Datasheet AT34C02N-10SI-2.7, AT34C02N-10SI-1.8, AT34C02N-10SI, AT34C02N-10SC-2.7, AT34C02N-10SC-1.8 Datasheet (ATMEL)

...

Features

•

Permanent Software Write Protection for the First-Half of the Array

– Software Procedure to Verify Write Protect Status

•

Hardware Write Protection for the Entire Array

•

Low Voltage and S tandard Voltage Operation

– 5.0 (VCC = 4.5V to 5.5V)

– 2.7 (VCC = 2.7V to 5.5V)

– 1.8 (VCC = 1.8V to 5.5V)

•

Internally Organized 256 x 8

•

2-Wire Serial Interface

•

Schmitt Trigger, Filtered Inputs for Noise Suppression

•

Bidirectional Data Transfer Protocol

•

100 KHz (1.8V and 2.7V) and 400 KHz (5.0V) Compatibility

•

16-Byte Page Wri te Modes

•

Partial Page Writes Are Allowed

•

Self-Timed Write Cycle (10 ms max)

•

High Reliability

– Endurance: 1 Million Write Cycles

– Data Retention: 100 Years

– ESD Protection: >3,000V

•

Automotive Grade and Extended Temperature Devices Available

•

8-Pin PDIP, 8-Pin JEDEC SOIC and 8-Pin TSSOP Packages

Description

The AT34C02 provides 2048 bits of serial electrically erasable and programmable

read only memory ( EEPRO M ) or gan iz ed as 25 6 wo rds of 8 bi ts ea ch . The fi rst- hal f o f

the device incorporates a software write protection feature while hardware write protection for the entire array is available via an external pin as well. Once the software

write protection is enabled, by s end ing a special comm and t o the device, it ca nnot b e

reversed. The hardware write protection is controlled with the WP pin and can be used

to protect the entire array, whether or not the software write protection has been

enabled. This allows the user to protect none, first-half, or all of the array depending

on the applica tion . The device is opti mi zed for u se in ma ny i nd us tri al a nd c om mer cial

applications where low power and low voltage operations are essential. The AT34C02

is available in space sa ving 8-pin PDIP, 8-pi n JEDEC SOIC, and 8-pin TSSO P packages and is accessed via a 2-wire se rial interface. In addition, it is av ailable in 5.0V

(4.5V to 5.5V), 2.7V (2.7V to 5.5V), and 1.8V (1.8V to 5.5V) versions.

2-Wire Serial

EEPROM

with Permanent

Software Write

Protect

2K (256 x 8)

