Features

•

Fulfills IEC 1036, Class 1 Accuracy Requirements

•

Fulfills IEC 687, Class 0.5 and Class 0.2 Accuracy, with External Temperature

Compensated Voltage Reference

•

Simultaneous Active, Reactive and Apparent Power and Energy Measurement

•

Power Factor, Frequency, Voltage and Current Measurement

•

Single and Poly Phase Operation

•

Three Basic Operating Modes: Stand-Alone Mode, Microprocessor Mode and MultiChannel Mode

•

Flexible Interfacing, 8-bit Microprocessor Interface, 8-bit Status Output and Eight

Impulse Outputs

•

Calibration of Gain and Phase Error

•

Compensation of the Non-Linearity of Low Power Measurement

•

Adjustable Starting Current and Meter Constant

•

Measurement Bandwidth of 1000 Hz

•

Tamper Proof Design

•

Single +5V Supply

Description

A two chip solution, consisting of AT73C500 and AT73C501 (or AT73C502), offers all

main features required for the measurement and calculation of various power and

energy quantiti es in static Watt-h our meters. The dev ices operate acco rding to

IEC1036, class 1, specification. IEC 687, class 0.5 and 0.2 requirements are fulfilled

when used with external temperature compensated voltage reference.

The AT73C501 contains six, high-performance, Sigma-Delta analog-to-digital converters (ADC). The AT73C500 is based on an efficient digital signal processor (DSP) core

and it supports interfacing both with the AT73C501 and with an external microprocessor. The AT73C500 DSP can also be used with the differential input ADC, AT73C502.

With this chipset, only a minimum of discrete components is required to develop products ranging from si mple domestic Wa tt-hour meters to sop histicated indus trial

meters. The chipset can be used in single-pha se as well as in poly- phase systems .

The DSP core of th e AT73C500 is easy to co nfigure . By changi ng the mode of the

AT73C500, the device can be operate d in a stand-al one enviro nment or be used wit h

a separate contr ol proc essor . It i s als o pos sible to co nfigure the c ircui t to p erform the

functions of three independent single phase Wh meters.

The chips support calibration of gain and phase error. All calibrations are done in the

digital domain and no trimming components are needed. The calibration coefficients

are either stored in an EEPROM memory or supplied by an external microprocessor.

(continued)

