BDTIC www.bdtic.com/ATMEL

Features

•

Compatible with MCS®51 Products

•

2K/4K Bytes of In-System Programmable (ISP) Flash Program Memory

– Serial Interface for Program Downloading

– Endurance: 10,000 Write/Erase Cycles

•

2.7V to 5.5V Operating Range

•

Fully Static Operation: 0 Hz to 24 MHz (x1 and x2 Modes)

•

Two-level Program Memory Lock

•

256 x 8-bit Internal RAM

•

15 Programmable I/O Lines

•

Two 16-bit Timer/Counters

•

Six Interrupt Sources

•

Programmable Serial UART Channel

•

Direct LED Drive Outputs

•

On-chip Analog Comparator with Selectable Interrupt

•

8-bit PWM (Pulse-width Modulation)

•

Low Power Idle and Power-down Modes

•

Brownout Reset

•

Enhanced UART Serial Port with Framing Error Detection and Automatic

Address Recognition

•

Internal Power-on Reset

•

Interrupt Recovery from Power-down Mode

•

Programmable and Fuseable x2 Clock Option

•

Four-level Enhanced Interrupt Controller

•

Power-off Flag

•

Flexible Programming (Byte and Page Modes)

– Page Mode: 32 Bytes/Page

•

User Serviceable Signature Page (32 Bytes)

8-bit

Microcontroller

with 2K/4K

Bytes Flash

AT89S2051

AT89S4051

1. Description

The AT89S2051/S4051 is a low-voltage, high-performance CMOS 8-bit microcontroller with 2K/4K bytes of In-System Programmable (ISP) Flash program memory. The

device is manufactured using Atmel’s high-density nonvolatile memory technology

and is compatible with the industry-standard MCS-51 instruction set. By combining a

versatile 8-bit CPU with Flash on a monolithic chip, the Atmel AT89S2051/S4051 is a

powerful microcontroller which provides a highly-flexible and cost-effective solution to

many embedded control applications. Moreover, the AT89S2051/S4051 is designed

to be function compatible with the AT89C2051/C4051 devices, respectively.

The AT89S2051/S4051 provides the following standard features: 2K/4K bytes of

Flash, 256 bytes of RAM, 15 I/O lines, two 16-bit timer/counters, a six-vector, fourlevel interrupt architecture, a full duplex enhanced serial port, a precision analog

comparator, on-chip and clock circuitry. Hardware support for PWM with 8-bit resolution and 8-bit prescaler is available by reconfiguring the two on-chip timer/counters. In

addition, the AT89S2051/S4051 is designed with static logic for operation down to

zero frequency and supports two software-selectable power saving modes. The Idle

Mode stops the CPU while allowing the RAM, timer/counters, serial port and interrupt

system to continue functioning. The power-down mode saves the RAM contents

but freezes the disabling all other chip functions until the next external interrupt or

hardware reset.

3390D–MICRO–3/07

The on-board Flash program memory is accessible through the ISP serial interface. Holding

RST active forces the device into a serial programming interface and allows the program memory to be written to or read from, unless one or more lock bits have been activated.

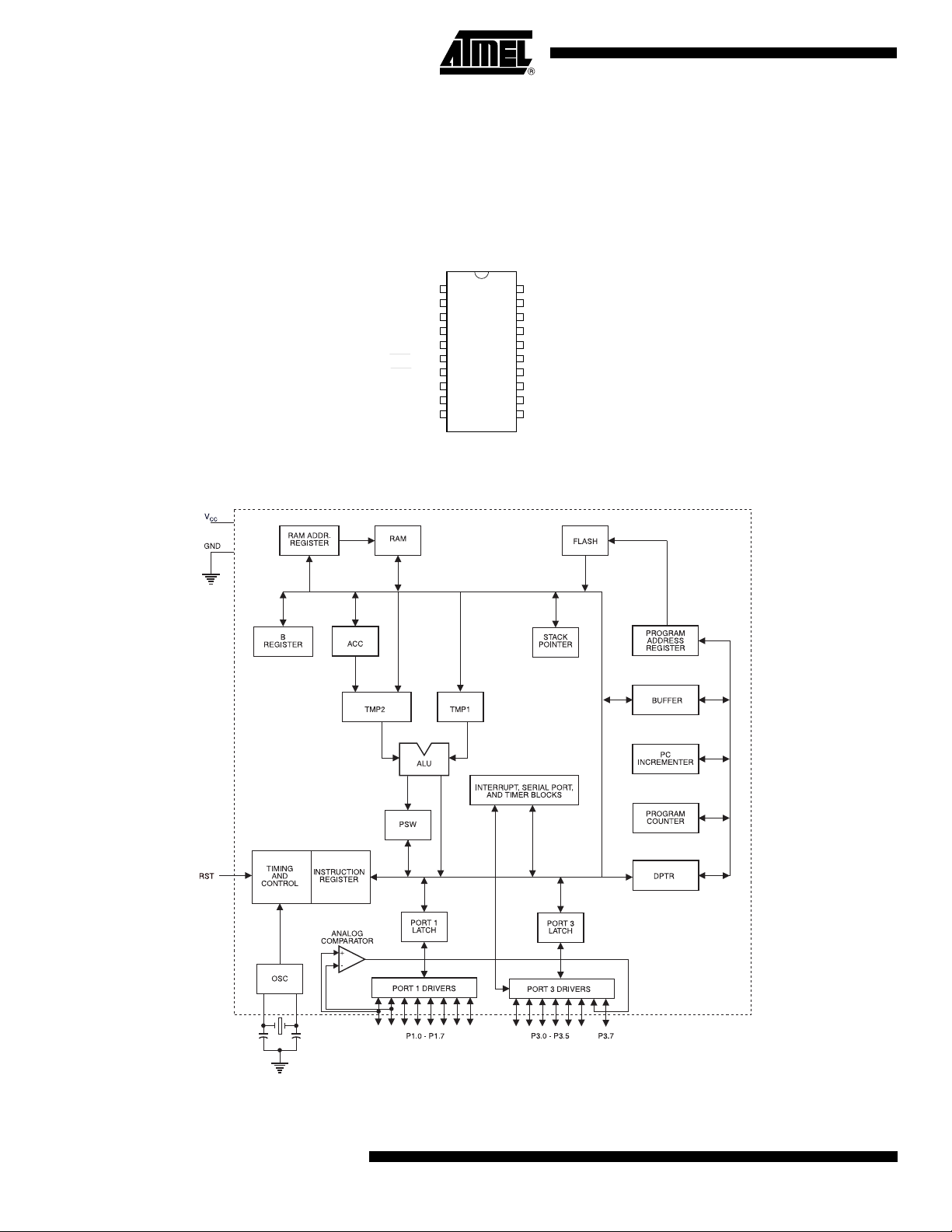

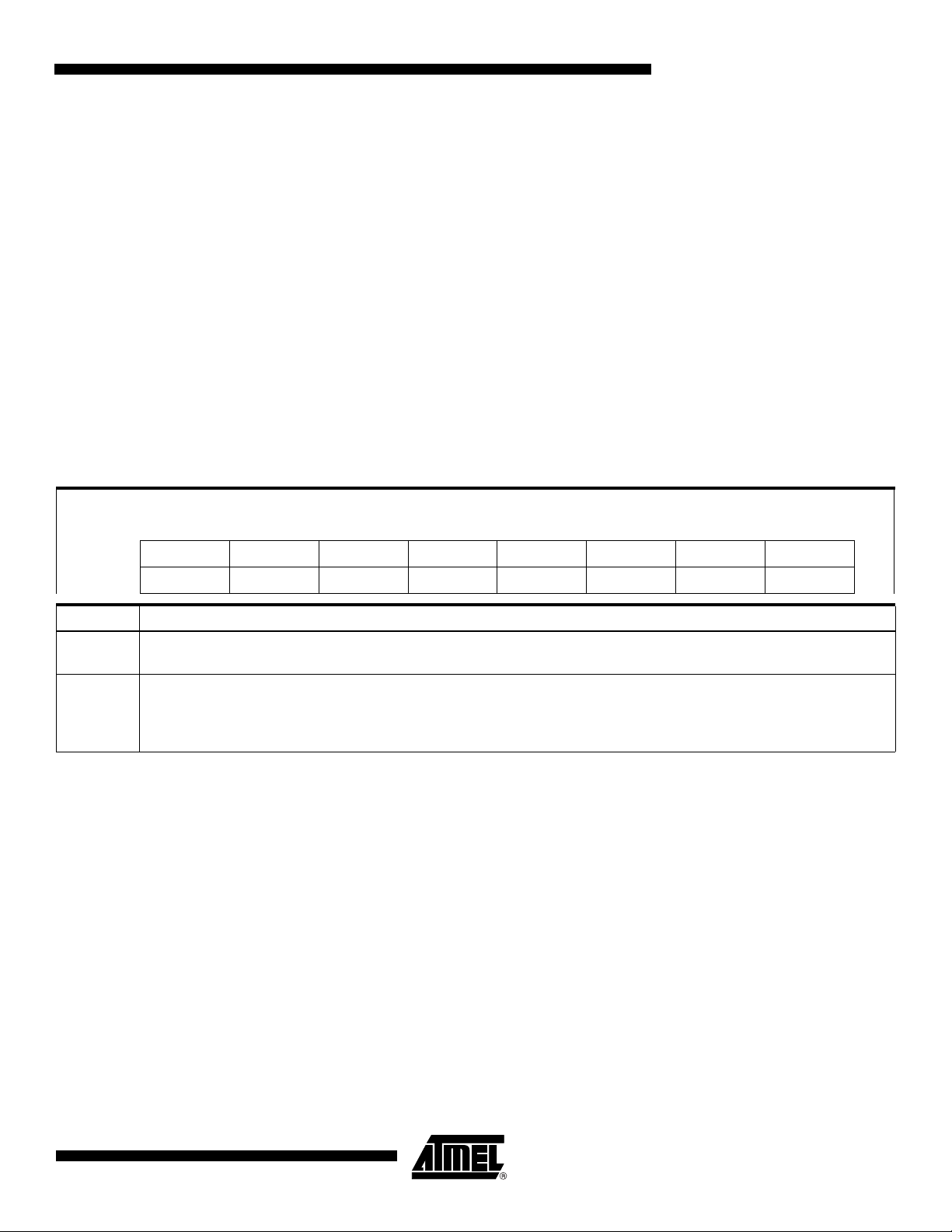

2. Pin Configuration

2.1 20-lead PDIP/SOIC

3. Block Diagram

RST/VPP

(RXD) P3.0

(TXD) P3.1

XTAL2

XTAL1

(INT0) P3.2

(INT1) P3.3

(T0) P3.4

(T1) P3.5

GND

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

VCC

P1.7 (SCK)

P1.6 (MISO)

P1.5 (MOSI)

P1.4

P1.3

P1.2

P1.1 (AIN1)

P1.0 (AIN0)

P3.7

2

AT89S2051/S4051

3390D–MICRO–3/07

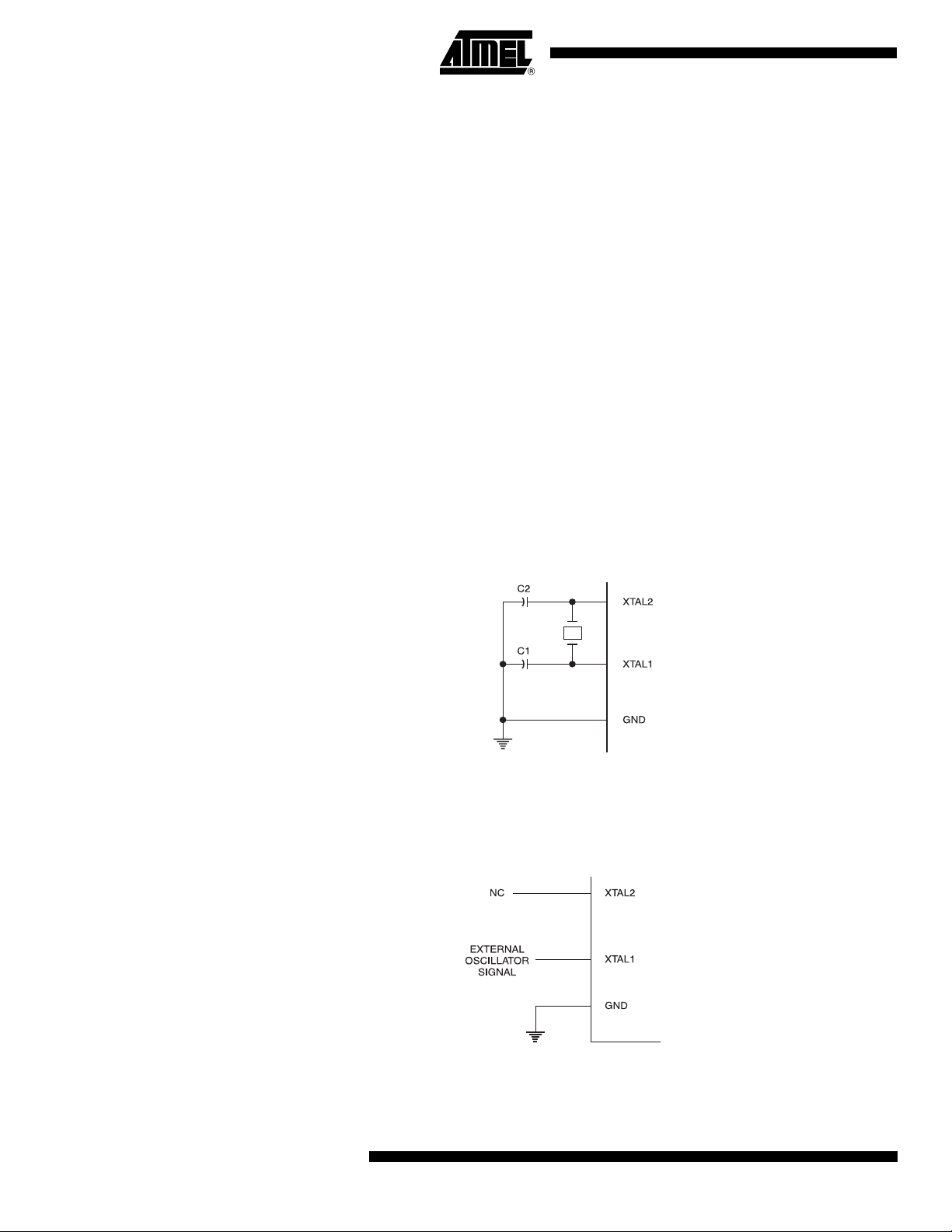

4. Pin Description

4.1 VCC

Supply voltage.

