Features

• High Performance, Low Power AVR

– Compact Single-cycle RISC Instruction Set Including DSP Instruction Set

– Read-Modify-Write Instructions and Atomic Bit Manipulation

– Performing 1.49 DMIPS / MHz

Up to 91 DMIPS Running at 66 MHz from Flash (1 Wait-State)

Up to 49 DMIPS Running at 33MHz from Flash (0 Wait-State)

– Memory Protection Unit

• Multi-hierarchy Bus System

– High-Performance Data Transfers on Separate Buses for Increased Performance

– 15 Peripheral DMA Channels Improves Speed f or Peripheral Communication

• Internal High-Speed Flash

– 512K Bytes, 256K Bytes, 128K Bytes Versions

– Single Cycle Access up to 33 MHz

– Prefetch Buffer Optimizing Instruction Execution at Maximum Speed

– 4ms Page Programming Time and 8ms Full-Chip Erase Time

– 100,000 Write Cycles, 15-year Data Retention Capability

– Flash Security Locks and User Defined Configuration Area

• Internal High-Speed SRAM, Single-Cycle Access at Full Speed

– 64K Bytes (512KB and 256KB Flash), 32K Bytes (128KB Flash)

• External Memory Interface on AT32UC3A0 Derivatives

– SDRAM / SRAM Compatible Memory Bus (16-bit Data and 24-bit Address Buses)

• Interrupt Controller

– Autovectored Lo w Latency Interrupt Service with Programmable Priority

• System Functions

– Power and Clock Manager Including Internal RC Clock and One 32KHz Oscillator

– Two Multipurpose Oscillators and Two Phase-Lock-Loop (PLL) allowing

Independant CPU Frequency from USB Frequency

– Watchdog Timer, Real-Time Clock Timer

• Universal Serial Bus (USB)

– Device 2.0 Full Speed and On-The-Go (OTG) Low Speed and Full Speed

– Flexible End-Point Configuration and Management with Dedicated DMA Channels

– On-chip Transceivers Including Pull-Ups

• Ethernet MAC 10/100 Mbps interface

– 802.3 Ethernet Media Access Controller

– Supports Media Independent Interface (MII) and Reduced MII (RMII)

• One Three-Channel 16-bit Timer/Counter (TC)

– Three External Clock Inputs, PWM, Capture and Various Counting Capabilities

• One 7-Channel 16-bit Pulse Width Modulation Controller (PWM)

• Four Universal Synchronous/Asynchronous Receiver/Transmitters (USART)

– Independant Baudrate Generator, Support for SPI, IrDA and ISO7816 interfaces

– Support for Hardware Handshaking, RS485 Interfaces and Modem Line

• Two Master/Slave Serial Peripheral Interfaces (SPI) with Chip Select Signals

• One Synchronous Serial Protocol Controller

– Supports I2S and Generic Frame-Based Protocols

• One Master/Slave Two-Wire Interface (TWI), 400kbit/s I2C-compatible

• One 8-channel 10-bit Analog-To-Digital Converter

• 16-bit Stereo Audio Bitstream

– Sample Rate Up to 50 KHz

®

32 UC 32-Bit Microcontroller

AVR®32

32-Bit

Microcontroller

AT32UC3A0512

AT32UC3A0256

AT32UC3A0128

AT32UC3A1512

AT32UC3A1256

AT32UC3A1128

Summary

Preliminary

32058HS–AVR32–03/09

• On-Chip Debug System (JTAG interface)

– Nexus Class 2+, Runtime Control, Non-Intrusive Data and Program Trace

• 100-pin TQFP (69 GPIO pins), 144-pin LQFP (109 GPIO pins) , 144 BGA (109 GPIO pins)

• 5V Input Tolerant I/Os

• Single 3.3V Power Supply or Dual 1.8V-3.3V Power Supply

AT32UC3A

32058HS–AVR32–03/09

2

1. Description

AT32UC3A

The AT32UC3A is a complete System-On-Chip microcontroller based on the AVR32 UC RISC

processor running at frequencies up to 66 MHz. AVR32 UC is a high-performance 32-bit RISC

microprocessor core, designed for cost- sensit ive embed ded applicat ion s, with p ar ticular emph asis on low power consumption, high code density and high performance.

The processor implements a Memory Protection Unit (MPU) and a fast and flexible int errupt controller for supporting modern operating systems and real-time operating systems. Higher

computation capabilities are achievable using a rich set of DSP instructions.

The AT32UC3A incorporates on-chip Flash and SRAM memories for secure and fast access.

For applications requiring additional memory, an external memory interface is provided on

AT32UC3A0 derivatives.

The Peripheral Direct Memory Access cont roller (PDCA) enables data transfers between peripherals and memories without processor involvement. PDCA drastically reduces processing

overhead when transferring continuous and large data streams between modules within the

MCU.

The PowerManager improves design flexibility and security: the on-chip Brown-Out Detector

monitors the power supply, the CPU runs from the on-chip RC oscillator or from one of external

oscillator sources, a Real-Time Clock and its associated timer keeps track of the time.

The Timer/Counter includes three identical 16-bit timer/counter channels. Each channel can be

independently programmed to perform frequency measurement, event counting, interval measurement, pulse generation, delay timing and pulse width modulation.

The PWM modules provides seven independent channels with many configuration options

including polarity, edge alignment and waveform non overlap control. O ne PWM channel can

trigger ADC conversions for more accurate close loop control implementations.

The AT32UC3A also features many communication interfaces for communication intensive

applications. In addition to standard serial int erfa ces like UART, SPI or TWI , ot he r int erface s like

flexible Synchronous Serial Controller, USB and Ethernet MAC are available.

The Synchronous Serial Controller provides easy access to serial communication protocols and

audio standards like I2S.

The Full-Speed USB 2.0 Device interface supports several USB Classes at the same time

thanks to the rich End-Point configuration. The On-The-GO (OTG) Host interface allows device

like a USB Flash disk or a USB printer to be directly connected to the processor.

The media-independent interface (MII) and reduced MII (RMII) 10/100 Ethernet MAC module

provides on-chip solutions for network-connecte d devices.

AT32UC3A integrates a class 2+ Nexus 2.0 On-Chip Debug (OCD) System, with non-intrusive

real-time trace, full-speed read/write memory access in addition to basic runtime control.

