Datasheet AT29LV512-25TC, AT29LV512-25JI, AT29LV512-25JC, AT29LV512-20TI, AT29LV512-20TC Datasheet (ATMEL)

...

512K (64K x 8)

3-volt Only

CMOS Flash

Memory

Features

0177I

Single Supply Voltage, Range 3V to 3.6V

•

3-Volt-Only Read and Write Operation

•

Software Protected Program ming

•

Low Power Dissipation

•

15 mA Active Current

20 µA CMOS Standby Curre nt

Fast Read Access Time - 200 ns

•

Sector Program Operatio n

•

Single Cycle Repro gra m (Eras e and Program)

512 Sectors (128 bytes/ se cto r)

Internal Address and Data Latches for 128-Bytes

Fast Sector Program Cycl e Ti me - 20 ms Max.

•

Internal Program Control and Timer

•

DATA Polling for End of Program Detec tio n

•

Typical Endurance > 10,000 Cycles

•

CMOS and TTL Compatible Inputs and Outputs

•

Commercial and Industrial Temperature Ranges

•

Description

The AT29LV512 is a 3-volt-only in-system Flash programmable erasable read only

memory (PEROM). Its 512K of memory is organized as 65,536 words by 8 bits. Manufactured with Atmel’s advanced nonvolatile CMOS technology, the device offers access times to 200 ns with power dissipation of just 54 mW over the commercial temperature range. When the device is deselected, the CMOS standby current is less

than 20 µA. The device endurance is such that any sector can typically be written to

in excess of 10,000 times.

(continued)

