BDTIC www.BDTIC.com/ATMEL

Features

•

Fast Read Access Time – 120 ns

•

Automatic Page Write Operation

– Internal Address and Data Latches for 128 Bytes

– Internal Control Timer

•

Fast Write Cycle Time

– Page Write Cycle Time – 10 ms Maximum

– 1 to 128-byte Page Write Operation

•

Low Power Dissipation

– 40 mA Active Current

– 200 µA CMOS Standby Current

•

Hardware and Software Data Protection

•

DATA Polling for End of Write Detection

•

High Reliability CMOS Technology

– Endurance: 10

– Data Retention: 10 Years

•

Single 5V ± 10% Supply

•

CMOS and TTL Compatible Inputs and Outputs

•

JEDEC Approved Byte-wide Pinout

•

Industrial Temperature Ranges

•

Green (Pb/Halide-free) Packaging Option

4

or 105 Cycles

1-megabit

(128K x 8)

Paged Parallel

EEPROM

AT28C010

1. Description

The AT28C010 is a high-performance electrically-erasable and programmable readonly memory. Its 1 megabit of memory is organized as 131,072 words by 8 bits. Manufactured with Atmel’s advanced nonvolatile CMOS technology, the device offers

access times to 120 ns with power dissipation of just 220 mW. When the device is

deselected, the CMOS standby current is less than 200 µA.

The AT28C010 is accessed like a Static RAM for the read or write cycle without the

need for external components. The device contains a 128-byte page register to allow

writing of up to 128 bytes simultaneously. During a write cycle, the address and 1 to

128 bytes of data are internally latched, freeing the address and data bus for other

operations. Following the initiation of a write cycle, the device will automatically write

the latched data using an internal control timer. The end of a write cycle can be

detected by DATA

new access for a read or write can begin.

Atmel’s AT28C010 has additional features to ensure high quality and manufacturability. The device utilizes internal error correction for extended endurance and improved

data retention characteristics. An optional software data protection mechanism is

available to guard against inadvertent writes. The device also includes an extra

128 bytes of EEPROM for device identification or tracking.