32058HS–AVR32–03/09

3

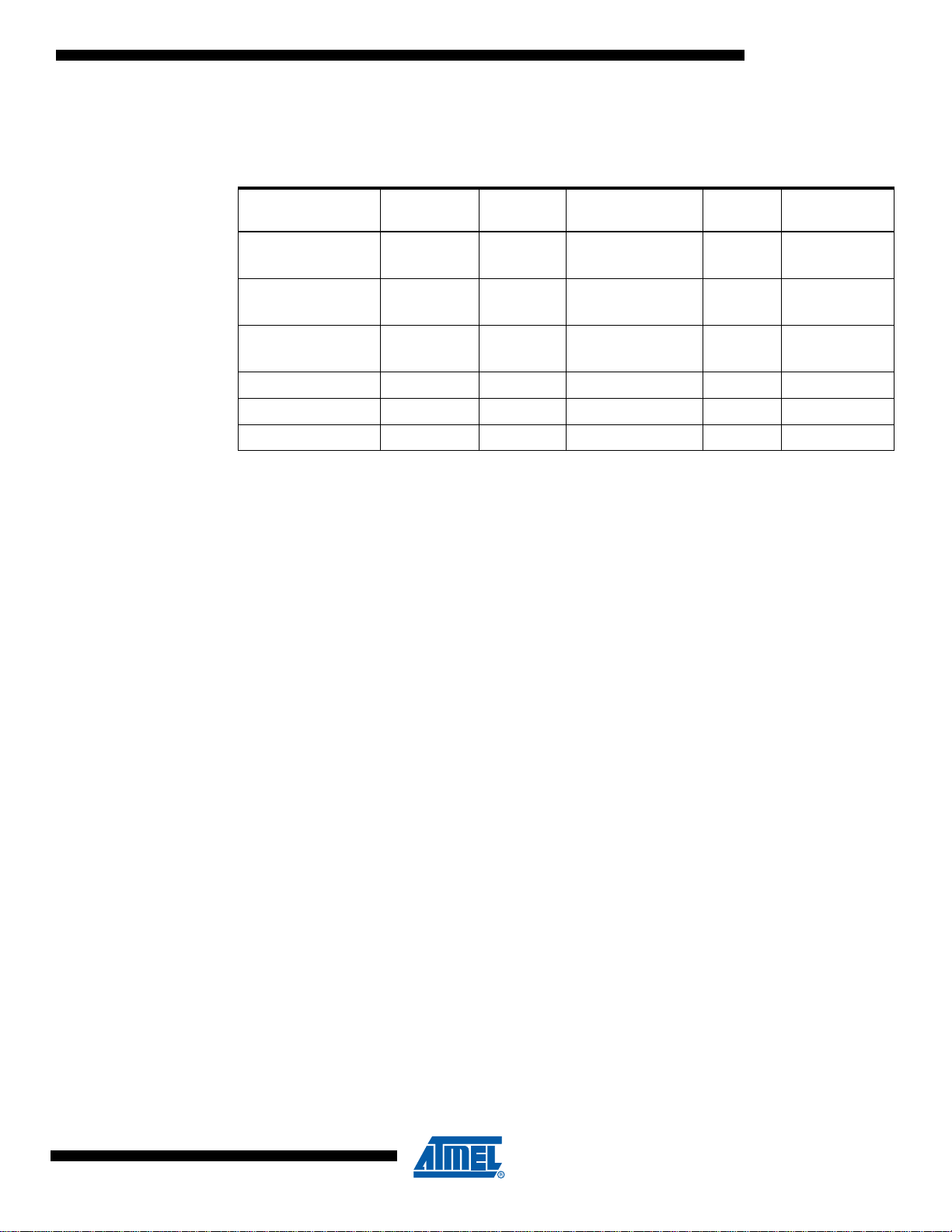

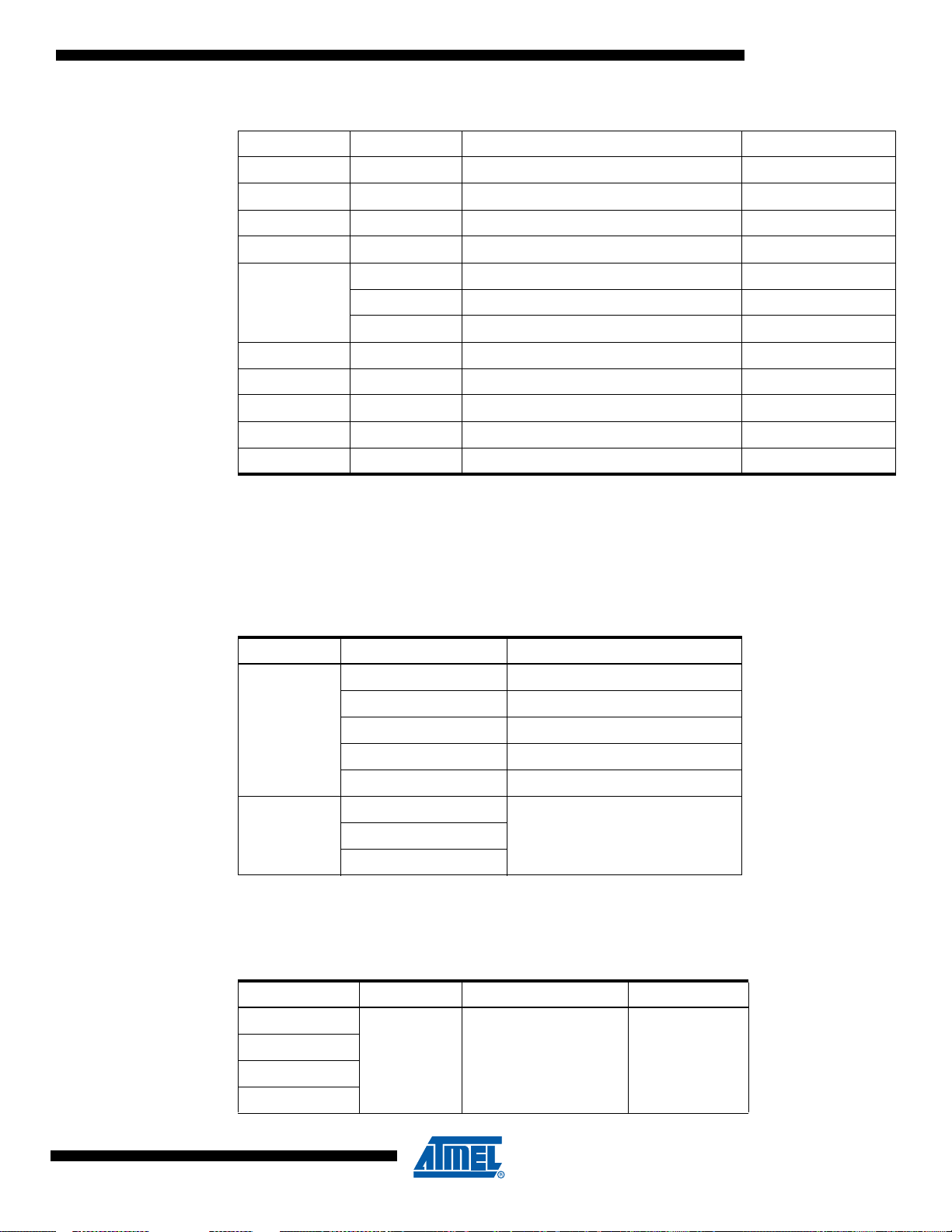

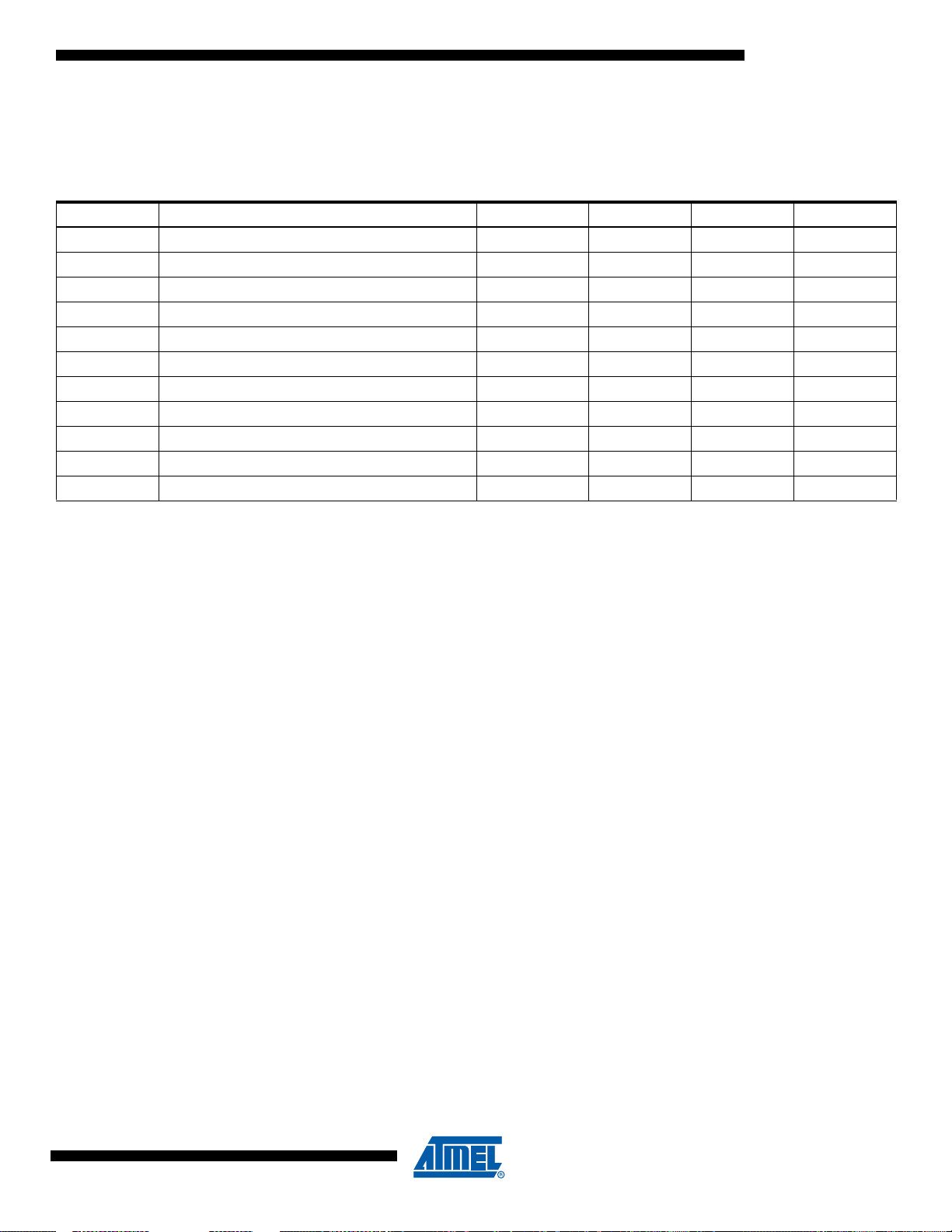

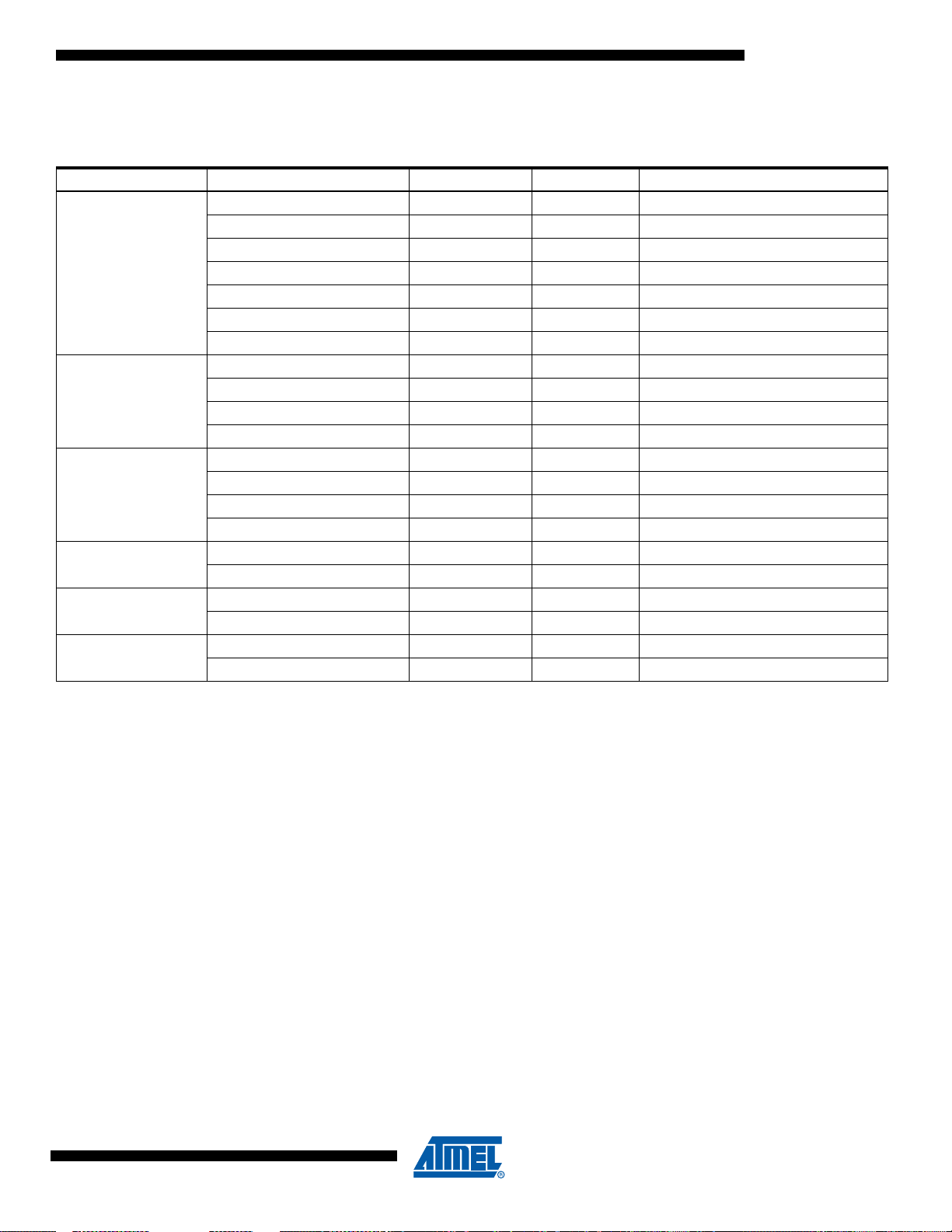

2. Configuration Summary

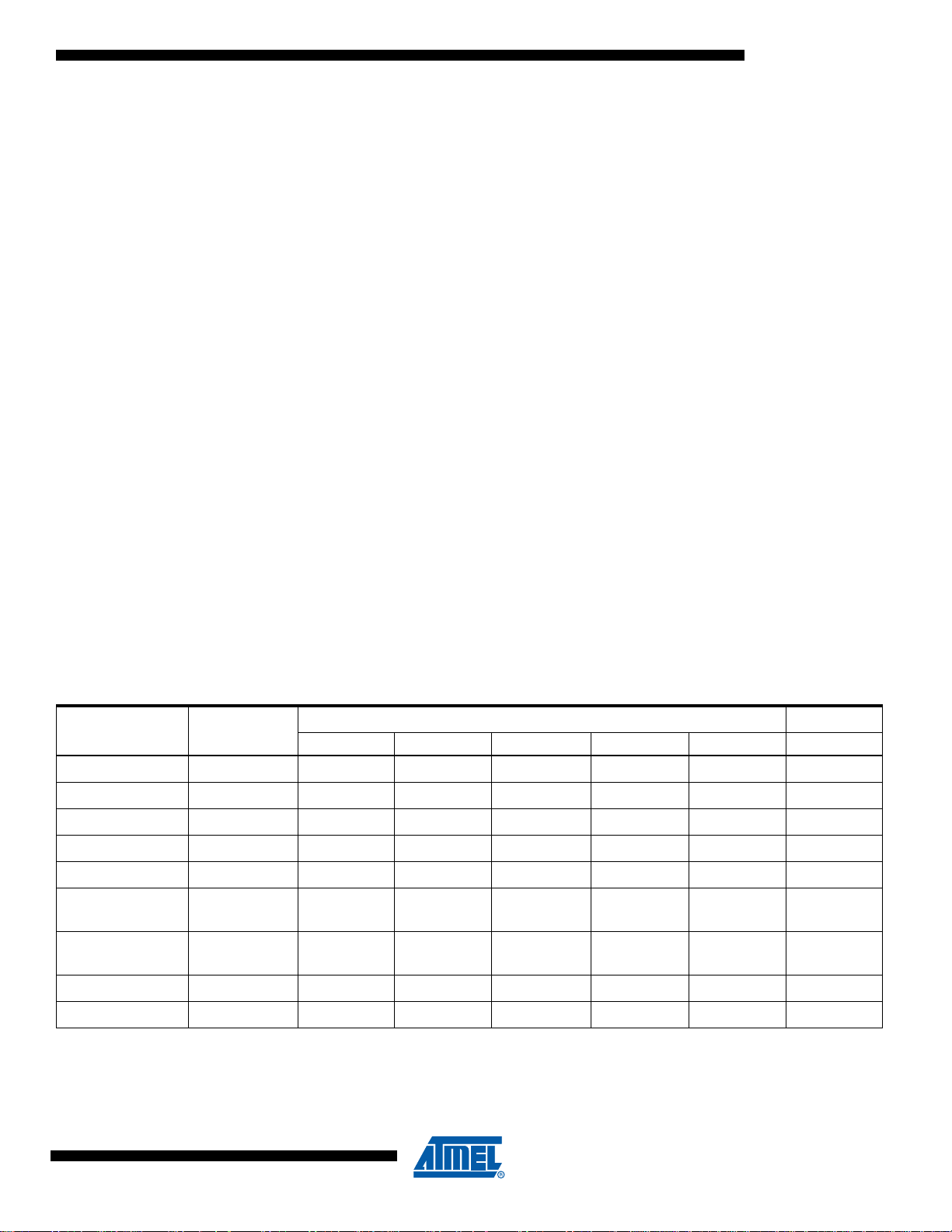

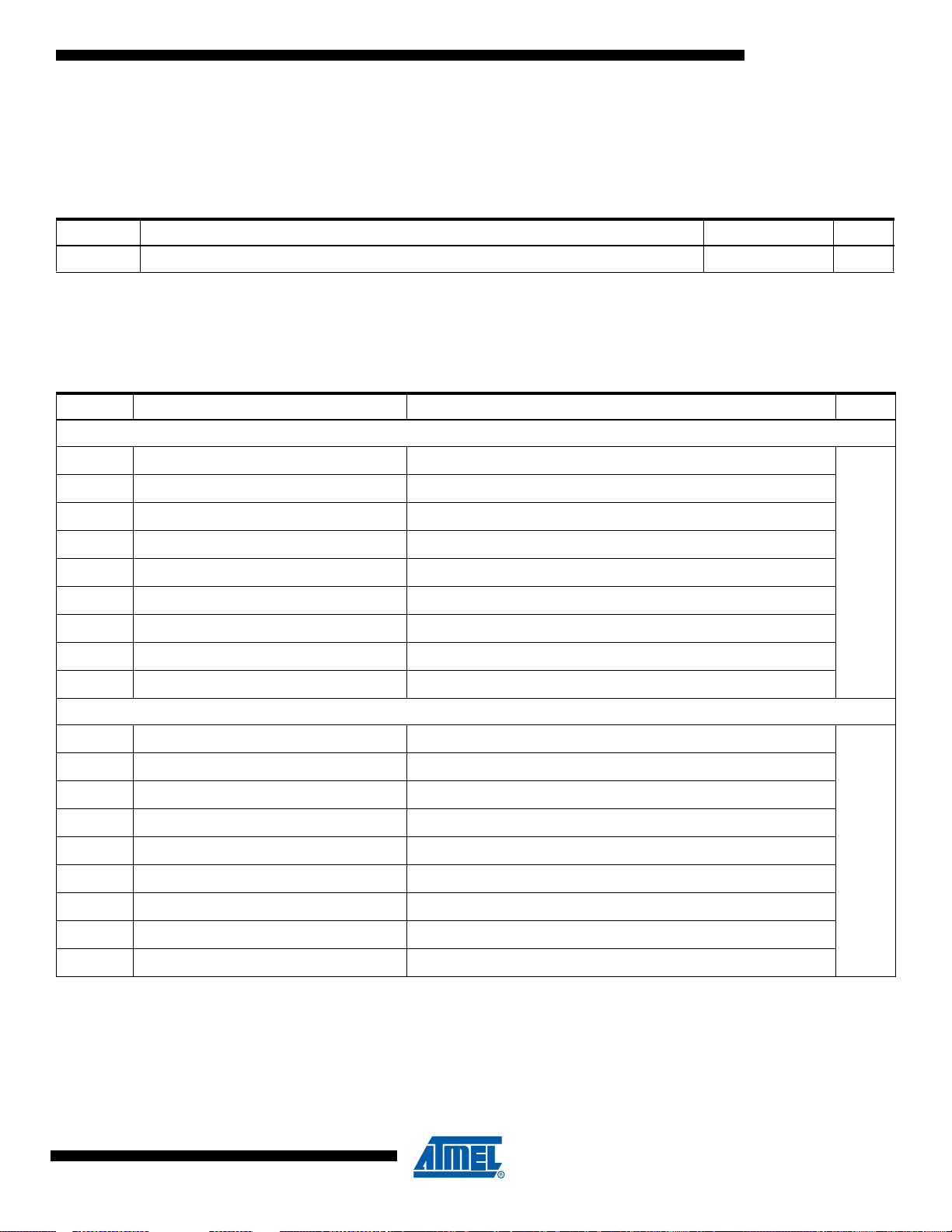

The table below lists all AT32UC3A memory and package configurations:

Device Flash SRAM Ext. Bus Interface

AT32UC3A0512 512 Kbytes 64 Kbytes yes yes 144 pin LQFP

AT32UC3A0256 256 Kbytes 64 Kbytes yes yes 144 pin LQFP

AT32UC3A0128 128 Kbytes 32 Kbytes yes yes 144 pin LQFP

AT32UC3A1512 512 Kbytes 64 Kbytes no yes 100 pin TQFP

AT32UC3A1256 256 Kbytes 64 Kbytes no yes 100 pin TQFP

AT32UC3A1128 128 Kbytes 32 Kbytes no yes 100 pin TQFP

AT32UC3A

Ethernet

MAC Package

144 pin BGA

144 pin BGA

144 pin BGA

3. Abbreviations

• GCLK: Power Manager Generic Clock

• GPIO: General Purpose Input/Output

• HSB: High Speed Bus

• MPU: Memory Protection Unit

• OCD: On Chip Debug

• PB: Peripheral Bus

• PDCA: Peripheral Direct Memory Access Controller (PDC) version A

• USBB: USB On-The-GO Controller version B

32058HS–AVR32–03/09

4

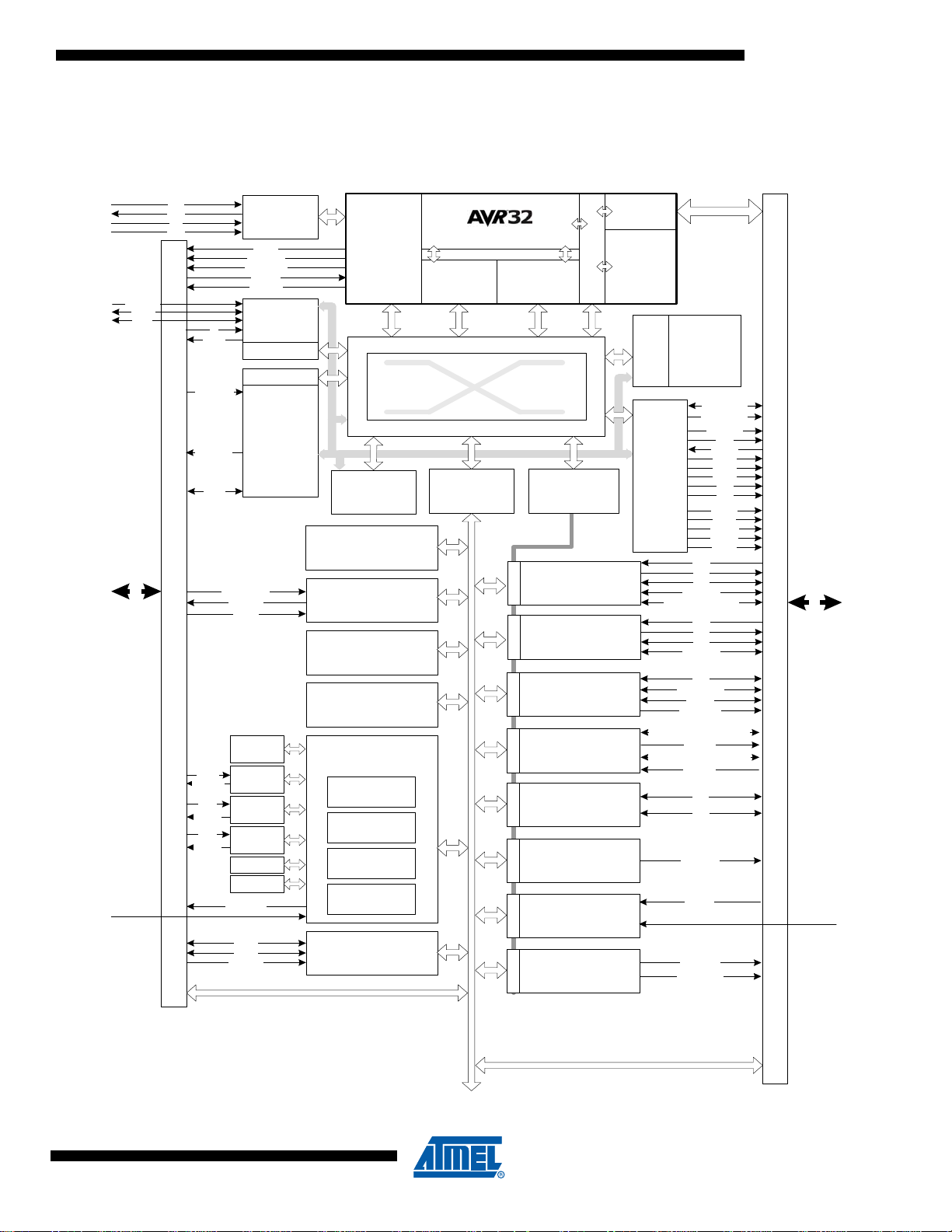

4. Blockdiagram

UC CPU

NEXUS

CLASS 2+

OCD

INS T R

INTERFACE

DATA

INTERFACE

TIMER/COUNTER

INTERRUPT

CONTROLLER

REAL TIME

COUNTER

PERIPHERAL

DMA

CONTROLLER

512 KB

FLASH

HSB-PB

BR IDGE B

HSB-PB

BRIDGE A

MEMORY INTERFACE

S

MM M

M

M

S

S

S

S

S

M

EXTERNAL

INTERRUPT

CONTROLLER

HIGH SPEED

BUS MATRIX

FAST GPIO

GENERAL PURPOSE IOs

64 KB

SRAM

GENERAL PURPOSE IOs

PA

PB

PC

PX

A[2..0]

B[2..0]

CLK[2..0]

EXTINT[7..0]

KPS [7 ..0 ]

NMI_N

GCLK[3..0]

XIN32

XOUT32

XIN0

XOUT0

PA

PB

PC

PX

RESET_N

EXTERNAL BUS INTERFACE

(SDRAM & STATIC MEMORY

CONTROLLER)

CAS

RAS

SDA10

SDCK

SDCKE

SDCS0

SDWE

NCS [3 ..0 ]

NRD

NWAIT

NWE0

DATA[15..0]

USB

INT E RFA CE

DMA

ID

VBOF

VBUS

D-

D+

ETHERNET

MAC

DMA

32 KHz

OSC

115 kHz

RCOSC

OSC0

PLL0

PULSE WIDTH

MODULATION

CONTROLLER

SERIAL

PERIPHERAL

INTERFACE 0/1

TWO-WIRE

INTERFACE

PDCPDC PDC

MISO, MOSI

NPC S[3..1]

PW M[6..0]

SCL

SDA

USART1

PDC

RXD

TXD

CLK

RTS, CTS

DSR, DTR, DCD, RI

USART0

USART2

USART3

PDC

RXD

TXD

CLK

RTS, CTS

SYNCHRONOUS

SERIAL

CONTROLLER

PDC

TX_CLOCK , TX_FR A ME _S Y NC

RX_DATA

TX_DATA

RX_CLOCK , RX_F RA M E _SY N C

ANALOG TO

DIGITAL

CONVERTER

PDC

AD[7 ..0 ]

ADVREF

WATCHDOG

TIMER

XIN1

XOUT1

OSC1

PLL1

SCK

JTAG

INT E RFA CE

MCKO

MDO[5..0]

MSE O[1..0]

EVTI_N

EVTO_N

TCK

TDO

TDI

TMS

POWER

MANAGER

RESET

CONTROLLER

ADD R [23..0]

SLEEP

CONTROLLER

CLOCK

CONTROLLER

CLOCK

GENERATOR

COL,

CRS,

RXD[3..0],

RX_CLK,

RX_DV,

RX_ER

MDC,

TXD [3..0 ],

TX_CLK,

TX_EN,

TX_ER,

SPEED

MDIO

FLASH

CONTROLLER

CONFIGURATION REGISTERS BUS

MEMORY PROTECTION UNIT

PB

PB

HSB

HS

B

NWE1

NWE3

PBA

PBB

NPCS0

LOCAL BUS

INTE R F ACE

AUDIO

BITSTREAM

DAC

PDC

DAT A [1 ..0 ]

DATAN[1..0]

Figure 4-1. Blockdiagram

AT32UC3A

32058HS–AVR32–03/09

5

4.1 Processor and architecture

4.1.1 AVR32 UC CPU

•

32-bit load/store AVR32A RISC architecture.

– 15 general-purpose 32-bit registers.

– 32-bit Stack Poin ter, Program Counter and Link Register reside in register file.

– Fully orthogonal instruction set.

– Privileged and unprivileged modes enabling efficient and secure Operating Systems.

– Innovative instruction set together with variable instruction length ensuring industry leading

code density.

– DSP extention with saturating arithmetic, and a wide variety of multiply instru ctio ns.

• 3 stage pipeline allows one instruction per clock cycle for most instructions.

– Byte, half-word, word and double word memory access.

– Multiple interrupt priority levels.

• MPU allows for operating systems with memory protection.

4.1.2 Debug and Test system

IEEE1149.1 compliant JTAG and boundary scan

•

• Direct memory access and programming capabilities through JTAG interface

• Extensive On-Chip Debug features in compliance with IEEE-ISTO 5001-2003 (Nexus 2.0) Class 2+

– Low-cost NanoTrace supported.

• Auxiliary port for high-speed trace information

• Hardware support for 6 Program and 2 data breakpoints

• Unlimited number of software breakpoints supported

• Advanced Program, Data, Ownersh ip , and Watchpoint trace supported

AT32UC3A

4.1.3 Peripheral DMA Controller

Transfers from/to peripheral to/from any memory space without intervention of the processor.

•

• Next Pointer Support, forbids strong real-time constraints on buffer management.

• Fifteen channels

– Two for each USART

– Two for each Serial Synchronous Controller

– Two for each Serial Peripheral Interface

– One for each ADC

– Two for each TWI Interface

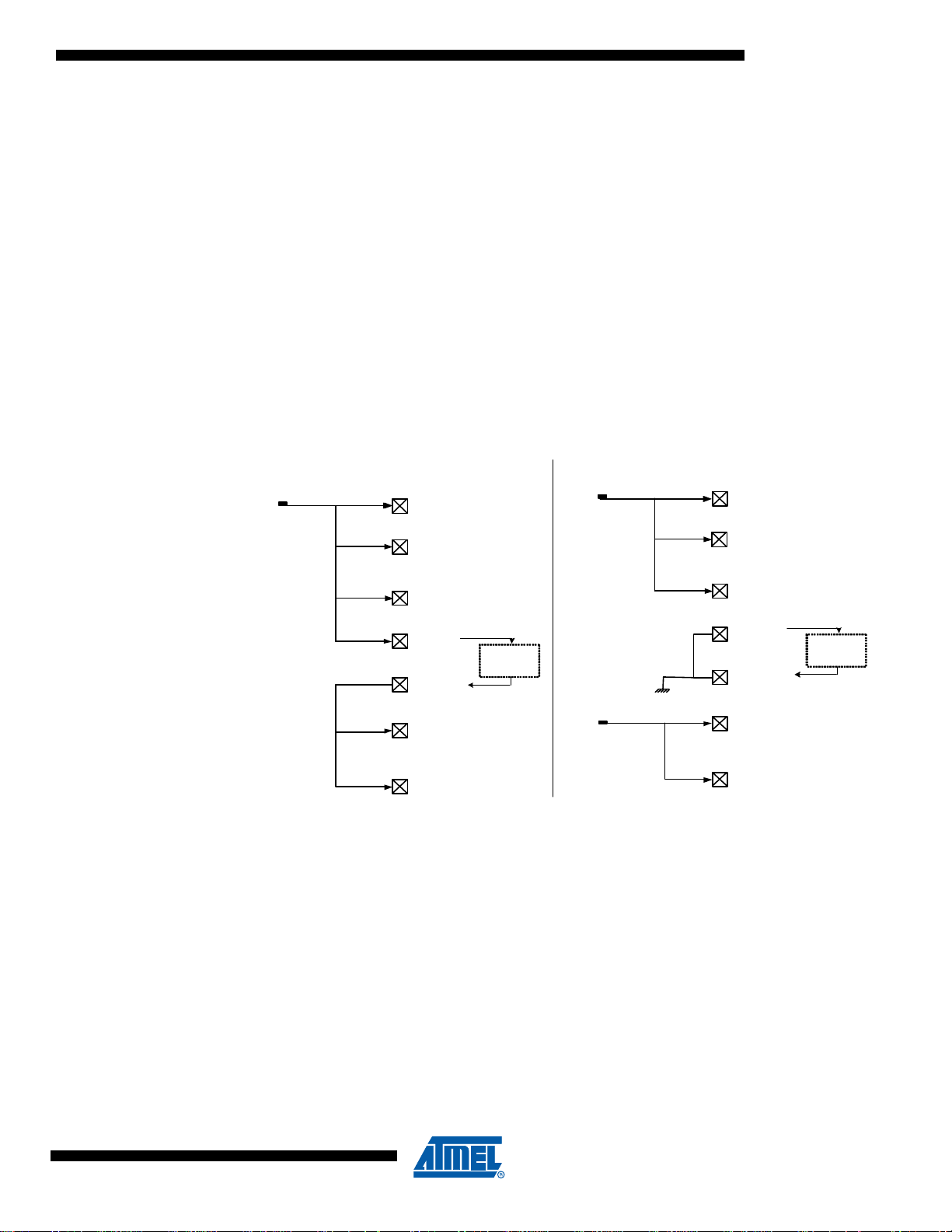

4.1.4 Bus system

High Speed Bus (HSB) matrix with 6 Masters and 6 Slaves handled

•

– Handles Requests from the CPU Data Fetch, CPU Instruction Fetch, PDCA, USBB, Ethernet

Controller, CPU SAB, and to internal Flash, internal SRAM, Peripheral Bus A, Peripheral Bus

B, EBI.

– Round-Robin Arbitration (three modes supported: no default master, last

master, fixed default master)

– Burst Breaking with Slot Cycle Limit

– One Address Decoder Provided per Master

accessed default

32058HS–AVR32–03/09

6

AT32UC3A

• Peripheral Bus A able to run on at divided bus speeds compared to the High Speed Bus

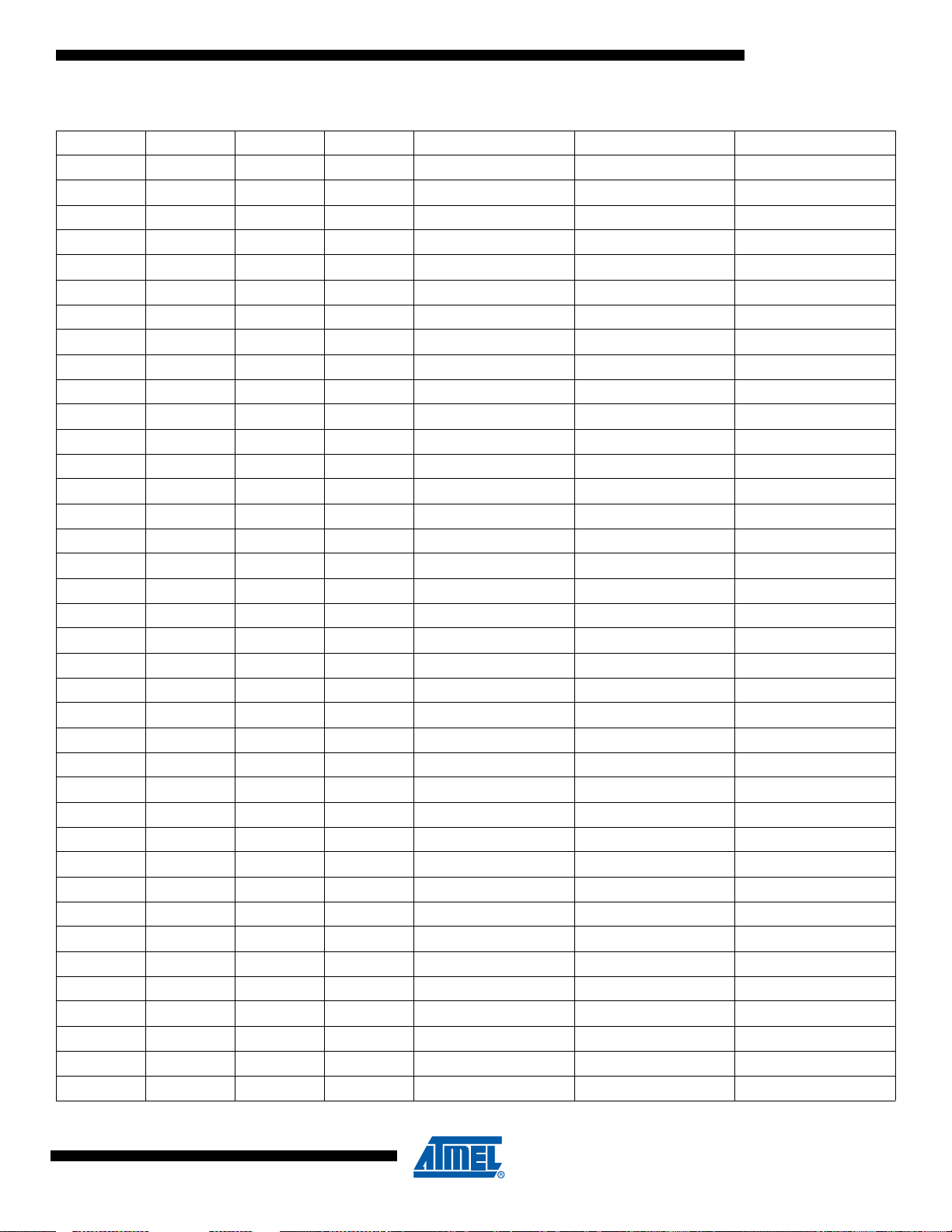

Figure 4-1 gives an overview of the bus system. All modules connected to the same bus use the

same clock, but the clock to each module can be individually shut off by the Power Manage r.

