Features

• Compatible with MCS

• 20K Bytes of Reprogrammable Flash Memory

• Endurance: 1000 Write/Erase Cycles

• 4V to 5.5V Operating Range

• Fully Static Operation: 0 Hz to 33 MHz

• Three-level Program Memory Lock

• 256 x 8-bit Internal RAM

• 32 Programmable I/O Lines

• Three 16-bit Timer/Counters

• Eight Interrupt Sources

• Programmable Serial Channel

• Low-power Idle and Power-down Modes

• Interrupt Recovery from Power-down Mode

• Hardware Watchdog Timer

• Dual Data Pointer

• Power-off Flag

• Green (Pb/Halide-free) Packaging Option

®

-51 Products

1. Description

The AT89C55WD is a low-power, high-performance CMOS 8-bit microcontroller with

20K bytes of Flash programmable read only memory and 256 bytes of RAM. The

device is manufactured using Atmel’s high-density nonvolatile memory technology

and is compatible with the industry standard 80C51 and 80C52 instruction set and

pinout. The on-chip Flash allows the program memory to be user programmed by a

conventional nonvolatile memory programmer. By combining a versatile 8-bit CPU

with Flash on a monolithic chip, the Atmel AT89C55WD is a powerful microcomputer

which provides a highly flexible and cost effective solution to many embedded control

applications.

8-bit

Microcontroller

with 20K Bytes

Flash

AT89C55WD

The AT89C55WD provides the following standard features: 20K bytes of Flash, 256

bytes of RAM, 32 I/O lines, three 16-bit timer/counters, a six-vector, two-level interrupt

architecture, a full-duplex serial port, on-chip oscillator, and clock circuitry. In addition,

the AT89C55WD is designed with static logic for operation down to zero frequency

and supports two software selectable power saving modes. The Idle Mode stops the

CPU while allowing the RAM, timer/counters, serial port, and interrupt system to continue functioning. The Power-down Mode saves the RAM contents but freezes the

oscillator, disabling all other chip functions until the next external interrupt or hardware

reset.

1921C–MICRO–3/05

2. Pin Configurations

2.1 44A – 44-lead TQFP

2.2 44J – 44-lead PLCC

(RXD) P3.0

(TXD) P3.1

(INT0) P3.2

(INT1) P3.3

(T0) P3.4

(T1) P3.5

P1.5

P1.6

P1.7

RST

(RXD) P3.0

NC

(TXD) P3.1

(INT0) P3.2

(INT1) P3.3

(T0) P3.4

(T1) P3.5

P1.4

P1.3

P1.2

P1.1 (T2 EX)

4443424140393837363534

1

P1.5

2

P1.6

3

P1.7

4

RST

5

6

NC

7

8

9

10

11

1213141516171819202122

XTAL2

XTAL1

(RD) P3.7

(WR) P3.6

P1.4

P1.3

P1.2

P1.1 (T2 EX)

65432

7

8

9

10

11

12

13

14

15

16

17

1819202122232425262728

XTAL2

XTAL1

(RD) P3.7

(WR) P3.6

P1.0 (T2)NCVCC

GND

GND

(A8) P2.0

P1.0 (T2)NCVCC

1

4443424140

NC

GND

(A8) P2.0

P0.0 (AD0)

P0.1 (AD1)

P0.2 (AD2)

(A9) P2.1

(A10) P2.2

(A11) P2.3

P0.0 (AD0)

P0.1 (AD1)

(A9) P2.1

(A10) P2.2

P0.3 (AD3)

33

32

31

30

29

28

27

26

25

24

23

(A12) P2.4

P0.2 (AD2)

P0.3 (AD3)

39

38

37

36

35

34

33

32

31

30

29

(A11) P2.3

(A12) P2.4

P0.4 (AD4)

P0.5 (AD5)

P0.6 (AD6)

P0.7 (AD7)

EA/VPP

NC

ALE/PROG

PSEN

P2.7 (A15)

P2.6 (A14)

P2.5 (A13)

P0.4 (AD4)

P0.5 (AD5)

P0.6 (AD6)

P0.7 (AD7)

EA/VPP

NC

ALE/PROG

PSEN

P2.7 (A15)

P2.6 (A14)

P2.5 (A13)

2.3 40P6 – 40-lead PDIP

2

AT89C55WD

(T2) P1.0

(T2EX) P1.1

P1.2

P1.3

P1.4

P1.5

P1.6

P1.7

RST

(RXD) P3.0

(TXD) P3.1

(INT0) P3.2

(INT1) P3.3

(T0) P3.4

(T1) P3.5

(WR) P3.6

(RD) P3.7

XTAL2

XTAL1

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

VCC

P0.0 (AD0)

P0.1 (AD1)

P0.2 (AD2)

P0.3 (AD3)

P0.4 (AD4)

P0.5 (AD5)

P0.6 (AD6)

P0.7 (AD7)

EA/VPP

ALE/PROG

PSEN

P2.7 (A15)

P2.6 (A14)

P2.5 (A13)

P2.4 (A12)

P2.3 (A11)

P2.2 (A10)

P2.1 (A9)

P2.0 (A8)

1921C–MICRO–3/05

3. Block Diagram

AT89C55WD

V

CC

GND

RAM ADDR.

REGISTER

B

REGISTER

ACC

TMP2

P0.0 - P0.7

PORT 0 DRIVERS

RAM

ALU

PORT 0

LATCH

TMP1

PORT 2 DRIVERS

PORT 2

LATCH

POINTER

P2.0 - P2.7

QUICK

FLASH

STACK

PROGRAM

ADDRESS

REGISTER

BUFFER

PC

INCREMENTER

PSEN

ALE/PROG

EA / V

RST

INTERRUPT, SERIAL PORT,

AND TIMER BLOCKS

PROGRAM

PSW

TIMING

AND

PP

CONTROL

OSC

INSTRUCTION

REGISTER

WATCH

DOG

PORT 1

LATCH

PORT 1 DRIVERS

P1.0 - P1.7

PORT 3

LATCH

PORT 3 DRIVERS

P3.0 - P3.7

COUNTER

DUAL

DPTR

1921C–MICRO–3/05

3

4. Pin Description

4.1 VCC

Supply voltage.

4.2 GND

Ground.

4.3 Port 0

Port 0 is an 8-bit open drain bi-directional I/O port. As an output port, each pin can sink eight TTL

inputs. When 1s are written to port 0 pins, the pins can be used as high-impedance inputs.

Port 0 can also be configured to be the multiplexed low-order address/data bus during accesses

to external program and data memory. In this mode, P0 has internal pull-ups.

Port 0 also receives the code bytes during Flash programming and outputs the code bytes during program verification. External pull-ups are required during program verification.

4.4 Port 1

Port 1 is an 8-bit bi-directional I/O port with internal pull-ups. The Port 1 output buffers can

sink/source four TTL inputs. When 1s are written to Port 1 pins, they are pulled high by the internal pull-ups and can be used as inputs. As inputs, Port 1 pins that are externally being pulled low

will source current (I

In addition, P1.0 and P1.1 can be configured to be the timer/counter 2 external count input

(P1.0/T2) and the timer/counter 2 trigger input (P1.1/T2EX), respectively, as shown in the following table.

) because of the internal pull-ups.

IL

4.5 Port 2

Port 1 also receives the low-order address bytes during Flash programming and verification.

Port Pin Alternate Functions

P1.0 T2 (external count input to Timer/Counter 2), clock-out

P1.1 T2EX (Timer/Counter 2 capture/reload trigger and direction control)

Port 2 is an 8-bit bi-directional I/O port with internal pull-ups. The Port 2 output buffers can

sink/source four TTL inputs. When 1s are written to Port 2 pins, they are pulled high by the internal pull-ups and can be used as inputs. As inputs, Port 2 pins that are externally being pulled low

will source current (I

Port 2 emits the high-order address byte during fetches from external program memory and during accesses to external data memory that use 16-bit addresses (MOVX @ DPTR). In this

application, Port 2 uses strong internal pull-ups when emitting 1s. During accesses to external

data memory that use 8-bit addresses (MOVX @ RI), Port 2 emits the contents of the P2 Special

Function Register.

Port 2 also receives the high-order address bits and some control signals during Flash programming and verification.

) because of the internal pull-ups.

IL

4

AT89C55WD

1921C–MICRO–3/05

4.6 Port 3

AT89C55WD

Port 3 is an 8-bit bi-directional I/O port with internal pull-ups. The Port 3 output buffers can

sink/source four TTL inputs. When 1s are written to Port 3 pins, they are pulled high by the internal pull-ups and can be used as inputs. As inputs, Port 3 pins that are externally being pulled low

will source current (I

Port 3 receives some control signals for Flash programming and verification.

Port 3 also serves the functions of various special features of the AT89C55WD, as shown in the

following table.

Port Pin Alternate Functions

P3.0 RXD (serial input port)

P3.1 TXD (serial output port)

P3.2 INT0

) because of the pull-ups.