AT29LV512

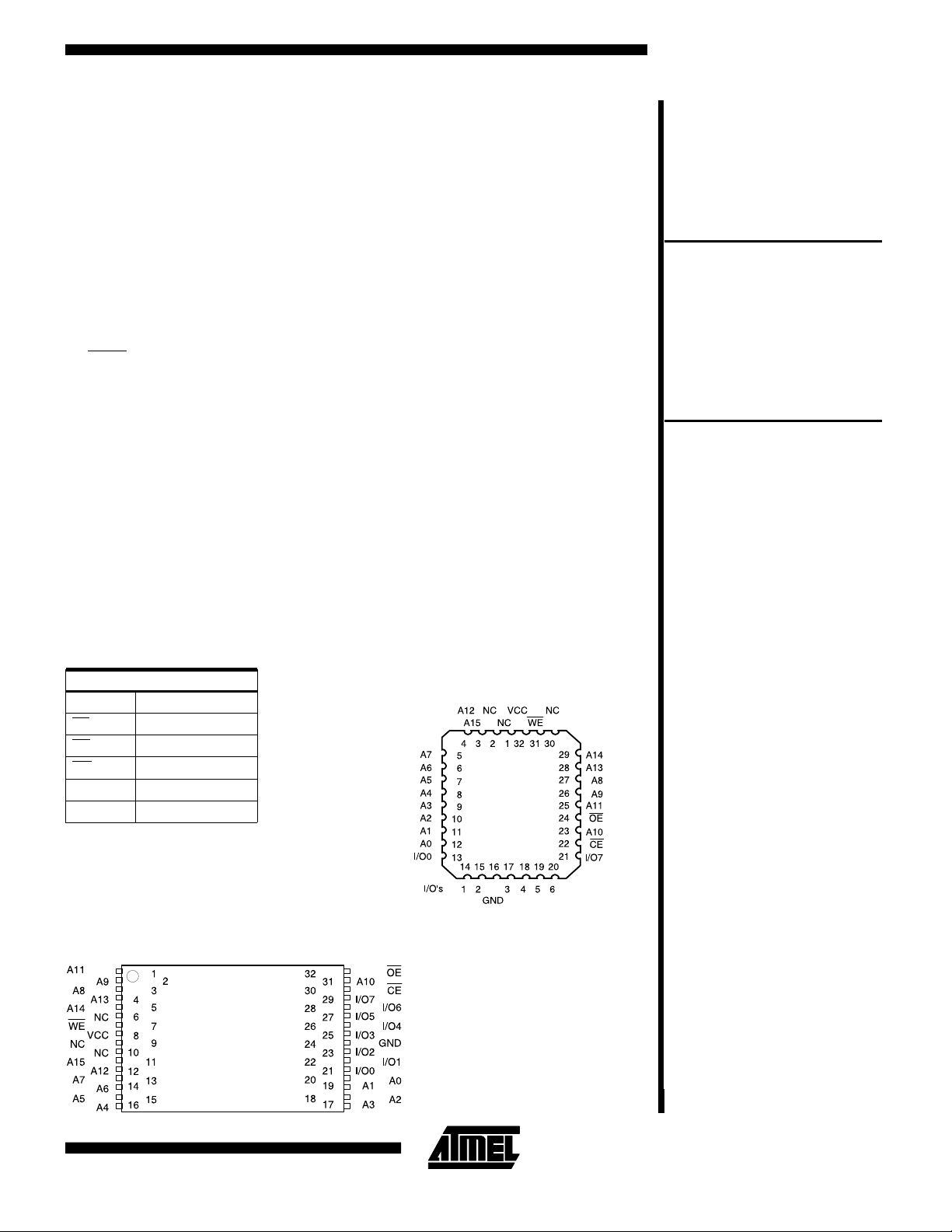

Pin Configurations

Pin Name Function

A0 - A15 Addresses

CE Chip Enable

OE Output E nable

WE Write Enable

I/O0 - I/O7 Data Inputs/Output s

NC No Connect

TSOP Top View

Type 1

AT29LV512

PLCC Top View

4-43

Description (Continued)

To allow for simple in-system reprogrammability, the

AT29LV512 does not require high input voltages for programming. Three-volt-only commands determine the operation of the device. Reading data out of the device is

similar to reading from an EPROM. Reprogramming the

AT29LV512 is performed on a sector basis; 128-bytes of

data are loaded into the device and then simultaneously

programmed.