The figure identifies the number o f mast er and slave int er faces of each mo du le con nected t o the

High Speed Bus, and which DMA controller is connected to which peripheral.

32058HS–AVR32–03/09

7

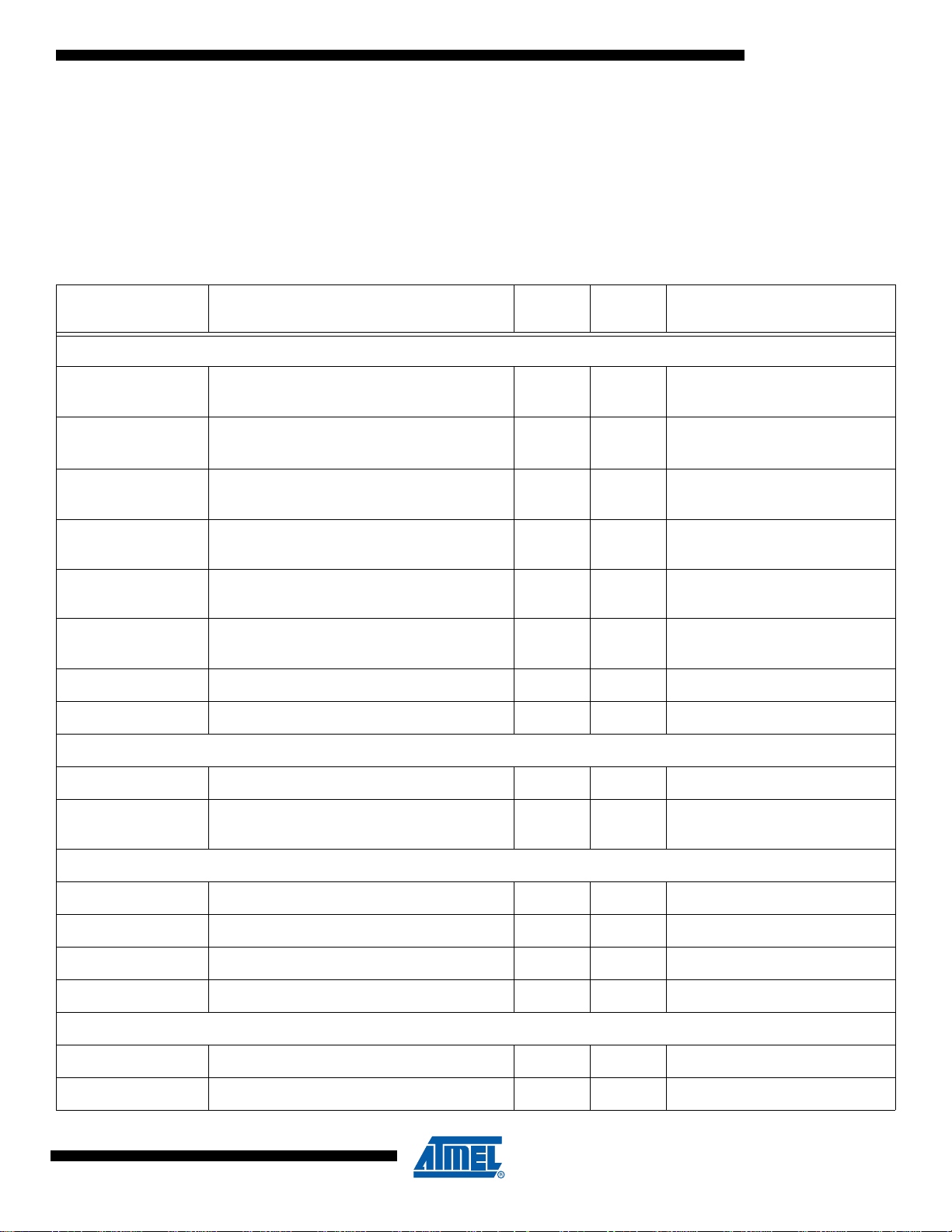

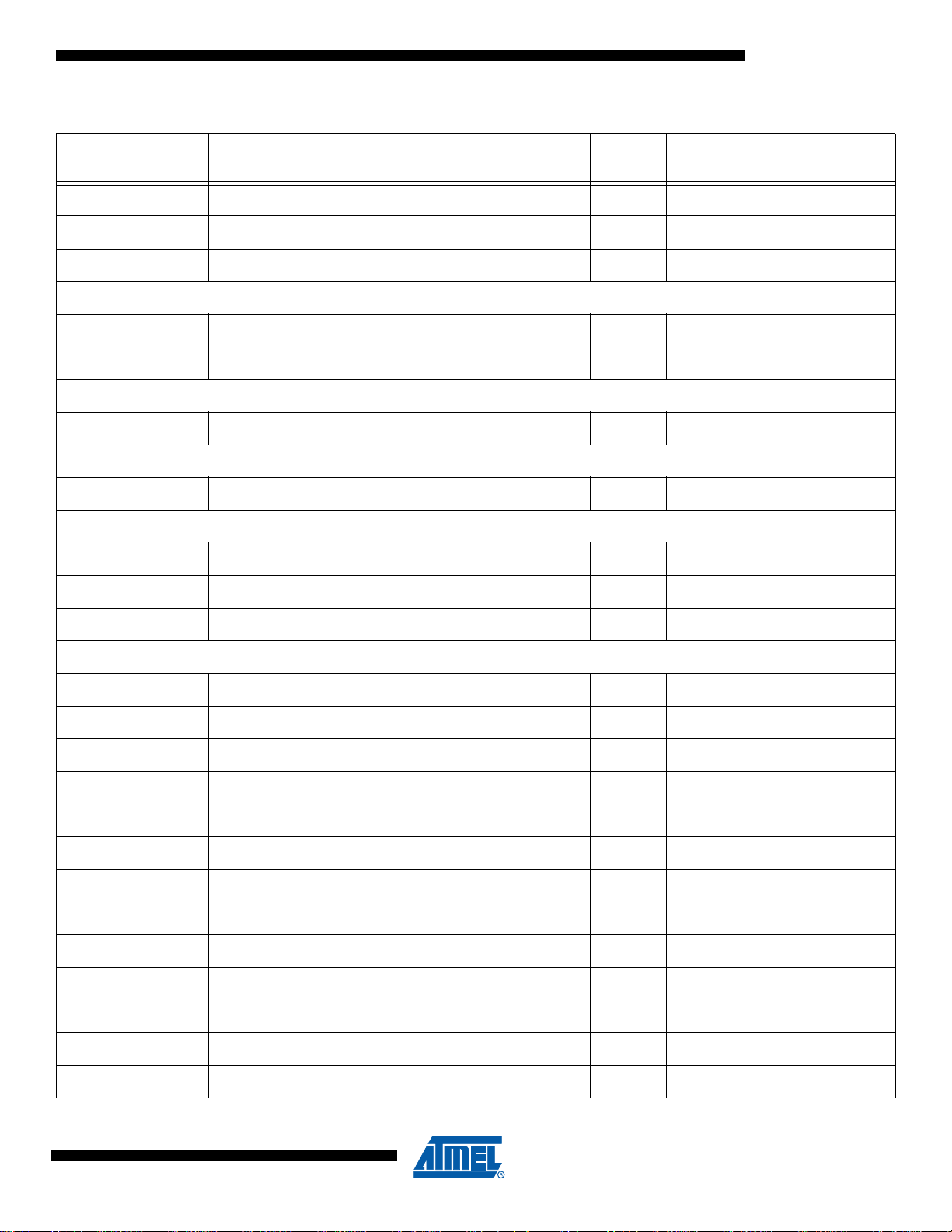

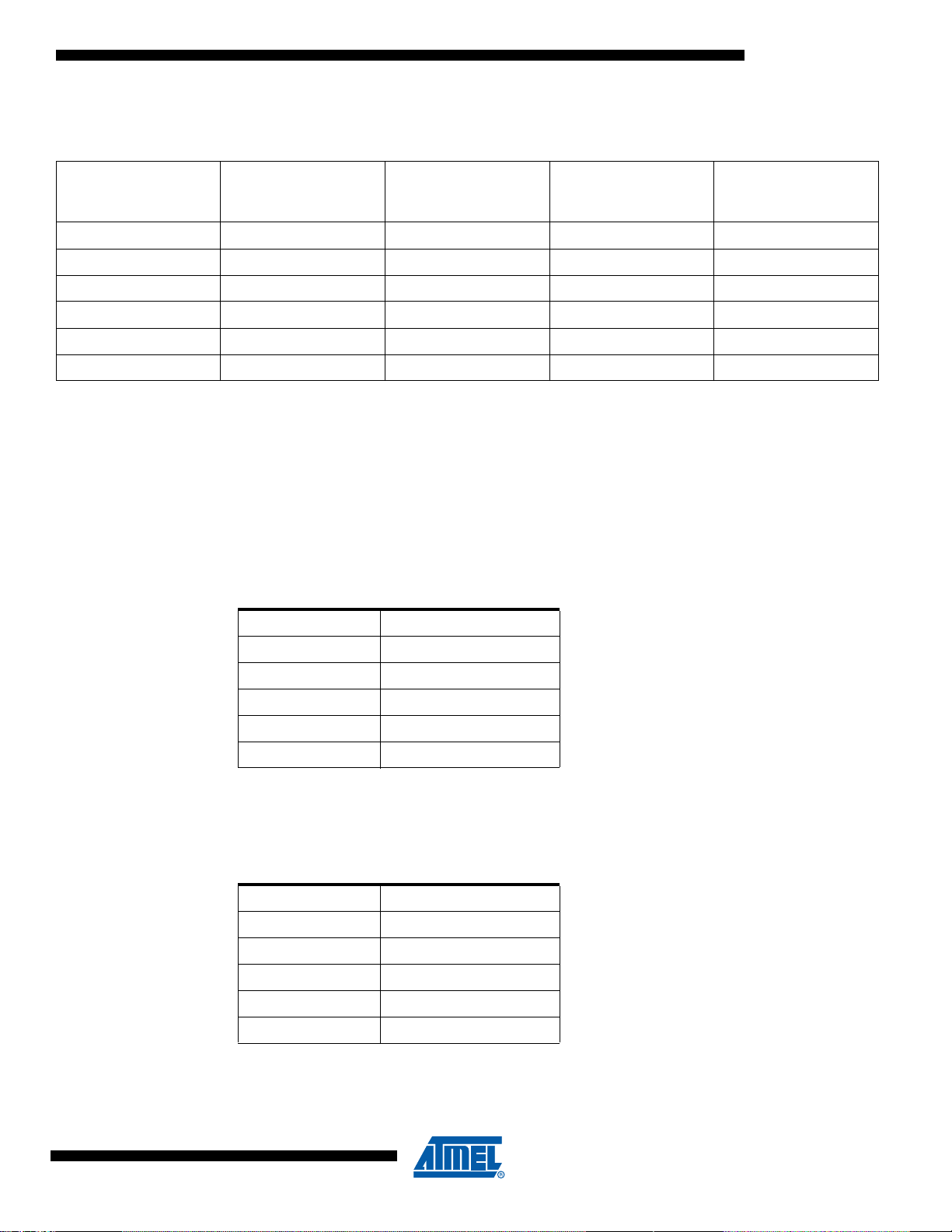

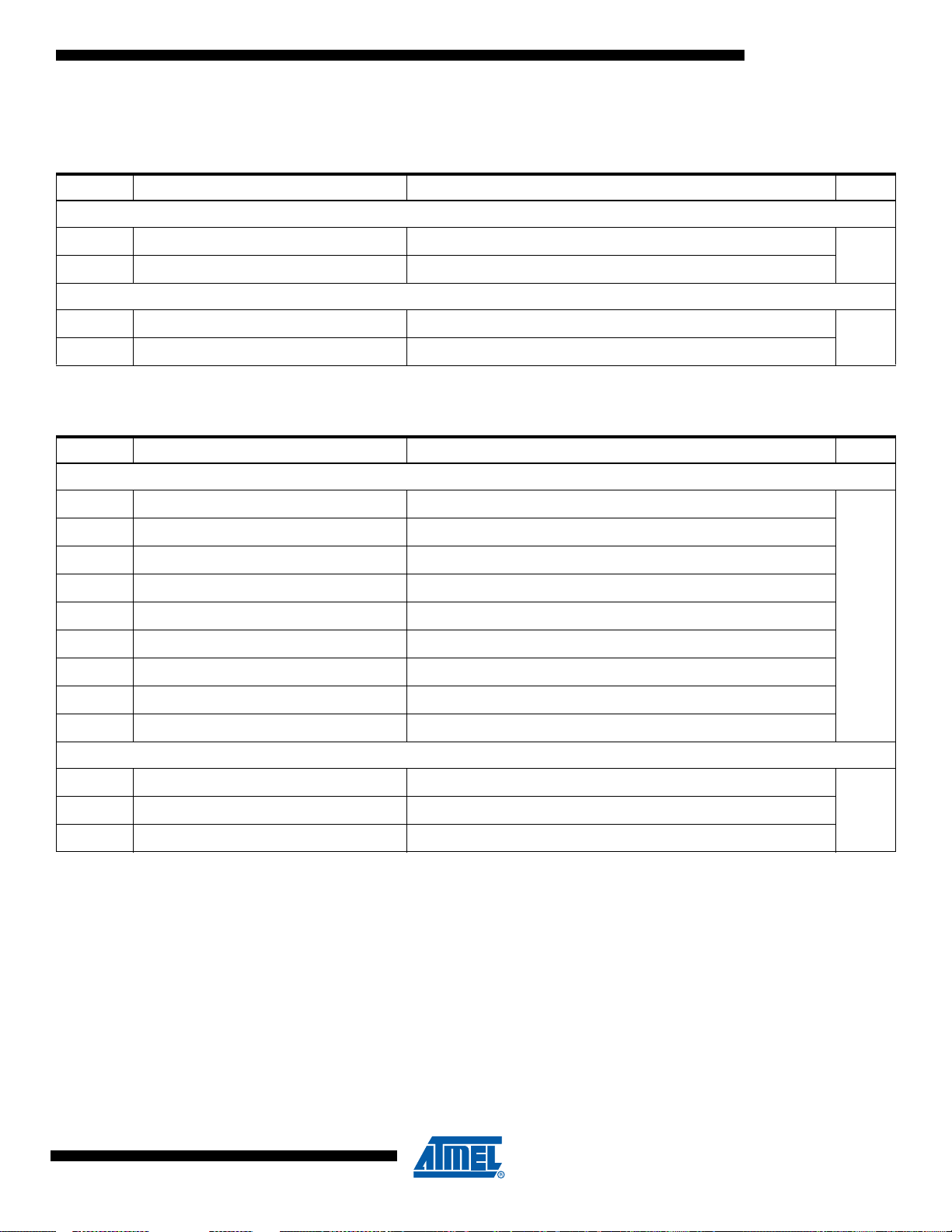

5. Signals Description

The following table gives details on the signal name classified by peripheral

The signals are multiplexed with GPIO pins as described in ”Peripheral Multiplexing on I/O lines”

on page 31.