polling of I/O7. Once the end of a write cycle has been detected a

0353G–PEEPR–10/06

AT28C010

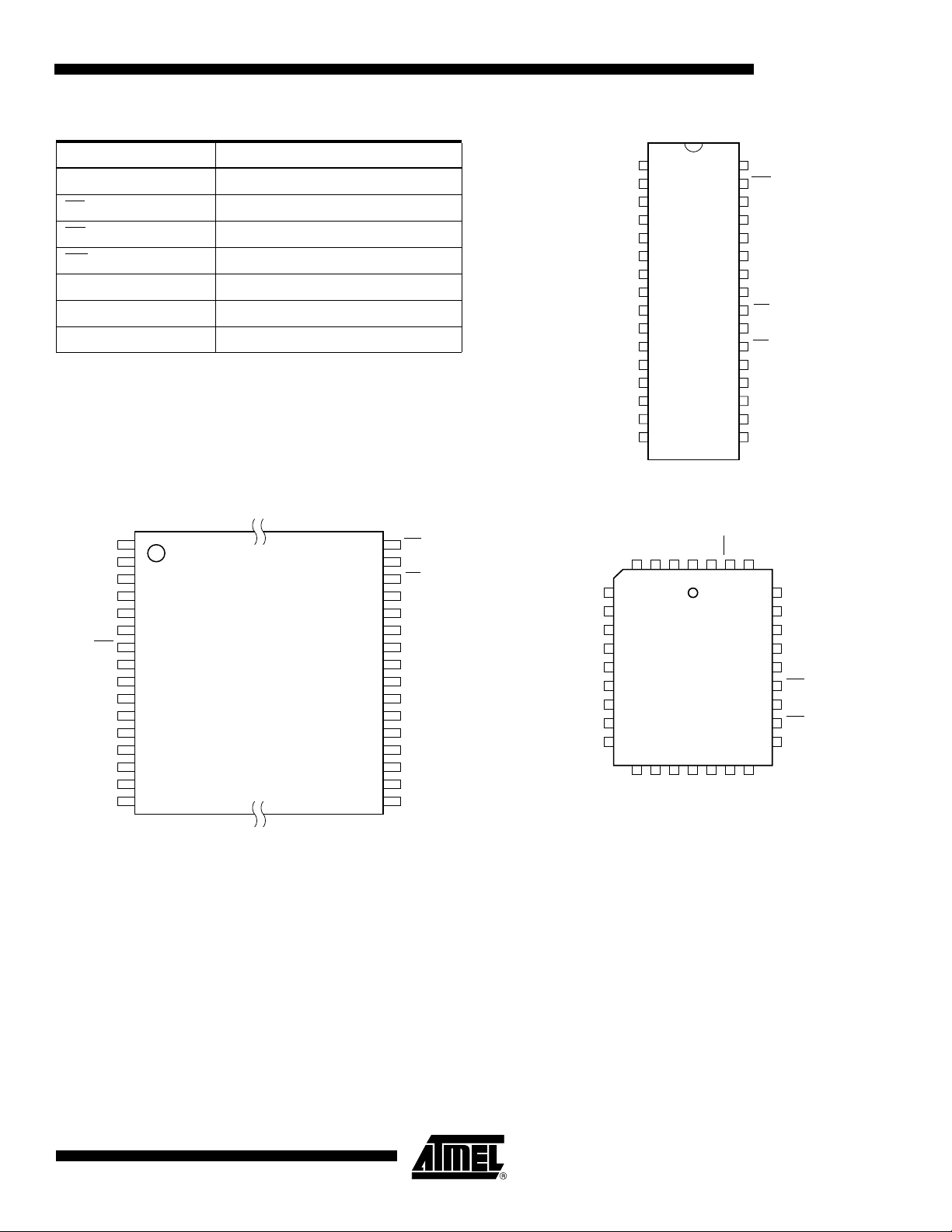

2. Pin Configurations

Pin Name Function

A0 - A16 Addresses

CE Chip Enable

OE

WE

I/O0 - I/O7 Data Inputs/Outputs

NC No Connect

DC Don’t Connect

2.1 32-lead TSOP Top View

A9

A8

NC

WE

NC

A7

A6

A5

A4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

A11

A13

A14

VCC

A16

A15

A12

Output Enable

Write Enable

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

OE

A10

CE

I/O7

I/O6

I/O5

I/O4

I/O3

GND

I/O2

I/O1

I/O0

A0

A1

A2

A3

2.2 32-lead PDIP Top View

1

NC

A16

A15

A12

A7

A6

A5

A4

A3

A2

A1

A0

I/O0

I/O1

I/O2

GND

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

VCC

WE

NC

A14

A13

A8

A9

A11

OE

A10

CE

I/O7

I/O6

I/O5

I/O4

I/O3

2.3 32-lead PLCC Top View

A12

A15

A16DCVCCWENC

432

5

A7

6

A6

7

A5

8

A4

9

A3

10

A2

11

A1

12

A0

13

I/O0

14151617181920

I/O1

Note: PLCC package pin 1 is Don’t Connect.