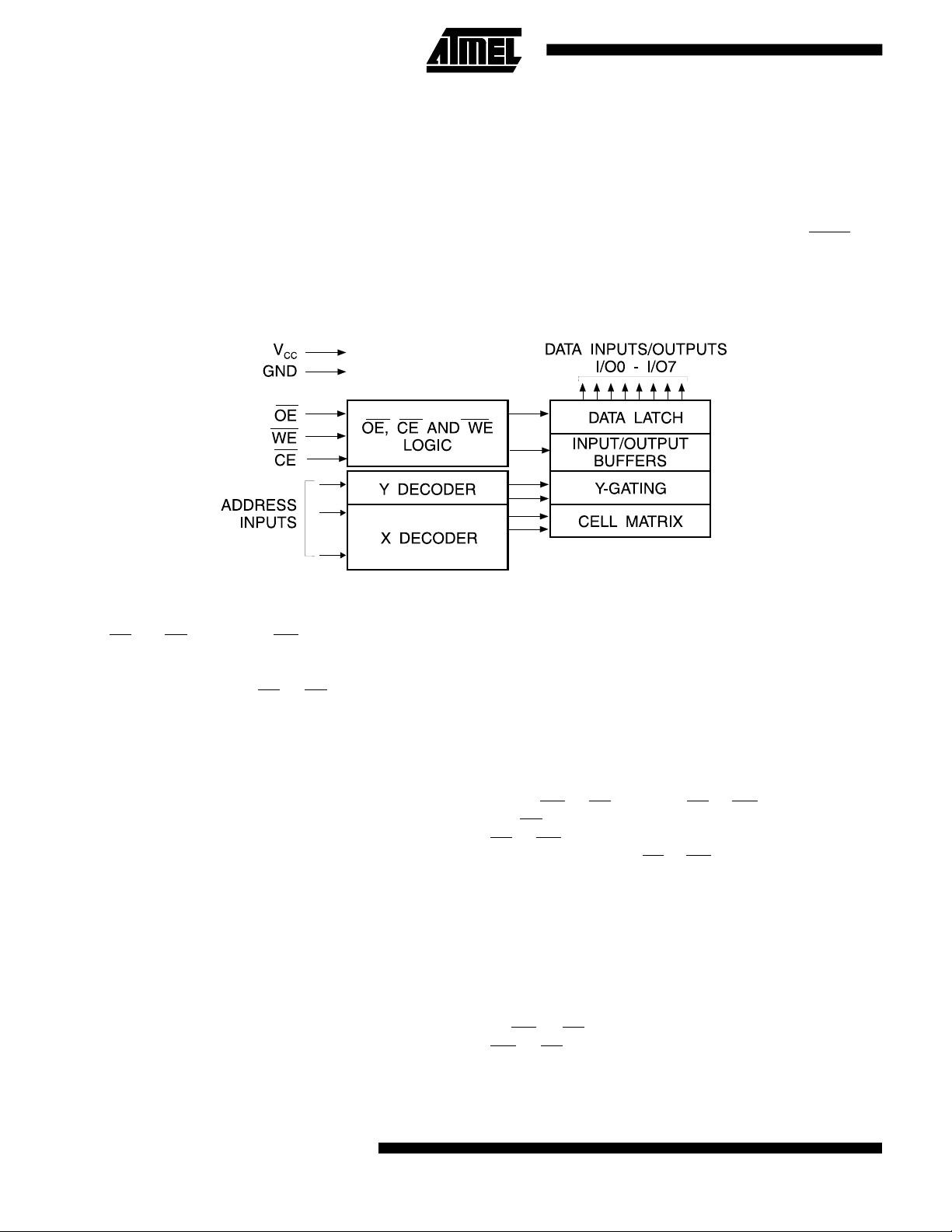

Block Diagram

During a reprogram cycle, the address locations and 128bytes of data are captured at microprocessor speed and

internally latched, freeing the address and data bus for

other operations. Following the initiation of a program cycle, the device will automatically erase the sector and then

program the latched data using an internal control timer.

The end of a program cycle can be detected by

ing of I/O7. Once the end of a program cycle has been

detected, a new access for a read or program can begin.

DATA poll-

Device Operation

READ: The AT29LV512 is accessed like an EPROM.

CE and OE are low and WE is high, the data stored

When

at the memory location determined by the address pins is

asserted on the outputs. The outputs are put in the high

impedance state whenever

line control gives designers flexibility in preventing bus

contention.

SOFTWARE DATA PROTECTION PROGRAMMING:

The AT29LV512 has 512 individual sectors, each 128bytes. Using the software data protection feature, byte

loads are used to enter the 128-bytes of a sector to be

programmed. The AT29LV512 can only be programmed

or reprogrammed using the software data protection feature. The device is programmed on a sector basis. If a byte

of data within the sector is to be changed, data for the entire 128-byte sector must be loaded into the device. The

AT29LV512 automatically does a sector erase prior to

loading the data into the sector. An erase command is not

required.

Software data protection protects the devic e from inadvertent programming. A series of three program commands

to specific addresses with specific data must be presented

to the device before programming may occur. After writing

the three-byte command sequence (and after t

tire device is protected. The same three program commands must begin each program operation. All software

CE or OE is high. This dual-

), the en-

WC

program commands must obey the sector program timing

specifications. Power transitions will not reset the software

data protection feature, however the software feature will

guard against i nadvertent program c ycles during power

transitions.

Any attempt to write to the device without the 3-byte command sequence will start the internal write timers. No data

will be written to the device; however, for the duration of

, a read operation will effectively be a polling operation.

t

WC

After the software data protection’s 3-byte command code

is given, a byte load is performed by applying a low pulse

on the

and

CE or WE, whichever occurs last. The data is latched by

the first rising edge of

The 128-bytes of data must be loaded into each sector.

Any byte that is not loaded during the programming of its

sector will be erased to read FFh. Once the bytes of a sector are loaded into the device, they are simultaneously

programmed during the internal programming period. After the first data byte has been loaded into the devic e, successive bytes are entered in the same manner. Each new

byte to be programmed must have its high to low trans ition

on

WE (or CE) of the preceding byte. If a high to low transition

is not detected within 150 µs of the last low to high transition, the load period will end and the internal programming

WE or CE input with CE or WE low (respectively)

OE high. The address is latched on the falling edge of

CE or WE.