Chip Set

Solution for

Watt-Hour

Meters

AT73C500 with

AT73C501 or

AT73C502

Rev. 1035A–08/98

1

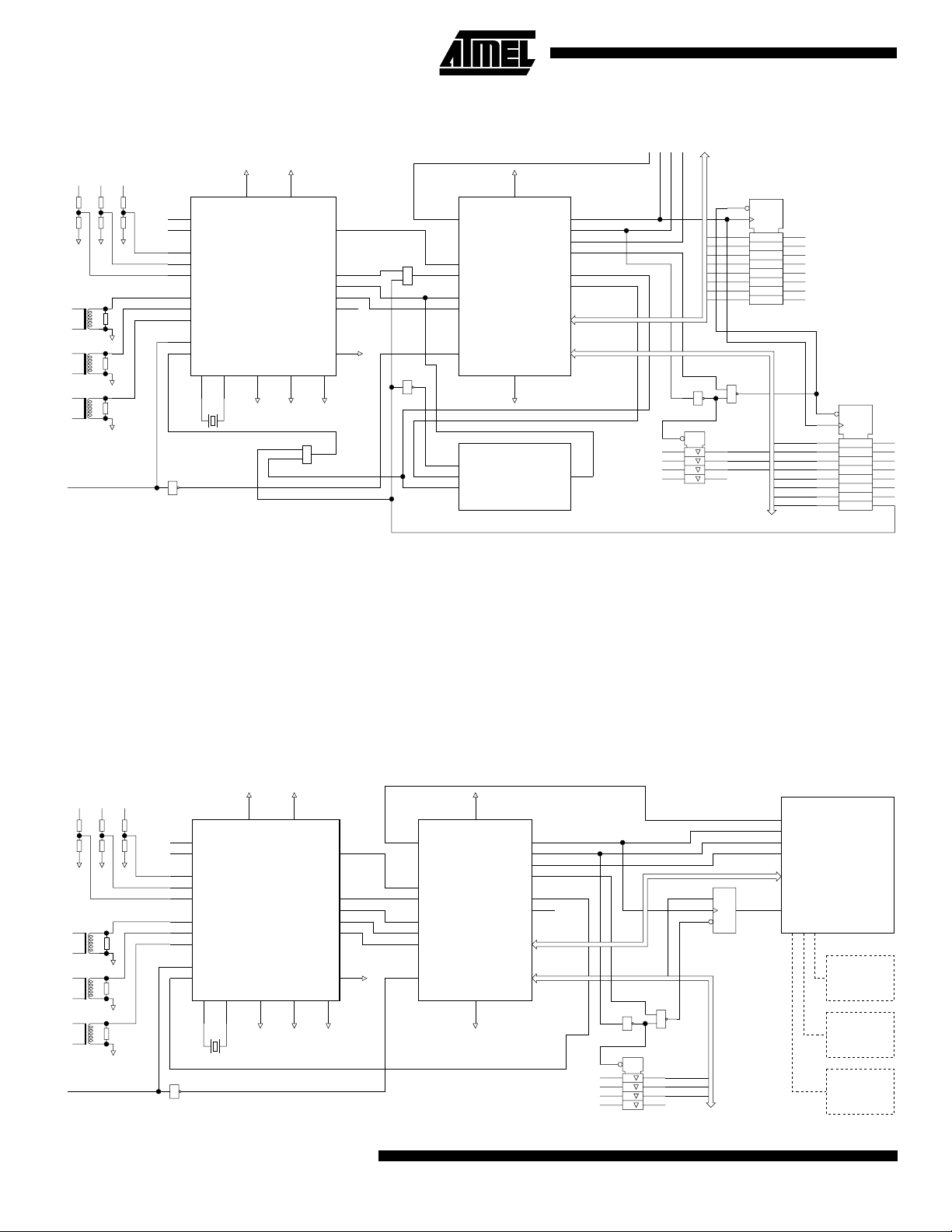

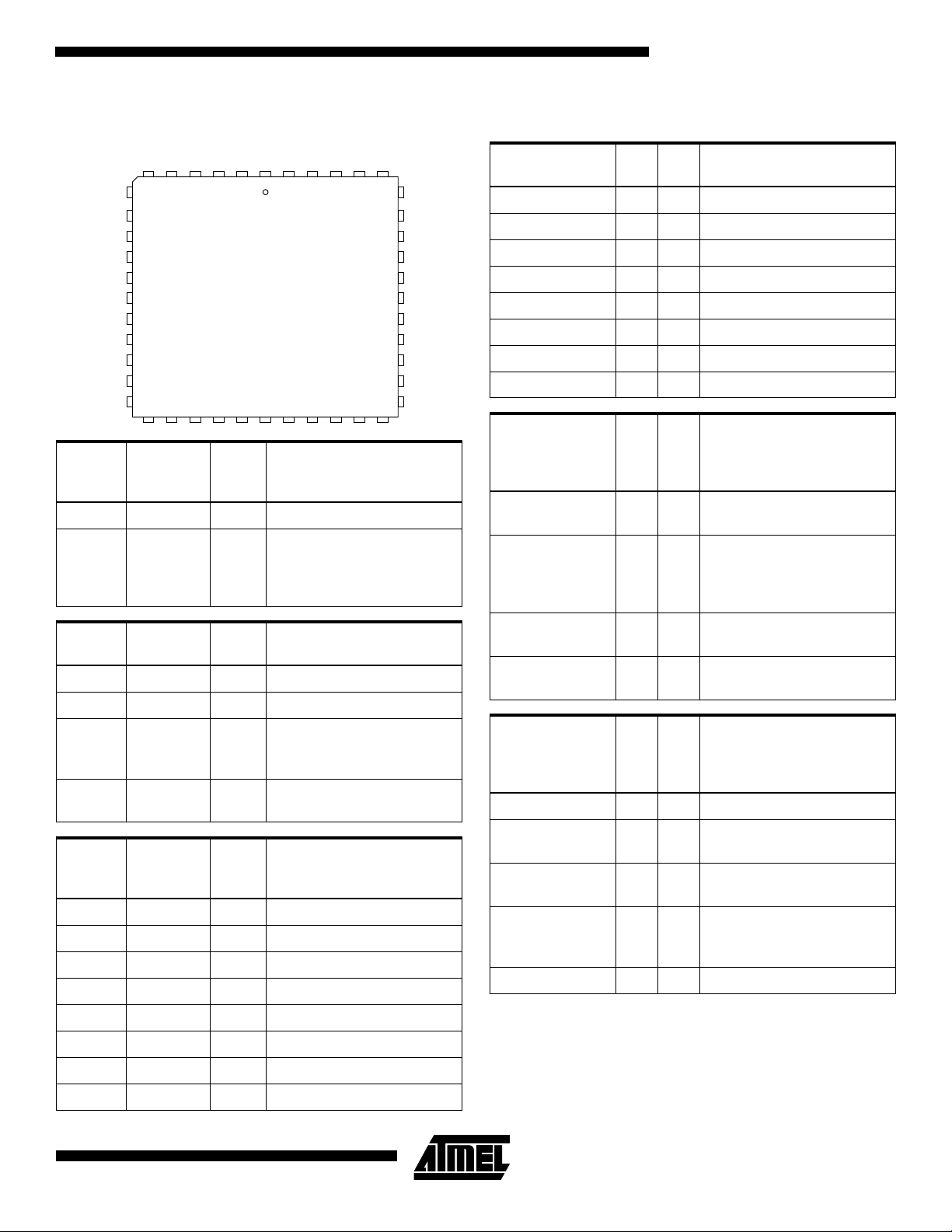

Figure 1.

Block diagram of the AT73C500 chipset in stand-alone configuration

EXTERNAL CONNECTOR

L1 L2 L3

L1

VREF

BGD

RESET

VI1

VI2

VI3

CI1

CI2

CI3

CS

VDA

VDDA

VCC

AT73501

SIX SINGLE-ENDED,

INDEPENDENT

SIGMA-DELTA

CONVERTERS

PFAIL

ACK

DATA

CLKR

CLK

AGND

BRDY

IRQ0

IRQ1

&

SIN

SCLK

XRES

L2

XI XO MODE

VSA

VSSA

GND

1

L3

RESET

&

1

CS

SK

The AT73C500 is progra mmed to m easure act ive, rea ctive

and apparent phase powers. Phase factors, phase voltages, phase currents and line frequenc y are also measured, simultaneously. Based on the individu al phase

powers, total active power is determined.

The power value s are calc ulated ove r one-li ne freque ncy

cycle. The negative and positive results are accumulated in

different registers, which allows for separate billing of

imported and e xported act ive energ y. Also, the reactive

results are sorted depending on whether capacitive or

inductive load is applied.

VCC

STROBE

RD/WR

DEDICATED DSP

DI

AT73500

FOR ENERGY

METERING

GND

AT93C46

EEPROM

128*8 bit

ADDR1

ADDR0

SOUT1

SOUT0

DATA BUS

STATUS BUS

DO

MODE2

MODE1

MODE0

1

1

1

1

1

-VArh

+VArh

-Wh

+Wh

+Wh

-Wh

+VArh

-VArh

&

Eight pulse outputs are provided. Each billing quantity

(+Wh, -Wh, +VArh, -Varh) is supplied with its own meter

constant output, as well as a display counter output. In

multi-channel mode, AT73C500 per forms the fu nctions of

three independent s ingle phase Wh me ters and three

impulse outputs are available, one for each meter element.

All measurement inform ation is av ailab le on an 8-bit microprocessor bus. The results are o utput in six packages, 16

bytes each. Mode and s tatus information of the meter is

also transferred with each data block.