AT34C02

2-Wire Serial

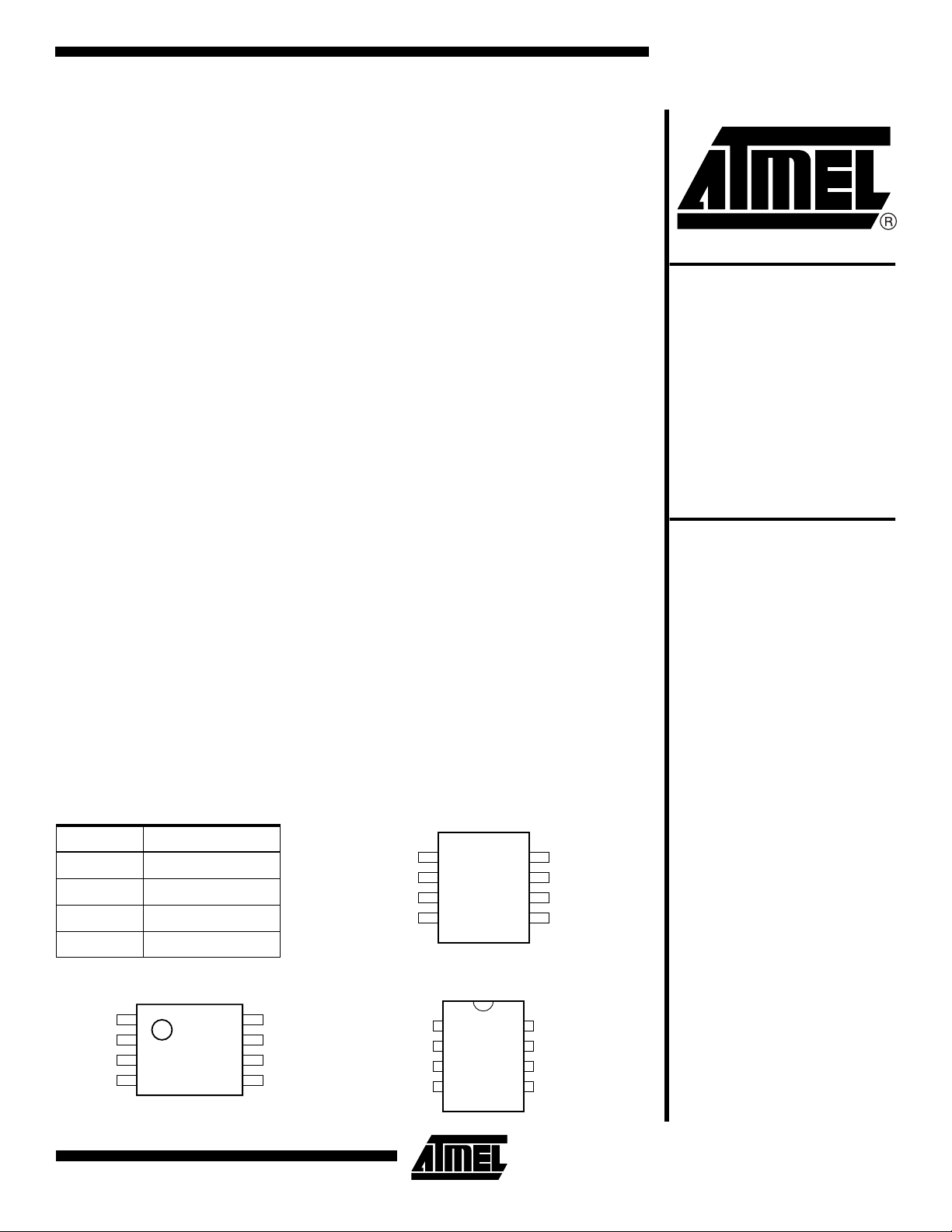

Pin Configurations

Pin Name Function

A0 to A2 Address Inputs

SDA Serial Data

SCL Serial Clock Input

WP Write Protect

8-Pin TSSOP

A0

A1

A2

GND

1

2

3

4

8

7

6

5

VCC

WP

SCL

SDA

A0

A1

A2

GND

GND

A0

A1

A2

8-Pin SOIC

1

2

3

4

8-Pin PDIP

1

2

3

4

EEPROM with

VCC

8

WP

7

SCL

6

SDA

5

Permanent

Software Write

Protec

8

VCC

7

WP

6

SCL

5

SDA

Rev. 0958D–07/98

1

Absolute Maximum Ratings*

Operating Temperature .................................. -55°C to +125 °C

Storage Temperature.....................................-65°C to +150°C

Voltage on Any Pin

with Respect to Ground.....................................-1.0V to +7.0V

Maximum Operating Voltage........................................... 6.25V

DC Output Current........................................................5.0 mA

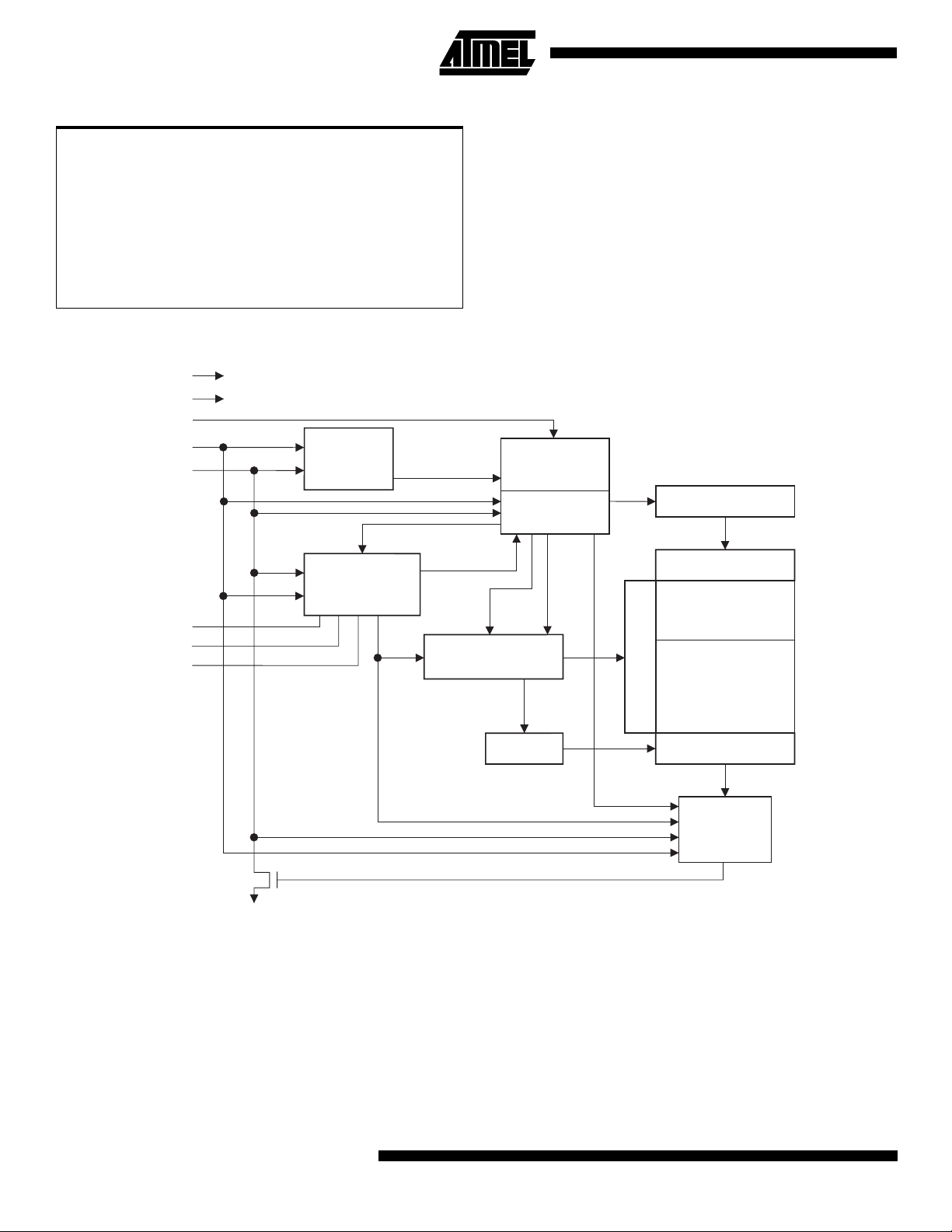

Block Diagram

V

CC

GND

WP

SCL

SDA

A

2

A

1

A

0

START

STOP

LOGIC

LOAD

DEVICE

ADDRESS

COMPARATOR

R/W

*NOTICE: Stresses beyond those listed under “Absolute

SERIAL

CONTROL

WRITE PROTECT

CIRCUITRY

COMP

DATA WORD

ADDR/COUNTER

LOGIC

INCLOAD

Maximum Ratings” may cause permanent damage to the de vic e. T his is a stres s rat ing onl y and

functional oper a tion of the device at these o r any

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximu m rating

conditions f or ex tended periods ma y aff ect dev ice

reliability.

EN

H.V. PUMP/TIMING

