Page 1

BDTIC www.BDTIC.com/ATMEL

Features

• 80C51 Compatible CPU Core High-speed Architecture

• X2 Speed Improvement Capability (6 Clocks/Machine Cycle)

• 16 MHz in Standard or X2 mode

• 256 Bytes RAM

• 256 Bytes XRAM

• 12K Bytes ROM/OTP Program Memory

• Two 16-bit Timer/Counters T0, T1

• 5 Channels Programmable Counter Array with High-speed Output, Compare/Capture,

Pulse Width Modulation and Watchdog Timer Capabilities

• SPI Interface (Master and Slave mode)

• Interrupt Structure with:

– 6 Interrupt Sources

– 4 Interrupt Priority Levels

• Power Supply: 3 - 5.5V

• Temperature Range: Industrial (-40

• Package: SSOP16, SSOP24

o

C to 85oC), Automotive (-40oC to 125oC)

Low-pin Count

8-bit

Microcontroller

Description

The AT8xC5103 is a high-performance ROM/OTP version of the 80C51 8-bit Microcontroller in 16 and 24-pin packages.

The AT8xC5103 contains a standard C51 CPU core with 12 Kbytes ROM/OTP program memory, 256 bytes of internal RAM, 256 bytes of extended internal RAM, a 5sources 4-level interrupt system, two timer/counters and a SPI serial bus controller.

The AT8xC5103 is also dedicated for analog interfacing applications. For this, it has a

five channels Programmable Counter Array.

In addition, the AT8xC5103 implements the X2 speed improvement mechanism. The

X2 feature allows to keep the same C PU power at a divided by two oscillator

frequency.

The fully static design of the AT8xC5103 allows to reduce system power consumption

by bringing the clock frequency down to any value, even DC, without loss of data.

AT87C5103

AT83C5103

Rev. 4134D–8051–02/08

1

Page 2

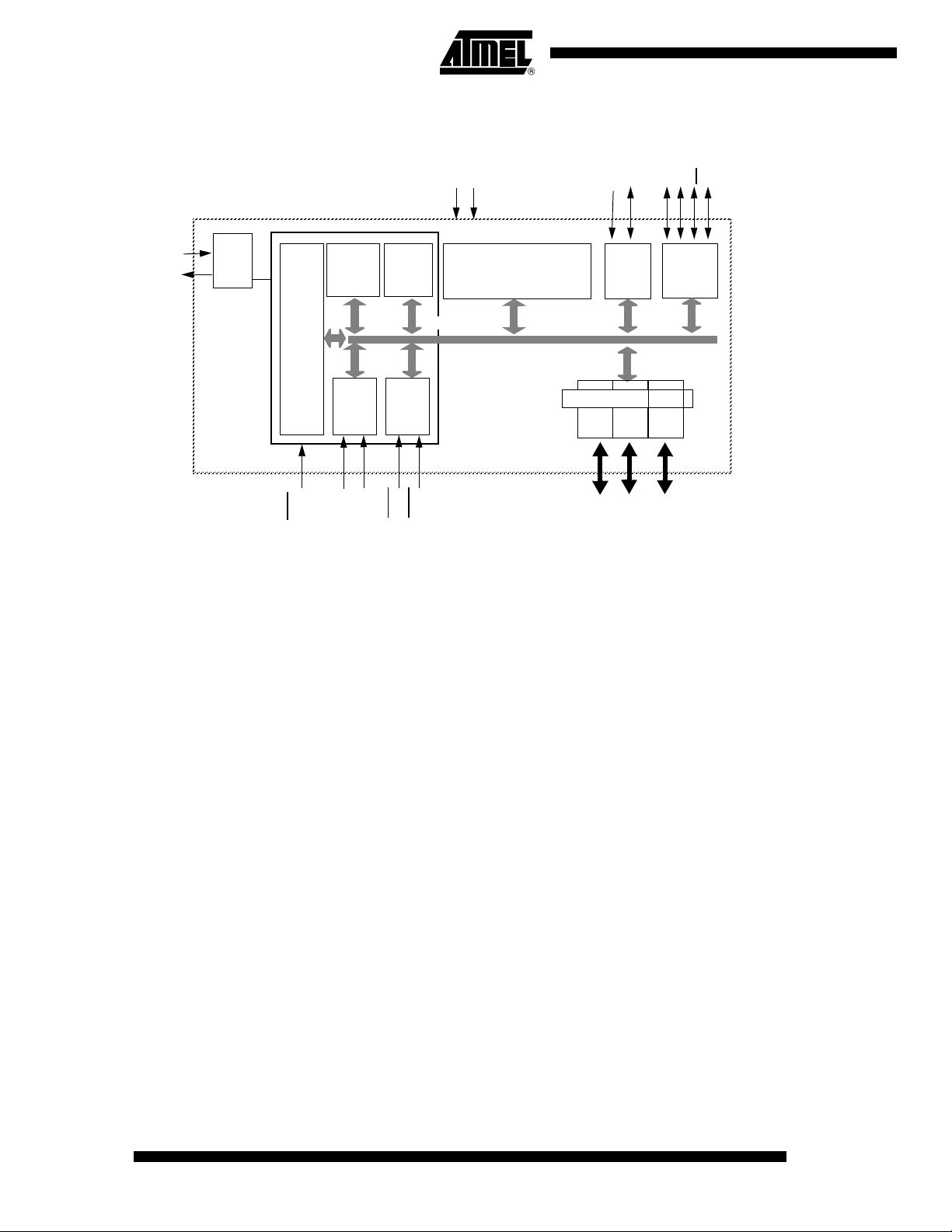

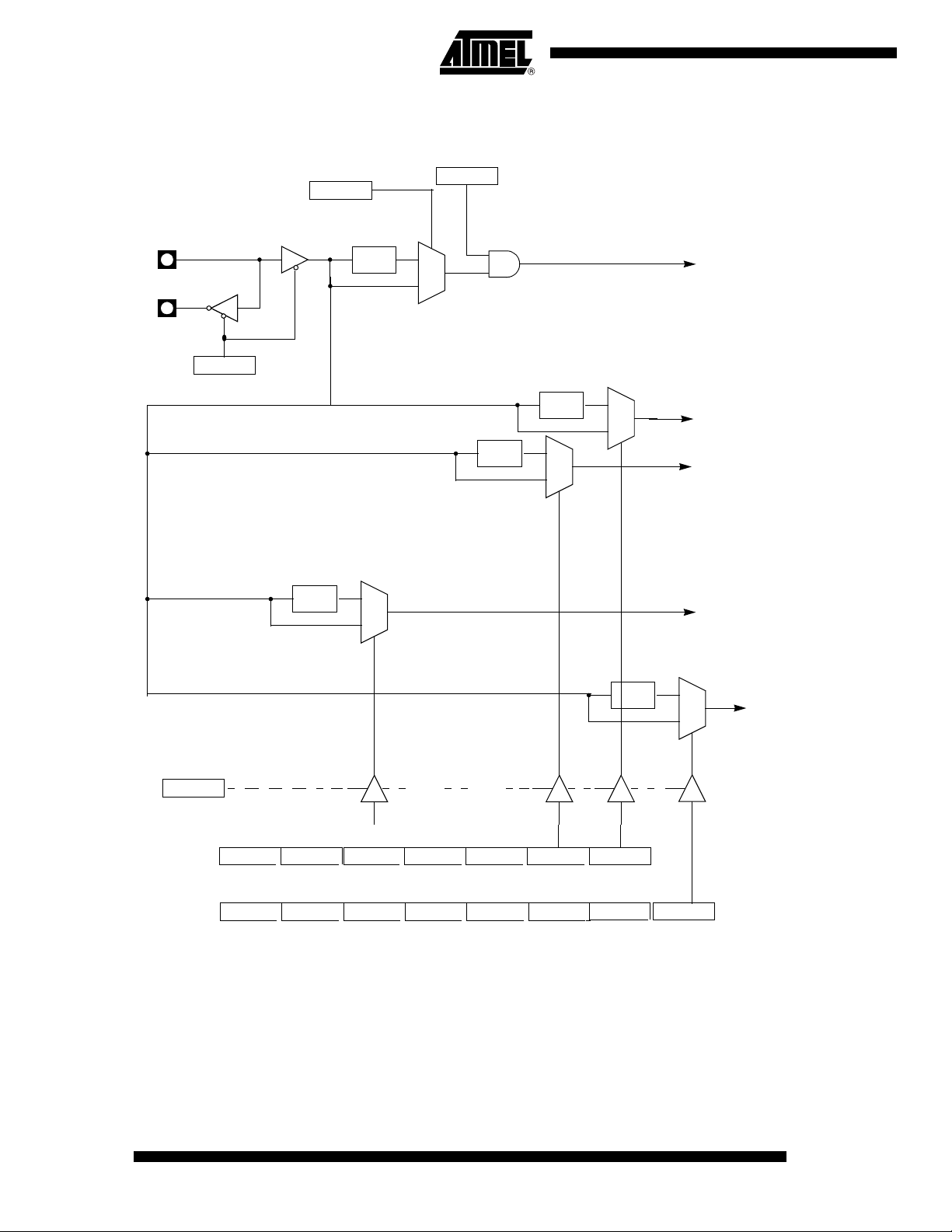

Block Diagram

Timer 0

INT

RAM

256x8

T0

XTAL2

XTAL1

CPU

Timer 1

Ctrl

INT0

C51

CORE

(3) (3)

Port 1

P1

P3

IB-bus

Vss

Vcc

ROM

12 K *8

CEX0-4

Xtal

Osc

(1)

Port 3

PCA

MISO

(1)

MOSI

(1)

SPSCK

(3)

SPI

SS

(1)

RST

ECI

(1)

256x8

Parallel I/O Ports

EXRAM

P4

Port 4

INT1

(3)

T1

(3)

Notes: 1. Alternate function of Port 1.

