ATMEL AT49LV4096-20TI, AT49LV4096-20TC, AT49LV4096-20RI, AT49LV4096-20RC, AT49LV4096-15TI Datasheet

...

Features

Low Voltage Operation

•

- 2.7V Read

- 5V Program/Erase

Fast Read Access Time - 120 ns

•

Internal Erase/Program Control

•

Sector Architecture

•

- One 8K Words (16K bytes) Boot Block with Programming Lockout

- Two 8K Words (16K bytes) Parameter Blocks

- One 232K Words (464K bytes) Main Memory Array Block

Fast Sector Erase Time - 10 seconds

•

Word-By-Word Programming - 10 µs/Word

•

Hardware Data Protection

•

DATA Polling For End Of Program Detection

•

Low Power Dissipation

•

- 25 mA Active Current

- 50 µA CMOS Standby Current

Typical 10,000 Write Cycles

•

Description

The AT49BV4096 and AT49LV4096 are 3-volt, 4-megabit Flash Memories organized

as 256K words of 16 bits each. Manufactured with Atmel’s advanced nonvolatile

CMOS technology, the devices offer access times to 120 ns with power dissipation of

just 67 mW at 2.7V read. When deselected, the CMOS standby current is less than

50 µA.

To allow for simple in-system reprogrammability, the AT49BV4096/LV4096 does not

require high input voltages for programming. Reading data out of the device is similar

to reading from an EPROM; it has standard

CE, OE, and WE inputs to avoid bus

4-Megabit

(256K x 16)

3-volt Only

CMOS Flash

Memory

AT49BV4096

AT49LV4096

Preliminary

Pin Configurations

Pin Name Function

A0 - A17 Addresses

CE Chip Enable

OE Output Enable

WE Write Enable

RESET Reset

V

PP

I/O0 - I/O15

NC No Connect

A15

A14

A13

A12

A11

A10

A9

NC

NC

WE

RESET

VPP

NC

NC

NC

A17

A6

A4

A2

Program/Erase

Power Supply

Data

Inputs/Outputs

TSOP Top View

Type 1

1

2

3

4

5

6

7

A8

8

9

10

11

12

13

14

15

16

18

A7

19 I/O8

A5

20

21

22

A3

23

24

A1

(continued)

AT49BV4096/LV4096

SOIC (SOP)