TAMP

STUP

L3

L2

L1

FAIL

DATRDY

INI

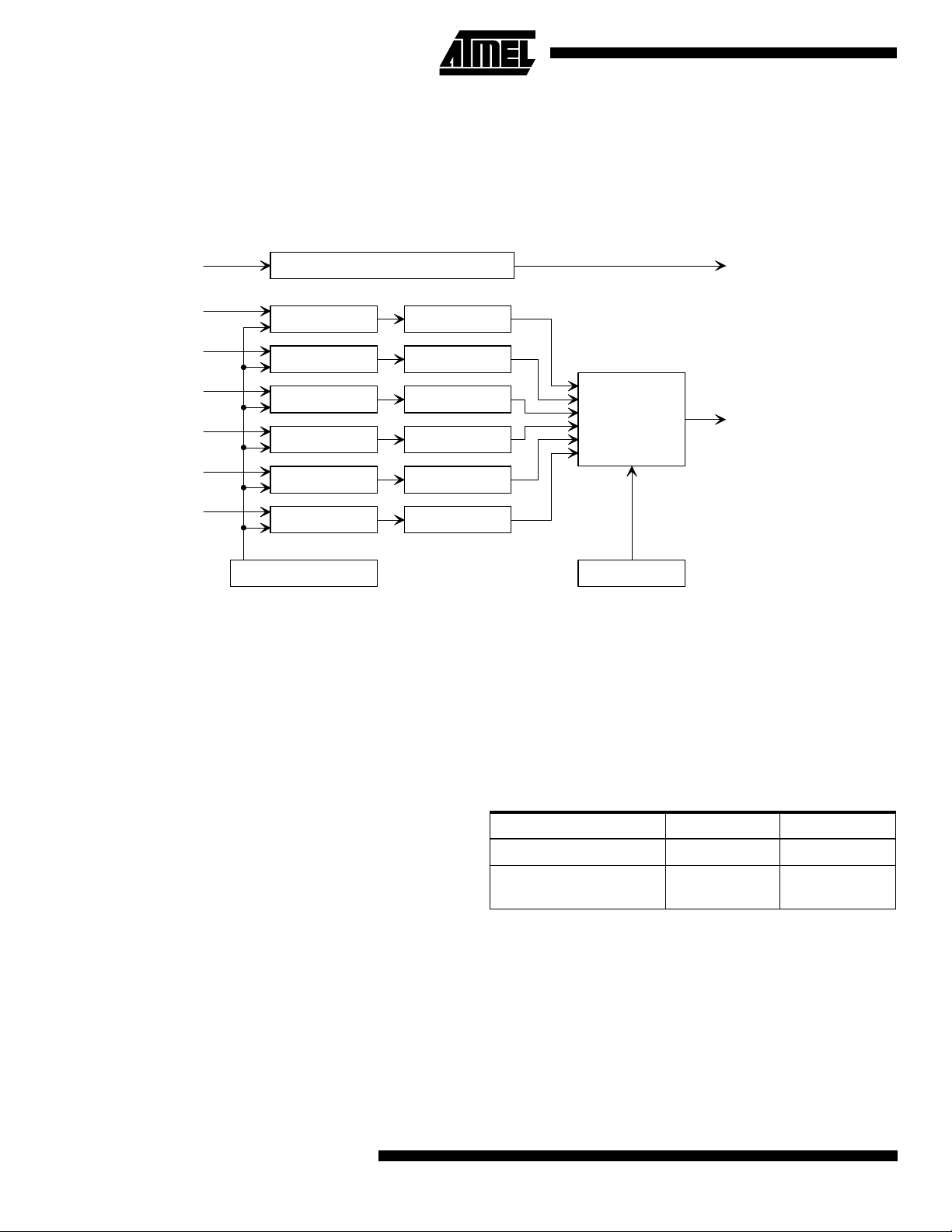

Figure 2.

L1 L2 L3

L1

L2

L3

RESET

2

Block diagram of the AT73C500 chipset in microprocessor configuration

VDA

VREF

BGD

RESET

1

VI1

VI2

VI3

CI1

CI2

CI3

CS

VDDA

AT73501

SIX SINGLE-ENDED,

INDEPENDENT

SIGMA-DELTA

CONVERTERS

XI XO MODE

VCC

VSA

VSSA

GND

PFAIL

ACK

DATA

CLKR

CLK

AGND

BRDY

IRQ0

IRQ1

SIN

SCLK

XRES

VCC

AT73500

DEDICATED DSP

FOR ENERGY

METERING

GND

STROBE

RD/WR

ADDR1

ADDR0

SOUT1

SOUT0

DATA BUS

STATUS BUS

MODE2

MODE1

MODE0

AT73C500

AT90Sxx

D

DATRDY

B9

&

1

1

1

1

1

B14

B13

B12

MICROCONTROLLER

MODEM

LCD

EEPROM

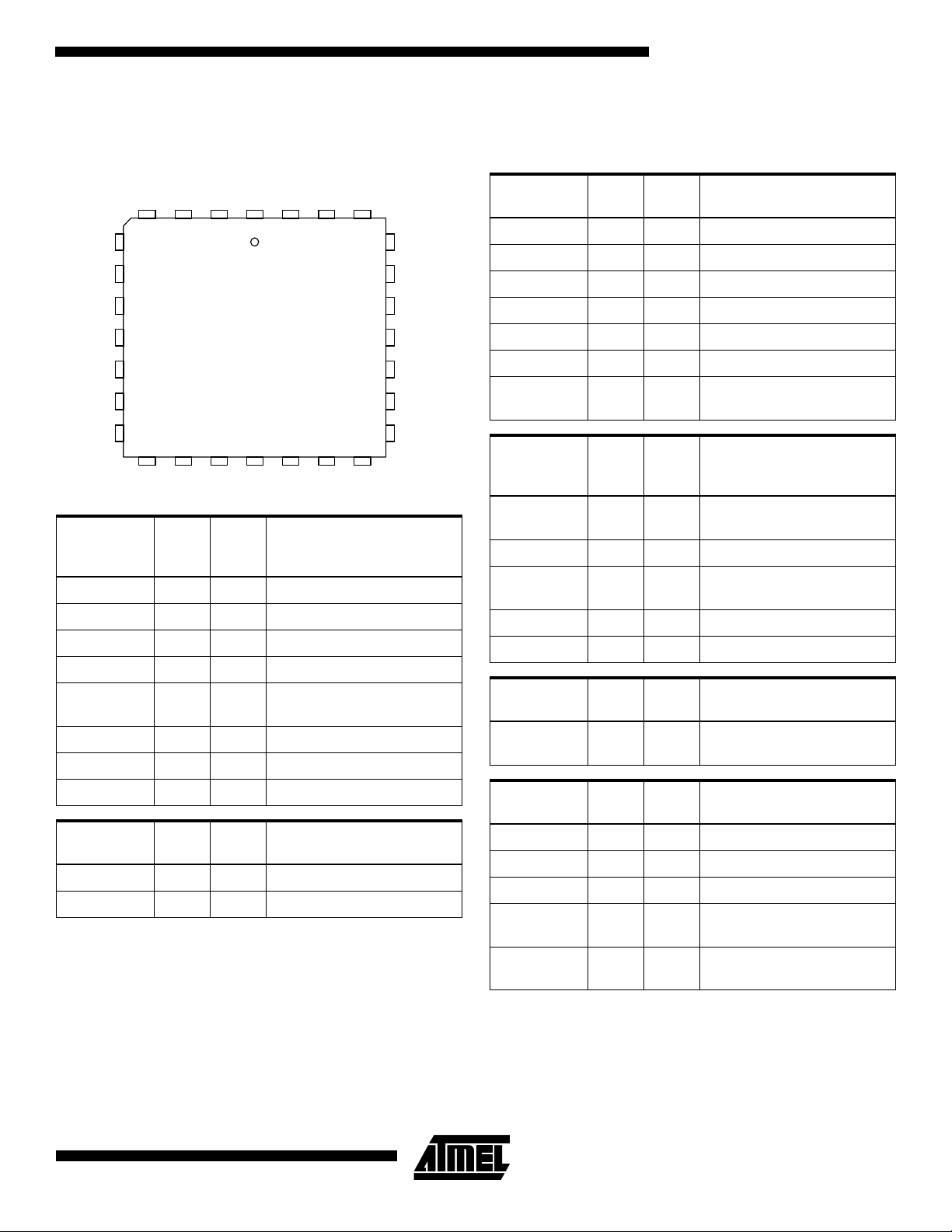

Pin Description

AT73C501 Single-ended ADC

AT73C500

Figure 3.