Table 5-1. Signal Description List

Signal Name Function Type

Power

AT32UC3A

Active

Level Comments

VDDPLL Power supply for PLL

VDDCORE Core Power Supply

VDDIO I/O Power Supply

VDDANA Analog Power Supply

VDDIN Voltage Regulator Input Supply

VDDOUT Voltage Regulator Output

GNDANA Analog Ground Ground

GND Ground Ground

Clocks, Oscillators, and PLL’s

XIN0, XIN1, XIN32 Crystal 0, 1, 32 Input Analog

XOUT0, XOUT1,

XOUT32

Crystal 0, 1, 32 Output Analog

Power

Input

Power

Input

Power

Input

Power

Input

Power

Input

Power

Output

1.65V to 1.95 V

1.65V to 1.95 V

3.0V to 3.6V

3.0V to 3.6V

3.0V to 3.6V

1.65V to 1.95 V

JTAG

TCK Test Clock Input

TDI Test Data In Input

TDO Test Data Out Output

TMS Test Mode Select Input

Auxiliary Port - AUX

MCKO Trace Data Output Clock Output

MDO0 - MDO5 Trace Data Output Output

32058HS–AVR32–03/09

8

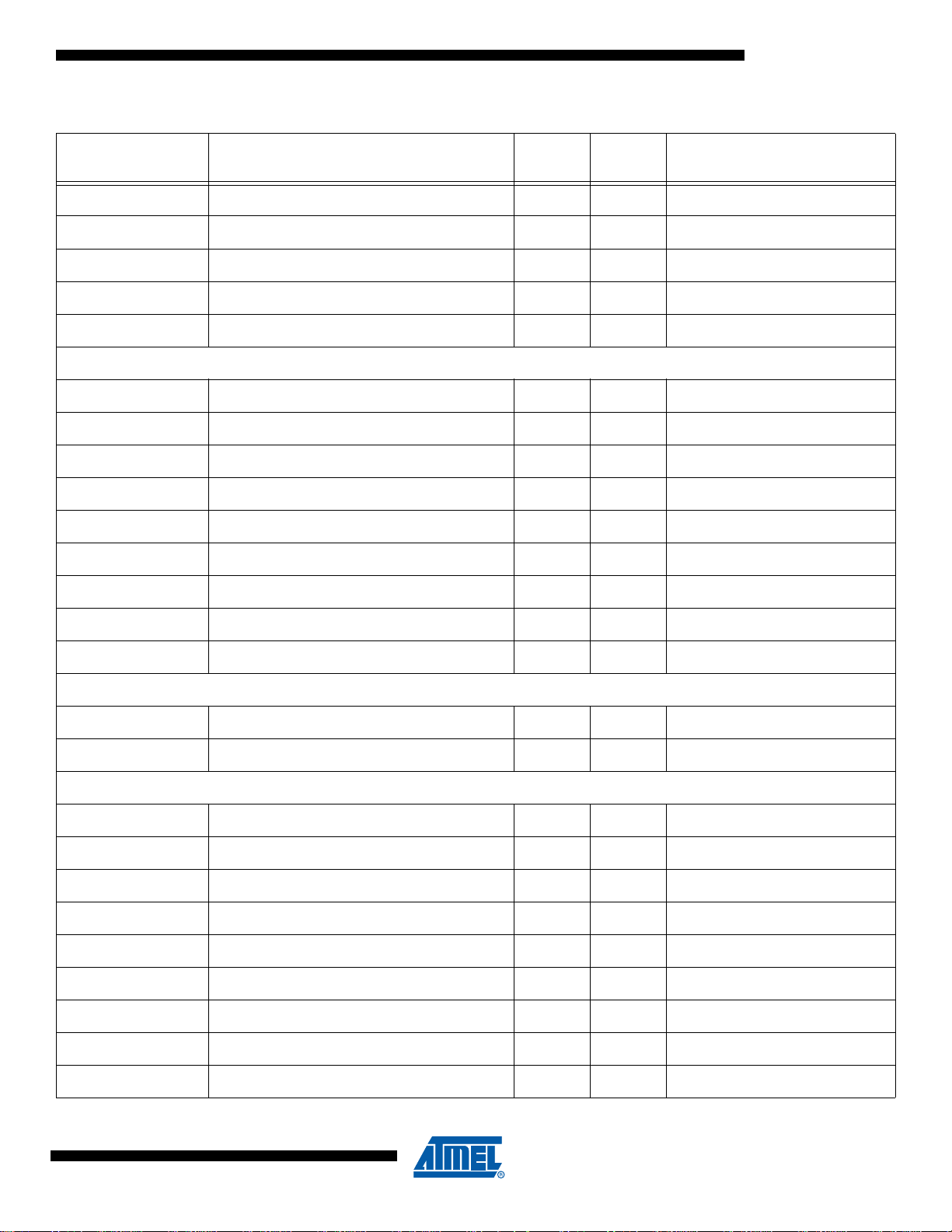

Table 5-1. Signal Description List

Active

Signal Name Function Type

MSEO0 - MSEO1 Trace Frame Control Output

EVTI_N Event In Output Low

EVTO_N Event Out Output Low

Power Manager - PM

GCLK0 - GCLK3 Generic Clock Pins Output

RESET_N Reset Pin Input Low

Real Time Counter - RTC

RTC_CLOCK RTC clock Output

Watchdog Timer - WDT

WDTEXT External Watchdog Pin Output

Level Comments

AT32UC3A

External Interrupt Controller - EIC

EXTINT0 - EXTINT7 External Interrupt Pins Input

KPS0 - KPS7 Keypad Scan Pins Output

NMI_N Non-Maskable Interrupt Pin Input Low

Ethernet MAC - MACB

COL Collision Detect Input

CRS Carrier Sense and Data Valid Input

MDC Management Data Clock Output

MDIO Management Data Input/Output I/O

RXD0 - RXD3 Receive Data Input

RX_CLK Receive Clock Input

RX_DV Receive Data Valid Input

RX_ER Receive Coding Error Input

SPEED Speed

TXD0 - TXD3 Transmit Data Output

TX_CLK Transmit Clock or Reference Clock Output

TX_EN Transmit Enable Output

TX_ER Transmit Coding Error Output

32058HS–AVR32–03/09

9

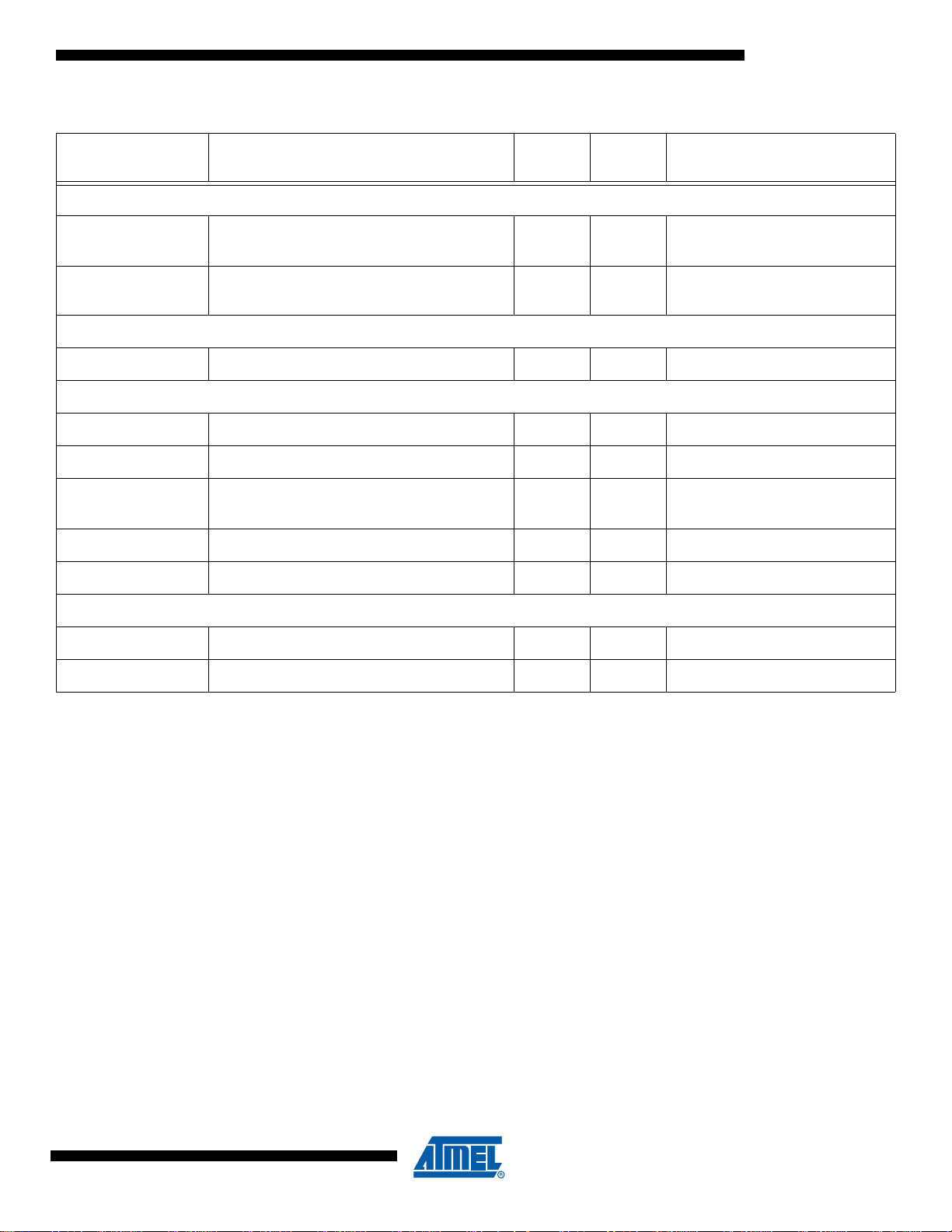

Table 5-1. Signal Description List

Active

Signal Name Function Type

External Bus Interface - HEBI

ADDR0 - ADDR23 Address Bus Output

CAS Column Signal Output Low

DATA0 - DATA15 Data Bus I/O

NCS0 - NCS3 Chip Select Output Low

NRD Read Signal Output Low

NWAIT External Wait Signal Input Low

NWE0 Write Enable 0 Output Low

NWE1 Write Enable 1 Output Low

NWE3 Write Enable 3 Output Low

Level Comments

AT32UC3A

RAS Row Signal Output Low

SDA10 SDRAM Address 10 Line Output

SDCK SDRAM Clock Output

SDCKE SDRAM Clock Enable Output

SDCS0 SDRAM Chip Select Output Low

SDWE SDRAM Write Enable Output Low

General Purpose Input/Output 2 - GPIOA, GPIOB, GPIOC

P0 - P31 Parallel I/O Controller GPIOA I/O

P0 - P31 Parallel I/O Controller GPIOB I/O

P0 - P5 Parallel I/O Controller GPIOC I/O

P0 - P31 Parallel I/O Controller GPIOX I/O

Serial Peripheral Interface - SPI0, SPI1

MISO Master In Slave Out I/O

MOSI Master Out Slave In I/O

NPCS0 - NPCS3 SPI Peripheral Chip Select I/O Low

SCK Clock Output

Synchronous Serial Controll er - SSC

RX_CLOCK SSC Receive Clock I/O

32058HS–AVR32–03/09

10

Table 5-1. Signal Description List

Signal Name Function Type

RX_DATA SSC Receive Data Input

RX_FRAME_SYNC SSC Receive Frame Sync I/O

TX_CLOCK SSC Transmit Clock I/O

TX_DATA SSC Transmit Data Output

TX_FRAME_SYNC SSC Transmit Frame Sync I/O

Timer/Counter - TIMER

A0 Channel 0 Line A I/O

A1 Channel 1 Line A I/O

A2 Channel 2 Line A I/O

B0 Channel 0 Line B I/O

AT32UC3A

Active

Level Comments

B1 Channel 1 Line B I/O

B2 Channel 2 Line B I/O

CLK0 Channel 0 External Clock Input Input

CLK1 Channel 1 External Clock Input Input

CLK2 Channel 2 External Clock Input Input

Two-wire Interface - TWI

SCL Serial Clock I/O

SDA Serial Data I/O

Universal Synchronous Asynchronous Receiver Transmitter - USART0, USART1, USART2, USART3

CLK Clock I/O

CTS Clear To Send Input

DCD Data Carrier Detect Only USART1

DSR Data Set Ready Only USART1

DTR Data Terminal Ready Only USART1

RI Ring Indicator Only USART1

RTS Request To Send Output

RXD Receive Data Input

TXD Transmit Data Output

32058HS–AVR32–03/09

11

Table 5-1. Signal Description List

Signal Name Function Type

Analog to Digital Converter - ADC

AT32UC3A

Active

Level Comments

AD0 - AD7 Analog input pins

ADVREF Analog positive reference voltage input

Pulse Width Modulator - PWM

PWM0 - PWM6 PWM Output Pins Output

Universal Serial Bus Device - USB

DDM USB Device Port Data - Analog

DDP USB Device Port Data + Analog

VBUS USB VBUS Monitor and OTG Negociation

USBID ID Pin of the USB Bus Input

USB_VBOF USB VBUS On/off: bus power control port output

Audio Bitstream DAC (ABDAC)

DATA0-DATA1 D/A Data out Outpu

DATAN0-DATAN1 D/A Data inverted out Outpu

Analog

input

Analog

input

Analog

Input

2.6 to 3.6V

32058HS–AVR32–03/09

12

AT32UC3A

125

26

50

5175

76

100

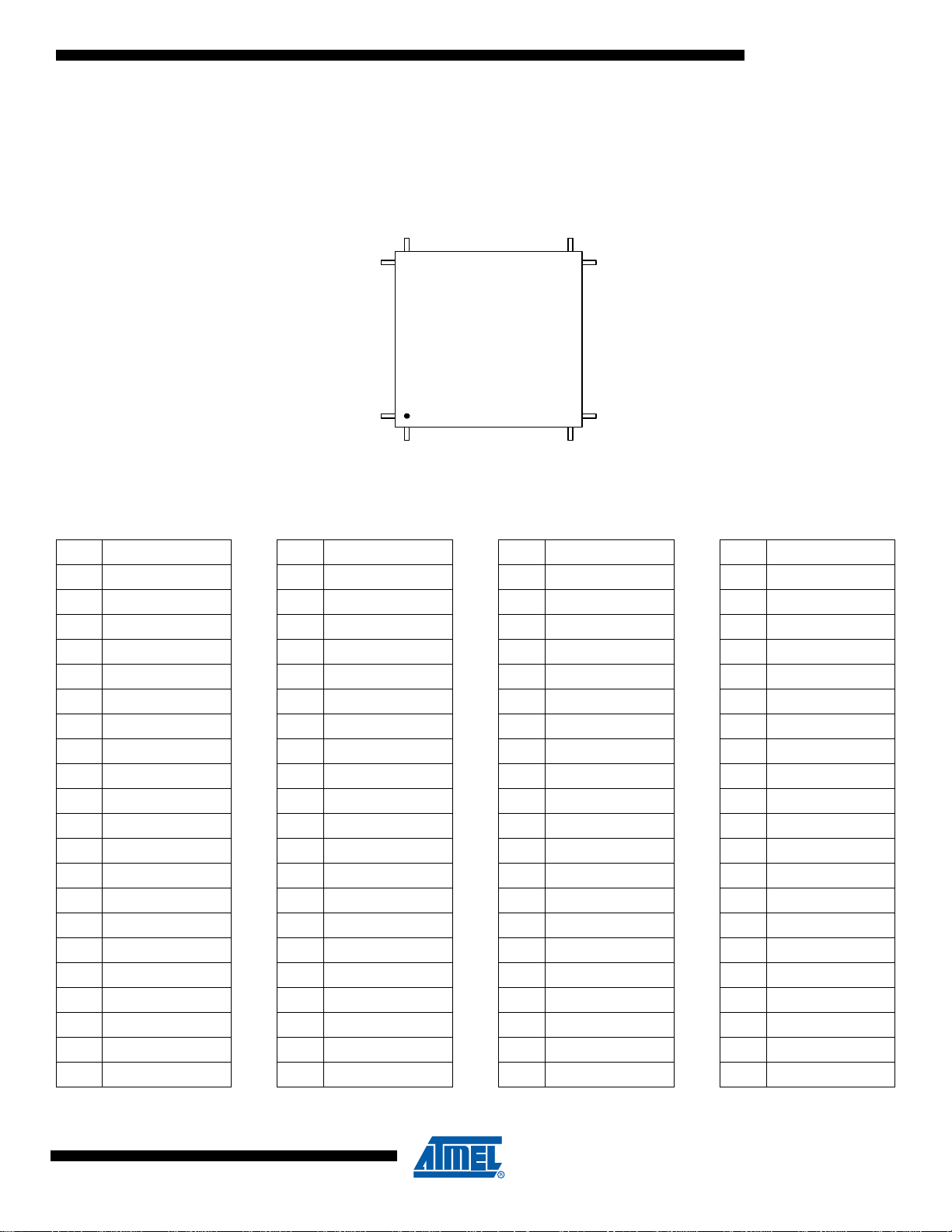

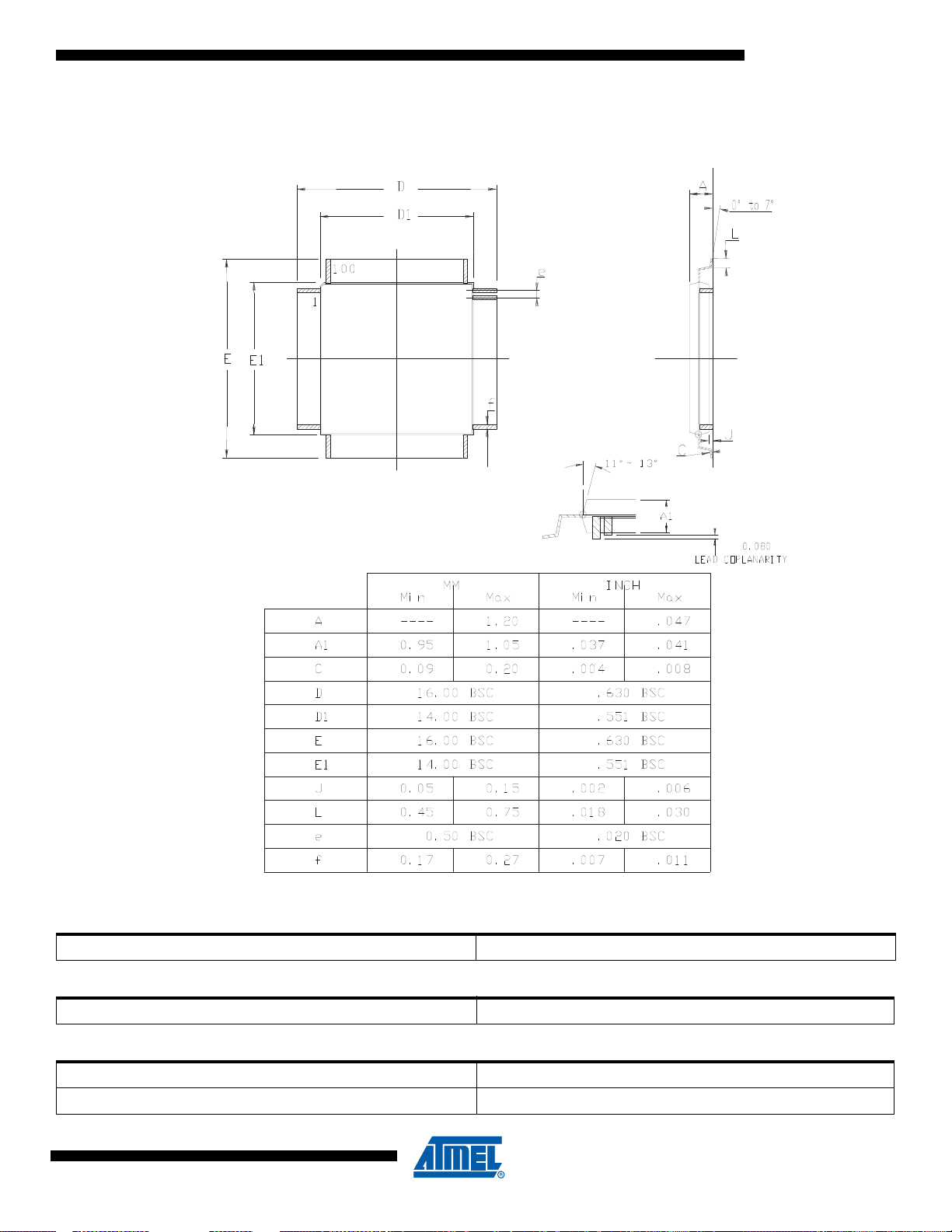

6. Package and Pinout

The device pins are multiplexed with peripheral functions as described in ”Peripheral Multiplexing on I/O lines” on page 31.

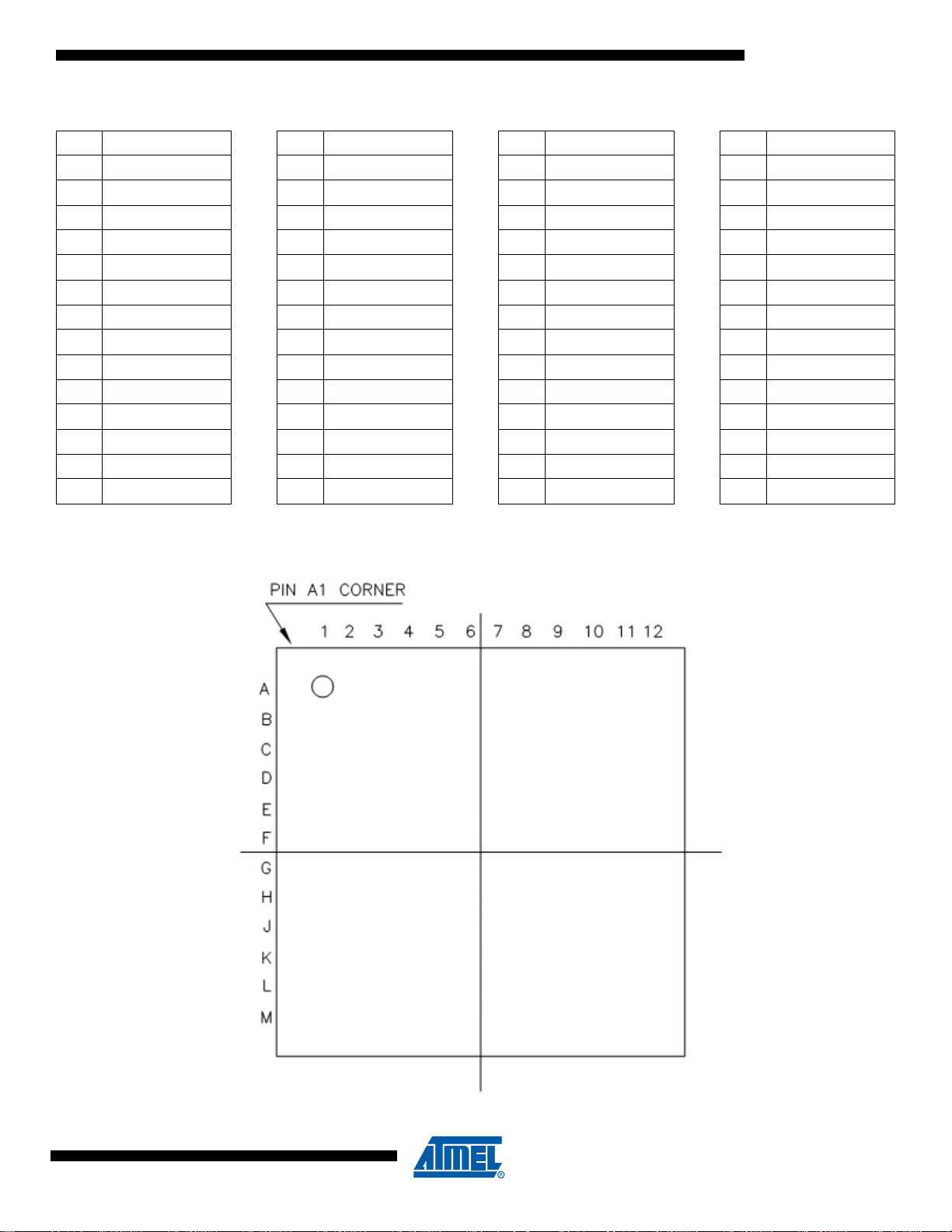

Figure 6-1. TQFP100 Pinout

Table 6-1. TQFP100 Package Pinout

1 PB20 26 PA05 51 PA21 76 PB08

2 PB21 27 PA06 52 PA22 77 PB09

3 PB22 28 PA07 53 PA23 78 PB10

4 VDDIO 29 PA08 54 PA24 79 VDDIO

5 GND 30 PA09 55 PA25 80 GND

6 PB23 31 PA10 56 PA26 81 PB11

7 PB24 32 N/C 57 PA27 82 PB12

8 PB25 33 PA11 58 PA28 83 PA29

9 PB26 34 VDDCORE 59 VDDANA 84 PA30

10 PB27 35 GND 60 ADVREF 85 PC02

11 VDDOUT 36 PA12 61 GNDANA 86 PC03

12 VDDIN 37 PA13 62 VDDPLL 87 PB13

13 GND 38 VDDCORE 63

14 PB28 39 PA14 64 PC01 89 TMS

15 PB29 40 PA15 65 PB00 90 TCK

16 PB30 41 PA16 66 PB01 91 TDO

17 PB31 42 PA17 67 VDDIO 92 TDI

18 RESET_N 43 PA18 68 VDDIO 93 PC04

19 PA00 44 PA19 69 GND 94 PC05

20 PA01 45 PA20 70 PB02 95 PB15

21 GND 46 VBUS 71 PB03 96 PB16

22 VDDCORE 47 VDDIO 72 PB04 97 VDDCORE

PC00 88 PB14

32058HS–AVR32–03/09

13

AT32UC3A

136

37

72

73108

109

144

Table 6-1. TQFP100 Package Pinout

23 PA02 48 DM 73 PB05 98 PB17

24 PA03 49 DP 74 PB06 99 PB18

25 PA04 50 GND 75 PB07 100 PB19

Figure 6-2. LQFP144 Pinout

Table 6-2. VQFP144 Package Pinout

1 PX00 37 GND 73 PA21 109 GND

2 PX01 38 PX10 74 PA22 110 PX30

3 PB20 39 PA05 75 PA23 111 PB08

4 PX02 40 PX11 76 PA24 112 PX31

5 PB21 41 PA06 77 PA25 113 PB09

6 PB22 42 PX12 78 PA26 114 PX32

7 VDDIO 43 PA07 79 PA27 115 PB10

8 GND 44 PX13 80 PA28 116 VDDIO

9 PB23 45 PA08 81 VDDANA 117 GND

10 PX03 46 PX14 82 ADVREF 118 PX33

11 PB24 47 PA09 83 GNDANA 119 PB11

12 PX04 48 PA10 84 VDDPLL 120 PX34

13 PB25 49 N/C 85

14 PB26 50 PA11 86 PC01 122 PA29

15 PB27 51 VDDCORE 87 PX20 123 PA30

16 VDDOUT 52 GND 88 PB00 124 PC02

17 VDDIN 53 PA12 89 PX21 125 PC03

18 GND 54 PA13 90 PB01 126 PB13

19 PB28 55 VDDCORE 91 PX22 127 PB14

20 PB29 56 PA14 92 VDDIO 128 TMS

21 PB30 57 PA15 93 VDDIO 129 TCK

PC00 121 PB12

32058HS–AVR32–03/09

14

AT32UC3A

Table 6-2. VQFP144 Package Pinout

22 PB31 58 PA16 94 GND 130 TDO

23 RESET_N 59 PX15 95 PX23 131 TDI

24 PX05 60 PA17 96 PB02 132 PC04

25 PA00 61 PX16 97 PX24 133 PC05

26 PX06 62 PA18 98 PB03 134 PB15

27 PA01 63 PX17 99 PX25 135 PX35

28 GND 64 PA19 100 PB04 136 PB16

29 VDDCORE 65 PX18 101 PX26 137 PX36

30 PA02 66 PA20 102 PB05 138 VDDCORE

31 PX07 67 PX19 103 PX27 139 PB17

32 PA03 68 VBUS 104 PB06 140 PX37

33 PX08 69 VDDIO 105 PX28 141 PB18

34 PA04 70 DM 106

35 PX09 71 DP 107 PX29 143 PB19

36 VDDIO 72 GND 108 VDDIO 144 PX39

PB07 142 PX38

Figure 6-3. BGA144 Pinout

32058HS–AVR32–03/09

15

AT32UC3A

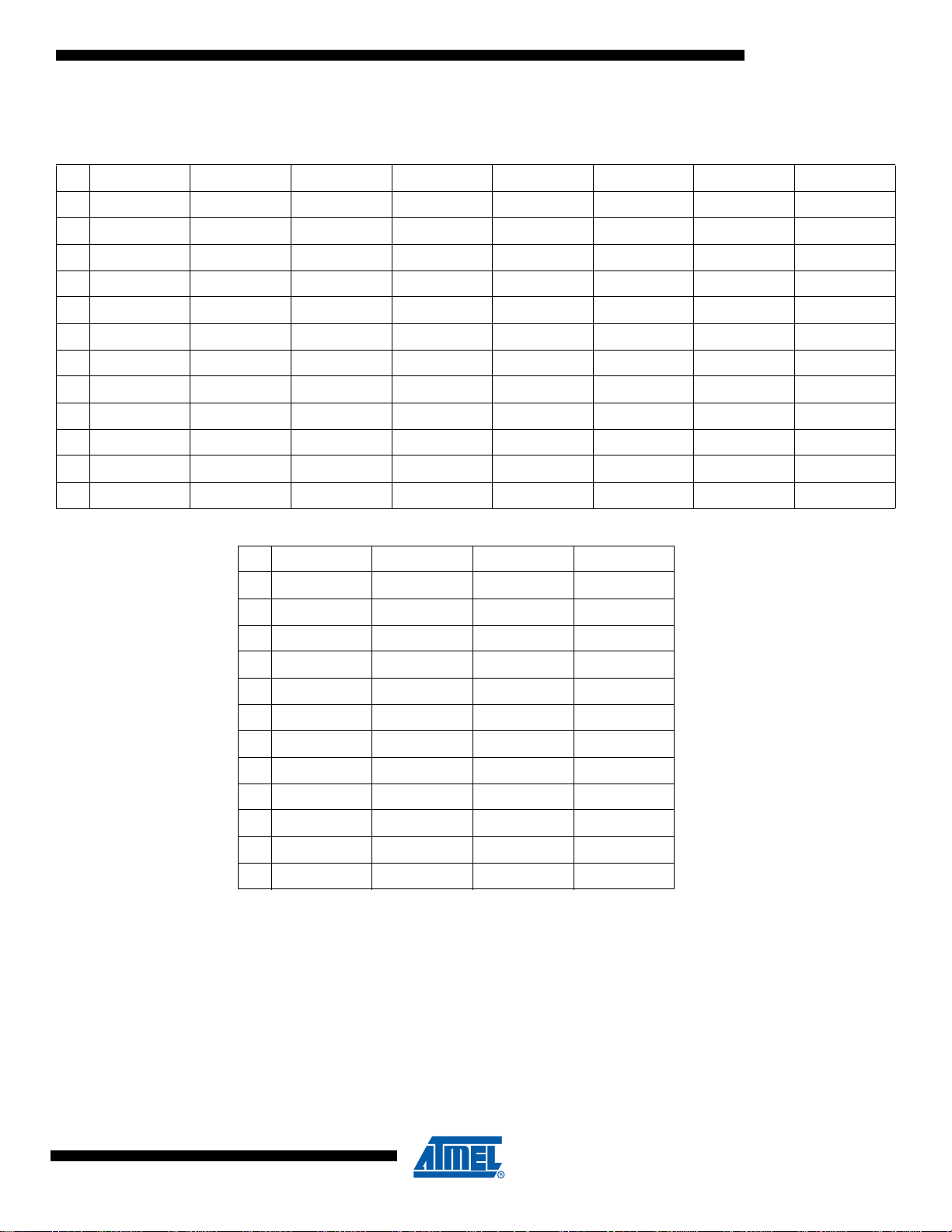

Table 6-3. BGA144 Package Pinout A1..M8

12345678

VDDIO PB07 PB05 PB02 PB03 PB01 PC00 PA28

A

PB08 GND PB06 PB04 VDDIO PB00 PC01 VDDPLL

B

PB09 PX33 PA29 PC02 PX28 PX26 PX22 PX21

C

PB11 PB13 PB12 PX30 PX29 PX25 PX24 PX20

D

PB10 VDDIO PX32 PX31 VDDIO PX27 PX23 VDDANA

E

PA30 PB14 PX34 PB16 TCK GND GND PX16

F

TMS PC03 PX36 PX35 PX37 GND GND PA16

G

TDO VDDCORE PX38 PX39 VDDIO PA01 PA10 VDDCORE

H

TDI PB17 PB15 PX00 PX01 PA00 PA03 PA04

J

PC05 PC04 PB19 PB20 PX02 PB29 PB30 PA02

K

PB21 GND PB18 PB24 VDDOUT PX04 PB31 VDDIN

L

PB22 PB23 PB25 PB26 PX03 PB27 PB28 RESET_N

M

Table 6-4. BGA144 Package Pinout A9..M12

9 101112

PA26 PA25 PA24 PA23

A

PA27 PA21 GND PA22

B

ADVREF GNDANA PX19 PA19

C

PA18 PA20 DP DM

D

PX18 PX17 VDDIO VBUS

E

PA17 PX15 PA15 PA14

F

PA13 PA12 PA11 NC

G

PX11 PA08 VDDCORE VDDCORE

H

PX14 PA07 PX13 PA09

J

PX08 GND PA05 PX12

K

PX06 PX10 GND PA06

L

PX05 PX07 PX09 VDDIO

M

Note: NC is not connected.

