Datasheet AT27C800-15TI, AT27C800-15TC, AT27C800-12RC, AT27C800-12PI, AT27C800-12PC Datasheet (ATMEL)

...

Features

µ

µ

•

Read Access Time - 100 ns

•

Word-wide or Byte-wide Configurable

•

8-Megabit Flash and Mask ROM Compatable

•

Low Power CMOS Operation

-100

A Maximum Standby

- 50 mA Maximum Active at 5 MHz

•

Wide Selection of JEDEC Standard Packages

- 42-Lead 600 mil Cerdip and PDIP

- 44-Lead SOIC (SOP)

- 48-Lead TSOP (12 mm x 20 mm)

•

5V ± 10% Power Supply

•

High Reliability CMOS Technology

- 2,000 ESD Protection

- 200 mA Latchup Immunity

•

RapidTM Programming Algorithm - 50

•

CMOS and TTL Compatible Inputs and Outputs

•

Integrated Product Identification Code

•

Commercial and Industrial Temperature Ranges

s/word (typical)

Description

The AT27C800 is a low-power, high performance 8,388,608-bit UV erasable programmable read only memory (EPROM) organized as either 512K by 16 or 1024K by 8

bits. It requires a single 5 V power supply in normal r ead mode oper ation. Any word

can be accessed in less than 100 ns, eliminating the need for speed-reducing WAIT

states. The x16 organization makes this part ideal for high-performance 16- and 32-bit

microprocessor systems.

(continued)

AT27C800

8-Megabit

(512K x 16 or

1024K x 8)