WE (or CE) within 150 µs of the low to high transition of

(continued)

4-44 AT29LV512

Device Operation (Continued)

period will start. A7 to A15 specify the sector addr ess. The

sector address must be valid during each high to low transition of

within the sector. The bytes may be loaded in any order;

sequential loading is not required. Once a programming

operation has been initiated, and for the duration of t

read operation will effectively be a polling operation.

HARDWARE DATA PROTECTION: Hardware features

protect against inadvertent programs to the AT29LV512 in

the following ways: (a) V

(typical), the program function is inhibited. (b) V

on delay— once V

the device will automatically time out 10 ms (typical) before programming. (c) Program inhibit— holding any one

of

Noise filter— pulses of less than 15 ns (typical) on the

or

INPUT LEVELS: While operating with a 3.3V ±10%

power supply, the address inputs and control inputs (

CE and WE) may be driven from 0 to 5.5V without adversely affecting the operation of the device. The I/O lines

can only be driven from 0 to 3.6 volts.

PRODUCT IDE NTIFICATION: The product identification mode identifies the device and manufacturer as Atmel. It may be accessed by hardware or software operation. The hardware operation mode can be us ed by an external programmer to identify the correct programming algorithm for the Atmel product. In addition, users may wish

WE (or CE). A0 to A6 specify the byte address

, a

WC

sense— if VCC is below 1.8V

CC

power

CC

has reached the VCC sense level,

CC

OE low, CE high or WE high inhibits program cycles. (d)

WE

CE inputs will not initiate a program cycle.

OE,

AT29LV512

to use the software product identification mode to identify

the part (i.e. using the device code), and have the system

software use the appropriate sector size for program operations. In th is manner, the user can have a common

board design for 256K to 4-megabit densities and, with

each density’s sector size in a memory map, have the system software apply the appropriate sector size.

For details, see Operating Modes (for hardware operation)

or Software Product Identification. The manufacturer and

device code is the same for both modes.

DATA POLLING: The AT29LV512 features DATA polling to indicate the end of a program cycle. During a program cycle an attempted read of the last byte loaded will

result in the complement of the loaded data on I/O7. Once

the program cycle has been completed, true data is valid

on all outputs and the next cycle may begin.

may begin at any time during the program cycle.

TOGGLE BIT: In addition to

AT29LV512 provides another method for determining the

end of a program or erase cycle. During a program or

erase operation, successive attempts to read data from

the device will result in I/O6 toggling between one and

zero. Once the program cycle has completed, I/O6 will

stop toggling and valid data will be read. Examining the

toggle bit may begin at any time during a program cycle.

OPTIONAL CHIP ERASE MODE: The entire device

can be erased by using a 6-byte software code. Please

see Software Chip Erase application note for details.

DATA p o l li n g th e

DATA polling

Absolute Maximum Ratings*

Temperature Under Bias.................-55°C to +125°C

Storage Temperature...................... -65°C to +150°C

All Input Voltages

(including NC Pins)

with Respect to Ground ................... -0.6V to +6.25V

All Output Voltages

with Respect to Ground .............-0.6V to V

Voltage on A9

(including NC Pins)

with Respect to Ground ................... -0.6V to +13.5V

+ 0.6V

CC

*NOTICE: Stresses beyond those listed un der “Abso lute Maxi-

mum Ratings” may cause permanen t dama ge to th e de vice .

This is a stress rating only and functional operation of the

device at these or any other conditions beyond those indicated in the operational sections of this specification is not

implied. Exposure to absolute maximum rating conditions

for extended periods may affect device reliability.

4-45

DC and AC Operating Range

AT29LV512-15 AT29LV512-20 AT29LV512-25

Operating

Temperature (Case)

V

Power Supply

CC

1. After power is applied and VCC is at the minimum specified data sheet value, the system should wait 20 ms before an operational

mode is started.

Com. 0°C - 70°C 0°C - 70°C 0°C - 70°C

Ind. -40°C - 85°C -40°C - 85°C -40°C - 85°C

(1)

3.3V ± 0.3V 3.3V ± 0.3V 3.3V ± 0.3V

Operating Modes

Mode CE OE WE Ai I/O

Read V

Program

(2)

Standby/Write Inhibit V

IL

V

IL

IH

Program Inhibit X X V

Program Inhibit X V

Output Disable X V

Product Identification

Hardware V

Software

Notes: 1. X can be VIL or VIH.