VPP

1

2

NC

A17

3

A7

4

A6

5

A5

6

A4

7

A3

8

9

A2

10

A1

11

A0

NC

I/O15

I/O14

I/O13

I/O12

VCC

I/O3

I/O2

I/O1

I/O0

GND

A0

A16

GND

I/O7

I/O6

I/O5

I/O4

I/O11

I/O10

I/O9

OE

CE

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

3217

31

30

29

28

27

26

25

CE

GND

OE

I/O0

I/O8

I/O1

I/O9

I/O2

I/O10

I/O3

I/O11

12

13

14

15

16

17

18

19

20

21

22

RESET

44

WE

43

A8

42

A9

41

A10

40

A11

39

A12

38

A13

37

A14

36

A15

35

A16

34

NC

33

GND

32

31

I/O15

I/O7

30

I/O14

29

I/O6

28

I/O1327

I/O5

26

I/O1225

I/O4

24

VCC23

0874A–5/97

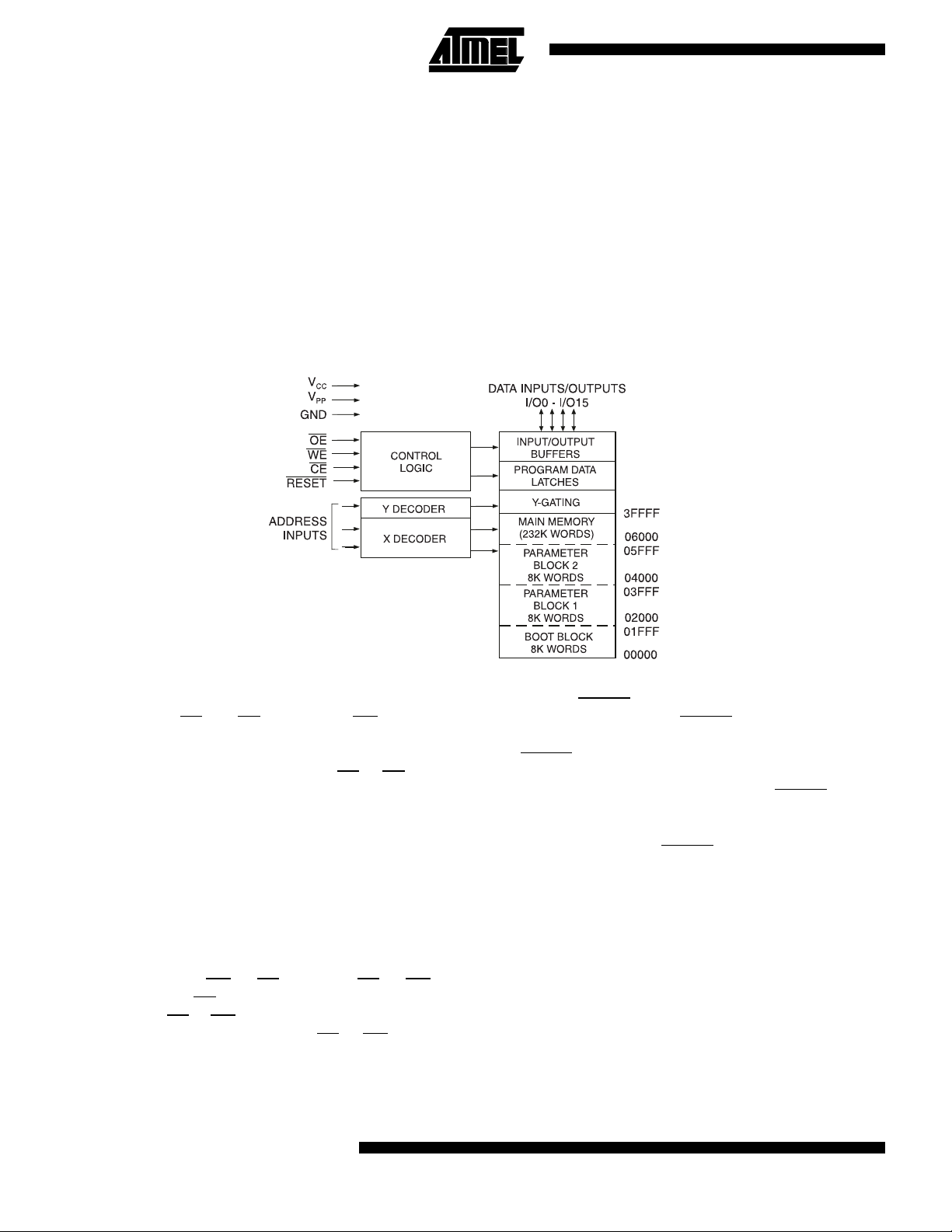

contention. Reprogramming the AT49BV4096/LV4096 is

performed by first erasing a block of data and then programming on a word-by-word basis.

The device is erased by executing the erase command

sequence; the device internally controls the erase oper ation. The memory is divided into three blocks for erase operations. There are two 8K word parameter block sections

and one sector consisting of the boot block and the main

memory array block. The AT49B V4096/LV4096 is programmed on a word-by-word basis.

The device has the capability to protect the data in the

boot block; this feature is en abled by a command se-

Block Diagram

quence. Once the boot block programming lockout feature

is enabled, the data in the boot block cannot be changed

when input levels of 3.6 volts or less are used. The typical

number of program and erase cycles is in excess of

10,000 cycles.

The optional 8K word boot block section includes a reprogramming lock out feature to provide data integrity. The

boot sector is designed to contain user secure code, and

when the feature is enabled, the boot sector is pr otected

from being reprogrammed.

During a chip erase, sector erase, or word programming,

the V

pin must be at 5V ± 10%.

PP

Device Operation

READ:

EPROM. When

data stored at the memory location determined by the address pins is asserted on the outputs. The outputs are put

in the high impedance state whenever

This dual-line control gives designers flexibility in preventing bus contention.

COMMAND SEQUENCES:

ered on it will be reset to the read or standby mode depending upon the state of the control line inputs. In order

to perform other device functions, a series of command

sequences are entered into the device. The command sequences are shown in the Command Definitions table

(I/O8 - I/O15 are don’t care inputs for the command

codes). The command sequences are written by applying

a low pulse on the

(respectively) and

falling edge of

is latched by the first rising edge of

microprocessor write timings are used. The address locations used in the command sequences are not affected by

entering the command sequences.