UV Erasable

EPROM

AT27C800

Preliminary

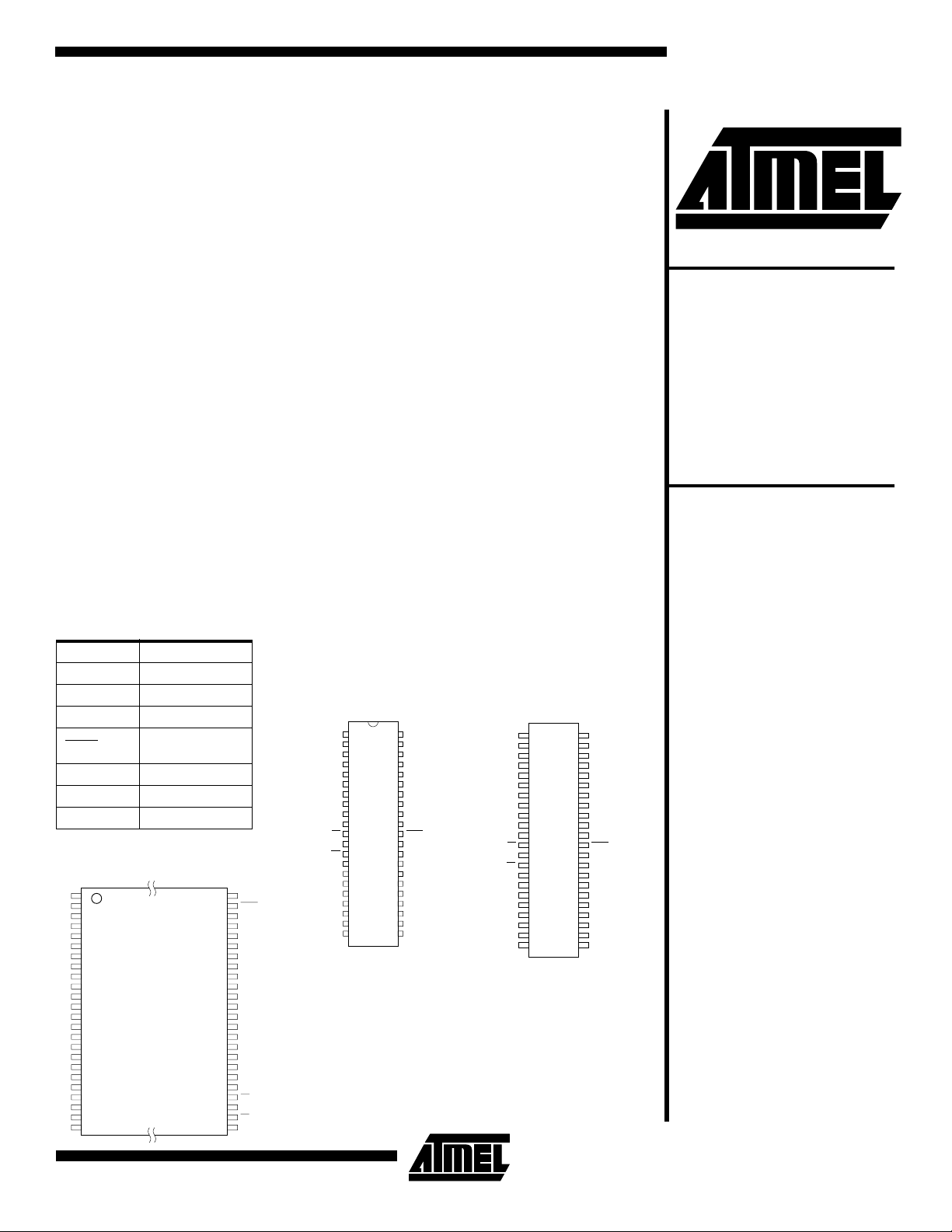

Pin Configurations

Pin Name Function

A0 - A18 Addresses

O0 - O15 Outputs

O15/A-1 Output/Address

/VPP

BYTE

CE Chip Enable

OE Output Enable

NC No Connect

1

A15

2

A14

3

A13

4

A12

5

A11

6

A10

7

A9

8

A8

9

NC

10

NC

11

NC

12

NC

13

NC

14

NC

15

NC

16

A18

17

A17

18

A7

19

A6

20

A5

21

A4

22

A3

23

A2

24

A1

Byte Mode/

Program Supply

TSOP

Type 1

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

A16

BYTE/VPP

GND

O15/A-1

O7

O14

O6

O13

O5

O12

O4

VCC

O11

O3

O10

O2

O9

O1

O8

O0

OE

GND

CE

A0

CDIP, PDIP Top View

1

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

NC

A8

A9

A10

A11

A12

A13

A14

A15

A16

BYTE/VPP

GND

O15/A-1

O7

O14

O6

O13

O5

O12

O4

VCC

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

GND

A18

A17

O10

O11

A7

A6

A5

A4

A3

A2

A1

A0

CE

OE

O0

O8

O1

O9

O2

O3

SOIC (SOP)