(5)

2. Refer to AC Programming Waveforms.

3. V

= 12.0V ± 0.5V.

H

IL

V

V

X

V

IL

IH

(1)

IL

IH

IL

V

IH

V

IL

Ai D

Ai D

OUT

IN

X X High Z

IH

X

X High Z

A1 - A15 = VIL, A9 = VH

V

IH

A1 - A15 = VIL, A9 = VH

4. Manufacturer Code: 1F, Device Code: 3D.

5. See details unde r Soft ware Product Identif ication Entry/Exit.

A0 = V

A0 = V

A0 = V

A0 = V

IL

IH

IL

IH

(3)

(3)

,

Manufacturer Code

,

Device Code

Manufacturer Code

Device Code

(4)

(4)

(4)

(4)

DC Characteristics

Symbol Parameter Condition Min Max Units

I

LI

I

LO

I

SB1

I

SB2

I

CC

V

IL

V

IH

V

OL

V

OH

4-46 AT29LV512

Input Load Current VIN = 0V to V

Output Leakage Current V

VCC Standby Current CMOS CE = V

= 0V to V

I/O

CC

- 0.3V to V

VCC Standby Current TTL CE = 2.0V to V

V

Active Current f = 5 MHz; I

CC

OUT

CC

CC

CC

CC

Com. 20 µA

Ind. 50 µA

= 0 mA; VCC = 3.6V 15 mA

1 µA

1 µA

1mA

Input Low Voltage 0.6 V

Input High Voltage 2.0 V

Output Low Voltage IOL = 1.6 mA; VCC = 3.0V .45 V

Output High Voltage IOH = -100 µA; VCC = 3.0V 2.4 V

AC Read Characteristics

Symbol Parameter

t

ACC

t

CE

t

OE

t

DF

t

OH

(1)

(2)

(3, 4)

Address to Output Delay 150 200 250 ns

CE to Output Delay 150 200 250 ns

OE to Output Delay 0 70 0 100 0 120 ns

CE or OE to Output Float 0 40 0 50 0 60 ns

Output Hold from OE, CE or

Address, whichever occurred first

AT29LV512

AT29LV512-15 AT29LV512-20 AT29LV512-25

Min Max Min Max Min Max

000ns

Units

AC Read Waveforms

Notes: 1. CE may be delayed up to t

transition without impact on t

OE may be delayed up to tCE - tOE after the falling

2.

edge of

after an address change without impact on t

CE without impact on tCE or by t

(1, 2, 3, 4)

- tCE after the address

ACC

.

ACC

ACC

- tOE

ACC

is specified from OE or CE whi chever occurs first

3. t

DF

= 5 pF).

(C

L

4. This parameter is characterized and is not 100% tested.

.

Input Test Waveforms and Me as ur em ent Level

Output Test Load

tR, tF < 5 ns

Pin Capacitance

(f = 1 MHz, T = 25°C)

(1)

Typ Max Units Conditions

C

IN

C

OUT

Note: 1. These parameters are characterized an d no t 10 0% tes te d.

46pFV

812pFV

= 0V

IN

= 0V

OUT

4-47

AC Byte Load Characteristics

Symbol Parameter Min Max Units

t

AS

t

AH

t

CS

t

CH

t

WP

t

DS

t

DH

t

WPH

, t

, t

OES

OEH

Address, OE Set-up Time 10 ns

Address Hold Time 100 ns

Chip Select Set-up Time 0 ns

Chip Select Hold Time 0 ns

Write Pulse Width (WE or CE) 200 ns

Data Set-up Time 100 ns

Data, OE Hold Time 10 ns

Write Pulse Width High 200 ns

AC Byte Load Waveforms

WE Controlled

(1, 2)

CE Controlled

4-48 AT29LV512

AT29LV512

Program Cycle Characteristics

Symbol Parameter Min Max Units

t

WC

t

AS

t

AH

t

DS

t

DH

t

WP

t

BLC

t

WPH

Write Cycle Time 20 ms

Address Set-up Time 10 ns

Address Hold Time 100 ns

Data Set-up Time 100 ns

Data Hold Time 10 ns

Write Pulse Width 200 ns

Byte Load Cycle Time 150 µs

Write Pulse Width High 200 ns

Software Prot ected Program Wave form

(1, 2, 3)

Notes: 1.