2. Alternate function of Port 3.

2

4134D–8051–02/08

Page 3

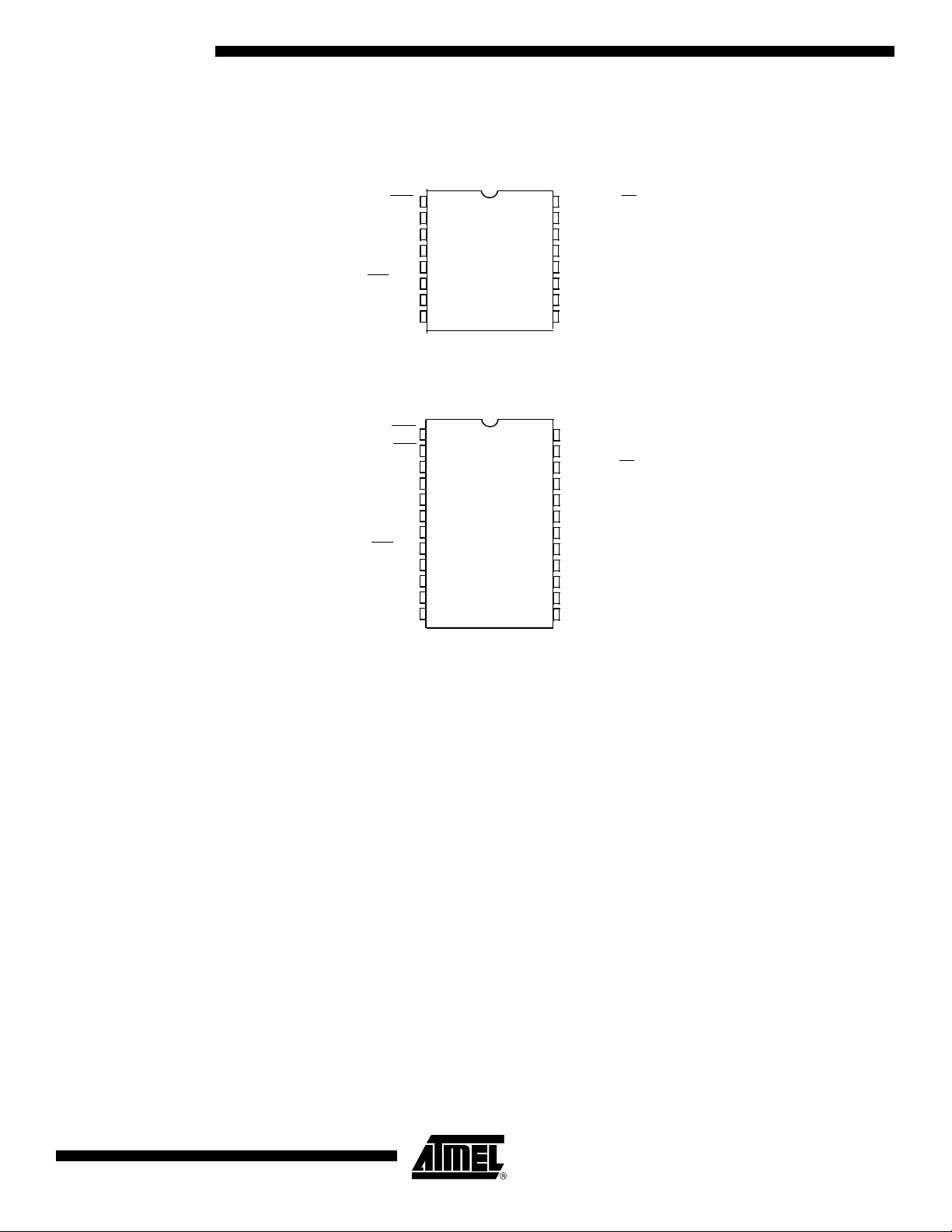

Pin Configurations

XTAL1

VCC

VSS

1

RST/VPP

XTAL2

P1.2/ECI/DIG2

P3.2/DIG0/INT0

P3.6/SPICK

P3.4/DIG1/T0

P1.7/CEX4/SS

P1.6/CEX3

P1.5/CEX2

P1.4/CEX1

P1.3/CEX0

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

P1.1/MOSI

P1.0/MISO

SSOP16

P1.1/MOSI

P1.0/MISO

VCC

XTAL2

P1.5/CEX2

VSS

XTAL1

P1.2/ECI/DIG2

RST/VPP

P3.1

P3.6/SPICK

1

2

3

4

5

6

7

8

16

15

14

13

9

10

11

12

P1.6/CEX3

P3.7

P3.5/T1

20

19

18

17

24

23

22

21

P3.4/DIG1/T0

P4.0

P4.1

P4.2

P1.3/CEX0

P1.4/CEX1

P3.0

P1.7/CEX4/SS

P3.3/INT1

P3.2/DIG0/INT0

SSOP24

4134D–8051–02/08

3

Page 4

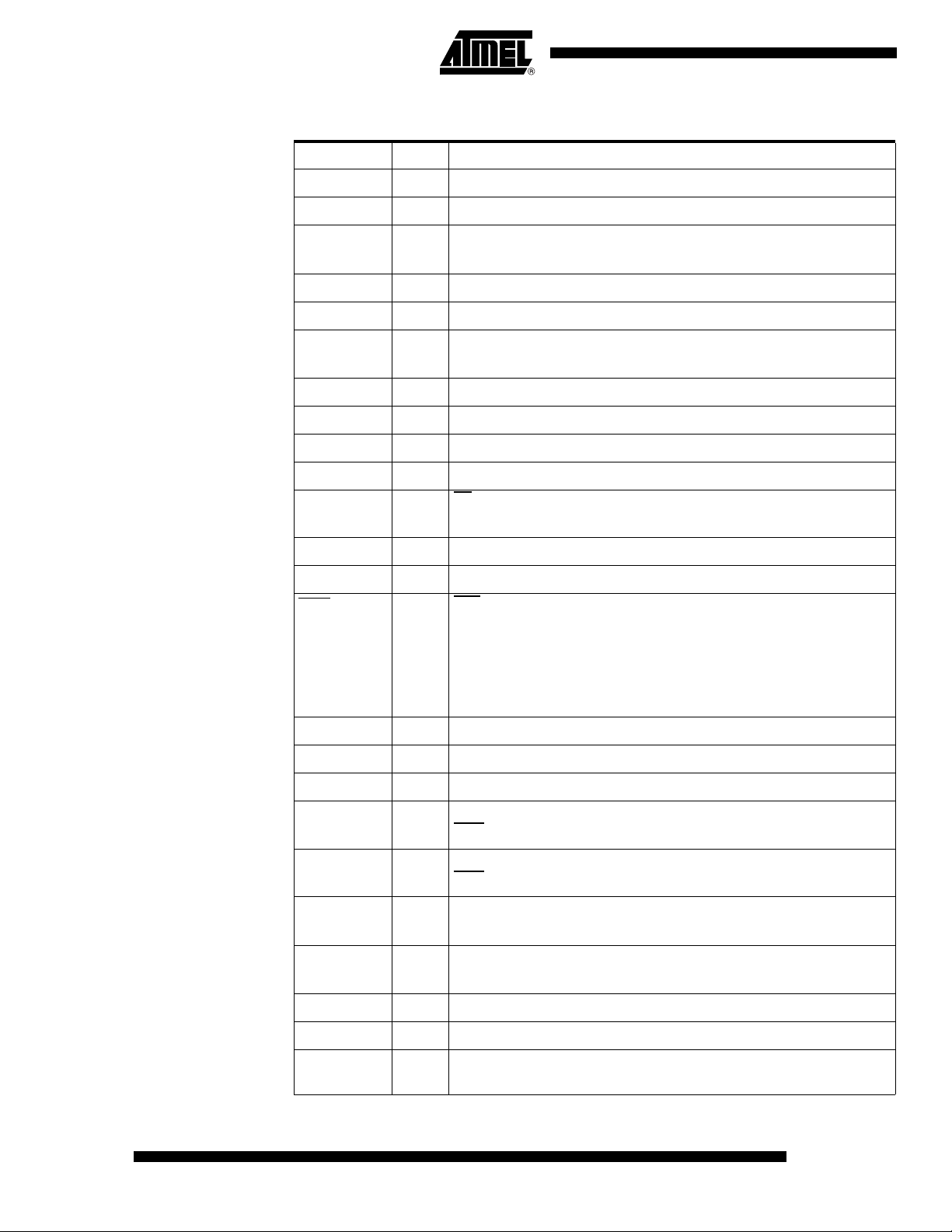

Pin Description

Mnemonic Type Name and Function

V

SS

V

CC

P1.0 - P1.7

I Ground: 0V reference

I Power Supply: 3.0V or 5.5V

Port 1: Port 1 is an 8-bit programmable I/O port with internal pull-up

I/O

Alternate functions for Port 1 include:

I/O MISO (P1.0): Master IN, Slave OUT of the SPI controller

I/O MOSI (P1.1): Master OUT, Slave IN of the SPI controller

DIG2 (P1.2): Programmable as Output with Push-pull

I/O

ECI: External Clock for PCA

I/O CEX0 (P1.3): Capture/Compare External I/O for PCA module 0

I/O CEX1 (P1.4): Capture/Compare External I/O for PCA module 1

I/O CEX2 (P1.5): Capture/Compare External I/O for PCA module 2

I/O CEX3 (P1.6): Capture/Compare External I/O for PCA module 3

SS (P1.7): Slave select input of the SPI controller

I/O

CEX4: Capture/Compare External I/O for PCA module 3

XTAL1 I Input to the inverting oscillator amplifier

XTAL2 O Output from the inverting oscillator amplifier

RST/VPP

RST: Negative Reset input

A low on this pin for two machine cycles while the oscillator is running,

resets the device.

I

This pin will include a pull-down to reset the circuit if no external reset

level is applied.

VPP: High voltage input for OTP programming

P3.0 - P3.7 I/O Port 3: Port 3 is a 8-bit programmable I/O port with internal pull-up.

I/O P3.0: Programmable as Output with Push-pull.

I/O P3.1: Programmable as Output with Push-pull.

DIG0 (P3.2): Programmable as Output with Push-pull.

I/O

INT0: External Interrupt 0

P3.3: Programmable as Output with Push-pull.

I/O

INT1: External Interrupt 1

DIG1 (P3.4): Programmable as Output with Push-pull.

I/O

T0: Timer 0 external Input

P3.5: Programmable as Output with Push-pull.

I/O

T1: Timer 1 external Input

I/O SPICK (P3.6): Clock I/O of the SPI controller

I/O P3.7: Programmable as Output with Push-pull.

P4.0-P4.2 I/O

Port 4: Port 4 is an 3-bit I/O port with internal pull-up

4

4134D–8051–02/08

Page 5

Clock

The Errata Sheet core needs only 6 clock periods per machine cycle. This feature,

called ”X2”, provides the following advantages:

• Divides frequency crystals by 2 (cheaper crystals) while keeping the same CPU

power.

• Saves power consumption while keeping the same CPU power (oscillator power

saving).

• Saves power consumption by dividing dynamic operating frequency by 2 in

operating and idle modes.

• Increases CPU power by 2 while keeping the same crystal frequency.

In order to keep the original C51 compatibility, a divider-by-2 is inserted between the

XTAL1 signal and the main clock input of the core (phase generator). This divider may

be disabled by the software.

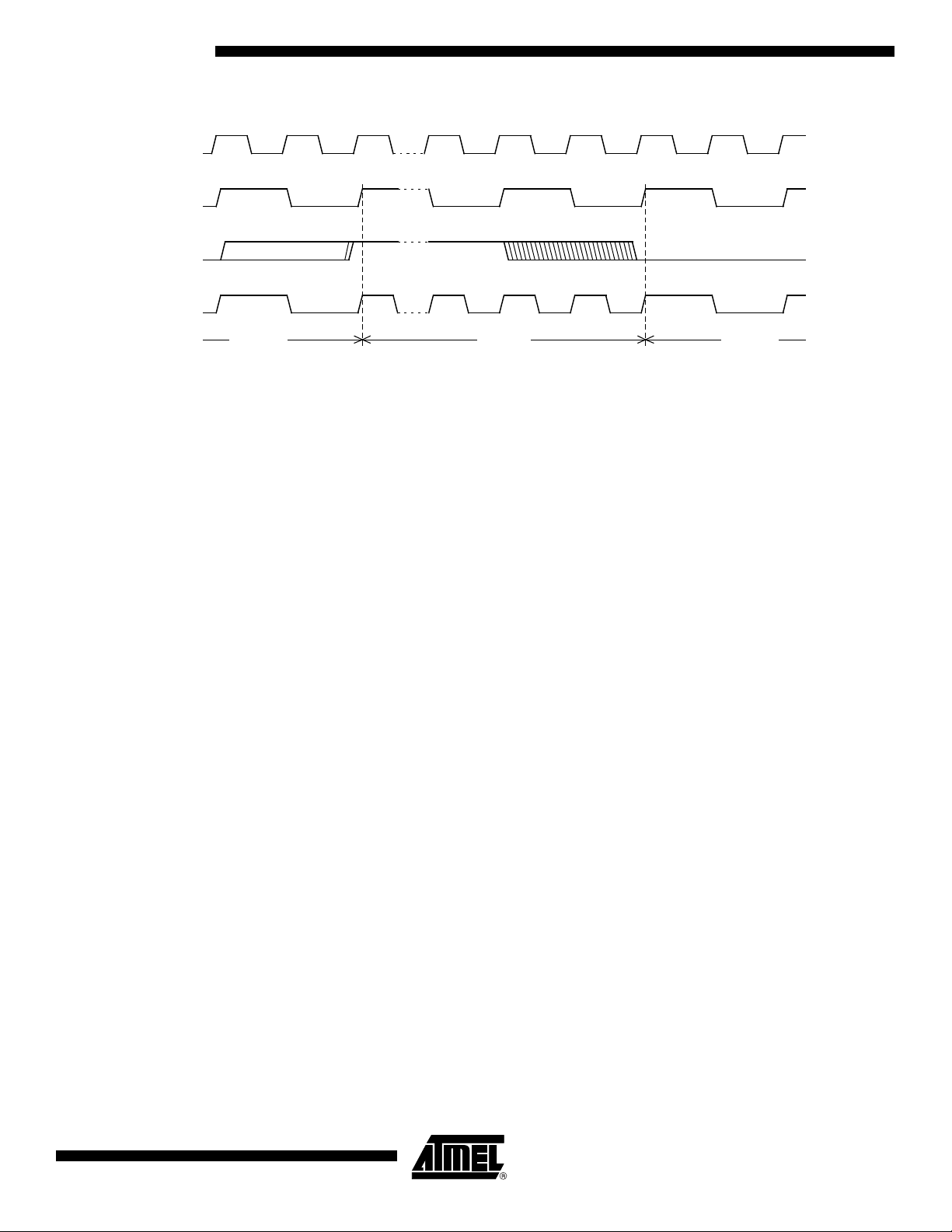

Description

The clock for the whole circuit and peripheral is first divided by 2 before being used by

the CPU core and peripherals. This allows any cyclic ratio to be accepted on the XTAL1

input. In X2 Mode, as this divider is bypassed, the signals on XTAL1 must have a cyclic

ratio between 40 to 60%. Figure 1. shows the clock generation block diagram. The X2

bit is validated on the XTAL1 ÷ 2 rising edge to avoid glitches when switching from the

X2 to the STD mode. Figure 2 shows the mode switching waveforms.

4134D–8051–02/08

5

Page 6

Figure 1. Clock CPU Generation Diagram

XTAL1

XTAL2

PD

PCON.1

1

0

÷

2

FCLK_PERIPH

Peripheral

X2

CKCON.0

CKCON0.7 CKCON0.6

PCAX2

CKCON0.5 CKCON0.4 CKCON0.3

T1X2

CKCON0.2

T0X2

CKCON0.1

IDL

PCON.0

1

0

÷

2

1

0

÷

2

1

0

÷

2

1

0

÷

2

X2

CKCON0.0

FSPI Clock

FPCA Clock

FT1 Clock

FT0 Clock

FCPU

CKCON1.7 CKCON1.6

CKCON1.5

CKCON1.4 CKCON1.3 CKCON1.2

CKCON1.1

SPIX2

CKCON1.0

Clock Symbol

6

4134D–8051–02/08

Page 7

Figure 2. Mode Switching Waveforms

XTAL2

XTAL1

CPU Clock

X2 Bit

X2 ModeSTD Mode STD Mode

The X2 bit in the CKCON register (See Table 1) allows switching from 12 clock cycles

per instruction to 6 clock cycles and vice versa. At reset, the standard speed is activated

(STD mode). Setting this bit activates the X2 feature (X2 Mode).

Note: In order to prevent any incorrect operation while operating in the X2 Mode, users must be

aware that all peripherals using the clock frequency as a time reference (timers, PCA,

SPI) will have their time reference divided by 2. For example, a free running timer generating an interrupt every 20 ms will then generate an interrupt every 10 ms.

4134D–8051–02/08

7

Page 8

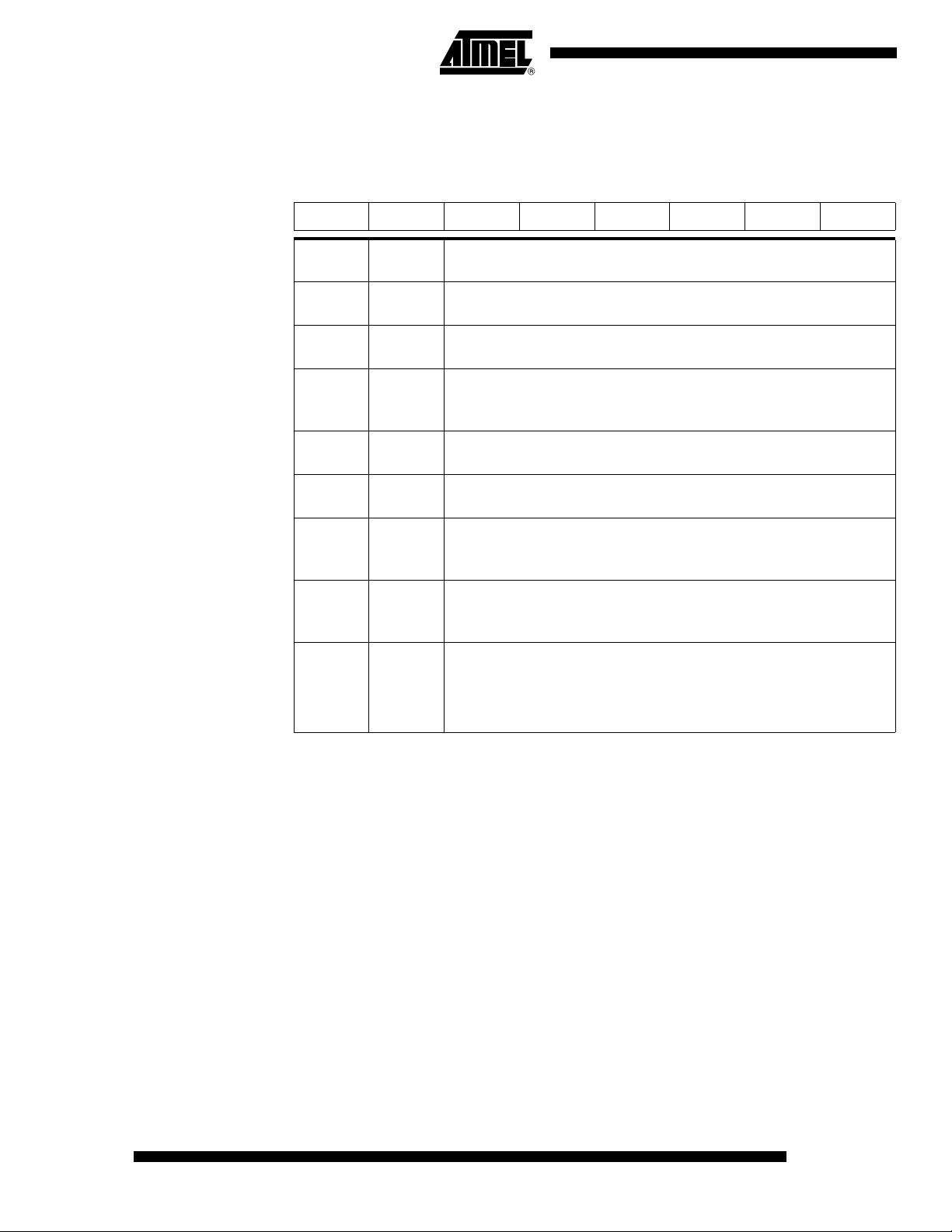

Registers

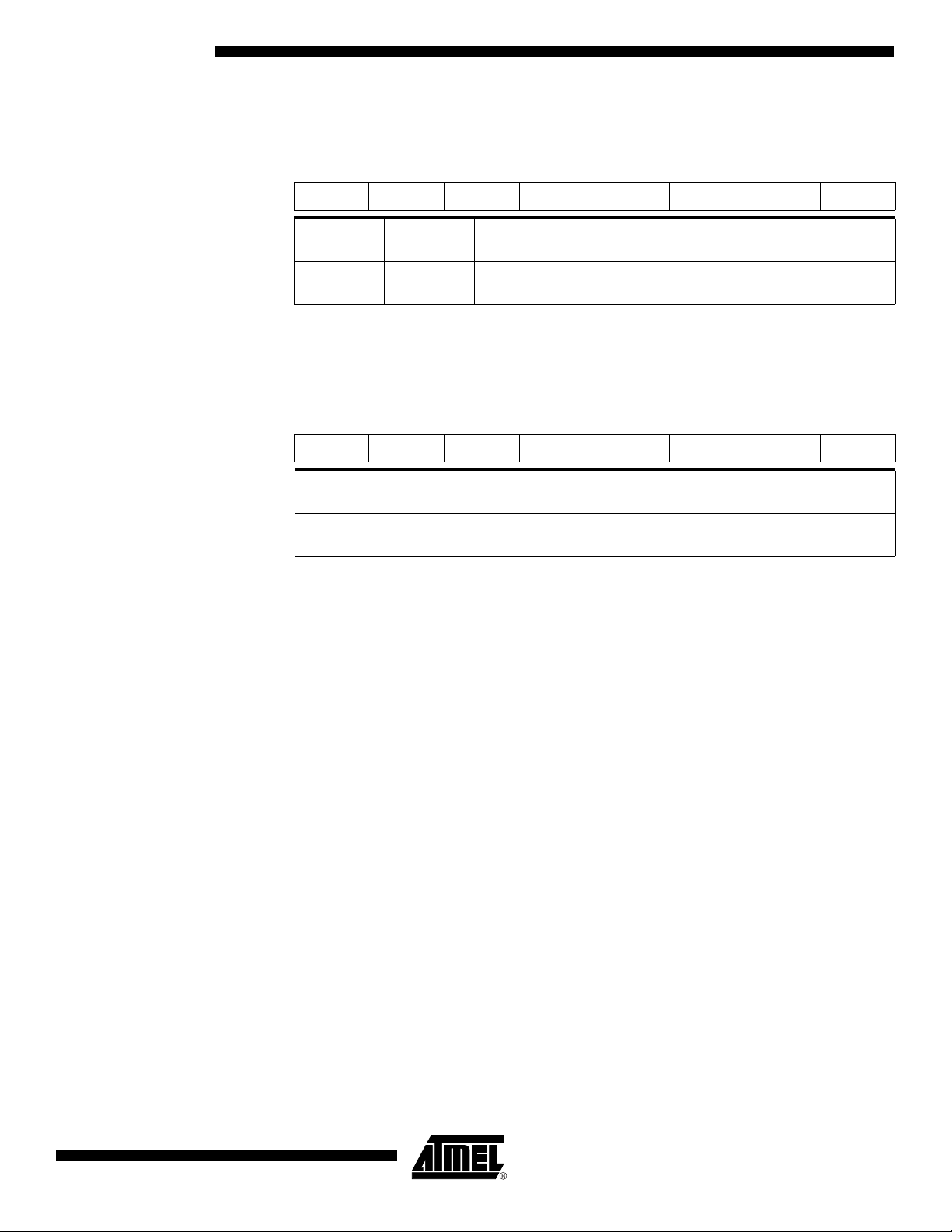

Table 1. CKCON0 Register

CKCON0 (S:8Fh)