IL

(external interrupt 0)

4.7 RST

4.8 ALE/PROG

P3.3 INT1

P3.4 T0 (timer 0 external input)

P3.5 T1 (timer 1 external input)

P3.6 WR

P3.7 RD

(external interrupt 1)

(external data memory write strobe)

(external data memory read strobe)

Reset input. A high on this pin for two machine cycles while the oscillator is running resets the

device. This pin drives High for 98 oscillator periods after the Watchdog times out. The DISRTO

bit in SFR AUXR (address 8EH) can be used to disable this feature. In the default state of bit

DISRTO, the RESET HIGH out feature is enabled.

Address Latch Enable is an output pulse for latching the low byte of the address during

accesses to external memory. This pin is also the program pulse input (PROG

) during Flash

programming.

In normal operation, ALE is emitted at a constant rate of 1/6 the oscillator frequency and may be

used for external timing or clocking purposes. Note, however, that one ALE pulse is skipped during each access to external data memory.

If desired, ALE operation can be disabled by setting bit 0 of SFR location 8EH. With the bit set,

ALE is active only during a MOVX or MOVC instruction. Otherwise, the pin is weakly pulled high.

Setting the ALE-disable bit has no effect if the microcontroller is in external execution mode.

4.9 PSEN

1921C–MICRO–3/05

Program Store Enable is the read strobe to external program memory.

When the AT89C55WD is executing code from external program memory, PSEN

twice each machine cycle, except that two PSEN

activations are skipped during each access to

external data memory.

is activated

5

4.10 EA/VPP

External Access Enable. EA must be strapped to GND in order to enable the device to fetch

code from external program memory locations starting at 0000H up to FFFFH. Note, however,

that if lock bit 1 is programmed, EA

should be strapped to VCC for internal program executions.

EA

will be internally latched on reset.

This pin also receives the 12V programming enable voltage (V

) during Flash programming.

PP

4.11 XTAL1

Input to the inverting oscillator amplifier and input to the internal clock operating circuit.

4.12 XTAL2

Output from the inverting oscillator amplifier.

5. Special Function Registers

A map of the on-chip memory area called the Special Function Register (SFR) space is shown in Table 5-1.

Table 5-1. AT89C55WD SFR Map and Reset Values

0F8H 0FFH

0F0H

0E8H 0EFH

0E0H

0D8H 0DFH

0D0H

0C8H

B

00000000

ACC

00000000

PSW

00000000

T2CON

00000000

T2MOD

XXXXXX00

RCAP2L

00000000

RCAP2H

00000000

TL2

00000000

TH2

00000000

0F7H

0E7H

0D7H

0CFH

0C0H 0C7H

0B8H

0B0H

0A8H

0A0H

98H

90H

88H

80H

6

IP

XX000000

P3

11111111

IE

0X000000

P2

11111111

SCON

00000000

P1

11111111

TCON

00000000

P0

11111111

SBUF

XXXXXXXX

TMOD

00000000

SP

00000111

AT89C55WD

AUXR1

XXXXXXX0

TL0

00000000

DP0L

00000000

TL1

00000000

DP0H

00000000

TH0

00000000

DP1L

00000000

TH1

00000000

DP1H

00000000

WDTRST

XXXXXXXX

AUXR

XXX00XX0

PCON

0XXX0000

1921C–MICRO–3/05

0BFH

0B7H

0AFH

0A7H

9FH

97H

8FH

87H

AT89C55WD

Note that not all of the addresses are occupied, and unoccupied addresses may not be implemented on the chip. Read accesses to these addresses will in general return random data, and

write accesses will have an indeterminate effect.

User software should not write 1s to these unlisted locations, since they may be used in future

products to invoke new features. In that case, the reset or inactive values of the new bits will

always be 0.

Timer 2 Registers: Control and status bits are contained in registers T2CON (shown in Table 5-

2) and T2MOD (shown in Table 5-2) for Timer 2. The register pair (RCAP2H, RCAP2L) are the

Capture/Reload registers for Timer 2 in 16-bit capture mode or 16-bit auto-reload mode.

Interrupt Registers: The individual interrupt enable bits are in the IE register. Two priorities can

be set for each of the six interrupt sources in the IP register.

Dual Data Pointer Registers: To facilitate accessing both internal and external data memory,

two banks of 16-bit Data Pointer Registers are provided: DP0 at SFR address locations 82H83H and DP1 at 84H-85H. Bit DPS = 0 in SFR AUXR1 selects DP0 and DPS = 1 selects DP1.

The user should always initialize the DPS bit to the appropriate value before accessing the

respective Data Pointer Register.

Power Off Flag: The Power Off Flag (POF) is located at bit 4 (PCON.4) in the PCON SFR. POF

is set to “1” during power up. It can be set and reset under software control and is not affected by

reset.

Table 5-2. T2CON—Timer/Counter 2 Control Register

T2CON Address = 0C8H Reset Value = 0000 0000B

Bit Addressable

Bit

Symbol Function

TF2

EXF2

RCLK

TCLK

EXEN2

TR2 Start/Stop control for Timer 2. TR2 = 1 starts the timer.

C/T2

CP/RL2

TF2 EXF2 RCLK TCLK EXEN2 TR2 C/T2

76543210

Timer 2 overflow flag set by a Timer 2 overflow and must be cleared by software. TF2 will not be set when either RCLK

= 1 or TCLK = 1.

Timer 2 external flag set when either a capture or reload is caused by a negative transition on T2EX and EXEN2 = 1.

When Timer 2 interrupt is enabled, EXF2 = 1 will cause the CPU to vector to the Timer 2 interrupt routine. EXF2 must be

cleared by software. EXF2 does not cause an interrupt in up/down counter mode (DCEN = 1).

Receive clock enable. When set, causes the serial port to use Timer 2 overflow pulses for its receive clock in serial port

Modes 1 and 3. RCLK = 0 causes Timer 1 overflow to be used for the receive clock.

Transmit clock enable. When set, causes the serial port to use Timer 2 overflow pulses for its transmit clock in serial port

Modes 1 and 3. TCLK = 0 causes Timer 1 overflows to be used for the transmit clock.

Timer 2 external enable. When set, allows a capture or reload to occur as a result of a negative transition on T2EX if

Timer 2 is not being used to clock the serial port. EXEN2 = 0 causes Timer 2 to ignore events at T2EX.

Timer or counter select for Timer 2. C/T2 = 0 for timer function. C/T2 = 1 for external event counter (falling edge

triggered).

Capture/Reload select. CP/RL2 = 1 causes captures to occur on negative transitions at T2EX if EXEN2 = 1. CP/RL2 = 0

causes automatic reloads to occur when Timer 2 overflows or negative transitions occur at T2EX when EXEN2 = 1.

When either RCLK or TCLK = 1, this bit is ignored and the timer is forced to auto-reload on Timer 2 overflow.

CP/RL2

1921C–MICRO–3/05

7

Table 5-3. AUXR: Auxiliary Register

AUXR Address = 8EH Reset Value = XXX00XX0B

Not Bit Addressable

– – – WDIDLE DISRTO – – DISALE

Bit 7 6 5 4 3 2 1 0

– Reserved for future expansion

DISALE Disable/Enable ALE

DISALE Operating Mode

0 ALE is emitted at a constant rate of 1/6 the oscillator frequency

1 ALE is active only during a MOVX or MOVC instruction

DISRTO Disable/Enable Reset out

DISRTO Operating Mode

0 Reset pin is driven High after WDT times out

1 Reset pin is input only

WDIDLE Disable/Enable WDT in IDLE mode

WDIDLE Operating Mode

0 WDT continues to count in IDLE mode

1 WDT halts counting in IDLE mode

Table 5-4. AUXR1: Auxiliary Register 1

AUXR1 Address = A2H Reset Value = XXXXXXX0B

Not Bit Addressable

––– – – – –DPS

Bit 7 6 5 4 3 2 1 0

– Reserved for future expansion

DPS Data Pointer Register Select

DPS

0 Selects DPTR Registers DP0L, DP0H

1 Selects DPTR Registers DP1L, DP1H

8

AT89C55WD

1921C–MICRO–3/05

6. Memory Organization

The MCS-51 devices have a separate address space for Program and Data Memory. Up to

64 Kbytes each of external Program and Data Memory can be addressed.

6.1 Program Memory

If the EA pin is connected to GND, all program fetches are directed to external memory.

AT89C55WD

6.2 Data Memory

On the AT89C55WD, if EA

4FFFH are directed to internal memory and fetches to addresses 5000H through FFFFH are to

external memory.

The AT89C55WD implements 256 bytes of on-chip RAM. The upper 128 bytes occupy a parallel

address space to the Special Function Registers. That means the upper 128 bytes have the

same addresses as the SFR space but are physically separate from SFR space.

When an instruction accesses an internal location above address 7FH, the address mode used

in the instruction specifies whether the CPU accesses the upper 128 bytes of RAM or the SFR

space. Instructions that use direct addressing access SFR space.

For example, the following direct addressing instruction accesses the SFR at location 0A0H

(which is P2).

MOV 0A0H, #data

Instructions that use indirect addressing access the upper 128 bytes of RAM. For example, the

following indirect addressing instruction, where R0 contains 0A0H, accesses the data byte at

address 0A0H, rather than P2 (whose address is 0A0H).