4.2 GND

Ground.

4.3 Port 1

Port 1 is an 8-bit bi-directional I/O port. Port pins P1.2 to P1.7 provide internal pull-ups. P1.0 and

P1.1 require external pull-ups. P1.0 and P1.1 also serve as the positive input (AIN0) and the

negative input (AIN1), respectively, of the on-chip precision analog comparator. The Port 1 output buffers can sink 20 mA and can drive LED displays directly. When 1s are written to Port 1

pins, they can be used as inputs. When pins P1.2 to P1.7 are used as inputs and are externally

pulled low, they will source current (I

Port 1 also receives code data during Flash programming and verification.

) because of the internal pull-ups.

IL

Port Pin Alternate Functions

AT89S2051/S4051

4.4 Port 3

P1.5 MOSI (Master data output, slave data input pin for ISP channel)

P1.6 MISO (Master data input, slave data output pin for ISP channel)

P1.7 SCK (Master clock output, slave clock input pin for ISP channel)

Port 3 pins P3.0 to P3.5, P3.7 are seven bi-directional I/O pins with internal pull-ups.

P3.6 is hard-wired as an input to the output of the on-chip comparator and is not accessible as a

general-purpose I/O pin. The Port 3 output buffers can sink 20 mA. When 1s are written to Port

3 pins they are pulled high by the internal pull-ups and can be used as inputs. As inputs, Port 3

pins that are externally being pulled low will source current (I

) because of the pull-ups.

IL

Port 3 also serves the functions of various special features of the AT89S2051/S4051 as listed

below:

Port Pin Alternate Functions

P3.0 RXD (serial input port)

P3.1 TXD (serial output port)

P3.2 INT0

P3.3 INT1

P3.4 T0 (timer 0 external input)

(external interrupt 0)

(external interrupt 1)

3390D–MICRO–3/07

P3.5 T1 (timer 1 external input)/ PWM output

Port 3 also receives some control signals for Flash programming and verification.

3

4.5 RST

Reset input. Holding the RST pin high for two machine cycles while the is running resets the

device.

Each machine cycle takes 6 or clock cycles.

4.6 XTAL1

Input to the inverting amplifier and input to the internal clock operating circuit.

4.7 XTAL2

Output from the inverting amplifier.

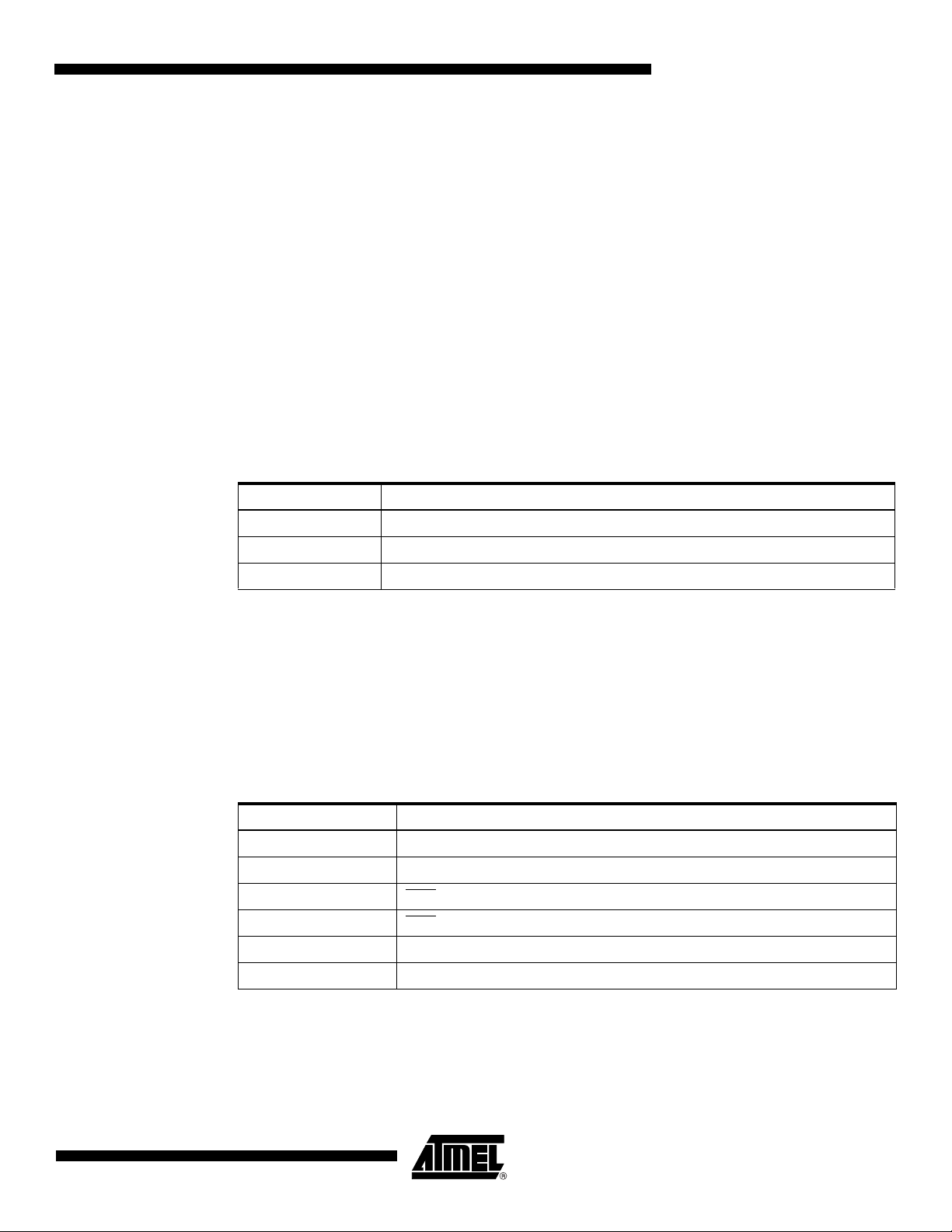

5. Characteristics

XTAL1 and XTAL2 are the input and output, respectively, of an inverting amplifier which can be

configured for use as an on-chip , as shown in Figure 5-1. Either a quartz crystal or ceramic resonator may be used. To drive the device from an external clock source, XTAL2 should be left

unconnected while XTAL1 is driven as shown in Figure 5-2. There are no requirements on the

duty cycle of the external clock signal, since the input to the internal clocking circuitry is through

a divide-by-two flip-flop, but minimum and maximum voltage high and low time specifications

must be observed.

Figure 5-1. Connections

Note: C1, C2 = 5 pF ± 5 pF for Crystals

= 5 pF ± 5 pF for Ceramic Resonators

Figure 5-2. External Clock Drive Configuration

4

AT89S2051/S4051

3390D–MICRO–3/07

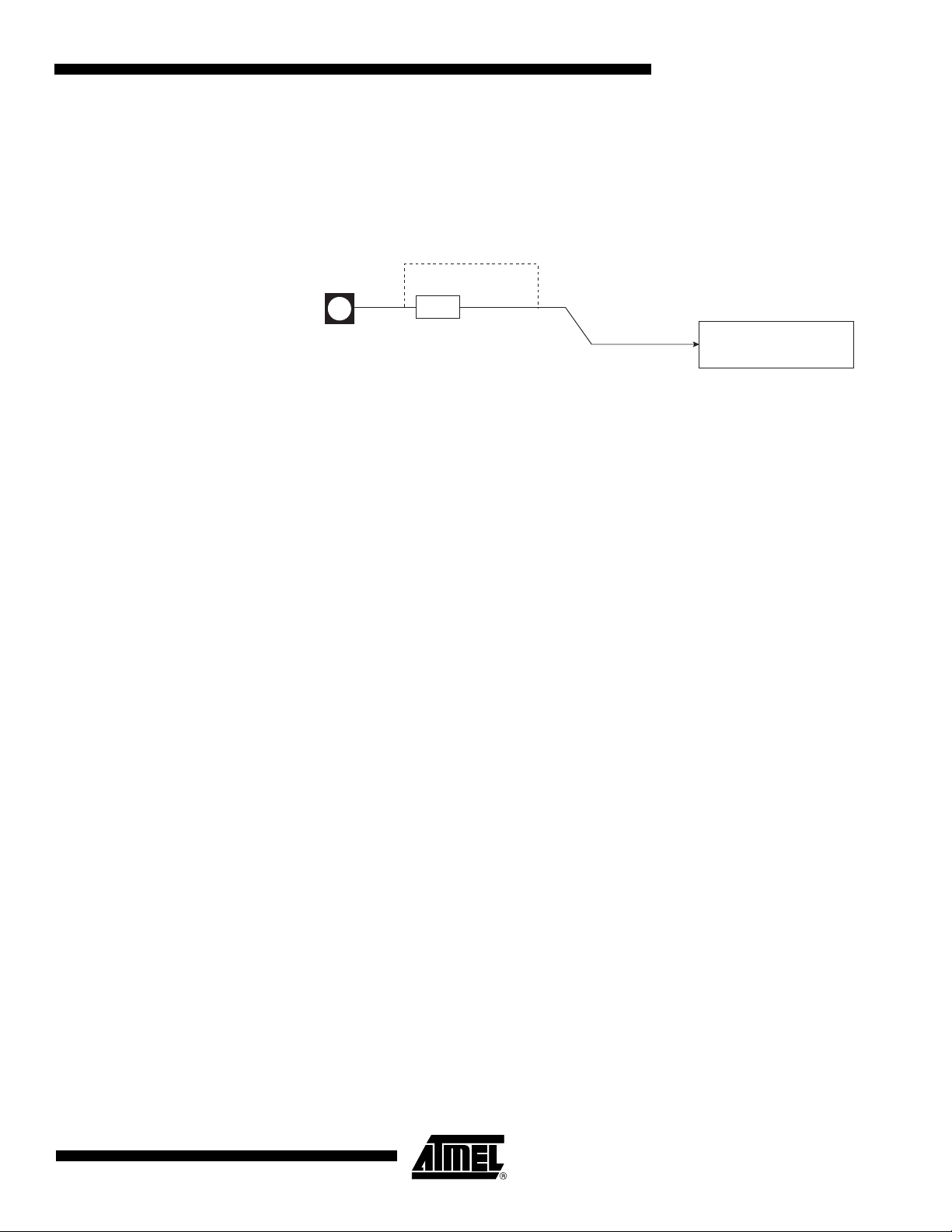

6. X2 Mode Description

The clock for the entire circuit and peripherals is normally divided by 2 before being used by the

CPU core and peripherals. This allows any cyclic ratio (duty cycle) to be accepted on XTAL1

input. In X2 mode this divider is bypassed. Figure 6-1 shows the clock generation block diagram.

Figure 6-1. Clock Generation Block Diagram

XTAL1

X2 Mode

÷

2

AT89S2051/S4051

(XTAL1)/2

F

XTAL

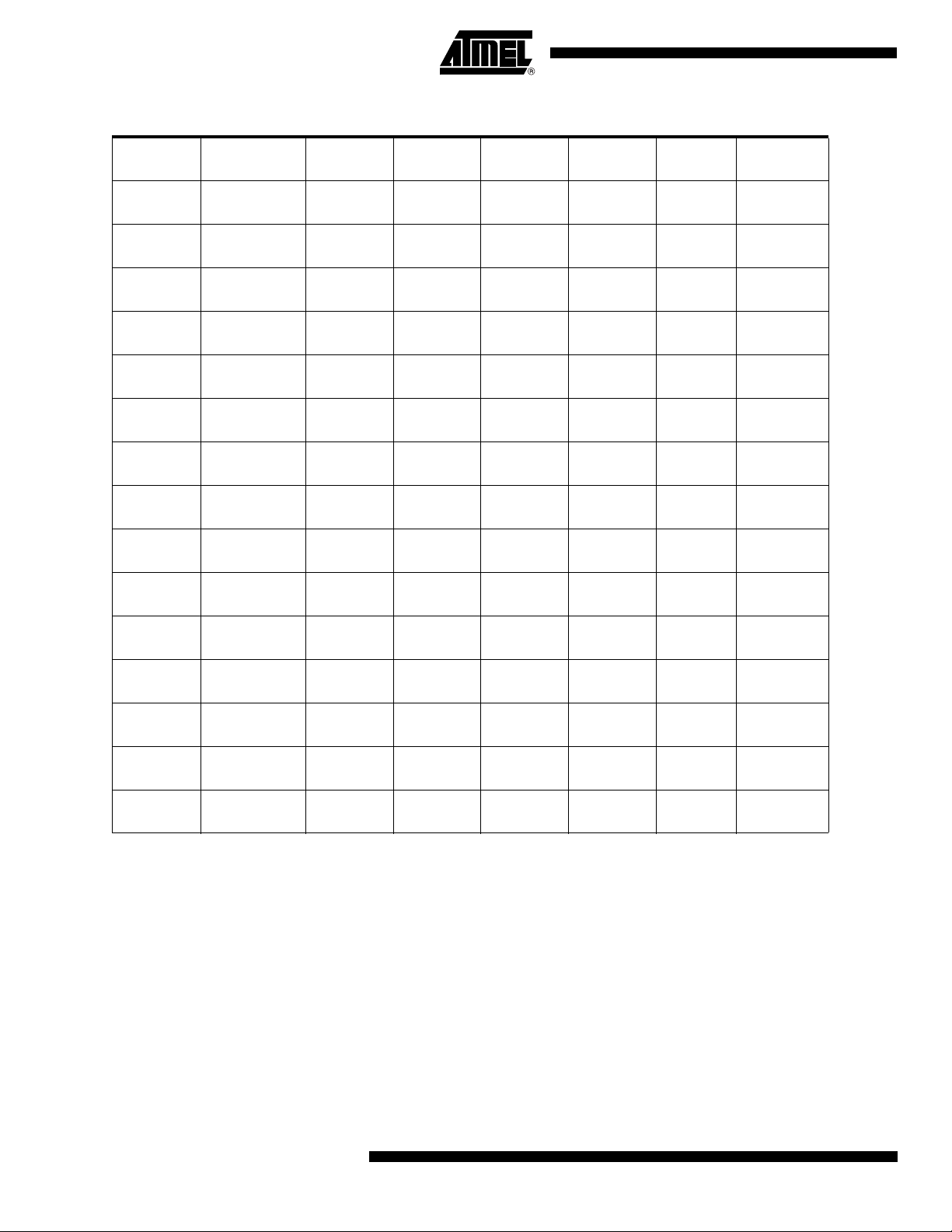

7. Special Function Registers

A map of the on-chip memory area called the Special Function Register (SFR) space is shown in

Table 7-1.

