ATMEL ATA5567, AT42QT2160 Datasheet

Features

• Number of keys: up to 16 keys, and one slider (constructed from 2 to 8 keys)

• Number of I/O lines: 11 (3 dedicated - configurable for input or output, 8 shared -

output only), PWM control for LED driving

• Technology: patented spread-spectrum charge-transfer (transverse mode)

• Key outline sizes: 6 mm x 6 mm or larger (panel thickness dependent); widely different

sizes and shapes possible

• Key spacings: 8 mm or wider, center to center (panel thickness dependent)

• Slider design: 2 to 8 keys placed in sequence, same design as keys

• Electrode design: two-part electrode shapes (drive-receive); wide variety of possible

layouts

• PCB layers required: one layer (with jumpers), two layers (no jumpers)

• Electrode materials: PCB, FPCB, silver or carbon on film, ITO on film

• Panel materials: plastic, glass, composites, painted surfaces (low particle density

metallic paints possible)

• Adjacent metal: compatible with grounded metal immediately next to keys

• Panel thickness: up to 3 mm glass, 2.5 mm plastic (key size dependent)

• Key sensitivity: individually settable via simple commands over I

2

C-compatible

interface

• Interface: I

2

C-compatible slave mode (100kHz)

• Moisture tolerance: best in class

• Power: 1.8 V to 5.5 V

• Package: 28-pin 4 x 4 mm MLF RoHS compliant

• Signal processing: self-calibration, auto drift compensation, noise filtering, Adjacent

Key Suppression

TM

technology

• Applications: laptop, mobile, consumer appliances, PC peripheral etc.

• Patents: AKS™ (patented Adjacent Key Suppression™) technology

QMatrix™ (patented charge-transfer method)

QSlide™ (patented charge-transfer method) (patent-pending QSlide sensing

configuration)

• This datasheet is applicable to revision 4R0 chips only

1. Overview

The AT42QT2160-MMU (QT2160) is designed for use with up to 16 keys and a slider

(constructed from 2 keys up to 8 keys). There are three dedicated General Purpose

Input/Outputs (GPIOs) which can be used as inputs for mechanical switches etc. or as driven

outputs. There are eight shared General Purpose Outputs (GPOs) (X0...X7) which are driven

outputs only. There is PWM control for all GPIO/GPOs.

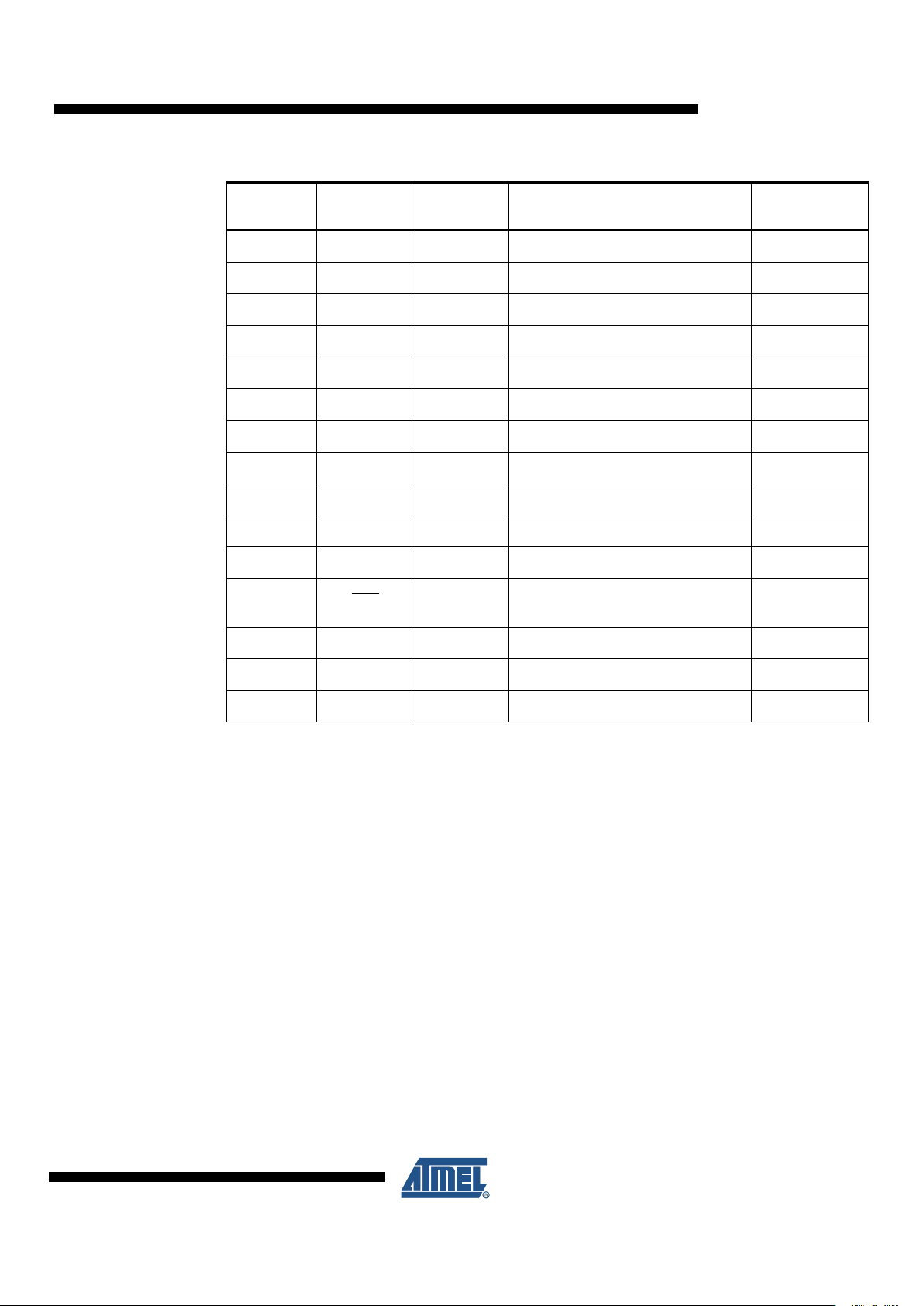

The QMatrix™ technology employs transverse charge-transfer sensing electrode

designs which can be made very compact and are easily wired. Charge is forced from

an emitting electrode into the overlying panel dielectric, and then collected on a

receiver electrode. This directs the charge into a sampling capacitor which is then

converted directly to digital form, without the use of amplifiers.

The keys are configured in a matrix format that minimizes the number of required scan

lines and device pins. The key electrodes can be designed into a conventional Printed

Circuit Board (PCB) or Flexible Printed Circuit Board (FPCB) as a copper pattern, or

as printed conductive ink on plastic film.