DATA RECOVERY

SOFTWARE WRITE

PROTECTED AREA

(00H - 7FH)

X DEC

2

E

PROM

D

IN

D

OUT

Pin Description

SERIAL CLOCK (SCL):

edge clock data into each EEPROM device and negative

edge clock data out of each device.

SERIAL DATA (SDA):

serial data transfer. This pin is open-drain driven and may

be wire-ORed with any number of other open-drain or open

collector devices.

2

The SCL input is used to positive

The SDA pin is bidirectional for

AT34C02

Y DEC

DEVICE/PAGE ADDRESSES (A2 , A1, A0):

SERIAL MUX

D

/ACK

OUT

LOGIC

The A2, A1

and A0 pins are device address inputs that are hard wired

for the AT34C02. As many as eight 2K devices may be

addressed on a single bus system (device addressin g is

discussed in detail under the Device Addressing section).

WRITE PROTECT (WP):

The AT34C02 has a Write Protect pin that provides hardware data protection. The Write

Protect pin allows normal read/write operations when con-

AT34C02

nected to ground (GND) or when left floating. When the

Write Protect pin is connected to V

, the write protection

CC

feature is enabled for the entire array. The write protection

modes are shown in the following table.

AT34C02 Write Protection Modes

WP Pin Status Write Protect Register Part of the Array Write Protected

V

CC

— Full Array (2K)

GND or Floating Not Programmed Normal Read/Write

GND or Floating Programmed

Pin Capacitance

(1)

First-Half of Array

(1K: 00H - 7FH)

Applicable over recommended operating range from TA = 25°C, f = 1.0 MHz, VCC = +1.8V