Note that not all of the addresses are occupied, and unoccupied addresses may not be implemented on the chip. Read accesses to these addresses will in general return random data, and

write accesses will have an indeterminate effect.

User software should not write 1s to these unlisted locations, since they may be used in future

products to invoke new features. In that case, the reset or inactive values of the new bits will

always be 0.

F

OSC

State Machine: 6 Clock Cycles

CPU Control

3390D–MICRO–3/07

5

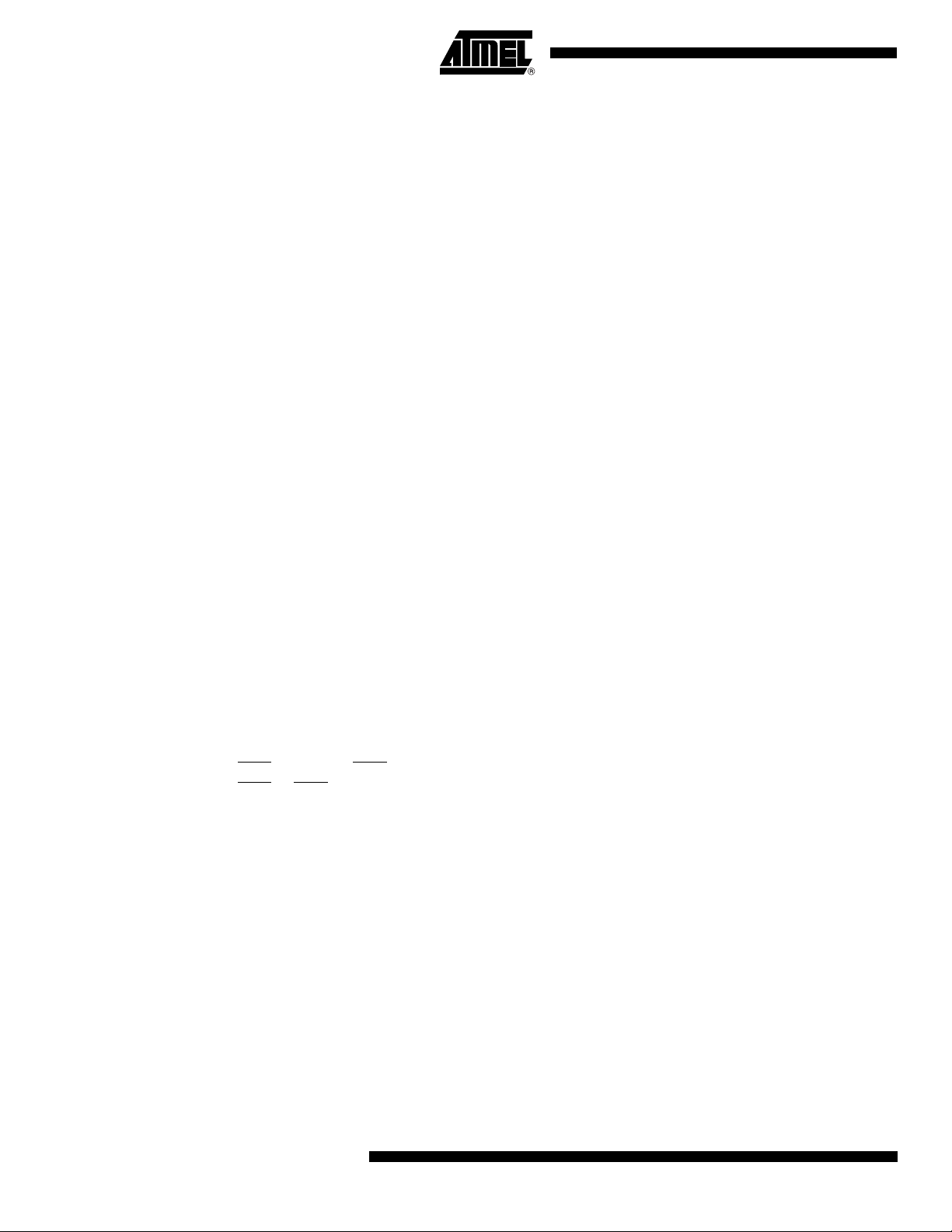

Table 7-1. AT89S2051/S4051 SFR Map and Reset Values

0F8H 0FFH

0F0H

0E8H 0EFH

0E0H

0D8H 0DFH

0D0H

0C8H

0C0H 0C7H

0B8H

0B0H

0A8H

0A0H

B

00000000

ACC

00000000

PSW

00000000

IP

X0X00000

P3

11111111

IE

00X00000

SADEN

00000000

SADDR

00000000

IPH

X0X00000

0F7H

0E7H

0D7H

0CFH

0BFH

0B7H

0AFH

0A7H

98H

90H

88H

80H

SCON

00000000

P1

11111111

TCON

00000000

SBUF

XXXXXXXX

TMOD

00000000

SP

00000111

TL0

00000000

DPL

00000000

TL1

00000000

DPH

00000000

TH0

00000000

TH1

00000000

ACSR

XXX00000

CLKREG

XXXXXX0X

PCON

000X0000

9FH

97H

8FH

87H

6

AT89S2051/S4051

3390D–MICRO–3/07

8. Restrictions on Certain Instructions

The AT89S2051/S4051 is an economical and cost-effective member of Atmel’s family of microcontrollers. It contains 2K/4K bytes of Flash program memory. It is fully compatible with the

MCS-51 architecture, and can be programmed using the MCS-51 instruction set. However,

there are a few considerations one must keep in mind when utilizing certain instructions to program this device.

All the instructions related to jumping or branching should be restricted such that the destination

address falls within the physical program memory space of the device, which is 2K/4K for the

AT89S2051/S4051. This should be the responsibility of the software programmer. For example,

LJMP 7E0H would be a valid instruction for the AT89S2051 (with 2K of memory), whereas LJMP

900H would not.

8.1 Branching Instructions

LCALL, LJMP, ACALL, AJMP, SJMP, JMP @A+DPTR. These unconditional branching

instructions will execute correctly as long as the programmer keeps in mind that the destination

branching address must fall within the physical boundaries of the program memory size (locations 00H to 7FFH/FFFH for the AT89S2051/S4051). Violating the physical space limits may

cause unknown program behavior.

CJNE [...], DJNZ [...], JB, JNB, JC, JNC, JBC, JZ, JNZ. With these conditional branching

instructions, the same rule above applies. Again, violating the memory boundaries may cause

erratic execution.

AT89S2051/S4051

For applications involving interrupts, the normal interrupt service routine address locations of the

80C51 family architecture have been preserved.

8.2 MOVX-related Instructions, Data Memory

The AT89S2051/S4051 contains 256 bytes of internal data memory. External DATA memory

access is not supported in this device, nor is external PROGRAM memory execution. Therefore,

no MOVX [...] instructions should be included in the program.

A typical 80C51 assembler will still assemble instructions, even if they are written in violation of

the restrictions mentioned above. It is the responsibility of the user to know the physical features

and limitations of the device being used and adjust the instructions used accordingly.

9. Program Memory Lock Bits

On the chip are two lock bits which can be left unprogrammed (U) or can be programmed (P) to

obtain the additional features listed in Table 9-1:

Table 9-1. Lock Bit Protection Modes

Program Lock Bits

LB1 LB2 Protection Type

1 U U No program lock features.

2 P U Further programming of the Flash is disabled.

3 P P Same as mode 2, also verify is disabled.

(1)

3390D–MICRO–3/07

Note: 1. The Lock Bits can only be erased with the Chip Erase operation.

7

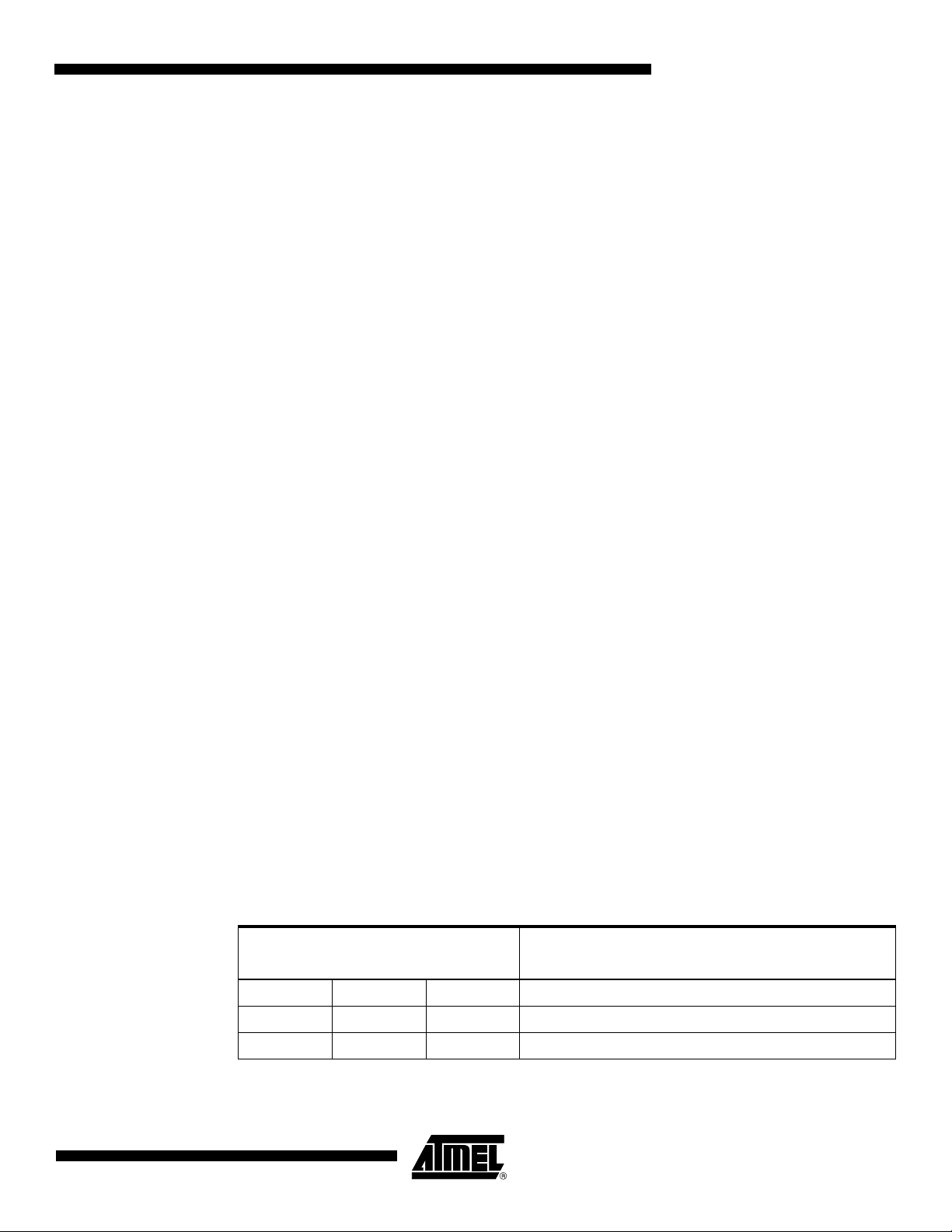

10. Reset

During reset, all I/O Registers are set to their initial values, the port pins are weakly pulled to

V

, and the program starts execution from the Reset Vector, 0000H. The AT89S2051/S4051

CC

has three sources of reset: power-on reset, brown-out reset, and external reset.

10.1 Power-On Reset

A Power-On Reset (POR) is generated by an on-chip detection circuit. The detection level is

nominally 1.4V. The POR is activated whenever V

cuit can be used to trigger the start-up reset or to detect a supply voltage failure in devices

without a brown-out detector. The POR circuit ensures that the device is reset from power-on.

When V

XTAL Oscillator Bypass fuse is OFF). Only after V

detection) level (see Section 10.2 ”Brown-out Reset”), the BOD delay counter starts measuring a

2-ms delay after which the Internal Reset is deasserted and the microcontroller starts executing.

The built-in 2-ms delay allows the V

ing, thus guaranteeing the maximum operating clock frequency. The POR signal is activated

again, without any delay, when V

a cold reset) will set the POF flag in PCON. Refer to Figure 10-1 for details on the POR/BOD

behavior.

Figure 10-1. Power-up and Brown-out Detection Sequence

reaches the Power-on Reset threshold voltage, the Pierce Oscillator is enabled (if the

CC

is below the detection level. The POR cir-

CC

has also reached the BOD (brown-out

CC

voltage to reach the minimum 2.7V level before execut-

CC

falls below the POR threshold level. A Power-On Reset (i.e.

CC

Level 2.7V

Min V

CC

BOD Level 2.3V

POR Level 1.4V

XTAL1

Internal

RESET

POR

BOD

V

CC

t

t

2.4V

1.2V

t

t

t

POR

(2 ms)

t

POR

(2 ms)

t

POR

(2 ms)

t

0

8

AT89S2051/S4051

3390D–MICRO–3/07

10.2 Brown-out Reset

The AT89S2051/S4051 has an on-chip Brown-out Detection (BOD) circuit for monitoring the V

level during operation by comparing it to a fixed trigger level. The trigger level for the BOD is

nominally 2.0V. The purpose of the BOD is to ensure that if V

speed, the system will gracefully enter reset without the possibility of errors induced by incorrect

execution. When V

diately activated. When V

microcontroller after the timeout period has expired in approximately 2 ms.

10.3 External Reset

The RST pin functions as an active-high reset input. The pin must be held high for at least two

machine cycles to trigger the internal reset. RST also serves as the In-System Programming

(ISP) enable input. ISP mode is enabled when the external reset pin is held high and the ISP

Enable fuse is set.

AT89S2051/S4051

fails or dips while executing at

CC

decreases to a value below the trigger level, the Brown-out Reset is imme-

CC

increases above the trigger level, the BOD delay counter starts the

CC

CC

11. Clock Register

.

Table 11-1.