PFAIL

AGND

VREF

PLCC-28 package pin layout

34

5

BGD

6

CS

7

VCC

8

9

10

VCIN

11

VSSA VDDA AIN2 AIN4 AIN6 AIN1 AIN3

DATAFSRACKCLKRCLKXIXO

26272812

25

24

23

22

21

20

19

18171615141312

Power

Supply

Pins Pin I/O Description

VDDA 13 PWR Analog Supply, Positive, +5V

VSSA 12 PWR Analog Supply, Negative, 0V

VDA 21 PWR Analog Supply, Positive, +5V

VSA 20 PWR Analog Supply, Negative, 0V

AGND 9 PWR

Analog Ground Reference

Output

VREF 11 PWR Reference Voltage Output

VCC 7 PWR Digital Supply, Positive, +5V

VGND 23 PWR Digital Supply, Negative, 0V

Crystal Osc

Signals Pin I/O Description

XI 3 I Crystal Oscillator Input

XO 4 O Crystal Oscillator Output

RESET

MODE

GND

PD

VDA

VSA

AIN5

Analog

Signals Pin I/O Description

AIN1 17 I Input to Converter #1

AIN2 14 I Input to Converter #2

AIN3 18 I Input to Converter #3

AIN4 15 I Input to Converter #4

AIN5 19 I Input to Converter #5

AIN6 16 I Input to Converter #6

VCIN 10 I

Input to Voltage Monitoring

Block

Digital

Control

Signals Pin I/O Description

BGD 5 I

By-pass Control

for Reference Voltage

CS 6 I Chip Select Input

PD 22 I

Power Down Cont r o l

for A/D Modulators

MODE 24 I Mode Selection Control

RESET 25 I Reset Input, Active High

Status

Flags Pin I/O Description

PFAIL 8 O

Output of V olta ge Monitoring

Block

Output Bus

Signals Pin I/O Description

CLK 2 O Master Clock Output

CLKR 1 O Serial Bus Clock Output

DATA 26 O Serial Data Output

FSR 27 O

Output Sample Frame

Signal

ACK 28 O

Data Ready Acknowledge

Output

3

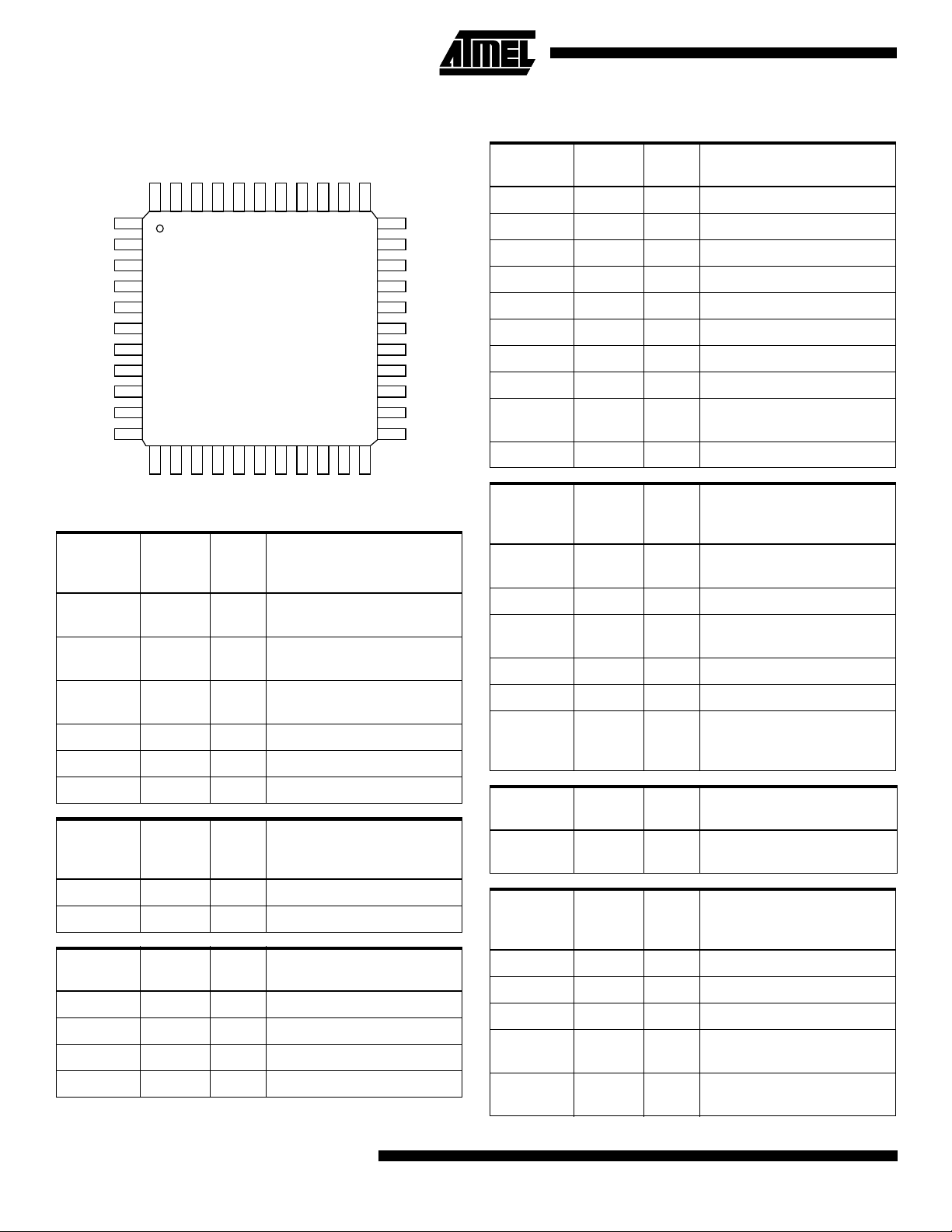

AT73C502 Differential-Ended ADC

T

A

A

Figure 4.

IADJUS

QFP-44 package pin layout

XI

BGD MODE

CS

VCC

VCC

PFAIL

AGND

VCIN

VREF

VS

VS

4344 42 41 40 39 38 37 36 35 34

133

3

4

5

6

7

8

9

10

11

1312 14 15 16 17 18 19 20 21 22

CLKRCLK

N/CN/CN/C

FSR

DATAACK

RESETXO

322

31

30

29

28

27

26

25

24

23

IINP2IINP1VINP3VINP2VINP1VDA

IINN1VINN3VINN2VINN1VDA

Power

Supply

Pins Pin I/O Description

VDA

VSA

AGND 6 PWR

12, 13,

29, 30

10, 11,

27, 28

PWR

PWR

Analog Supply, Positive, +5V

Analog Supply, Negative, 0V

Analog Ground Reference

Output

VREF 8 PWR Reference Voltage Output

VCC 3, 4 PWR Digital Supply, Positive, +5V

GND

PD

VDA

VDA

VSA

VSA

SINGLE

IINN3

IINP3

IINN2

Analog

Signals Pin I/O Description

VINP3 18 I Input to Converter #3 (+)

VINN3 19 I Input to Converter #3 (-)

IINP1 20 I Input to Converter #4 (+)

IINN1 21 I Input to Converter #4 (-)

IINP2 22 I Input to Converter #5 (+)

IINN2 23 I Input to Converter #5 (-)

IINP3 24 I Input to Converter #6 (+)

IINN3 25 I Input to Converter #6 (-)

VCIN 7 I

Input to Voltage Monitoring

Block

IADJUST 9 I Must be left floating

Digital

Control

Signals Pin I/O Description

BGD 1 I

By-pass Control for

Reference Voltage

CS 2 I Chip Select Input

PD 31 I

Power Down Control for A/D

Modulators

MODE 33 I Mode Selection Control

RESET 35 I Reset Input, Active High

Single / Differential selector.