1

NC

2

A18

3

A17

4

A7

5

A6

6

A5

7

A4

8

A3

9

A2

10

A1

11

A0

12

CE

13

GND

14

OE

15

O0

16

O8

17

O1

18

O9

19

O2

20

O10

21

O3

22

O11

44

NC

43

NC

42

A8

41

A9

40

A10

39

A11

38

A12

37

A13

36

A14

35

A15

34

A16

33

BYTE/VPP

32

GND

31

O15/A-1

30

O7

29

O14

28

O6

27

O13

26

O5

25

O12

24

O4

23

VCC

0801A-A

1

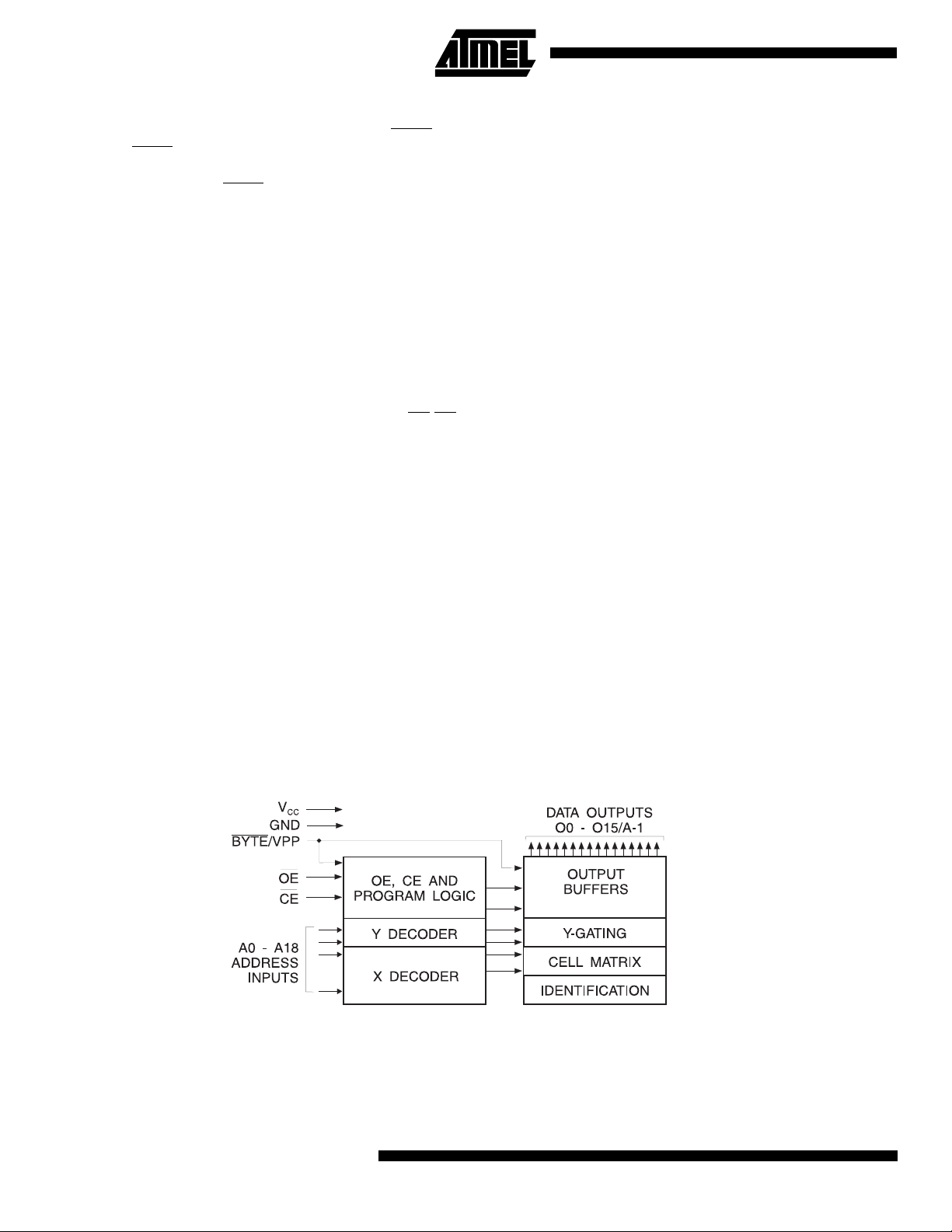

The AT27C800 can be organized as either word-wide or

µ

µ

µ

µ

µ

byte-wide. The organi zation is selected via the BYTE

/V

PP

pin. When BYTE/VPP is asserted high (VIH), the word-wide

organization is selected and the O15/A-1 pin is used for

O15 data output. When BYT E

/VPP is asserted low (VIL),the

byte wide organization is se lected and the O 15/A-1 pin is

used for the address pin A-1. When the AT27C800 is logically regarded as x 16 (word-wide), but read in the bytewide mode, then with A-1=V

bit word are selected with A-1 =V

the lower eight bits of the 16

IL

the upper 8 bits of the

IH

16-bit word are selected.

In read mode, the AT27C800 typically consumes 15 mA.

Standby mode supply current is typically less than 10

A.

The AT27C800 is available in industry standard JEDECapproved one-time program mable (OTP)PDIP, SOIC

(SOP), and TSOP as well as UV erasable windowed Cerdip packages. The device features two-line contro l(CE

,OE)

to eliminate bus contention in high-speed systems.

With high den sity 51 2K word o r 1 024K -bit stora ge c apab il-

ity, the AT27C800 allo ws firm ware to b e to be st ored reliably and to be accessed by the system without the delays

of mass storage media.

Atmel’s AT27C800 has additional features that ensure high

quality and effici ent pr oducti on us e. The Rapid

TM

Programming Algorithm reduces the time required to program the

part and guarantees reliable programming. Programming

time is typically only 50

s/word. The Integrated Product

Identification Code elect ronically i dentifies th e device and

manufacturer. This feature is used by industry standard

programming equi pmen t to sele ct t he prop er progr ammi ng

equipment and voltages.