I/O2

GND

1

323130

I/O3

I/O4

I/O5

29

28

27

26

25

24

23

22

21

I/O6

A14

A13

A8

A9

A11

OE

A10

CE

I/O7

0353G–PEEPR–10/06

2

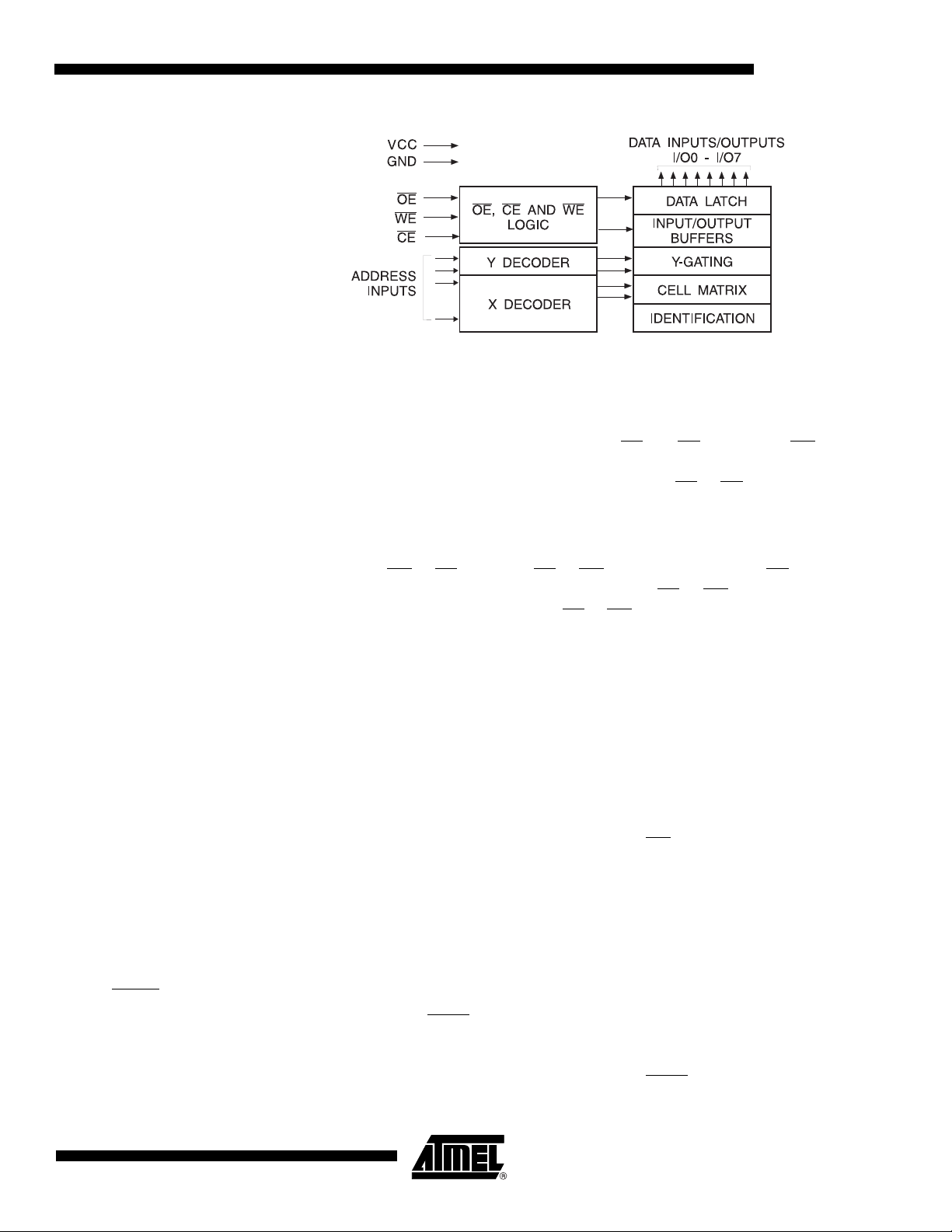

3. Block Diagram

4. Device Operation

4.1 Read

The AT28C010 is accessed like a Static RAM. When CE and OE are low and WE is high, the

data stored at the memory location determined by the address pins is asserted on the outputs.

The outputs are put in the high impedance state when either CE

control gives designers flexibility in preventing bus contention in their system.

AT28C010

or OE is high. This dual-line

4.2 Byte Write

4.3 Page Write

4.4 DATA Polling

A low pulse on the WE or CE input with CE or WE low (respectively) and OE high initiates a

write cycle. The address is latched on the falling edge of CE

The data is latched by the first rising edge of CE

will automatically time itself to completion. Once a programming operation has been initiated

and for the duration of t

The page write operation of the AT28C010 allows 1 to 128 bytes of data to be written into the

device during a single internal programming period. A page write operation is initiated in the

same manner as a byte write; the first byte written can then be followed by 1 to 127 additional

bytes. Each successive byte must be written within 150 µs (t

t

limit is exceeded the AT28C010 will cease accepting data and commence the internal

BLC

programming operation. All bytes during a page write operation must reside on the same page

as defined by the state of the A7 - A16 inputs. For each WE

page write operation, A7 - A16 must be the same.

The A0 to A6 inputs are used to specify which bytes within the page are to be written. The

bytes may be loaded in any order and may be altered within the same load period. Only bytes

which are specified for writing will be written; unnecessary cycling of other bytes within the

page does not occur.