MOV @R0, #data

Note that stack operations are examples of indirect addressing, so the upper 128 bytes of data

RAM are available as stack space.

is connected to VCC, program fetches to addresses 0000H through

7. Hardware Watchdog Timer (One-time Enabled with Reset-out)

The WDT is intended as a recovery method in situations where the CPU may be subjected to

software upsets. The WDT consists of a 13-bit counter and the WatchDog Timer Reset

(WDTRST) SFR. The WDT is defaulted to disable from exiting reset. To enable the WDT, a user

must write 01EH and 0E1H in sequence to the WDTRST register (SFR location 0A6H). When

the WDT is enabled, it will increment every machine cycle while the oscillator is running. The

WDT time-out period is dependent on the external clock frequency. There is no way to disable

the WDT except through reset (either hardware reset or WDT overflow reset). When WDT overflows, it will drive an output RESET HIGH pulse at the RST pin.

1921C–MICRO–3/05

9

8. Using the WDT

To enable the WDT, a user must write 01EH and 0E1H in sequence to the WDTRST register

(SFR location 0A6H). When the WDT is enabled, the user needs to service it by writing 01EH

and 0E1H to WDTRST to avoid a WDT overflow. The 13-bit counter overflows when it reaches

8191 (1FFFH), and this will reset the device. When the WDT is enabled, it will increment every

machine cycle while the oscillator is running. This means the user must re-initialize the WDT at

least every 8191 machine cycles. To re-initialize the WDT the user must write 01EH and 0E1H

to WDTRST. WDTRST is a write-only register. The WDT counter cannot be read or written.

When WDT overflows, it will generate an output RESET pulse at the RST pin. The RESET pulse

duration is 98xTOSC, where TOSC=1/FOSC. To make the best use of the WDT, it should be

serviced in those sections of code that will periodically be executed within the time required to

prevent a WDT reset.

9. WDT During Power-down and Idle

In Power-down mode the oscillator stops, which means the WDT also stops. While in Powerdown mode, the user does not need to service the WDT. There are two methods of exiting

Power-down mode: by a hardware reset or via a level-activated external interrupt which is

enabled prior to entering Power-down mode. When Power-down is exited with hardware reset,

servicing the WDT should occur as it normally does whenever the AT89C55WD is reset. Exiting

Power-down with an interrupt is significantly different. The interrupt is held low long enough for

the oscillator to stabilize. When the interrupt is brought high, the interrupt is serviced. To prevent

the WDT from resetting the device while the interrupt pin is held low, the WDT is not started until

the interrupt is pulled high. It is suggested that the WDT be reset during the interrupt service for

the interrupt used to exit Power-down.

10. UART

11. Timer 0 and 1

To ensure that the WDT does not overflow within a few states of exiting Power-down, it is best to

reset the WDT just before entering Power-down.

Before going into the IDLE mode, the WDIDLE bit in SFR AUXR is used to determine whether

the WDT continues to count if enabled. The WDT keeps counting during IDLE (WDIDLE bit = 0)

as the default state. To prevent the WDT from resetting the AT89C55WD while in IDLE mode,

the user should always set up a timer that will periodically exit IDLE, service the WDT, and reenter IDLE mode.

With WDIDLE bit enabled, the WDT will stop to count in IDLE mode and resumes the count

upon exit from IDLE.

The UART in the AT89C55WD operates the same way as the UART in the AT89C51 and

AT89C52. For more detailed information on the UART operation, please click on the document

link below:

http://www.atmel.com/dyn/resources/prod_documents/DOC4316.PDF

Timer 0 and Timer 1 in the AT89C55WD operate the same way as Timer 0 and Timer 1 in the

AT89C51 and AT89C52. For further information on the timers’ operation, please click on the

document link below:

10

http://www.atmel.com/dyn/resources/prod_documents/DOC4316.PDF

AT89C55WD

1921C–MICRO–3/05

12. Timer 2

AT89C55WD

Timer 2 is a 16-bit Timer/Counter that can operate as either a timer or an event counter. The

type of operation is selected by bit C/T2

three operating modes: capture, auto-reload (up or down counting), and baud rate generator.

The modes are selected by bits in T2CON, as shown in Table 5-2.

Timer 2 consists of two 8-bit registers, TH2 and TL2. In the Timer function, the TL2 register is

incremented every machine cycle. Since a machine cycle consists of 12 oscillator periods, the

count rate is 1/12 of the oscillator frequency.

Table 12-1. Timer 2 Operating Modes

RCLK +TCLK CP/RL2 TR2 MODE

0 0 1 16-bit Auto-Reload

0 1 1 16-bit Capture

1 X 1 Baud Rate Generator

X X 0 (Off)

In the Counter function, the register is incremented in response to a 1-to-0 transition at its corresponding external input pin, T2. In this function, the external input is sampled during S5P2 of

every machine cycle. When the samples show a high in one cycle and a low in the next cycle,

the count is incremented. The new count value appears in the register during S3P1 of the cycle

following the one in which the transition was detected. Since two machine cycles (24 oscillator

periods) are required to recognize a 1-to-0 transition, the maximum count rate is 1/24 of the

oscillator frequency. To ensure that a given level is sampled at least once before it changes, the

level should be held for at least one full machine cycle.

in the SFR T2CON (shown in Table 5-2). Timer 2 has

12.1 Capture Mode

In the capture mode, two options are selected by bit EXEN2 in T2CON. If EXEN2 = 0, Timer 2 is

a 16-bit timer or counter which upon overflow sets bit TF2 in T2CON. This bit can then be used

to generate an interrupt. If EXEN2 = 1, Timer 2 performs the same operation, but a 1-to-0 transition at external input T2EX also causes the current value in TH2 and TL2 to be captured into

RCAP2H and RCAP2L, respectively. In addition, the transition at T2EX causes bit EXF2 in

T2CON to be set. The EXF2 bit, like TF2, can generate an interrupt. The capture mode is illustrated in Figure 12-1.

12.2 Auto-reload (Up or Down Counter)

Timer 2 can be programmed to count up or down when configured in its 16-bit auto-reload

mode. This feature is invoked by the DCEN (Down Counter Enable) bit located in the

SFR T2MOD (see Table 12-2). Upon reset, the DCEN bit is set to 0 so that timer 2 will default to

count up. When DCEN is set, Timer 2 can count up or down, depending on the value of the

T2EX pin.

1921C–MICRO–3/05

11

Figure 12-1. Timer in Capture Mode

OSC

T2 PIN

T2EX PIN

÷12

TRANSITION

DETECTOR

C/T2 = 0

C/T2 = 1

EXEN2

CONTROL

TR2

CAPTURE

CONTROL

TH2 TL2

RCAP2LRCAP2H

EXF2

TF2

OVERFLOW

TIMER 2

INTERRUPT

Figure 12-2 shows Timer 2 automatically counting up when DCEN=0. In this mode, two options

are selected by bit EXEN2 in T2CON. If EXEN2 = 0, Timer 2 counts up to 0FFFFH and then sets

the TF2 bit upon overflow. The overflow also causes the timer registers to be reloaded with the

16-bit value in RCAP2H and RCAP2L. The values in Timer in Capture Mode RCAP2H and

RCAP2L are preset by software. If EXEN2 = 1, a 16-bit reload can be triggered either by an

overflow or by a 1-to-0 transition at external input T2EX. This transition also sets the EXF2 bit.

Both the TF2 and EXF2 bits can generate an interrupt if enabled.

Setting the DCEN bit enables Timer 2 to count up or down, as shown in Figure 12-2. In this

mode, the T2EX pin controls the direction of the count. A logic 1 at T2EX makes Timer 2 count

up. The timer will overflow at 0FFFFH and set the TF2 bit. This overflow also causes the 16-bit

value in RCAP2H and RCAP2L to be reloaded into the timer registers, TH2 and TL2,

respectively.

A logic 0 at T2EX makes Timer 2 count down. The timer underflows when TH2 and TL2 equal

the values stored in RCAP2H and RCAP2L. The underflow sets the TF2 bit and causes 0FFFFH

to be reloaded into the timer registers.

The EXF2 bit toggles whenever Timer 2 overflows or underflows and can be used as a 17th bit

of resolution. In this operating mode, EXF2 does not flag an interrupt.

Figure 12-2. Timer 2 Auto Reload Mode (DCEN = 0)

OSC

T2 PIN

T2EX PIN

÷12

TRANSITION

DETECTOR

C/T2 = 0

C/T2 = 1

EXEN2

CONTR OL

TR2

RELOAD

CONTROL

TH2 TL2

RCAP2LRCAP2H

OVERFLOW

TF2

EXF2

TIMER 2

INTERRUPT

12

AT89C55WD

1921C–MICRO–3/05

AT89C55WD

Table 12-2. T2MOD – Timer 2 Mode Control Register

T2MOD Address = 0C9H Reset Value = XXXX XX00B

Not Bit Addressable

––––––T2OEDCEN

Bit76543210

Symbol Function

– Not implemented, reserved for future

T2OE Timer 2 Output Enable bit

DCEN When set, this bit allows Timer 2 to be configured as an up/down counter

Figure 12-3. Timer 2 Auto Reload Mode (DCEN = 1)

TOGGLE

TF2

OSC

(DOWN COUNTING RELOAD VALUE)

0FFH0FFH

12

÷

C/T2 = 0

TH2 TL2

OVERFLOW

EXF2

T2 PIN

C/T2 = 1

CONTROL

TR2

RCAP2LRCAP2H

(UP COUNTING RELOAD VALUE)

TIMER 2

INTERRUPT

COUNT

DIRECTION

1=UP

0=DO

T2EX PIN

1921C–MICRO–3/05

13

13. Baud Rate Generator

Timer 2 is selected as the baud rate generator by setting TCLK and/or RCLK in T2CON (Table

5-2). Note that the baud rates for transmit and receive can be different if Timer 2 is used for the

receiver or transmitter and Timer 1 is used for the other function. Setting RCLK and/or TCLK

puts Timer 2 into its baud rate generator mode, as shown in Figure 13-1.