Erasure Characteristics

The entire memory array of the AT27C8 00 is erased (all

outputs re ad as V

) after exposure to ultraviolet light at a

OH

wavelength of 2,537Å. Complete erasure i s as su red after a

minimum of 20 minutes of exposure using 12,000

W/cm

intensity lamps spaced one inch away from the chip. Minimum erase time for lamps a t other intensi ty rating s can be

calculated from the minimum integrated erasure dose of 15

W.sec/cm

2

. To prevent unintentional erasure, an opaque

label is recommended to cover the clear window on any UV

erasable EPROM that will be subjected to co ntinuous

flourescent indoor lighting or sunlight.

System Considerations

Switching between active and standby conditions via the

Chip Enable pin may produce tran sient voltage excursions.

Unless accommodated by the system design, these transients may exceed data sheet limits, resulting in device

non-conformance. At a minimum, a 0.1

low inherent inductance, ceramic capacitor should be utilized for each device. This capacitor should be connec ted

between the V

and Ground terminals of the device, as

CC

close to the device as possible. Additionally, to stabilize the

supply voltage level on printed circuit boards with large

EPROM arrays, a 4.7

F bulk electrolytic capacitor should

be utilized, again connected between the V

terminals. This capacitor should be positioned as close as

possible to the point where the power supply is connected

to the array.

F high frequency,

and Ground

CC

2

Block Diagram

2

AT27C800

Absolute Maximum Ratings*

AT27C800

Temperature Under Bias...................-55 ° C to +125°C

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent dam-

Storage Temperature ........................-65 ° C to +150°C

age to the device . This is a stress rating only and

functional oper atio n of the device at the se o r any

Voltage on Any Pin with

with Respect to Ground.....................-2.0V to +7.0V

Voltage on A9 with

Respect to Ground .........................-2.0V to +14.0V

VPP Supply Voltage with

Respect to Ground ..........................-2.0V to +14.0V

Integrated UV Erase Dose............... 7258 W •sec/cm

(1)

(1)

Note: 1. Minimum voltage is -0.6V DC which may under-

(1)

2

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions f or extende d periods may aff ect de vice

reliability .

shoot to -2.0V for pulses of less than 20 ns. Maximum output pin voltag e is Vcc + 0.75V DC which

may overshoot to + 7.0V for pulses of less than

20 ns.