Clock Control Register

7 6 5 4 3 2 1 0

PCAX2 T1X2 T0X2 X2

Bit

Number

7 –

6 –

5 PCAX2

4 –

3 –

2 T1X2

1 T0X2

0 X2

Bit

Mnemonic Description

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Programmable Counter Array clock

Clear to select 6 clock periods per peripheral clock cycle.

Set to select 12 clock periods per peripheral clock cycle.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Timer1 Clock

Clear to select 6 clock periods per peripheral clock cycle.

Set to select 12 clock periods per peripheral clock cycle.

Timer0 Clock

Clear to select 6 clock periods per peripheral clock cycle.

Set to select 12 clock periods per peripheral clock cycle.

CPU Clock

Clear to select 12 clock periods per machine cycle (STD mode) for CPU and all

the peripherals.

Set to select 6 clock periods per machine cycle (X2 Mode) and to enable the

individual peripherals "X2" bits.

(1)

(1)

(1)

Note: 1. This control bit is validated when the CPU clock bit X2 is set; when X2 is low, this bit

has no effect.

Reset Value = XX0X X000b

8

4134D–8051–02/08

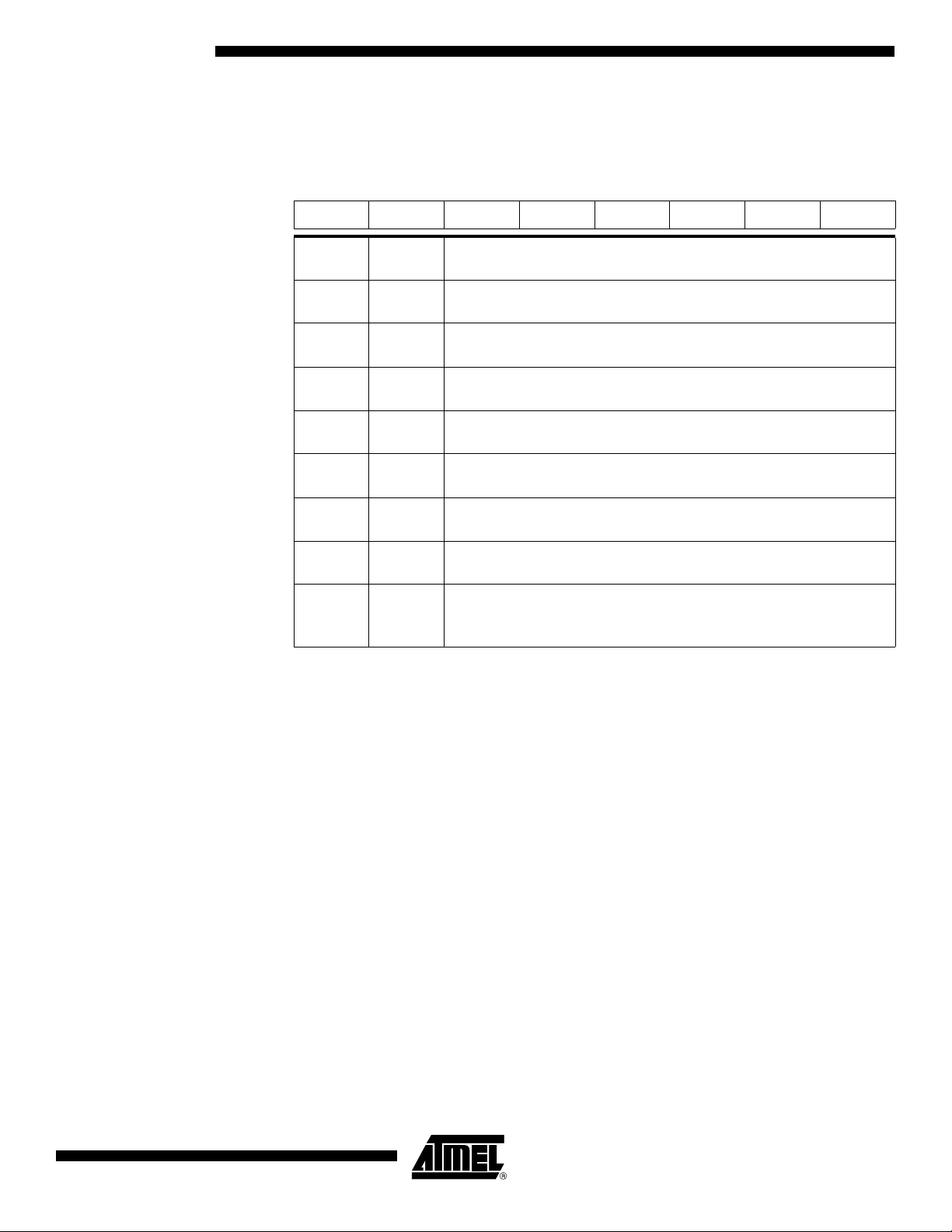

Page 9

Table 2. CKCON1 Register

CKCON1 (S:AFh)

Clock Control Register

7 6 5 4 3 2 1 0

SPIX2

Bit

Number

7 –

6 –

5 –

4 –

3 –

2 –

1 –

0 SPIX2

Bit

Mnemonic Description

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

SPI clock

Clear to select 6 clock periods per peripheral clock cycle.

Set to select 12 clock periods per peripheral clock cycle.

(1)

Note: 1. This control bit is validated when the CPU clock bit X2 is set; when X2 is low, this bit

has no effect.

Reset Value = XXXX XXX0b

4134D–8051–02/08

9

Page 10

SFR Mapping

The Special Function Registers (SFRs) of the AT8xC5103 belong to the following

categories:

• C51 core registers: ACC, B, DPH, DPL, PSW, SP, AUXR1

• I/O port registers: P1, P3, P4, P1M1, P1M2, P3M1, P3M2

• Timer registers: TCON, TH0, TH1, TMOD, TL0, TL1

• Power and clock control registers: CKCON0, CKCON1, PCON

• Interrupt system registers: IE, IE1, IPL0, IPL1, IPH0, IPH1

• SPI: SPCON, SPSTA, SPDAT

• PCA: CCAP0L, CCAP1L, CCAP2L, CCAP3L, CCAP4L, CCAP0H, CCAP1H,

CCAP2H, CCAP3H, CCAP4H, CCAPM0, CCAPM1, CCAPM2, CCAPM3,

CCAPM4, CL, CH, CMOD, CCON

10

4134D–8051–02/08

Page 11

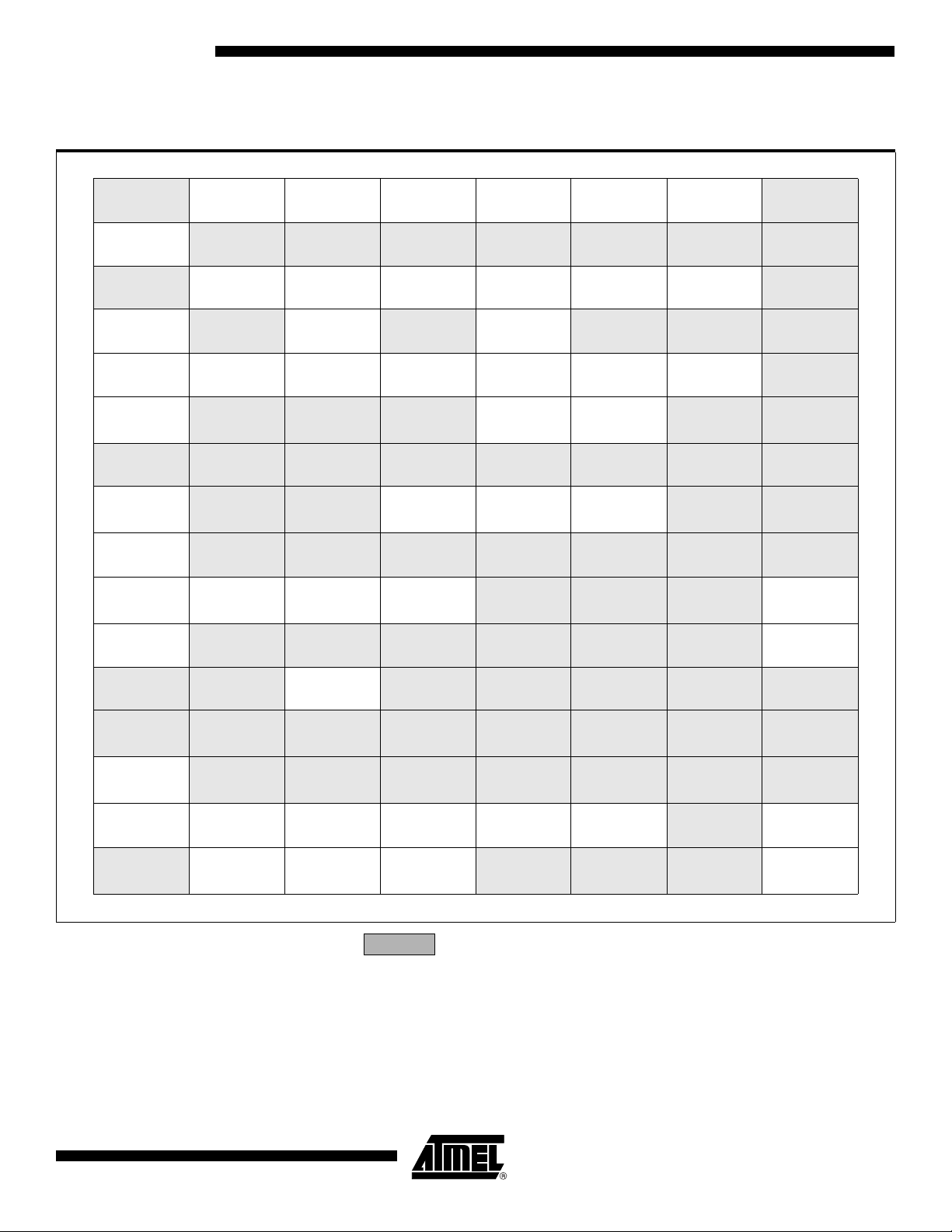

Table 3. SFR Addresses and Reset Values

0/8 1/9 2/A 3/B 4/C 5/D 6/E 7/F

F8h

F0h

E8h

E0h

D8h

D0h

C8h

C0h

B8h

B0h

A8h

B

0000 0000

ACC

0000 0000

CCON

00X0 0000

PSW

0000 0000

P4

XXXX X111

IPL0

X0XX 0000

P3

1111 1111

IE0

00XX 0000

CH

0000 0000

CL

0000 0000

CMOD

00XX X000

IE1

XXXX X0XX

CCAP0H

0000 0000

CCAP0L

0000 0000

P1M2

0000 0000

CCAPM0

X000 0000

IPL1

XXXX X0XX

CCAP1H

0000 0000

CCAP1L

0000 0000

CCAPM1

X000 0000

SPCON

0001 0100

IPH1

XXXX X0XX

CCAP2H

0000 0000

CCAP2L

0000 0000

P3M2

0000 0000

CCAPM2

X000 0000

P1M1

0000 0000

SPSTA

00X0 XXXX

CCAP3H

0000 0000

CCAP3L

0000 0000

CCAPM3

X000 0000

P3M1

0000 0000

SPDAT

XXXX XXXX

CCAP4H

0000 0000

CCAP4L

0000 0000

CCAPM4

X000 0000

IPH0

X0XX 0000

CKCON1

XXXX XXX0

FFh

F7h

EFh

E7h

DF

h

D7h

CF

h

C7h

BFh

B7h

AFh

A0h

98h 9Fh

90h

88h

80h

P1

1111 1111

TCON

0000 0000

0/8 1/9 2/A 3/B 4/C 5/D 6/E 7/F

TMOD

0000 0000

SP

0000 0111

AUXR1

XXXXX0X0

TL0

0000 0000

DPL

0000 0000

TL1

0000 0000

DPH

0000 0000

TH0

0000 0000

TH1

0000 0000

CKCON0

XX0X X000b

PCON

XXX1 0000

A7h

97h

8Fh

87h

Reserved

4134D–8051–02/08

11

Page 12

Ports

Port Types

The AT8xC5103 has 3 I/O ports, port 1, port 3 and port 4.

Except RST, and port 4, all port 1 and port 3 I/O port pins on the AT8xC5103 may be

software configured to one of four types on a bit-by-bit basis, as shown in Table 2 These

are: quasi-bi-directional (standard 80C51 port outputs), push-pull, open drain, and input

only. Two configuration registers for each port choose the output type for each port pin.