The baud rate generator mode is similar to the auto-reload mode, in that a rollover in TH2

causes the Timer 2 registers to be reloaded with the 16-bit value in registers RCAP2H and

RCAP2L, which are preset by software.

The baud rates in Modes 1 and 3 are determined by Timer 2’s overflow rate according to the following equation.

Modes 1 and 3 Baud Rates

The Timer can be configured for either timer or counter operation. In most applications, it is configured for timer operation (CP/T2

used as a baud rate generator. Normally, as a timer, it increments every machine cycle (at 1/12

the oscillator frequency). As a baud rate generator, however, it increments every state time (at

1/2 the oscillator frequency). The baud rate formula is given below.

Modes 1 and 3

-------------------------------------- -

Baud Rate

where (RCAP2H, RCAP2L) is the content of RCAP2H and RCAP2L taken as a 16-bit unsigned

integer.

Timer 2 as a baud rate generator is shown in Figure 13-1. This figure is valid only if RCLK or

TCLK = 1 in T2CON. Note that a rollover in TH2 does not set TF2 and will not generate an interrupt. Note too, that if EXEN2 is set, a 1-to-0 transition in T2EX will set EXF2 but will not cause a

reload from (RCAP2H, RCAP2L) to (TH2, TL2). Thus when Timer 2 is in use as a baud rate generator, T2EX can be used as an extra external interrupt.

Note that when Timer 2 is running (TR2 = 1) as a timer in the baud rate generator mode, TH2 or

TL2 should not be read from or written to. Under these conditions, the Timer is incremented

every state time, and the results of a read or write may not be accurate. The RCAP2 registers

may be read but should not be written to, because a write might overlap a reload and cause

write and/or reload errors. The timer should be turned off (clear TR2) before accessing the Timer

2 or RCAP2 registers.

= 0). The timer operation is different for Timer 2 when it is

------------------------------------------------------------------------------------- -=

32 x [65536-RCAP2H,RCAP2L)]

Timer 2 Overflow Rate

----------------------------------------------------------- -=

Oscillator Frequency

16

14

AT89C55WD

1921C–MICRO–3/05

Figure 13-1. Timer 2 in Baud Rate Generator Mode

NOTE: OSC. FREQ. IS DIVIDED BY 2, NOT 12

TIMER 1 OVERFLOW

2

÷

"0"

AT89C55WD

"1"

SMOD1

OSC

T2 PIN

T2EX PIN

2

÷

TRANSITION

DETECTOR

C/T2 = 0

C/T2 = 1

14. Programmable Clock Out

A 50% duty cycle clock can be programmed to come out on P1.0, as shown in Figure 14-1. This

pin, besides being a regular I/O pin, has two alternate functions. It can be programmed to input

the external clock for Timer/Counter 2 or to output a 50% duty cycle clock ranging from 61 Hz to

4 MHz for a 16 MHz operating frequency.

TR2

EXEN2

CONTROL

CONTROL

TH2 TL2

RCAP2LRCAP2H

EXF2

"1"

"1"

TIMER 2

INTERRUPT

"0"

"0"

RCLK

16

÷

TCLK

÷

16

Rx

CLOCK

Tx

CLOCK

1921C–MICRO–3/05

To configure the Timer/Counter 2 as a clock generator, bit C/T2

(T2CON.1) must be cleared and

bit T2OE (T2MOD.1) must be set. Bit TR2 (T2CON.2) starts and stops the timer.

The clock-out frequency depends on the oscillator frequency and the reload value of Timer 2

capture registers (RCAP2H, RCAP2L), as shown in the following equation.

Clock-Out Frequency

Oscillator Frequency

------------------------------------------------------------------------------------ -=

4 x [65536-(RCAP2H,RCAP2L)]

In the clock-out mode, Timer 2 roll-overs will not generate an interrupt. This behavior is similar to

when Timer 2 is used as a baud-rate generator. It is possible to use Timer 2 as a baud-rate generator and a clock generator simultaneously. Note, however, that the baud-rate and clock-out

frequencies cannot be determined independently from one another since they both use

RCAP2H and RCAP2L.

15

Figure 14-1. Timer 2 in Clock-Out Mode

OSC

P1.0

(T2)

P1.1

(T2EX)

15. Interrupts

TRANSITION

DETECTOR

÷2

EXEN2

TR2

C/T2 BIT

EXF2

TL2

(8-BITS)

RCAP2L RCAP2H

÷2

TIMER 2

INTERRUPT

TH2

(8-BITS)

T2OE (T2MOD.1)

The AT89C55WD has a total of six interrupt vectors: two external interrupts (INT0 and INT1),

three timer interrupts (Timers 0, 1, and 2), and the serial port interrupt. These interrupts are all

shown in Figure 15-1.

Each of these interrupt sources can be individually enabled or disabled by setting or clearing a

bit in Special Function Register IE. IE also contains a global disable bit, EA, which disables all

interrupts at once.

Note that Table 5 shows that bit position IE.6 is unimplemented. User software should not write

a ‘1’ to this bit position, since it may be used in future AT89 products.

Timer 2 interrupt is generated by the logical OR of bits TF2 and EXF2 in register T2CON. Neither of these flags is cleared by hardware when the service routine is vectored to. In fact, the

service routine may have to determine whether it was TF2 or EXF2 that generated the interrupt,

and that bit will have to be cleared in software.

16

AT89C55WD

1921C–MICRO–3/05

AT89C55WD

The Timer 0 and Timer 1 flags, TF0 and TF1, are set at S5P2 of the cycle in which the timers

overflow. The values are then polled by the circuitry in the next cycle. However, the Timer 2 flag,

TF2, is set at S2P2 and is polled in the same cycle in which the timer overflows.

Table 15-1. Interrupt Enable (IE) Register

(MSB) (LSB)

EA – ET2 ES ET1 EX1 ET0 EX0

Enable Bit = 1 enables the interrupt.

Enable Bit = 0 disables the interrupt.

Symbol Position Function

Disables all interrupts. If EA = 0, no interrupt is acknowledged. If EA

EA IE.7

– IE.6 Reserved.

ET2 IE.5 Timer 2 interrupt enable bit.

ES IE.4 Serial Port interrupt enable bit.

ET1 IE.3 Timer 1 interrupt enable bit.

= 1, each interrupt source is individually enabled or disabled by

setting or clearing its enable bit.

EX1 IE.2 External interrupt 1 enable bit.

ET0 IE.1 Timer 0 interrupt enable bit.

EX0 IE.0 External interrupt 0 enable bit.

User software should never write 1s to reserved bits, because they may be used in future AT89

products.

Figure 15-1. Interrupt Sources

0

INT0

TF0

INT1

1

0

1

IE0

IE1

1921C–MICRO–3/05

TF1

TI

RI

TF2

EXF2

17

16. Oscillator Characteristics

XTAL1 and XTAL2 are the input and output, respectively, of an inverting amplifier that can be

configured for use as an on-chip oscillator, as shown in Figure 18-1. Either a quartz crystal or

ceramic resonator may be used. To drive the device from an external clock source, XTAL2

should be left unconnected while XTAL1 is driven, as shown in Figure 18-2. There are no

requirements on the duty cycle of the external clock signal, since the input to the internal clocking circuitry is through a divide-by-two flip-flop, but minimum and maximum voltage high and low

time specifications must be observed.

17. Idle Mode

In idle mode, the CPU puts itself to sleep while all the on-chip peripherals remain active. The

mode is invoked by software. The content of the on-chip RAM and all the special functions registers remain unchanged during this mode. The idle mode can be terminated by any enabled

interrupt or by a hardware reset.

Note that when idle mode is terminated by a hardware reset, the device normally resumes program execution from where it left off, up to two machine cycles before the internal reset

algorithm takes control. On-chip hardware inhibits access to internal RAM in this event, but

access to the port pins is not inhibited. To eliminate the possibility of an unexpected write to a

port pin when idle mode is terminated by a reset, the instruction following the one that invokes

idle mode should not write to a port pin or to external memory.