Symbol Test Condition Max Units Conditions

C

I/O

C

IN

Input/Output Capacitance (SDA) 8 pF V

Input Capacitance (A0, A1, A2, SCL) 6 pF VIN = 0V

Note: 1. This parameter is characterized and is not 100% tested

I/O

= 0V

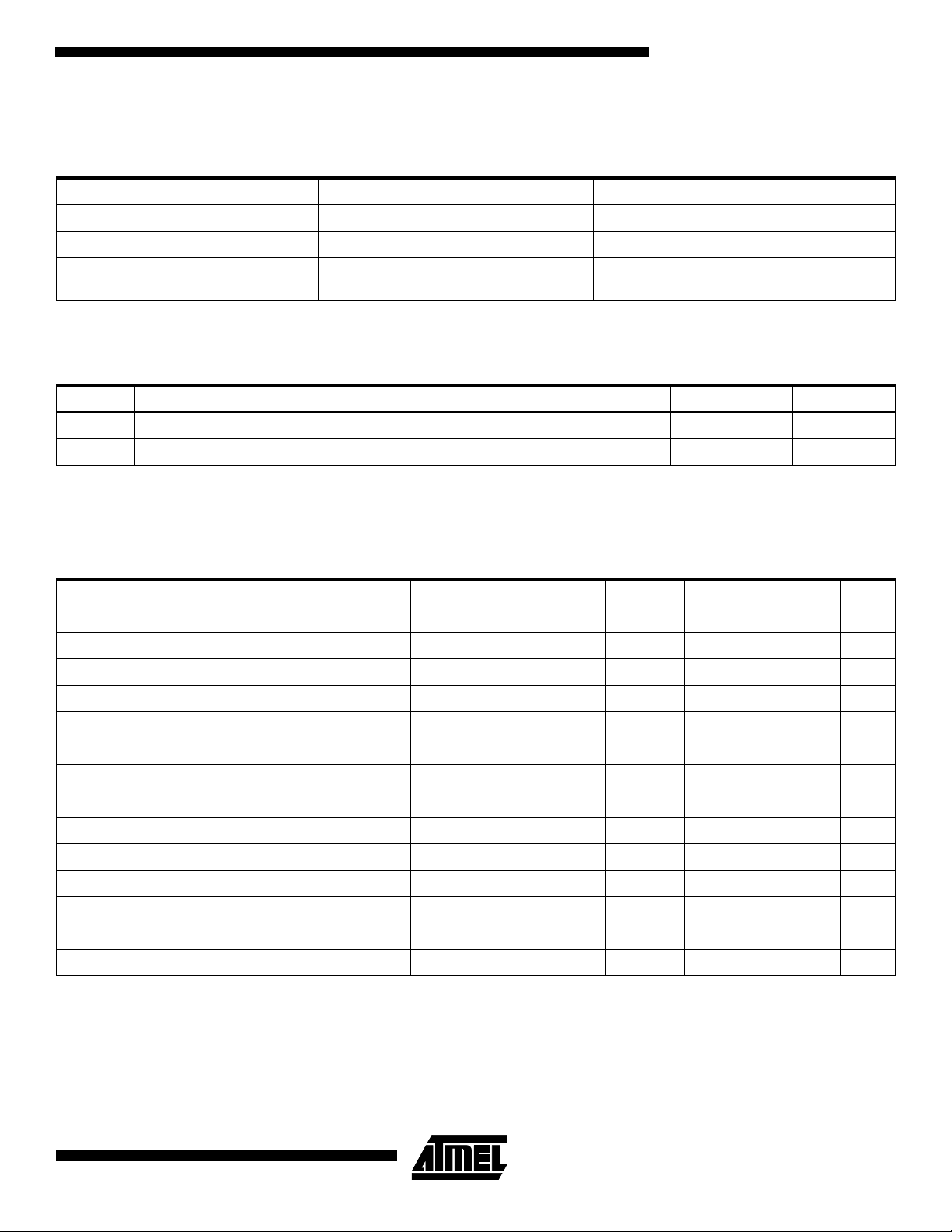

DC Characteristics

Applicable over recommended operating range from: TAI = -40°C to +85°C, V

= +1.8V to +5.5V (unless otherwise noted).

V

CC

Symbol Parameter Test Condition Min Typ Max Units

V

CC1

V

CC2

V

CC3

I

CC

I

CC

I

SB1

I

SB2

I

SB3

I

LI

I

LO

V

IL

V

IH

V

OL2

V

OL1

Note: 1. VIL min and VIH max are reference only and are not tested.

Supply Voltage 1.8 5.5 V

Supply Voltage 2.7 5.5 V

Supply Voltage 4.5 5.5 V

Supply Current VCC = 5.0V READ at 100 KHz 0.4 1.0 mA

Supply Current VCC = 5.0V WRITE at 100 KHz 2.0 3.0 mA

Standby Current VCC = 1.8V VIN = VCC or V

Standby Current VCC = 2.7V VIN = VCC or V

Standby Current VCC = 5.0V VIN = VCC or V

Input Leakage Current VIN = VCC or V

Output Leakage Current V

Input Low Level

Input High Level

(1)

(1)