The AT28C010 features DATA Polling to indicate the end of a write cycle. During a byte or

page write cycle an attempted read of the last byte written will result in the complement of the

written data to be presented on I/O

valid on all outputs, and the next write cycle may begin. DATA

during the write cycle.

, a read operation will effectively be a polling operation.

WC

. Once the write cycle has been completed, true data is

7

or WE. Once a byte write has been started it

or WE, whichever occurs last.

) of the previous byte. If the

BLC

high to low transition during the

Polling may begin at anytime

0353G–PEEPR–10/06

3

4.5 Toggle Bit

In addition to DATA Polling the AT28C010 provides another method for determining the end of

a write cycle. During the write operation, successive attempts to read data from the device will

result in I/O6 toggling between one and zero. Once the write has completed, I/O6 will stop toggling and valid data will be read. Reading the toggle bit may begin at any time during the write

cycle.

4.6 Data Protection

If precautions are not taken, inadvertent writes may occur during transitions of the host system

power supply. Atmel

the memory against inadvertent writes.

4.6.1 Hardware Protection

Hardware features protect against inadvertent writes to the AT28C010 in the following ways:

(a) V

CC

delay – once V

allowing a write; (c) write inhibit – holding any one of OE

cycles; and (d) noise filter—pulses of less than 15 ns (typical) on the WE

initiate a write cycle.

4.6.2 Software Data Protection

A software controlled data protection feature has been implemented on the AT28C010. When

enabled, the software data protection (SDP), will prevent inadvertent writes. The SDP feature

may be enabled or disabled by the user; the AT28C010 is shipped from Atmel with SDP

disabled.

®

has incorporated both hardware and software features that will protect

sense – if VCC is below 3.8V (typical) the write function is inhibited; (b) VCC power-on

has reached 3.8V the device will automatically time out 5 ms (typical) before

CC

low, CE high or WE high inhibits write

or CE inputs will not

SDP is enabled by the host system issuing a series of three write commands; three specific

bytes of data are written to three specific addresses (refer to Software Data Protection Algorithm). After writing the 3-byte command sequence and after t

protected against inadvertent write operations. It should be noted, that once protected the host

may still perform a byte or page write to the AT28C010. This is done by preceding the data to

be written by the same 3-byte command sequence used to enable SDP.

Once set, SDP will remain active unless the disable command sequence is issued. Power

transitions do not disable SDP and SDP will protect the AT28C010 during power-up and

power-down conditions. All command sequences must conform to the page write timing specifications. The data in the enable and disable command sequences is not written to the device

and the memory addresses used in the sequence may be written with data in either a byte or

page write operation.

After setting SDP, any attempt to write to the device without the 3-byte command sequence

will start the internal write timers. No data will be written to the device; however, for the duration of t

, read operations will effectively be polling operations.

WC

4.7 Device Identification

An extra 128 bytes of EEPROM memory are available to the user for device identification. By

raising A9 to 12V ± 0.5V and using address locations 1FF80H to 1FFFFH the bytes may be

written to or read from in the same manner as the regular memory array.

4.8 Optional Chip Erase Mode

The entire device can be erased using a 6-byte software code. Please see Software Chip

Erase application note for details.