18. Power-down Mode

In the Power-down mode, the oscillator is stopped, and the instruction that invokes Power-down

is the last instruction executed. The on-chip RAM and Special Function Registers retain their

values until the Power-down mode is terminated. Exit from Power-down can be initiated either

by a hardware reset or by an enabled external interrupt. Reset redefines the SFRs but does not

change the on-chip RAM. The reset should not be activated before V

operating level and must be held active long enough to allow the oscillator to restart and

stabilize.

is restored to its normal

CC

18

AT89C55WD

1921C–MICRO–3/05

Figure 18-1. Oscillator Connections

C2

C1

Note: C1, C2 = 30 pF ± 10 pF for Crystals

= 40 pF ± 10 pF for Ceramic Resonators

Figure 18-2. External Clock Drive Configuration

AT89C55WD

XTAL2

XTAL1

GND

NC

XTAL2

EXTERNAL

OSCILLATOR

XTAL1

SIGNAL

GND

Table 18-1. Status of External Pins During Idle and Power-down Modes

Program

Mode

Idle Internal 1 1 Data Data Data Data

Idle External 1 1 Float Data Address Data

Power-down Internal 0 0 Data Data Data Data

Power-down External 0 0 Float Data Data Data

Memory ALE PSEN PORT0 PORT1 PORT2 PORT3

1921C–MICRO–3/05

19

19. Program Memory Lock Bits

The AT89C55WD has three lock bits that can be left unprogrammed (U) or can be programmed

(P) to obtain the additional features listed in the following table.

Table 19-1. Lock Bit Protection Modes

Program Lock Bits

1 U U U No program lock features.

2PUU

3 P P U Same as mode 2, but verify is also disabled.

4 P P P Same as mode 3, but external execution is also disabled.

Protection TypeLB1 LB2 LB3

MOVC instructions executed from external program memory are

disabled from fetching code bytes from internal memory, EA

sampled and latched on reset, and further programming of the Flash

memory is disabled.

is

When lock bit 1 is programmed, the logic level at the EA

If the device is powered up without a reset, the latch initializes to a random value and holds that

value until reset is activated. The latched value of EA

that pin in order for the device to function properly.

20. Programming the Flash

The AT89C55WD is shipped with the on-chip Flash memory array ready to be programmed. The

programming interface needs a high-voltage (12-volt) program enable signal and is compatible

with conventional third-party Flash or EPROM programmers.

The AT89C55WD code memory array is programmed byte-by-byte.

Programming Algorithm: Before programming the AT89C55WD, the address, data, and control signals should be set up according to the Flash programming mode table and Figures 21-1

and 21-2. To program the AT89C55WD, take the following steps:

1. Input the desired memory location on the address lines.

2. Input the appropriate data byte on the data lines.

3. Activate the correct combination of control signals.

4. Raise EA

5. Pulse ALE/PROG

write cycle is self-timed and typically takes no more than 50 µs. Repeat steps 1

through 5, changing the address and data for the entire array or until the end of the

object file is reached.

pin is sampled and latched during reset.

must agree with the current logic level at

/VPP to 12V.

once to program a byte in the Flash array or the lock bits. The byte-

20

AT89C55WD

1921C–MICRO–3/05

AT89C55WD

Chip Erase Sequence: Before the AT89C55WD can be reprogrammed, a Chip Erase operation

needs to be performed. To erase the contents of the AT89C55WD, follow this sequence:

1. Raise V

2. Pulse ALE/PROG

3. Wait for 150 ms.

4. Power V

5. Pulse ALE/PROG

6. Wait for 150 ms.

7. Power V

Data

Polling: The AT89C55WD features Data Polling to indicate the end of a write cycle. During

a write cycle, an attempted read of the last byte written will result in the complement of the written data on P0.7. Once the write cycle has been completed, true data is valid on all outputs, and

the next cycle may begin. Data

Ready/Busy

signal. P3.0 is pulled low after ALE goes high during programming to indicate BUSY

pulled high again when programming is done to indicate READY.

Program Verify: If lock bits LB1 and LB2 have not been programmed, the programmed code

data can be read back via the address and data lines for verification. The status of the individual

lock bits can be directly verified by reading them back.

Reading the Signature Bytes: The signature bytes are read by the same procedure as a normal verification of locations 000H, 100H, and 200H, except that P3.6 and P3.7 must be pulled to

a logic low. The values returned are as follows:

to 6.5V.

CC

once (duration of 200 - 500 ns).

down and up to 6.5V.

CC

once (duration of 200 - 500 ns).

down and up.

CC

Polling may begin any time after a write cycle has been initiated.

: The progress of byte programming can also be monitored by the RDY/BSY output

. P3.0 is

(000H) = 1EH indicates manufactured by Atmel

(100H) = 55H

(200H) = 06H indicates 89C55WD

21. Programming Interface

Every code byte in the Flash array can be programmed by using the appropriate combination of

control signals. The write operation cycle is self-timed and once initiated, will automatically time

itself to completion.

Most major worldwide programming vendors offer support for the Atmel AT89 microcontroller

series. Please contact your local programming vendor for the appropriate software revision.

1921C–MICRO–3/05

21

Table 21-1. Flash Programming Modes

P3.4 P2.5-0 P1.7-0

IN

A14 A13-8 A7-0

A14 A13-8 A7-0

XX X

Address

Mode V

Write Code

Data

Read Code

Data

CC

5V H L

5VHL HH/12VL LLHHD

Write Lock Bit 16.5

V

Write Lock Bit 26.5

V

Write Lock Bit 36.5

V

Read Lock Bits

1, 2, 3

Chip Erase

5V H L H H H H L H L

6.5

V

RST PSEN

HL

HL

HL

HL

ALE/

PROG

EA/

V

(1)

P2.6 P2.7 P3.3 P3.6 P3.7

PP

P0.7-0

Data

12V L H H H H D

OUT

(2)

12V H H H H H X X X X

(2)

12V H H H L L X X X X

(2)

12V H L H H L X X X X

P0.2,

P0.3,

P0.4

(3)

12V H L H L L X X X X

Read Atmel ID 5V H L H H L L L L L 1EH X XX 0000 00H

Read Device

ID

Read Device

ID

5V H L H H L L L L L 55H X XX 0001 00H

5V H L H H L L L L L 06H X XX 0010 00H

Notes: 1. Write Code Data requires a 200 ns PROG pulse.

2. Write Lock Bits requires a 100 µs PROG

3. Chip Erase requires a 200 ns - 500 ns PROG

4. RDY/BSY

signal is output on P3.0 during programming.

pulse.

pulse.

22

AT89C55WD

1921C–MICRO–3/05

Figure 21-1. Programming the Flash Memory

ADDR.

0000H/4FFFH

SEE FLASH

PROGRAMMING

MODES TABLE

A0 - A7

A8 - A13

A14*

P1.0 - P1.7

P2.0 - P2.5

P3.4

P2.6

P2.7

P3.3

P3.6

P3.7

XTAL2 EA

AT89C55WD

ALE

V

CC

P0

4.5V to 5.5V

PGM

DATA

PROG

V/V

AT89C55WD

IH PP

3 - 33 MHz

Figure 21-2. Verifying the Flash Memory

ADDR.

0000H/4FFFH

SEE FLASH

PROGRAMMING

MODES TABLE

3 - 33 MHz

A0 - A7

A8 - A13

A14*

P3.0

1

XTAL

GND

RST

PSEN

AT89C55WD

P1.0 - P1.7

P2.0 - P2.5

P3.4

P2.6

P2.7

P3.3

P3.6

P3.7

XTAL 2 EA

V

P0

ALE

4.5V to 5.5V

CC

RDY/

BSY

V

IH

PGM DATA

(USE 10K

PULL-UPS)

V

IH

1921C–MICRO–3/05

XTAL1

GND

RST

PSEN

V

IH

Note: *Programming address line A14 (P3.4) is not the same as the external memory address line A14

(P2.6).

23

22. Flash Programming and Verification Characteristics

TA = 20°C to 30°C, VCC = 4.5V to 5.5V

Symbol Parameter Min Max Units

V

PP

I

PP

I

CC

1/t

t

AVG L

t

GHAX

t

DVGL

t

GHDX

t

EHSH

t

SHGL

t

GHSL

t

GLGH

t

AVQ V

t

ELQV

t

EHQZ

t

GHBL

t

WC

CLCL

Programming Supply Voltage 11.5 12.5 V

Programming Supply Current 10 mA

VCC Supply Current 30 mA

Oscillator Frequency 3 33 MHz

Address Setup to PROG Low 48t

Address Hold After PROG 48t

Data Setup to PROG Low 48t

Data Hold After PROG 48t

P2.7 (ENABLE) High to V

PP

48t

CLCL

CLCL

CLCL

CLCL

CLCL

VPP Setup to PROG Low 10 µs

VPP Hold After PROG 10 µs

PROG Width 0.2 1 µs

Address to Data Valid 48t

ENABLE Low to Data Valid 48t

Data Float After ENABLE 048t

CLCL

CLCL

CLCL

PROG High to BUSY Low 1.0 µs

Byte Write Cycle Time 80 µs

24

AT89C55WD

1921C–MICRO–3/05

23. Flash Programming and Verification Waveforms

P1.0 - P1.7

P2.0 - P2.5

P3.4

PORT 0

ALE/PROG

EA/V

P2.7

(ENABLE)