CLKREG = 8FH Reset Value = XXXX XX0XB

Not Bit Addressable

––––––PWDEXX2

Bit76543210

Symbol Function

PWDEX

X2

CLKREG

Power-down Exit Mode. When PWDEX = 1, wake up from Power-down is externally controlled. When PWDEX = 0, wake

up from Power-down is internally timed.

When X2 = 0, the frequency (at XTAL1 pin) is internally divided by 2 before it is used as the device system frequency.

When X2 = 1, the divide by 2 is no longer used and the XTAL1 frequency becomes the device system frequency. This

enables the user to use a 6 MHz crystal instead of a 12 MHz crystal in order to reduce EMI. The X2 bit is initialized on

power-up with the value of the X2 user fuse and may be changed at runtime by software.

– Clock Register

3390D–MICRO–3/07

9

12. Power Saving Modes

The AT89S2051/S4051 supports two power-reducing modes: Idle and Power-down. These

modes are accessed through the PCON register.

12.1 Idle Mode

Setting the IDL bit in PCON enters idle mode. Idle mode halts the internal CPU clock. The CPU

state is preserved in its entirety, including the RAM, stack pointer, program counter, program

status word, and accumulator. The Port pins hold the logical states they had at the time that Idle

was activated. Idle mode leaves the peripherals running in order to allow them to wake up the

CPU when an interrupt is generated. Timer 0, Timer 1, and the UART will continue to function

during Idle mode. The analog comparator is disabled during Idle. Any enabled interrupt source

or reset may terminate Idle mode. When exiting Idle mode with an interrupt, the interrupt will

immediately be serviced, and following RETI, the next instruction to be executed will be the one

following the instruction that put the device into Idle.

P1.0 and P1.1 should be set to “0” if no external pull-ups are used, or set to “1” if external pullups are used.

12.2 Power-down Mode

Setting the PD bit in PCON enters Power-down mode. Power-down mode stops the and powers

down the Flash memory in order to minimize power consumption. Only the power-on circuitry

will continue to draw power during Power-down. During Power-down the power supply voltage

may be reduced to the RAM keep-alive voltage. The RAM contents will be retained; however,

the SFR contents are not guaranteed once V

by external reset, power-on reset, or certain interrupts.

has been reduced. Power-down may be exited

CC

The user should not attempt to enter (or re-enter) the power-down mode for a minimum of 4 µs

until after one of the following conditions has occurred: Start of code execution (after any type of

reset), or Exit from power-down mode.

12.3 Interrupt Recovery from Power-down

Two external interrupts may be configured to terminate Power-down mode. External interrupts

INT0

(P3.2) and INT1 (P3.3) may be used to exit Power-down. To wake up by external interrupt

INT0

or INT1, the interrupt must be enabled and configured for level-sensitive operation.

When terminating Power-down by an interrupt, two different wake up modes are available.

When PWDEX in CLKREG.2 is zero, the wake up period is internally timed. At the falling edge

on the interrupt pin, Power-down is exited, the is restarted, and an internal timer begins counting. The internal clock will not be allowed to propagate and the CPU will not resume execution

until after the timer has counted for nominally 2 ms. After the timeout period the interrupt service

routine will begin. To prevent the interrupt from re-triggering, the ISR should disable the interrupt

before returning. The interrupt pin should be held low until the device has timed out and begun

executing.

When PWDEX = 1 the wakeup period is controlled externally by the interrupt. Again, at the falling edge on the interrupt pin, Power-down is exited and the is restarted. However, the internal

clock will not propagate and CPU will not resume execution until the rising edge of the interrupt

pin. After the rising edge on the pin, the interrupt service routine will begin. The interrupt should

be held low long enough for the to stabilize.

10

AT89S2051/S4051

3390D–MICRO–3/07

12.4 Reset Recovery from Power-down

Wakeup from Power-down through an external reset is similar to the interrupt with PWDEX = 0.

At the rising edge of RST, Power-down is exited, the is restarted, and an internal timer begins

counting. The internal clock will not be allowed to propagate to the CPU until after the timer has

counted for nominally 2 ms. The RST pin must be held high for longer than the timeout period to

ensure that the device is reset properly. The device will begin executing once RST is brought

low.

It should be noted that when idle is terminated by a hardware reset, the device normally

resumes program execution, from where it left off, up to two machine cycles before the internal

reset algorithm takes control. On-chip hardware inhibits access to internal RAM in this event, but

access to the port pins is not inhibited. To eliminate the possibility of an unexpected write to a

port pin when Idle is terminated by reset, the instruction following the one that invokes Idle

should not be one that writes to a port pin or to external memory.

P1.0 and P1.1 should be set to “0” if no external pull-ups are used, or set to “1” if external pullups are used.

.

AT89S2051/S4051

Table 12-1.

PCON = 87H Reset Value = 000X 0000B

Not Bit Addressable

SMOD1 SMOD0 PWMEN POF GF1 GF0 PD IDL

Bit76543210

Symbol Function

SMOD1 Double Baud Rate bit. Doubles the baud rate of the UART in modes 1, 2, or 3.

SMOD0

PWMEN

POF

GF1, GF0 General-purpose Flags

PD Power Down bit. Setting this bit activates power down operation.

IDL Idle Mode bit. Setting this bit activates idle mode operation

PCON

– Power Control Register

Frame Error Select. When SMOD0 = 0, SCON.7 is SM0. When SMOD0 = 1, SCON.7 is FE. Note that FE will be set after

a frame error regardless of the state of SMOD0.

Pulse Width Modulation Enable. When PWMEN = 1, Timer 0 and Timer 1 are configured as an 8-bit PWM counter with

8-bit auto-reload prescaler. The PWM outputs on T1 (P3.5).

Power Off Flag. POF is set to “1” during power up (i.e. cold reset). It can be set or reset under software control and is not

affected by RST or BOD (i.e. warm resets).

3390D–MICRO–3/07

11

13. Interrupts

The AT89S2051/S4051 provides 6 interrupt sources: two external interrupts, two timer interrupts, a serial port interrupt, and an analog comparator interrupt. These interrupts and the

system reset each have a separate program vector at the start of the program memory space.

Each interrupt source can be individually enabled or disabled by setting or clearing a bit in the

interrupt enable register IE. The IE register also contains a global disable bit, EA, which disables

all interrupts.

Each interrupt source can be individually programmed to one of four priority levels by setting or

clearing bits in the interrupt priority registers IP and IPH. An interrupt service routine in progress

can be interrupted by a higher priority interrupt, but not by another interrupt of the same or lower

priority. The highest priority interrupt cannot be interrupted by any other interrupt source. If two

requests of different priority levels are pending at the end of an instruction, the request of higher

priority level is serviced. If requests of the same priority level are pending at the end of an

instruction, an internal polling sequence determines which request is serviced. The polling

sequence is based on the vector address; an interrupt with a lower vector address has higher

priority than an interrupt with a higher vector address. Note that the polling sequence is only

used to resolve pending requests of the same priority level.

The External Interrupts INT0

depending on bits IT0 and IT1 in Register TCON. The flags that actually generate these interrupts are the IE0 and IE1 bits in TCON. When the service routine is vectored to, hardware clears

the flag that generated an external interrupt only if the interrupt was transition-activated. If the

interrupt was level activated, then the external requesting source (rather than the on-chip hardware) controls the request flag.

The Timer 0 and Timer 1 Interrupts are generated by TF0 and TF1, which are set by a rollover in

their respective Timer/Counter registers (except for Timer 0 in Mode 3). When a timer interrupt is

generated, the on-chip hardware clears the flag that generated it when the service routine is

vectored to.

The Serial Port Interrupt is generated by the logical OR of RI and TI in SCON. Neither of these

flags is cleared by hardware when the service routine is vectored to. In fact, the service routine

normally must determine whether RI or TI generated the interrupt, and the bit must be cleared in

software.

The CF bit in ACSR generates the Comparator Interrupt. The flag is not cleared by hardware

when the service routine is vectored to and must be cleared by software.

Most of the bits that generate interrupts can be set or cleared by software, with the same result

as though they had been set or cleared by hardware. That is, interrupts can be generated and

pending interrupts can be canceled in software.

Interrupt Source Vector Address

System Reset RST or POR or BOD 0000H

and INT1 can each be either level-activated or transition-activated,

12

External Interrupt 0 IE0 0003H

Timer 0 Overflow TF0 000BH

External Interrupt 1 IE1 0013H

Timer 1 Overflow TF1 001BH

Serial Port RI or TI 0023H

Analog Comparator CF 0033H

AT89S2051/S4051

3390D–MICRO–3/07

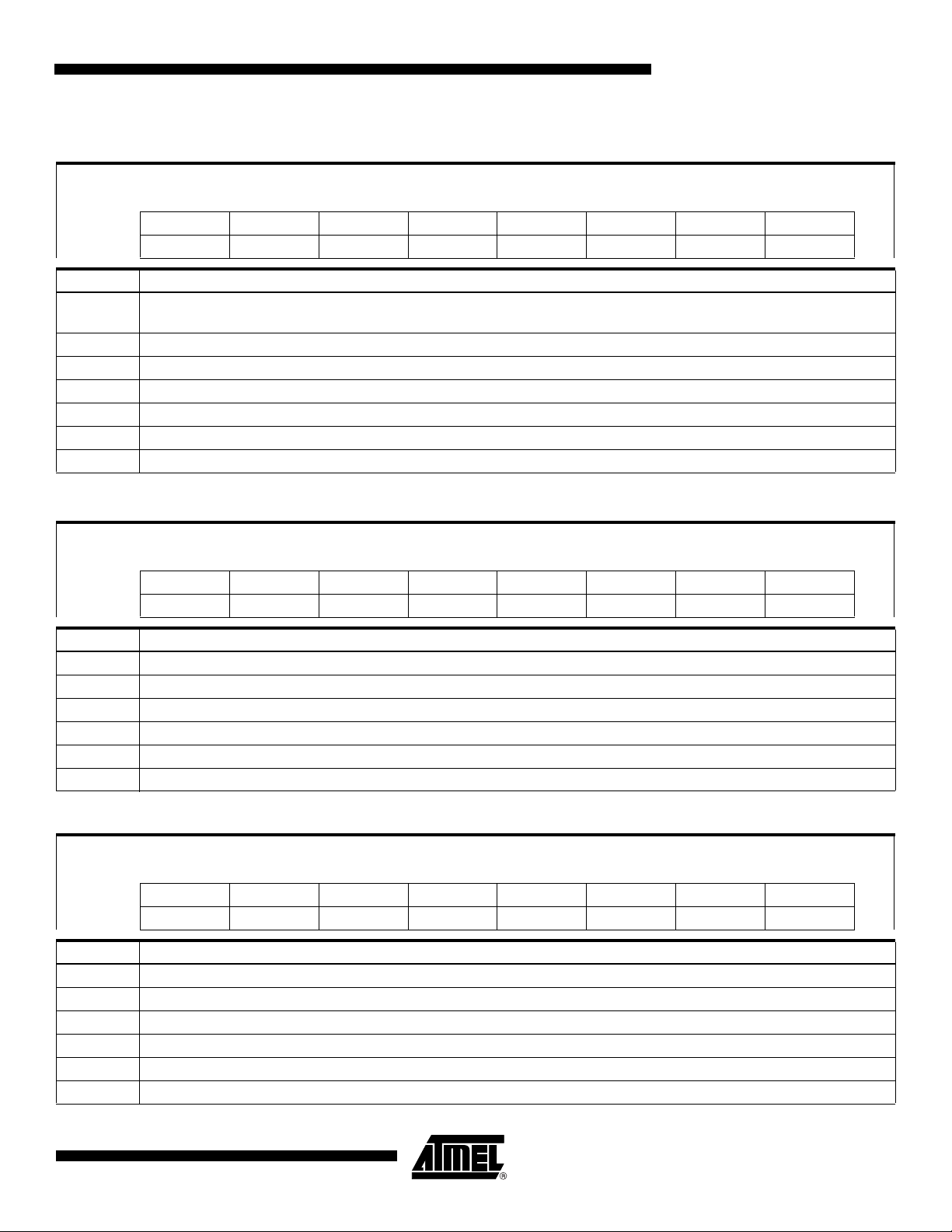

14. Interrupt Registers

AT89S2051/S4051

Table 14-1.

IE = A8H Reset Value = 00X0 0000B

Bit Addressable

EA EC – ES ET1 EX1 ET0 EX0

Bit76543210

Symbol Function

EA

EC Comparator Interrupt Enable

ES Serial Port Interrupt Enable

ET1 Timer 1 Interrupt Enable

EX1 External Interrupt 1 Enable

ET0 Timer 0 Interrupt Enable

EX0 External Interrupt 0 Enable

Table 14-2.

IP = B8H Reset Value = X0X0 0000B

Bit Addressable

– PC – PS PT1 PX1 PT0 PX0

Bit76543210

IE

– Interrupt Enable Register

Global enable/disable. All interrupts are disabled when EA = 0. When EA = 1, each interrupt source is enabled/disabled

by setting/clearing its own enable bit.

.

IP

– Interrupt Priority Register

Symbol Function

PC Comparator Interrupt Priority Low

PS Serial Port Interrupt Priority Low

PT1 Timer 1 Interrupt Priority Low

PX1 External Interrupt 1 Priority Low

PT0 Timer 0 Interrupt Priority Low

PX0 External Interrupt 0 Priority Low

Table 14-3.

IPH = B7H Reset Value = X0X0 0000B

Not Bit Addressable

– PCH – PSH PT1H PX1H PT0H PX0H

Bit76543210

Symbol Function

PCH Comparator Interrupt Priority High

PSH Serial Port Interrupt Priority High

PT1H Timer 1 Interrupt Priority High

PX1H External Interrupt 1 Priority High

PT0H Timer 0 Interrupt Priority High

PX0H External Interrupt 0 Priority High

IPH

– Interrupt Priority High Register

.