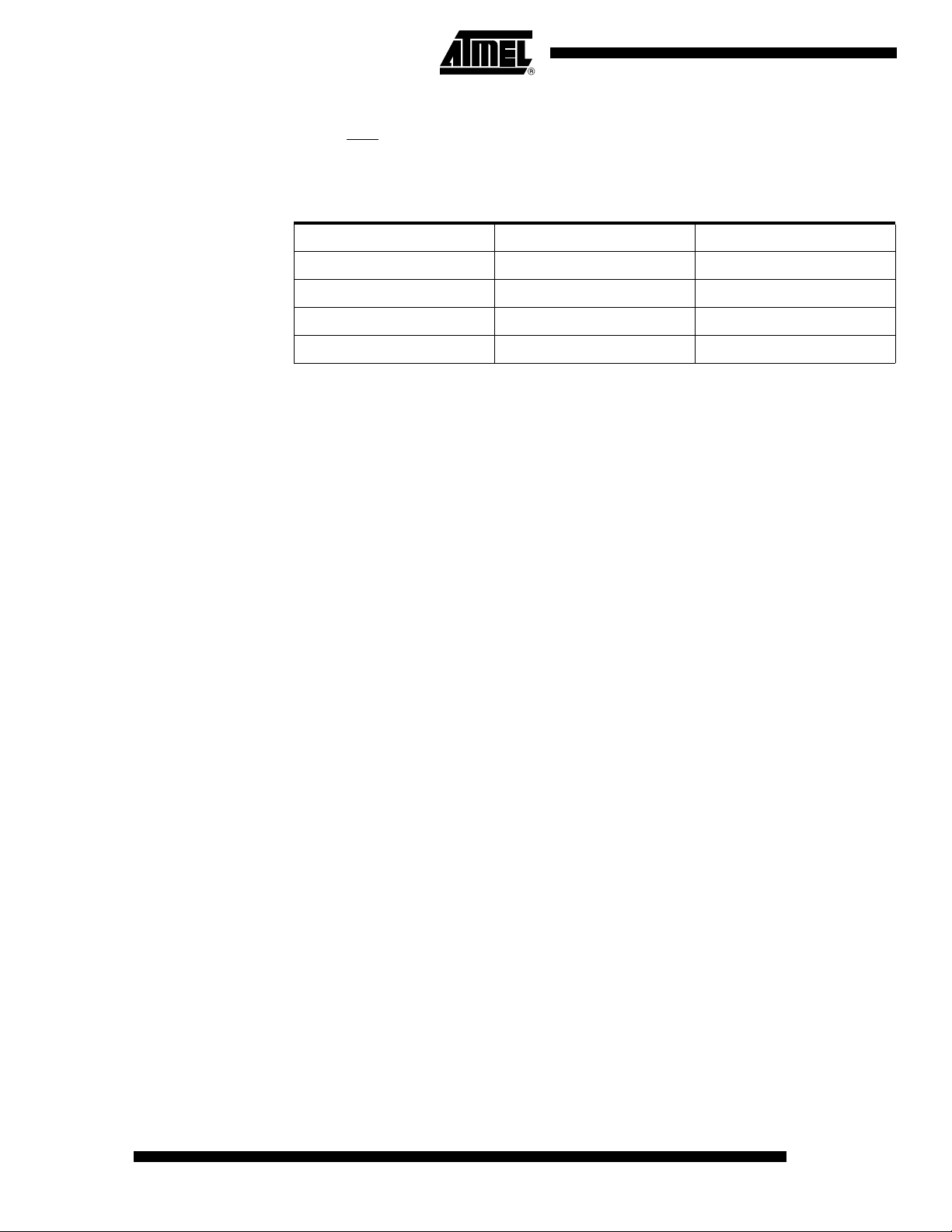

PxM1.y BIt PxM2.y Bit Port Output Mode

0 0 Quasi bi-directional

0 1 Push-pull

1 0 Input Only (High Impedance)

1 1 Open Drain

Quasi-Bi-directional Output Configuration

The default port output configuration for standard AT8xC5103 I/O ports is the quasi-bidirectional output that is common on the 80C51 and most of its derivatives. This output

type can be used as both an input and output without the need to reconfigure the port.

This is possible because when the port outputs a logic high, it is weakly driven, allowing

an external device to pull the pin low. When the pin is pulled low, it is driven strongly and

able to sink a fairly large current. These features are somewhat similar to an open drain

output except that there are three pull-up transistors in the quasi-bi-directional output

that serve different purposes. One of these pull-ups, called the ‘very weak’ pull-up, is

turned on whenever the port latch for the pin contains a logic 1. The very weak pull-up

sources a very small current that will pull the pin high if it is left floating. A second pullup, called the ‘weak’ pull-up, is turned on when the port latch for the pin contains a logic

1 and the pin itself is also at a logic 1 level. This pull-up provides the primary source current for a quasi-bi-directional pin that is outputting a 1. If a pin that has a logic 1 on it is

pulled low by an external device, the weak pull-up turns off, and only the very weak pullup remains on. In order to pull the pin low under these conditions, the external device

has to sink enough current to overpower the weak pull-up and take the voltage on the

port pin below its input threshold.

The third pull-up is referred to as the ‘strong’ pull-up. This pull-up is used to speed up

low-to-high transitions on a quasi-bi-directional port pin when the port latch changes

from a logic 0 to a logic 1. When this occurs, the strong pull-up turns on for a brief time,

two CPU clocks, in order to pull the port pin high quickly. Then it turns off again.

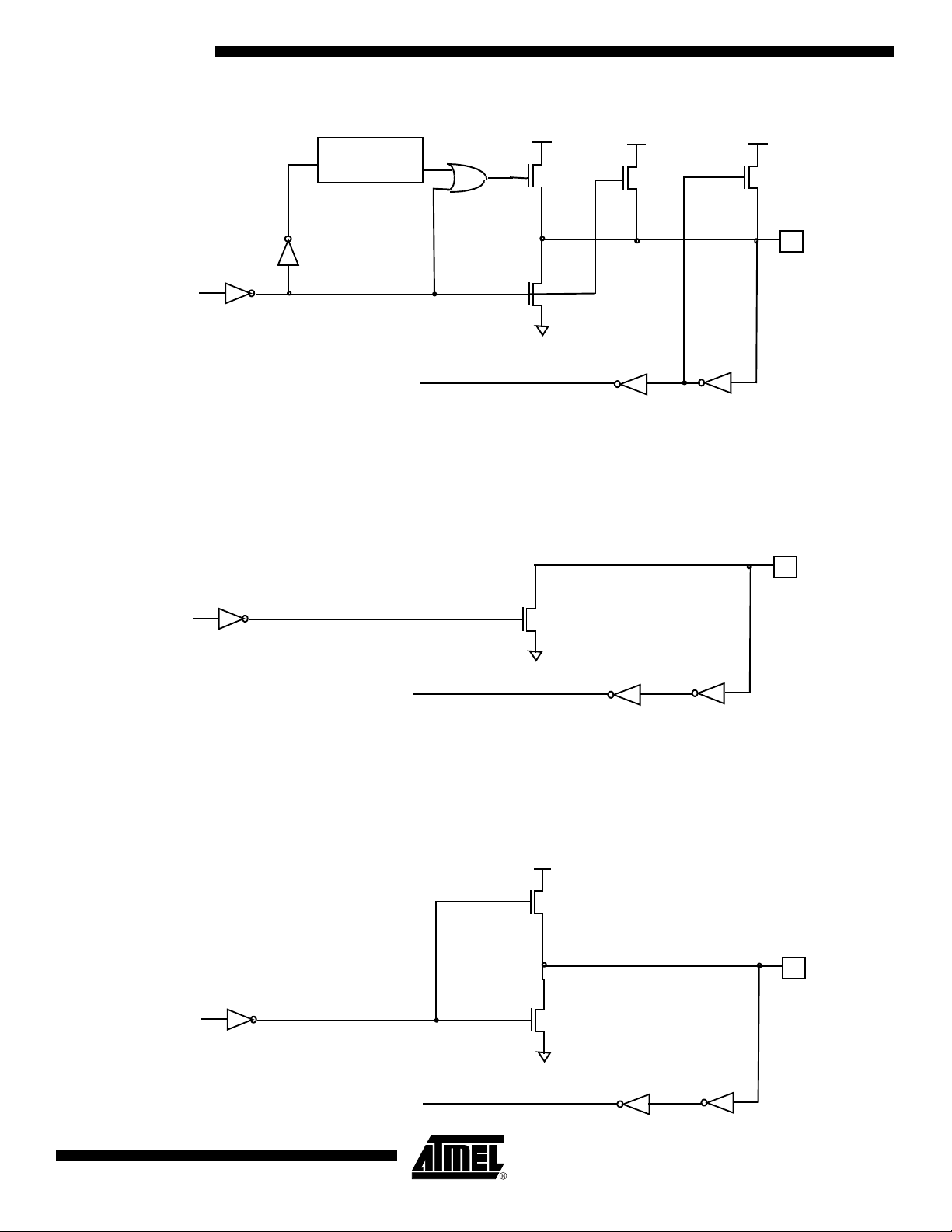

The quasi-bi-directional port configuration is shown in Figure 3.

12

4134D–8051–02/08

Page 13

Figure 3. Quasi-Bi-directional Output

2 CPU

Input

Pin

Strong

Very

Weak

N

P

P

Weak

P

Clock Delay

Port latch

Data

Data

Input

Pin

N

Port latch

Data

Data

Input

Pin

Strong

N

P

Port Latch

Data

Data

Open Drain Output Configuration

Figure 4. Open Drain Output

Push-Pull Output Configuration

Figure 5. Push-pull Output

The open-drain output configuration turns off all pull-ups and only drives the pull-down

transistor of the port driver when the port latch contains a logic 0. To be used as a logic

output, a port configured in this manner must have an external pull-up, typically a resistor tied to VDD. The pull-down for this mode is the same as for the quasi-bi-directional

mode. The open drain port configuration is shown in Figure 4.

The push-pull output configuration has the same pull-down structure as both the open

drain and the quasi-bi-directional output modes, but provides a continuous strong pullup when the port latch contains a logic 1. The push-pull mode may be used when more

source current is needed from a port output. The push-pull port configuration is shown in

Figure 5.

4134D–8051–02/08

13

Page 14

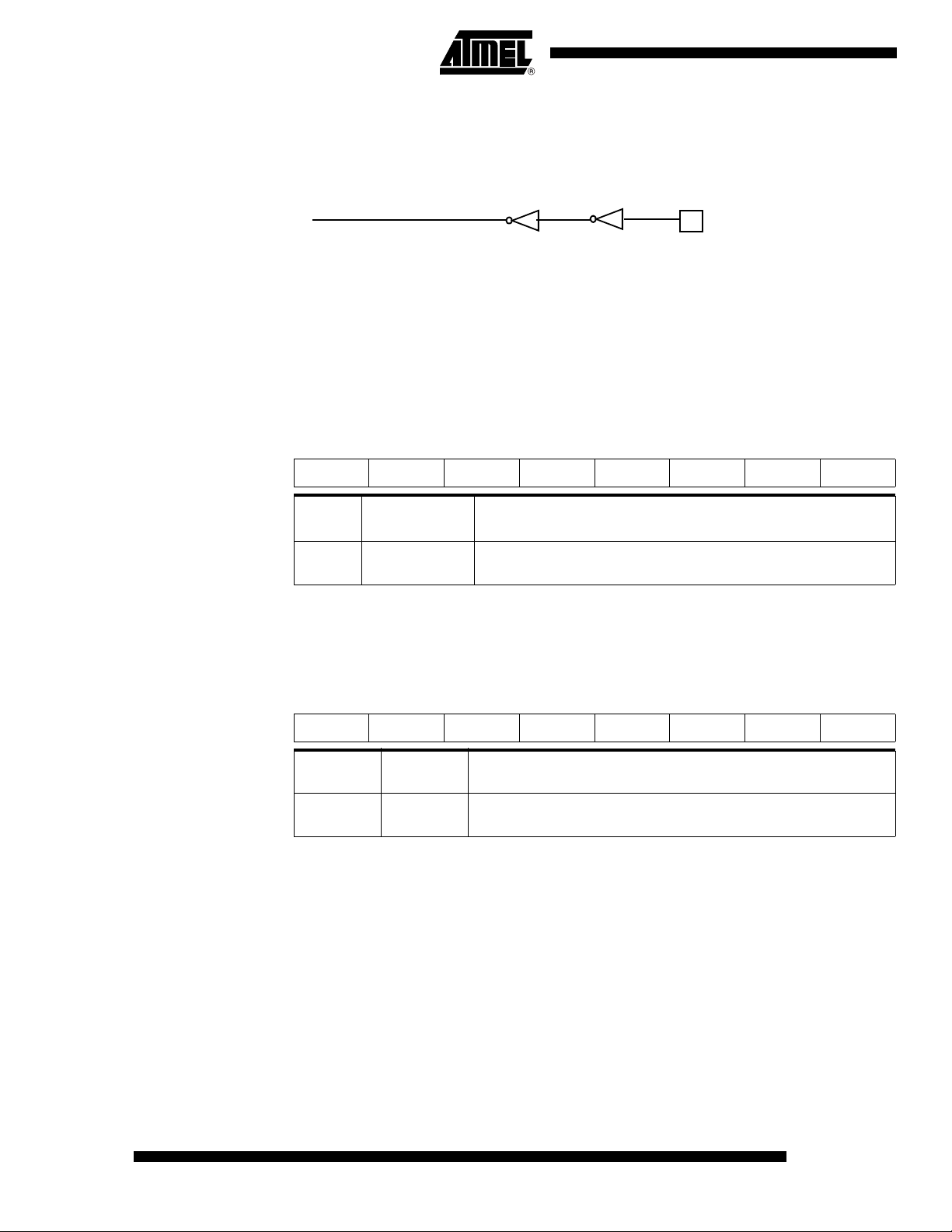

Input Only Configuration The input only configuration is a pure input with neither pull-up nor pull-down.

Input

Pin

Data

The input only configuration is shown in Figure 6.

Figure 6. Input Only

Ports Description

Ports P1 and P3

The inputs of each I/O port of the AT8xC5103 are TTL level Schmitt triggers with

hysteresis.

Registers Table 4. P1M1 Register

P1M1 Address (D4h)

7 6 5 4 3 2 1 0

P1M1.7 P1M1.6 P1M1.5 P1M1.4 P1M1.3 P1M1.2 P1M1.1 P1M1.0

Bit

Number

0-7 P1M1.x

Bit

Mnemonic Description

Reset Value = 0000 0000

Table 5. P1M2 Register

P1M2 Address (E2h)

7 6 5 4 3 2 1 0

P1M2.7 P1M2.6 P1M2.5 P1M2.4 P1M2.3 P1M2.2 P1M2.1 P1M2.0

Bit

Bit Number

Mnemonic Description

Port Output configuration Bit

See Table 2 for configuration definition

14

0-7 P1M2.x

Reset Value = 0000 0000

Port Output configuration bit

See Table 2 for configuration definition

4134D–8051–02/08

Page 15

Table 6. P3M1 Register

P3M1 Address (D5h)

7 6 5 4 3 2 1 0

P3M1.7 P3M1.6 P3M1.5 P3M1.4 P3M1.3 P3M1.2 P3M1.1 P3M1.0

Bit Number

0-7 P3M1.x

Bit

Mnemonic Description

Port Output configuration bit

See Table 2 for configuration definition

Reset Value = 0000 0000

Table 7. P3M2 Register

P3M2 Address (E4h)

7 6 5 4 3 2 1 0

P3M2.7 P3M2.6 P3M2.5 P3M2.4 P3M2.3 P3M2.2 P3M2.1 P3M2.0

Bit Number

0-7 P3M2.x

Bit

Mnemonic Description

Port Output configuration bit

See Table 2 for configuration definition

Reset Value = 0000 0000

4134D–8051–02/08

15

Page 16

Dual-data Pointer

External Data Memory

AUXR1(A2H)

DPS

DPH(83H) DPL(82H)

07

DPTR0

DPTR1

Register (DPTR)