P3.0

(RDY/BSY)

t

AVGL

t

SHGL

PP

PROGRAMMING

ADDRESS

DATA I N

t

t

DVGL

t

GLGH

V

PP

t

EHSH

t

GHBL

GHDX

t

t

ELQV

GHAX

t

GHSL

LOGIC 1

LOGIC 0

BUSY

t

WC

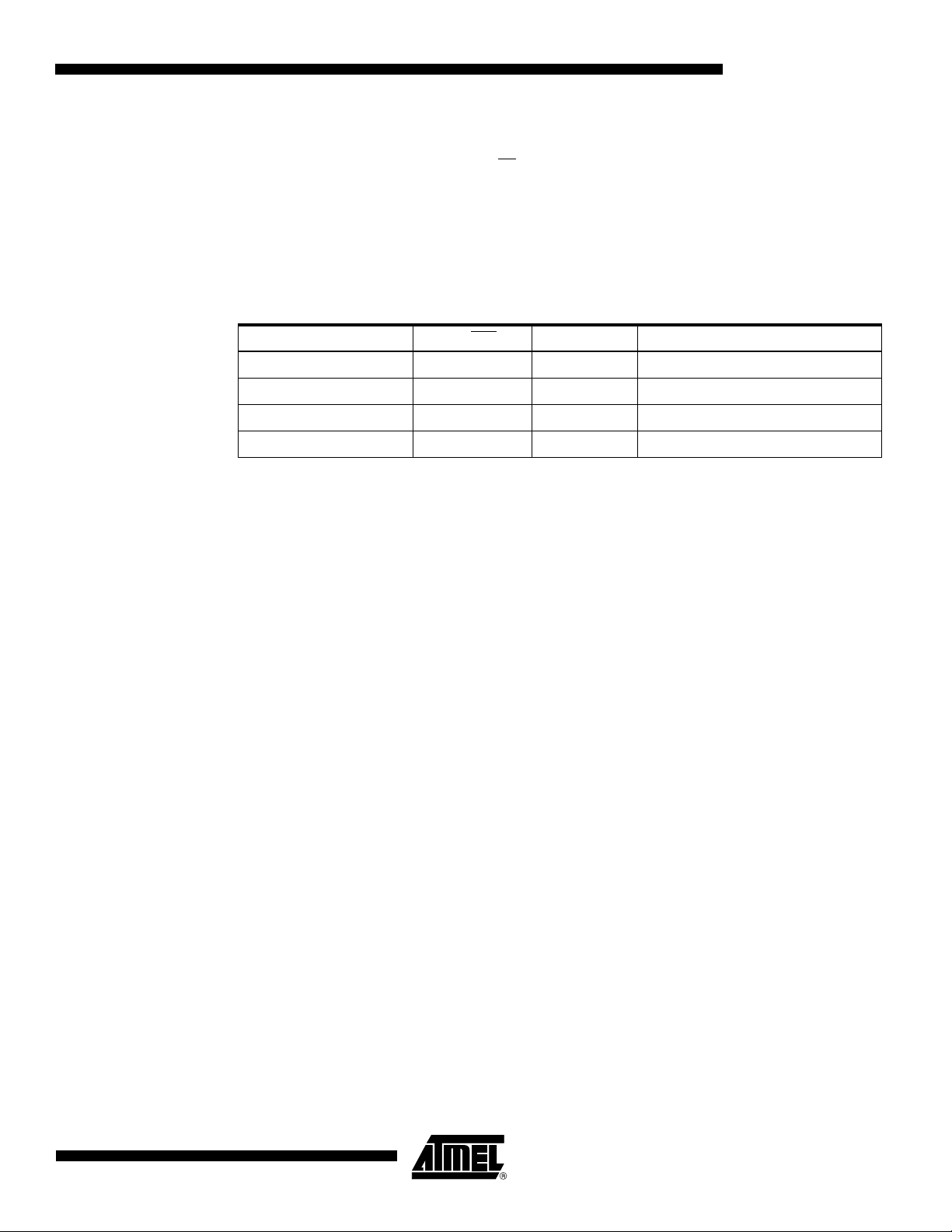

24. Lock Bit Programming

VERIFICATION

ADDRESS

t

AVQV

DATA O UT

READY

AT89C55WD

t

EHQZ

Test Conditions

Setup

Lockbit_1, 2 or 3

Data Setup

ALE/PROG

V

= 6.5V

CC

25. Parallel Chip Erase Mode

Test Conditions

Setup

ALE/PROG

P3<0>

200 ns

Erase

DC

Erase

100 µs

Test Conditions Setup

200 ns

Erase

V

= 4.5V to 5.5V

CC

Wait 10 ms to reload

new lock bit status

DC

Erase

1921C–MICRO–3/05

V

CC

= 6.5V

= 4.5V to 5.5V

V

CC

Wait 10 ms before

10 ms

reprogramming

25

26. Absolute Maximum Ratings*

Operating Temperature.................................. -55°C to +125°C

Storage Temperature ..................................... -65°C to +150°C

Voltage on Any Pin

with Respect to Ground.....................................-1.0V to +7.0V

Maximum Operating Voltage ............................................ 6.6V

DC Output Current...................................................... 15.0 mA

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent damage to the device. This is a stress rating only and

functional operation of the device at these or any

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions for extended periods may affect

device reliability.

27. DC Characteristics

The values shown in this table are valid for TA = -40°C to 85°C and VCC = 4.0V to 5.5V, unless otherwise noted.

Symbol Parameter Condition Min Max Units

V

IL

V

IL1

V

IH

V

IH1

V

OL

V

OL1

V

OH

Input Low Voltage (Except EA)-0.50.2 V

Input Low Voltage (EA)-0.50.2 V

-0.1 V

CC

-0.3 V

CC

Input High Voltage (Except XTAL1, RST) 0.2 VCC+0.9 VCC+0.5 V

Input High Voltage (XTAL1, RST) 0.7 V

Output Low Voltage

Output Low Voltage

Output High Voltage

(Ports 1,2,3, ALE, PSEN

(1)

(Ports 1,2,3) IOL = 1.6 mA 0.45 V

(1)

(Port 0, ALE, PSEN)IOL = 3.2 mA 0.45 V

= -60 µA, VCC = 5V ± 10% 2.4 V

I

OH

I

= -25 µA 0.75 V

)

OH

IOH = -10 µA 0.9 V

CC

CC

CC

VCC+0.5 V

IOH = -800 µA, VCC = 5V ± 10% 2.4 V

V

OH1

I

IL

I

TL

I

LI

Output High Voltage

(Port 0 in External Bus Mode)

Logical 0 Input Current (Ports 1,2,3) VIN = 0.45V -50 µA

Logical 1 to 0 Transition Current (Ports 1,2,3) VIN = 2V, VCC = 5V ± 10% -650 µA

Input Leakage Current (Port 0, EA)0.45 < V

I

= -300 µA 0.75 V

OH

IOH = -80 µA 0.9 V

< V

IN

CC

CC

CC

±10 µA

RRST Reset Pulldown Resistor 10 30 kΩ

C

IO

Pin Capacitance Test Freq. = 1 MHz, TA = 25°C 10 pF

Active Mode, 12 MHz 25 mA

Power Supply Current

I

CC

Power-down Mode

(1)

Idle Mode, 12 MHz 6.5 mA

VCC = 5.5V 100 µA

Notes: 1. Under steady state (non-transient) conditions, IOL must be externally limited as follows:

Maximum I

Maximum I

per port pin: 10 mA

OL

per 8-bit port:

OL

Port 0: 26 mA Ports 1, 2, 3: 15 mA

Maximum total IOL for all output pins: 71 mA

exceeds the test condition, V

If I

OL

may exceed the related specification. Pins are not guaranteed to sink current greater

OL

than the listed test conditions.

2. Minimum V

for Power-down is 2V.

CC

V

V

V

V

26

AT89C55WD

1921C–MICRO–3/05

AT89C55WD

28. AC Characteristics

Under operating conditions, load capacitance for Port 0, ALE/PROG, and PSEN = 100 pF; load capacitance for all other

outputs = 80 pF.