The AT49BV4096/LV4096 is accessed like an

CE and OE are low and W E is high, the

CE or OE is high.

When the device is first pow-

WE or CE input with CE or WE low

OE high. The address is latched on the

CE or WE, whichever occurs last. The data

CE or WE. Standard

RESET input pin is provided to ease some

RESET:

system applications. When

the device is in its standard operating mode. A low level on

the

puts the outputs of the device in a high impedance state.

When a high level is reasserted on the

device returns to the Read or Standby mode, depending

upon the state of the control inputs. By applying a 12V ±

0.5V input signal to the

can be reprogrammed even if the boot block program lockout feature has been enabled (see Boot Block Programming Lockout Override section).

ERASURE:

be erased. The erased state of memory bits is a logical “1”.

The entire device can be erased by using the Chip Erase

command or individual sectors can be erased by using the

Sector Erase commands.

CHIP ERASE:

time by using the 6-byte chip erase software code. After

the chip erase has been initiated, the device will internally

time the erase operation so that no external clocks are required. The maximum time to erease the chip is t

A

RESET is at a logic high level,

RESET input halts the present device operation and

RESET pin, the

RESET pin the boot block array

Before a word can be reprogrammed, it must

The entire device can be erased at one

.

EC

2

AT49BV/LV4096

AT49BV/LV4096

If the boot block lockout has been enabled, the Chip Erase

will not erase the data in the boot block; it will erase the

main memory block and the parameter blocks only. After

the chip erase, the device will return to the read or standby

mode.

SECTOR ERASE: As an alternative to a full chip erase,

the device is organized into three sectors that can be individually erased. There are two 8K word parameter block

sections and one sector consisting of the boot block and

the main memory array block. The Sector Erase command

is a six bus cycle operation. The sector address is latched

on the falling

data input command is latched at the rising edge of

The sector erase starts after the rising edge of

sixth cycle. The erase operation is internally controlled; it

will automatically time to completion. When the boot block

programming lockout feature is not enabled, the boot

block and the main memory block will erase together (from

the same sector erase command). Once the boot region

has been protected, only the main memory array sector

will erase when its sector erase command is issued.

WORD PROGRAMMING: Once a memory block is

erased, it is programmed (to a logical “0”) on a word-byword basis. Programming is accomplished via the internal

device command register and is a 4 bus cycle operation.

The device will automatically generate the required internal program pulses.

Any commands written to the chip during the embedded

programming cycle will be ignored. If a hardware reset

happens during programming, the data at the location being programmed will be corrupted. Please note that a data

“0” cannot be programmed back to a “1”; only erase operations can convert “0”s to “1”s. Programming is completed

after the specified t

ture may also be used to indicate the end of a program

cycle.

BOOT BLOCK PROGRAMMING LOCKOUT: The device has one designated block that has a programming

lockout fea ture. This feature p revents programming of

data in the designated block once the featur e has been

enabled. The size of the block is 8K words. This block,

referred to as the boot block, can contain secure code that

is used to bring up the system. Enabling the lockout feature will allow the boot code to stay in the device while data

in the rest of the device is updated. This featur e does not

have to be activated; the boot block’s usage as a write

protected region is optional to the user. The address range

of the boot block is 00000H to 01FFFH.

Once the feature is enabled, the data in the boot block can

no longer be erased or programmed when input levels of

5.5V or less are used. Data in the main memory block can

still be changed through the regular programming method.

To activate the lockout feature, a series of six program

WE edge of the sixth cycle while the 30H

WE.

WE of the

cycle time. The DATA polling fea-

BP

commands to specific addresses with specific data must

be performed. Please refer to the Command Definitions

table.

BOOT BLOCK LOCKOUT DETECTION: A software

method is available to determine if programming of the

boot block section is locked out. When the device is in the

software product identification mode (see Software Product Identification Entry and Exit sections) a read from address location 00002H will show if programming the boot

block is locked out. If the data on I/O0 is low, the boot

block can be programmed; if the data on I/O0 is high, the

program lockout feature has been enabled and the block

cannot be programmed. The software product identification exit code should be used to return to standard operation.