the entire AT28C010 will be

WC

4

AT28C010

0353G–PEEPR–10/06

AT28C010

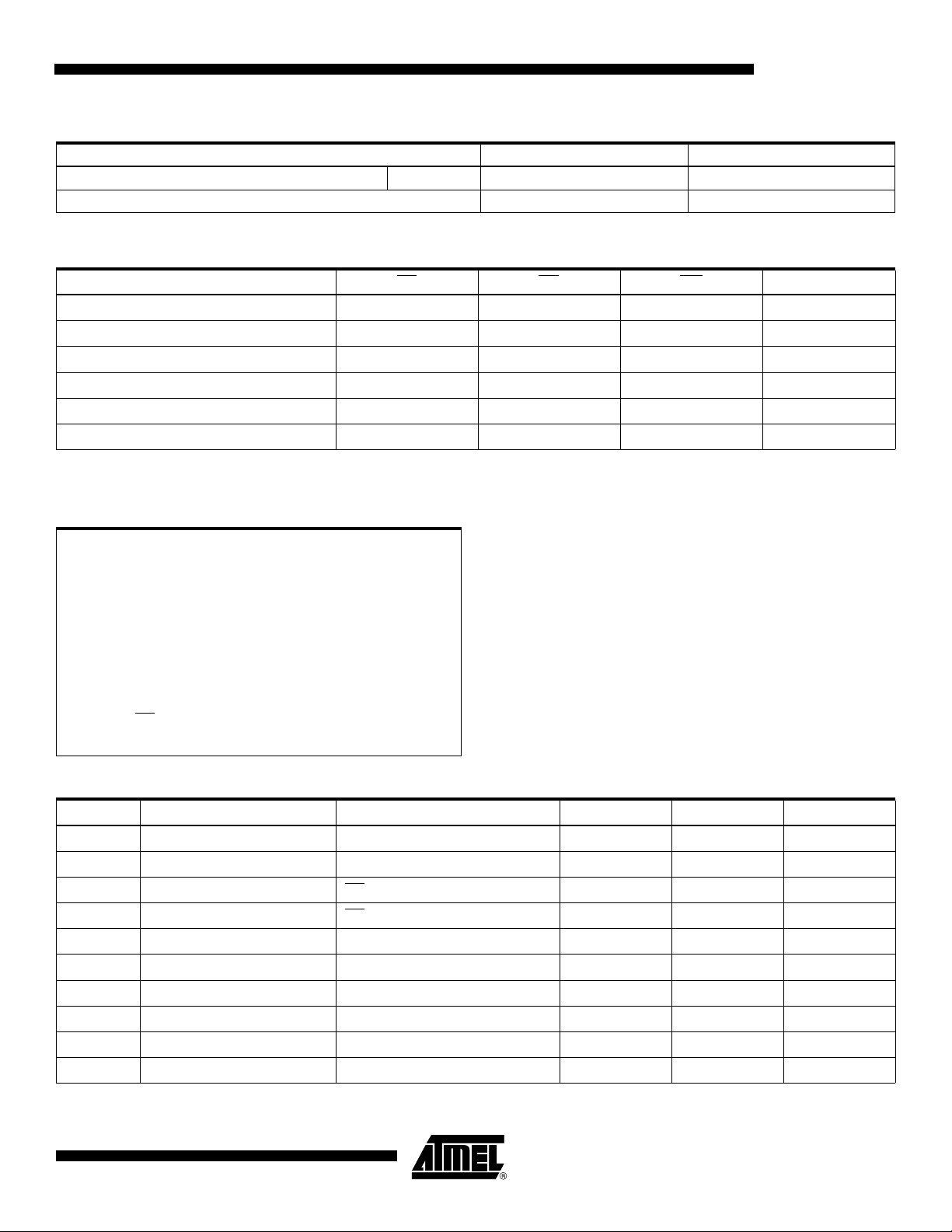

5. DC and AC Operating Range

AT28C010-12 AT28C010-15

Operating Temperature (Case)

V

Power Supply 5V ± 10% 5V ± 10%

CC

6. Operating Modes

Mode CE OE WE I/O

Read V

(2)

Write

Standby/Write Inhibit V

Write Inhibit X X V

Write Inhibit X V

Output Disable X V

Notes: 1. X can be VIL or VIH.

2. Refer to AC Programming Waveforms.

7. Absolute Maximum Ratings*

Temperature Under Bias................................ -55°C to +125°C

Storage Temperature ..................................... -65°C to +150°C

All Input Voltages

(including NC Pins)

with Respect to Ground ...................................-0.6V to +6.25V

All Output Voltages

with Respect to Ground .............................-0.6V to V

Ind. -40°C - 85°C -40°C - 85°C

X

V

IL

V

IH

(1)