28.1 External Program and Data Memory Characteristics

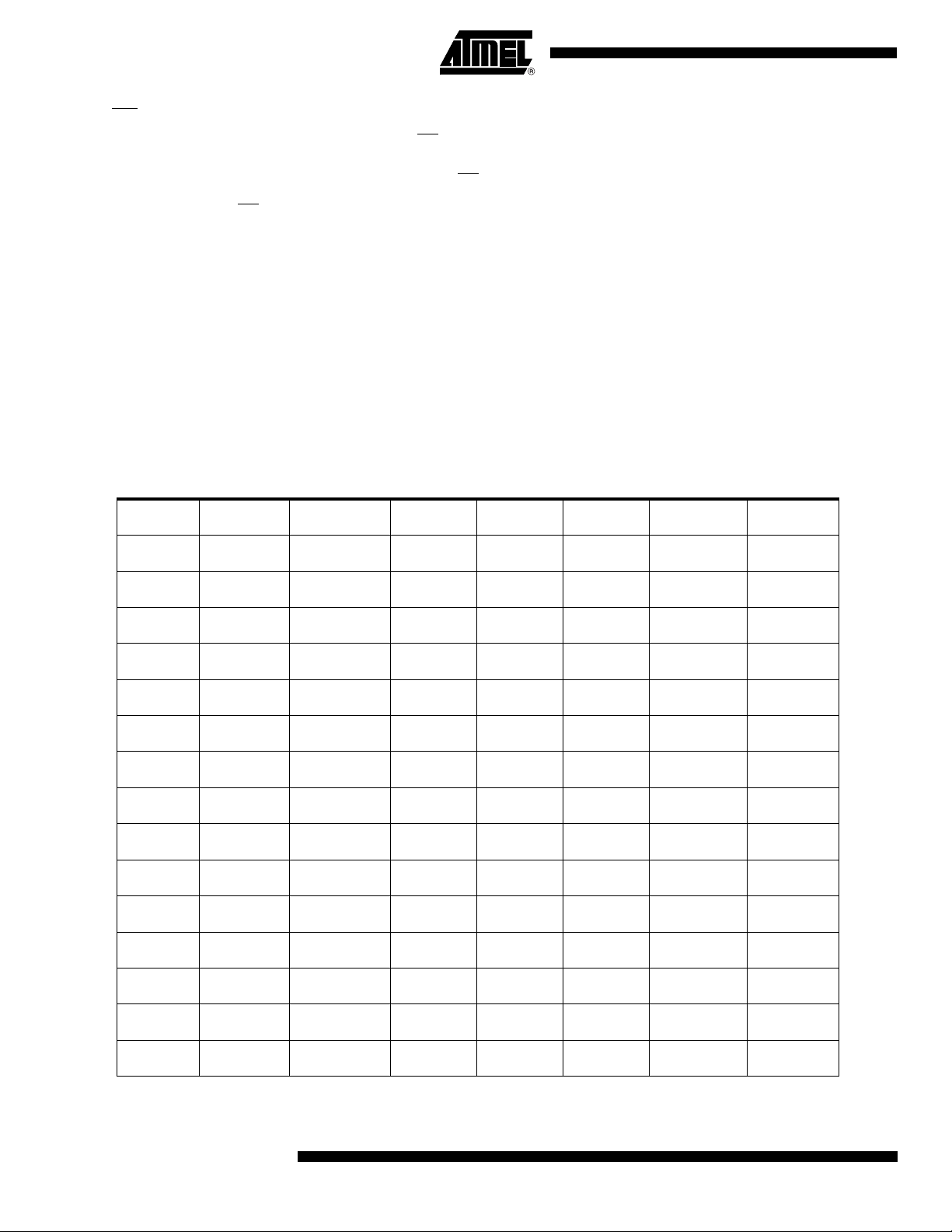

12 MHz Oscillator Variable Oscillator

Symbol Parameter

UnitsMin Max Min Max

1/t

t

LHLL

t

AVL L

t

LLAX

t

LLIV

t

LLPL

t

PLPH

t

PLIV

t

PXIX

t

PXIZ

t

PXAV

t

AVI V

t

PLAZ

t

RLRH

t

WLWH

t

RLDV

t

RHDX

t

RHDZ

t

LLDV

t

AVDV

t

LLWL

t

AVW L

t

QVWX

t

QVWH

t

WHQX

t

RLAZ

t

WHLH

CLCL

Oscillator Frequency 0 33 MHz

ALE Pulse Width 127 2t

Address Valid to ALE Low 43 t

Address Hold After ALE Low 48 t

ALE Low to Valid Instruction In 233 4t

ALE Low to PSEN Low 43 t

PSEN Pulse Width 205 3t

PSEN Low to Valid Instruction In 145 3t

-40 ns

CLCL

-25 ns

CLCL

-25 ns

CLCL

-65 ns

CLCL

-25 ns

CLCL

-45 ns

CLCL

-60 ns

CLCL

Input Instruction Hold After PSEN 00ns

Input Instruction Float After PSEN 59 t

PSEN to Address Valid 75 t

-8 ns

CLCL

Address to Valid Instruction In 312 5t

-25 ns

CLCL

-80 ns

CLCL

PSEN Low to Address Float 10 10 ns

RD Pulse Width 400 6t

WR Pulse Width 400 6t

RD Low to Valid Data In 252 5t

-100 ns

CLCL

-100 ns

CLCL

-90 ns

CLCL

Data Hold After RD 00ns

Data Float After RD 97 2t

ALE Low to Valid Data In 517 8t

Address to Valid Data In 585 9t

ALE Low to RD or WR Low 200 300 3t

Address to RD or WR Low 203 4t

Data Valid to WR Transition 23 t

Data Valid to WR High 433 7t

Data Hold After WR 33 t

-50 3t

CLCL

-75 ns

CLCL

-30 ns

CLCL

-130 ns

CLCL

-25 ns

CLCL

-28 ns

CLCL

-150 ns

CLCL

-165 ns

CLCL

+50 ns

CLCL

RD Low to Address Float 0 0 ns

RD or WR High to ALE High 43 123 t

-25 t

CLCL

+25 ns

CLCL

1921C–MICRO–3/05

27

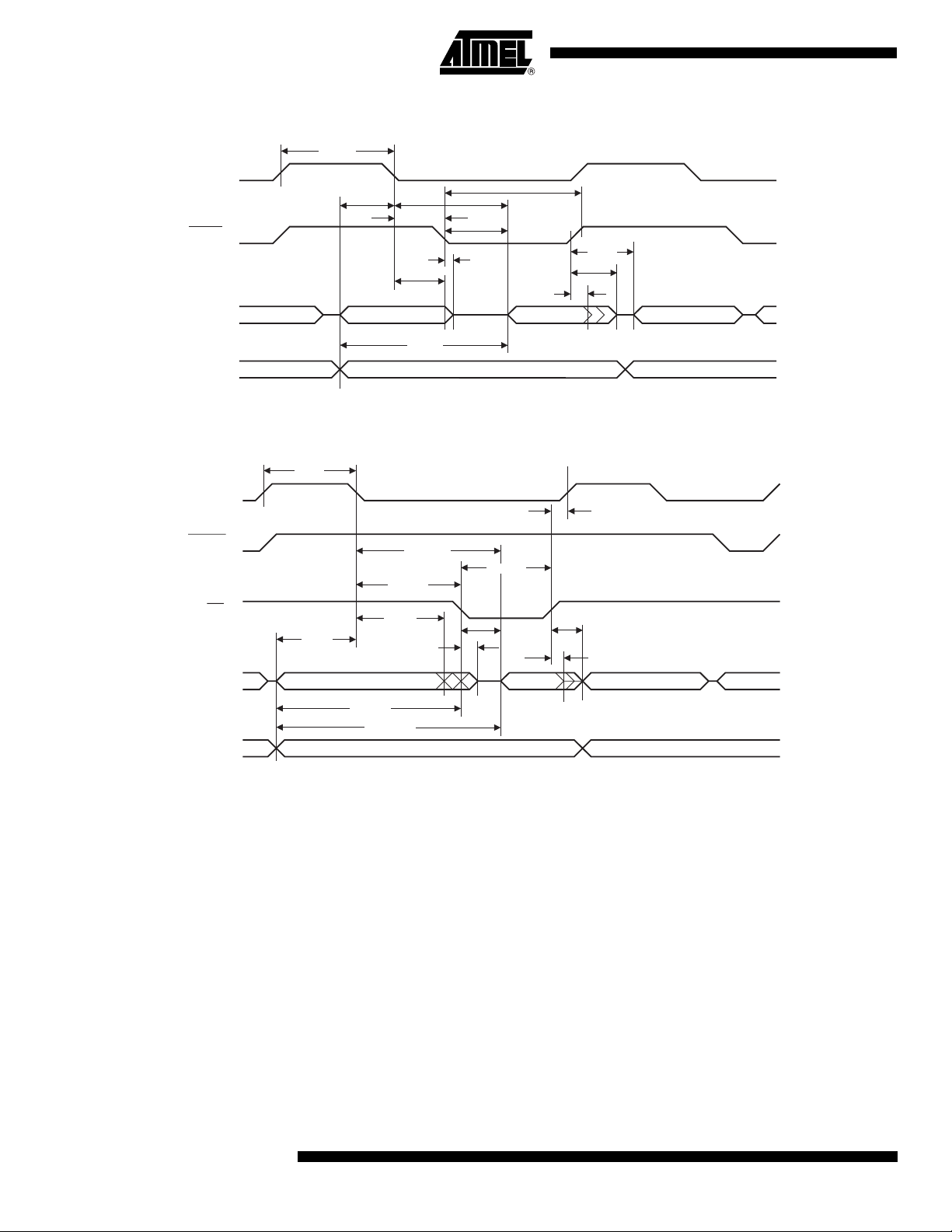

29. External Program Memory Read Cycle

t

LHLL

ALE

t

AVLL

t

LLPL

PSEN

t

PLAZ

A8 - A15

PORT 0

PORT 2

t

LLAX

A0 - A7 A0 - A7

t

AVIV

30. External Data Memory Read Cycle

t

LHLL

ALE

t

LLIV

t

PLIV

t

PXIZ

t

PXIX

INSTR IN

t

PLPH

t

PXAV

t

A8 - A15

WHLH

PSEN

RD

PORT 0

PORT 2

t

LLDV

t

LLWL

t

LLAX

t

AVLL

A0 - A7 FROM RI OR DPL

t

AVWL

P2.0 - P2.7 OR A8 - A15 FROM DPH

t

AVDV

t

RLAZ

t

RLRH

t

RLDV

DATA IN INSTR IN

t

RHDZ

t

RHDX

A0 - A7 FROM PCL

A8 - A15 FROM PCH

28

AT89C55WD

1921C–MICRO–3/05

31. External Data Memory Write Cycle

t

LHLL

ALE

PSEN

t

LLWL

t

WLWH

t

WHLH

AT89C55WD

WR

PORT 0

PORT 2

t

AVLL

A0 - A7 FROM RI OR DPL

P2.0 - P2.7 OR A8 - A15 FROM DPH

t

AVWL

t

LLAX

t

QVWX

32. External Clock Drive Waveforms

t

0.7 V

CC

CHCX

CC

0.45V

V - 0.5V

CC

0.2 V - 0.1V

t

t

QVWH

DATA OUT INSTR IN

t

CLCH

t

CLCX

WHQX

A0 - A7 FROM PCL

A8 - A15 FROM PCH

t

CHCX

t

CLCL

t

CHCL

33. External Clock Drive

Symbol Parameter Min Max Units

1/t

CLCL

t

CLCL

t

CHCX

t

CLCX

t

CLCH

t

CHCL

1921C–MICRO–3/05

Oscillator Frequency 0 33 MHz

Clock Period 30 ns

High Time 12 ns

Low Time 12 ns

Rise Time 5 ns

Fall Time 5 ns

29

34. Serial Port Timing: Shift Register Mode Test Conditions

The values in this table are valid for V

= 4.0V to 5.5V and Load Capacitance = 80 pF.

CC

12 MHz Osc Variable Oscillator

Symbol Parameter

t

XLXL

t

QVXH

t

XHQX

t

XHDX

t

XHDV

Serial Port Clock Cycle Time 1.0 12t

Output Data Setup to Clock Rising Edge 700 10t

Output Data Hold After Clock Rising Edge 50 2t

Input Data Hold After Clock Rising Edge 0 0 ns

Clock Rising Edge to Input Data Valid 700 10t

35. Shift Register Mode Timing Waveforms

INSTRUCTION

ALE

CLOCK

WRITE TO SBUF

OUTPUT DATA

CLEAR RI

INPUT DATA

0

t

QVXH

1

t

XHDV

2

t

XLXL

t

0

VALID VALIDVALID VALIDVALID VALIDVALID VALID

1

XHQX

3

2

t

XHDX

UnitsMin Max Min Max

CLCL

-133 ns

CLCL

-80 ns

CLCL

-133 ns

CLCL

4

5

3

4

6

5

7

8

6

µs

7

SET TI

SET RI

36. AC Testing Input/Output Waveforms

V - 0.5V

CC

0.45V

Note: 1. AC Inputs during testing are driven at VCC - 0.5V for a logic 1 and 0.45V for a logic 0. Timing

measurements are made at V

37. Float Waveforms

(1)

+ 0.1V

V

LOAD

V

LOAD

V

LOAD

- 0.1V

Timing Reference

Note: 1. For timing purposes, a port pin is no longer floating when a 100 mV change from load voltage

occurs. A port pin begins to float when a 100 mV change from the loaded V

occurs.

(1)

0.2 V + 0.9V

CC

TEST POINTS

0.2 V - 0.1V