3390D–MICRO–3/07

13

15. Timer/Counters

C

The AT89S2051/S4051 have two 16-bit Timer/Counters: Timer 0 and Timer 1. The

Timer/Counters are identical to those in the AT89C2051/C4051. For more detailed information

on the Timer/Counter operation, please click on the document link below:

http://www.atmel.com/dyn/resources/prod_documents/DOC4316.PDF

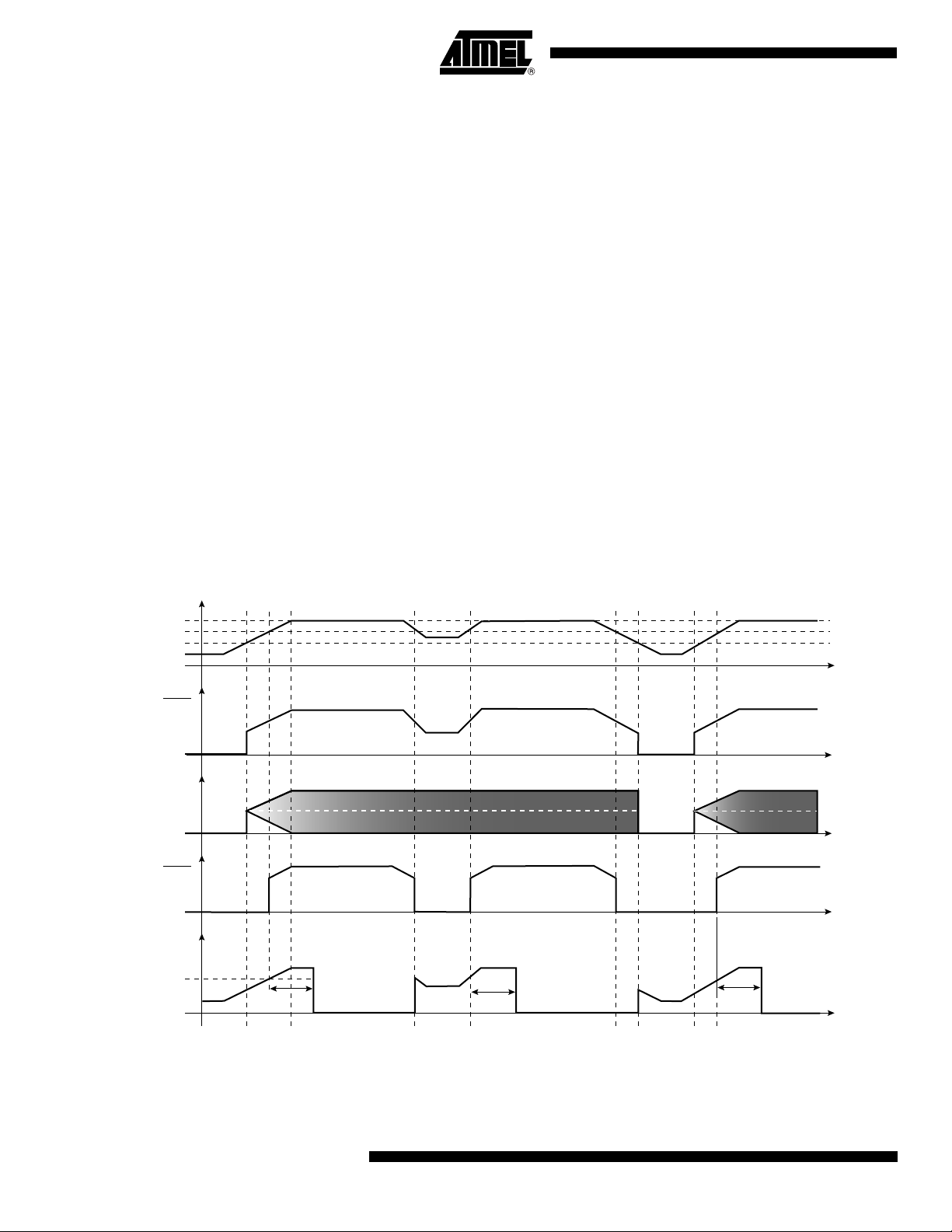

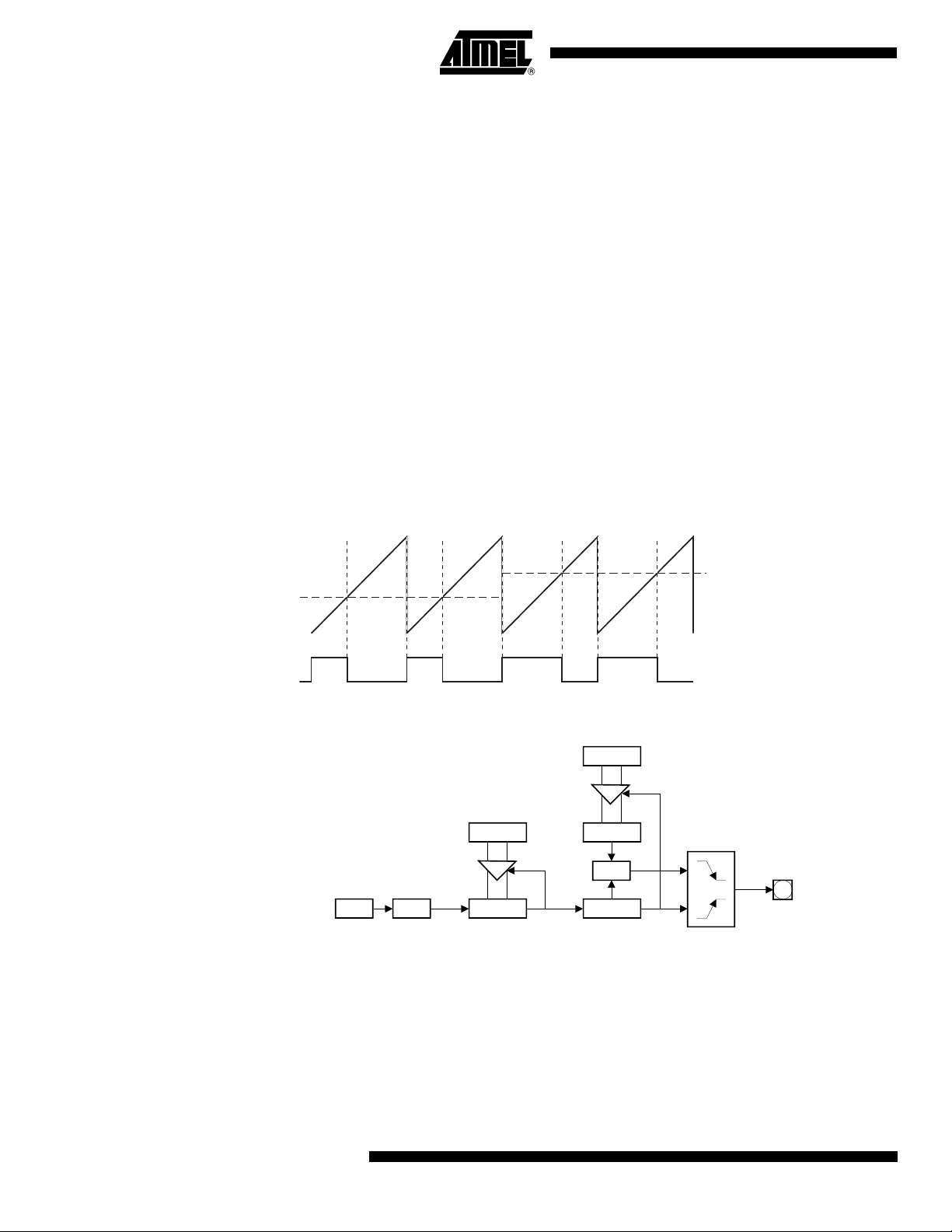

16. Pulse Width Modulation

Timer 0 and Timer 1 may be configured as an 8-bit pulse width modulator by setting the PWMEN

bit in PCON. The generated waveform is output on the Timer 1 input pin, T1. In PWM mode

Timer 0 acts as an 8-bit prescaler to select the PWM timebase. Timer 0 is forced into Mode 2 (8bit auto-reload) by PWMEN and the value in TH0 will determine the clock division from 0 (FFh)

to 256 (00h). Timer 1 acts as the 8-bit PWM counter. TL1 counts once on every overflow from

TL0. TH1 stores the 8-bit pulse width value. On the FFh-->00h overflow of TL1, the PWM output

is set high. When the count in TL1 matches the value in TH1, the PWM output is set low. Therefore, the output pulse width is proportional to the value in TH1. To prevent glitches, writes to TH1

only take effect on the FFh-->00h overflow of TL1. However, a read from TH1 will read the new

value at any time after a write to TH1. See Figure 16-1 for PWM waveform example.

Figure 16-1. Pulse Width Modulation (PWM) Output Waveform

Counter Value (TL1)

Compare Value (TH1)

PWM Output (T1)

Figure 16-2. Timer 0/1 Pulse Width Modulation Mode

TH1

TH0

S

O

12

÷÷

T

L0

OCR

=

T

L1

P3.

?

PWM

5

TL0 counts once every machine cycle (1 machine cycle = 12 clocks in X1 mode) and TH0 is the

reload value for when TL0 overflows. Every time TL0 overflows TL1 increments by one, with TL0

overflowing after counting 256 minus TH0 machine cycles.

To calculate the pulse width for the PWM output on pin T1, users should use the following

formula:

TH1 * (256 - TH0) * (1/clock_freq) * 12 = Pulse Width

14

AT89S2051/S4051

3390D–MICRO–3/07

AT89S2051/S4051

T

TL1 will always count from 00h to FFh. The output on the Timer 1 (T1) pin will be high from when

TL1 equals 00h until TL1 equals TH1 (see Figure 16-3). TH1 does not act as the reload value for

TL1 on overflow. Instead, TH1 is used strictly as a compare value (see Figure 16-2).

Figure 16-3. Example of a PWM Output

17. UART

The UART in the AT89S2051/S4051 operates the same way as the UART in the

AT89C2051/C4051. For more detailed information on the UART operation, please click on the

document link below:

17.1 Enhanced UART

In addition to all of its usual modes, the UART can perform framing error detection by looking for

missing stop bits, and automatic address recognition. The UART also fully supports multiprocessor communication as does the standard 80C51 UART.

When used for framing error detect, the UART looks for missing stop bits in the communication.

A missing bit will set the FE bit in the SCON register. The FE bit shares the SCON.7 bit with SM0

and the function of SCON.7 is determined by PCON.6 (SMOD0). If SMOD0 is set then SCON.7

functions as FE. SCON.7 functions as SM0 when SMOD0 is cleared. When used as FE,

SCON.7 can only be cleared by software.

L1 Count

00 01 10 . . . TH1 . . . FF 00 . . .

T1

http://www.atmel.com/dyn/resources/prod_documents/DOC4316.PDF

17.2 Automatic Address Recognition

Automatic Address Recognition is a feature which allows the UART to recognize certain

addresses in the serial bit stream by using hardware to make the comparisons. This feature

saves a great deal of software overhead by eliminating the need for the software to examine

every serial address which passes by the serial port. This feature is enabled by setting the SM2

bit in SCON. In the 9-bit UART modes, mode 2 and mode 3, the Receive Interrupt flag (RI) will

be automatically set when the received byte contains either the “Given” address or the “Broadcast” address. The 9-bit mode requires that the 9th information bit is a 1 to indicate that the

received information is an address and not data.

The 8-bit mode is called mode 1. In this mode the RI flag will be set if SM2 is enabled and the

information received has a valid stop bit following the 8 address bits and the information is either

a Given or Broadcast address.

Mode 0 is the Shift Register mode and SM2 is ignored.

Using the Automatic Address Recognition feature allows a master to selectively communicate

with one or more slaves by invoking the given slave address or addresses. All of the slaves may

be contacted by using the Broadcast address. Two special Function Registers are used to

define the slave’s address, SADDR, and the address mask, SADEN. SADEN is used to define

which bits in the SADDR are to be used and which bits are “don’t care”. The SADEN mask can

3390D–MICRO–3/07

15

be logically ANDed with the SADDR to create the “Given” address which the master will use for

addressing each of the slaves. Use of the Given address allows multiple slaves to be recognized

while excluding others. The following examples will help to show the versatility of this scheme:

Slave 0 SADDR = 1100 0000

SADEN = 1111 1101

Given = 1100 00X0

Slave 1 SADDR = 1100 0000

SADEN = 1111 1110

Given = 1100 000X

In the previous example SADDR is the same and the SADEN data is used to differentiate

between the two slaves. Slave 0 requires a 0 in bit 0 and it ignores bit 1. Slave 1 requires a 0 in

bit 1 and bit 0 is ignored. A unique address for slave 0 would be 1100 0010 since slave 1

requires a 0 in bit 1. A unique address for slave 1 would be 1100 0001 since a 1 in bit 0 will

exclude slave 0. Both slaves can be selected at the same time by an address which has bit 0 = 0

(for slave 0) and bit 1 = 0 (for slave 1). Thus, both could be addressed with 1100 0000.

In a more complex system the following could be used to select slaves 1 and 2 while excluding

slave 0:

Slave 0 SADDR = 1100 0000

SADEN = 1111 1001

Given = 1100 0XX0

Slave 1 SADDR = 1110 0000

SADEN = 1111 1010

Given = 1110 0X0X

Slave 2 SADDR = 1110 0000

SADEN = 1111 1100

Given = 1110 00XX

In the above example the differentiation among the 3 slaves is in the lower 3 address bits. Slave

0 requires that bit 0 = 0 and it can be uniquely addressed by 1110 0110. Slave 1 requires that bit

1 = 0 and it can be uniquely addressed by 1110 and 0101. Slave 2 requires that bit 2 = 0 and its

unique address is 1110 0011. To select Slaves 0 and 1 and exclude Slave 2, use address 1110

0100, since it is necessary to make bit 2 = 1 to exclude slave 2.

The Broadcast Address for each slave is created by taking the logical OR of SADDR and

SADEN. Zeros in this result are trended as don’t cares. In most cases, interpreting the don’t

cares as ones, the broadcast address will be FF hexadecimal.

16

Upon reset SADDR (SFR address 0A9H) and SADEN (SFR address 0B9H) are loaded with 0s.

This produces a given address of all “don’t cares” as well as a Broadcast address of all “don’t

cares”. This effectively disables the Automatic Addressing mode and allows the microcontroller

to use standard 80C51-type UART drivers which do not make use of this feature.

AT89S2051/S4051

3390D–MICRO–3/07

AT89S2051/S4051

Table 17-1. SCON – Serial Port Control Register

SCON Address = 98H Reset Value = 0000 0000B

Bit Addressable

SM0/FE SM1 SM2 REN TB8 RB8 TI RI

Bit7 6543210

(SMOD = 0/1)

Symbol Function

Framing error bit. This bit is set by the receiver when an invalid stop bit is detected. The FE bit is not cleared by valid

FE

SM0 Serial Port Mode Bit 0, (SMOD must = 0 to access bit SM0)

SM1

frames but should be cleared by software. The SMOD0 bit must be set to enable access to the FE bit. FE will be set

regardless of the state of SMOD.