9502A–AT42–07/08

QSlide™, 16-key

QMatrix™

Sensor IC

AT42QT2160

2

9502A–AT42–07/08

AT42QT2160

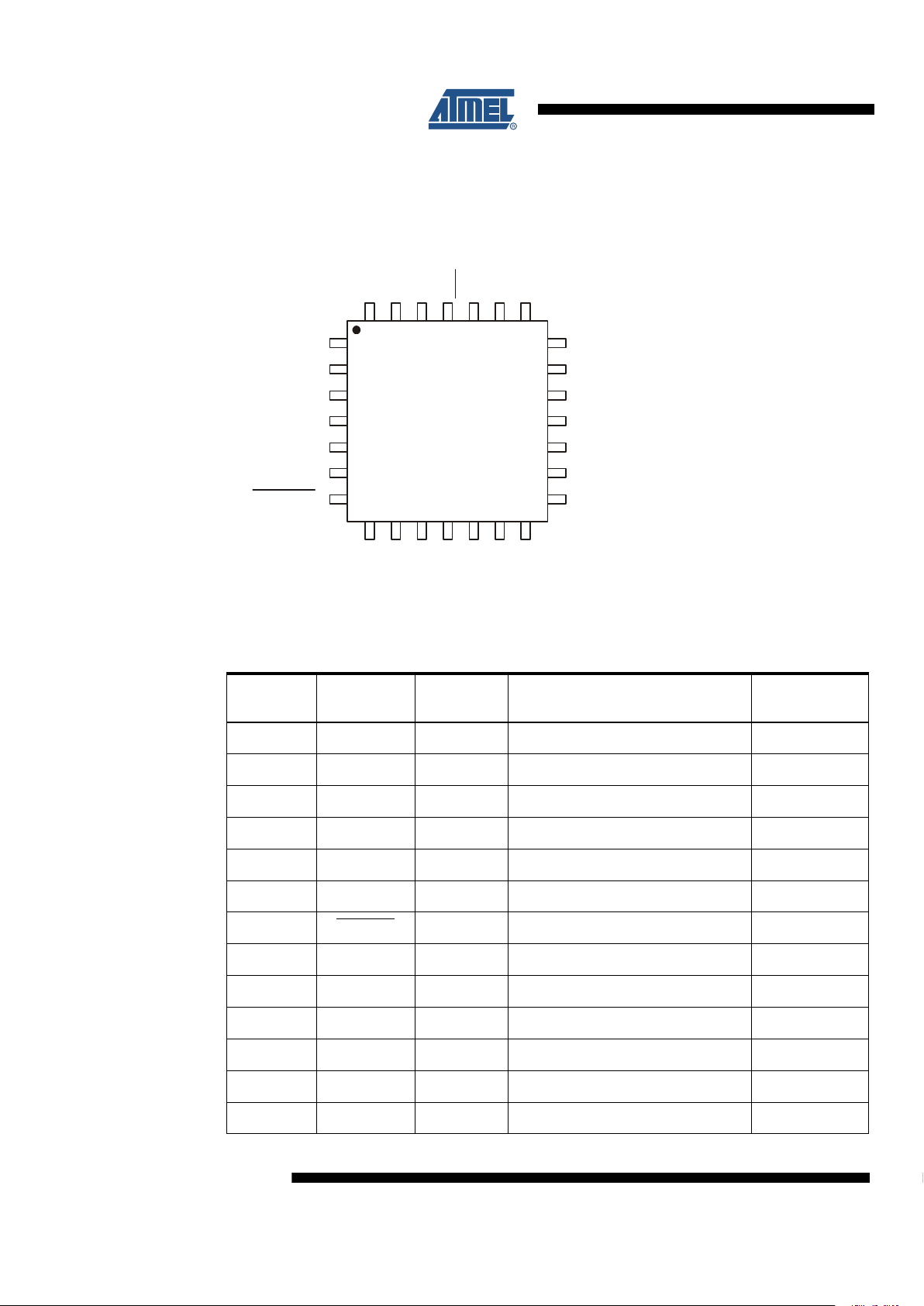

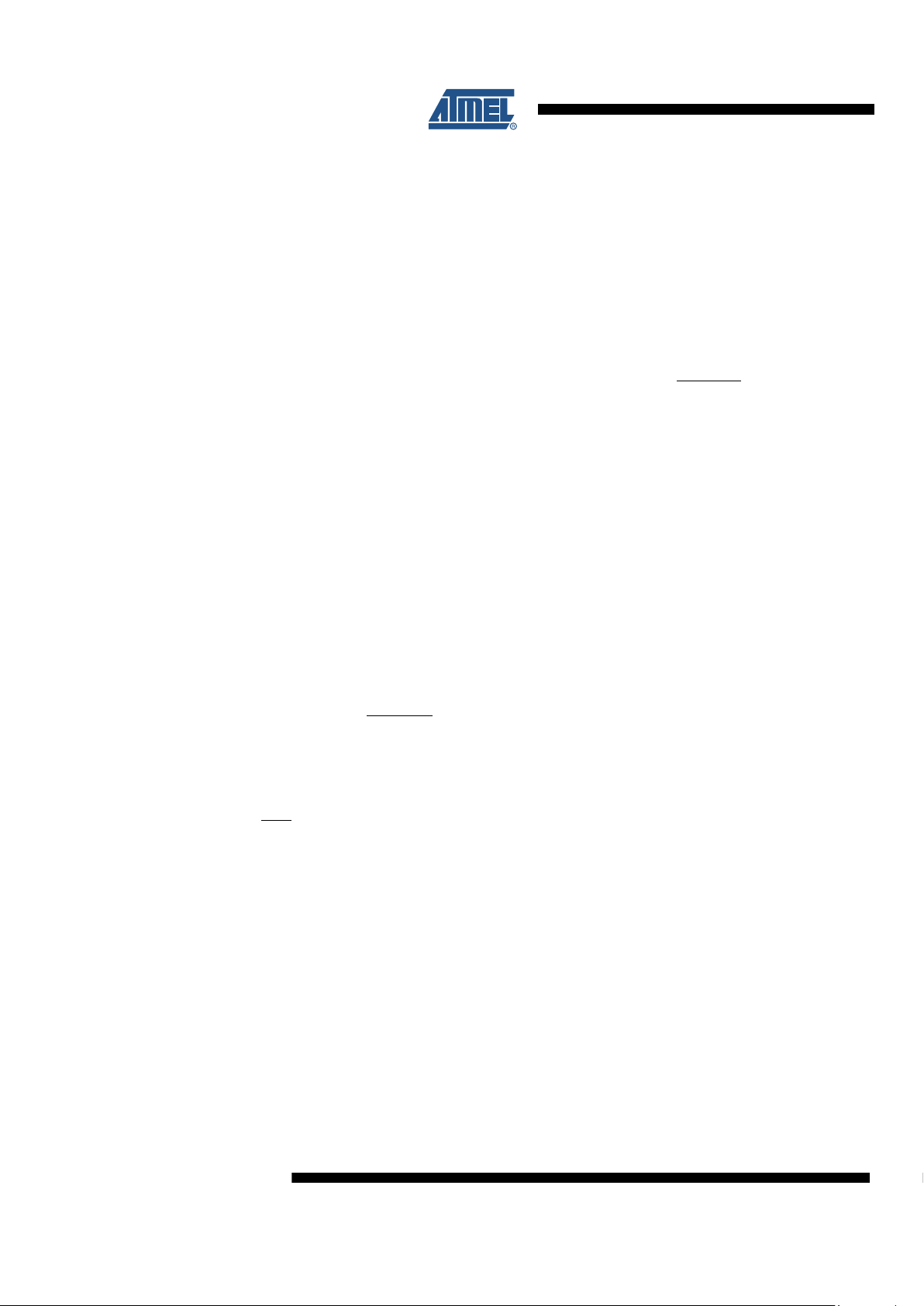

2. Pinout and Pin Listing Description

2.1 Pinout Description

2.2 Pin Listing Description

GPIO1

Y1A

Y0A

RST

VRef

X0

X2

GPIO2

GPIO3

VSS

VDD

X6

VSS

Y0B

Y1B

1

2

3

4

5

6

715

16

17

18

19

20

21

28

27

26

25

24 23

22

89 1413

12

11

10

QT2160

X7

CHANGE

X3

X4

VDD

I2CA0

SMP

X1

X5

VDD

I2CA1

SDA

SCL

Table 2-1.Pin Listing

Pin Function I/O Comments

If Unused,

Connect To...

1 GPIO2 I/O General purpose input/output 2 -

2 GPIO3 I/O General purpose input/output 3 -

3 Vdd P Power -

4 Vss P Supply ground -

5 X6 O X matrix drive line / shared GPO X6 Leave open

6 X7 O X matrix drive line / shared GPO X7 Leave open

7 CHANGE

OD State change notification Leave open

8 Vref P Supply ground -

9 SMP O Sample output. -

10 X0 O X matrix drive line / shared GPO X0 Leave open

11 X1 O X matrix drive line / shared GPO X1 Leave open

12 X2 O X matrix drive line / shared GPO X2 Leave open

13 X3 O X matrix drive line / shared GPO X3 Leave open

3

9502A–AT42–07/08

AT42QT2160

3. Introduction

The QT2160 device is a digital burst mode charge-transfer (QT) sensor designed specifically for

matrix layout touch controls; it includes all signal processing functions necessary to provide

stable sensing under a wide variety of changing conditions. Only a few external parts are

required for operation. The entire circuit can be built within a few square centimeters of

single-sided PCB area. CEM-1 and FR1 punched, single-sided materials can be used for the

lowest possible cost. The PCB’s rear can be mounted flush on the back of a glass or plastic

panel using a conventional adhesive, such as 3M VHB two-sided adhesive acrylic film.