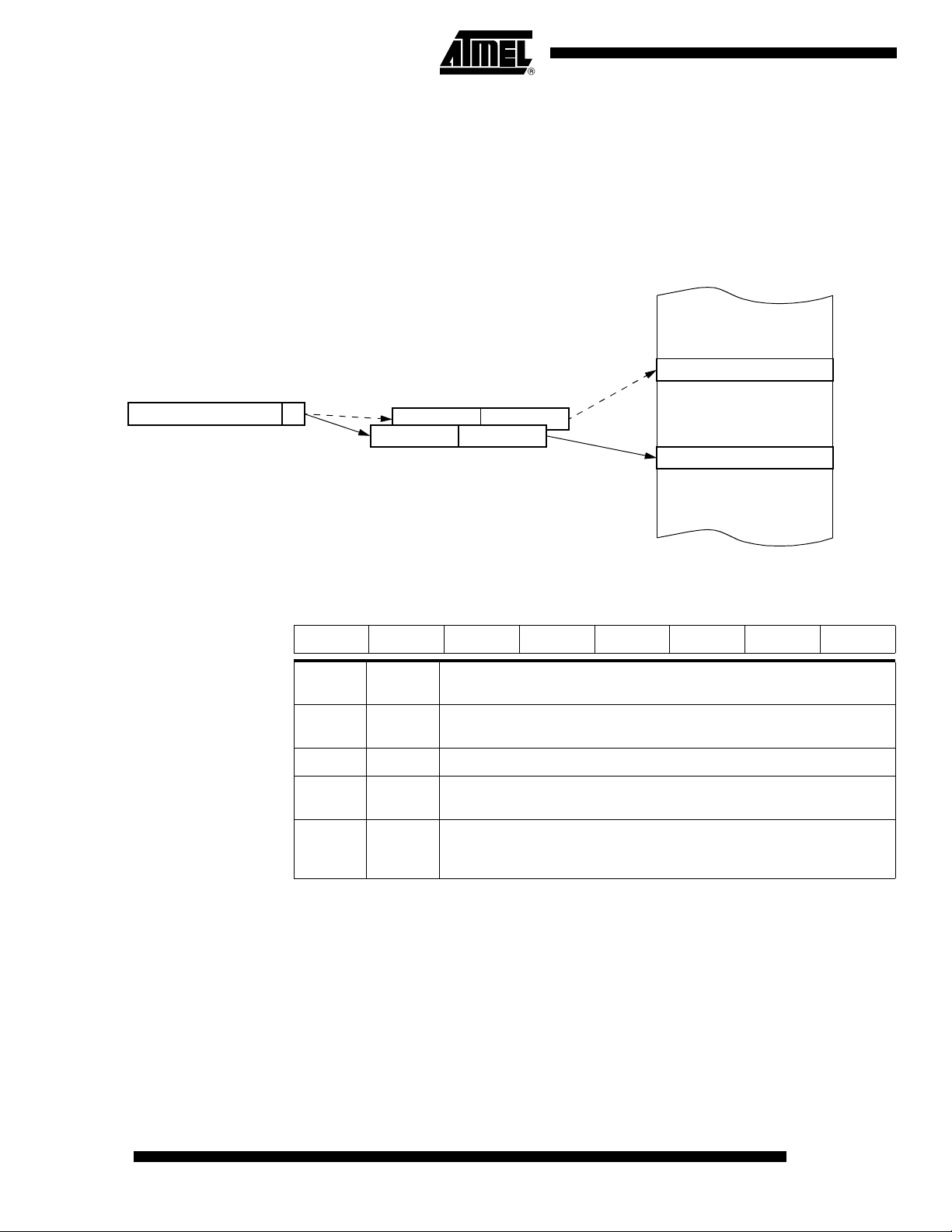

Figure 7. Use of Dual-data Pointer

The additional data pointer can be used to speed up code execution and reduce code

size in a number of ways.

The dual DPTR structure is a way by which the device will specify the address of an

external data memory location. There are two 16-bit DPTR registers that address the

external memory, and a single bit called DPS = AUXR1/bit0 (see Table 8) that allows

the program code to switch between them (Refer to Figure 7).

Table 8. AUXR1: Auxiliary Register 1

7 6 5 4 3 2 1 0

- - - - - 0 - DPS

Bit

Number

7-3 -

2 0 always stuck at 0

1 -

0 DPS

Bit

Mnemonic Description

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Data Pointer Selection

Clear to select DPTR0.

Set to select DPTR1.

(1)

Reset Value = XXXX X0X0

Note: 1. User software should not write 1s to reserved bits. These bits may be used in future

8051 family products to invoke new features. In that case, the reset value of the new

bit will be 0, and its active value will be 1. The value read from a reserved bit is

indeterminate.

16

4134D–8051–02/08

Page 17

Application

Software can take advantage of the additional data pointers to both increase speed and

reduce code size, for example, block operations (copy, compare, search...) are well

served by using one data pointer as a ’source’ pointer and the other one as a "destination" pointer.

ASSEMBLY LANGUAGE

; Block move using dual data pointers

; Destroys DPTR0, DPTR1, A and PSW

; note: DPS exits opposite of entry state

; unless an extra INC AUXR1 is added

;

00A2 AUXR1 EQU 0A2H

;

0000 909000MOV DPTR,#SOURCE ; address of SOURCE

0003 05A2 INC AUXR1 ; switch data pointers

0005 90A000 MOV DPTR,#DEST ; address of DEST

0008 LOOP:

0008 05A2 INC AUXR1 ; switch data pointers

000A E0 MOVX A,@DPTR ; get a byte from SOURCE

000B A3 INC DPTR ; increment SOURCE address

000C 05A2 INC AUXR1 ; switch data pointers

000E F0 MOVX @DPTR,A ; write the byte to DEST

000F A3 INC DPTR ; increment DEST address

0010 70F6JNZ LOOP ; check for 0 terminator

0012 05A2 INC AUXR1 ; (optional) restore DPS

INC is a short (2 bytes) and fast (12 clocks) way to manipulate the DPS bit in the AUXR1

SFR. However, note that the INC instruction does not directly force the DPS bit to a particular state, but simply toggles it. In simple routines, such as the block move example,

only the fact that DPS is toggled in the proper sequence matters, not its actual value. In

other words, the block move routine works the same whether DPS is “0” or “1” on entry.

Observe that without the last instruction (INC AUXR1), the routine will exit with DPS in

the opposite state.

4134D–8051–02/08

17

Page 18

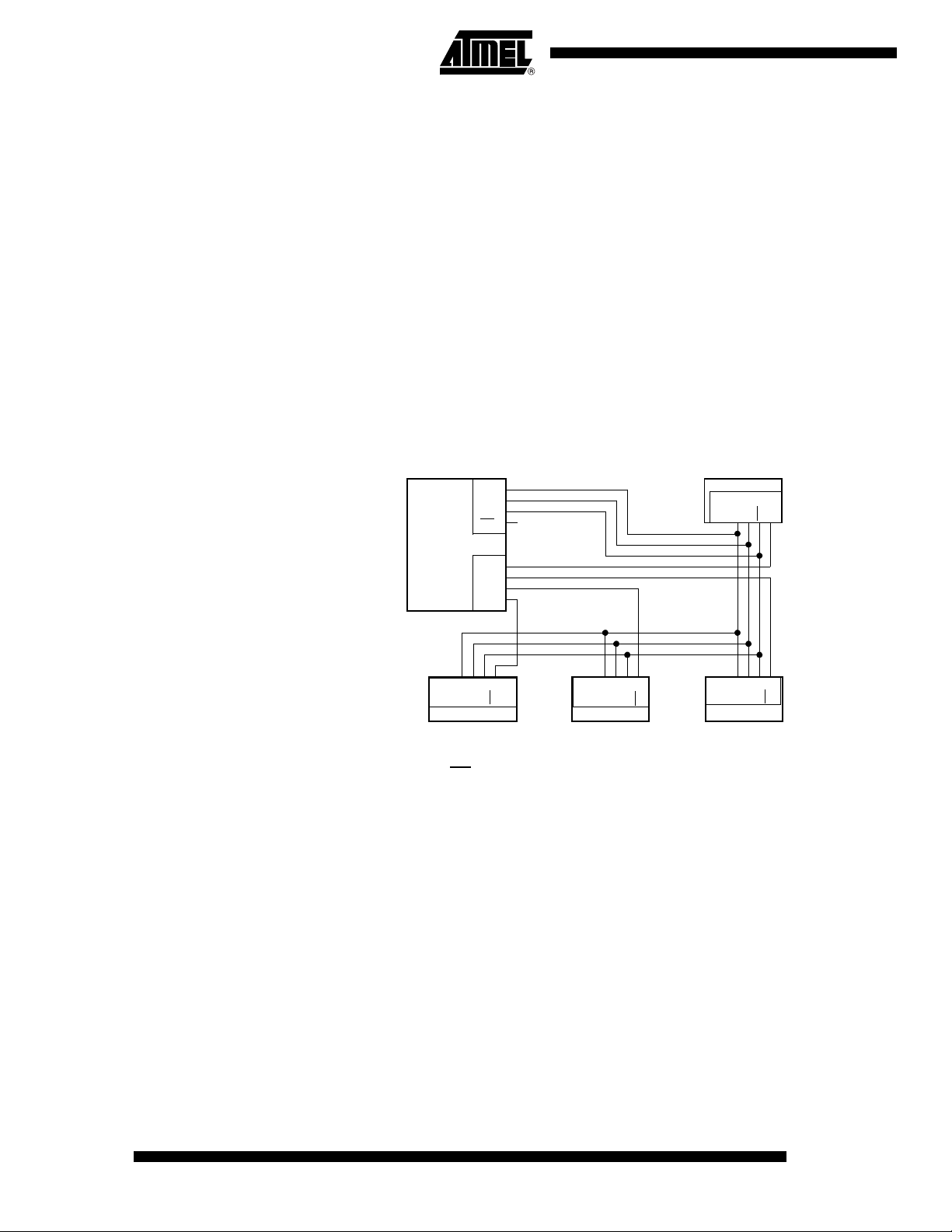

Serial Port Interface

Slave 1

MISO

MOSI

SCK

SS

MISO

MOSI

SCK

SS

PORT

0

1

2

3

Slave 3

MISO

MOSI

SCK

SS

Slave 4

MISO

MOSI

SCK

SS

Slave 2

MISO

MOSI

SCK

SS

V

DD

Master

(SPI)

The Serial Peripheral Interface module (SPI) which allows full-duplex, synchronous,

serial communication between the MCU and peripheral devices, including other MCUs.

Features

Signal Description

Features of the SPI module include the following:

• Full-duplex, three-wire synchronous transfers

• Master or Slave operation

• Eight programmable Master clock rates

• Serial clock with programmable polarity and phase

• Master Mode fault error flag with MCU interrupt capability

• Write collision flag protection

Figure 8 shows a typical SPI Bus configuration using one Master controller and many

Slave peripherals. The bus is made of three wires connecting all the devices.

Figure 8. Typical SPI Bus

The Master device selects the individual Slave devices by using four pins of a parallel

port to control the four SS pins of the Slave devices.

Master Output Slave Input (MOSI)

This 1-bit signal is directly connected between the Master device and a Slave device.

The MOSI line is used to transfer data in series from the Master to the Slave. Therefore,

it is an output signal from the Master, and an input signal to a Slave. A byte (8-bit word)

is transmitted most significant bit (MSB) first, least significant bit (LSB) last.

Master Input Slave Output (MISO)

This 1-bit signal is directly connected between the Slave device and a Master device.

The MISO line is used to transfer data in series from the Slave to the Master. Therefore,

it is an output signal from the Slave, and an input signal to the Master. A byte (8-bit

word) is transmitted most significant bit (MSB) first, least significant bit (LSB) last.

SPI Serial Clock (SCK) This signal is used to synchronize the data movement both in and out the devices

through their MOSI and MISO lines. It is driven by the Master for eight clock cycles

which allows to exchange one byte on the serial lines.

18

4134D–8051–02/08

Page 19

Slave Select (SS) Each Slave peripheral is selected by one Slave Select pin (SS). This signal must stay

low for any message for a Slave. It is obvious that only one Master (SS high level) can

drive the network. The Master may select each Slave device by software through port

pins (Figure 8). To prevent bus conflicts on the MISO line, only one slave should be

selected at a time by the Master for a transmission.

In a Master configuration, the SS line can be used in conjunction with the MODF flag in

the SPI Status register (SPSTA) to prevent multiple masters from driving MOSI and

SCK (See Error Conditions).

A high level on the SS pin puts the MISO line of a Slave SPI in a high-impedance state.

The SS pin could be used as a general purpose if the following conditions are met:

• The device is configured as a Master and the SSDIS control bit in SPCON is set.

This kind of configuration can be found when only one Master is driving the network

and there is no way that the SS pin will be pulled low. Therefore, the MODF flag in

the SPSTA will never be set

• The Device is configured as a Slave with CPHA and SSDIS control bits set

(1)

.

(2)

. This

kind of configuration can happen when the system comprises one Master and one

Slave only. Therefore, the device should always be selected and there is no reason

that the Master uses the SS pin to select the communicating Slave device.

Baud Rate In Master Mode, the baud rate can be selected from a baud rate generator which is con-

trolled by three bits in the SPCON register: SPR2, SPR1 and SPR0. The Master clock is

chosen from one of six clock rates resulting from the division of the internal clock by 4, 8,

16, 32, 64 or 128.

Table 9 gives the different clock rates selected by SPR2:SPR1:SPR0:

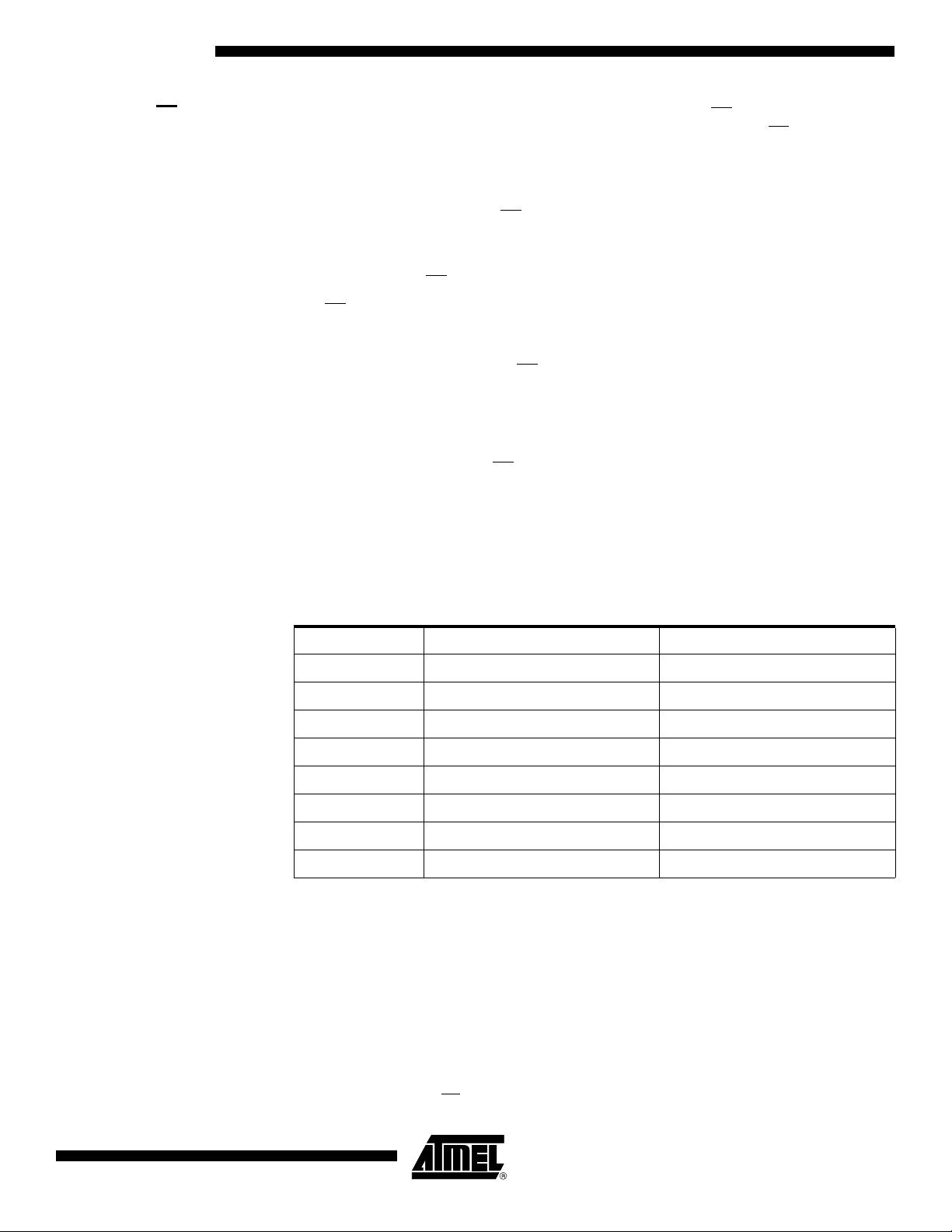

Table 9. SPI Master Baud Rate Selection

SPR2:SPR1:SPR0 Clock Rate Baud Rate Divisor (BD)

000 Don’t Use No BRG

001 F

010 F

011 F

100 F

101 F

110 F

111 Don’t Use No BRG

CLK_PERIPH

CLK_PERIPH

CLK_PERIPH

CLK_PERIPH

CLK_PERIPH

CLK_PERIPH

/4 4

/8 8

/16 16

/32 32

/64 64

/128 128

4134D–8051–02/08

1. Clearing SSDIS control bit does not clear MODF.

2. Special care should be taken not to set SSDIS control bit when CPHA = “0” because in

this mode, the SS is used to start the transmission.