32058HS–AVR32–03/09

16

7. Power Considerations

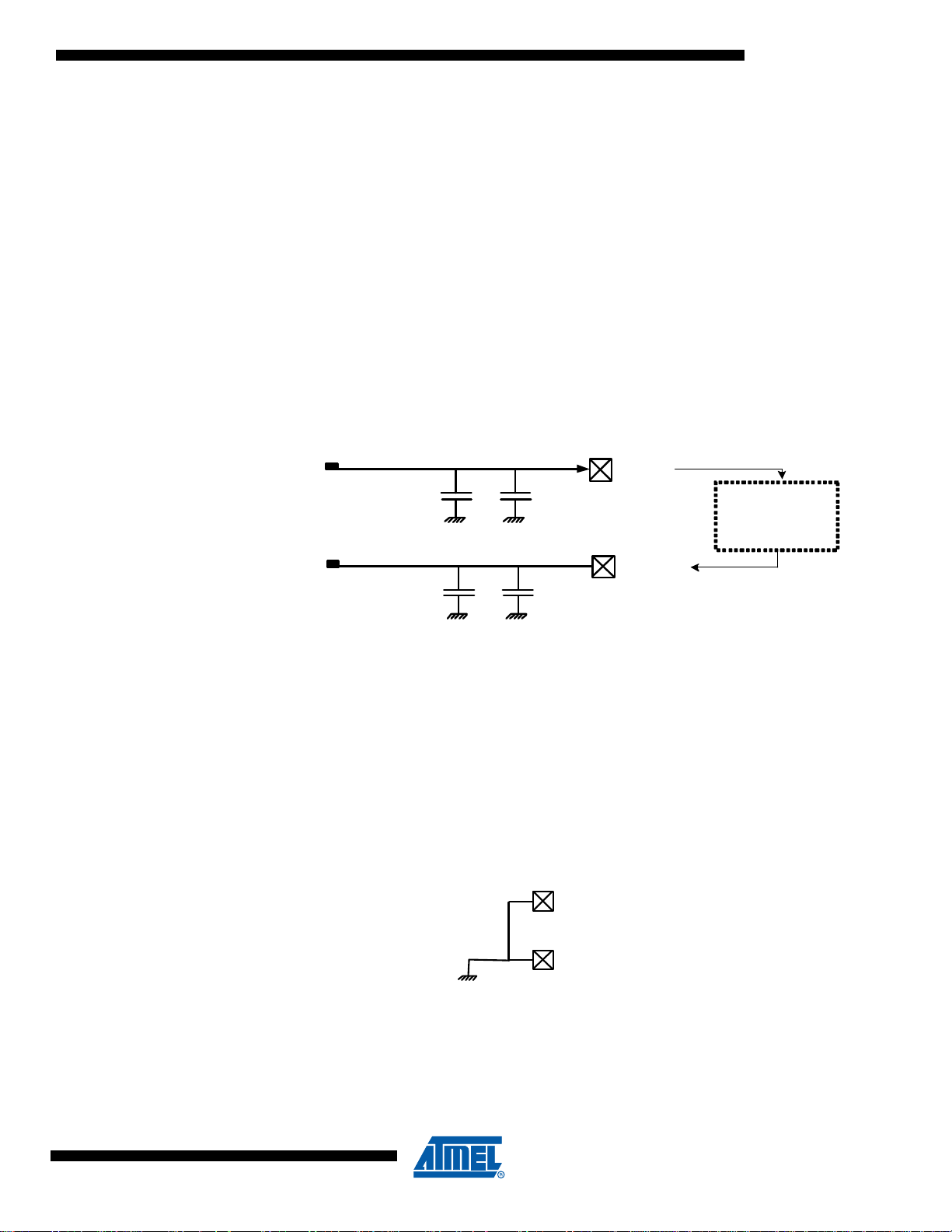

3.3V

VDDANA

VDDIO

VDDIN

VDDCORE

VDDOUT

VDDPLL

ADVREF

3.3V

1.8V

VDDANA

VDDIO

VDDIN

VDDCORE

VDDOUT

VDDPLL

ADVREF

Single Power Supply

Dual Power Supply

1.8V

Regulator

1.8V

Regulator

7.1 Power Supplies

The AT32UC3A has several types of power supply pins:

•

VDDIO: Powers I/O lines. Voltage is 3.3V nominal.

• VDDANA: P owers the ADC Voltage is 3.3V nominal.

• VDDIN: Input voltage for the voltage regulator. Voltage is 3.3V nomin al.

• VDDCORE: Powers the core, memories, and peripherals. Voltage is 1.8V nominal.

• VDDPLL: Powers the PLL. Voltage is 1.8V nominal.

The ground pins GND are common to VDDCORE, VDDIO, VDDPLL. The ground pin for

VDDANA is GNDANA.

Refer to ”Power Consumption” on page 44 for power consumption on the va rious supply pins.

AT32UC3A

32058HS–AVR32–03/09

17

7.2 Voltage Regulator

3.3V

1.8V

VDDIN

VDDOUT

1.8V

Regulator

C

IN1

C

OUT1

C

OUT2

C

IN2

VDDIN

VDDOUT

7.2.1 Single Power Supply

The AT32UC3A embeds a voltage regulator tha t converts from 3.3V to 1.8V. The r egulator takes

its input voltage from VDDIN, and supplies the output voltage on VDDOUT. VDDOUT should be

externally connected to the 1.8V domains.

Adequate input supply decoupling is mandatory for VDDIN in order to improve startup stability

and reduce source voltage drop. Two input decoupling capacitors must be placed close to the

chip.

Adequate output supply decoupling is mandatory for VDDOUT to reduce ripple and avoid oscillations. The best way to achieve this is to use two capacitors in parallel between VDDOUT and

GND as close to the chip as possible

AT32UC3A

Refer to Section 12.3 on page 42 for decoupling capacitors values and regulator characteristics

7.2.2 Dual Power Supply

In case of dual power supply, VDDIN and VDDOUT should be connected to ground to prevent

from leakage current.

32058HS–AVR32–03/09

18

7.3 Analog-to-Digital Converter (A.D.C) reference.

A DVREF

CC

VREF1VREF2

3.3V

The ADC reference (ADVREF) must be provided from an external source. Two decoupling

capacitors must be used to insure proper decoupling.

Refer to Section 12.4 on page 42 for decoupling capacitors values and electrical characteristics.

In case ADC is not used, the ADVREF pin should be connected to GND to avoid extra

consumption.

AT32UC3A

32058HS–AVR32–03/09

19

8. I/O Line Considerations

8.1 JTAG pins

TMS, TDI and TCK have pull-up resistors. TDO is an output, driven at up to VDDIO, and has no

pull-up resistor.

8.2 RESET_N pin

The RESET_N pin is a schmitt input and integrates a perm anent pull-up resistor to VDDIO. As

the product integrates a power-on reset cell, the RESET_N pin can be left unconnected in case

no reset from the system needs to be applied to the product.

8.3 TWI pins

When these pins are used for TWI, the pins are open-drain outputs with slew-rate limitation and

inputs with inputs with spike-filtering. When used as GPIO-pins or used for ot her peripher als, the

pins have the same characteristics as PIO pins.

8.4 GPIO pins

All the I/O lines integrate a programmable pull-up re sistor. Programming of this pull-up resistor is

performed independently for each I/O line through the GPIO Controllers. After reset, I/O lines

default as inputs with pull-up resistors disabled, except when indicated otherwise in the column

“Reset State” of the GPIO Controller multiplexing table s.

AT32UC3A

32058HS–AVR32–03/09

20

9. Memories

9.1 Embedded Memories

• Internal High-Speed Flash

– 512 KBytes (AT32UC3A0512, AT32UC3A1512)

– 256 KBytes (AT32UC3A0256, AT32UC3A1256)

– 128 KBytes (AT32UC3A1128, AT32UC3A2128)

- 0 Wait State Access at up to 33 MHz in Worst Case Conditions

- 1 Wait State Access at up to 66 MHz in Worst Case Conditions

- Pipelined Flash Architecture, allowing b ur st reads from sequential Flash locatio ns, hiding

penalty of 1 wait state access

- Pipelined Flash Architecture typically reduces the cycle penalty of 1 wait state operation

to only 15% compared to 0 wait state ope r a t ion

- 100 000 Write Cycles, 15-year Data Retention Capability

- 4 ms Page Programming Time, 8 ms Chip Erase Time

- Sector Lock Capabilities, Bootloader Protection, Security Bit

- 32 Fuses, Erased During Chip Erase

- User Page For Data To Be Preserved During Chip Erase

• Internal High-Speed SRAM, Single-cycle access at full speed

– 64 KBytes (AT32UC3A0512, AT32UC3A0256, AT32UC3A1512, AT32UC3A1256)

– 32KBytes (A T32UC3A1128)

9.2 Physical Memory Map

AT32UC3A

The system bus is implemented as a bus matrix. All system bus addresses are fixed, and they

are never remapped in any way, not even in boot. Note that AVR32 UC CPU uses unsegment ed

translation, as described in the AVR32 Architecture Manual. The 32-bit physical address space

is mapped as follows:

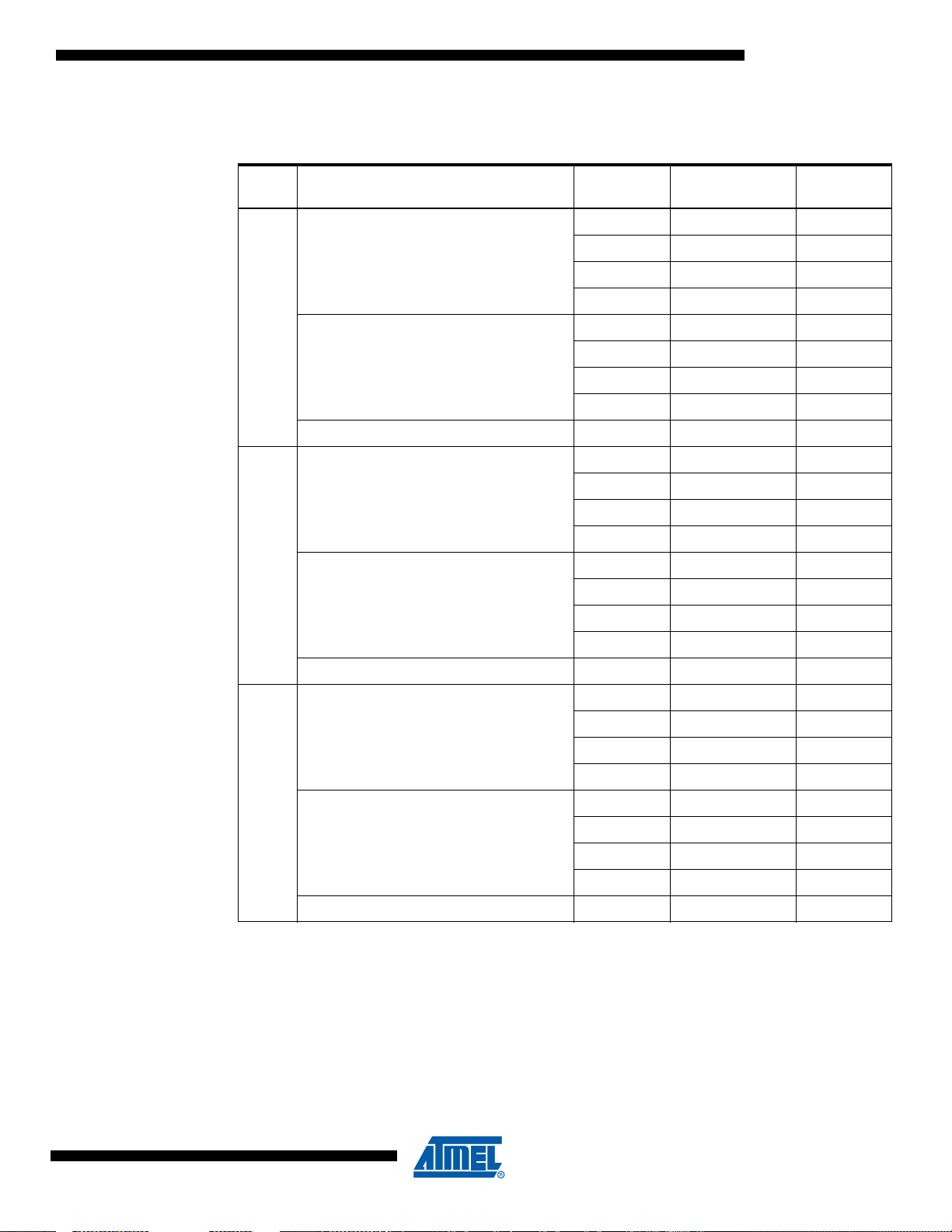

Table 9-1. AT32UC3A Physical Memory Map

Device Start Address

Embedded SRAM 0x0000_0000 64 Kbyte 64 Kbyte 64 Kbyte 64 Kbyte 32 Kbyte 32 Kbyte

Embedded Flash 0x8000_0000 512 Kbyte 512 Kbyte 256 Kbyte 256 Kbyte 128 Kbyte 128 Kbyte

EBI SRAM CS0 0xC000_0000 16 Mbyte - 16 Mbyte - 16 Mbyte EBI SRAM CS2 0xC800_0000 16 Mbyte - 16 Mbyte - 16 Mbyte EBI SRAM CS3 0xCC00_0000 16 Mbyte - 16 Mbyte - 16 Mbyte EBI SRAM CS1

/SDRAM CS0

USB

Configuration

HSB-PB Bridge A 0xFFFE_0000 64 Kbyte 64 Kbyte 64 Kbyte 64 Kbyte 64 Kbyte 64 Kbyte

HSB-PB Bridge B 0xFFFF_0000 64 Kbyte 64 Kbyte 64 kByte 64 kByte 64 Kbyte 64 Kbyte

0xD000_0000 128 Mbyte - 128 Mbyte - 128 Mbyte -

0xE000_0000 64 Kbyte 64 Kbyte 64 Kbyte 64 Kbyte 64 Kbyte 64 Kbyte

Size

AT32UC3A0512 AT32UC3A1512 AT32UC3A0256 AT32UC3A1256 AT32UC3A0128 AT32UC3A1128

32058HS–AVR32–03/09

21

Table 9-2. Flash Memory Parameters

General Purpose

Flash Size

Part Number

AT32UC3A0512 512 Kbytes 1024 128 words 32 fuses

AT32UC3A1512 512 Kbytes 1024 128 words 32 fuses

AT32UC3A0256 256 Kbytes 512 128 words 32 fuses

AT32UC3A1256 256 Kbytes 512 128 words 32 fuses

AT32UC3A1128 128 Kbytes 256 128 words 32 fuses

AT32UC3A0128 128 Kbytes 256 128 words 32 fuses

(FLASH_PW)

Number of pages

(FLASH_P)

Page size

(FLASH_W)

9.3 Bus Matrix Connections

Accesses to unused areas returns an error result to the master requesting such an access.

The bus matrix has the several masters and slaves. Each master has its own bus and its own

decoder, thus allowing a different memory mapping per master. The master number in the table

below can be used to index the HMATRIX control registers. For example, MCFG0 is associated

with the CPU Data master interface.

AT32UC3A

Fuse bits

(FLASH_F)

Table 9-3. High Speed Bus masters

Master 0 CPU Data

Master 1 CPU Instruction

Master 2 CPU SAB

Master 3 PDCA

Master 4 MACB DMA

Master 5 USBB DMA

Each slave has its own arbiter, thus allowing a different arbitration per slave. The slave number

in the table below can be used to index the HMATRIX control registers. For example, SCFG3 is

associated with the Internal SRAM Slave Interface.

Table 9-4. High Speed Bus slaves

Slave 0 Internal Flash

Slave 1 HSB-PB Bridge 0

Slave 2 HSB-PB Bridge 1

Slave 3 Internal SRAM

Slave 4 USBB DPRAM

Slave 5 EBI

32058HS–AVR32–03/09

22

Figure 9-1. HMatrix Master / Slave Connections

CPU Data 0

CPU

Instruction

1

CPU SAB 2

PDCA 3

MACB 4

Internal Flash

0

HSB-PB

Bridge 01HSB-PB

Bridge 1

2

Internal SRAM

Slave

3

USBB Slave

4

EBI

5

USBB DMA 5

HMATRIX MASTERS

HMATRIX SLAVES

AT32UC3A

32058HS–AVR32–03/09

23

10. Peripherals

10.1 Peripheral address map

Table 10-1. Peripheral Address Mapping

Address Peripheral Name Bus

AT32UC3A

0xE0000000

0xFFFE0000

0xFFFE1000

0xFFFE1400

0xFFFE1800

0xFFFE1C00

0xFFFE2000

0xFFFF0000

0xFFFF0800

0xFFFF0C00

USBB USBB Slave Interface - USBB HSB

USBB U SBB Configuration Interface - USBB PBB

HMATRIX HMATRIX Configuration Interface - HMATRIX PBB

FLASHC Flash Controller - FLASHC PBB

MACB MACB Configuration Interface - MACB PBB

SMC

SDRAMC

PDCA Peripheral DMA Interface - PDCA PBA

INTC Interrupt Controller Interface - INTC PBA

PM Power Manager - PM PBA

Static Memory Controller Configuration Interface SMC

SDRAM Controller Configuration Interface SDRAMC

PBB

PBB

32058HS–AVR32–03/09

0xFFFF0D00

0xFFFF0D30

0xFFFF0D80

0xFFFF1000

0xFFFF1400

0xFFFF1800

RTC Real Time Clock - RTC PBA

WDT WatchDog Timer - WDT PBA

EIC External Interrupt Controller - EIC PBA

GPIO General Purpose IO Controller - GPIO PBA

USART0

USART1

Universal Synchronous Asynchronous Receiver

Transmitter - USART0

Universal Synchronous Asynchronous Receiver

Transmitter - USART1

PBA

PBA

24

Table 10-1. Peripheral Address Mapping (Continued)

Address Peripheral Name Bus

AT32UC3A

0xFFFF1C00

0xFFFF2000

0xFFFF2400

0xFFFF2800

0xFFFF2C00

0xFFFF3000

0xFFFF3400

0xFFFF3800

0xFFFF3C00

USART2

USART3

SPI0 Serial Peripheral Interface - SPI0 PBA

SPI1 Serial Peripheral Interface - SPI1 PBA

TWI Two Wire Interface - TWI PBA

PWM Pulse Width Modulation Controller - PWM PBA

SSC Synchronou s Serial Controller - SSC PBA

TC Timer/Counter - TC PBA

ADC Analog To Digital Converter - ADC PBA

Universal Synchronous Asynchronous Receiver

Transmitter - USART2

Universal Synchronous Asynchronous Receiver

Transmitter - USART3

PBA

PBA

10.2 CPU Local Bus Mapping

Some of the registers in the GPIO module are mapped onto the CPU local bus, in addition to

being mapped on the Peripheral Bus. These registers can therefore be reached both by

accesses on the Peripheral Bus, and by accesses on the local bus.

Mapping these registers on the local bus allows cycle-deterministic toggling of GPIO pins since

the CPU and GPIO are the only modules connected to this bus. Also, since the local bus runs at

CPU speed, one write or read operation can be performed per clock cycle to the local busmapped GPIO registers.