The QT2160 employs transverse charge-transfer (QT) sensing, a technology that senses

changes in electrical charge forced across two electrode elements by a pulse edge (see

Figure 3-1). The QT2160 allows a wide range of key sizes and shapes to be mixed together in a

single touch panel.

The device uses an

I2C-compatible interface to allow key data to be extracted and to permit

individual key parameter setup. The command structure is designed to minimize the amount of

data traffic while maximizing the amount of information conveyed.

In addition to normal operating and setup functions the device can also report back actual signal

strengths.

14 X4 O X matrix drive line / shared GPO X4 Leave open

15 X5 O X matrix drive line / shared GPO X5 Leave open

16 Vdd P Power -

17 Vdd P Power -

18 Vss P Supply ground -

19 Y0B I/O Y line connection Leave open

20 Y1B I/O Y line connection Leave open

21 I2CA0 I I

2

C-compatible address select -

22 I2CA1 I I

2

C-compatible address select -

23 SDA OD Serial Interface Data -

24 SCL OD Serial Interface Clock -

25 RST

I

Reset low; has internal 30k - 60k pull-upLeave open or

Vdd

26 Y0A I/O Y line connection Leave open

27 Y1A I/O Y line connection Leave open

28 GPIO1 I/O General purpose input/output 1

Table 2-1.Pin Listing (continued)

Pin Function I/O Comments

If Unused,

Connect To...

4

9502A–AT42–07/08

AT42QT2160

Figure 3-1. Field Flow Between X and Y Elements

3.1 Keys and Slider

The QT2160 is capable of a maximum of 16 keys. These can be located anywhere within an

electrical grid of 8X and 2Y scan lines.

A lesser number of enabled keys will cause any unused acquisition burst timeslots to be pared

from the sampling sequence, to optimize acquire speed and lessen power consumption. Thus, if

only 8 keys are actually enabled, only 8 timeslots are used for scanning.

Additional processing can be done on the keys to form a slider. The slider will have to start at X0

and use only Y0. The slider can consist of a minimum of 2 keys and a maximum of 8 keys.

3.2 Enabling/Disabling Keys

Keys can be enabled by setting a nonzero burst length. A zero burst length disables the key.

4. Hardware and Functional

4.1 Matrix Scan Sequence

The circuit operates by scanning each key sequentially, key by key. Key scanning begins with

location X = 0, Y = 0 (key 0). X axis keys are known as rows while Y axis keys are referred to as

columns although this has no reflection on actual wiring. Keys are scanned sequentially by row,

for example the sequence X0Y0 X1Y0...X7Y0, X0Y1, X1Y1... etc. Keys are also numbered from

0...15. Key 0 is located at X0Y0. Table 4-1 shows the key numbering.

Table 4-1. Key Numbers

Each key is sampled in a burst of acquisition pulses whose length is determined by the Setups

parameter BL (Section 4.2 on page 5); this can be set on a per-key basis. A burst is completed

entirely before the next key is sampled; at the end of each burst the resulting signal is converted

to digital form and processed. The burst length directly impacts key gain; each key can have a

unique burst length in order to allow tailoring of key sensitivity on a key-by-key basis.

overlying panel

X

element

Y

element

X7 X6 X5 X4 X3 X2 X1 X0

Y0 76543210

Key numbers

Y1 15 14 13 12 11 10 9 8

5

9502A–AT42–07/08

AT42QT2160

4.2 Burst Paring

Keys that are disabled by setting their burst length to zero have their bursts removed from the

scan sequence to save scan time and thus power. The QT2160 operates on a fixed 16 ms cycle

and will go to sleep after all acquisitions and processing is done till the next 16ms cycle starts.

As a consequence, the fewer keys, the less power is consumed.

4.3 Cs Sample Capacitor Operation

Cs capacitors (Cs0...Cs1) absorb charge from the key electrodes on the rising edge of each X

pulse. On each falling edge of X, the Y matrix line is clamped to ground to allow the electrode

and wiring charges to neutralize in preparation for the next pulse. With each X pulse charge

accumulates on Cs causing a staircase increase in its differential voltage.

After the burst completes, the device clamps the Y line to ground causing the opposite terminal

to go negative. The charge on Cs is then measured using an external resistor to ramp the

negative terminal upwards until a zero crossing is achieved. The time required to zero cross

becomes the measurement result.

The Cs capacitors should be connected as shown in Figure 4-8 on page 15. The value of these

capacitors is not critical but 4.7 nF is recommended for most cases. They should be 10 percent

X7R ceramic. If the transverse capacitive coupling from X to Y is large enough the voltage on a

Cs capacitor can saturate, destroying gain. In such cases the burst length should be reduced

and/or the Cs value increased. See Section 4.4.

If a Y line is not used its corresponding Cs capacitor may be omitted and the pins left floating.

4.4 Sample Capacitor Saturation

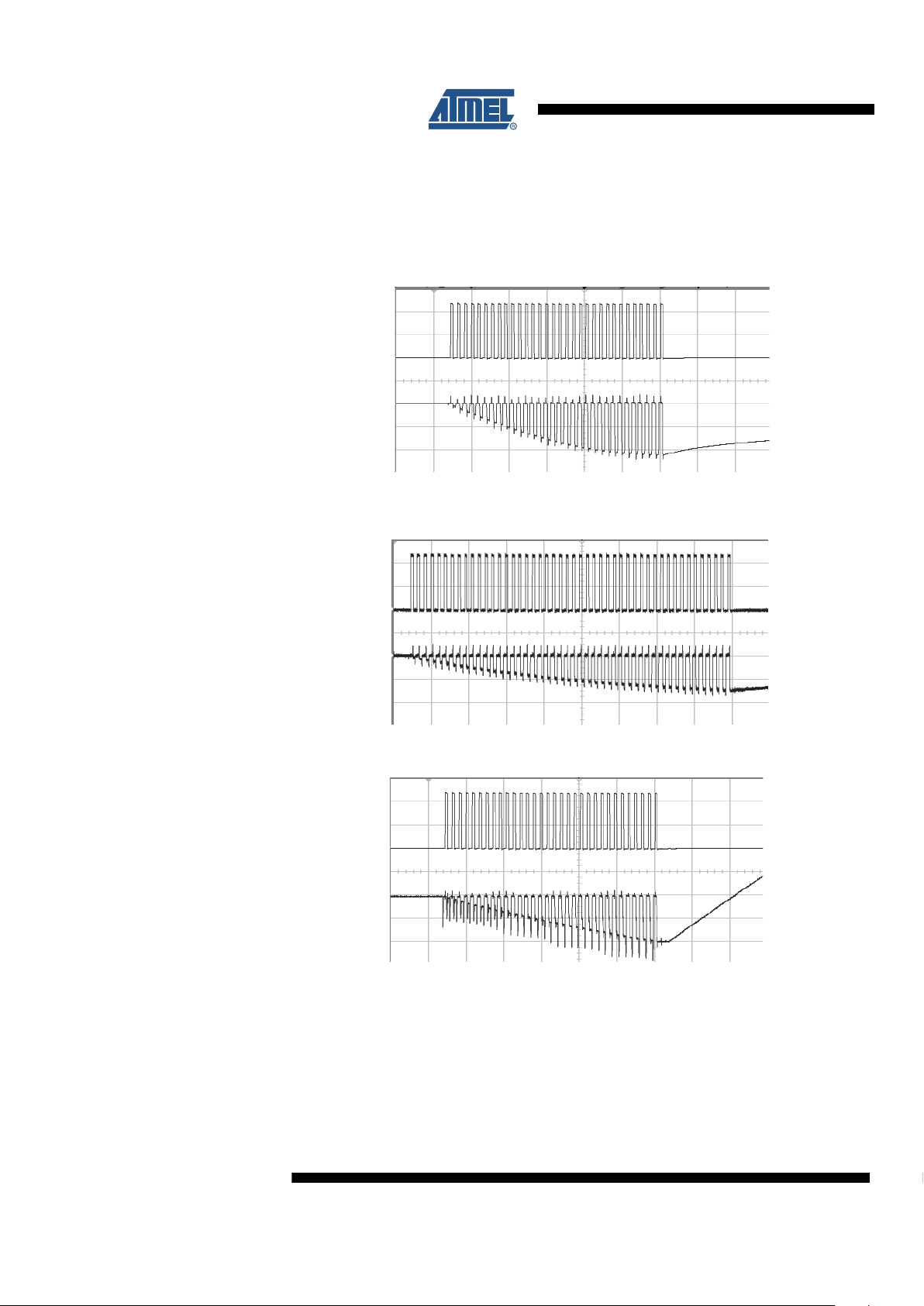

Cs voltage saturation at a pin YnB is shown in Figure 4-1. Saturation begins to occur when the