SINGLE 26 I

· Low: Differential

· High or n/c: Single-ended

GND 32 PWR Digital Supply, Negative, 0V

Crystal

Osc

Signals Pin I/O Description

XI 43 I C rystal O scillator Input

XO 44 O Crystal Oscillator Output

Analog

Signals Pin I/O Description

VINP1 14 I Input to Converter #1 (+)

VINN1 15 I Input to Converter #1 (-)

VINP2 16 I Input to Converter #2 (+)

VINN2 17 I Input to Converter #2 (-)

4

AT73C500

Status

Flags Pin I/O Description

PFAIL 5 O

Output of Voltage Monitoring

Block

Output

Bus

Signals Pin I/O Description

CLK 41 O Master Clock Output

CLKR 3 9 O Serial Bus Clock Output

DATA 35 O Serial Data Output

FSR 36 O

ACK 37 O

Output Sample Frame

Signal

Data Ready Acknowledge

Output

AT73C500 DSP

AT73C500

Figure 5.

PLCC-44 package pin layout

GND

SOUT15SOUT0

6

GND ADDR0

7 39

B0

8

B1

9

B2

10

GND

11

GND

12

B12

13

B13

14

B14

15

GND

16

B15

17

18

B3

IRQ0 /

GND2GND1CLK44STROBE43VCC42ADDR241ADDR1

PFAIL

4

3

B419GND20B521B622B723N/C24B825B926GND27B10

40

38

37

36

35

34

33

32

31

30

29

28

Power

Supply

Pins Pin I/O Description

VCC 35, 42 PWR Digital Supply, Positive, +5V

1, 2, 6, 7,

GND

11, 12,16,

20, 27, 30,

PWR Digital Supply, Negative, 0V

34

Digital

Inputs Pin I/O Description

CLK 44 I C lock Input

XRES 38 I Reset Input, active low

Interrupt Input, usually

IRQ0 3 I

connected to PFAIL output

of AT73C 501

IRQ1 31 I

Interrupt Input, connected to

ACK Output of AT73C501

Status/

Mode

Bus Pin I/O Description

B15 17 I/O Status/Mode Bus, Bit7

B14 15 I/O Status/Mode Bus, Bit6

B13 14 I/O Status/Mode Bus, Bit5

B12 13 I/O Status/Mode Bus, Bit4

B11 29 I/O Status/Mode Bus, Bit3

XRES

BRDY

RD/WR

VCC

GND

SIN

SCLK

IRQ1 / ACK

GND

B11

Microprocessor

Bus Pin I/O Description

B7 23 I/O

B6 22 I/O

B5 21 I/O

B4 19 I/O

B3 18 I/O

B2 10 I/O

B1 9 I/O

B0 8 I/O

P Bus, Bit7

µ

P Bus, Bit6

µ

P Bus, Bit5

µ

P Bus, Bit4

µ

P Bus, Bit3

µ

P Bus, Bit2

µ

P Bus, Bit1

µ

P Bus, Bit0

µ

AT73C501 /

AT73C502 and

EEPROM

Interface Pin I/O Description

SOUT0 4 O

Serial Output, used as a

clock for EEPROM

Serial Output, used as Chip

SOUT1 5 O

Select (CS) for AT73C501

and as Data Input (DI) for

EEPROM

SIN 33 I

SCLK 32 I

Serial Data Input, data from

AT73C501 or from EEPROM

Serial Clock Input, bit clock

from AT73C501

Control Signals

of µµµµP Bus and

Status/Mode

Bus Pin I/O Description

STROBE 43 O Strobe Output

BRDY 37 I

ADDR1 40 O

Microprocessor ready for

I/O, Active Low

Address Output 1, used for

P bus

µ

Address Output 0, used for

ADDR0 39 O

Status/ Mode bus and for

Impulse Outputs

RD/WR 36 O Read/Write Signal

B10 28 I/O Status/Mode Bus, Bit2

B9 26 I/O Status/Mode Bus, Bit1

B8 25 I/O Status/Mode Bus, Bit0

5

AT73C501 and AT73C502

The AT73C501 consis ts of s ix, 16-b it anal og-to-d igital c onverters. The converters are equipped with single-ended

inputs. For di fferential ended applic ations, the AT73C50 2

chip is used.

The converters contain a reference vo ltage gen erator , voltage monitoring bl ock and se rial output i nterfac e. Both converters are based on high-performance, oversampling

Sigma-Delta modulators and digital decimation filters.

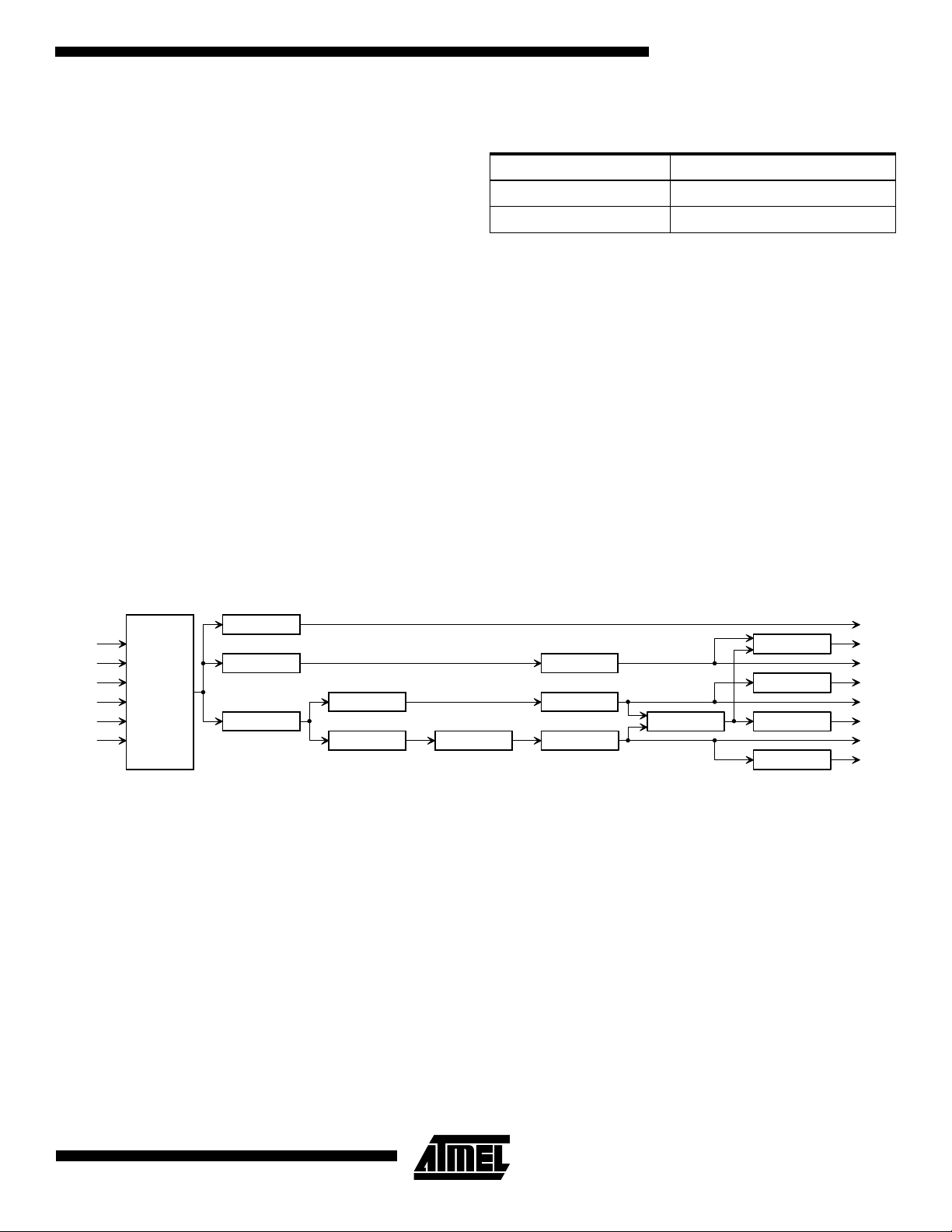

Figure 6.