BOOT BLOCK PROGRAMMING LOCKOUT OVERRIDE: The user can override the boot block programming

lockout by taking the

this protected boot block data can be altered through a

chip erase, sector erase or word programming. When the

RESET pin is brought back to TTL levels the boot block

programming lockout feature is again active.

PRODUCT IDENTIFICATION: The product identification

mode identifies the device and manufacturer as A tmel. It

may be accessed by hardware or software operation. The

hardware operation mode can be used by an external programmer to identify the correct programming algorithm for

the Atmel product.

For details, see Operating Modes (for hardware operation)

or Software Product Identification. The manufacturer and

device code is the same for both modes.

DATA POLLING: The AT49BV4096/LV4096 features

DATA polling to indicate the end of a program cycle. During a program cycle an attempted read of the last byte

loaded will result in the complement of the loaded data on

I/O7. Once the program cycle has been completed, true

data is valid on all outputs and the next cycle may begin.

Duri ng a chip o r sector erase ope ration, an attempt to

read the device will give a “0” on I/O7. Once the program

or erase cycle has completed, true data will be read from

the device.

program cycle.

TOGGLE BIT: In addition to

AT49BV4096/LV4096 provides another method for determining the end of a program or erase cycle. During a program or erase operation, successive attempts to read data

from the device will result in I/O6 toggling between one

and zero. Once the program cycle has completed, I/O6 will

stop toggling and valid data will be read. Examining the

toggle bit may begin at any time during a program cycle.

HARDWARE DATA PROTECTION: Hardware features

protect against inadvertent programs to the

AT49BV4 096/LV4096 in the following ways: ( a) V

DATA polling may begin at any time during the

RESET pin to 12 ± 0.5 volts. By doing

DATA polling the

CC

3

sense: if VCC is below 1.8V (typical), the program function

is inhibited. (b) V

reached the V

CC

power on delay: once VCC has

CC

sense level, the device will automatically time out 10 ms (typical) before programming. (c)

Program inhibit: holding any one of

OE low, CE high or

WE high inhibits program cycles. (d) Noise filter: pulses of

less than 15 ns (typical) on the

WE or CE inputs will not

initiate a program cycle.

INPUT LEVELS:

power supply, the address inputs and control inputs (

While operating with a 2.7V to 3.6V

OE,

CE, and WE) may be driven from 0 to 5.5V without adversely affecting the operation of the device. The I/O lines

can only be driven from 0 to V

+ 0.6V.

