SP1 Power protection circuit bypassing SOLDERED

R/nB2 CP1 Connect R/nB signal from NF#2 CLOSED

R/nB3 CP2 Connect R/nB signal from NF#3 CLOSED

Complete Schematics

Solder PADS

Configuration PADS

Optional components

Power

Protection

Circuit

NANDFlash

socket

See

BOM

Cut power supply if > 3.5V, and lights on

PWR_FAIL LED

J2, J4 Allow plug/unplug of the optional NAND Flash

module

NOT MOUNTED

NOT MOUNTED

ATEVK525 Mass Storage Board for AVR 7-29

7740B–AVR–03/08

Page 30

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

Eas t Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

Eas t Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Pos tfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

Disc laimer : The i nformation in this docu ment is pr ovided in connection wi th Atmel prod ucts. N o licen se, express o r implied, by estoppel or otherwi se,to anyintellectualprope rty right is g ran ted by this docum ent or in connection with t he sale of Atm el products. E XCE PT AS S ET FORTH I N ATMEL’S TERMS A ND CONDI-TIONS OF

SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSO EVER A ND DISCLAIMS A NY EXP RES S, IMPLIED OR STATUTORYWARRANTY RELATING TO ITS PRO DUCTS INCLUDING, BUT NOT LIMITED TO , THE IMPLIED WA RRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULARPURPOSE, O R NO N-I NFR INGEME NT. IN NO EVENT SHALL AT MEL BE LIABLE FOR ANY DIRECT, I NDIREC T, C ONS EQU ENT IAL , PUNITIVE , SPECIAL

OR INCIDEN-TAL DAMAGES (INC LUDING, WITHOUT LIMITATION, DAM AGE S FOR LOSS OF PRO FITS, BUSINESS INTERR UPTION, OR LOSS OF INFOR MATION ) ARISIN G O UTOF TH E USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISE D OF THE POSSIBILITY OF SUCH DAMAGES. Atm el makes n orepre sentations or wa rranti es with respect to the accura cy or comp let eness of the contents of t his documen t and reserves the right to mak e

changes to speci ficationsand produ ct descriptions at an y time without notice. Atmel does not make any co mmitment to upd ate th e information contained herein .

Unle ss specifically provided oth erwise, Atmel products are not su itable for, and shall no t be used in, autom oti ve applicati ons . Atmel’s produc ts are not intended ,

auth ori zed, or warranted for use as compon ents in ap pli cations intended to su ppo rt or sustain life.

©2008 Atmel Corporation. All rights reserved. Atmel®, logo and combinations thereof, and Everywhere You Are® are the trademarks or regis-

tered trademarks, of Atm el Corporation or its subsidiaries. Other terms and product names may be trademar ks of others.

Printed on recycled paper.

7740B–AVR–03/08

/xM

Loading...

Loading...