32058HS–AVR32–03/09

25

AT32UC3A

The following GPIO registers are mapped on the local bus:

Table 10-2. Local bus mapped GPIO registers

Local Bus

Port Register Mode

0 Output Driver Enable Register (ODER) WRITE 0x4000_0040 Write-only

SET 0x4000_0044 Write-only

CLEAR 0x4000_0048 Write-only

TOGGLE 0x4000_004C Write-only

Output Value Register (OVR) WRITE 0x4000_0 050 Write-only

SET 0x4000_0054 Write-only

CLEAR 0x4000_0058 Write-only

TOGGLE 0x4000_005C Write-only

Pin Value Register (PVR) - 0x4000_0060 Read-only

1 Output Driver Enable Register (ODER) WRITE 0x4000_0140 Write-only

SET 0x4000_0144 Write-only

CLEAR 0x4000_0148 Write-only

TOGGLE 0x4000_014C Write-only

Address Access

Output Value Register (OVR) WRITE 0x4000_0 150 Write-only

SET 0x4000_0154 Write-only

CLEAR 0x4000_0158 Write-only

TOGGLE 0x4000_015C Write-only

Pin Value Register (PVR) - 0x4000_0160 Read-only

2 Output Driver Enable Register (ODER) WRITE 0x4000_0240 Write-only

SET 0x4000_0244 Write-only

CLEAR 0x4000_0248 Write-only

TOGGLE 0x4000_024C Write-only

Output Value Register (OVR) WRITE 0x4000_0 250 Write-only

SET 0x4000_0254 Write-only

CLEAR 0x4000_0258 Write-only

TOGGLE 0x4000_025C Write-only

Pin Value Register (PVR) - 0x4000_0260 Read-only

32058HS–AVR32–03/09

26

Table 10-2. Local bus mapped GPIO registers

Port Register Mode

3 Output Driver Enable Register (ODER) WRITE 0x4000_0340 Write-only

Output Value Register (OVR) WRITE 0x4000_0 350 Write-only

Pin Value Register (PVR) - 0x4000_0360 Read-only

10.3 Interrupt Request Signal Map

The various modules may output Interrupt request signals. These signals are routed to th e Inte rrupt Controller (INTC), described in a later chapter. The Interrupt Controller supports up to 64

groups of interrupt requests. Each group can ha ve up to 32 inte rrupt request sign als. All interrupt

signals in the same group share the same autovector address and priority level. Refer to the

documentation for the individual submodules for a description of the semantics of the different

interrupt requests.

AT32UC3A

Local Bus

Address Access

SET 0x4000_0344 Write-only

CLEAR 0x4000_0348 Write-only

TOGGLE 0x4000_034C Write-only

SET 0x4000_0354 Write-only

CLEAR 0x4000_0358 Write-only

TOGGLE 0x4000_035C Write-only

The interrupt request signals are connected to the INTC as follows.

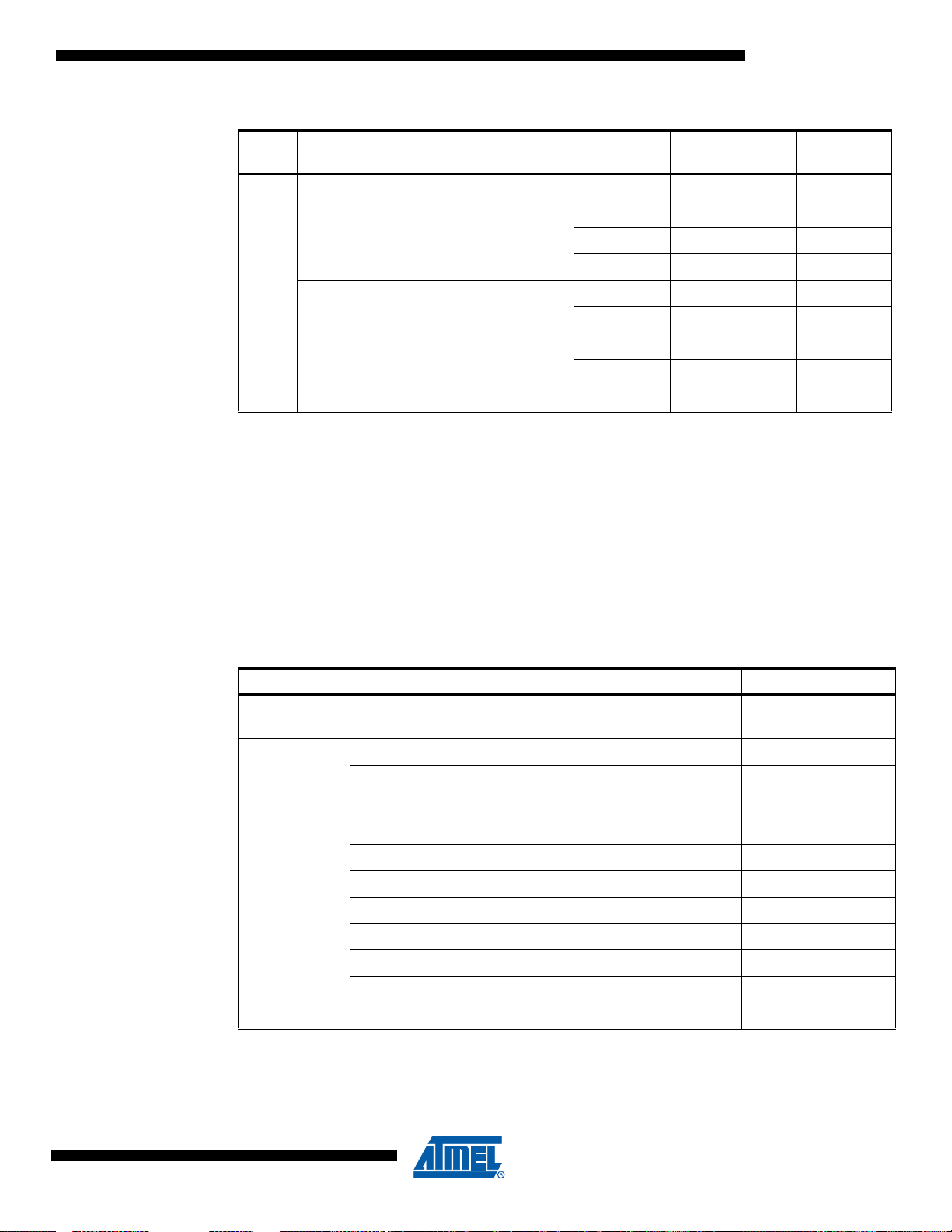

Table 10-3. Interrupt Request Signal Map

Group Line Module Signal

00

0 External Interrupt Controller EIC 0

1 External Interrupt Controller EIC 1

2 External Interrupt Controller EIC 2

3 External Interrupt Controller EIC 3

4 External Interrupt Controller EIC 4

1

5 External Interrupt Controller EIC 5

6 External Interrupt Controller EIC 6

7 External Interrupt Controller EIC 7

8 Real Time Counter RTC

9 Power Manager PM

10 Frequency Meter FREQM

AVR32 UC CPU with optional MPU and

optional OCD

SYSBLOCK

COMPARE

32058HS–AVR32–03/09

27

Table 10-3. Interrupt Request Signal Map

0 General Purpose Input/Output GPIO 0

1 General Purpose Input/Output GPIO 1

2 General Purpose Input/Output GPIO 2

3 General Purpose Input/Output GPIO 3

4 General Purpose Input/Output GPIO 4

5 General Purpose Input/Output GPIO 5

6 General Purpose Input/Output GPIO 6

2

7 General Purpose Input/Output GPIO 7

8 General Purpose Input/Output GPIO 8

9 General Purpose Input/Output GPIO 9

10 General Purpose Input/Output GPIO 10

11 General Purpose Input/Output GPIO 11

12 General Purpose Input/Output GPIO 12

13 General Purpose Input/Output GPIO 13

AT32UC3A

0 Peripheral DMA Controller PDCA 0

1 Peripheral DMA Controller PDCA 1

2 Peripheral DMA Controller PDCA 2

3 Peripheral DMA Controller PDCA 3

4 Peripheral DMA Controller PDCA 4

5 Peripheral DMA Controller PDCA 5

6 Peripheral DMA Controller PDCA 6

3

4 0 Flash Controller FLASHC

50

7 Peripheral DMA Controller PDCA 7

8 Peripheral DMA Controller PDCA 8

9 Peripheral DMA Controller PDCA 9

10 Peripheral DMA Controller PDCA 10

11 Peripheral DMA Controller PDCA 11

12 Peripheral DMA Controller PDCA 12

13 Peripheral DMA Controller PDCA 13

14 Peripheral DMA Controller PDCA 14

Universal Synchronous/Asynchronous

Receiver/Transmitter

USART0

32058HS–AVR32–03/09

60

70

80

Universal Synchronous/Asynchronous

Receiver/Transmitter

Universal Synchronous/Asynchronous

Receiver/Transmitter

Universal Synchronous/Asynchronous

Receiver/Transmitter

USART1

USART2

USART3

28

Table 10-3. Interrupt Request Signal Map

10.4 Clock Connections

AT32UC3A

9 0 Serial Peripheral Interface SPI0

10 0 Serial Peripheral Interface SPI1

11 0 Two-wire Interface TWI

12 0 Pulse Width Modulation Controller PWM

13 0 Synchronous Serial Controller SSC

0 Timer/Counter TC0

14

15 0 Analog to Digital Converter ADC

16 0 Ethernet MAC M ACB

17 0 USB 2.0 OTG Interface USBB

18 0 SDRAM Controller SDRAMC

19 0 Audio Bitstream DAC DAC

1 Timer/Counter TC1

2 Timer/Counter TC2

10.4.1 Timer/Counters

10.4.2 USARTs

Each Timer/Counter channel can independently select an internal or exter nal clock sou rce for it s

counter:

Table 10-4. Timer/Counter clock connections

Source Name Connection

Internal TIMER_CLOCK1 32 KHz Oscillator

TIMER_CLOCK2 PBA clock / 2

TIMER_CLOCK3 PBA clock / 8

TIMER_CLOCK4 PBA clock / 32

TIMER_CLOCK5 PBA clock / 128

External XC0 See Section 10.7

XC1

XC2

Each USART can be connected to an internally divided clock:

Table 10-5. USART clock connections

32058HS–AVR32–03/09

USART Source Name Connection

0 Internal CLK_DIV PBA clock / 8

1

2

3

29

10.4.3 SPIs

Each SPI can be connected to an internally divided clock:

Table 10-6. SPI clock connections

SPI Source Name Connection

0 Internal CLK_DIV PBA clock or

1

10.5 Nexus OCD AUX port connections

If the OCD trace system is enabled, the trace system will take control over a number of pins, irrespectively of the PIO configuration. Two different OCD trace pin mappings are possible,

depending on the configuration of the OCD AXS register. For details, see the AVR32 UC Technical Reference Manual.

Table 10-7. Nexus OCD AUX port connections

Pin AXS=0 AXS=1

EVTI_N PB19 PA08

AT32UC3A

PBA clock / 32

MDO[5] PB16 PA27

MDO[4] PB14 PA26

MDO[3] PB13 PA25

MDO[2] PB12 PA24

MDO[1] PB11 PA23

MDO[0] PB10 PA22

EVTO_N PB20 PB20

MCKO PB21 PA21

MSEO[1] PB04 PA07

MSEO[0] PB17 PA28

10.6 PDC handshake signals

The PDC and the peripheral modules communicate t hro ugh a set of han dshake sign als. The f ollowing table defines the valid settings for the Peripheral Identifier (PID) in the PDC Peripheral

Select Register (PSR).

Table 10-8. PDC Handshake Signals

PID Value Peripheral module & direction

0ADC

32058HS–AVR32–03/09

1 SSC - RX

2 USART0 - RX

3 USART1 - RX

30

Table 10-8. PDC Handshake Signals

PID Value Peripheral module & direction

4 USART2 - RX

5 USART3 - RX

6TWI - RX

7 SPI0 - RX

8 SPI1 - RX

9 SSC - TX

10 USART0 - TX

11 USART1 - TX

12 USART2 - TX

13 USART3 - TX

14 TWI - TX

15 SPI0 - TX

16 SPI1 - TX

AT32UC3A

17 ABDAC

10.7 Peripheral Multiplexing on I/O lines

Each GPIO line can be assigned to one of 3 peripheral functions; A, B or C. The following table

define how the I/O lines on the peripherals A, B and C are multiplexed by the GPIO.

Table 10-9. GPIO Controller Function Multiplexing

TQFP100 VQFP144 PIN GPIO Pin Function A Function B Function C

19 25 PA00 GPIO 0 USART0 - RXD TC - CLK0

20 27 PA01 GPIO 1 USART0 - TXD TC - CLK1

23 30 PA02 GPIO 2 USART0 - CLK TC - CLK2

24 32 PA03 GPIO 3 USART0 - RTS EIM - EXTINT[4] DAC - DATA[0]

25 34 PA04 GPIO 4 USART0 - CTS EIM - EXTINT[5] DAC - DATAN[0]

26 39 PA05 GPIO 5 USART1 - RXD PWM - PWM[4]

27 41 PA06 GPIO 6 USART1 - TXD PWM - PWM[5]

28 43 PA07 GPIO 7 USART1 - CLK PM - GCLK[0] SPI0 - NPCS[3]

29 45 PA08 GPIO 8 USART1 - RTS SPI0 - NPCS[1] EIM - EXTINT[7]

30 47 PA09 GPIO 9 USART1 - CTS SPI0 - NPCS[2] MACB - WOL

31 48 PA10 GPIO 10 SPI0 - NPCS[0] EIM - EXTINT[6]

33 50 PA11 GPIO 11 SPI0 - MISO USB - USB_ID

36 53 PA12 GPIO 12 SPI0 - MOSI USB - USB_VBOF

37 54 PA13 GPIO 13 SPI0 - SCK

39 56 PA14 GPIO 14

40 57 PA15 GPIO 15 SSC - TX_CLOCK SPI1 - SCK EBI - ADDR[20]

SSC -

TX_FRAME_SYNC

SPI1 - NPCS[0] EBI - NCS[0]

32058HS–AVR32–03/09

31

AT32UC3A

Table 10-9. GPIO Controller Function Multiplexing

41 58 PA16 GPIO 16 SSC - TX_DATA SPI1 - MOSI EBI - ADDR[21]

42 60 PA17 GPIO 17 SSC - RX_DATA SPI1 - MISO EBI - ADDR[22]

43 62 PA18 GPIO 18 SSC - RX_CLOCK SPI1 - NPCS[1] MACB - WOL

44 64 PA19 GPIO 19

45 66 PA20 GPIO 20 EIM - EXTINT[8] SPI1 - NPCS[3]

51 73 PA21 GPIO 21 ADC - AD[0] EIM - EXTINT[0] USB - USB_ID

52 74 PA22 GPIO 22 ADC - AD[1] EIM - EXTINT[1] USB - USB_VBOF

53 75 PA23 GPIO 23 ADC - AD[2] EIM - EXTINT[2] DAC - DATA[1]

54 76 PA24 GPIO 24 ADC - AD[3] EIM - EXTINT[3] DAC - DATAN[1]

55 77 PA25 GPIO 25 ADC - AD[4] EIM - SCAN[0] EBI - NCS[0]

56 78 PA26 GPIO 26 ADC - AD[5] EIM - SCAN[1] EBI - ADDR[20]

57 79 PA27 GPIO 27 ADC - AD[6] EIM - SCAN[2] EBI - ADDR[21]

58 80 PA28 GPIO 28 ADC - AD[7] EIM - SCAN[3] EBI - ADDR[22]

83 122 PA29 GPIO 29 TWI - SDA USART2 - RTS

84 123 PA30 GPIO 30 TWI - SCL USART2 - CTS

65 88 PB00 GPIO 32 MACB - TX_CLK USART2 - RTS USART3 - RTS

66 90 PB01 GPIO 33 MACB - TX_EN USART2 - CTS USART3 - CTS

70 96 PB02 GPIO 34 MACB - TXD[0] DAC - DATA[0]

71 98 PB03 GPIO 35 MACB - TXD[1] DAC - DATAN[0]

72 100 PB04 GPIO 36 MACB - CRS USART3 - CLK EBI - NCS[3]

73 102 PB05 GPIO 37 MACB - RXD[0] DAC - DATA[1]

74 104 PB06 GPIO 38 MACB - RXD[1] DAC - DATAN[1]

75 106 PB07 GPIO 39 MACB - RX_ER

76 111 PB08 GPIO 40 MACB - MDC

77 113 PB09 GPIO 41 MACB - MDIO

78 115 PB10 GPIO 42 MACB - TXD[2] USART3 - RXD EBI - SDCK

81 119 PB11 GPIO 43 MACB - TXD[3] USART3 - TXD EBI - SDCKE

82 121 PB12 GPIO 44 MACB - TX_ER TC - CLK0 EBI - RAS

87 126 PB13 GPIO 45 MACB - RXD[2] TC - CLK1 EBI - CAS

88 127 PB14 GPIO 46 MACB - RXD[3] TC - CLK2 EBI - SDWE

95 134 PB15 GPIO 47 MACB - RX_DV

96 136 PB16 GPIO 48 MACB - COL USB - USB_ID EBI - SDA10

98 139 PB17 GPIO 49 MACB - RX_CLK USB - USB_VBOF EBI - ADDR[23]

99 141 PB18 GPIO 50 MACB - SPEED ADC - TRIGGER PWM - PWM[6]

100 143 PB19 GPIO 51 PWM - PWM[0] PM - GCLK[0] EIM - SCAN[4]

1 3 PB20 GPIO 52 PWM - PWM[1] PM - GCLK[1] EIM - SCAN[5]

2 5 PB21 GPIO 53 PWM - PWM[2] PM - GCLK[2] EIM - SCAN[6]

3 6 PB22 GPIO 54 PWM - PWM[3] PM - GCLK[3] EIM - SCAN[7]

6 9 PB23 GPIO 55 TC - A0 USART1 - DCD

SSC -

RX_FRAME_SYNC

SPI1 - NPCS[2]

32058HS–AVR32–03/09

32

AT32UC3A

Table 10-9. GPIO Controller Function Multiplexing

7 11 PB24 GPIO 56 TC - B0 USART1 - DSR

8 13 PB25 GPIO 57 TC - A1 USART1 - DTR

9 14 PB26 GPIO 58 TC - B1 USART1 - RI

10 15 PB27 GPIO 59 TC - A2 PWM - PWM[4]

14 19 PB28 GPIO 60 TC - B2 PWM - PWM[5]

15 20 PB29 GPIO 61 USART2 - RXD PM - GCLK[1] EBI - NCS[2]

16 21 PB30 GPIO 62 USART2 - TXD PM - GCLK[2] EBI - SDCS

17 22 PB31 GPIO 63 USART2 - CLK PM - GCLK[3] EBI - NWAIT

63 85 PC00 GPIO 64

64 86 PC01 GPIO 65

85 124 PC02 GPIO 66

86 125 PC03 GPIO 67

93 132 PC04 GPIO 68

94 133 PC05 GPIO 69

1 PX00 GPIO 100 EBI - DATA[10] USART0 - RXD

2 PX01 GPIO 99 EBI - DATA[9] USART0 - TXD

4 PX02 GPIO 98 EBI - DATA[8] USART0 - CTS

10 PX03 GPIO 97 EBI - DATA[7] USART0 - RTS

12 PX04 GPIO 96 EBI - DATA[6] USART1 - RXD

24 PX05 GPIO 95 EBI - DATA[5] USART1 - TXD

26 PX06 GPIO 94 EBI - DATA[4] USART1 - CTS

31 PX07 GPIO 93 EBI - DATA[3] USART1 - RTS

33 PX08 GPIO 92 EBI - DATA[2] USART3 - RXD

35 PX09 GPIO 91 EBI - DATA[1] USART3 - TXD

38 PX10 GPIO 90 EBI - DATA[0] USART2 - RXD

40 PX11 GPIO 109 EBI - NWE1 USART2 - TXD

42 PX12 GPIO 108 EBI - NWE0 USART2 - CTS

44 PX13 GPIO 107 EBI - NRD USART2 - RTS

46 PX14 GPIO 106 EBI - NCS[1] TC - A0

59 PX15 GPIO 89 EBI - ADDR[19] USART3 - RTS TC - B0

61 PX16 GPIO 88 EBI - ADDR[18] USART3 - CTS TC - A1

63 PX17 GPIO 87 EBI - ADDR[17] TC - B1

65 PX18 GPIO 86 EBI - ADDR[16] TC - A2

67 PX19 GPIO 85 EBI - ADDR[15] EIM - SCAN[0] TC - B2

87 PX20 GPIO 84 EBI - ADDR[14] EIM - SCAN[1] TC - CLK0

89 PX21 GPIO 83 EBI - ADDR[13] EIM - SCAN[2] TC - CLK1

91 PX22 GPIO 82 EBI - ADDR[12] EIM - SCAN[3] TC - CLK2

95 PX23 GPIO 81 EBI - ADDR[11] EIM - SCAN[4]

97 PX24 GPIO 80 EBI - ADDR[10] EIM - SCAN[5]

32058HS–AVR32–03/09

33

Table 10-9. GPIO Controller Function Multiplexing

99 PX25 GPIO 79 EBI - ADDR[9] EIM - SCAN[6]

101 PX26 GPIO 78 EBI - ADDR[8] EIM - SCAN[7]

103 PX27 GPIO 77 EBI - ADDR[7] SPI0 - MISO

105 PX28 GPIO 76 EBI - ADDR[6] SPI0 - MOSI

107 PX29 GPIO 75 EBI - ADDR[5] SPI0 - SCK

110 PX30 GPIO 74 EBI - ADDR[4] SPI0 - NPCS[0]

112 PX31 GPIO 73 EBI - ADDR[3] SPI0 - NPCS[1]

114 PX32 GPIO 72 EBI - ADDR[2] SPI0 - NPCS[2]

118 PX33 GPIO 71 EBI - ADDR[1] SPI0 - NPCS[3]

120 PX34 GPIO 70 EBI - ADDR[0] SPI1 - MISO

135 PX35 GPIO 105 EBI - DATA[15] SPI1 - MOSI

137 PX36 GPIO 104 EBI - DATA[14] SPI1 - SCK

140 PX37 GPIO 103 EBI - DATA[13] SPI1 - NPCS[0]

142 PX38 GPIO 102 EBI - DATA[12] SPI1 - NPCS[1]

144 PX39 GPIO 101 EBI - DATA[11] SPI1 - NPCS[2]

AT32UC3A

10.8 Oscillator Pinout

The oscillators are not mapped to the normal A,B or C functions and their muxings are controlled

by registers in the Power Manager (PM). Please refer to the power manager chapter for more

information about this.