OUT

= V

CC

or V

SS

SS

SS

SS

SS

Output Low Level VCC = 3.0V IOL = 2.1 mA 0.4 V

Output Low Level VCC = 1.8V IOL = 0.15 mA 0.2 V

= +1.8V to +5.5V, TAC = 0°C to +70°C,

CC

0.6 3.0

1.6 4.0

8.0 18.0

0.10 3.0

0.05 3.0

-0.6 VCC x 0.3 V

VCC x 0.7 VCC + 0.5 V

A

µ

A

µ

A

µ

A

µ

A

µ

3

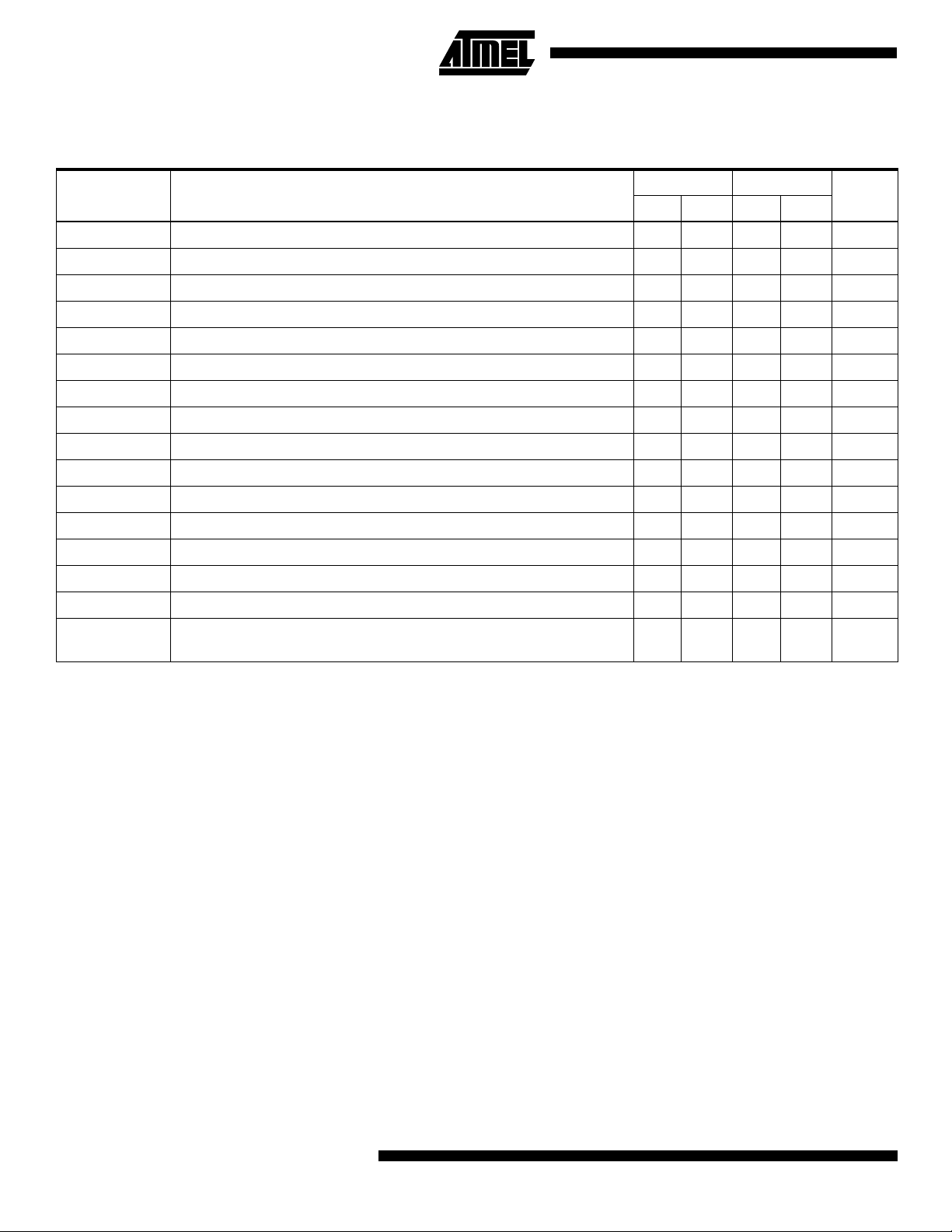

AC Characteristics

Applicable over recommended operating range from TA = -40°C to +85°C, VCC = +1.8V to +5.5V,

= 1 TTL Gate and 100 pF (unless otherwise noted).

C

L

1.8V, 2.7V 5.0V

Symbol Parameter

f

SCL

t

LOW

t

HIGH

t

I

t

AA

t

BUF

t

HD.STA

t

SU.STA

t

HD.DAT

t

SU.DAT

t

R

t

F

t

SU.STO

t

DH

t

WR

Endurance

Note: 1. This parameter is characterized and is not 100% tested.