OE must be high when WE and CE are both low.

2. A7 through A15 must specify the sector address

during each high to low transition of WE (or CE)

after the software code has been entere d.

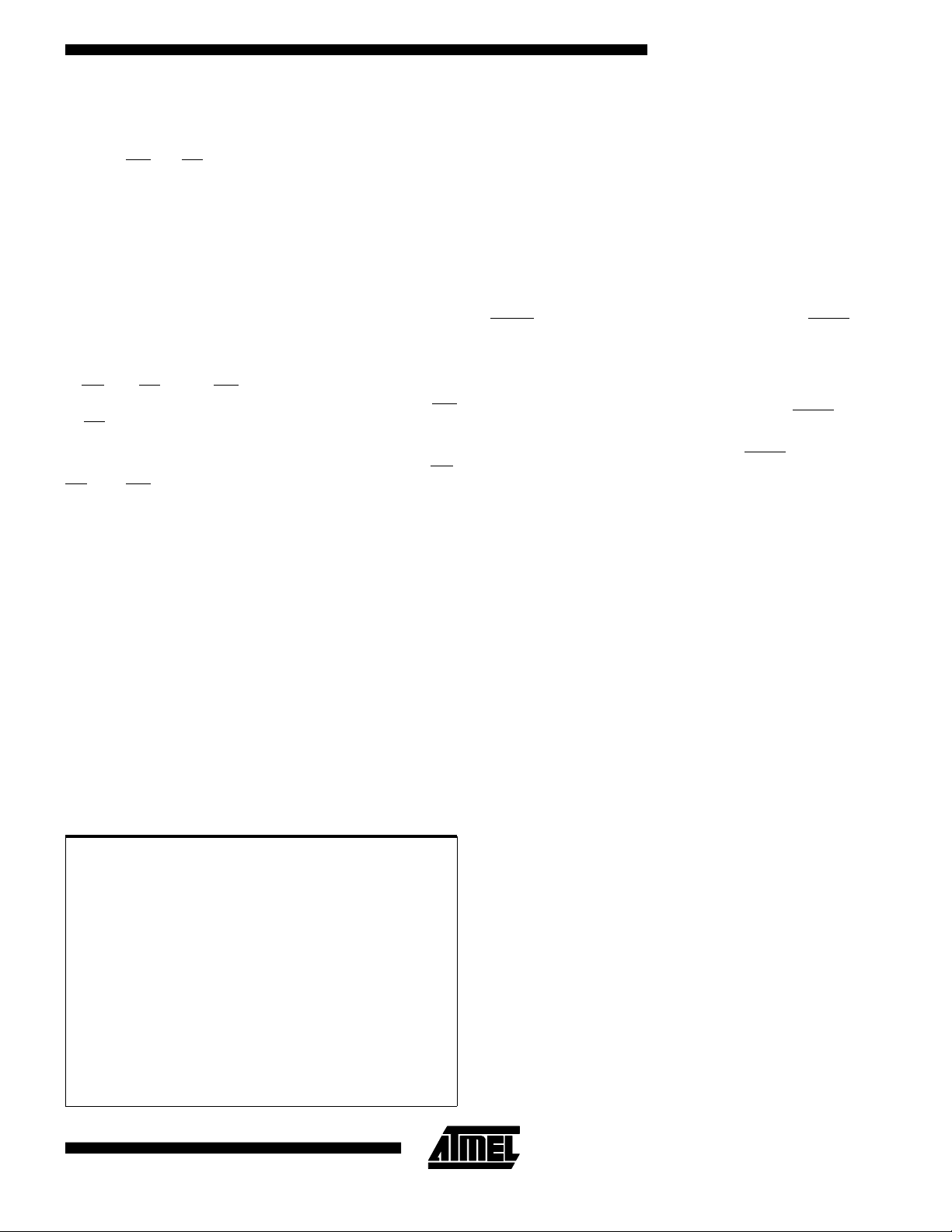

Programming Algorithm

LOAD DATA AA

TO

ADDRESS 5555

LOAD DATA 55

TO

ADDRESS 2AAA

LOAD DATA A0

TO

ADDRESS 5555

LOAD DATA

SECTOR (128 BYTES)

TO

(3)

(1)

WRITES ENABLED

ENTER DATA

PROTECT STATE

(2)

3. All bytes that are not loaded within the secto r bei ng

programmed will be indeterminate.