Serial Port Mode Bit 1

(1)

SM0 SM1 Mode Description Baud Rate

0 0 0 shift register f

0 1 1 8-bit UART variable

1 0 2 9-bit UART f

1 1 3 9-bit UART variable

/64 or f

osc

osc

/12

osc

(2)

/32

Enables the Automatic Address Recognition feature in modes 2 or 3. If SM2 = 1 then Rl will not be set unless the received

SM2

REN

TB8

RB8

TI

RI

Notes: 1. SMOD is located at PCON.7.

9th data bit (RB8) is 1, indicating an address, and the received byte is a Given or Broadcast Address. In mode 1, if SM2 =

1 then Rl will not be activated unless a valid stop bit was received, and the received byte is a Given or Broadcast Address.

In Mode 0, SM2 should be 0.

Enables serial reception. Set by software to enable reception. Clear by software to disable reception.

The 9th data bit that will be transmitted in modes 2 and 3. Set or clear by software as desired.

In modes 2 and 3, the 9th data bit that was received. In mode 1, if SM2 = 0, RB8 is the stop bit that was

received. In mode 0, RB8 is not used.

Transmit interrupt flag. Set by hardware at the end of the 8th bit time in mode 0, or at the beginning of the

stop bit in the other modes, in any serial transmission. Must be cleared by software.

Receive interrupt flag. Set by hardware at the end of the 8th bit time in mode 0, or halfway through the stop

bit time in the other modes, in any serial reception (except see SM2). Must be cleared by software.

= frequency.

2. f

osc

3390D–MICRO–3/07

17

18. Analog Comparator

A single analog comparator is provided in the AT89S2051/S4051. The comparator operation is

such that the output is a logical “1” when the positive input AIN0 (P1.0]) is greater than the negative input AIN1 (P1.1). Otherwise the output is a zero. Setting the CEN bit in ACSR enables the

comparator. When the comparator is first enabled, the comparator output and interrupt flag are

not guaranteed to be stable for 10 microseconds. The corresponding comparator interrupt

should not be enabled during that time, and the comparator interrupt flag must be cleared before

the interrupt is enabled in order to prevent an immediate interrupt service.

The comparator may be configured to cause an interrupt under a variety of output value conditions by setting the CM bits in ACSR. The comparator interrupt flag CF in ACSR is set whenever

the comparator output matches the condition specified by CM. The flag may be polled by software or may be used to generate an interrupt and must be cleared by software. The analog

comparator is always disabled during Idle or Power-down modes.

19. Comparator Interrupt with Debouncing

The comparator output is sampled at every State 4 (S4) of every machine cycle. The conditions

on the analog inputs may be such that the comparator output will toggle excessively. This is

especially true if applying slow moving analog inputs. Three debouncing modes are provided to

filter out this noise. In debouncing mode, the comparator uses Timer 1 to modulate its sampling

time. When a relevant transition occurs, the comparator waits until two Timer 1 overflows have

occurred before resampling the output. If the new sample agrees with the expected value, CF is

set. Otherwise, the event is ignored. The filter may be tuned by adjusting the timeout period of

Timer 1. Because Timer 1 is free running, the debouncer must wait for two overflows to guarantee that the sampling delay is at least 1 timeout period. Therefore after the initial edge event, the

interrupt may occur between 1 and 2 timeout periods later. See Figure 19-1.

Figure 19-1. Example of Negative Edge Comparator Interrupt with Debouncing

Comparator Out

Timer 1 Overflow

CF

START COMPARE

START COMPARE

18

AT89S2051/S4051

3390D–MICRO–3/07

AT89S2051/S4051

20. Analog Comparator Register

.

Table 20-1.

ACSR = 97H Reset Value = XXX0 0000B

Not Bit Addressable

– – – CF CEN CM2 CM1 CM0

Bit76543210

Symbol Function

CF

CEN

CM [2:0]

ACSR

– Analog Comparator Control & Status Register

Comparator Interrupt Flag. Set when the comparator output meets the conditions specified by the CM [2:0] bits and CEN

is set. The flag must be cleared by software. The interrupt may be enabled/disabled by setting/clearing bit 6 of IE.

Comparator Enable. Set this bit to enable the comparator. Clearing this bit will force the comparator output low and

prevent further events from setting CF.

Comparator Interrupt Mode

2 1 0 Interrupt Mode

--- ---- ---- --------------------------------------0 0 0 Negative (Low) level

001 Positive edge

0 1 0 Toggle with debounce

0 1 1 Positive edge with debounce

100 Negative edge

101 Toggle

1 1 0 Negative edge with debounce

1 1 1 Positive (High) level

3390D–MICRO–3/07

19

21. Parallel Programming Specification

Atmel’s AT89S2051/S4051 offers 2K/4K bytes of In-System Programmable Flash code memory.

In addition, the device contains a 32-byte User Signature Row and a 32-byte read-only Atmel

Signature Row.

Table 21-1. Memory Organization

Device # Page Size # Pages Address Range Page Range

AT89S2051 32 bytes 64 0000H - 07FFH 00H - 3FH

AT89S4051 32 bytes 128 0000H - 0FFFH 00H - 7FH

Figure 21-1. Flash Parallel Programming Device Connections

AT89S2051/S4051

V

RDY/BSY

Note: 1. Sampling of pin P3.1 (RDY/BSY) is optional. In Parallel Mode, P3.1 will be pulled low while the

device is busy. However, it requires an external passive pull-up to VCC. Also, note that P3.6

does not exist, so TestCode connects to P3.7, P3.5, P3.4, and P3.3.

(1)

PROG

TestCode

INC

P3.1

P3.2

P3.7-3

XTAL1

GND

P1.7 - P1.0

RST

CC

2.7V to 5.5V

DATA IN/OUT

V

PP

20

AT89S2051/S4051

3390D–MICRO–3/07

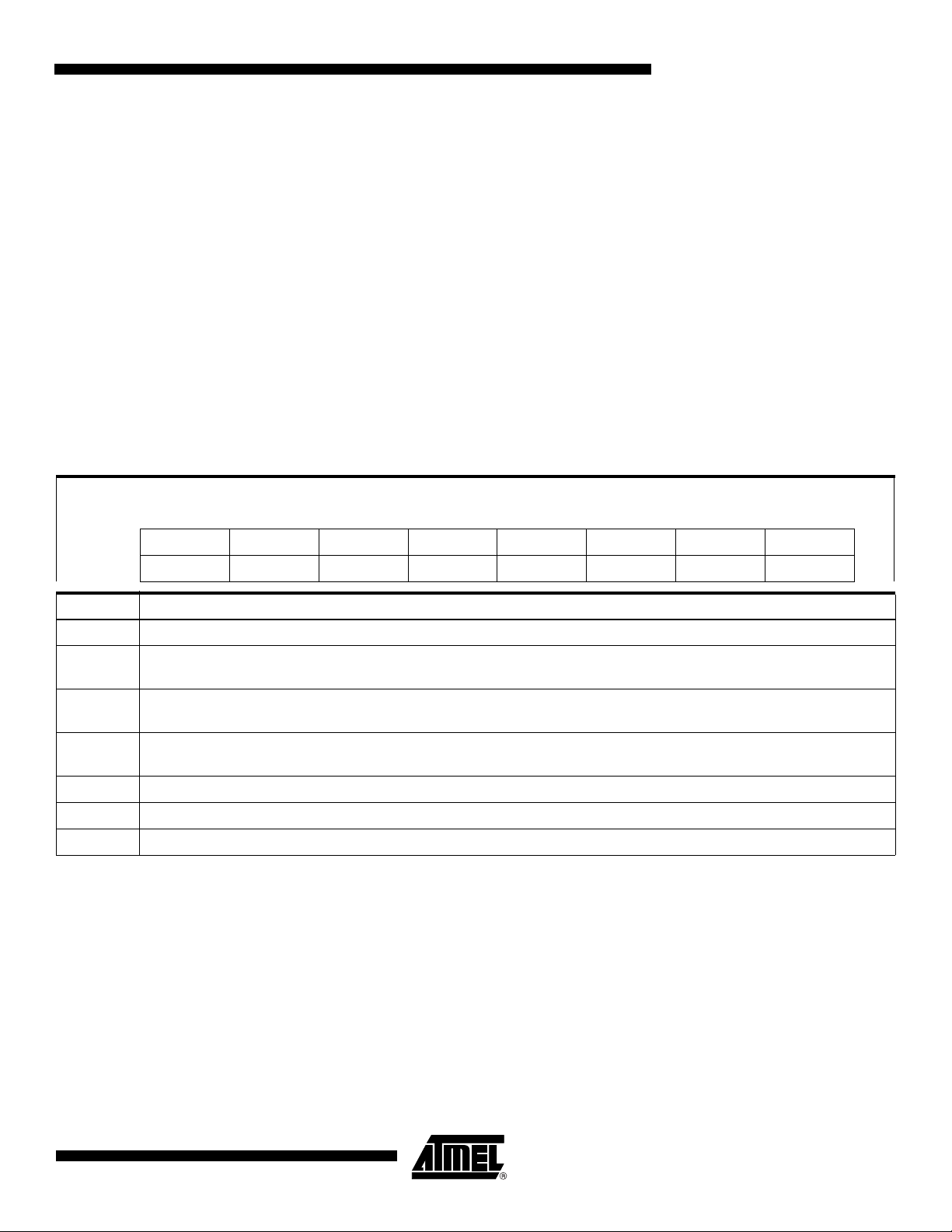

Table 21-2. Parallel Programming Mode Command Summary

Test Control Test Selects Data I/O

AT89S2051/S4051

Mode

Chip Erase

Load X-Address

Page Write

Page Read

Page Write

Page Read

(5)

(2)

(3)(4)(6)

(3)

(3)(4)(6)(7)

(3)(8)(10)

Write Fuse/Lock Bit

Read Fuse/Lock Bit

(5)(9)

(9)

P3.2

(1)

RST

1.0 µs 12V L H L L L XX

H 12V 0.1 µs H L H H D

Code Memory 1.0 µs 12V 0.1 µs L H H H D

Code Memory H 12V 0.1 µs L L H H D

Sig. Row 1.0 µs 12V 0.1 µs L L L L D

Sig. Row H 12V 0.1 µs L L L H D

1.0 µs12V L HHHHD

H12VL HHLLD

INC

P3.3 P3.4 P3.5 P3.7 P1.7-0

Notes: 1. The internal Y-address counter is reset to 00H on the rising/falling edge of RST.

2. A positive pulse on XTAL1 loads the address data on Port P1 into the X-address (page) register and resets the Y-address.

3. A positive pulse on XTAL1 advances the Y-address counter.

4. A low pulse on P3.2 loads data from Port P1 for the current address. If another P3.2 low pulse does not arrive within 150 µs,

programming starts.

5. Internally timed for 4 ms.

6. Internally timed for 2 ms.

7. 00H must be loaded into the X-address before executing this command.

8. Will read User Signature if X-address is 00H, will read Atmel Signature if X-address is 01H.

Fuse/Lock Bit Definitions:

9.

IN

IN

OUT

IN

OUT

IN

OUT

Bit 7

XTAL Osc Bypass

Bit 6

User Row Programming

Bit 5

x2 Clock

Bit 4

Serial Programming

Bit 1

Lock Bit 2

Bit 0

Lock Bit 1

10. Atmel Signature Bytes:

AT89S2051: Address 00H = 1EH

AT89S4051: Address 00H = 1EH

Enable = 0/Disable = 1

Enable = 0/Disable = 1

Enable = 0/Disable = 1

Enable = 0/Disable = 1

Locked = 0/Unlocked = 1

Locked = 0/Unlocked = 1

01H = 23H

02H = FFH

01H = 43H

02H = FFH

3390D–MICRO–3/07

21

22. Power-up Sequence

Execute the following sequence to power-up the device before programming.

1. Apply power between VCC and GND pins.

2. After V

3. Wait 4 ms for the internal Power-on Reset to timeout.

4. Bring P3.2 to “H” and drive P3.7, P3.5, P3.4, and P3.3 to known values, then wait

10 µs.

5. Raise RST/V

6. After V

Figure 22-1. Power-up Operation

has settled, wait 10 µs and bring RST to “H”.

CC

to 12V to enable the parallel programming modes.

PP

has settled, wait an additional 10 µs before programming.

PP

V

CC

RST/V

PP

P3.2

XTAL1

P3.3 - P3.7

P1.0 - P1.7

RDY/BSY

23. Power-down Sequence

Execute the following sequence to power-down the device after programming.

1. Tri-state Port P1.

2. Bring RST/V

3. Bring XTAL and P3.2 to “L” and tri-state P3.7, P3.5, P3.4, and P3.3.

4. Bring RST to “L” and wait 10 µs.

5. Power off V

Figure 23-1. Power-down Operation

RST/V

High Z

High Z

High Z

down from 12V to VCC and wait 10 µs.

PP

.

CC

V

CC

PP

P3.2

22

XTAL1

P3.3 - P3.7

P1.0 - P1.7

RDY/BSY

AT89S2051/S4051

High Z

High Z

High Z

3390D–MICRO–3/07

24. Chip Erase

AT89S2051/S4051

Function:

1. FFH programmed to every address location.

2. FFH programmed to User Signature Row if User Row Fuse bit is enabled.

3. Lockbit1 and Lockbit2 programmed to “unlock” state.

Usage:

1. Apply “0001” TestCode to P3.7, P3.5, P3.4, P3.3.

2. Pulse P3.2 low for 1 µs.

3. Wait 4 ms, monitor P3.1, or poll data.

Note: This and the following waveforms are not to scale.

Figure 24-1. Chip Erase Sequence

P3.2

XTAL1

25. Load X-Address

Function:

1. Loads the X-Address register with data on Port P1. The loaded address will select the

2. Resets the Y-Address counter to 00H. The Y-Address is equivalent to bits [4:0] of the

Usage:

1. Apply “1101” TestCode to P3.7, P3.5, P3.4, P3.3.

2. Drive Port P1 with 8-bit X-address data.

3. Pulse XTAL1 high for at least 100 ns. The address is latched on the falling edge of

Figure 25-1. Load X-Address Sequence

P3.3 - P3.7

P1.0 - P1.7

RDY/BSY

High Z

0001

page for subsequent write/read commands. The X-Address is equivalent to bits [11:5]

of the full byte address.

full byte address and selects a byte within a page.