19

Page 20

Functional Description

Shift Register

01

234567

Internal Bus

Pin

Control

Logic

MISO

MOSI

SCK

M

S

Clock

Logic

Clock

Divider

Clock

Select

/4

/64

/128

SPI Interrupt Request

8-bit bus

1-bit signal

SS

IntClk

/32

/8

/16

Receive Data Register

SPDAT

SPI

Control

SPSTA

CPHA

SPR0

SPR1

CPOLMSTRSSDISSPENSPR2

SPCON

WCOL MODFSPIF

-

- - - -

Figure 9 shows a detailed structure of the SPI module.

Figure 9. SPI Module Block Diagram

Operating Modes The Serial Peripheral Interface can be configured as one of the two modes: Master

Mode or Slave Mode. The configuration and initialization of the SPI module is made

through one register:

• The Serial Peripheral Control register (SPCON)

Once the SPI is configured, the data exchange is made using:

• SPCON

• The Serial Peripheral Status register (SPSTA)

• The Serial Peripheral Data register (SPDAT)

During an SPI transmission, data is simultaneously transmitted (shifted out serially) and

received (shifted in serially). A serial clock line (SCK) synchronizes shifting and sampling on the two serial data lines (MOSI and MISO). A Slave Select line (SS) allows

individual selection of a Slave SPI device; Slave devices that are not selected do not

interfere with SPI bus activities.

When the Master device transmits data to the Slave device via the MOSI line, the Slave

device responds by sending data to the Master device via the MISO line. This implies

full-duplex transmission with both data out and data in synchronized with the same clock

(Figure 10).

20

4134D–8051–02/08

Page 21

Figure 10. Full-Duplex Master-Slave Interconnection

8-bit Shift Register

SPI

Clock Generator

Master MCU

8-bit Shift Register

MISOMISO

MOSI

MOSI

SCK SCK

VSS

V

DD

SSSS

Slave MCU

Master Mode The SPI operates in Master Mode when the Master bit, MSTR

is set. Only one Master SPI device can initiate transmissions. Software begins the transmission from a Master SPI module by writing to the Serial Peripheral Data Register

(SPDAT). If the shift register is empty, the byte is immediately transferred to the shift

register. The byte begins shifting out on MOSI pin under the control of the serial clock,

SCK. Simultaneously, another byte shifts in from the Slave on the Master’s MISO pin.

The transmission ends when the Serial Peripheral transfer data flag, SPIF, in SPSTA

becomes set. At the same time that SPIF becomes set, the received byte from the Slave

is transferred to the receive data register in SPDAT. Software clears SPIF by reading

the Serial Peripheral Status register (SPSTA) with the SPIF bit set, and then reading the

SPDAT.

When the pin SS is pulled down during a transmission, the data is interrupted and when

the transmission is established again, the data present in the SPDAT is resent.

Slave Mode The SPI operates in Slave Mode when the Master bit, MSTR

(2)

cleared. Before a data transmission occurs, the Slave Select pin, SS, of the Slave

device must be set to “0”. SS must remain low until the transmission is complete.

In a Slave SPI module, data enters the shift register under the control of the SCK from

the Master SPI module. After a byte enters the shift register, it is immediately transferred

to the receive data register in SPDAT, and the SPIF bit is set. To prevent an overflow

condition, Slave software must then read the SPDAT before another byte enters the

shift register

(3)

. A Slave SPI must complete the write to the SPDAT (shift register) at

least one bus cycle before the Master SPI starts a transmission. If the write to the data

register is late, the SPI transmits the data already in the shift register from the previous

transmission.

(1)

, in the SPCON register

, in the SPCON register is

Transmission Formats Software can select any of four combinations of serial clock (SCK) phase and polarity

using two bits in the SPCON: the Clock POLarity (CPOL

(CPHA

(4)

). CPOL defines the default SCK line level in idle state. It has no significant

(4)

) and the Clock PHAse

effect on the transmission format. CPHA defines the edges on which the input data are

sampled and the edges on which the output data are shifted (Figure 11 and Figure 12).

The clock phase and polarity should be identical for the Master SPI device and the communicating Slave device.

1. The SPI module should be configured as a Master before it is enabled (SPEN set). Also

the Master SPI should be configured before the Slave SPI.

2. The SPI module should be configured as a Slave before it is enabled (SPEN set).

3. The maximum frequency of the SCK for an SPI configured as a Slave is the bus clock

speed.

4. Before writing to the CPOL and CPHA bits, the SPI should be disabled (SPEN = "0").

4134D–8051–02/08

21

Page 22

Figure 11. Data Transmission Format (CPHA = 0)

MSB bit6 bit5 bit4 bit3 bit2 bit1 LSB

bit6 bit5 bit4 bit3 bit2 bit1MSB LSB

1 32 4 5 6 7 8

Capture Point

SS (to Slave)

MISO (from Slave)

MOSI (from Master)

SCK (CPOL = 1)

SCK (CPOL = 0)

SPEN (Internal)

SCK Cycle Number

MSB bit6 bit5 bit4 bit3 bit2 bit1 LSB

bit6 bit5 bit4 bit3 bit2 bit1

MSB LSB

1 32 4 5 6 7 8

Capture Point

SS (to Slave)

MISO (from Slave)

MOSI (from Master)

SCK (CPOL = 1)

SCK (CPOL = 0)

SPEN (Internal)

SCK Cycle Number

Byte 1 Byte 2

Byte 3

MISO/MOSI

Master SS

Slave SS

(CPHA = 1)

Slave SS

(CPHA = 0)

Figure 12. Data Transmission Format (CPHA = 1)

22

As shown in Figure 11, the first SCK edge is the MSB capture strobe. Therefore, the

Slave must begin driving its data before the first SCK edge, and a falling edge on the SS

pin is used to start the transmission. The SS pin must be toggled high and then low

between each byte transmitted (Figure 13).

Figure 13. CPHA/SS Timing

Figure 12 shows an SPI transmission in which CPHA is “1”. In this case, the Master

begins driving its MOSI pin on the first SCK edge. Therefore the Slave uses the first

SCK edge as a start transmission signal. The SS pin can remain low between transmissions (Figure 13). This format may be preferable in systems having only one Master and

only one Slave driving the MISO data line.

4134D–8051–02/08

Page 23

Error Conditions The following flags in the SPSTA signal SPI error conditions.

Mode Fault (MODF) Mode Fault error in Master Mode SPI indicates that the level on the Slave Select (SS)

pin is inconsistent with the actual mode of the device. MODF is set to warn that there

may have a multi-master conflict for system control. In this case, the SPI system is

affected in the following ways:

• An SPI receiver/error CPU interrupt request is generated.

• The SPEN bit in SPCON is cleared. This disable the SPI.

• The MSTR bit in SPCON is cleared.

When SS DISable (SSDIS) bit in the SPCON register is cleared, the MODF flag is set

when the SS signal becomes “0”.

However, as stated before, for a system with one Master, if the SS pin of the Master

device is pulled low, there is no way that another Master is attempting to drive the network. In this case, to prevent the MODF flag from being set, software can set the SSDIS

bit in the SPCON register and therefore making the SS pin as a general-purpose I/O pin.

Clearing the MODF bit is accomplished by a read of SPSTA register with MODF bit set,

followed by a write to the SPCON register. SPEN Control bit may be restored to its original set state after the MODF bit has been cleared.

Write Collision (WCOL) A Write Collision (WCOL) flag in the SPSTA is set when a write to the SPDAT register is

done during a transmit sequence.

WCOL does not cause an interruption, and the transfer continues uninterrupted.

Clearing the WCOL bit is done through a software sequence of an access to SPSTA

and an access to SPDAT.

Overrun Condition An overrun condition occurs when the Master device tries to send several data bytes

and the Slave device has not cleared the SPIF bit issuing from the previous data byte

transmitted. In this case, the receiver buffer contains the byte sent after the SPIF bit was

last cleared. A read of the SPDAT returns this byte. All others bytes are lost.

This condition is not detected by the SPI peripheral.

SS Error Flag (SSERR) A Synchronous Serial Slave Error occurs when SS goes high before the end of a

received data in Slave Mode. SSERR does not cause in interruption, this bit is cleared

by writing 0 to SPEN bit (reset of the SPI state machine).

Interrupts Two SPI status flags can generate a CPU interrupt requests (See Table 10)

Table 10. SPI Interrupts

Flag Request

SPIF (SP data transfer) SPI Transmitter Interrupt request

MODF (Mode Fault) SPI Receiver/Error Interrupt Request (if SSDIS = "0")

Serial Peripheral data transfer flag, SPIF: This bit is set by hardware when a transfer

has been completed. SPIF bit generates transmitter CPU interrupt requests.

4134D–8051–02/08

Mode Fault flag, MODF: This bit becomes set to indicate that the level on the SS is

inconsistent with the mode of the SPI. MODF with SSDIS reset, generates receiver/error

CPU interrupt requests.

Figure 14 gives a logical view of the above statements.

23

Page 24

Figure 14. SPI Interrupt Requests Generation

SSDIS

MODF

CPU Interrupt Request

SPI Receiver/Error

CPU Interrupt Request

SPI Transmitter

SPI

CPU Interrupt Request

SPIF

Registers There are three registers in the module that provide control, status and data storage

functions. These registers are describes in the following paragraphs.

Serial Peripheral Control Register (SPCON)

The Serial Peripheral Control Register does the following:

• Selects one of the Master clock rates

• Configure the SPI module as Master or Slave

• Selects serial clock polarity and phase

• Enables the SPI module

• Frees the SS pin for a general purpose

Table 11 describes this register and explains the use of each bit.

Table 11. SPCON Register: Serial Peripheral Control Register - SPCON (S:C3h)

7 6 5 4 3 2 1 0

SPR2 SPEN SSDIS MSTR CPOL CPHA SPR1 SPR0

Bit

Number Bit Mnemonic R/W Mode Description

7 SPR2 R/W

6 SPEN R/W

5 SSDIS R/W

Serial Peripheral Rate 2

Bit with SPR1 and SPR0 define the clock rate

Serial Peripheral Enable

Clear to disable the SPI interface (internal reset of the SPI)

Set to enable the SPI interface

SS Disable

Clear to enable SS in both Master and Slave Modes

Set to disable SS in both Master and Slave Modes. In Slave Mode, this bit has no effect if CPHA = "0"

4 MSTR R/W

3 CPOL R/W

2 CPHA R/W

1 SPR1 R/W

24

Serial Peripheral Master

Clear to configure the SPI as a Slave

Set to configure the SPI as a Master

Clock Polarity

Clear to have the SCK set to ‘0’ in idle state

Set to have the SCK set to ’1’ in idle low

Clock Phase

Clear to have the data sampled when the SPSCK leaves the idle state (see CPOL)

Set to have the data sampled when the SPSCK returns to idle state (see CPOL)

Serial Peripheral Rate (SPR2:SPR1:SPR0)

000: N.A.

001: F

010: F

011: F

CLK PERIPH

CLK PERIPH

CLK PERIPH

/4

/8

/16

4134D–8051–02/08

Page 25

Bit

Number Bit Mnemonic R/W Mode Description

0 SPR0 R/W

100: F

CLK PERIPH

101: F

CLK PERIPH

110: F

CLK PERIPH

111: Don’t Use

/32

/64

/128

Reset Value = 00010100b

Serial Peripheral Status Register (SPSTA)

The Serial Peripheral Status Register contains flags to signal the following conditions:

• Data transfer complete

• Write collision

• Inconsistent logic level on SS pin (mode fault error)

Table 12 describes the SPSTA register and explains the use of every bit in the register.

Table 12. SPSTA: Serial Peripheral Status and Control Register - SPSTA (S:C4h)

7 6 5 4 3 2 1 0

SPIF WCOL SSERR MODF - - - -

Bit

Number Bit Mnemonic R/W Mode Description

Serial Peripheral Data Transfer Flag

7 SPIF R

6 WCOL R

Clear by hardware to indicate data transfer is in progress or has been approved by a clearing sequence.

Set by hardware to indicate that the data transfer has been completed.

Write Collision Flag

Cleared by hardware to indicate that no collision has occurred or has been approved by a clearing sequence.

Set by hardware to indicate that a collision has been detected.

5 SSERR R

4 MODF R

3 - R/W

2 - R/W

1 - R/W

0 - R/W

Reset Value = 00X0XXXXb

Synchronous Serial Slave Error Flag

Set by hardware when SS is deasserted before the end of a received data.

Cleared by disabling the SPI (clearing SPEN bit in SPCON).

Mode Fault

Cleared by hardware to indicate that the SS pin is at appropriate logic level, or has been approved by a

clearing sequence.

Set by hardware to indicate that the SS pin is at inappropriate logic level

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

4134D–8051–02/08

25

Page 26

Serial Peripheral Data Register (SPDAT)

The Serial Peripheral Data Register (Table 13) is a read/write buffer for the receive data

register. A write to SPDAT places data directly into the shift register. No transmit buffer

is available in this model.

A Read of the SPDAT returns the value located in the receive buffer and not the content

of the shift register.

Table 13. SPDAT (S:C5h): Serial Peripheral Data Register

7 6 5 4 3 2 1 0

R7 R6 R5 R4 R3 R2 R1 R0

Reset Value = XXXX XXXXb

R7:R0: Receive data bits

SPCON, SPSTA and SPDAT registers may be read and written at any time while there

is no on-going exchange. However, special care should be taken when writing to them

while a transmission is on-going:

• Do not change SPR2, SPR1 and SPR0

• Do not change CPHA and CPOL

• Do not change MSTR

• Clearing SPEN would immediately disable the peripheral

• Writing to the SPDAT will cause an overflow

26

4134D–8051–02/08

Page 27

Timers/Counters

The Errata Sheet implements two general-purpose, 16-bit Timers/Counters. They are

identified as Timer 0 and Timer 1, and can be independently configured to operate in a

variety of modes as a Timer or as an event Counter. When operating as a Timer, the

Timer/Counter runs for a programmed length of time, then issues an interrupt request.

When operating as a Counter, the Timer/Counter counts negative transitions on an

external pin. After a preset number of counts, the Counter issues an interrupt request.

The various operating modes of each Timer/Counter are described in the following

sections.

Timer/Counter Operations

For instance, a basic operation is Timer registers THx and TLx (x = 0, 1) connected in

cascade to form a 16-bit Timer. Setting the run control bit (TRx) in TCON register (see

Figure 14) turns the Timer on by allowing the selected input to increment TLx. When

TLx overflows it increments THx; when THx overflows it sets the Timer overflow flag

(TFx) in TCON register. Setting the TRx does not clear the THx and TLx Timer registers.

Timer registers can be accessed to obtain the current count or to enter preset values.

They can be read at any time but TRx bit must be cleared to preset their values,

other/wise the behavior of the Timer/Counter is unpredictable.

The C/Tx# control bit selects Timer operation or Counter operation by selecting the

divided-down peripheral clock or external pin Tx as the source for the counted signal.