CC

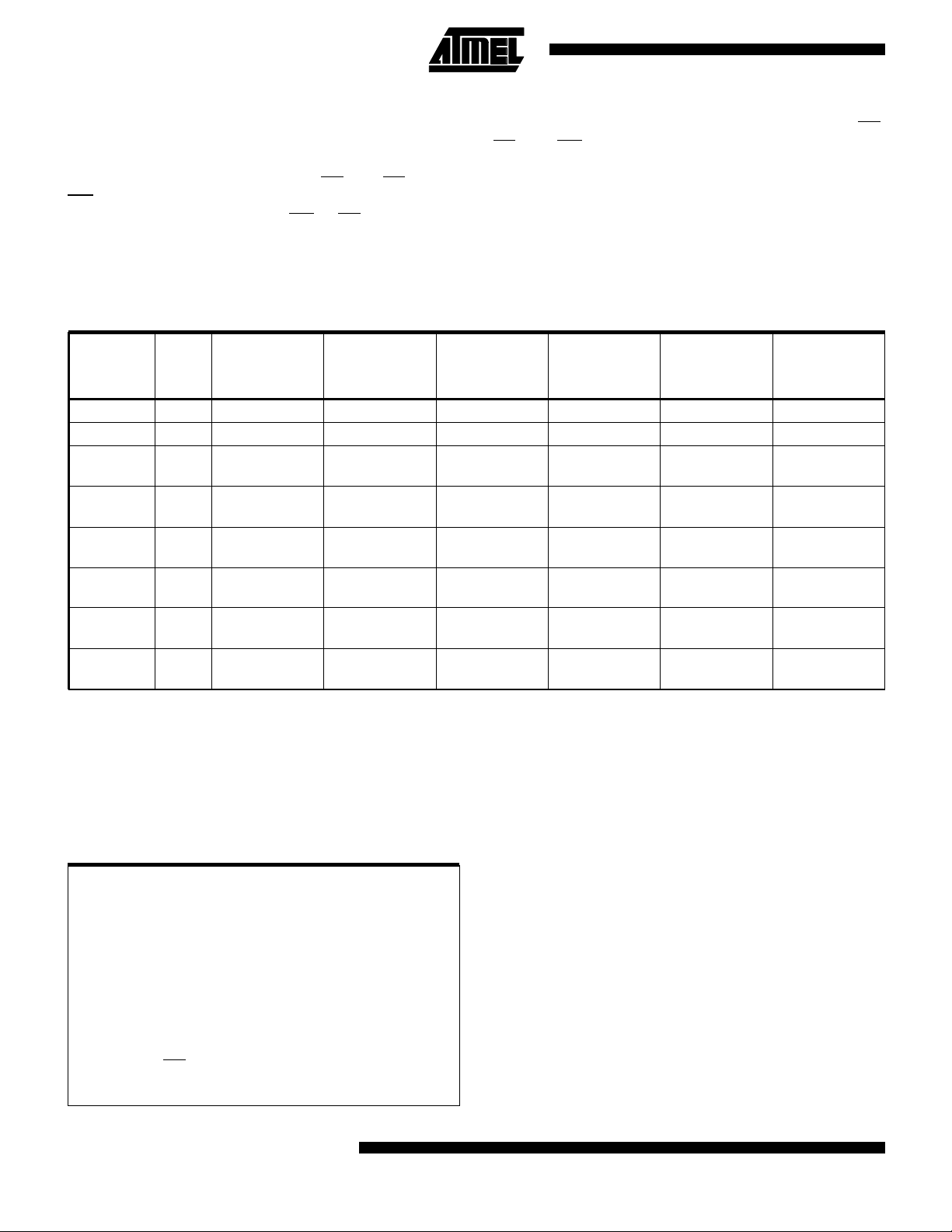

Command Definition (in Hex)

Command

Sequence

Read

Chip Erase

Sector

Erase

Word

Program

Boot Block

Lockout

Product ID

Entry

Product ID

(3)

Exit

Product ID

(3)

Exit

Notes: 1. The DATA FORMAT in each bus cycle is as follows :

2. The 8K word boot sector has the address rang e

3. Either one of the Product ID Exit commands

Bus

Cycles

1AddrD

6 5555 AA 2AAA 55 5555 80 5555 AA 2AAA 55 5555 10

6 5555 AA 2AAA 55 5555 80 5555 AA 2AAA 55 SA

4 5555 AA 2AAA 55 5555 A0 Addr D

(2)

6 5555 AA 2AAA 55 5555 80 5555 AA 2AAA 55 5555 40

3 5555 AA 2AAA 55 5555 90

3 5555 AA 2AAA 55 5555 F0

1xxxxF0

I/O15 - I/O8 (Don’t Care); I/O7 - I/O0 (Hex)

00000H to 01FFF H.

can be used.

1st Bus

Cycle

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

OUT

(1)

2nd Bus

Cycle

3rd Bus

Cycle

4. SA = sector addresses:

SA = 03XXX for PARAMETER BLOCK 1

SA = 05XXX for PARAMETER BLOCK 2

SA = 1FXXX for MAIN MEMORY ARRAY

5. When the boot block programming lockout feature is not

enabled, the boot block and the main memory block will erase

4th Bus

Cycle

5th Bus

Cycle

(4, 5)

IN

6th Bus

Cycle

30

Absolute Maximum Ratings*

Temperature Under Bias.................-55°C to +125°C

Storage Temperature......................-65°C to +150°C

All Input Voltages

(including NC Pins)

with Respect to Ground ................... -0.6V to +6.25V

All Output Voltages

with Respect to Ground .............-0.6V to V

Voltage on

OE

with Respect to Ground ................... -0.6V to +13.5V

4

AT49BV/LV4096

+ 0.6V

CC

*NOTICE: Stresses beyond thos e listed under “Absolute Maxi-

mum Ratings” may cause permanent damage to the device.

This is a stress rating only and functional operation of the

device at these or an y ot he r con ditions beyond t ho se ind icated in the oper ational sections of this specification is not

implied. Exposure to absolute maximum rating conditio ns

for extended periods may affect device reliability.

Loading...

Loading...