Table 10-10. Oscillator pinout

TQFP100 pin VQFP144 pin Pad Oscillator pin

85 124 PC02 xin0

93 132 PC04 xin1

63 85 PC00 xin32

86 125 PC03 xout0

94 133 PC05 xout1

64 86 PC01 xout32

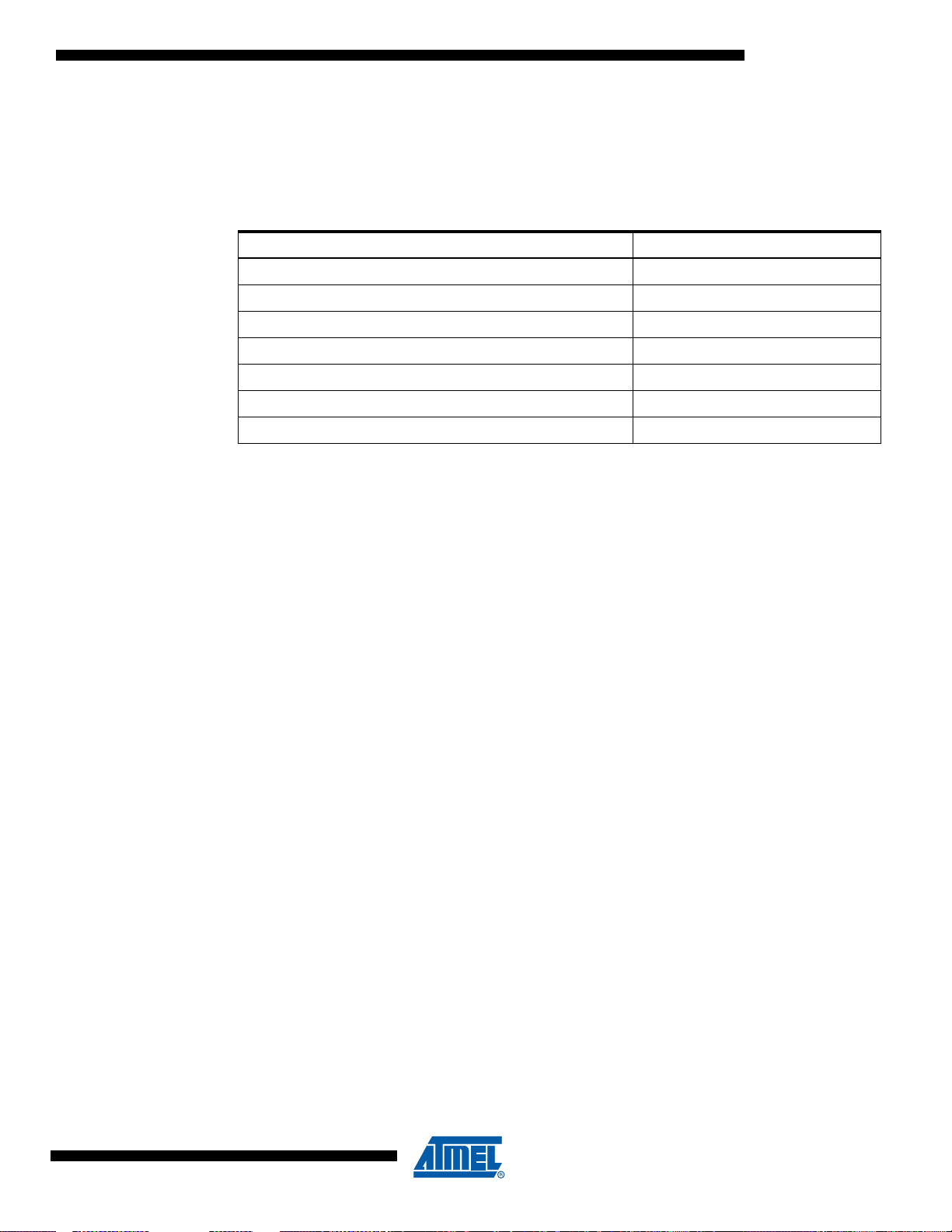

10.9 USART Configuration

Table 10-11. USART Supported Mode

SPI RS485 ISO7816 IrDA Modem

USART0YesNoNoNoNoNo

Manchester

Encoding

USART1 Yes Yes Yes Yes Yes Yes

USART2YesNoNoNoNoNo

USART3YesNoNoNoNoNo

32058HS–AVR32–03/09

34

10.10 GPIO

The GPIO open drain feature (GPIO ODMER register (Open Drain Mode Enable Register)) is

not available for this device.

10.11 Peripheral overview

10.11.1 External Bus Interface

Optimized for Application Memory Space support

•

• Integrates Two External Memory Controllers:

– Static Memory Controller

– SDRAM Controller

• Optimized External Bus:

–16-bit Data Bus

– 24-bit Address Bus, Up to 16-M bytes Addressable

– Optimized pin multiplexing to reduce latencies on External Memories

• 4 SRAM Chip Selects, 1SDRAM Chip Select:

– Static Memory Controller on NCS0

– SDRAM Controller or Static Memory Controller on NCS1

– Static Memory Controller on NCS2

– Static Memory Controller on NCS3

10.11.2 Static Memory Controller

AT32UC3A

•

• 64-Mbyte Address Space per Chip Select

• 8-, 16-bit Data Bus

• Word, Halfword, Byte Transfers

• Byte Write or Byte Select Lines

• Programmable Setup, Pulse And Hold Time for Read Signals per Chip Select

• Programmable Setup, Pulse And Hold Time for Write Signals per Chip Select

• Programmable Data Float Time per Chip Select

• Compliant with LCD Module

• External Wait Request

• Automatic Switch to Slow Clock Mode

• Asynchronous Read in Page Mode Supported: Page Size Ranges from 4 to 32 Bytes

10.11.3 SDRAM Controller

•

• Programming Facilities

• Energy-saving Capabilities

4 Chip Selects Available

Numerous Configurations Supported

– 2K, 4K, 8K Row Address Memory Parts

– SDRAM with Two or Four Internal Banks

– SDRAM with 16-bit Data Path

– Word, Half-word, Byte Access

– Automatic Page Break When Memory Boundary Has Been Reached

– Multibank Ping-pong Access

– Timing Parameters Specified by Software

– Automatic Refresh Operation, Refresh Rate is Programmable

– Self-refresh, Power-down and Deep Power Modes Supported

32058HS–AVR32–03/09

35

– Supports Mobile SDRAM Devices

• Error Detection

– Refresh Error Interrupt

• SDRAM Power-up Initialization by Software

• CAS Latency of 1, 2, 3 Supported

• Auto Precharge Command Not Used

10.11.4 USB Controller

USB 2.0 Compliant, Full-/Low-Speed (FS/LS) and On-The-Go (OTG), 12 Mbit/s

•

• 7 Pipes/Endpoints

• 960 bytes of Embedded Dual-Port RAM (DPRAM) for Pipes/Endpoints

• Up to 2 Memory Banks per Pipe/Endpoint (Not for Control Pipe/Endpoint)

• Flexible Pipe/Endpoint Configuration and Management with D edicated DMA Channels

• On-Chip Transceivers Including Pull-Ups

10.11.5 Serial Peripheral Interface

Supports communication with serial external devices

•

– Four chip selects with external decoder support allow communication with up to 15

peripherals

– Serial memories, such as DataFlash and 3-wire EEPROMs

– Serial peripherals, such as ADCs, DACs, LCD Controllers, CAN Controllers and Sensors

– External co-processors

• Master or slave serial peripheral bus interface

– 8- to 16-bit programmable data length per chip select

– Programmable phase and polarity per chip select

– Programmable transfer delays between consecutive transfers and between clock and data

per chip select

– Programmable delay between consecutive transfers

– Selectable mode fault detection

• Very fast transfers supported

– Transfers with baud rates up to Peripheral Bus A (PBA) max frequency

– The chip select line may be left active to speed up transfers on the same device

10.11.6 Two-wire Interface

AT32UC3A

10.11.7 USART

32058HS–AVR32–03/09

High speed up to 400kbit/s

•

• Compatibility with standard two-wire serial memory

• One, two or three bytes for slave address

• Sequential read/write operations

Programmable Baud Rate Generator

•

• 5- to 9-bit full-duplex synchronous or asynchronous serial communications

– 1, 1.5 or 2 stop bits in Asynchronous Mode or 1 or 2 stop bits in Synchronous Mode

– Parity generation and error detection

– Framing error detection, overrun error detection

– MSB- or LSB-first

– Optional break generation and detection

– By 8 or by-16 over-sampling receiver frequency

– Hardware handshaking RTS-CTS

– Receiver time-out and transmitter timegu ard

– Optional Multi-drop Mode with address generation and detection

36

– Optional Manchester Encoding

• RS485 with driver control signal

• ISO7816, T = 0 or T = 1 Protocols for interfacing with smart cards

– NACK handling, err o r counter with repet itio n an d iterati on limit

• IrDA modulation and demodulation

– Communication at up to 115.2 Kbps

• Test Modes

– Remote Loopback, Local Loopback, Automatic Echo

• SPI Mode

– Master or Slave

– Serial Clock Programmable Phase and Polarity

– SPI Serial Clock (SCK) Frequency up to Internal Clock Frequency PBA/4

• Supports Connection of Two Peripheral DMA Controller Channels (PDC)

– Offers Buffer Transfer without Processor Intervention

10.11.8 Serial Synchronous Controller

Provides serial synchronous communication links used in audio and telecom applications (with

•

CODECs in Master or Slave Modes, I2S, TDM Buses, Magnetic Card Reader, etc.)

• Contains an independent receiver and transmitter and a common clock divider

• Offers a configurable frame sync and data length

• Receiver and transmitter can be programmed to start automatically or on detection of different

event on the frame sync signal

• Receiver and transmitter include a data signal, a clock signal and a frame synchronization signal

10.11.9 Timer Counter

AT32UC3A

Three 16-bit Timer Counter Channels

•

• Wide range of functions including:

– Frequency Measurement

– Event Counting

– Interval Measurement

– Pulse Generation

– Delay Timing

– Pulse Width Modulation

– Up/down Capabilities

• Each channel is user-configurable and contains:

– Three external clock inputs

– Five internal clock inputs

– Two multi-purpose input/output signals

• Two global registers that act on all three TC Channels

10.11.10 Pulse Width Modulation Controller

7 channels, one 20-bit counter per channel

•

• Common clock generator, providing Thirteen Different Clocks

– A Modulo n counter providing eleven clocks

– Two independent Linear Dividers working on modulo n counter outputs

• Independent channel programming

– Independent Enable Disable Commands

– Independent Clock

– Independent Period and Duty Cycle, with Double Bufferization

– Programmable selection of the output waveform polarity

– Programmable center or left aligned output waveform

32058HS–AVR32–03/09

37

10.11.11 Ethernet 10/100 MAC

Compatibility with IEEE Standard 802.3

•

• 10 and 100 Mbits per second data throughput capability

• Full- and half-duplex operations

• MII or RMII interface to the physical layer

• Register Interface to address, data, status and control registers

• DMA Interface, operating as a master on the Memory Controller

• Interrupt generation to signal receive and transmit completion

• 28-byte transmit and 28-byte receive FIFOs

• Automatic pad and CRC generation on transmitted frames

• Address checking logic to recognize four 48-bit addresses

• Support promiscuous mode where all valid frames are copied to memory

• Support physical layer management through MDIO interface control of alarm and update

time/calendar data

10.11.12 Audio Bitstream DAC

Digital Stereo DAC

•

• Oversampled D/A conversion architecture

– Oversampling ratio fixed 128x

– FIR equalization filter

– Digital interpolation filter: Comb4

– 3rd Order Sigma-Delta D/A converters

• Digital bitstream outputs

• Parallel interface

• Connected to Peripheral DMA Controller for background transfer without CPU intervention

AT32UC3A

32058HS–AVR32–03/09

38

11. Boot Sequence

This chapter summarizes the boot sequence of the AT32UC3A. The behaviou r afte r power- up is

controlled by the Power Manager. For specific details, refer to Section 13. ”Power Manager

(PM)” on page 53.

11.1 Starting of clocks

After power-up, the device will be held in a reset state by the Power-On Reset circuitry, until the

power has stabilized throughout the device. Once th e power has stabilized, the device will use

the internal RC Oscillator as clock source.

On system start-up, the PLLs are disabled. All clocks to all modules are running. No clocks have

a divided frequency, all parts of the system recieves a clock with the same frequency as the

internal RC Oscillator.

11.2 Fetching of initial instructions

After reset has been released, the AVR32 UC CPU starts fetching instructions from the reset

address, which is 0x8000_0000. This address points to the first address in the internal Flash.

The code read from the internal Flash is free to configure the system to use for example the

PLLs, to divide the frequency of the clock routed to some of the peripherals, and to gate the

clocks to unused peripherals.

AT32UC3A

32058HS–AVR32–03/09

39

12. Electrical Characteristics

12.1 Absolute Maximum Ratings*

Operating Temperature......................................-40⋅C to +85⋅C

Storage Temperature..................................... -60°C to +150°C

Voltage on Input Pin

with respect to Ground except for PC00, PC01, PC02, PC03,

PC04, PC05..........................................................-0.3V to 5.5V

Voltage on Input Pin

with respect to Ground for PC00, PC01, PC02, PC03, PC04,

PC05.....................................................................-0.3V to 3.6V

Maximum Operating Voltage (VDDCORE, VDDPLL)..... 1.95V

Maximum Operating Voltage (VDDIO, VDDIN, VDDANA).3.6V

Total DC Output Current on all I/O Pin

for TQFP100 package.................................................370 mA

for LQGP144 package................................................. 470 mA

AT32UC3A

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent damage to the device. This is a stress rating only and

functional operation of the device at these or

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions for extended periods may affect

device reliability.

32058HS–AVR32–03/09

40

AT32UC3A

12.2 DC Characteristics

The following characteristics are applicable to t he operating temp erature rang e: TA = -40°C to 85°C, unless otherwise specified and are certified for a junction temperature up to T

Table 12-1. DC Characteristics

Symbol Parameter Condition Min. Typ. Max Units

V

VDDCOR

E

V

VDDPLL

V

VDDIO

V

REF

V

IL

V

IH

V

OL

V

OH

I

OL

I

OH

DC Supply Core 1.65 1.95 V

DC Supply PLL 1.65 1.95 V

DC Supply Peripheral I/Os 3.0 3.6 V

Analog reference voltage 2.6 3.6 V

Input Low-level Voltage -0.3 +0.8 V

All GPIOS except for PC00, PC01, PC02,

Input High-level Voltage

PC03, PC04, PC05.

PC00, PC01, PC02, PC03, PC04, PC05. 2.0 3.6V V

=-4mA for PA0-PA20, PB0, PB4-PB9,

I

OL

PB11-PB18, PB24-PB26, PB29-PB31,

PX0-PX39

Output Low-level Voltage

=-8mA for PA21-PA30, PB1-PB3,

I

OL

PB10, PB19-PB23, PB27-PB28, PC0PC5

=4mA for PA0-PA20, PB0, PB4-PB9,

I

OH

PB11-PB18, PB24-PB26, PB29-PB31,

PX0-PX39

Output High-level Voltage

=8mA for PA21-PA30, PB1-PB3,

I

OH

PB10, PB19-PB23, PB27-PB28, PC0PC5

PA0-PA20, PB0, PB4-PB9, PB11-PB18,

PB24-PB26, PB29-PB31, PX0-PX39

Output Low-level Current

PA21-PA30, PB1-PB3, PB10, PB19PB23, PB27-PB28, PC0-PC5

PA0-PA20, PB0, PB4-PB9, PB11-PB18,

PB24-PB26, PB29-PB31, PX0-PX39

Output HIgh-level Current

PA21-PA30, PB1-PB3, PB10, PB19PB23, PB27-PB28, PC0-PC5

= 100°C.

J

2.0 5.5V V

0.4 V

0.4 V

-

V

VDDIO

0.4

-

V

VDDIO

0.4

-4 mA

-8 mA

4mA

8mA

V

V

I

LEAK

C

IN

Input Leakage Current Pullup resistors disabled 1 µA

Input Capacitance

R

PULLUP

32058HS–AVR32–03/09

Pull-up Resistance All GPIO and RESET_N pin. 10K 15K Ohm

TQFP100 Package 7 pF

LQFP144 Package 7 pF

41

AT32UC3A

12.3 Regulator characteristics

Table 12-2. Electrical characteristics

Symbol Parameter Condition Min. Typ. Max. Units

V

VDDIN

V

VDDOUT

I

OUT

I

SCR

Symbol Parameter Condition Typ. T echno. Units

C

IN1

C

IN2

C

OUT1

C

OUT2

Supply voltage (input) 3 3.3 3.6 V

Supply voltage (output) 1.81 1.85 1.89 V

Maximum DC output current with V

Maximum DC output current with V

Static Current of internal regulator

VDDIN = 3.3V

VDDIN = 2.7V

Low Power mode (stop, deep stop

or static) at T

=25°C

A

100 mA

90 mA

10 µA

Table 12-3. Decoupling requirements

Input Regulator Capacitor 1 1 NPO nF

Input Regulator Capacitor 2 4.7 X7 R uF

Output Regulator Capacitor 1 470 NPO pF

Output Regulator Capacitor 2 2.2 X7R uF

12.4 Analog characteristics

Table 12-4. Electrical characteristics

Symbol Parameter Condition Min. Typ. Max. Units

V

ADVREF

Symbol Parameter Condition Typ.

C

VREF1

C

VREF2

12.4.1 BOD

Analog voltage reference (input) 2.6 3.6 V

Table 12-5. Decoupling requirement

s

Techno

.Units

Voltage reference Capacitor 1 10 - nF

Voltage reference Capacitor 2 1 - uF

Table 12-6. BODLEVEL Values

BODLEVEL Value

00 0000b

01 0111b

01 1111b

Typ. Typ. Typ. Units.

1.40 1.47 1.55 V

1.45 1.52 1.6 V

1.55 1.6 1.65 V

32058HS–AVR32–03/09

10 0111b

1.65 1.69 1.75 V

The values in Table 12-6 describes the values of the BODLEVEL in the flash FGPFR register.

42

AT32UC3A

Table 12-7. BOD Timing

Symbol Parameter Test Conditions Typ. Max. Units.

Minimum time with

T

BOD

VDDCORE < VBOD to

detect power failure

Falling VDDCORE

from 1.8V to 1.1V

300 800 ns

12.4.2 POR

Table 12-8. Electrical Characteristic

Symbol Parameter Test Conditions Min. Typ. Max. Units.

V

DDRR

V

SSFR

V

POR+

V

POR-

V

RESTART

T

POR

VDDCORE rise rate to ensure power-on-reset 0.01 V/ms

VDDCORE fall rate to ensure power-on-reset 0.01 400 V/ms

Rising threshold voltage: voltage up to which

device is kept under reset by POR on rising

VDDCORE

Falling threshold voltage: voltage when POR

resets device on falling VDDCORE

On falling VDDCORE, voltage must go down to

this value before supply can rise again to ensure

reset signal is released at

Minimum time with VDDCORE < V

V

POR+

POR-

Rising VDDCORE:

V

RESTART

-> V

POR+

Falling VDDCORE:

1.8V -> V

POR+

Falling VDDCORE:

1.8V -> V

RESTART

Falling VDDCORE:

1.8V -> 1.1V

1.35 1.5 1.6 V

1.25 1.3 1.4 V

-0.1 0.5 V

15 us

T

RST

Time for reset signal to be propagated to system 200 400 us

32058HS–AVR32–03/09

43

12.5 Po wer Consumption

Internal

Voltage

Regulator

Amp0

Amp1

VDDANA

VDDIO

VDDIN

VDDOUT

VDDCORE

VDDPLL

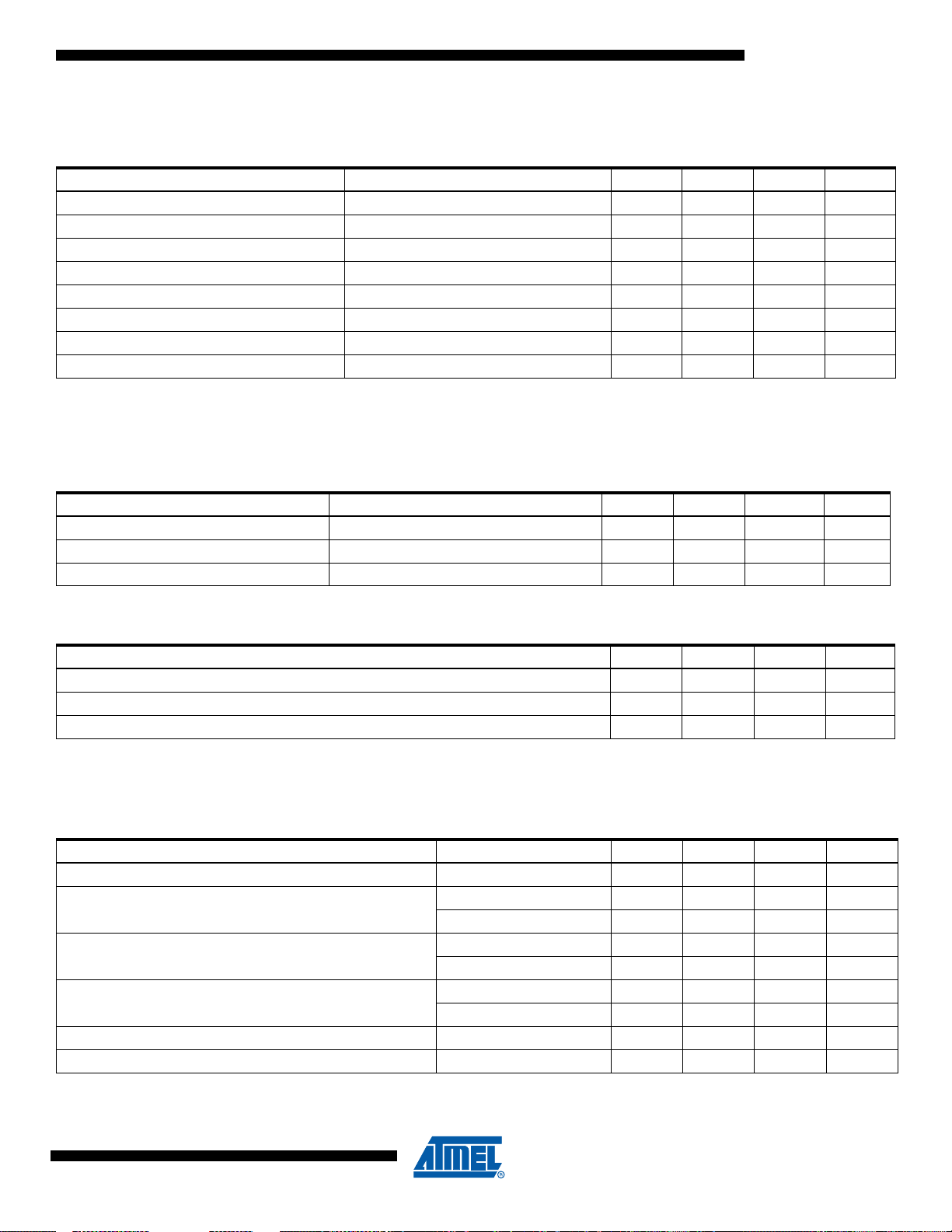

The values in Table 12-9 and Table 12-10 on page 46 are measured values of power consumption with operating conditions as follows:

•V

DDIO

•V

DDCORE

•T

A = 25°C, TA = 85°C

•I/Os are configured in input, pull-up enabled.

Figure 12-1. Measurement setup

= 3.3V

= V

DDPLL

AT32UC3A

= 1.8V

32058HS–AVR32–03/09

44

These figures represent the power consumption me asured on the power supplies.