TRx bit must be cleared when changing the mode of operation, other/wise the behavior

of the Timer/Counter is unpredictable.

For Timer operation (C/Tx# = 0), the Timer register counts the divided-down peripheral

clock. The Timer register is incremented once every peripheral cycle (6 peripheral clock

periods). The Timer clock rate is F

/6, i.e. F

PER

/12 in standard mode or F

OSC

OSC

/6 in X2

Mode.

For Counter operation (C/Tx# = 1), the Timer register counts the negative transitions on

the Tx external input pin. The external input is sampled every peripheral cycles. When

the sample is high in one cycle and low in the next one, the Counter is incremented.

Since it takes 2 cycles (12 peripheral clock periods) to recognize a negative transition,

the maximum count rate is F

/12, i.e. F

PER

/24 in standard mode or F

OSC

/12 in X2

OSC

Mode. There are no restrictions on the duty cycle of the external input signal, but to

ensure that a given level is sampled at least once before it changes, it should be held for

at least one full peripheral cycle.

Timer 0

4134D–8051–02/08

Timer 0 functions as either a Timer or event Counter in four modes of operation.

Figure 15 through Figure 18 show the logical configuration of each mode.

Timer 0 is controlled by the four lower bits of TMOD register (See Figure 15) and bits 0,

1, 4 and 5 of TCON register (see Figure 14). TMOD register selects the method of Timer

gating (GATE0), Timer or Counter operation (T/C0#) and mode of operation (M10 and

M00). TCON register provides Timer 0 control functions: overflow flag (TF0), run control

bit (TR0), interrupt flag (IE0) and interrupt type control bit (IT0).

For normal Timer operation (GATE0 = 0), setting TR0 allows TL0 to be incremented by

the selected input. Setting GATE0 and TR0 allows external pin INT0# to control Timer

operation.

Timer 0 overflow (count rolls over from all 1s to all 0s) sets TF0 flag generating an interrupt request.

It is important to stop Timer/Counter before changing mode.

27

Page 28

Mode 0 (13-bit Timer) Mode 0 configures Timer 0 as an 13-bit Timer which is set up as an 8-bit Timer (TH0

PERIPH

CLOCK

TRx

TCON Reg

TFx

TCON Reg

0

1

GATEx

TMOD Reg

÷

6

Overflow

Timer x

Interrupt

Request

C/Tx#

TMOD Reg

TLx

(5 Bits)

THx

(8 Bits)

INTx#

Tx

TRx

TCON Reg

TFx

TCON Reg

0

1

GATEx

TMOD Reg

Overflow

Timer x

Interrupt

Request

C/Tx#

TMOD Reg

TLx

(8 Bits)

THx

(8 Bits)

INTx#

Tx

PERIPH

CLOCK

÷

6

TRx

TCON Reg

TFx

TCON Reg

0

1

GATEx

TMOD Reg

Overflow

Timer x

Interrupt

Request

C/Tx#

TMOD Reg

TLx

(8 Bits)

THx

(8 Bits)

INTx#

Tx

PERIPH

CLOCK

÷

6

register) with a modulo 32 prescaler implemented with the lower five bits of TL0 register

(see Figure 15). The upper three bits of TL0 register are indeterminate and should be

ignored. Prescaler overflow increments TH0 register.

Figure 15. Timer/Counter x (x = 0 or 1) in Mode 0

Mode 1 (16-bit Timer) Mode 1 configures Timer 0 as a 16-bit Timer with TH0 and TL0 registers connected in

cascade (see Figure 16). The selected input increments TL0 register.

Figure 16. Timer/Counter x (x = 0 or 1) in Mode 1

Mode 2 (8-bit Timer with AutoReload)

Mode 2 configures Timer 0 as an 8-bit Timer (TL0 register) that automatically reloads

from TH0 register (see Figure 17). TL0 overflow sets TF0 flag in TCON register and

reloads TL0 with the contents of TH0, which is preset by software. When the interrupt

request is serviced, hardware clears TF0. The reload leaves TH0 unchanged. The next

reload value may be changed at any time by writing it to TH0 register.

Figure 17. Timer/Counter x (x = 0 or 1) in Mode 2

28

4134D–8051–02/08

Page 29

Mode 3 (Two 8-bit Timers) Mode 3 configures Timer 0 such that registers TL0 and TH0 operate as separate 8-bit

TR0

TCON.4

TF0

TCON.5

INT0

#

0

1

GATE0

TMOD.3

Overflow

Timer 0

Interrupt

Request

C/T0#

TMOD.2

TL0

(8 Bits)

TR1

TCON.6

TH0

(8 Bits)

TF1

TCON.7

Overflow

Timer 1

Interrupt

Request

T0

PERIPH

CLOCK

÷

6

PERIPH

CLOCK

÷

6

Timers (see Figure 18). This mode is provided for applications requiring an additional 8bit Timer or Counter. TL0 uses the Timer 0 control bits C/T0# and GATE0 in TMOD register, and TR0 and TF0 in TCON register in the normal manner. TH0 is locked into a

Timer function (counting F

/6) and takes over use of the Timer 1 interrupt (TF1) and

PER

run control (TR1) bits. Thus, operation of Timer 1 is restricted when Timer 0 is in Mode

3.

Figure 18. Timer/Counter 0 in Mode 3: Two 8-bit Counters

Timer 1

Timer 1 is identical to Timer 0 excepted for Mode 3 which is a hold-count mode. The following comments help to understand the differences:

• Timer 1 functions as either a Timer or event Counter in three modes of operation.

Figure 15 through Figure 17 show the logical configuration for modes 0, 1, and 2.

Timer 1’s Mode 3 is a hold-count mode.

• Timer 1 is controlled by the four high-order bits of TMOD register (see Figure 15)

and bits 2, 3, 6 and 7 of TCON register (see Figure 14). TMOD register selects the

method of Timer gating (GATE1), Timer or Counter operation (C/T1#) and mode of

operation (M11 and M01). TCON register provides Timer 1 control functions:

overflow flag (TF1), run control bit (TR1), interrupt flag (IE1) and interrupt type

control bit (IT1).

• Timer 1 can serve as the Baud Rate Generator for the Serial Port. Mode 2 is best

suited for this purpose.

• For normal Timer operation (GATE1 = 0), setting TR1 allows TL1 to be incremented

by the selected input. Setting GATE1 and TR1 allows external pin INT1# to control

Timer operation.

• Timer 1 overflow (count rolls over from all 1s to all 0s) sets the TF1 flag generating

an interrupt request.

• When Timer 0 is in Mode 3, it uses Timer 1’s overflow flag (TF1) and run control bit

(TR1). For this situation, use Timer 1 only for applications that do not require an

interrupt (such as a Baud Rate Generator for the Serial Port) and switch Timer 1 in

and out of Mode 3 to turn it off and on.

• It is important to stop Timer/Counter before changing mode.

4134D–8051–02/08

29

Page 30

Mode 0 (13-bit Timer) Mode 0 configures Timer 1 as a 13-bit Timer, which is set up as an 8-bit Timer (TH1 reg-

TF0

TCON.5

ET0

IE0.1

Timer 0

Interrupt Request

TF1

TCON.7

ET1

IE0.3

Timer 1

Interrupt Request

ister) with a modulo-32 prescaler implemented with the lower 5 bits of the TL1 register

(see Figure 15). The upper 3 bits of TL1 register are ignored. Prescaler overflow increments TH1 register.

Mode 1 (16-bit Timer) Mode 1 configures Timer 1 as a 16-bit Timer with TH1 and TL1 registers connected in

cascade (see Figure 16). The selected input increments TL1 register.

Mode 2 (8-bit Timer with AutoReload)

Mode 2 configures Timer 1 as an 8-bit Timer (TL1 register) with automatic reload from

TH1 register on overflow (see Figure 17). TL1 overflow sets TF1 flag in TCON register

and reloads TL1 with the contents of TH1, which is preset by software. The reload

leaves TH1 unchanged.

Mode 3 (Halt) Placing Timer 1 in Mode 3 causes it to halt and hold its count. This can be used to halt

Timer 1 when TR1 run control bit is not available i.e. when Timer 0 is in Mode 3.

Interrupt

Each Timer handles one interrupt source that is the timer overflow flag TF0 or TF1. This

flag is set every time an overflow occurs. Flags are cleared when vectoring to the Timer

interrupt routine. Interrupts are enabled by setting ETx bit in IE0 register. This assumes

interrupts are globally enabled by setting EA bit in IE0 register.

Figure 19. Timer Interrupt System

30

4134D–8051–02/08

Page 31

Registers

Table 14. TCON Register

TCON (S:88h)

Timer/Counter Control Register

7 6 5 4 3 2 1 0

TF1 TR1 TF0 TR0 IE1 IT1 IE0 IT0

Bit

Number

7 TF1

6 TR1

5 TF0

4 TR0

3 IE1

2 IT1

1 IE0

Bit

Mnemonic Description

Timer 1 Overflow Flag

Cleared by hardware when processor vectors to interrupt routine.

Set by hardware on Timer/Counter overflow, when Timer 1 register overflows.

Timer 1 Run Control Bit

Clear to turn off Timer/Counter 1.

Set to turn on Timer/Counter 1.

Timer 0 Overflow Flag

Cleared by hardware when processor vectors to interrupt routine.

Set by hardware on Timer/Counter overflow, when Timer 0 register overflows.

Timer 0 Run Control Bit

Clear to turn off Timer/Counter 0.

Set to turn on Timer/Counter 0.

Interrupt 1 Edge Flag

Cleared by hardware when interrupt is processed if edge-triggered (see IT1).

Set by hardware when external interrupt is detected on INT1# pin.

Interrupt 1 Type Control Bit

Clear to select low level active (level triggered) for external interrupt 1 (INT1#).

Set to select falling edge active (edge triggered) for external interrupt 1.

Interrupt 0 Edge Flag

Cleared by hardware when interrupt is processed if edge-triggered (see IT0).

Set by hardware when external interrupt is detected on INT0# pin.

4134D–8051–02/08

Interrupt 0 Type Control Bit

0 IT0

Clear to select low level active (level triggered) for external interrupt 0 (INT0#).

Set to select falling edge active (edge triggered) for external interrupt 0.

Reset Value = 0000 0000b

31

Page 32

Table 15. TMOD Register

TMOD (S:89h)

Timer/Counter Mode Control Register

7 6 5 4 3 2 1 0

GATE1 C/T1# M11 M01 GATE0 C/T0# M10 M00

Bit Number Bit Mnemonic Description

Timer 1 Gating Control Bit

7 GATE1

Clear to enable Timer 1 whenever TR1 bit is set.

Set to enable Timer 1 only while INT1# pin is high and TR1 bit is set.

6 C/T1#

5 M11

4 M01

3 GATE0

2 C/T0#

1 M10

0

M00

Reset Value = 0000 0000b

Timer 1 Counter/Timer Select Bit

Clear for Timer operation: Timer 1 counts the divided-down system clock.

Set for Counter operation: Timer 1 counts negative transitions on external pin T1.

Timer 1 Mode Select Bits

M11 M01 Operating Mode

0 0 Mode 0: 8-bit Timer/Counter (TH1) with 5-bit prescaler (TL1).

0 1 Mode 1: 16-bit Timer/Counter.

1 0 Mode 2: 8-bit auto-reload Timer/Counter (TL1). Reloaded from TH1 at overflow.

1 1 Mode 3: Timer 1 halted. Retains count.

Timer 0 Gating Control Bit

Clear to enable Timer 0 whenever TR0 bit is set.

Set to enable Timer/Counter 0 only while INT0# pin is high and TR0 bit is set.

Timer 0 Counter/Timer Select Bit

Clear for Timer operation: Timer 0 counts the divided-down system clock.

Set for Counter operation: Timer 0 counts negative transitions on external pin T0.

Timer 0 Mode Select Bit

M10 M00 Operating Mode

0 0 Mode 0: 8-bit Timer/Counter (TH0) with 5-bit prescaler (TL0).

0 1 Mode 1: 16-bit Timer/Counter.

1 0 Mode 2: 8-bit auto-reload Timer/Counter (TL0). Reloaded from TH0 at overflow.

1 1 Mode 3: TL0 is an 8-bit Timer/Counter.

TH0 is an 8-bit Timer using Timer 1’s TR0 and TF0 bits.

Table 16. TH0 Register

TH0 (S:8Ch)

32

Timer 0 High Byte Register

7 6 5 4 3 2 1 0

Bit

Number

7:0

Bit

Mnemonic Description

High Byte of Timer 0

Reset Value = 0000 0000b

4134D–8051–02/08

Page 33

Table 17. TL0 Register

TL0 (S:8Ah)

Timer 0 Low Byte Register

7 6 5 4 3 2 1 0

Bit

Number

7:0

Bit

Mnemonic Description

Low Byte of Timer 0

Reset Value = 0000 0000b

Table 18. TH1 Register

TH1 (S:8Dh)

Timer 1 High Byte Register

7 6 5 4 3 2 1 0

Bit Number Bit Mnemonic Description

7:0

High Byte of Timer 1

Reset Value = 0000 0000b

Table 19. TL1 Register

TL1 (S:8Bh)

Timer 1 Low Byte Register

7 6 5 4 3 2 1 0

4134D–8051–02/08

Bit Number

7:0

Bit

Mnemonic Description

Reset Value = 0000 0000b

Low Byte of Timer 1

33

Page 34

Power Management

Table 20. PCON Register

PCON - Power Control Register (87h)

7 6 5 4 3 2 1 0

- - - - GF1 GF0 PD IDL

Bit

Number

7 -

6 -

5 -

4 -

3 GF1

2 GF0

1 PD

0 IDL

Bit

Mnemonic Description

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

Reserved

The value read from this bit is indeterminate. Do not set this bit.

General-purpose Flag

Cleared by user for general purpose usage.

Set by user for general purpose usage.

General-purpose Flag

Cleared by user for general purpose usage.

Set by user for general purpose usage.

Power-Down Mode Bit

Cleared by hardware when reset occurs.

Set to enter Power-down Mode.

Idle Mode Bit

Cleared by hardware when interrupt or reset occurs.

Set to enter Idle Mode.

Idle Mode

Reset Value = XXX1 0000b

Not bit addressable

An instruction that sets PCON.0 indicates that it is the last instruction to be executed

before going into the Idle Mode. In the Idle Mode, the internal clock signal is gated off to

the CPU, but not to the interrupt, Timer, and Serial Port functions. The CPU status is

preserved in its entirety: the Stack Pointer, Program Counter, Program Status Word,

Accumulator and all other registers maintain their data during Idle. The port pins hold

the logical states they had at the time Idle was activated.

There are two ways to terminate the Idle Mode. Activation of any enabled interrupt will

cause PCON.0 to be cleared by hardware, terminating the Idle Mode. The interrupt will

be serviced, and following RETI the next instruction to be executed will be the one following the instruction that put the device into idle.

The flag bits GF0 and GF1 can be used to give an indication if an interrupt occurred during normal operation or during an Idle. For example, an instruction that activates Idle

can also set one or both flag bits. When Idle is terminated by an interrupt, the interrupt

service routine can examine the flag bits.

The other way of terminating the Idle Mode is with a hardware reset. Since the clock

oscillator is still running, the hardware reset needs to be held active for only two

machine cycles (24 oscillator periods) to complete the reset.

34

4134D–8051–02/08

Page 35

Power-down Mode

INT1

INT0

XTALA

Power-down Phase Oscillator Restart Phase

Active PhaseActive Phase

or

XTALB

To save maximum power, a power-down mode can be invoked by software (refer to

Table 20, PCON register).

In power-down mode, the oscillator is stopped and the instruction that invoked powerdown mode is the last instruction executed. The internal RAM and SFRs retain their

value until the power-down mode is terminated. VCC can be lowered to save further

power. Either a hardware reset or an external interrupt can cause an exit from powerdown. To properly terminate power-down mode, the reset or external interrupt should

not be executed before VCC is restored to its normal operating level and must be held

active long enough for the oscillator to restart and stabilize.