XTAL1.

P3.2

3390D–MICRO–3/07

XTAL1

P3.3 - P3.7

P1.0 - P1.7

RDY/BSY

1101

High Z High Z

XADDR

23

26. Page Write 4K Code

Function:

1. Programs 1 page (1 to 32 bytes) of data into the Code Memory array.

2. X-address (page) determined by previous Load-X command.

3. Y-address (offset) incremented by positive pulse on XTAL1.

4. 1 byte of data is loaded from Port P1 for the current X- and Y-address by a low pulse on

P3.2.

Usage:

1. Execute the Load-X command to set the page address and reset the offset.

2. Apply “1110” TestCode to P3.7, P3.5, P3.4, P3.3.

3. Drive Port P1 with 8-bit data.

4. Pulse P3.2 low for 1 µs to load the data from Port P1.

5. For additional bytes (up to 32), pulse XTAL1 high for at least 100 ns to increment the

Y-address and repeat steps 3 and 4 within 150 µs.

6. Wait 2 ms, monitor P3.1, or poll data.

Note: It is possible to skip bytes by pulsing XTAL1 high multiple times before pulsing P3.2 low.

Figure 26-1. Page Write 4K Code Programming Sequence

P3.2

XTAL1

P3.3 - P3.7

P1.0 - P1.7

RDY/BSY

1101 1110

XADDR

DIN0 DIN1

DIN N-1

High Z

24

AT89S2051/S4051

3390D–MICRO–3/07

27. Read 4K Code

AT89S2051/S4051

Function:

1. Read 1 page (1 to 32 bytes) of data from the Code Memory array.

2. X-address (page) determined by previous Load-X command.

3. Y-address (offset) incremented by positive pulse on XTAL1.

Usage:

1. Execute the Load-X command to set the page address and reset the offset.

2. Apply “1100” TestCode to P3.7, P3.5, P3.4, P3.3.

3. Read 8-bit data on Port P1.

4. For additional bytes (up to 32), pulse XTAL1 high for at least 100 ns to increment the

Y-address and repeat step 3. The address will change on the falling edge of XTAL1.

Figure 27-1. Read 4K Code Programming Sequence

P3.2

XTAL1

P3.3 - P3.7

P1.0 - P1.7

RDY/BSY

1101 1100

XADDR

DOUT0 DOUT1

DOUT N-1

3390D–MICRO–3/07

25

28. Page Write User Signature Row

Function:

1. Programs 1 to 32 bytes of data into the User Signature Row.

2. X-address (page) should be 00H from a previous Load-X command.

3. Y-address (offset) incremented by positive pulse on XTAL1.

4. 1 byte of data is loaded from Port P1 for the current Y-address by a low pulse on P3.2.

5. Disabled if User Row Fuse bit is disabled.

Usage:

1. Execute the Load-X command to set the page to 00H and reset the offset.

2. Apply “0000” TestCode to P3.7, P3.5, P3.4, P3.3.

3. Drive Port P1 with 8-bit data.

4. Pulse P3.2 low for 1 µs to load the data from Port P1.

5. For additional bytes (up to 32), pulse XTAL1 high for at least 100 ns to increment the Yaddress and repeat steps 3 and 4 within 150 µs.

6. Wait 2 ms, monitor P3.1, or poll data.

Note: It is possible to skip bytes by pulsing XTAL1 high multiple times before pulsing P3.2 low.

Figure 28-1. Page Write User Signature Row Sequence

P3.2

XTAL1

P3.3 - P3.7

P1.0 - P1.7

RDY/BSY

1101 0000

00H

DIN0 DIN1

DIN N-1

26

AT89S2051/S4051

3390D–MICRO–3/07

29. Read User Signature Row

Function:

1. Reads 1 to 32 bytes of data from the User Signature Row.

2. X-address (page) should be 00H from a previous Load-X command.

3. Y-address (offset) incremented by positive pulse on XTAL1.

Usage:

1. Execute the Load-X command to set the page to 00H and reset the offset.

2. Apply “1000” TestCode to P3.7, P3.5, P3.4, P3.3.

3. Read 8-bit data on Port P1.

4. For additional bytes (up to 32), pulse XTAL1 high for at least 100 ns to increment the Yaddress and repeat step 3. The address will change on the falling edge of XTAL1.

Figure 29-1. Read User Signature Row Sequence

P3.2

XTAL1

AT89S2051/S4051

P3.3 - P3.7

P1.0 - P1.7

RDY/BSY

1101 1000

00H

DOUT0 DOUT1

DOUT N-1

3390D–MICRO–3/07

27

30. Read Atmel Signature Row

Function:

1. Reads 1 to 32 bytes of data from the Atmel Signature Row.

2. X-address (page) should be 01H from a previous Load-X command.

3. Y-address (offset) incremented by positive pulse on XTAL1.

Usage:

1. Execute the Load-X command to set the page to 01H and reset the offset.

2. Apply “1000” TestCode to P3.7, P3.5, P3.4, P3.3.

3. Read 8-bit data on Port P1.

4. For additional bytes (up to 32), pulse XTAL1 high for at least 100 ns to increment the Yaddress and repeat step 3. The address will change on the falling edge of XTAL1.

Figure 30-1. Read Atmel Signature Row Sequence

P3.2

XTAL1

P3.3 - P3.7

P1.0 - P1.7

RDY/BSY

1101 1000

01H

DOUT0 DOUT1

DOUT N-1

28

AT89S2051/S4051

3390D–MICRO–3/07

31. Write Lock Bits/User Fuses

Function:

1. Program Lock Bits 1 and 2.

2. Program user fuses.

Usage:

1) Apply “1111” TestCode to P3.7, P3.5, P3.4, P3.3.

3. Drive Port P1 with fuse data, bits [7:4] for fuses and bits [1:0] for lock bits.

4. Pulse P3.2 low for 1 µs.

5. Wait 4 ms, monitor P3.1, or poll data.

Figure 31-1. Write Lock Bits/User Fuses

P3.2

XTAL1

AT89S2051/S4051

P3.3 - P3.7

P1.0 - P1.7

RDY/BSY

32. Read Lock Bits/User Fuses

Function:

1. Read status of Lock Bits 1 and 2.

2. Read status of user fuses.

Usage:

1. Apply “0011” TestCode to P3.7, P3.5, P3.4, P3.3.

2. Read fuse data from Port P1, bits [7:4] for fuses and bits [1:0] for lock bits.

Figure 32-1. Read Lock Bits/User Fuses

P3.2

XTAL1

High Z

1111

DATA

High Z

3390D–MICRO–3/07

P3.3. - P3.7

P1.0 - P1.7

RDY/BSY

High Z

0011

DOUT

High Z

29

Figure 32-2. Flash Programming and Verification Waveforms in Parallel Mode

(RDY/BSY)

XTAL1

P3.1

PORT0

P3.3...P3.7

P3.2/PROG

t

POR

RST/VPP

t

PWRUP

VCC

t

PHBL

t

WC

t

XTW

t

ASTP

t

AHLD

t

XLP

t

PHX

t

MSTP

t

PSTP

t

DSTP

t

DHLD

LOADX

MSTP

PAGE WRITE LOADX PAGE READ

t

t

PGW

t

BLT

XADDR DATA0 DATA1 DATAN XADDR DATA0 DATA1 DATAN

t

HSTL

30

t

RDT

AT89S2051/S4051

t

MHLD

t

VFY

t

HSTL

t

PWRDN

3390D–MICRO–3/07

AT89S2051/S4051

Table 32-1. Parallel Flash Programming and Verification Parameters

Symbol Parameter

V

PP

I

PP

t

PWRUP

t

POR

t

PSTP

t

HSTL

t

MSTP

t

MHLD

t

XTW

t

ASTP

t

AHLD

t

PGW

t

DSTP

t

DHLD

t

XLP

t

PHX

t

BLT

t

PHBL

t

WC

t

RDT

t

VFY

t

PWRDN

Programming Enable Voltage 11.5 12.5 V

Programming Enable Current 1.0 mA

Power-on to RST High 10 µs

Power-on Reset Time 2 ms

PROG Setup to VPP High 10 µs

High Voltage Setting time 10 µs

Mode Setup to PROG or XTAL1 1 µs

Mode Hold after PROG or XTAL2 1 µs

XTAL1 High Width 0.5 µs

Address Setup to XTAL1 High 0.5 µs

Address Hold after XTAL1 Low 0.5 µs

PROG Low Width 1 µs

Data Setup to PROG Low 0.5 µs

Data Hold after PROG High 0.5 µs

XTAL1 Low to PROG Low 0.5 µs

PROG High to XTAL1 High 0.5 µs

Byte Load Period 150 µs

PROG High to BUSY Low 256 µs

Wire Cycle Time 4.5 ms

Read Byte Time 1 µs

XTAL1 Low to Data Verify Valid 0.25 µs

RST Low to Power Off 1 µs

Min Max Units

3390D–MICRO–3/07

31

33. In-System Programming (ISP) Specification

Atmel’s AT89S2051/S4051 offers 2K/4K bytes of In-System Programmable Flash code memory.

In addition, the device contains a 32-byte User Signature Row and a 32-byte read-only Atmel

Signature Row.

Table 33-1. Memory Organization

Device # Page Size # Pages Address Range Page Range

AT89S2051 32 bytes 64 0000H - 07FFH 00H - 3FH

AT89S4051 32 bytes 128 0000H - 0FFFH 00H - 7FH

Figure 33-1. ISP Programming Device Connections

AT89S2051/S4051

V

CC

(1)

SCK

SERIAL IN

(MOSI)

Note: 1. SCK frequency should be less than (XTAL frequency)/8.

P1.7

P1.5

XTAL1

GND

P1.6

RST

2.7V to 5.5V

SERIAL OUT

(MISO)

V

CC

32

AT89S2051/S4051

3390D–MICRO–3/07

AT89S2051/S4051

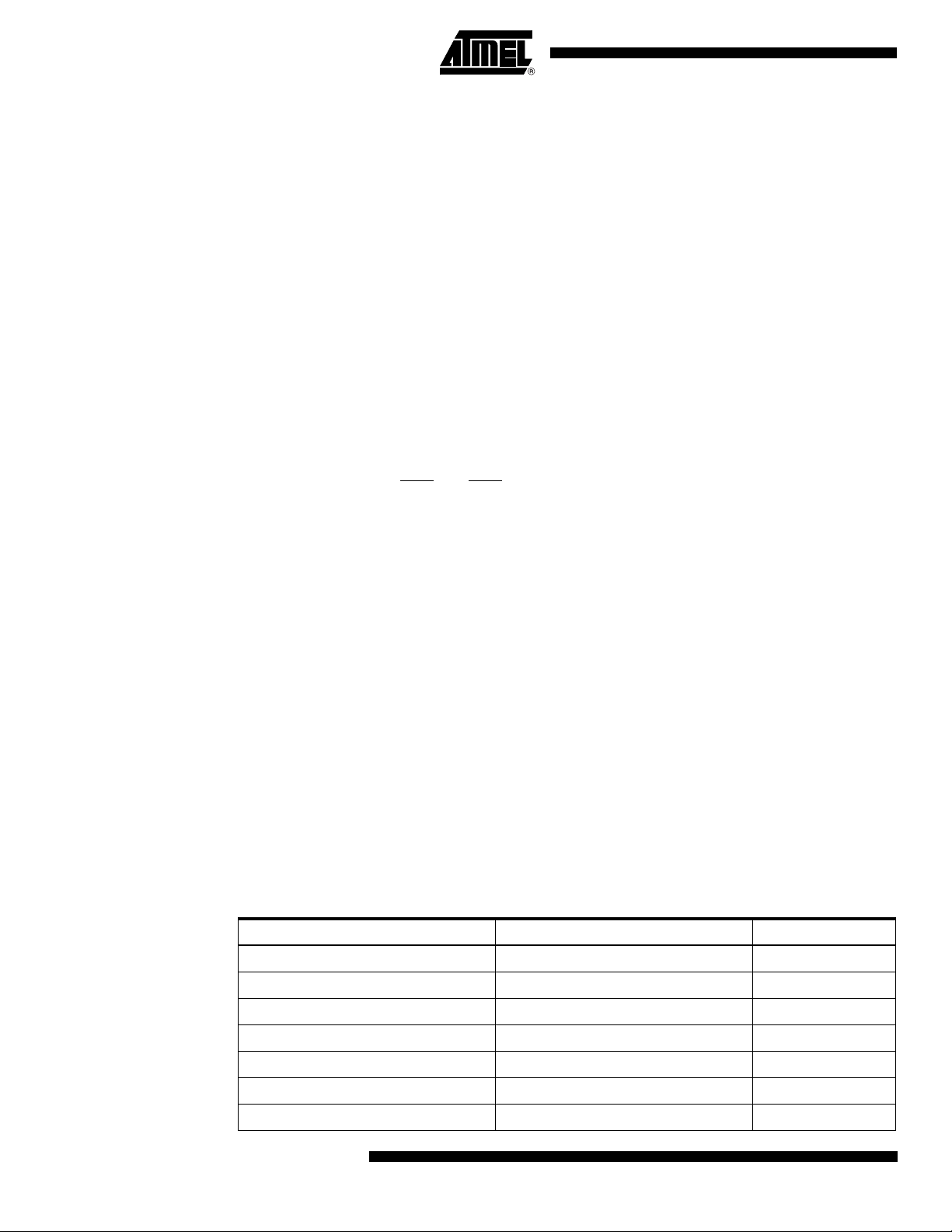

34. Serial Programming Command Summary

Command Byte 1 Byte 2 Byte 3 Byte 4 Byte ...