IL

IH

IL

V

IL

IH

V

IH

V

IL

X High Z

IH

X

X High Z

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent damage to the device. This is a stress rating only and

functional operation of the device at these or any

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions for extended periods may affect

device reliability

+ 0.6V

CC

D

OUT

D

IN

Voltage on OE and A9

with Respect to Ground ...................................-0.6V to +13.5V

8. DC Characteristics

Symbol Parameter Condition Min Max Units

I

LI

I

LO

I

SB1

I

SB2

I

CC

V

IL

V

IH

V

OL

V

OH1

V

OH2

0353G–PEEPR–10/06

Input Load Current VIN = 0V to VCC + 1V 10 µA

Output Leakage Current V

VCC Standby Current CMOS CE = V

= 0V to V

I/O

CC

CC

10 µA

- 0.3V to VCC + 1V 200 µA

VCC Standby Current TTL CE = 2.0V to VCC + 1V 3 mA

V

Active Current f = 5 MHz; I

CC

= 0 mA 40 mA

OUT

Input Low Voltage 0.8 V

Input High Voltage 2.0 V

Output Low Voltage IOL = 2.1 mA 0.45 V

Output High Voltage IOH = -400 µA 2.4 V

Output High Voltage CMOS IOH = -100 µA; VCC = 4.5V 4.2 V

5

9. AC Read Characteristics

Symbol Parameter

AT28C010-12 AT28C010-15

UnitsMin Max Min Max

t

t

t

t

t

ACC

CE

OE

DF

OH

(1)

(2)

(3)(4)

Address to Output Delay 120 150 ns

CE to Output Delay 120 150 ns

OE to Output Delay 0 50 0 55 ns

CE or OE to Output Float 0 50 0 55 ns

Output Hold from OE, CE or Address, Whichever

Occurred First

10. AC Read Waveforms

00ns

(1)(2)(3)(4)

Notes: 1. CE may be delayed up to t

2. OE may be delayed up to tCE - tOE after the falling edge of CE without impact on tCE or by t

without impact on t

3. t

is specified from OE or CE whichever occurs first (CL = 5 pF).

DF

ACC

.

4. This parameter is characterized and is not 100% tested.

- tCE after the address transition without impact on t

ACC

ACC

.

- tOE after an address change

ACC

6

AT28C010

0353G–PEEPR–10/06

11. Input Test Waveforms and Measurement Level

, tF < 5 ns

t

R

12. Output Test Load

13. Pin Capacitance

f = 1 MHz, T = 25°C

(1)

AT28C010

Symbol Typ Max Units Conditions

C

IN

C

OUT

Note: 1. This parameter is characterized and is not 100% tested.

410pFV

812pFV

IN

OUT

= 0V

= 0V

0353G–PEEPR–10/06

7

14. AC Write Characteristics

Symbol Parameter Min Max Units

, t

t

AS

OES

t

AH

t

CS

t

CH

t

WP

t

DS

t

, t

DH

OEH

Address, OE Set-up Time 0 ns

Address Hold Time 50 ns

Chip Select Set-up Time 0 ns

Chip Select Hold Time 0 ns

Write Pulse Width (WE or CE)100ns

Data Set-up Time 50 ns

Data, OE Hold Time 0 ns

15. AC Write Waveforms

15.1 WE Controlled

15.2 CE

8

AT28C010

Controlled

0353G–PEEPR–10/06

AT28C010

t

t

V

16. Page Mode Characteristics

Symbol Parameter Min Max Units

t

WC

t

AS

t

AH

t

DS

t

DH

t

WP

t

BLC

t

WPH

Write Cycle Time 10 ms

Address Set-up Time 0 ns

Address Hold Time 50 ns

Data Set-up Time 50 ns

Data Hold Time 0 ns

Write Pulse Width 100 ns

Byte Load Cycle Time 150 µs

Write Pulse Width High 50 ns

17. Page Mode Write Waveforms

(1)(2)

Notes: 1. A7 through A16 must specify the same page address during each high to low transition of WE (or CE).

2. OE must be high only when WE and CE are both low.

18. Chip Erase Waveforms

= 5 µsec (min.)

S

= tH = 10 msec (min.)

W

= 12.0V ± 0.5V

H

9

0353G–PEEPR–10/06

19. Software Data Protection

Enable Algorithm

LOAD DATA AA

TO

ADDRESS 5555

(1)

20. Software Data Protection

Disable Algorithm

LOAD DATA AA

TO

ADDRESS 5555

(1)

LOAD DATA 55

TO

ADDRESS 2AAA

LOAD DATA A0

TO

ADDRESS 5555

LOAD DATA XX

TO

ANY ADDRESS

LOAD LAST BYTE

TO

LAST ADDRESS

WRITES ENABLED

(4)

ENTER DATA

PROTECT STATE

Notes: 1. Data Format: I/O7 - I/O0 (Hex);

Address Format: A14 - A0 (Hex).