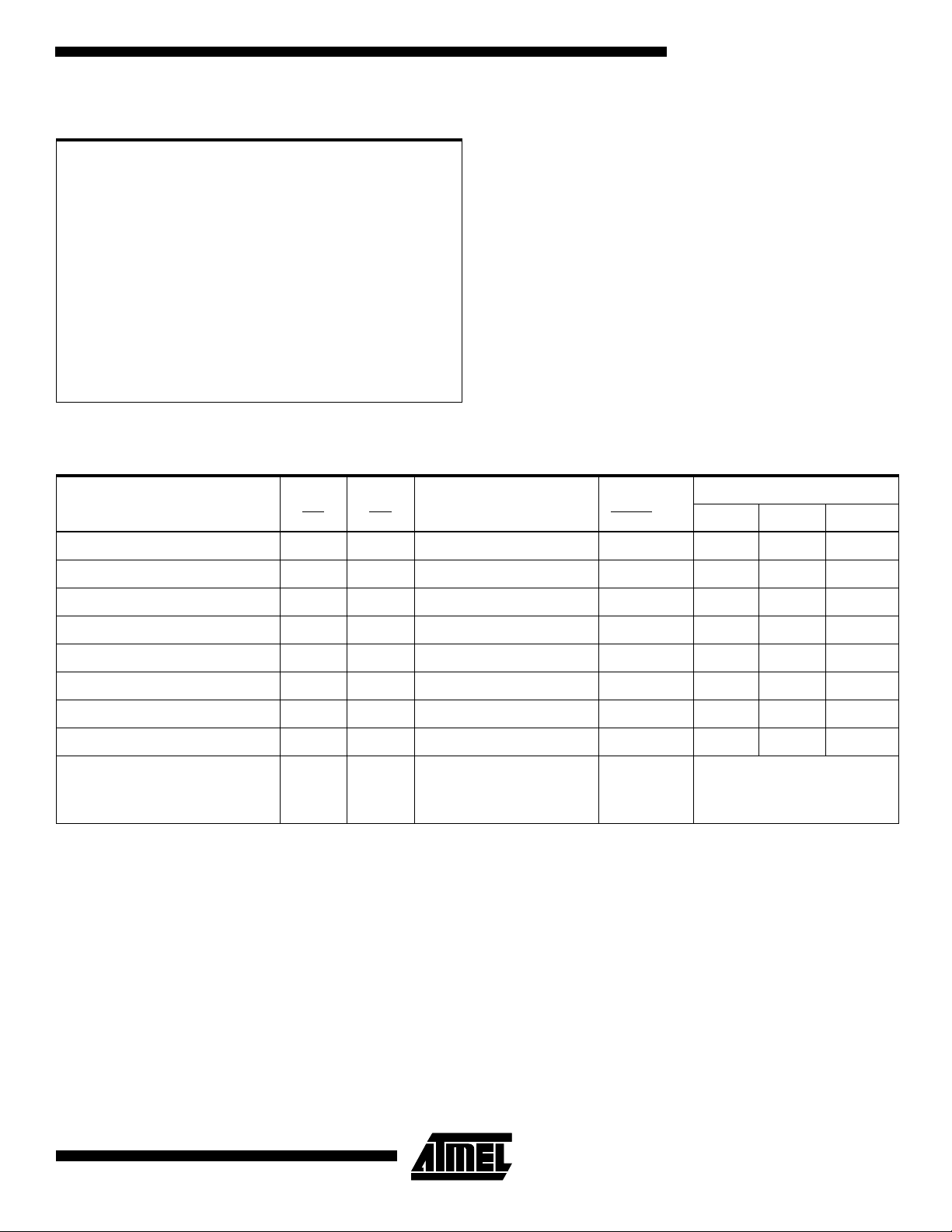

Operating Modes

Mode\Pin CE OE Ai BYTE/V

Read Word-wide V

Read Byte-wide Upper V

Read Byte-wide Lower V

Output Disable X

Standby V

Rapid Program

(2)

IL

IL

IL

(1)

IH

V

IL

X

PGM Verify X V

PGM Inhibit V

Product Identification

(4)

IH

V

IL

V

IL

V

IL

V

IL

V

IH

(1)

V

IH

IL

V

IH

V

IL

A0 = VIH or V

A1 - A18 = V

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

Ai V

Ai V

(1)

X

A9 = V

(3)

H

IL

IL

V

V

V

X

V

V

Outputs

O

PP

IH

IL

IL

0-O7

D

D

D

OUT

OUT

OUT

O8-O

D

OUT

14

O15/A-1

D

High Z V

High Z V

OUT

IH

IL

XHigh Z

(5)

PP

PP

PP

IH

High Z

D

IN

D

OUT

High Z

Identification Code

Notes: 1. X can be VIL or V

2. Refer to the programming characteristics tables in this data sheet.

3. VH = 12.0 ± 0.5V.

4. Two identifier words may be selected. All Ai inputs are held low (V

low (V

) to select the Manufacturer’s Identification word and high (VIH) to select the Device Code word.

IL

5. Standby VCC current (ISB) is specified with VPP = VCC.

IH.

) except A9,which is set to VH, and A0, which is toggled

IL

> VPP will cause a slight increase in I

V

CC

SB

.

3

µ

µ

µ

µ

DC and AC Operating Conditions for Read Operation

-10 -12 -15

AT27C800

Operating Temperature (Case)

Com. 0°C - 70°C0°C - 70°C0°C - 70°C

Ind. -40°C - 85°C -40°C - 85°C-40°C - 85°C

V

Power Suppl y 5V ± 10% 5V ± 10% 5V ± 10%

CC

DC and Operating Characteristics for Read Operation

Symbol Pa rameter Condition Min Max Units

V

I

I

I

I

V

V

V

V

LI

LO

PP1

SB

IL

IH

OL

OH

(2)

Input Load Current

Output Leakage Current

(1)

V

Read/Standby Current

PP

(1)