Block diagram of the single-ended ADC chip, AT73C501

VOLTAGE

MONITORING

SIGMA-DELTA

MODULATOR

SIGMA-DELTA

MODULATOR

SIGMA-DELTA

MODULATOR

SIGMA-DELTA

MODULATOR

SIGMA-DELTA

MODULATOR

SIGMA-DELTA

MODULATOR

VOLTAGE

REFERENCE

DECIMATION

FILTER

DECIMATION

FILTER

DECIMATION

FILTER

DECIMATION

FILTER

DECIMATION

FILTER

DECIMATION

FILTER

In a 50 Hz meter, the nominal decimated sampling rate of

3200 Hz is used. This corresponds to 64 sa mpl es per eac h

line frequency cycle. 60 H z meters operate with 3840 Hz

sample rate. The master clock frequency of the ADC is

1024 times higher than the above frequencies, i.e. 3.2768

MHz in 50 Hz meters and 3.9321 6 MHz in 60 Hz system s.

The default meter constant of AT73C500 energy counters

is based on the above sample rates.

Other sample frequenci es can be used, bu t the energy

results have to be scaled accordingly. If higher sampling

rate is selected, the meter constant will also be increased

by the same ratio.

The three current inputs of AT73C501 are fed from secondary outputs of current transformers, from Hall sensors or

other similar sensors. In differential-ended applications,

such as with current shunt resistors, the AT73C502 ADC

can be used. On a ny of these converter s, the voltage

inputs must be equipped with simple external voltage dividers.

The input voltage range of each converter is 2V

PP

. The

characteristics of a Watt-hour meter operating, according to

IEC1036 specification, are based on a certain basic current, I

. As a default, the basic current of AT73C500

B

chipset is to 6.25% of the current input full scale value. This

means that if a meter is designed for I

= 5A

B

RMS

, the full

scale range of the current channels will be:

SERIAL OUTPUT

LOGIC

TIMING AND

CONTROL

100

-----------

IFS = 5 A

× 80 A

RMS

6.25

=

RMS

The following current transformer and voltage divider configuration is recommended for a 230V, 3-phase system,

with 5A basic current:

Voltage Inputs Current Inputs

Converter full-scal e input 2.0V

Corresponding full-scale

line voltage / current

270V

PP

RMS

2.0V

80A

PP

RMS

With the above settings, the nominal pulse rate of the

meter constant outp uts is 1250 impulses/kWh (1 250

impulses/kVArh) and the rate of four display outputs 100

impulses/kWh (100 imp/kVArh).

When used in a 5A transformer operated meter, the maximum current range ca n b e s c al ed down to 8A f or exam pl e.

In this case, the me ter constant wi ll be ten times hi gher

than in an 80A meter, i.e. 12500 impulses/kWh. Similarly,

the starting current level will be tra nsferred 2mA from

20mA.

6

AT73C500

AT73C500

If the nominal voltage is chosen to be 120V, the vo ltage

divider can either ha ve the same config uration as in the

230V meter, or it can be modified to produce 2.0V

pp

with

140V phase voltage. In the latter case, the default meter

constant will be roughly twice the constant of 230V meter,

i.e. 2411 impulses/ kWh. The mete r constan t can be s cale d

to an even number value by means of calibration.

As described above, th e config uration of voltag e divider s

and current trans form ers aff ects to a lmost all param eters

being metered, like energy counters and impuls e outputs.

A calibration coefficient is provided for the adjustment of

the display pulse rates. With this coefficient, the effect of

various voltage divider and current transformer configurations can be compensated. Care should be tak en that the

dynamic range of the A/D conve rters is a lways effectiv ely

utilized. The use o f calibrat ion coeff icients i s described in

the next section.

Current and voltage samples of AT73C501/AT73C502 are

multiplexed and transferred to AT73C500 through a serial

interface. The ti ming of the interf ace is presented in the

next section.

AT73C501/AT73C502 c ontai n an internal band gap v oltag e

reference. When used in cl ass 0.5 and 0.2 meter s, smaller

temperature drift is required. This can be achieved by

bypassing the internal reference and using temperature

compensated external reference instead. The reference is

selected with the BGD input.

BGD Reference

) Internal

0 (V

SS

1 (VDD) External

There is an integrated voltage mo ni tor ing blo ck on the converter chip. The PFAIL output is forced high if the level of

voltage supplied to V

input drops below 4.2V. There is a

CIN

hysteresis in the monitoring function and PFAIL returns low

if voltage at V

is raised back above 4.3V.

CIN

PFAIL output of AT73C501/AT73C502 can be connected

to an interrupt input o f AT73C500. A T73C500 det ects the

rising edge of PFAIL. To as sure reliable power -down procedure after voltage break, the V

supply of AT73C500

CC

must be equipped with a 470 µF or larger capacitor.

AT73C500

AT73C500 performs p ower and energy calculations. It a lso

controls the interfacing to the AT73C501 (or AT73C502)

and to an external microprocessor. The block diagram of

the DSP is presented below.

Figure 7.

u1(n)

u2(n)

u3(n)

i1(n)

i2(n)

i3(n)

Block diagram of DSP software

FREQUENCY

MEASUREMENT

VOLTAGE

MEASUREMENT

DC OFFSET

SUPPRESSION

PHASE

CALIBRATION

ACTIVE POWER

MEASUREMENT

HILBERT

TRANSFORM

REACTIVE POWER

MEASUREMENT

Serial Bus Interface

The timing of the serial bus interface connec ting the ADC

and DSP devices is presented in Figure 5. The same bus is

used to read the calibration data from an exter nal

EEPROM. This operation is described in section “Loading

of Calibration Coefficients” on page 19.