2. Write Protect state will be activated at end of write

even if no other data is loaded.

3. Write Protect state will be deactivated at end of write

period even if no other data is loaded.

4. 1 to 128 bytes of data are loaded.

LOAD DATA 55

TO

ADDRESS 2AAA

LOAD DATA 80

TO

(2)

ADDRESS 5555

LOAD DATA AA

TO

ADDRESS 5555

LOAD DATA 55

TO

ADDRESS 2AAA

LOAD DATA 20

TO

ADDRESS 5555

LOAD DATA XX

TO

ANY ADDRESS

LOAD LAST BYTE

TO

LAST ADDRESS

EXIT DATA

PROTECT STATE

(4)

(3)

21. Software Protected Write Cycle Waveforms

(1)(2)(3)

Notes: 1. A0 through A14 must conform to the addressing sequence for the first 3 bytes as shown above.

2. After the command sequence has been issued and a page write operation follows, the page address inputs (A7 - A16) must

be the same for each high to low transition of WE (or CE).

3. OE

must be high only when WE and CE are both low.

10

AT28C010

0353G–PEEPR–10/06

AT28C010

22. Data Polling Characteristics

(1)

Symbol Parameter Min Typ Max Units

t

DH

t

OEH

t

OE

t

WR

Data Hold Time 10 ns

OE Hold Time 10 ns

OE to Output Delay

(2)

Write Recovery Time 0 ns

Notes: 1. These parameters are characterized and not 100% tested.

2. See AC Read Characteristics.

23. Data Polling Waveforms

ns

24. Toggle Bit Characteristics

(1)

Symbol Parameter Min Typ Max Units

t

DH

t

OEH

t

OE

t

OEHP

t

WR

Data Hold Time 10 ns

OE Hold Time 10 ns

OE to Output Delay

(2)

OE High Pulse 150 ns

Write Recovery Time 0 ns

Notes: 1. These parameters are characterized and not 100% tested.

2. See AC Read Characteristics.

25. Toggle Bit Waveforms

Notes: 1. Toggling either OE or CE or both OE and CE will operate toggle bit.

2. Beginning and ending state of I/O6 will vary.

3. Any address location may be used but the address should not vary.

ns

0353G–PEEPR–10/06

11

26. Ordering Information

(1)

26.1 Standard Package

I

t

ACC

(ns)

120 40 0.2

150 40 0.2

Note: 1. See “Valid Part Numbers” on page 13.

CC

(mA)

Ordering Code Package Operation RangeActive Standby

AT28C010(E)-12JI

AT28C010(E)-12PI

AT28C010(E)-12TI

AT28C010(E)-15JI

AT28C010(E)-15PI

AT28C010(E)-15TI

26.2 Green Package Option (Pb/Halide-free)

I

t

ACC

(ns)

120 40 0.2

150 40 0.2

CC

(mA)

Ordering Code Package Operation RangeActive Standby

AT28C010-12JU

AT28C010-12TU

AT28C010(E)-12JU

AT28C010(E)-12PU

AT28C010(E)-12TU

AT28C010-15JU

AT28C010-15TU

AT28C010(E)-15JU

AT28C010(E)-15PU

AT28C010(E)-15TU

32J

32P6

32T

32J

32P6

32T

32J

32T

32J

32P6

32T

32J

32T

32J

32P6

32T

Industrial

(-40° to 85° C)

Industrial

(-40° to 85° C)

Package Type

32J 32-lead, Plastic J-leaded Chip Carrier (PLCC)

32P6 32-lead, 0.600" Wide, Plastic Dual Inline Package (PDIP)

32T

W

Blank Standard Device: Endurance = 10K Write Cycles; Write Time = 10 ms

E High-endurance Option: Endurance = 100K Write Cycles

12

32-lead, Plastic Thin Small Outline Package (TSOP)

Die

Options

AT28C010

0353G–PEEPR–10/06

27. Valid Part Numbers

The following table lists standard Atmel products that can be ordered.