Notes for software program code:

1. Data Format: I/O7 - I/O0 (Hex );

Address Format: A14 - A0 (Hex).

2. Data Protect sta te will be re-a ct iv at ed at en d of prog ram cyc le .

3. 128-bytes of data

MUST BE loaded.

4-49

Data Polling Characteristics

(1)

Symbol Parameter Min Typ Max Units

t

DH

t

OEH

t

OE

t

WR

Notes: 1. These parameters are characterized and not 10 0% tes te d.

2. See t

Data Hold Time 10 ns

OE Hold Time 10 ns

OE to Output Delay

(2)

Write Recovery Time 0 ns

spec in AC Read Characteristics.

OE

Data Polling Waveforms

Toggle Bit Characteristic s

(1)

ns

Symbol Parameter Min T yp Max Units

t

DH

t

OEH

t

OE

t

OEHP

t

WR

Notes: 1. These parameters are characterized and not 10 0% tes te d.

2. See t

Data Hold Time 10 ns

OE Hold Time 10 ns

OE to Output Delay

(2)

OE High Pulse 150 ns

Write Recovery Time 0 ns

spec in AC Read Characteristics.

OE

(1, 3)

Toggle Bit Waveforms

Notes: 1. Toggling either OE or CE or both OE and CE will

operate toggle bit.

2. Beginning and ending state of I/O6 will vary.

3. Any address location may be used but the address

should not vary.

ns

4-50 AT29LV512

AT29LV512

Software Product

(1)

Identification Entry

LOAD DATA AA

TO

ADDRESS 5555

LOAD DATA 55

TO

ADDRESS 2AAA

LOAD DATA 90

TO

ADDRESS 5555

PAUSE 20 mS

Notes for software product identification:

1. Data Format: I/O7 - I/O0 (Hex);

Address Format: A14 - A0 (Hex).

2. A1 - A15 = V

Manufacture Code is read for A0 = V

Device Code is read for A0 = V

3. The device doe s no t remain in identific at io n mo de if

powered down.

4. The devi ce re tu rns to standard operation mod e.

5. Manufacturer Code: 1F

Device Code: 3D

.

IL

ENTER PRODUCT

IDENTIFICATION

MODE

;

IL

.

IH

(2, 3, 5)

Software Product

Identification Exit

LOAD DATA AA

TO

ADDRESS 5555

LOAD DATA 55

TO

ADDRESS 2AAA

LOAD DATA F0

TO

ADDRESS 5555

PAUSE 20 mS

(1)

EXIT PRODUCT

IDENTIFICATION

(4)

MODE

4-51

Ordering Information

t

ACC

(ns)

Active Standby

I

CC

(mA)

Ordering Code Package

Operation Range

150 15 0.02 AT29LV512-15JC 32J Commercial

AT29LV512-15TC 32T (0° to 70°C)

15 0.05 AT29LV512-15JI 32J Industrial

AT29LV512-15TI 32T (-40° to 85°C)

200 15 0.02 AT29LV512-20JC 32J Commercial

AT29LV512-20TC 32T (0° to 70°C)

15 0.05 AT29LV512-20JI 32J Industrial

AT29LV512-20TI 32T (-40° to 85°C)

250 15 0.02 AT29LV512-25JC 32J Commercial

AT29LV512-25TC 32T (0° to 70°C)

15 0.05 AT29LV512-25JI 32J Industrial

AT29LV512-25TI 32T (-40° to 85°C)

Package Type

32J 32 Lead, Plastic J-Leade d Chi p Carrier (PLCC)

32T 32 Lead, Thin Small Outline Package (TSOP)

4-52 AT29LV512

Loading...

Loading...