Only external interrupts INT0, INT1 are useful for exiting from power-down. For that,

interrupt must be enabled and configured as level or edge sensitive interrupt input.

Holding the pin low restarts the oscillator but bringing the pin high completes the exit as

detailed in Figure 20. When both interrupts are enabled, the oscillator restarts as soon

as one of the two inputs is held low and power-down exit will be completed when the first

input is released. In this case the higher priority interrupt service routine is executed.

Once the interrupt is serviced, the next instruction to be executed after RETI will be the

one following the instruction that put AT8xC5103 into power-down mode.

Figure 20. Power-Down Exit Waveform

4134D–8051–02/08

Exiting from power-down by reset redefines all the SFRs, exiting from power-down by

external interrupt does no affect the SFRs.

Exiting from power-down by either reset or external interrupt does not affect the internal

RAM content.

Note: If idle mode is activated with power-down mode (IDL and PD bits set), the exit sequence

is unchanged, when execution is vectored to interrupt, PD and IDL bits are cleared and

idle mode is not entered.

Table 21 shows the state of ports during idle and power-down modes.

Table 21. State of Ports

Mode Program Memory PORT1 PORT3

Idle Internal Port Data Port Data

Power-down Internal Port Data Port Data

Note: 1. Port 0 can force a 0 level. A ‘one’ will leave port floating.

(1)

35

Page 36

Programmable Counter Array (PCA)

The PCA provides more timing capabilities with less CPU intervention than the standard

timer/counters. Its advantages include reduced software overhead and improved accuracy. The PCA consists of a dedicated timer/counter which serves as the time base for

an array of five compare/capture modules. Its clock input can be programmed to count

any one of the following signals:

• Oscillator frequency ÷ 12 (÷ 6 in X2 Mode)

• Oscillator frequency ÷ 4 (÷ 2 in X2 Mode)

• Timer 0 overflow

• External input on ECI (P1.2)

Each compare/capture modules can be programmed in any one of the following modes:

• Rising and/or falling edge capture,

• Software timer

• High-speed output

• Pulse width modulator

Module 4 can also be programmed as a watchdog timer.

When the compare/capture modules are programmed in the capture mode, software

timer, or high speed output mode, an interrupt can be generated when the module executes its function. All five modules and the PCA timer overflow share one interrupt

vector.

The PCA timer/counter and compare/capture modules share Port 1 for external I/O.

These pins are listed below. If the port is not used for the PCA, it can still be used for

standard I/O.

PCA Component External I/O Pin

16-bit Counter P1.2/ECI

16-bit Module 0 P1.3/CEX0

16-bit Module 1 P1.4/CEX1

16-bit Module 2 P1.5/CEX2

16-bit Module 3 P1.6/CEX3

16-bit Module 4 P1.7/CEX4

The PCA timer is a common time base for all five modules (See Figure 21). The timer

count source is determined from the CPS1 and CPS0 bits in the CMOD SFR (see

Table 21) and can be programmed to run at:

• 1/12 the oscillator frequency (or 1/6 in X2 Mode)

• 1/4 the oscillator frequency (or 1/2 in X2 Mode)

• The Timer 0 overflow

• The input on the ECI pin (P1.2)

36

4134D–8051–02/08

Page 37

PCA Timer

CIDL CPS1 CPS0 ECF

It

CH CL

16-bit Up/Down Counter

To PCA

Modules

Fosc/12

Fosc/4

T0 OVF

P1.2

Idle

CMOD

0xD9

WDTE

CF CR

CCON

0xD8

CCF4 CCF3 CCF2 CCF1 CCF0

Overflow

Figure 21. PCA Timer/Counter

Table 22. CMOD: PCA Counter Mode Register

CMOD

Address 0D9H CIDL WDTE - - - CPS1 CPS0 ECF

Reset value 0 0 X X X 0 0 0

Symbol Function

CIDL

WDTE Watchdog Timer Enable: WDTE = 0 disables Watchdog Timer function on PCA Module 4. WDTE = 1 enables it.

- Not implemented, reserved for future use.

CPS1 PCA Count Pulse Select bit 1.

CPS0 PCA Count Pulse Select bit 0.

ECF

Counter Idle control: CIDL = 0 programs the PCA Counter to continue functioning during idle Mode. CIDL = 1 programs it to be

gated off during idle.

CPS1 CPS0 Selected PCA input.

0 0 Internal clock f

0 1 Internal clock f

1 0 Timer 0 Overflow

1 1 External clock at ECI/P1.2 pin (max rate = f

PCA Enable Counter Overflow interrupt: ECF = 1 enables CF bit in CCON to generate an interrupt. ECF = 0 disables that

function of CF.

(1)

(2)

/12 (Or f

osc

/4 (Or f

osc

/6 in X2 Mode).

osc

/2 in X2 Mode).

osc

/ 8)

osc

1. User software should not write 1s to reserved bits. These bits may be used in future 8051 family products to invoke new features. In that case, the reset or inactive value of the new bit will be 0, and its active value will be 1. The value read from a

reserved bit is indeterminate.

2. f

4134D–8051–02/08

= oscillator frequency

osc

37

Page 38

The CMOD SFR includes three additional bits associated with the PCA (See Figure 21

and Table 21).

• The CIDL bit which allows the PCA to stop during idle mode.

• The WDTE bit which enables or disables the watchdog function on module 4.

• The ECF bit which when set causes an interrupt and the PCA overflow flag CF (in

the CCON SFR) to be set when the PCA timer overflows.

The CCON SFR contains the run control bit for the PCA and the flags for the PCA timer

(CF) and each module (Refer to Table 23).

• Bit CR (CCON.6) must be set by software to run the PCA. The PCA is shut off by

clearing this bit.

• Bit CF: The CF bit (CCON.7) is set when the PCA counter overflows and an

interrupt will be generated if the ECF bit in the CMOD register is set. The CF bit can

only be cleared by software.

• Bits 0 through 4 are the flags for the modules (bit 0 for module 0, bit 1 for module 1,

etc.) and are set by hardware when either a match or a capture occurs. These flags

also can only be cleared by software.

•

Table 23. CCON: PCA Counter Control Register

CCON

Address 0D8H

Reset Value 0 0 X 0 0 0 0 0

Symbol Function

PCA Counter Overflow flag. Set by hardware when the counter rolls over. CF flags

CF

CR

- Not implemented, reserved for future use.

CCF4

CCF3

CCF2

CCF1

CCF0

an interrupt if bit ECF in CMOD is set. CF may be set by either hardware or software but

can only be cleared by software.

PCA Counter Run control bit. Set by software to turn the PCA counter on. Must be cleared

by software to turn the PCA counter off.

PCA Module 4 interrupt flag. Set by hardware when a match or capture occurs. Must be

cleared by software.

PCA Module 3 interrupt flag. Set by hardware when a match or capture occurs. Must be

cleared by software.

PCA Module 2 interrupt flag. Set by hardware when a match or capture occurs. Must be

cleared by software.

PCA Module 1 interrupt flag. Set by hardware when a match or capture occurs. Must be

cleared by software.

PCA Module 0 interrupt flag. Set by hardware when a match or capture occurs. Must be

cleared by software.

CF CR - CCF4 CCF3 CCF2 CCF1 CCF0

(1)

38

1. User software should not write 1s to reserved bits. These bits may be used in future 8051

family products to invoke new features. In that case, the reset or inactive value of the

new bit will be 0, and its active value will be 1. The value read from a reserved bit is

indeterminate.

The watchdog timer function is implemented in module 4 (See Figure 24).

The PCA interrupt system is shown in Figure 22.

4134D–8051–02/08

Page 39

Figure 22. PCA Interrupt System

CF CR

CCON

0xD8

CCF4 CCF3 CCF2 CCF1 CCF0

Module 4

Module 3

Module 2

Module 1

Module 0

ECF

PCA Timer/Counter

ECCFn

CCAPMn.0CMOD.0

IE.6 IE.7

To Interrupt

Priority Decoder

EC EA

PCA Modules: each one of the five compare/capture modules has six possible functions. It can perform:

• 16-bit Capture, positive-edge triggered

• 16-bit Capture, negative-edge triggered

• 16-bit Capture, both positive and negative-edge triggered

• 16-bit Software Timer

• 16-bit High Speed Output

• 8-bit Pulse Width Modulator

4134D–8051–02/08

In addition, module 4 can be used as a Watchdog Timer.

Each module in the PCA has a special function register associated with it. These registers are: CCAPM0 for module 0, CCAPM1 for module 1, etc. (See Table 24). The

registers contain the bits that control the mode that each module will operate in.

• The ECCF bit (CCAPMn.0 where n = 0, 1, 2, 3, or 4 depending on the module)

enables the CCF flag in the CCON SFR to generate an interrupt when a match or

compare occurs in the associated module.

• PWM (CCAPMn.1) enables the pulse width modulation mode.

• The TOG bit (CCAPMn.2) when set causes the CEX output associated with the

module to toggle when there is a match between the PCA counter and the module's

capture/compare register.

• The match bit MAT (CCAPMn.3) when set will cause the CCFn bit in the CCON

register to be set when there is a match between the PCA counter and the module's

capture/compare register.

• The next two bits CAPN (CCAPMn.4) and CAPP (CCAPMn.5) determine the edge

that a capture input will be active on. The CAPN bit enables the negative edge, and

the CAPP bit enables the positive edge. If both bits are set both edges will be

enabled and a capture will occur for either transition.

• The last bit in the register ECOM (CCAPMn.6) when set enables the comparator

function.

39

Page 40

Table 24 shows the CCAPMn settings for the various PCA functions.

Table 24. CCAPMn: PCA Modules Compare/Capture Control Registers

CCAPM0 (0DAH)

CCAPMn

Address

n = 0 - 4

Symbol Function

ECOMn Enable Comparator. ECOMn = 1 enables the comparator function.

CAPPn Capture Positive, CAPPn = 1 enables positive edge capture.

CAPNn Capture Negative, CAPNn = 1 enables negative edge capture.

CCAPM1 (0DBH)

CCAPM2 (0DCH)

CCAPM3 (0DDH)

CCAPM4 (0DEH)

- ECOMn CAPPn CAPNn MATn TOGn PWMm ECCFn

Reset value X 0 0 0 0 0 0 0

- Not implemented, reserved for future use.

(1)

MATn

TOGn

PWMn

ECCFn

Match. When MATn = 1, a match of the PCA counter with this module's compare/capture

register causes the CCFn bit in CCON to be set, flagging an interrupt.

Toggle. When TOGn = 1, a match of the PCA counter with this module's compare/capture

register causes the CEXn pin to toggle.

Pulse Width Modulation Mode. PWMn = 1 enables the CEXn pin to be used as a pulse

width modulated output.

Enable CCF interrupt. Enables compare/capture flag CCFn in the CCON register to

generate an interrupt.

1. User software should not write 1s to reserved bits. These bits may be used in future 8051

family products to invoke new features. In that case, the reset or inactive value of the

new bit will be 0, and its active value will be 1. The value read from a reserved bit is

indeterminate.

Table 25. PCA Module Modes (CCAPMn Registers)

ECOMn CAPPn CAPNn MATn TOGn PWMm ECCFn Module Function

0 0 0 0 0 0 0 No Operation

X 1 0 0 0 0 X

X 0 1 0 0 0 X

X 1 1 0 0 0 X

16-bit capture by a positive-edge

trigger on CEXn

16-bit capture by a negative trigger

on CEXn

16-bit capture by a transition on

CEXn

40

1 0 0 1 0 0 X

1 0 0 1 1 0 X 16-bit High Speed Output

1 0 0 0 0 1 0 8-bit PWM

1 0 0 1 X 0 X Watchdog Timer (module 4 only)

16-bit Software Timer/Compare

mode.

4134D–8051–02/08

Page 41

There are two additional registers associated with each of the PCA modules. They are

CCAPnH and CCAPnL and these are the registers that store the 16-bit count when a

capture occurs or a compare should occur. When a module is used in the PWM mode

these registers are used to control the duty cycle of the output (See Table 26 &

Table 27)

Table 26. CCAPnH: PCA Modules Capture/Compare Registers High

CCAP0H (0FAH)

CCAPnH

Address

n = 0 - 4

CCAP1H (0FBH)

CCAP2H (0FCH)

CCAP3H (0FDH)

CCAP4H (0FEH)

7 6 5 4 3 2 1 0

Reset value 0 0 0 0 0 0 0 0

Table 27. CCAPnL: PCA Modules Capture/Compare Registers Low

CCAP0L (0EAH)

CCAPnL

Address

n = 0 - 4

CCAP1L (0EBH)

CCAP2L (0ECH)

CCAP3L (0EDH)

CCAP4L (0EEH)

7 6 5 4 3 2 1 0

Reset value 0 0 0 0 0 0 0 0

Table 28. CH: PCA Counter High

CH

Address

0F9H

7 6 5 4 3 2 1 0

Reset value 0 0 0 0 0 0 0 0

Table 29. CL: PCA Counter Low

CL

Address

0E9H

7 6 5 4 3 2 1 0

Reset value 0 0 0 0 0 0 0 0

4134D–8051–02/08

41

Page 42

PCA Capture Mode

CF CR

CCON

0xD8

CH CL

CCAPnH CCAPnL

CCF4 CCF3 CCF2 CCF1 CCF0

PCA IT

PCA Counter/Timer

ECOMn

CCAPMn, n = 0 to 4

0xDA to 0xDE

CAPNn MATn TOGn PWMn ECCFnCAPPn

Cex.n

Capture

Figure 23. PCA Capture Mode

To use one of the PCA modules in the capture mode either one or both of the CCAPM

bits CAPN and CAPP for that module must be set. The external CEX input for the module (on port 1) is sampled for a transition. When a valid transition occurs the PCA

hardware loads the value of the PCA counter registers (CH and CL) into the module's

capture registers (CCAPnL and CCAPnH). If the CCFn bit for the module in the CCON

SFR and the ECCFn bit in the CCAPMn SFR are set then an interrupt will be generated

(see Figure 23).

42

4134D–8051–02/08

Page 43

16-bit Software Timer/

CH CL

CCAPnH CCAPnL

ECOMn

CCAPMn, n = 0 to 4

0xDA to 0xDE

CAPNn MATn TOGn PWMn ECCFnCAPPn

16 bit comparator

Match

CCON

0xD8

PCA IT

Enable

PCA counter/timer

RESET

(1)

CIDL CPS1 CPS0 ECF

CMOD

0xD9

WDTE

Reset

Write to

CCAPnL

Write to

CCAPnH

CF CCF2 CCF1 CCF0

CR

CCF3

CCF4

1 0

Compare Mode

The PCA modules can be used as software timers by setting both the ECOM and MAT

bits in the modules CCAPMn register. The PCA timer will be compared to the module's

capture registers and when a match occurs an interrupt will occur if the CCFn (CCON

SFR) and the ECCFn (CCAPMn SFR) bits for the module are both set (see Figure 24).

Figure 24. PCA Compare Mode and PCA Watchdog Timer

Note: 1. Only for Module 4

Before enabling ECOM bit, CCAPnL and CCAPnH should be set with a non zero value,

other/wise an unwanted match could happen. Writing to CCAPnH will set the ECOM bit.

Once ECOM set, writing CCAPnL will clear ECOM so that an unwanted match doesn’t

occur while modifying the compare value. Writing to CCAPnH will set ECOM. For this

reason, user software should write CCAPnL first, and then CCAPnH. Of course, the

ECOM bit can still be controlled by accessing to CCAPMn register.

4134D–8051–02/08

43

Page 44

High Speed Output Mode

CH CL

CCAPnH CCAPnL

ECOMn

CCAPMn, n = 0 to 4

0xDA to 0xDE

CAPNn MATn TOGn PWMn ECCFnCAPPn

16-bit Comparator

Match

CF CR

CCON

0xD8

CCF4 CCF3 CCF2 CCF1 CCF0

PCA IT

Enable

CEXn

PCA Counter/Timer

Write to