Device Numbers Speed Package and Temperature Combinations

AT28C010 12 JI, JU, PI, TI, TU, PU

AT28C010E 12 JI, PI, TI, JU, PU, TU

AT28C010 15 JI, JU, PI, TI, TU, PU

AT28C010E 15 JI, PI, TI, JU, PU, TU

28. Die Products

Reference Section: Parallel EEPROM Die Products

AT28C010

0353G–PEEPR–10/06

13

29. Packaging Information

29.1 32J – PLCC

1.14(0.045) X 45˚

B

e

0.51(0.020)MAX

45˚ MAX (3X)

Notes: 1. This package conforms to JEDEC reference MS-016, Variation AE.

2. Dimensions D1 and E1 do not include mold protrusion.

Allowable protrusion is .010"(0.254 mm) per side. Dimension D1

and E1 include mold mismatch and are measured at the extreme

material condition at the upper or lower parting line.

3. Lead coplanarity is 0.004" (0.102 mm) maximum.

PIN NO. 1

IDENTIFIER

D1

D

D2

1.14(0.045) X 45˚

E1 E

0.318(0.0125)

0.191(0.0075)

E2

B1

A2

A1

A

COMMON DIMENSIONS

(Unit of Measure = mm)

SYMBOL

A 3.175 – 3.556

A1 1.524 – 2.413

A2 0.381 – –

D 12.319 – 12.573

D1 11.354 – 11.506 Note 2

D2 9.906 – 10.922

E 14.859 – 15.113

E1 13.894 – 14.046 Note 2

E2 12.471 – 13.487

B 0.660 – 0.813

B1 0.330 – 0.533

e 1.270 TYP

MIN

NOM

MAX

NOTE

10/04/01

14

2325 Orchard Parkway

R

San Jose, CA 95131

AT28C010

TITLE

32J, 32-lead, Plastic J-leaded Chip Carrier (PLCC)

DRAWING NO.

32J

0353G–PEEPR–10/06

REV.

B

29.2 32P6 – PDIP

PIN

1

E1

A1

B

REF

E

B1

C

L

SEATING PLANE

A

AT28C010

D

e

0º ~ 15º

eB

Note: 1. Dimensions D and E1 do not include mold Flash or Protrusion.

Mold Flash or Protrusion shall not exceed 0.25 mm (0.010").

TITLE

2325 Orchard Parkway

R

San Jose, CA 95131

32P6, 32-lead (0.600"/15.24 mm Wide) Plastic Dual

Inline Package (PDIP)

COMMON DIMENSIONS

(Unit of Measure = mm)

SYMBOL

A – – 4.826

A1 0.381 – –

D 41.783 – 42.291 Note 1

E 15.240 – 15.875

E1 13.462 – 13.970 Note 1

B 0.356 – 0.559

B1 1.041 – 1.651

L 3.048 – 3.556

C 0.203 – 0.381

eB 15.494 – 17.526

e 2.540 TYP

MIN

NOM

MAX

DRAWING NO.

32P6

NOTE

09/28/01

REV.

B

0353G–PEEPR–10/06

15

29.3 32T – TSOP

PIN 1

Pin 1 Identifier

D1

D

e

E

b

A2

A

SEATING PLANE

A1

Notes: 1. This package conforms to JEDEC reference MO-142, Variation BD.

2. Dimensions D1 and E do not include mold protrusion. Allowable

protrusion on E is 0.15 mm per side and on D1 is 0.25 mm per side.

3. Lead coplanarity is 0.10 mm maximum.

0º ~ 8º

L

COMMON DIMENSIONS

SYMBOL

A – – 1.20

A1 0.05 – 0.15

A2 0.95 1.00 1.05

D 19.80 20.00 20.20

D1 18.30 18.40 18.50 Note 2

E 7.90 8.00 8.10 Note 2

L 0.50 0.60 0.70

L1 0.25 BASIC

b 0.17 0.22 0.27

c 0.10 – 0.21

e 0.50 BASIC

c

L1

GAGE PLANE

(Unit of Measure = mm)

MIN

NOM

MAX

NOTE

16

2325 Orchard Parkway

R

San Jose, CA 95131

AT28C010

TITLE

32T, 32-lead (8 x 20 mm Package) Plastic Thin Small Outline

Package, Type I (TSOP)

DRAWING NO.

32T

0353G–PEEPR–10/06

10/18/01

REV.

B

Loading...

Loading...