voltage at a YnB pin becomes more negative than -0.25V at the end of the burst. This

nonlinearity is caused by excessive voltage accumulation on Cs inducing conduction in the pin

protection diodes. This badly saturated signal destroys key gain and introduces a strong thermal

coefficient which can cause phantom detection. The cause of this is either from the burst length

being too long, the Cs value being too small, or the X-Y transfer coupling being too large.

Solutions include loosening up the key structure interleaving, more separation of the X and Y

lines on the PCB, increasing Cs, and decreasing the burst length.

Increasing Cs will make the part slower; decreasing burst length will make it less sensitive. A

better PCB layout and a looser key structure (up to a point) have no negative effects.

Cs voltages should be observed on an oscilloscope with the matrix layer bonded to the panel

material; if the Rs side of any Cs ramps more negative than -0.25 volts during any burst (not

counting overshoot spikes which are probe artifacts), there is a potential saturation problem.

Figure 4-2 shows a defective waveform similar to that of Figure 4-1, but in this case the

distortion is caused by excessive stray capacitance coupling from the Y line to AC ground; for

example, from running too near and too far alongside a ground trace, ground plane, or other

traces. The excess coupling causes the charge-transfer effect to dissipate a significant portion of

the received charge from a key into the stray capacitance. This phenomenon is more subtle; it

can be best detected by increasing BL to a high count and watching what the waveform does as

it descends towards and below -0.25V. The waveform will appear deceptively straight, but it will

slowly start to flatten even before the -0.25V level is reached.

A correct waveform is shown in Figure 4-3. Note that the bottom edge of the bottom trace is

substantially straight (ignoring the downward spikes).

6

9502A–AT42–07/08

AT42QT2160

Unlike other QT circuits, the Cs capacitor values on QT2160 devices have no effect on

conversion gain. However, they do affect conversion time.

Unused Y lines should be left open.

Figure 4-1. VCs – Nonlinear During Burst

(Burst too long, or Cs too small, or X-Y transcapacitance too large)

Figure 4-2. VCs – Poor Gain, Nonlinear During Burst

(Excess capacitance from Y line to Gnd)