(1)

Clock Frequency, SCL 100 400 kHz

Clock Pulse Width Low 4.7 1.2

Clock Pulse Width High 4.0 0.6

Noise Suppression Time

Clock Low to Data Out Valid 0.1 4.5 0.1 0.9

Time the bus must be free before a new transmission can start

Start Hold Time 4.0 0.6

Start Set-up Time 4.7 0.6

Data In Hold Time 0 0

Data In Set-up Time 200 100 ns

Inputs Rise Time

Inputs Fall Time

Stop Set-up Time 4.7 0.6

Data Out Hold Time 100 50 ns

Write Cycle Time 10 10 ms

5.0V, 25°C, Page Mode 1M 1M

(1)

(1)

(1)

UnitsMinMaxMinMax

µ

s

µ

s

100 50 ns

µ

s

(1)

4.7 1.2

1.0 0.3

300 300 ns

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

Write

Cycles

Memory Organization

AT34C02, 2K Serial EEPROM:

nized with 256 pages of 1 byte each. Random word

addressing requires a 8-bit data word address.

The 2K is internally orga-

Device Operation

CLOCK and DATA TRANSITIONS:

mally pulled high with an external de vice . Data on th e SDA

pin may chan ge only dur ing SC L lo w ti me p eri ods (re fer to

Data Validity timing diagram). Data changes during SCL

high periods will indicate a start or stop condition as defined

below.

START CONDITION:

A high-to-low transition of SDA with

SCL high is a start condition which must precede any other

command (refer to Start and Stop Definition timing diagram).

STOP CONDITION:

A low-to-high transition of SDA with

SCL high is a stop condition. After a read sequence, the

4

AT34C02

The SDA pin is nor-

stop command will pla ce the EEP ROM in a stan dby power

mode (refer to Start and Stop Definition timing diagram).

ACKNOWLEDGE:

All addresses and data words are serially transmitted to and from the EEPROM in 8-bit words.

The EEPROM sends a z ero to acknowledge that it has

received each word. This happens during the ninth clock

cycle.

STANDBY MODE:

The AT34C02 features a low power

standby mode which is enabled: (a) up on power-up or (b)

after the receipt of th e STO P bit and th e co mpleti on of any

internal operations.

MEMORY RESET:

After an interruption in protocol, power

loss or system reset, any 2-wire part can be reset by following these steps:

(a) Clock up to 9 cycles, (b) look for SDA high in each cycle

while SCL is high and then (c) create a start condition as

SDA is high.

Bus Timing SCL: Serial Clock SDA: Ser ial Data I/O

Write Cycle Timing SCL: Serial Clock SDA: Serial Data I/O

AT34C02

(1)

Note: 1. The write cycle time tWR is the time from a valid stop condition of a write sequence to the end of the internal clear/write

cycle.

5

Data Validity

Start and Stop Condition

Output Acknowledge

6

AT34C02

AT34C02

Device Addressing

The 2K EEPROM device requires an 8-bit device address

word following a start condition to enable the chip for a read

or write operation (refer to Figure 2).

The device address word consists of a mandatory one-zero

sequence for the first four most-significant bits (1010) for

normal read and write operations and 0110 for writing to

the write protect register.

The next 3 bits are the A2, A1 and A0 device address bits

for the AT34C02 EEPROM. These 3 bits must compare to

their corresponding hard-wired input pins.

The eighth bit of the device address is the read/write operation select bit. A read operation is initiated if this bit is high

and a write operation is initiated if this bit is low.

Upon a compare of the device address, the EEPROM will

output a zero. If a compare is no t mad e, th e chip will return

to a standby state. The de vice will not ackno wledge i f the

write protect register has been programmed and the control

code is 0110.

Write Operations

BYTE WRITE:

word address following the device address word and

acknowledgmen t. Upon receipt of this address, the

EEPROM will again respond with a zero and then clock in

the first 8-bit data word. Following receipt of the 8-bit data

word, the EEPROM wi ll output a zero and the addre ssing

device, such as a mi crocon troller, must ter minate the write

sequence with a stop condition. At this time the EEPROM

enters an internally-timed write cycle, t

memory. All in puts ar e disa bled du ring thi s writ e cycle and

the EEPROM will not respond until the write is complete

(refer to Figure 3).

The device will acknowledge a write c ommand, but not

write the data, if the software or hardware write protection

has been enabled. The write cycle time must be observed

even when the write protection is enabled.

PAGE WRITE:

write.

A page write is ini tiated th e sa me as a byte write, but the

microcontroller does not send a stop condition after the first

data word is clocked in. Instead, after the EEPROM

acknowledges receipt of the first data word, the microcontroller can transmit up to fifteen more data words. The

EEPROM will respond with a zero after each data word

received. The m icrocontroll er must termin ate the page

write sequence with a stop condition (refer to Figure 4).