V

Standby Current

CC

Active Current f = 5MHz, I

V

CC

Input Low Voltage -0.6 0.8 V

Input High Voltage 2.0 VCC + 0.5 V

Output Low Voltage IOL= 2.1 mA 0.4 V

Output High Voltage IOH = -400 mA 2.4 V

= 0V to V

IN

V

= 0V to V

OUT

V

= V

PP

CC

I

(CMOS)

SB1

= VCC ± 0.3V

CE

(TTL)

I

SB2

= 2.0 to V

CE

CE

= V

IL

CC

CC

OUT

CC

+ 0.5V

= 0 mA,

±1.0

±5.0

±10

100

1.0 mA

50 mA

A

A

A

A

Notes: 1. VCC must be applied simultaneously or before VPP, and removed simultaneously or after VPP.

2. VPP may be connected directly to VCC except during programming. The supply current would then be the sum of I

AC Characteristics for Read Operation

AT27C800

-10 -12 -15

Symbol Parameter Condition

(3)

t

ACC

(2)

t

CE

(2,3)

t

OE

(4,5)

t

DF

(4)

t

OH

t

ST

t

STD

Notes: 2,3,4,5. See the AC Waveforms for Read Operation diagram.

Address to Output Delay CE = OE = V

CE to Output Delay OE = V

OE to Output Delay CE = V

IL

IL

OE or CE High to Output Float,

whichever occured first

Output Hold from Address CE or OE,

whichever occured first

BYTE High to Output Valid 100 120 150 ns

BYTE Low to Output Transition 40 50 60 ns

Min Max Min Max Min Max

IL

100 120 150 ns

100 120 150 ns

40 40 50 ns

30 35 40 ns

5.0 5.0 5.0 ns

and IPP.

CC

Units

4

AT27C800

AT27C800

Byte-Wide Read Mode AC Waveforms

Note: 1. BYTE/VPP = V

IL

Byte-Wide Read Mode AC Waveforms

(1)

(1)

Note: 1. BYTE/VPP = V

BYTE

Transition AC Wa veforms

A0-A18

BYTE/V

O-O

07

O-O

815

A-1

IH

VALID

VALID

t

PP

t

OH

t

STD

ACC

DATAOUT

HI-Z

t

OH

t

ST

DATAOUT

DATAOUT

Notes: 1. Timing measurement references are 0.8V and 2.0V. Input AC drive levels are 0.45V and 2.4V, unless otherwise specified.

2. OE

3. OE may be delayed up to t

may be delayed up to tCE - tOE after the falling edge of CE without impact on t

- tOE after the address is valid without impact on t

ACC

CE.

ACC

.

4. This parameter is only sampled and is not 100% tested.

5. Output float is defined as the point when data is no longer driven.

5

Input Test Waveforms and Measurement Levels

Output Test Load

tR, tF < 20 ns (10% to 90%)

Pin Capaticance

C

IN

C

OUT

Note: 1. Typical values for nominal supply voltage. This parameter is only sampled and is not 100% tested.

(f = 1 MHz, T = 25°V)

Typ Max Units Conditions

410pFV

812pFV

(1)

Note: 1. CL = 100 pF includin g

jig capacitance.

= 0V

IN

= 0V

OUT

6

AT27C800

AT27C800

µ

Programming Waveforms

(1)

Notes: 1. The Input Timing reference is 0.8V for VIL and 2.0V for VIH.

and t

2. t

OE

3. When programming the AT27C800, a 0.1 µF capacitor is required across VPP and ground to suppress voltage transients.

are characteristics of the device but must be accommodated by the programmer.