Figure 4-3. VCs – Correct

X Driv

eYnB

X Driv

eYnB

X Driv

e

Yn

B

7

9502A–AT42–07/08

AT42QT2160

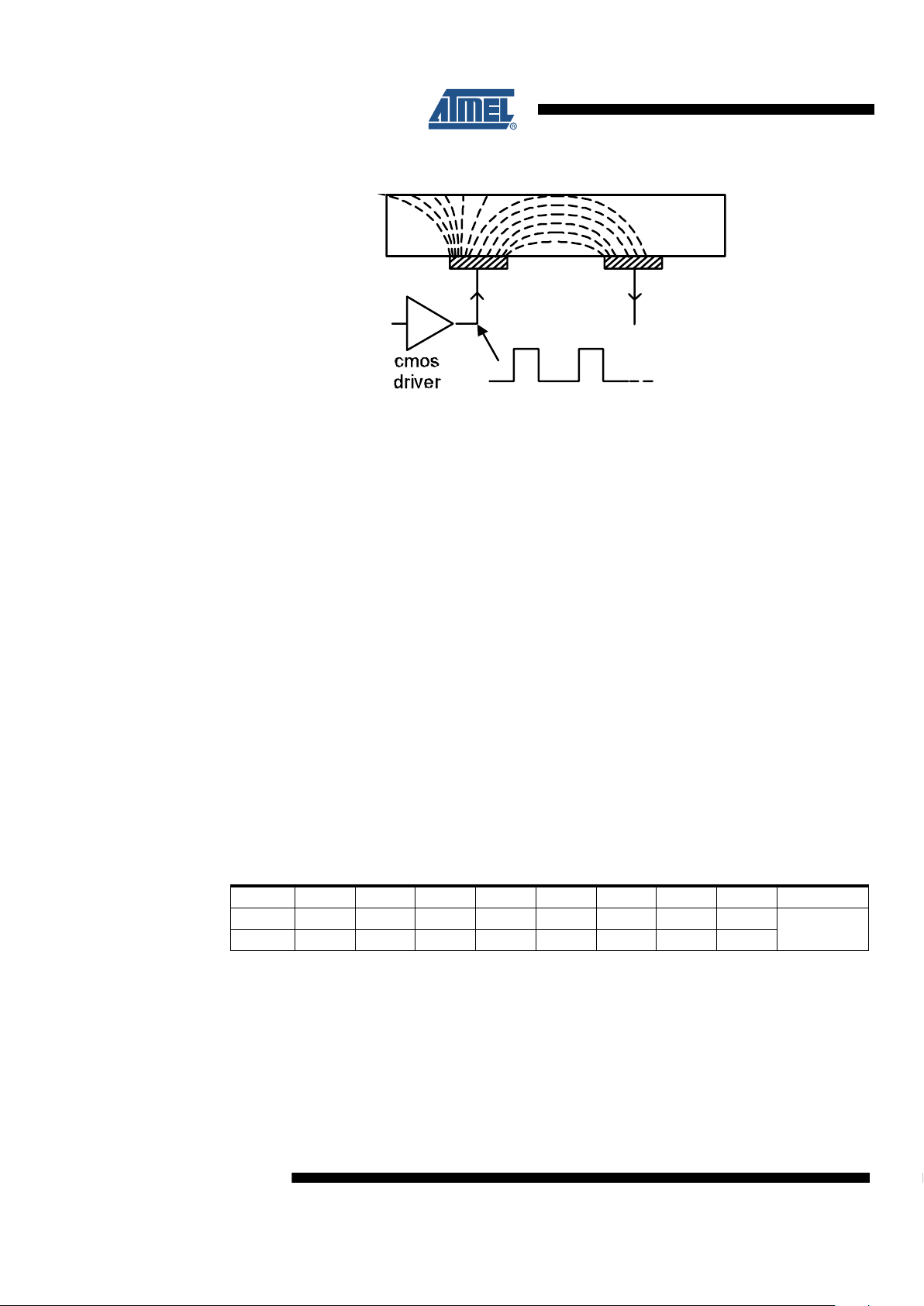

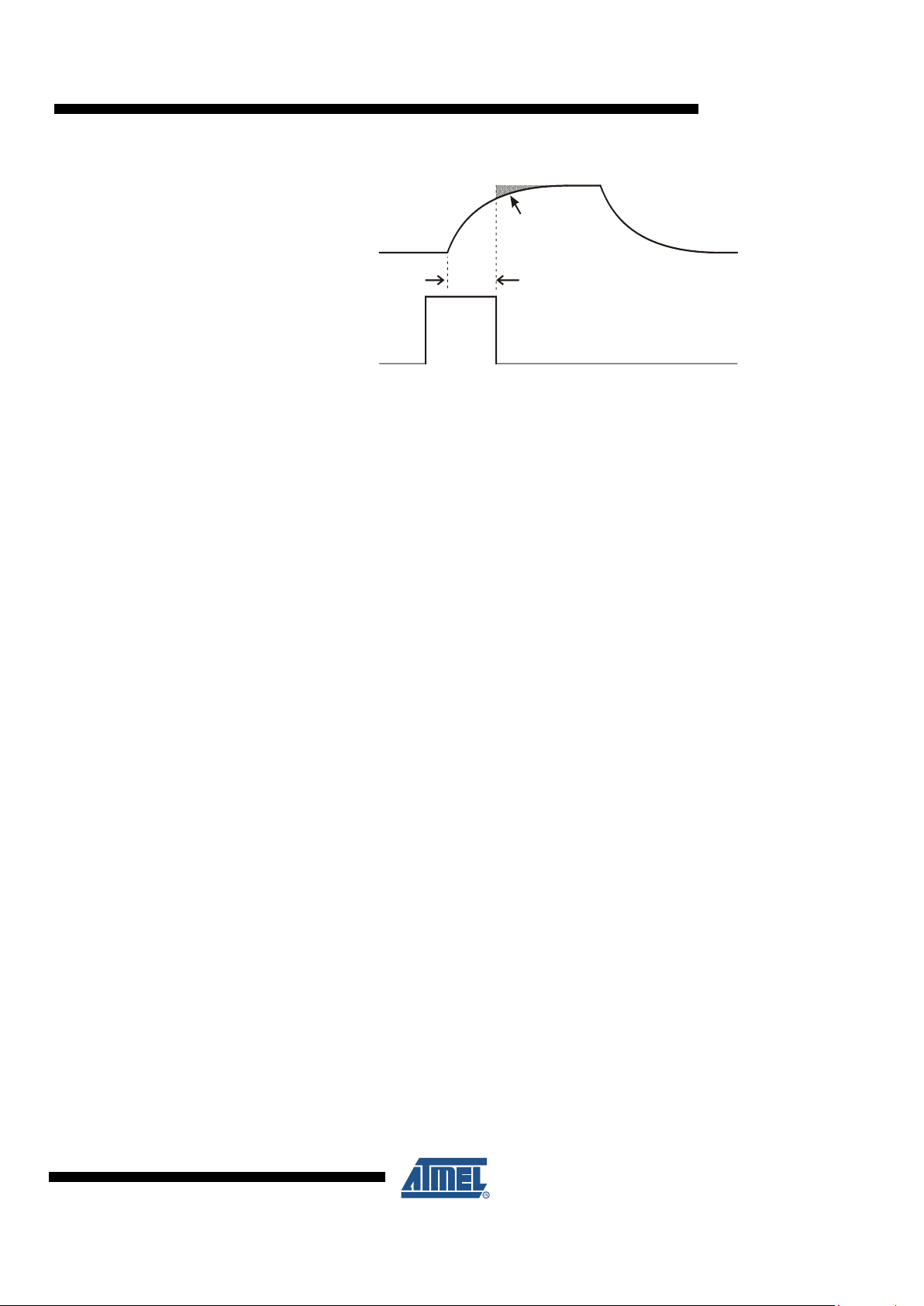

Figure 4-4. Drive Pulse Roll-off and Dwell Time

Note: The Dwell time is a minimum of ~250ns - see Section 4.7

4.5 Sample Resistors

The sample resistors (Rs0...Rs1) are used to perform single-slope ADC conversion of the

acquired charge on each Cs capacitor. These resistors directly control acquisition gain; larger

values of Rs will proportionately increase signal gain. For most applications Rs should be 1MΩ.

Unused Y lines do not require an Rs resistor.

4.6 Signal Levels

The signal values should normally be in the range of 200 to 750 counts with properly designed

key shapes and values of Rs. However, long adjacent runs of X and Y lines can also artificially

boost the signal values, and induce signal saturation; this is to be avoided. The X-to-Y coupling

should come mostly from intra-key electrode coupling, not from stray X-to-Y trace coupling.

The signal swing from the smallest finger touch should preferably exceed 8 counts, with 12

being a reasonable target. The signal threshold setting (NTHR) should be set to a value

guaranteed to be less than the signal swing caused by the smallest touch.

Increasing the burst length (BL) parameter will increase the signal strengths, as will increasing

the sampling resistor (Rs) values.

4.7 Matrix Series Resistors

The X and Y matrix scan lines can use series resistors (Rx0...Rx7 and Ry0...Ry1 respectively)

for improved EMC performance (Figure 4-8 on page 15).

X drive lines require Rx in most cases to reduce edge rates and thus reduce RF emissions.

Values range from 1 kΩ to 20 kΩ, typically 1 kΩ.

Y lines need Ry to reduce EMC susceptibility problems and in some extreme cases, ESD.

Typical Y values are about 1 kΩ. Y resistors act to reduce noise susceptibility problems by

forming a natural low-pass filter with the Cs capacitors.

It is essential that the Rx and Ry resistors and Cs capacitors be placed very close to the chip.

Placing these parts more than a few millimeters away opens the circuit up to high frequency

interference problems (above 20 MHz) as the trace lengths between the components and the

chip start to act as RF antennae.

The upper limits of Rx and Ry are reached when the signal level and hence key sensitivity are

clearly reduced. The limits of Rx and Ry will depend on key geometry and stray capacitance,

and thus an oscilloscope is required to determine optimum values of both.

X drive

Lost charge due to

inadequate settling

before end of dwell time

Y gate

Dwell time

8

9502A–AT42–07/08

AT42QT2160

Dwell time is the duration in which charge coupled from X to Y is captured (Figure 4-4

on page 7). Increasing Rx values will cause the leading edge of the X pulses to increasingly roll

off, causing the loss of captured charge (and hence loss of signal strength) from the keys.

The dwell time is a minimum of 250 ns. If the X pulses have not settled within 250 ns, key gain

will be reduced; if this happens, either the stray capacitance on the X line(s) should be reduced

(by a layout change, for example by reducing X line exposure to nearby ground planes or

traces), or, the Rx resistor needs to be reduced in value (or a combination of both approaches).

One way to determine X line settling time is to monitor the fields using a patch of metal foil or a

small coin over the key (Figure 4-5). Only one key along a particular X line needs to be

observed, 250 ns dwell time should exceed the observed 95 percent settling of the X-pulse by

25 percent or more.

In almost all cases, Ry should be set equal to Rx, which will ensure that the charge on the Y line

is fully captured into the Cs capacitor.