A write operation requires an 8-bit data

, to the nonvolatile

WR

The 2K device is capable of 16-byte page

The data word address lower four bits are internally incremented following the re ce ip t of e ac h d ata w or d. Th e hi ghe r

data word address bits ar e not increm ented, retain ing the

memory page row location. When the word address, internally generated, reaches the page boundary, the following

byte is placed at the beginning of the sa me page. If more

than sixteen data words are transmitted to the EEPROM,

the data word address will “roll ov er” and prev ious data will

be overwritten. The address “roll over” during write is from

the last byte of the current page to the first byte of the same

page.

The device will acknowledge a wri te command, but not

write the data, if the software or hardware write protection

has been enabled. The write cycle time must be observed

even when the write protection is enabled.

ACKNOWLEDGE POLLING:

write cycle has started and the EEPROM inputs are dis abled, acknowledge polling can be initiated. This involves

sending a start condition followed by the device address

word. The read/write bit is repres entative of the op eration

desired. Only if the internal write cycle ha s completed will

the EEPROM respond with a zero allowing the read or write

sequence to continue.

Once the internally-timed

Write Protection

The software write protection, once enabled, permanently

write protects only the first-half of the array (00H - 7FH)

while the hardware write protection, via the WP pin, is used

to protect the entire array.

SOFTWARE WRITE PROTECTION:

protection is enabled by sending a com mand, similar to a

normal write command, to the dev ice which pr ograms the

write protect regi ster. This must be don e with the WP pin

low. The write protect re gister i s pr ogr am me d by s en din g a

write command with the devic e address of 0110 ins tead of

1010 with the addres s and data bit be ing d on’t car es (r efer

to Figure 1). Once the software write protectio n has been

enabled, the device will no longer acknowledge the 0110

control byte. The software write protection cannot be

reversed even if the device is powered down. The write

cycle time must be observed.

HARDWARE WRITE PROTECTION:

connected to V

pin to V

whether or not the software write protection has been

enabled. The software write protection regi ster cannot be

programmed when the WP pin is connected to V

WP pin is connected to GND or left floating, the write protection mode is determined by the status of the software

write protect register.

will write protect the entir e array, regardless of

CC

, GND, or left floating. Connecting the WP

CC

The software write

The WP pin can be

. If the

CC

7

WP Connected to GND or Floating

Acknowledgment

Start R/W Bit Write Protect Register

1010 R X ACK Read Array

1010 W Programmed ACK Can Write to First Half Only

1010 W Not Programmed ACK Can Write to Full Array

0110 R Programmed No ACK Stop - Indicates Write Protect Register is Programmed

0110 R Not Programmed ACK Read Out Data Don’t Care. Indicates WP Register is Not Prog

0110 W Programmed No ACK Stop - Indicates Write Protect Register is Programmed

0110 W Not Programmed ACK Program Write Protect Register (irreversible)

WP Connected to V

1010 R X ACK Read Array

1010 W Programmed ACK Device Write Protect

1010 W Not Programmed ACK Device Write Protect

0110 R Programmed No ACK Stop - Indicates Write Protect Register is Programmed

0110 R Not Programmed ACK Read Out Data Don’t Care. Indicates WP Register is Not Prog

0110 W Programmed No ACK Stop - Indicates Write Protect Register is Programmed

0110 W Not Programmed ACK Cannot Program Write Protect Register

CC

from Device Action from Device

Figure 1.

Setting Write Protect Register

S

T

A

R

T

SDA LINE

CONTROL

BYTE

0110 0

A

C

K

Read Operations

Read operations are initiated the same way as write operations with t he exce ption th at t he read/w rite sel ect b it in t he

device address word is set to on e. There a re three read

operations: current address read, random address read

and sequential read.

CURRENT ADDRES S READ:

address counter maintains the last address accessed during the last read or write operation, incremented by one.

This address stays valid between operations as long as the

chip power is maintained. T he address “ro ll over” during

read is from the last byte of the last memory page to the

first byte of the first page.

Once the device address with the read/write select bit set to

one is clocked in and acknowledged by the EEPROM, the

current address data word is serially clocked out. To end

The internal data word

WORD

ADDRESS DATA

A

C

K

A

C

K

S

T

O

P

the command, the microcontroller does not respond with an

input zero but does generate a following stop condition

(refer to Figure 5).

RANDOM READ:

A random read requi res a “dummy” byte

write sequence to load i n the data w ord a ddress . Onc e the

device address word and dat a wor d add re ss ar e cl oc ke d in

and acknowledge d by the EEPROM , the micro controller

must generate another start condition. The microcontroller

now initiates a current address read by sending a device

address with the r ead/write sel ect bit hi gh. The E EPROM

acknowledges the device address and serially clocks out

the data word. To end the command, the microcontroller

does not respond with a zero but does generate a following

stop condition (refer to Figure 6).