f

I

U

W

P

PF

Q

Wq

GAIN

CALIBRATION

GAIN AND OFFSET

CALIBRATION

GAIN AND OFFSET

CALIBRATION

APPARENT POWER

EVALUATION

CURRENT

DERIVATION

ACTIVE ENERGY

CALCULATION

POWER FACTOR

DERIVATION

REACTIVE ENERGY

CALCULATION

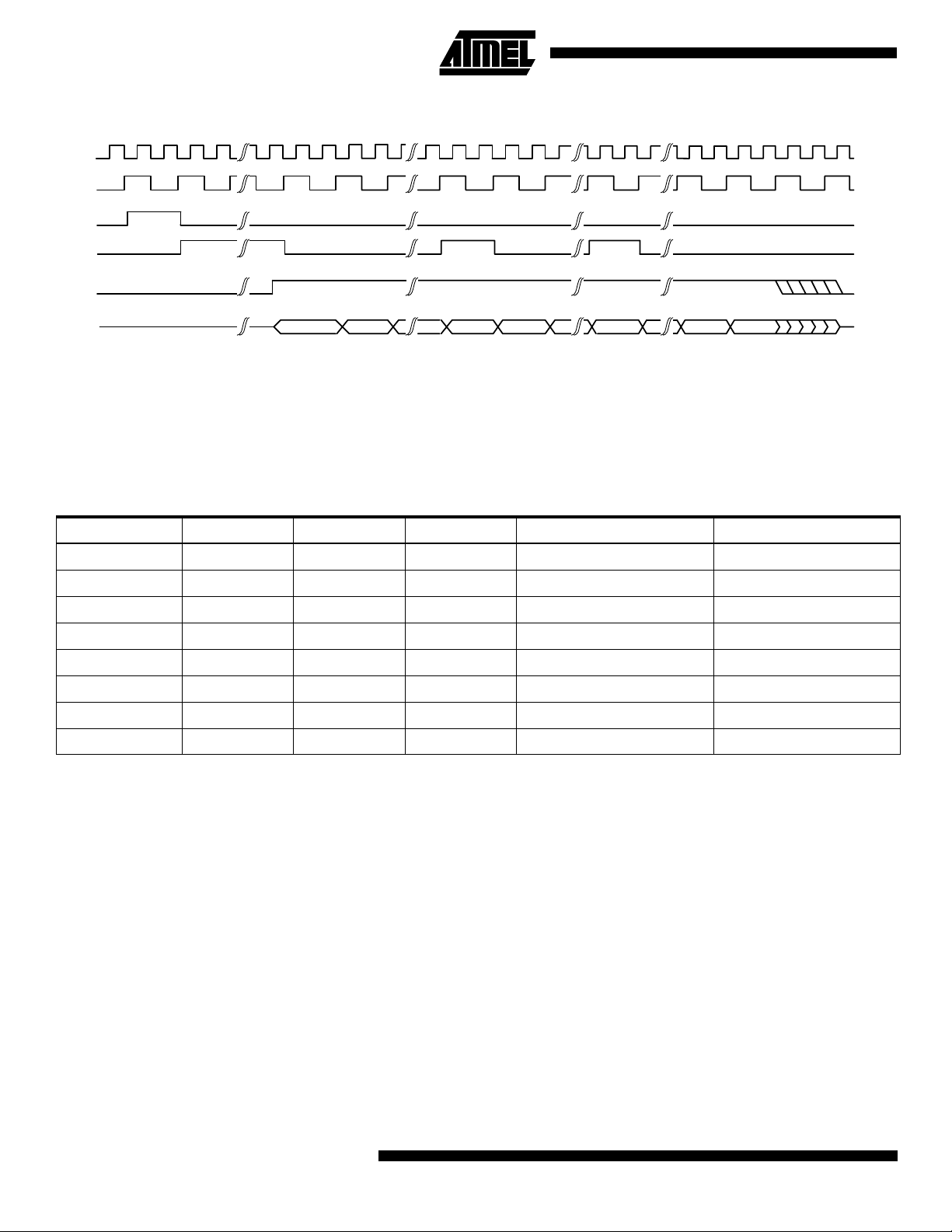

When the three current and three voltage samples are

ready, AT73C50 1/AT73C502 raises the ACK output.

AT73C500 detects the ri sing edge of ACK, and, after a f ew

clock cycles, it i s ready to read the sample s through the

serial bus. Th e transfer is initiated by CS/SOUT1 signal

and the data bits are strobed in at the falling edge of

CLKR/SCLK clock. Six 16-bit samples is transferred in the

following sequence: I1, U1, I2, U2, I3 and U3.

7

Figure 8.

CLK

CLKR

ACK

FSR

CS

DATA

Serial bus timing

CH1, B15

MSB

6 * 16 BITS

CH1, B14 CH1, B0

LSB

CH2, B15

MSB

CH2, B0

LSB

CH6, B1 CH6, B0

Operating Modes of AT73C500

The AT73C500 chips et has six operating modes. The

mode is selected by three mode control inputs which

AT73C500 reads through a bus during the initialization procedure after a reset state. The operation of

AT73C501/AT73C502 is independent of the mode

selected.

Mode Number Mode Bit 2 Mode Bit 1 Mode Bit 0 Operating Mode Calibration Data Storage

0 000 Not in use

In operating mode 7, the default display pul se rate is 10

impulses per kWh, instead of 100 impulses per kWh, as in

other modes.

1 0 0 1 Normal operation EEPROM

2 0 1 0 Multi-channel operation EEPROM

3 0 1 1 Normal operation Micro-processor

4 1 0 0 Multi-channel operation Micro-processor

5 101 Test mode None

6 110 Not in use

7 1 1 1 Normal operation EEPROM

Normal Measurement Mode

AT73C500 devices support both stand-alone and microprocessor configurati on. The cal ibrat ion coe fficient s ca n either

be supplied by a processor or stored in an 128 x 8-bit

EEPROM. The ROM is interfaced with AT73C500 via three

pin serial bus. AT73C500 and the processor communicate

through an 8-bit bus.

The only operational difference be tween stand- alone and

µP mode is the way of readi ng c al ib ra tio n c oeffi c ien ts. This

allows various combinations of these two configurations to

be utilized. For example, th e calibratio n data can be store d

in an EEPROM even though the processor reads and displays the measurement results supplied by AT73C500

device.

In most cases, the use of external EEPROM gives flexibility

to the meter testing and calibra tion, and also makes the

processor inte rface easier to implement. Th erefore, th is

configuration is recommended even in meters equipped

with a separate microprocessor.

The same sequence of basic ca lculations is performed

both in poly-phase and single-phase meters. This

sequence consists of DC offset suppression, phase, gain

and offset cal ibr atio n, ca lcul atio ns of m easu remen t qu ant ities and data transfer to µP bus and pulse outputs.

AT73C500 constantly m oni tor s v ar ious ta mpe ri ng an d faul t

situations, which are indicated by status bits.

After a reset state, AT73C500 goes through an initialization

sequence. The device reads the operating mode and

fetches the calibration coefficients an d adjustment factors

for output pulse rate and starting current level, either from a

non-volatile memory or from a microprocessor. After that

the normal measurement starts. The reset state is normally

activated by power-up reset following the recovery from a

voltage interruption.

8

AT73C500

AT73C500

Measurements and Calculations

The first operation performed by AT73C500 is digital highpass filtering. The purpose of the filtering is to remove the

DC offset of both current and voltage samples.

From offset free samples, active power i s calculated

phase-by-phase with simple multiplication and additio n

operations.