Figure 4-5. Probing X-Drive Waveforms With a Coin

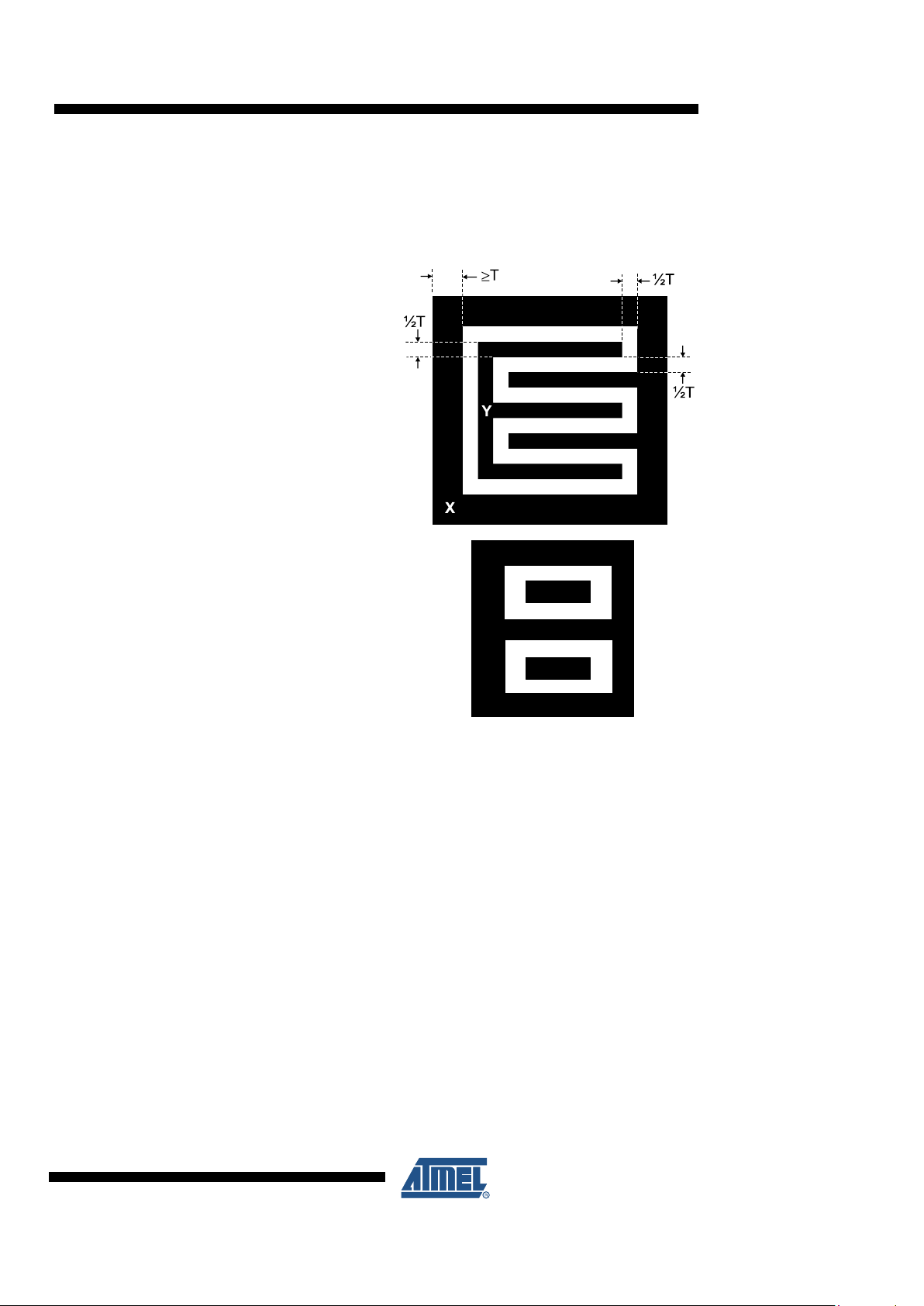

4.8 Key Design

Circuits can be constructed out of a variety of materials including conventional FR-4, Flexible

Printed Circuit Boards (FPCB), silver silk-screened on PET plastic film, and even inexpensive

punched single-sided CEM-1 and FR-2.

The actual internal pattern style is not as important as the need to achieve regular X and Y

widths and spacings of sufficient size to cover the desired graphical key area or a little bit more;

~3mm oversize is acceptable in most cases, since the key’s electric fields drop off near the

edges anyway. The overall key size can range from 6mm x 6mm up to 100mm x 100mm but

these are not hard limits. The keys can be any shape including round, rectangular, square, etc.

The internal pattern can be interdigitated as shown in Figure 4-6.

For small, dense keypads, electrodes such as shown in the lower half of Figure 4-6 can be used.

Where the panels are thin (under 2 mm thick) the electrode density can be quite high.

9

9502A–AT42–07/08

AT42QT2160

For better surface moisture suppression, the outer perimeter of X should be as wide as possible,

and there should be no ground planes near the keys. The variable “T" in this drawing represents

the total thickness of all materials that the keys must penetrate.

Figure 4-6. Recommended Key Structure

Note: “T" should ideally be similar to the complete thickness the fields need to penetrate to the touch

surface. Smaller dimensions will also work but will give less signal strength. If in doubt, make the

pattern coarser. The lower figure shows a simpler structure used for compact key layouts, for

example for mobile phones. A layout with a common X drive and two receive electrodes is

depicted

4.9 Setting the Slider

4.9.1 Introduction

Groups of keys can be configured as a slider, in addition to their use as keys. The slider uses the

Y0 line of the matrix and must start at X0, with the keys placed in consecutive numerical order.

The slider can take up a programmable number of keys on the Y0 line. The remaining keys on

that Y line behave as normal.

Positional data is calculated in a customizable range of 2 bits (0-3) to 8 bits (0-255). Geometric

constraints may mean that the data will not reach the full range. Thinner dielectric or the use of

more keys in a slider will increase the data range towards the ends.

Stability of the reported position will be dependent on the amount of signal on the slider keys.

Running at higher resolutions, with a thick panel might produce a fluctuating reported position.

Y1

Y0

X0

10

9502A–AT42–07/08

AT42QT2160

Key sizes should be in the 5-7mm range when used in the slider to get the best linearity. The

slider should be made up of however many of these elements are required to fit their

dimensions.

The slider will be treated as an object in the Adjacent Key Suppression (AKS) groupings. The

keys in the slider would normally be set to the same burst length and threshold, although

adjustments can be made in these at the expense of linearity.

4.9.2 AKS Technology and the Slider

There can be up to three AKS groups, implemented so that only one key in each group may be

reported as being touched at any one time. The AKS technique will lock onto the dominant key,

and until this key is released, other keys in the group will not be reported as in detection. This

allows a user to slide a finger across multiple keys with only the dominant key reporting touch.

Each key may be in one of the groups 1...3, or in group 0 meaning that it is not AKS enabled.

Keys in the slider are not able to use AKS technique against each other. This is necessary to

enable smooth scrolling. Multiple keys within the slider can be in detect at the same time,

regardless of the AKS settings. The AKS technique will, however, work against keys outside the

object or within another object. For example, if a slider is in the same AKS group as keys, then

touching anywhere on the slider will cause the AKS technique to suppress the keys. Similarly

touching the keys first will suppress the slider.

Note: For normal operation all keys in the slider should be placed in the same AKS group.