8

AT34C02

AT34C02

SEQUENTIAL READ:

either a current address read or a random address read.

After the microcontroller receives a data word, it responds

with an acknowledge. As long as the EEPROM receives an

acknowledge, it will continue to increment the data word

address and serially clock out sequential data words. When

the memory address limit is reached, the data word

address will “roll over” and the sequential read will continue. The sequential read operation is termin ated when

Figure 2.

Figure 3.

Device Address

Byte Write

Sequential reads are initiated by

the microcontroller does not respond with a zero but does

generate a following stop condition (refer to Figure 7).

WRITE PROTECT REGISTER STATUS:

register has been program med, the same procedure is

used as to program the register except that the R/W bit is

set to 1. If the device ackn owledge s, then the wri te protect

register has not been pr ogrammed. Otherwi se, it has be en

programmed and the devi ce is perma nen tly wr ite p rotec ted

at the first half of the array.

To find out if the

Figure 4.

Figure 5.

Page Write

Current Address Read

9

Figure 6.

Random Read

Figure 7.

Sequential Read

10

AT34C02

Ordering Information

tWR (max)

(ms)

10 3000 18 400 AT34C02-10PC

10 1500 4 100 AT34C02-10PC-2.7

10 800 3 100 AT34C02-10PC-1.8

ICC (max)

(µA)

3000 18 400 AT34C02-10PI

1500 4 100 AT34C02-10PI-2.7

800 3 100 AT34C02-10PI-1.8

ISB (max)

(µA)

f

MAX

(kHz) Ordering Code Package Operation Range

AT34C02N-10SC

AT34C02-10TC

AT34C02N-10SI

AT34C02-10TI

AT34C02N-10SC-2.7

AT34C02-10TC-2.7

AT34C02N-10SI-2.7

AT34C02-10TI-2.7

AT34C02N-10SC-1.8

AT34C02-10TC-1.8

AT34C02N-10SI-1.8

AT34C02-10TI-1.8

AT34C02

8P3

8S1

8T

8P3

8S1

8T

8P3

8S1

8T

8P3

8S1

8T

8P3

8S1

8T

8P3

8S1

8T

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Package Type

8P3 8-Lead, 0.300" Wide, Plastic Dual Inline Package (PDIP)

8S1 8-Lead, 0.150" Wide, Plastic Gull Wing Small Outline Package(JEDEC SOIC)

8T 8-Lead, 0.170" Wide, Thin Shrink Small Outline Package (TSSOP)

Options

Blank Standard Operation (4.5V to 5.5V)

-2.7 Low Voltage (2.7V to 5.5V)

-1.8 Low Voltage (1.8V to 5.5V)

11

Packaging Information

8P3

, 8-Lead, 0.300" Wide, Plastic Dual Inline

Package (PDIP)

Dimensions in Inches and (Millimeters)

.400 (10.16)

.355 (9.02)

PIN

1

.280 (7.11)

.240 (6.10)

.037 (.940)

.300 (7.62) REF

.210 (5.33) MAX

SEATING

PLANE

.150 (3.81)

.115 (2.92)

.012 (.305)

.008 (.203)

.070 (1.78)

.045 (1.14)

.027 (.690)

.100 (2.54) BSC

.015 (.380) MIN

.022 (.559)

.014 (.356)

.325 (8.26)

.300 (7.62)

0

REF

15

.430 (10.9) MAX

8S1

, 8-Lead, 0.150" Wide, Plastic Gull Wing Small

Outline (JEDEC SOIC)

Dimensions in Inches and (Millimeters)

.020 (.508)

.013 (.330)

.244 (6.20)

.228 (5.79)

.068 (1.73)

.053 (1.35)

.010 (.254)

.007 (.203)

PIN 1

0

8

.157 (3.99)

.150 (3.81)

.050 (1.27) BSC

.196 (4.98)

.189 (4.80)

.010 (.254)

.004 (.102)

REF

.050 (1.27)

.016 (.406)

8T

, 8-Lead, 0.170" Wide, Thin Shrink Small Outline

Package (TSSOP)

Dimensions in Millimeters and (Inches)

PIN 1

6.50 (.256)

6.25 (.246)

0.30 (.012)

0.19 (.008)

3.10 (.122)

0

REF

8

2.90 (.114)

0.15 (.006)

0.05 (.002)

4.5 (.177)

4.3 (.169)

0.75 (.030)

0.45 (.018)

1.20 (.047) MAX

0.20 (.008)

0.09 (.004)

1.05 (.041)

0.80 (.033)

.65 (.026) BSC

12

AT34C02

Loading...

Loading...