First, the current samples are multiplied by voltage samples. The multiplic ation resu lts are s ummed ov er one lin e

period and finally the sum value is divided by 64. This discrete time operation gives the average power of one

50/60Hz period and the result corresponds to the following

continuous time formula:

N

T

1

---

P

ANUNsin n wt

=

×

∑

n0

∫

T

0

=

N

1

=

-- -

A

∑

n0

=

nAnUnIn

2

A

×{}

N

I

sin n wt

×××××[]

N

cos

∅

()×××××

n

dt

∅+×N{}

where

T = 1/50 Hz or 1/60 Hz,

n = 1, 2, 3,..., 20 (basic 50/60 Hz frequency and the

harmonics),

= frequency response of calculations.

A

n

The total power is calculated by summing the power of

each line phase. Reactive power calculation is based on a

similar procedure. Before multipl ying the current an d voltage samples AT73C500 performs a frequency independent

-90 degree phase shift of the voltage signal. This is realized

with a digital Hilbert transformation filter. The bandwidth of

reactive power measuremen t is limited to 360 Hz.

Based on the active and reactive results apparent power

and power factors are d etermined. RMS phase voltages

are calculated by squaring and summing the voltage samples and fina lly tak ing a s quare r oot of the re sults. Curr ent

is determined by divi ding apparent po wer result by cor responding phase voltage.

Frequency measurement is based on a comparison of the

line frequency and AT73C500 sampling clock frequency.

The measurement range is from 20 Hz to 350 Hz.

All measurements and calculations, except frequency measurement, are made ov er 1 0 l ine cy cle per io ds . The resu lts

are updated and transferred to processor bus once in 200

ms.

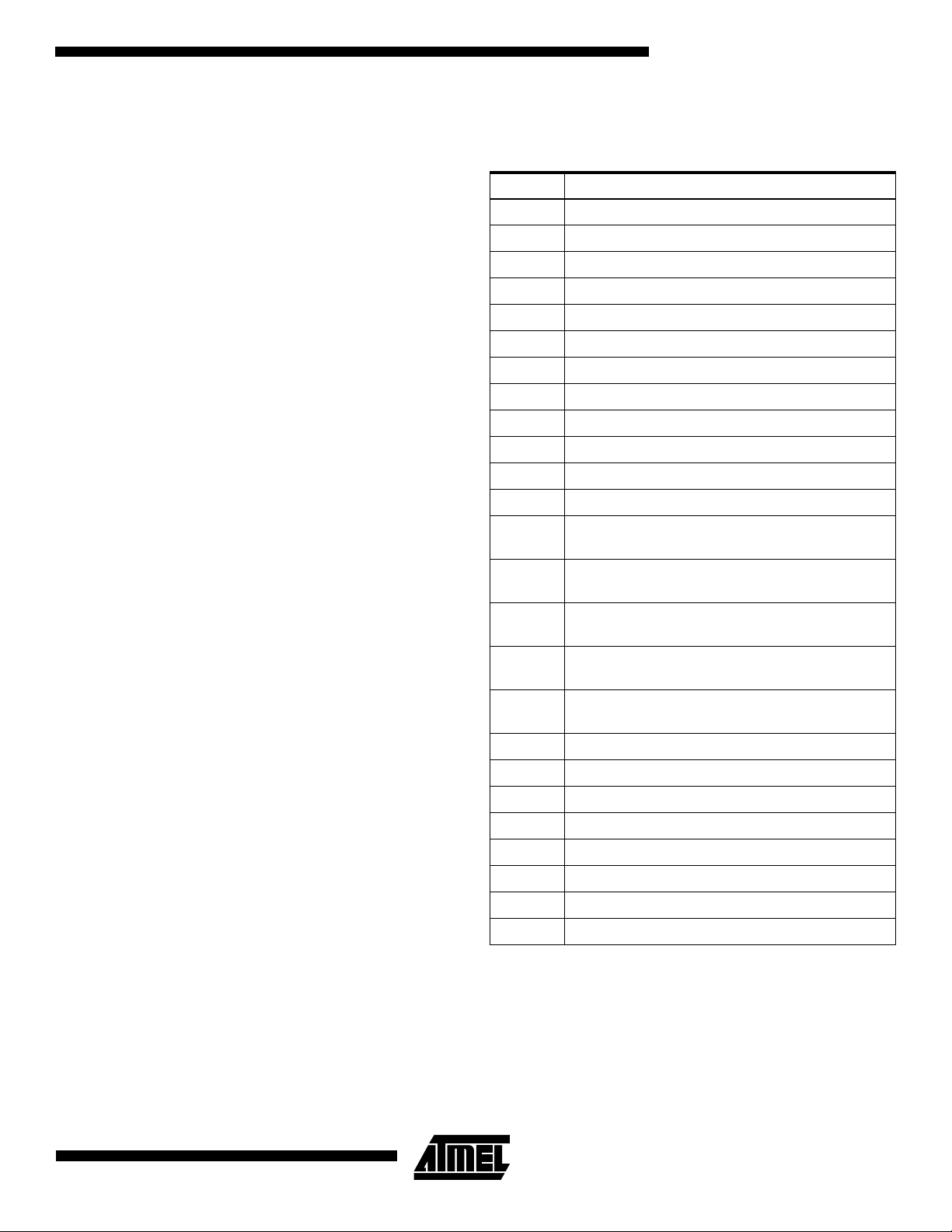

Measurement Registers

For the measurement parameters 25 registers are allocated:

Register Meaning

REG0 Phase 1, active power, P1(10T), 32-bit register;

REG1 Phase 2, active power, P2(10T), 32-bit register;

REG2 Phase 3, active power, P3(10T), 32-bit register;

REG3 Phase 1, reactive power, Q1(10T), 32-bit register;

REG4 Phase 2, reactive power, Q2(10T), 32-bit register;

REG5 Phase 3, reactive power, Q3(10T), 32-bit register;

REG6 Phase 1, apparent power, S1(10T), 16-bit register;

REG7 Phase 2, apparent power, S2(10T), 16-bit register;

REG8 Phase 3, apparent power, S3(10T), 16-bit register;

REG9 Phase 1, power factor, PF1, 16-bit register;

REG10 Phase 2, power factor, PF2, 16-bit register;

REG11 Phase 3, power factor, PF3, 16-bit register;

REG12

REG13

REG14

REG15

REG16

REG17 Frequency, f, 16-bit register;

REG18 Reserved for further use, 16-bit register;

REG19 Phase 1, voltage U1, 16-bit register;

REG20 Phase 2, voltage U2, 16-bit register;

REG21 Phase 3, voltage U3, 16-bit register;

REG22 Phase 1, current I1, 16-bit register;

REG23 Phase 2, current I2, 16-bit register;

REG24 Phase 3, current I3, 16-bit register.

Active e xported energy since the lates t reset, +Wp ,

32-bit counter;

Active imported energ y s ince the l atest re set, -Wp,

32-bit counter;

Reactive energy, inductive load, Wqind, 32-bit

counter;

Reactive energy, capacitive load, Wqcap, 32-bit

counter;

Number of 10T periods elapsed since the latest

reset, 32-bit counter;

The size of the registers is either 16-bit or 32-bit. IEC specifications apply to the calculations of active and reactive

power and energy (REG 0-5 and REG 12-15). Other results

are intended mainly for demand recording and for va rious

diagnostic and display functions. The accuracy of those are

limited due to the finite resolution.

9

Loading...

Loading...