Program Enable

Chip Erase 1010 1100 100x xxxx xxxx xxxx xxxx xxxx

Write Code Byte 0100 0000

(1)

1010 1100 0101 0011 xxxx xxxx xxxx xxxx

xxxx

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

D7

D6

D5

D4

D3

D2

D1

D0

Read Code Byte 0010 0000

Write Code Page

Read Code Page

Write User Fuses

Read User Fuses

Write Lock Bits

Read Lock Bits

(4)

(4)

(2)

(2)

(3)

(3)

0101 0000

0011 0000

1010 1100

0010 0001 xxxx xxxx xxxx xxxx

1010 1100

0010 0100 xxxx xxxx xxxx xxxx

xxxx

A11

A10

xxxx

A11

A10

xxxx

A11

A10

0001 xxxx xxxx xxxx xxxx

1110 0x

F3

F2

LB2

Write User Signature Byte 0100 0010 xxxx xxxx

Read User Signature Byte 0010 0010 xxxx xxxx

Write User Signature Page

Read User Signature Page

Read Atmel Signature Byte

(2)

(2)

(5)

0101 0010 xxxx xxxx xxxx xxxx Data 0 ... Data 31

0011 0010 xxxx xxxx xxxx xxxx Data 0 ... Data 31

0010 1000 xxxx xxxx xxx

A9

A9

A9

F1

A8

A8

A8

F0

LB1

A6

A7

0 0000 Data 0 ... Data 31

A7

A6

A5

0 0000 Data 0 ... Data 31

A7

A6

A5

A4

A0

xxxx

D7

D6

D5

F3

D4

F2

F1

D3

F0

D2

D1

D0

A1

A5

A3

A2

xxxx xxxx xxxx xxxx

xxxx xx

LB1

LB2

xxx

xxx

A4

A4

A4

A3

A3

A3

A2

A2

A2

A1

A1

A1

A0

A0

A0

D7

D7

D7

D6

D6

D6

D5

D5

D5

D4

D4

D4

D3

D3

D3

D2

D2

D2

D1

D1

D1

D0

D0

D0

Notes: 1. Program Enable must be the first command issued after entering into the serial programming mode.

2. All 32 Data bytes must be written/read.

3. Fuse Bit Definitions:

Bit 0

ISP Enable*

Bit 1

x2 Clock

Bit 2

User Row Programming

Bit 3

XTAL Osc Bypass**

Enable = 0/Disable = 1

Enable = 0/Disable = 1

Enable = 0/Disable = 1

Enable = 0/Disable = 1

*The ISP Enable Fuse must be enabled before entering ISP mode.

When disabling the ISP fuse during ISP mode, the current fuse state will remain active until RST is brought low.

**Any change will only take effect after the next power-down/power-up cycle event.

4. Lock Bit Definitions:

Bit 0

Bit 1

Lock Bit 1

Lock Bit 2

Locked = 0/Unlocked = 1

Locked = 0/Unlocked = 1

5. Atmel Signature Bytes:

AT89S2051: Address 00H = 1EH

01H = 23H

02H = FFH

AT89S4051: Address 00H = 1EH

01H = 43H

02H = FFH

3390D–MICRO–3/07

33

35. Power-up Sequence

Execute this sequence to power-up the device before programming.

1. Apply power between VCC and GND pins.

2. Keep SCK (P1.7) at GND.

3. Wait 10 µs and bring RST to “H”.

4. If a crystal is connected between XTAL1 and XTAL2, wait at least 10 ms; otherwise,

apply a 3 - 24 MHz clock to XTAL1 and wait 4 ms.

Figure 35-1. ISP Power-up Sequence

P1.7/SCK

V

CC

RST

XTAL1

P1.6/MISO

P1.5/MOSI

36. ISP Start Sequence

Execute this sequence to enter ISP when the device is already operational.

1. Bring SCK (P1.7) to GND.

2. Tri-state MISO (P1.6).

3. Bring RST to “H”.

Figure 36-1. ISP Start Sequence

P1.7/SCK

V

CC

RST

XTAL1

High Z

34

P1.6/MISO

P1.5/MOSI

AT89S2051/S4051

High Z

3390D–MICRO–3/07

37. Power-down Sequence

Execute this sequence to power-down the device after programming.

1. Set XTAL1 to “L” if a crystal is not used.

2. Bring RST to “L”.

3. Tri-state MOSI (P1.5).

Figure 37-1. ISP Power-down Sequence

P1.7/SCK

V

CC

RST

XTAL1

AT89S2051/S4051

P1.6/MISO

P1.5/MOSI

38. ISP Byte Sequence

1. Data shifts in/out MSB first.

2. MISO changes at rising of SCK.

3. MOSI is sampled at falling edge of SCK.

Figure 38-1. ISP Byte Sequence

P1.7/SCK

P1.6/MISO

P1.5/MOSI

39. ISP Command Sequence

1. Byte Format: 4 byte packet (3 header bytes + 1 data byte)

2. Page Format: 35 byte packet (3 header bytes + 32 data bytes)

3. All bytes are required, even if they are don’t care.

High Z

76

data is sampled

76

High Z

5

5

4

4

3 2

3 2

10

10

Figure 39-1. ISP Command Sequence

SCK

SO

7 ??? 0 7 ??? 0 7 ??? 0 7 DATAOUT 0

SI

7 OPCODE 0 0 07 ADDRH 7 ADDRL 7 DATAIN 0

3390D–MICRO–3/07

35

40. Absolute Maximum Ratings*

Operating Temperature ................................. -55°C to +125°C

Storage Temperature ..................................... -65°C to +150°C

Voltage on Any Pin with Respect to Ground ...... -0.7V to +6.2V

Maximum Operating Voltage ............................................ 5.5V

DC Output Current............. 25.0 mA (15.0 mA for AT89S4051)

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent damage to the device. This is a stress rating only and

functional operation of the device at these or any

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions for extended periods may affect

device reliability.

41. DC Characteristics

TA = -40°C to 85°C, VCC = 2.7V to 5.5V (unless otherwise noted)

Symbol Parameter Condition Min Max Units

V

IL

V

IH

V

IH1

V

OL

V

OH

I

IL

I

TL

I

LI

V

OS

V

CM

RRST Reset Pull-down Resistor 50 150 KΩ

C

IO

I

CC

Notes: 1. Under steady state (non-transient) conditions, IOL must be externally limited as follows:

2. Minimum V

3. P1.0 and P1.1 are comparator inputs and have no internal pullups. They should not be left floating.

Input Low-voltage -0.5 0.2 V

Input High-voltage (Except XTAL1, RST) 0.2 V

Input High-voltage (XTAL1, RST) 0.7 V

Output Low-voltage

(1)

(Ports 1, 3) IOL = 10 mA, VCC = 2.7V, TA = 85°C 0.5 V

+ 0.9 V

CC

CC

- 0.1 V

CC

+ 0.5 V

CC

V

+ 0.5 V

CC

IOH = -80 µA, VCC = 5V ± 10% 2.4 V

Output High-voltage (Ports 1, 3)

Logical 0 Input Current

(Ports 1, 3)

Logical 1 to 0 Transition Current

(Ports 1, 3)

Input Leakage Current

(Port P1.0, P1.1)

IOH = -30 µA 0.75 V

I

= -12 µA 0.9 V

OH

= 0.45V -50 µA

V

IN

V

= 2V, VCC = 5V ± 10% -350 µA

IN

< V

0 < V

IN

CC

CC

CC

±10 µA

Comparator Input Offset Voltage VCC = 5V 20 mV

Comparator Input Common

Mode Voltage

0V

CC

Pin Capacitance Test Freq. = 1 MHz, TA = 25°C 10 pF

CC

=

CC

= 5V/3V

CC

CC

CC

10.5/3.5 mA

4.5/2.5 mA

(3)

(3)

10 µA

5µA

Power Supply Current (without

the )

Power-down Mode

(2)

Active Mode, 24/12 MHz, V

5V/3V

Idle Mode, 24/12 MHz, V

P1.0 & P1.1 = 0V or V

VCC = 5V, P1.0 & P1.1 = 0V or V

V

= 3V, P1.0 & P1.1 = 0V or V

CC

Maximum IOL per port pin: 10 mA

Maximum total I

for all output pins: 25 mA (15 mA for AT89S4051)

OL

If IOL exceeds the test condition, VOL may exceed the related specification. Pins are not guaranteed to sink current greater

than the listed test conditions.

for Power-down is 2V.

CC

V

V

V

36

AT89S2051/S4051

3390D–MICRO–3/07

42. External Clock Drive Waveforms

43. External Clock Drive

Symbol Parameter

1/t

t

CLCL

t

CHCX

t

CLCX

t

CLCH

t

CHCL

CLCL

Frequency 0 24 MHz

Clock Period 41.6 ns

High Time 12 ns

Low Time 12 ns

Rise Time 5ns

Fall Time 5ns

V

= 2.7V to 5.5V

CC

AT89S2051/S4051

UnitsMin Max

3390D–MICRO–3/07

37

44. Serial Port Timing: Shift Register Mode Test Conditions

The values in this table are valid for VCC = 2.7V to 5.5V and Load Capacitance = 80 pF.

Symbol Parameter

Variable

UnitsMin Max

t

XLXL

t

QVXH

t

XHQX

t

XHDX

t

XHDV

Serial Port Clock Cycle Time 12t

Output Data Setup to Clock Rising Edge 10t

Output Data Hold after Clock Rising Edge 2t

Input Data Hold after Clock Rising Edge t

Input Data Valid to Clock Rising Edge 0 ns

45. Shift Register Mode Timing Waveforms

46. AC Testing Input/Output Waveforms

(1)

-15 µs

CLCL

-15 ns

CLCL

-15 ns

CLCL

CLCL

ns

Note: 1. AC Inputs during testing are driven at VCC - 0.5V for a logic 1 and 0.45V for a logic 0. Timing

47. Float Waveforms

Note: 1. For timing purposes, a port pin is no longer floating when a 100 mV change from load voltage

38

AT89S2051/S4051

(1)

measurements are made at V

min. for a logic 1 and VIL max. for a logic 0.

IH

occurs. A port pin begins to float when 100 mV change from the loaded VOH/V

level occurs.

OL

3390D–MICRO–3/07

AT89S2051/S4051

48. ICC Test Condition, Active Mode, All Other Pins are Disconnected

V

CC

I

CC

V

CC

P1, P3

V

CC

(NC)

CLOCK SIGNAL

RST

XTAL2

XTAL1

V

SS

49. I

Test Condition, Idle Mode, All Other Pins are Disconnected

CC

CLOCK SIGNAL

50. Clock Signal Waveform for I

t

CLCH

= t

CHCL

= 5 ns

VCC - 0.5V

0.45V

0.2 V

0.7 V

CC

t

CHCL

- 0.1V

V

CC

I

CC

RST

(NC)

Tests in Active and Idle Modes,

CC

CC

XTAL2

XTAL1

V

SS

t

CHCX

V

CC

P1, P3

t

CLCL

V

t

CLCH

CC

t

CHCX

51. I

3390D–MICRO–3/07

Test Condition, Power-down Mode, All Other Pins are Disconnected,

CC

= 2V to 5.5V

V

CC

(NC)

RST

XTAL2

XTAL1

VSS

V

CC

P1, P3

V

CC

I

CC

V

CC

39

52. ICC (Active Mode) Measurements

4.00

3.50

3.00

2.50

Active (mA)

2.00

CC

I

1.50

123456789101112

ICC Active @ 25oC

3.0V

4.0V

5.0V

Frequency (MHz)

ICC Active @ 90oC

4.00

3.50

3.00

2.50

Active (mA)

2.00

CC

I

1.50

123456789101112

3.0 V

4.0 V

5.0 V

Frequency (MHz)

40

AT89S2051/S4051

3390D–MICRO–3/07

53. ICC (Idle Mode) Measurements

3

2.5

AT89S2051/S4051

ICC Idle vs. Frequency

T = 25°C

54. I

2

(mA)

1.5

CC

I

1

0.5

0

0 5 10 15 20 25

(Power Down Mode) Measurements

CC

2.5

2

1.5

1

Pwd (uA)

CC

I

0.5

Vcc=3V

Vcc=4V

Vcc=5v

Frequency (MHz)

ICC in Power-down

0 deg C

25 deg C

90 deg C

3390D–MICRO–3/07

0

1234567

V

(V)

CC

41

55. Ordering Information

55.1 Standard Package

Speed

(MHz)

24 2.7V to 5.5V

Power

Supply Ordering Code Package Operation Range

AT89S2051/S4051-24PC

AT89S2051/S4051-24SC

AT89S2051/S4051-24PI

AT89S2051/S4051-24SI

55.2 Green Package Option (Pb/Halide-free)

Speed

(MHz)

24 2.7V to 5.5V

Power

Supply Ordering Code Package Operation Range

AT89S2051/S4051-24PU

AT89S2051/S4051-24SU

20P3

20S2

20P3

20S2

20P3

20S2

Commercial

(0° C to 70° C)

Industrial

(-40° C to 85° C)

Industrial

(-40° C to 85° C)

Package Type

20P3 20-lead, 0.300” Wide, Plastic Dual In-line Package (PDIP)

20S2 20-lead, 0.300” Wide, Plastic Gull Wing Small Outline (SOIC)

42

AT89S2051/S4051

3390D–MICRO–3/07

56. Package Information

PIN

1

E1

A1

B

E

B1

C

L

SEATING PLANE

A

56.1 20P3 – PDIP

AT89S2051/S4051

D

e

eC

eB

Notes: 1. This package conforms to JEDEC reference MS-001, Variation AD.

2. Dimensions D and E1 do not include mold Flash or Protrusion.

Mold Flash or Protrusion shall not exceed 0.25 mm (0.010").

2325 Orchard Parkway

R

San Jose, CA 95131

TITLE

20P3, 20-lead (0.300"/7.62 mm Wide) Plastic Dual

Inline Package (PDIP)

COMMON DIMENSIONS

(Unit of Measure = mm)

SYMBOL

A – – 5.334

A1 0.381 – –

D 24.892 – 26.924 Note 2

E 7.620 – 8.255

E1 6.096 – 7.112 Note 2

B 0.356 – 0.559

B1 1.270 – 1.551

L 2.921 – 3.810

C 0.203 – 0.356

eB – – 10.922

eC 0.000 – 1.524

e 2.540 TYP

MIN

NOM

MAX

DRAWING NO.

20P3

NOTE

1/23/04

REV.

D

3390D–MICRO–3/07

43

56.2 20S2 – SOIC

44

AT89S2051/S4051

3390D–MICRO–3/07

57. Revision History

Revision No. History

Revision D – Feb. 2007

AT89S2051/S4051

• Removed Preliminary Status.

• Added the qualifier “x1 and x2 Modes” to the Static Operation

range.

• Changed the value ranges for Capacitors C1 and C2 in Figure 5-1

on page 4.

• Changed the trigger level for the BOD from 2.2V to 2.0V.

3390D–MICRO–3/07

45

Loading...

Loading...