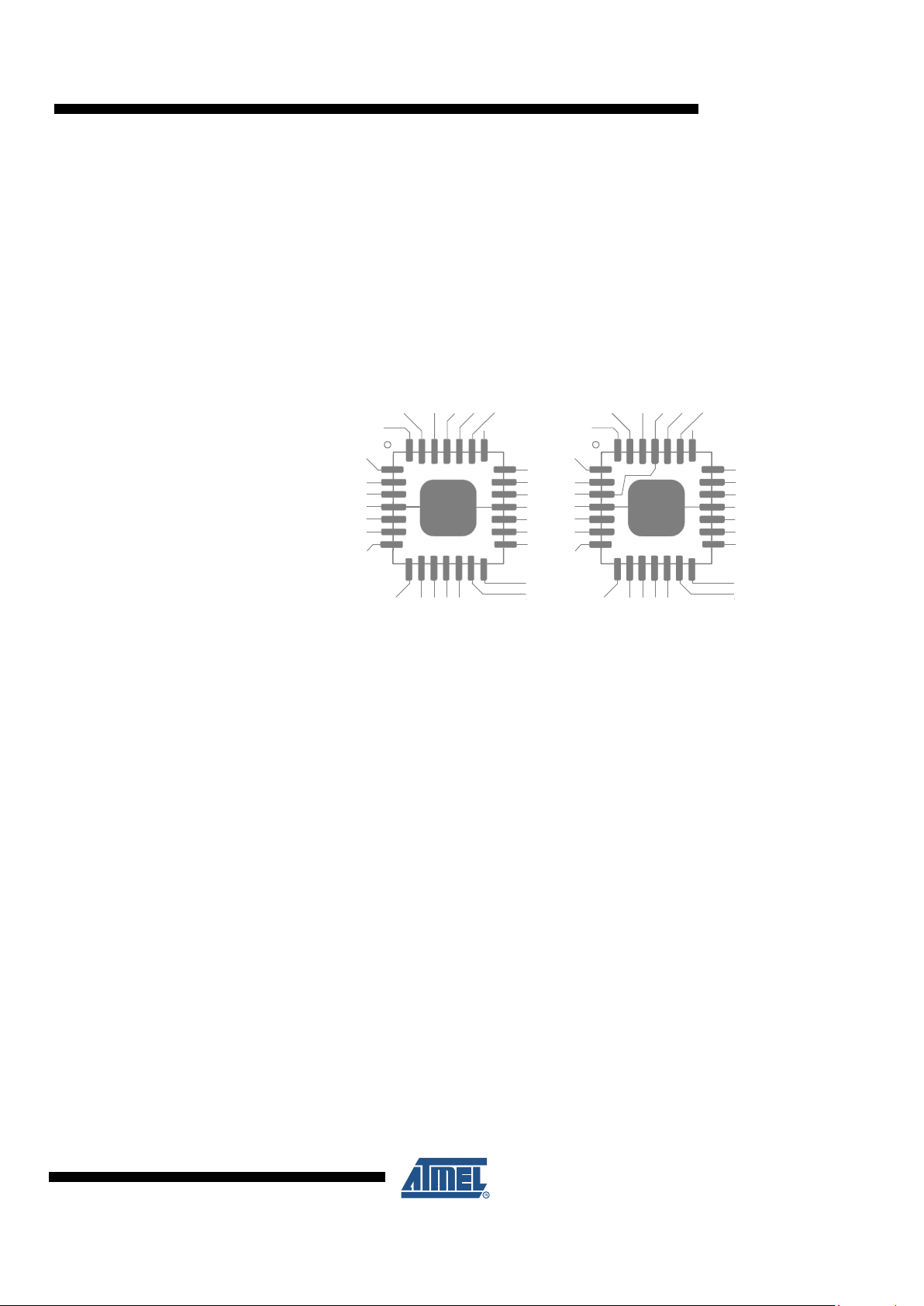

4.10 PCB Layout, Construction

4.10.1 Overview

It is best to place the chip near the touch keys on the same PCB so as to reduce X and Y trace

lengths, thereby reducing the chances for EMC problems. Long connection traces act as RF

antennae. The Y (receive) lines are much more susceptible to noise pickup than the X (drive)

lines.

Even more importantly, all signal related discrete parts (resistors and capacitors) should be very

close to the body of the chip. Wiring between the chip and the various resistors and capacitors

should be as short and direct as possible to suppress noise pickup.

Ground planes, if used, should be placed under or around the QT chip itself and the associated

resistors and capacitors in the circuit, under or around the power supply, and back to a

connector. Ground planes can be used to shield against radiated noise, but at the expense of a

reduction in sensitivity as described previously.

Note: When using ground planes/floods, parasitic capacitance on Y lines can lead to reduced charge-

transfer efficiency. For noise suppression, ground planes/floods can be beneficial around and

between keys on the touch side of the PCB. However, it is advisable to route Y lines on the PCB

layer furthest away from the plane/flood, to reduce parasitic capacitance. Cross-hatched ground

patterns can act as effective shields, while helping to reduce parasitic capacitance. Ground

planes/floods around the chip are generally acceptable, taking into account the same considerations as for the Y line parasitics.

4.10.2 LED Traces and Other Switching Signals

Digital switching signals near the Y lines will induce transients into the acquired signals,

deteriorating the SNR performance of the device. Such signals should be routed away from the

Y lines, or the design should be such that these lines are not switched during the course of

signal acquisition (bursts).

11

9502A–AT42–07/08

AT42QT2160

LED terminals which are multiplexed or switched into a floating state and which are within or

physically very near a key structure (even if on another nearby PCB) should be bypassed to

either Vss or Vdd with at least a 10nF capacitor to suppress capacitive coupling effects which

can induce false signal shifts. The bypass capacitor does not need to be next to the LED, in fact

it can be quite distant. The bypass capacitor is noncritical and can be of any type.

LED terminals which are constantly connected to Vss or Vdd do not need further bypassing.

4.10.3 Tracks

The central pad on the underside of the chip should be connected to ground. Do not run any

tracks underneath the body of the chip, only ground.

Figure 4-7. Position of Tracks

4.10.4 PCB Cleanliness

All capacitive sensors should be treated as highly sensitive circuits which can be influenced by

stray conductive leakage paths. QT devices have a basic resolution in the femtofarad range; in

this region, there is no such thing as “clean flux". Flux absorbs moisture and becomes

conductive between solder joints, causing signal drift and resultant false detections or transient

losses of sensitivity or instability. Conformal coatings will trap in existing amounts of moisture

which will then become highly temperature sensitive.

The designer should specify ultrasonic cleaning as part of the manufacturing process, and in

cases where a high level of humidity is anticipated, the use of conformal coatings after cleaning

to keep out moisture.

4.11 Power Supply Considerations

See Section 10.2 on page 43 for the Vdd range and short-term power supply fluctuations. If the

power supply fluctuates slowly with temperature, the device will track and compensate for these

changes automatically with only minor changes in sensitivity. If the supply voltage drifts or shifts

quickly, the drift compensation mechanism will not be able to keep up, causing sensitivity

anomalies or false detections.

As the device uses the power supply itself as an analog reference, the power should be very

clean and come from a separate regulator. A standard inexpensive Low Dropout (LDO) type

regulator should be used that is not also used to power other loads such as LEDs, relays, or

other high current devices. Load shifts on the output of the LDO can cause Vdd to fluctuate

enough to cause false detection or sensitivity shifts.

Example of g trackingood

Example of bad tracking

12

9502A–AT42–07/08

AT42QT2160

Caution: A regulator IC shared with other logic devices can result in erratic operation and is not

advised.

A regulator can be shared among two or more QT devices on one board. Refer to page 15 for

suggested regulator manufacturers.

A single ceramic 0.1uF bypass capacitor, with short traces, should be placed very close to

supply pins 3 and 4 of the IC. Failure to do so can result in device oscillation, high current

consumption, erratic operation etc. Pins 16 and 17 do not require bypassing if the traces

between these pins and power traces are short.

4.12 Startup/Calibration Times

The device requires initialization times of approximately 70ms. The CHANGE line will go low and

calibration will start (takes 15 matrix scans), after this start up period is over.

4.13 Calibration

Calibration does not occur periodically. Keys are only calibrated on power-up and when:

•Enabled

AND

– held in detect for too long. The negative recalibration delay (NRD) period is specified

by the user

OR

– the signal delta value is greater than the positive threshold value, defined as

reference value plus three-quarters of the negative threshold

OR

– the user issues a recalibrate command

An interrupt on the CHANGE

pin occurs when there is a change in the key status bytes. An

interrupt will occur on calibration only if at least one of the keys or objects was in detect as

recalibration will then cause a status change.

4.14 Reset Input

The RST pin can be used to reset the device to simulate a power-down cycle, in order to bring

the device up into a known state should communications with the device be lost. The pin is

active low, and a low pulse lasting at least 10µs must be applied to this pin to cause a reset.

If an external hardware reset is not used, the reset pin may be connected to Vdd.

13

9502A–AT42–07/08

AT42QT2160

4.15 Spread Spectrum Acquisitions

QT2160 uses spread-spectrum burst modulation. This has the effect of drastically reducing the

possibility of EMI effects on the sensor keys, while simultaneously spreading RF emissions. This

feature is hard-wired into the device and cannot be disabled or modified.

Spread spectrum is configured as a frequency chirp over a wide range of frequencies for robust

operation.

4.16 Detection Integrator

See also Section 4.2 on page 5.

The device features a detection integration mechanism, which acts to confirm a detection in a

robust fashion. A per-key counter is incremented each time the key has exceeded its threshold

and stayed there for a number of acquisitions. When this counter reaches a preset limit the key

is finally declared to be touched.

For example, if the limit value is 10, then the device has to exceed its threshold and stay there

for 10 acquisitions in succession without going below the threshold level, before the key is

declared to be touched. If on any acquisition the signal is not seen to exceed the threshold level,

the counter is cleared and the process has to start from the beginning.

4.17 Sleep

The device operates on a fixed 16ms cycle time basis. The device will perform a set of

measurements and then sleep for the rest of the cycle to conserve power.

There are two user-configurable sleep modes; Low Power (LP) mode and SLEEP mode.

The LP setting (see Section 4.2 on page 5) is used for conserving power when there are no

touches and is set to be a long time period. This will determine how often the device wakes up to

do drift compensation. It also determines the maximum response time to the first touch after

inactivity.