DFP

DC Programming Characteristics

TA = 25 ± 5°C, VCC = 6.5 ± 0.25V, VPP = 13.0 ± 0.25V

Symbol Parameter Test Conditions

I

LI

V

IL

V

IH

V

OL

V

OH

I

CC2

I

PP2

V

ID

Input Load Current VIN = VIL, V

Input Low Level -0.6 0.8 V

Input High Level 2.0 V

Output Low Voltage IOL = 2.1 mA 0.4 V

Output High Voltage IOH = -400 µA2.4 V

VCC Supply Current (Program and Verify) 50 mA

VPP Supply Current CE = V

A9 Product Identification Voltage 11.5 12.5 V

IH

IL

Limits

±10

+ 0.5 V

CC

30 mA

UnitsMin Max

A

7

AC Programming Characteristics

µ

µ

µ

µ

µ

µ

µ

µ

µ

TA = 25 ± 5°C, VCC = 6.5 ± 0.25V, VPP = 13.0 ± 0.25V

Symbol Parameter Test Conditions

(1)

Limits

UnitsMin Max

t

AS

t

OES

t

DS

t

AH

t

DH

t

DFP

t

VPS

t

VCS

t

PW

t

OE

t

PRT

Notes: 1. V

2. This parameter is only sampled and is not 100% tested. Output Float is defined as the point where data is no longer

3. Program Pulse width tolerance is 50

Address Setup Time

OE Setup Time 2

Input Rise and Fall Times:

(10% to 90%) 20 ns.

2

Data Setup Time 2

Address Hold Time 0

Input Pulse Levels:

45V to 2.4V

Data Hold Time 2

OE High to Output Float Delay

(2)

VPP Setup Time 2

VCC Setup Time 2

CE Program Pulse Width

(3)

Data Valid from OE 150 ns

BYTE /VPP Pulse Rise Time During

Input Pulse Levels:

0.8V to 2.0V

Input Timing Reference Level:

0.8V to 2.0V

Output Timing Reference Level:

0.8V to 2.0V

0 130 ns

47.5 52.5

50 ns

Programming

must be applied simultaneously or before V

cc

driven— see timing diagram.

s ± 5%.

and removed simultaneously or after VPP.

PP

s

s

s

s

s

s

s

s

Atmel’s 27C800 Integrated Product Identification Code

Pins

A0 015 014 013 012 011 010 09 08

Codes

07 06 05 04 03 02 01 00

Manufacturer 000011110 1E1E

Device Type 111111000 F8F8

Hex Data

8

AT27C800

Rapid Programming Algorithm

µ

µ

A 50 µs CE pulse width is used to program. The address is

set to the first location. V

is raised to 13.0V. Each address is first pr ogrammed with

one 50

reprogramming loop is executed for each address. In the

event a word fails to pass verification, up to 10 successive

50

pulse. If the word fails to verify after 10 pulses have been

applied, the part is considered failed. After the word verifies

properly, the next address is selected until all have been

checked. V

words are read again and compared with the original data

to determine if the device passes or fails.

s CE pulse without verification. Then a verification/

s pulses are applied with a verification after each

is then lowered to 5.0V and VCC to 5.0V. All

PP

is raised to 6.5V and BYTE/V

CC

PP

AT27C800

9

Order ing Information

(mA)

t

ACC

(ns)

I

CC

Ordering Code Package Operation RangeActive Standby

100 50 0.1 AT27C800-10DC

AT27C800-10PC

AT27C800-10RC

AT27C800-10TC

50 0.1 AT27C800-10DI

AT27C800-10PI

AT27C800-10RI

AT27C800-10TI

120 50 0.1 AT27C800-12DC

AT27C800-12PC

AT27C800-12RC

AT27C800-12TC

50 0.1 AT27C800-12DI

AT27C800-12PI

AT27C800-12RI

AT27C800-12TI

150 50 0.1 AT27C800-15DC

AT27C800-15PC

AT27C800-15RC

AT27C800-15TC

50 0.1 AT27C800-15DI

AT27C800-15PI

AT27C800-15RI

AT27C800-15TI

42DW6

42P6

44R

48T

42DW6

42P6

44R

48T

42DW6

42P6

44R

48T

42DW6

42P6

44R

48T

42DW6

42P6

44R

48T

42DW6

42P6

44R

48T

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

42DW6

42P6

44R

48T

10

Package Type

42 Lead, 0.600" Wide, Ceramic Dual Inline Package (CDIP)

42 Lead, 0.600" Wide, Plastic Dual Inline Package (PDIP)

44 Lead, 0.525" Wide, Plastic Gull Wing Small Outline Package (SOIC/SOP)

48 Lead, Plastic Thin Small Outline Package (TSOP) 12 x 20 mm

AT27C800

Loading...

Loading...