Table 12-9. Power Consumption for Different Modes

Mode Conditions Typ. Unit

AT32UC3A

Active

Idle

Frozen

Typ : Ta =25 °C

(1)

CPU running from flash

.

VDDIN=3.3 V. VDDCORE =1.8V.

CPU clocked from PLL0 at f MHz

V o ltage regulator is on.

XIN0 : external clock.

(1)

XIN1 stopped. XIN32 stopped

PLL0 running

All peripheral clocks activated.

GPIOs on internal pull-up.

JTAG unconnected with ext pull-up.

Typ : Ta = 25 °C

(1)

CPU running from flash

.

VDDIN=3.3 V. VDDCORE =1.8V.

CPU clocked from PLL0 at f MHz

V o ltage regulator is on.

XIN0 : external clock.

XIN1 stopped. XIN32 stopped

PLL0 running

All peripheral clocks activated.

GPIOs on internal pull-up.

JTAG unconnected with ext pull-up.

Typ : Ta = 25 °C

(1)

CPU running from flash

.

CPU clocked from PLL0 at f MHz

V o ltage regulator is on.

XIN0 : external clock.

XIN1 stopped. XIN32 stopped

PLL0 running

All peripheral clocks activated.

GPIOs on internal pull-up.

JTAG unconnected with ext pull-up.

f = 12 MHz 9 mA

f = 24 MHz 15 mA

f = 36MHz 20 mA

f = 50 MHz 28 mA

f = 66 MHz 36.3 mA

f = 12 MHz 5 mA

f = 24 MHz 10 mA

f = 36MHz 14 mA

f = 50 MHz 19 mA

f = 66 MHz 25.5 mA

f = 12 MHz 3 mA

f = 24 MHz 6 mA

f = 36MHz 9 mA

f = 50 MHz 13 mA

f = 66 MHz 16.8 mA

Typ : Ta = 25 °C

CPU running from flash

CPU clocked from PLL0 at f MHz

V o ltage regulator is on.

Standby

XIN0 : external clock.

XIN1 stopped. XIN32 stopped

PLL0 running

All peripheral clocks activated.

GPIOs on internal pull-up.

JTAG unconnected with ext pull-up.

32058HS–AVR32–03/09

(1)

.

f = 24 MHz 2 mA

f = 36MHz 3 mA

f = 50 MHz 4 mA

f = 66 MHz 4.8 mA

45

f = 12 MHz 1 mA

Table 12-9. Power Consumption for Different Modes

Mode Conditions Typ. Unit

Stop

Deepstop

Static

Typ : Ta = 25 °C.

CPU is in stop mode

GPIOs on internal pull-up.

All peripheral clocks de-activated.

DM and DP pins connected to ground.

XIN0,Xin1 and XIN2 are stopped

Typ : Ta = 25 °C.CPU is in deepstop mode

GPIOs on internal pull-up.

All peripheral clocks de-activated.

DM and DP pins connected to ground.

XIN0,Xin1 and XIN2 are stopped

Typ : Ta = 25 °C. CPU is in static mode

GPIOs on internal pull-up.

All peripheral clocks de-activated.

DM and DP pins connected to ground.

XIN0,Xin1 and XIN2 are stopped

on Amp0 47 uA

on Amp1 40 uA

on Amp0 36 uA

on Amp1 28 uA

on Amp0 25 uA

on Amp1 14 uA

AT32UC3A

1. Core frequency is generated from XIN0 using the PLL so that 140 MHz < fpll0 < 160 MHz and 10 MHz < fxin0

< 12MHz

Table 12-10. Power Consumption by Peripheral in Active Mode

Peripheral Typ. Unit

GPIO 37

SMC 10

SDRAMC 4

ADC 18

EBI 31

INTC 25

TWI 14

MACB 45

PDCA 30

PWM 36

RTC 7

SPI 13

SSC 13

µA/MHz

TC 10

USART 35

USB 45

12.6 Clock Characteristics

These parameters are given in the following conditions:

32058HS–AVR32–03/09

46

AT32UC3A

•V

DDCORE

= 1.8V

• Ambient Temperature = 25°C

12.6.1 CPU/HSB Clock Characteristics

Table 12-11. Core Clock Waveform Parameters

Symbol Parameter Conditions Min Max Units

1/(t

t

CPCPU

) CPU Clock Frequency 66 MHz

CPCPU

CPU Clock Period 15,15 ns

12.6.2 PBA Clock Characteristics

Table 12-12. PBA Clock Waveform Parameters

Symbol Parameter Conditions Min Max Units

1/(t

t

CPPBA

) PBA Clock Frequency 66 MHz

CPPBA

PBA Clock Period 15,15 ns

12.6.3 PBB Clock Characteristics

Table 12-13. PBB Clock Waveform Parameters

Symbol Parameter Conditions Min Max Units

1/(t

t

CPPBB

) PBB Clock Frequency 66 MHz

CPPBB

PBB Clock Period 15,15 ns

12.7 Crystal Oscillator Characteristis

The following characteristics are applicable to the operating temperature range: TA = -40°C to 85°C and worst case of

power supply, unless otherwise specified.

12.7.1 32 KHz Oscillator Characteristics

Table 12-14. 32 KHz Oscillator Characteristics

Symbol Parameter Conditions Min Typ Max Unit

1/(t

C

L

t

ST

I

OSC

Note: 1. CL is the equivalent load capacitance.

) Crystal Oscillator Frequency 32 768 Hz

CP32KHz

Equivalent Load Capacitance 6 12.5 pF

Startup Time

C

CL = 12.5pF

= 6pF

L

(1)

(1)

600

1200

ms

Active mode 1.8 µA

Current Consumption

Standby mode 0.1 µA

32058HS–AVR32–03/09

47

AT32UC3A

12.7.2 Main Oscillators Characteristic s

Table 12-15. Main Oscillator Characteristics

Symbol Parameter Conditions Min Typ Max Unit

1/(t

C

L1

) Crystal Oscillator Frequency 0.45 16 MHz

CPMAIN

, C

L2

Internal Load Capacitance

= CL2)

(C

L1

12 pF

Duty Cycle 40 50 60 %

t

ST

Startup Time TBD ms

External clock 50 MHz

1/(t

t

t

C

) XIN Clock Frequency

CPXIN

CHXIN

CLXIN

IN

XIN Clock High Half-period

XIN Clock Low Half-period

XIN Input Capacitance TBD pF

Crystal 0.45 16 MHz

0.4 x

t

CPXIN

0.4 x

t

CPXIN

0.6 x

t

CPXIN

0.6 x

t

CPXIN

12.7.3 PLL Characteristics

Table 12-16. Phase Lock Loop Characteristics

Symbol Parameter Conditions Min Typ Max Unit

F

F

I

OUT

IN

PLL

Output Frequency 80 240 MHz

Input Frequency TBD TBD MHz

active mode TBD mA

Current Consumption

standby mode TBD µA

32058HS–AVR32–03/09

48

AT32UC3A

12.8 ADC Characteristics

Table 12-17. Channel Conversion Time and ADC Clock

Parameter Conditions Min Typ Max Units

ADC Clock Frequency 10-bit resolution mode 5 MHz

ADC Clock Frequency 8-bit resolution mode 8 MHz

Startup Time Return from Idle Mode 20 µs

Track and Hold Acquisition Time 600 ns

Conversion Time ADC Clock = 5 MHz 2 µs

Conversion Time ADC Clock = 8 MHz 1.25 µs

Throughput Rate ADC Clock = 5 MHz 384

Throughput Rate ADC Clock = 8 MHz 533

Notes: 1. Corresponds to 13 clock cycles at 5 MHz: 3 clock cycles for track and hold acquisition time and 10 clock cycles for

conversion.

2. Corresponds to 15 clock cycles at 8 MHz: 5 clock cycles for track and hold acquisition time and 10 clock cycles for

conversion.

(1)

(2)

Table 12-18. External Voltage Reference Input

Parameter Conditions Min Typ Max Units

ADVREF Input Voltage Range 2.6 VDDANA V

ADVREF Average Current On 13 samples with ADC Clock = 5 MHz 200 250 µA

Current Consumption on VDDANA TBD mA

Note: ADVREF should be connected to GND to avoid e x tra consumption in case ADC is not used.

kSPS

kSPS

Table 12-19. Analog Inputs

Parameter Min Typ Max Units

Input Voltage Range 0V

Input Leakage Current TBD µA

Input Capacitance 17 pF

ADVREF

Table 12-20. Transfer Characteristics in 8-bit mode

Parameter Conditions Min Typ Max Units

Resolution 8Bit

Absolute Accuracy

Integral Non-linearity

Differential Non-linearity

Offset Error f=5MHz -0.5 0.5 LSB

Gain Error f=5MHz -0.5 0.5 LSB

f=5MHz 0.8 LSB

f=8MHz 1.5 LSB

f=5MHz 0.35 0.5 LSB

f=8MHz 0.5 1.0 LSB

f=5MHz 0.3 0.5 LSB

f=8MHz 0.5 1.0 LSB

32058HS–AVR32–03/09

49

AT32UC3A

Table 12-21. Transfer Characteristics in 10-bit mode

Parameter Conditions Min Typ Max Units

Resolution 10 Bit

Absolute Accuracy f=5MHz 3 LSB

Integral Non-linearity f=5MHz 1.5 2 LSB

Differential Non-linearity

Offset Error f=5MHz -2 2 LSB

Gain Error f=5MHz - 2 2 LSB

f=5MHz 1 2 LSB

f=2.5MHz 0.6 1 LSB

32058HS–AVR32–03/09

50

AT32UC3A

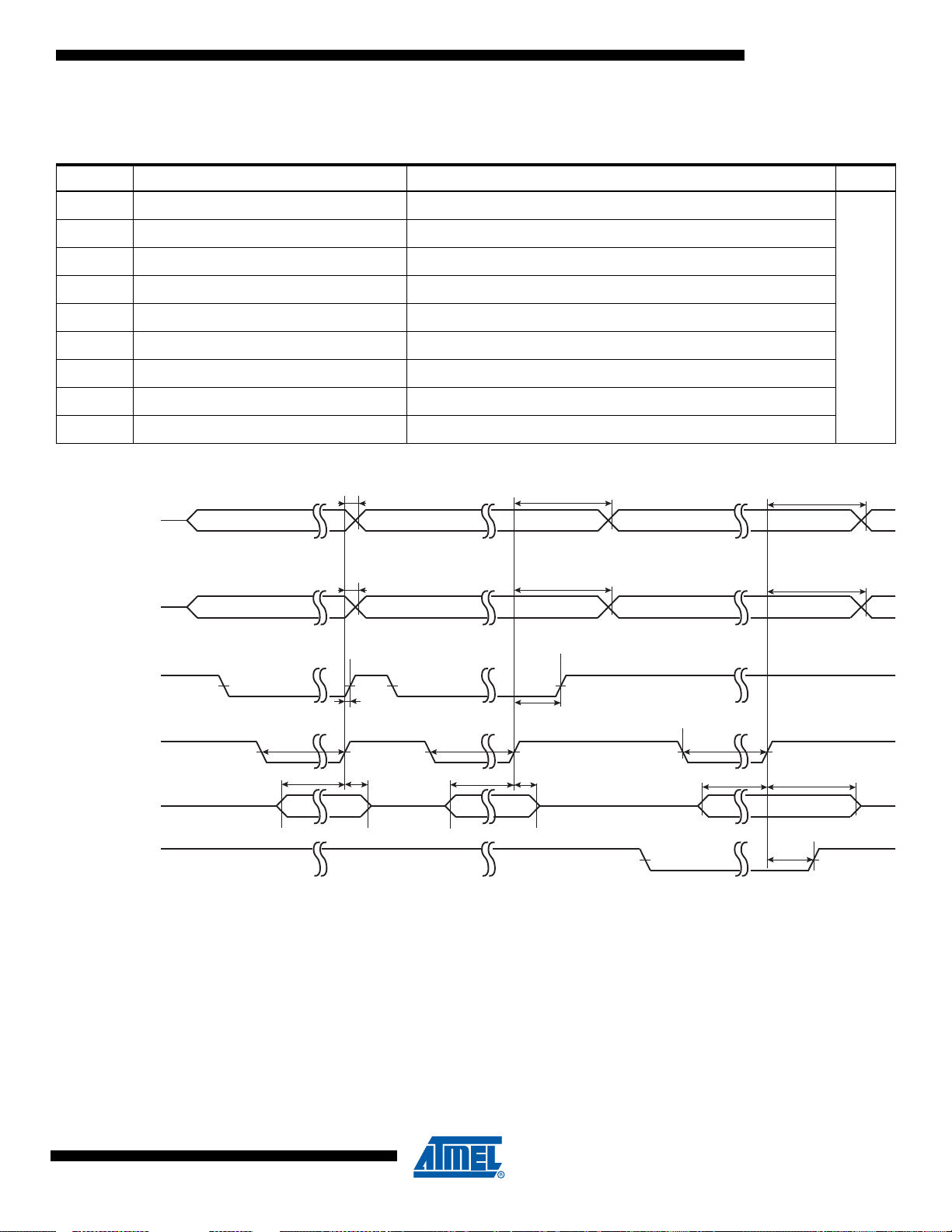

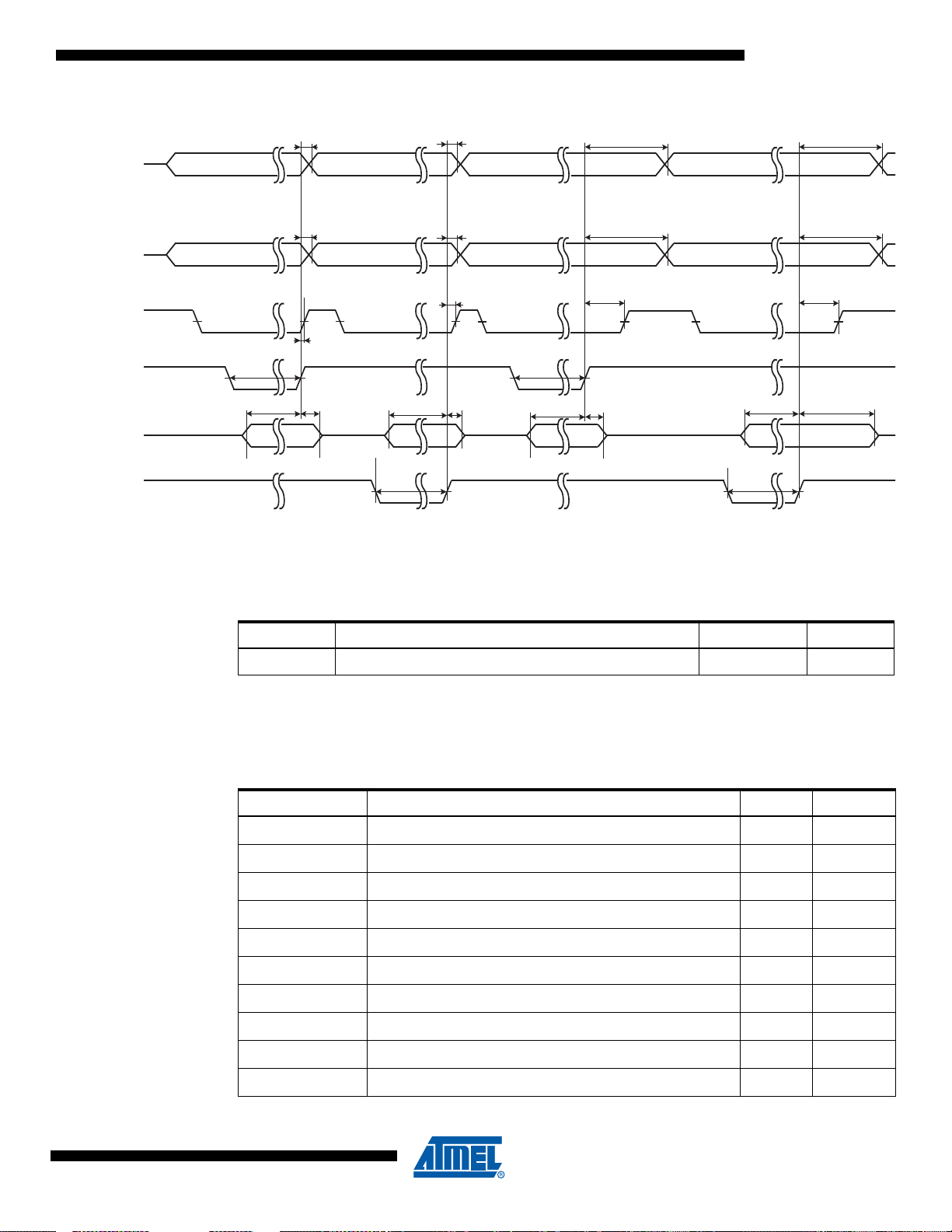

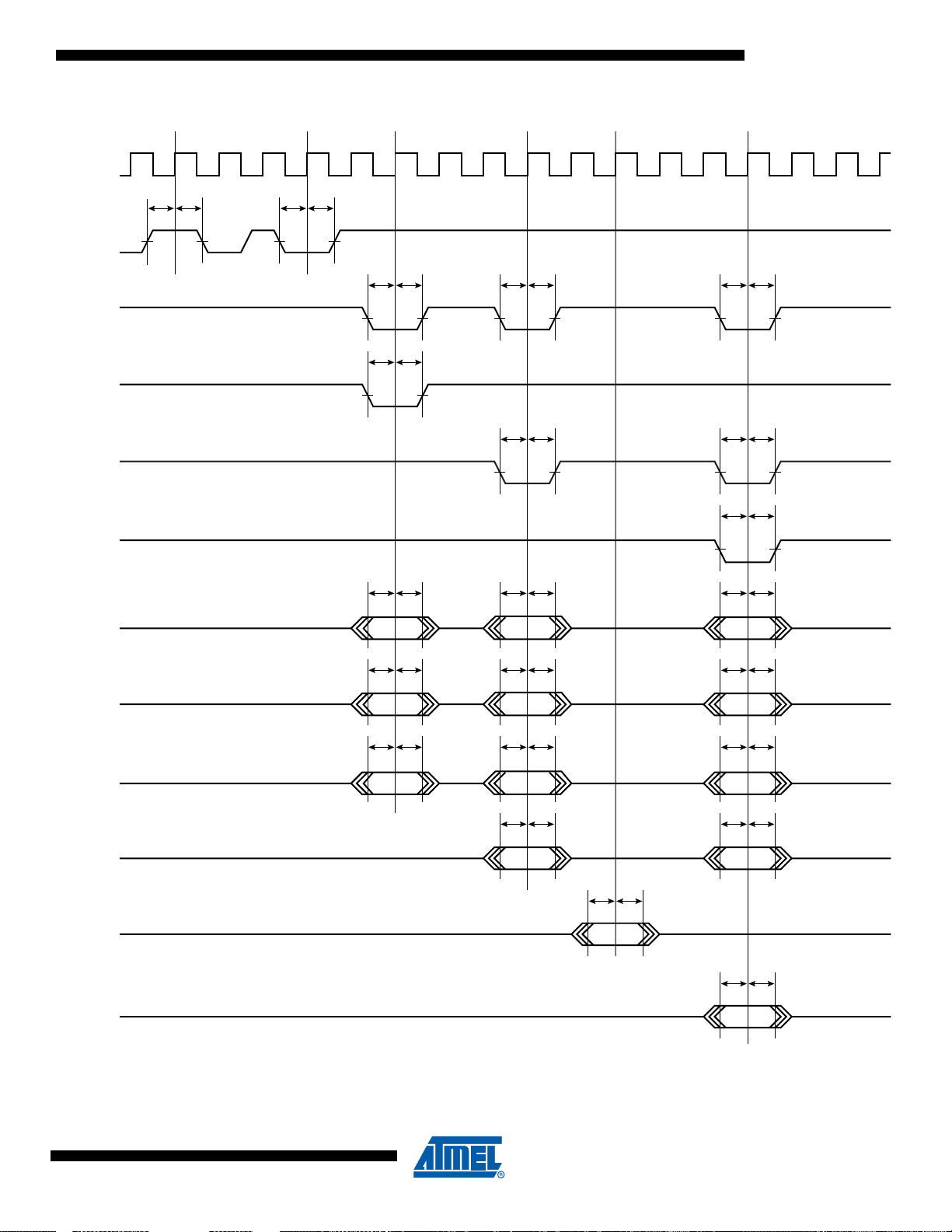

12.9 EBI Timings

These timings are given for worst case process, T = 85⋅C, VDDCORE = 1.65V, VDDIO = 3V and 40 pF load capacitance.

Table 12-22. SMC Clock Signal.

Symbol Parameter Max

1/(t

) SMC Controller Clock Frequency 1/(t

CPSMC

Note: 1. The maximum frequency of the SMC interface is the same as the max frequency for the HSB.

Table 12-23. SMC Read Signals with Hold Settings

Symbol Parameter Min Units

NRD Controlled (READ_MODE = 1)

(1)

)MHz

cpcpu

Units

SMC

SMC

SMC

SMC

SMC

SMC

SMC

SMC

SMC

SMC

SMC

SMC

SMC

SMC

SMC

SMC

SMC

SMC

Data Setup before NRD High

1

Data Hold after NRD High

2

(1)

(1)

(1)

(1)

(1)

(1)

nrd hold length * t

nrd hold length * t

nrd hold length * t

nrd hold length * t

nrd hold length * t

(nrd hold length - ncs rd hold length) * t

NRD High to NBS0/A0 Change

3

NRD High to NBS1 Change

4

NRD High to NBS2/A1 Change

5

NRD High to NBS3 Change

6

NRD High to A2 - A25 Change

7

NRD High to NCS Inactive

8

NRD Pulse Width nrd pulse length * t

9

NRD Controlled (READ_MODE = 0)

Data Setup before NCS High

10

Data Hold after NCS High

11

(1)

(1)

(1)

(1)

(1)

(1)

ncs rd hold length * t

ncs rd hold length * t

ncs rd hold length * t

ncs rd hold length * t

ncs rd hold length * t

ncs rd hold length - nrd hold length)* t

NCS High to NBS0/A0 Change

12

NCS High to NBS0/A0 Change

13

NCS High to NBS2/A1 Change

14

NCS High to NBS3 Change

15

NCS High to A2 - A25 Change

16

NCS High to NRD Inactive

17

NCS Pulse Width ncs rd pulse length * t

18

12

0

11.5

0

CPSMC

CPSMC

CPSMC

CPSMC

CPSMC

CPSMC

CPSMC

CPSMC

CPSMC

CPSMC

CPSMC

CPSMC

- 1.3

- 1.3

- 1.3

- 1.3

- 1.3

- 1.4

- 2.3

- 2.3

- 2.3

- 2.3

- 4

- 3.6

CPSMC

CPSMC

ns

- 2.3

ns

- 1.3

Note: 1. hold length = total cycle duration - setup duration - pulse duration. “hold length” is for “ncs rd hold length” or “nrd hold length”.