When a valid touch is registered, the device enters minimum cycle time (16ms) for a faster

response to key touch and object operation. The device will stay in this mode if it continues to

see keys being touched and released. There is a user-selectable inactivity timeout i.e. the

awake timeout.

The measurement period needs to be shorter than the 16ms fixed cycle time for optimum

operation. If the measurement time exceeds the 16ms fixed cycle time, a CYCLE OVERRUN bit

is set in the general status register. The QT2160 will still operate if the 16ms fixed cycle time is

exceeded, but the timing for the timed parameters, e.g. drift compensation negative recalibration

time out etc. will slightly change.

A low power setting of zero causes the device to enter an ultra-low power mode (SLEEP), where

no measurements are carried out. SLEEP mode also stops the internal watchdog timer, so that

the part is totally dormant, and current drain is <2µA. The PWM function will not be carried out

during SLEEP, therefore it is recommended driving the GPIOs/GPOs to known states before

entering SLEEP mode.

The QT2160 wakes from SLEEP mode if there is an address match on the

I2C-compatible bus, a

hardware reset on the RST

pin or an LP mode is set. If the Wake option is set for the dedicated

GPIO inputs, then the QT2160 will trigger the CHANGE

line if a change in status (either positive

or negative going edge) of the respective GPIO is detected, in SLEEP mode.

14

9502A–AT42–07/08

AT42QT2160

4.18 General Purpose Inputs/Outputs

There are three dedicated GPIOs (GPIO1...3) and eight GPOs shared with X lines (X0...7).

Shared GPOs are always outputs, whereas dedicated GPIOs can be set to be outputs or inputs.

GPIOs set to input can be used for reading dome switches or logic signals. Outputs can be used

to drive LEDs, or other devices. It is recommended driving external devices through the use of

bipolar transistors or MOSFETs, so as not to affect capacitive sensing if a load fluctuates the

power rail by drawing/sinking too much current.

All GPOs and GPIOs set to output can be PWM driven, if the corresponding PWM bit is set. Note

that the PWM duty cycle will be an approximation, as GPIOs will not be switched during

acquisition bursts.

The dedicated GPIOs have a Wake option, that if enabled will enable dedicated GPIOs set as

inputs, to be read in SLEEP mode.

Note that shared GPOs (X0...X7) are driven by the burst pulses during acquisition bursts, if the

corresponding X line is used in the keys/slider. A low pass filter can be inserted to eliminate

these burst pulses, as shown in Figure 4-9 on page 16.

15

9502A–AT42–07/08

AT42QT2160

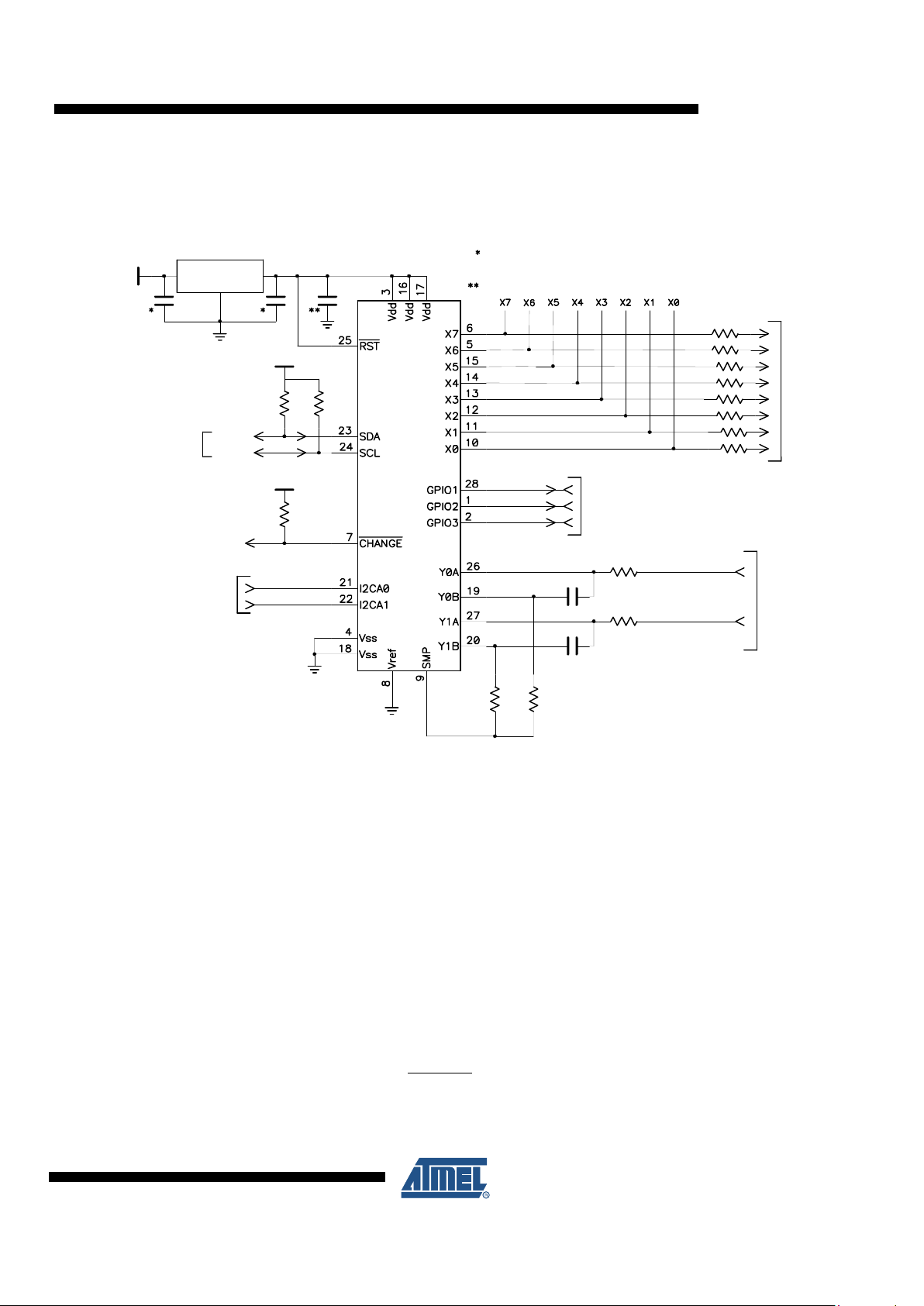

4.19 Wiring

Figure 4-8. Wiring Diagram

Suggested regulator manufacturers:

• Toko (XC6215 series)

• Seiko (S817 series)

• BCDSemi (AP2121 series)

Re Figure 4-8 check the following sections for component values:

• Section 4.3 on page 5: Cs capacitors (Cs0...Cs1)

• Section Note: on page 7: Sample resistors (Rs0...Rs1)

• Section 4.7 on page 7: Matrix resistors (Rx0...Rx7, Ry0...Ry1)

• Section 4.11 on page 11: Voltage levels

• Section 6.4 on page 22: SDA, SCL pull-up resistors (Rp)

• Section 4.2 on page 5: CHANGE

resistor (Rchg)

• Section 4.2 on page 5:

I2C-compatible addresses

Rp Rp

MATRIX Y SCAN IN

MATRIX X DRIVE

Rchg

VREG

Rx0

Rx3

Rx6

VDD

SCL

SDA

Rs1

Cs0

Cs1

Ry1

Rx2

Rx1

Rx7

Rx5

Vunreg

VDD

VDD

Ry0

Rx4

CHANGE

I2C

I2C ADDRESS

SELECT

QT2160

Rs0

General purpose

inputs/outp uts

Notes:

1) the central pad on the underside of the chip is a

Vss pin and should be connected to ground .

Do not put any other tracks underneath the body

of the chip.

2) it is important to place all Rx, Ry, Cs and Rs

components physically n ear to the chip .

3) leave YnA, YnB unconnected

if not used.

follow regu lator manuf acturers rec ommended values for input

and output bypass capacitors.

tightly wire a 100nF bypass capacitor between Vdd and Vss (pins 3 and 4).

Loading...

Loading...