CC

min. for a logic 1 and VIL max. for a logic 0.

IH

Points

- 0.1V

V

OL

+ 0.1V

V

OL

level

OH/VOL

30

AT89C55WD

1921C–MICRO–3/05

38. Ordering Information

38.1 Standard Package

Speed

(MHz)

24 4.0V to 5.5V

33 4.5V to 5.5V

38.2 Green Package Option (Pb/Halide-free)

Speed

(MHz)

24 4.0V to 5.5V

Power

Supply Ordering Code Package Operation Range

AT89C55WD-24AC

AT89C55WD-24JC

AT89C55WD-24PC

AT89C55WD-24AI

AT89C55WD-24JI

AT89C55WD-24PI

AT89C55WD-33AC

AT89C55WD-33JC

AT89C55WD-33PC

Power

Supply Ordering Code Package Operation Range

AT89C55WD-24AU

AT89C55WD-24JU

AT89C55WD-24PU

44A

44J

40P6

44A

44J

40P6

44A

44J

40P6

44A

44J

40P6

AT89C55WD

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Package Type

44A 44-lead, Thin Plastic Gull Wing Quad Flatpack (TQFP)

44J 44-lead, Plastic J-leaded Chip Carrier (PLCC)

40P6 40-pin, 0.600" Wide, Plastic Dual Inline Package (PDIP)

1921C–MICRO–3/05

31

39. Package Information

39.1 44A – TQFP

PIN 1

PIN 1 IDENTIFIER

B

e

E1 E

D1

D

C

0˚~7˚

A1

L

Notes: 1. This package conforms to JEDEC reference MS-026, Variation ACB.

2. Dimensions D1 and E1 do not include mold protrusion. Allowable

protrusion is 0.25 mm per side. Dimensions D1 and E1 are maximum

plastic body size dimensions including mold mismatch.

3. Lead coplanarity is 0.10 mm maximum.

A2 A

SYMBOL

COMMON DIMENSIONS

(Unit of Measure = mm)

MIN

A – – 1.20

A1 0.05 – 0.15

A2 0.95 1.00 1.05

D 11.75 12.00 12.25

D1 9.90 10.00 10.10 Note 2

E 11.75 12.00 12.25

E1 9.90 10.00 10.10 Note 2

B 0.30 – 0.45

C 0.09 – 0.20

L 0.45 – 0.75

e 0.80 TYP

NOM

MAX

NOTE

32

2325 Orchard Parkway

R

San Jose, CA 95131

AT89C55WD

TITLE

44A, 44-lead, 10 x 10 mm Body Size, 1.0 mm Body Thickness,

0.8 mm Lead Pitch, Thin Profile Plastic Quad Flat Package (TQFP)

10/5/2001

DRAWING NO.

44A

1921C–MICRO–3/05

REV.

B

39.2 44J – PLCC

AT89C55WD

1.14(0.045) X 45˚

B

e

0.51(0.020)MAX

45˚ MAX (3X)

Notes: 1. This package conforms to JEDEC reference MS-018, Variation AC.

2. Dimensions D1 and E1 do not include mold protrusion.

Allowable protrusion is .010"(0.254 mm) per side. Dimension D1

and E1 include mold mismatch and are measured at the extreme

material condition at the upper or lower parting line.

3. Lead coplanarity is 0.004" (0.102 mm) maximum.

PIN NO. 1

IDENTIFIER

D1

D

1.14(0.045) X 45˚

E1 E

0.318(0.0125)

0.191(0.0075)

NOM

D2/E2

MAX

B1

A2

A1

A

COMMON DIMENSIONS

(Unit of Measure = mm)

SYMBOL

A 4.191 – 4.572

A1 2.286 – 3.048

A2 0.508 – –

D 17.399 – 17.653

D1 16.510 – 16.662 Note 2

E 17.399 – 17.653

E1 16.510 – 16.662 Note 2

D2/E2 14.986 – 16.002

B 0.660 – 0.813

B1 0.330 – 0.533

e 1.270 TYP

MIN

NOTE

2325 Orchard Parkway

R

San Jose, CA 95131

1921C–MICRO–3/05

TITLE

44J, 44-lead, Plastic J-leaded Chip Carrier (PLCC)

DRAWING NO.

44J

10/04/01

REV.

B

33

39.3 40P6 – PDIP

PIN

1

E1

A1

B

REF

E

B1

C

L

SEATING PLANE

A

e

D

0º ~ 15º

eB

Notes: 1. This package conforms to JEDEC reference MS-011, Variation AC.

2. Dimensions D and E1 do not include mold Flash or Protrusion.

Mold Flash or Protrusion shall not exceed 0.25 mm (0.010").

TITLE

2325 Orchard Parkway

R

San Jose, CA 95131

40P6, 40-lead (0.600"/15.24 mm Wide) Plastic Dual

Inline Package (PDIP)

COMMON DIMENSIONS

(Unit of Measure = mm)

SYMBOL

A – – 4.826

A1 0.381 – –

D 52.070 – 52.578 Note 2

E 15.240 – 15.875

E1 13.462 – 13.970 Note 2

B 0.356 – 0.559

B1 1.041 – 1.651

L 3.048 – 3.556

C 0.203 – 0.381

eB 15.494 – 17.526

e 2.540 TYP

MIN

NOM

MAX

DRAWING NO.

40P6

NOTE

09/28/01

REV.

B

34

AT89C55WD

1921C–MICRO–3/05

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT

OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Atmel’s products are not

intended, authorized, or warranted for use as components in applications intended to support or sustain life.

© Atmel Corporation 2005. All rights reserved. Atmel®, logo and combinations thereof, and others, are registered trademarks, and

Everywhere You Are

trademarks of others.

SM

and others are the trademarks of Atmel Corporation or its subsidiaries. Other terms and product names may be

Printed on recycled paper.

1921C–MICRO–3/05

xM

Loading...

Loading...