Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

ATSAMW25

AT16225: Atmel Smart Plug Hardware User Guide

Application Note

Introduction

The Atmel® Smart Plug Reference Design provides a system solution for a Wi-Fi®

enabled power plug that can turn on/off power from the main plug in three ways:

using the QTouch® button, using the Android™ app with a Wi-Fi connection, or

using a scheduled on/off from the Android app. It is an IoT application using the

ATSAMW25 module (a highly integrated module with ATSAMD21, WINC1500,

ECC508A), and an ATM90E26 device to realize ARM® Cortex®-M0+ MCU

control, Wi-Fi connection, CryptoAuthentication with secure hardware key

storage, QTouch sensing, and energy metering functions with an optimized BOM.

This document describes the hardware design of the smart plug reference

design.

Features

Turnkey solution with small form factor

Three models following either US, EU, or Chinese standards

AC input 90-265V and 50/60Hz

Max output power: 2200W(10A)

Based on ATSAMW25 module

– ATSAMD21 Cortex-M0+ MCUWINC1500 IEEE 802.11 b/g/n 2.4G Wi-Fi

Controller

– ECC508A hardware Authentication and Encryption

ATM90E26 power and energy metering function

QTouch button

CE/FCC/UL&CUL Certification

Figure 1. Atmel Smart Plug Kits

2

2

Table of Contents

1 Overview ..................................................................................................................... 3

1.1 System Overview .................................................................................................................................. 3

2 MCU Board ................................................................................................................... 4

2.1 MCU Board Overview ............................................................................................................................ 4

2.2 ATSAMW25 .......................................................................................................................................... 5

2.3 Programming Interface .......................................................................................................................... 7

2.4 Header to Touch Board ......................................................................................................................... 7

2.5 Header to Power Board ......................................................................................................................... 8

2.6 DataFlash (Not Mounted) ...................................................................................................................... 8

3 Touch Board ................................................................................................ ................ 9

3.1 Touch Board Overview .......................................................................................................................... 9

3.2 Touch Sensors ...................................................................................................................................... 9

3.3 LEDs for Wi-Fi and Power ................................................................................................................... 10

3.3.1 Wi-Fi LED ............................................................................................................................... 10

3.3.2 Power LED ............................................................................................................................. 10

3.3.3 LED Pin Definition on SAM W25 ............................................................................................ 10

4 Power Board ................................................................................................ .............. 10

4.1 Power Board Overview ........................................................................................................................ 10

4.2 AC-DC .............................................................................................................................................. 11

4.3 The Fuse ............................................................................................................................................. 12

4.4 DC-DC .............................................................................................................................................. 12

4.5 Power Measurement ........................................................................................................................... 12

4.6 Power Measurement Calibration ......................................................................................................... 14

4.6.1 Calculation of the GL .............................................................................................................. 14

4.6.2 Calculation of the Ugain.......................................................................................................... 14

4.6.3 Calculation of the Igain ................................ ........................................................................... 14

4.6.4 Calculation of the PL_Constant .............................................................................................. 14

4.7 The Relay ............................................................................................................................................ 14

4.8 Plug and Socket .................................................................................................................................. 15

5 PCB Assembly ........................................................................................................... 17

5.1 PCB Stack Structure ........................................................................................................................... 17

6 Reprogram the Kit ..................................................................................................... 18

6.1 Open the Kit ........................................................................................................................................ 18

6.2 Power Supply ...................................................................................................................................... 18

6.2.1 Onboard AC Power ................................................................................................................ 18

6.2.2 External DC power ................................................................................................................. 19

6.3 Programming Tools ............................................................................................................................. 20

6.4 Programming ....................................................................................................................................... 21

7 Revision History ........................................................................................................ 22

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

3

3

ATSAMW25

Output Socket

AC/DC

3.3V

DC/DC

LEDs

12V

L

N

Button

Relay

Fuse

Input Plug

DataFlash

E

ATM90E26

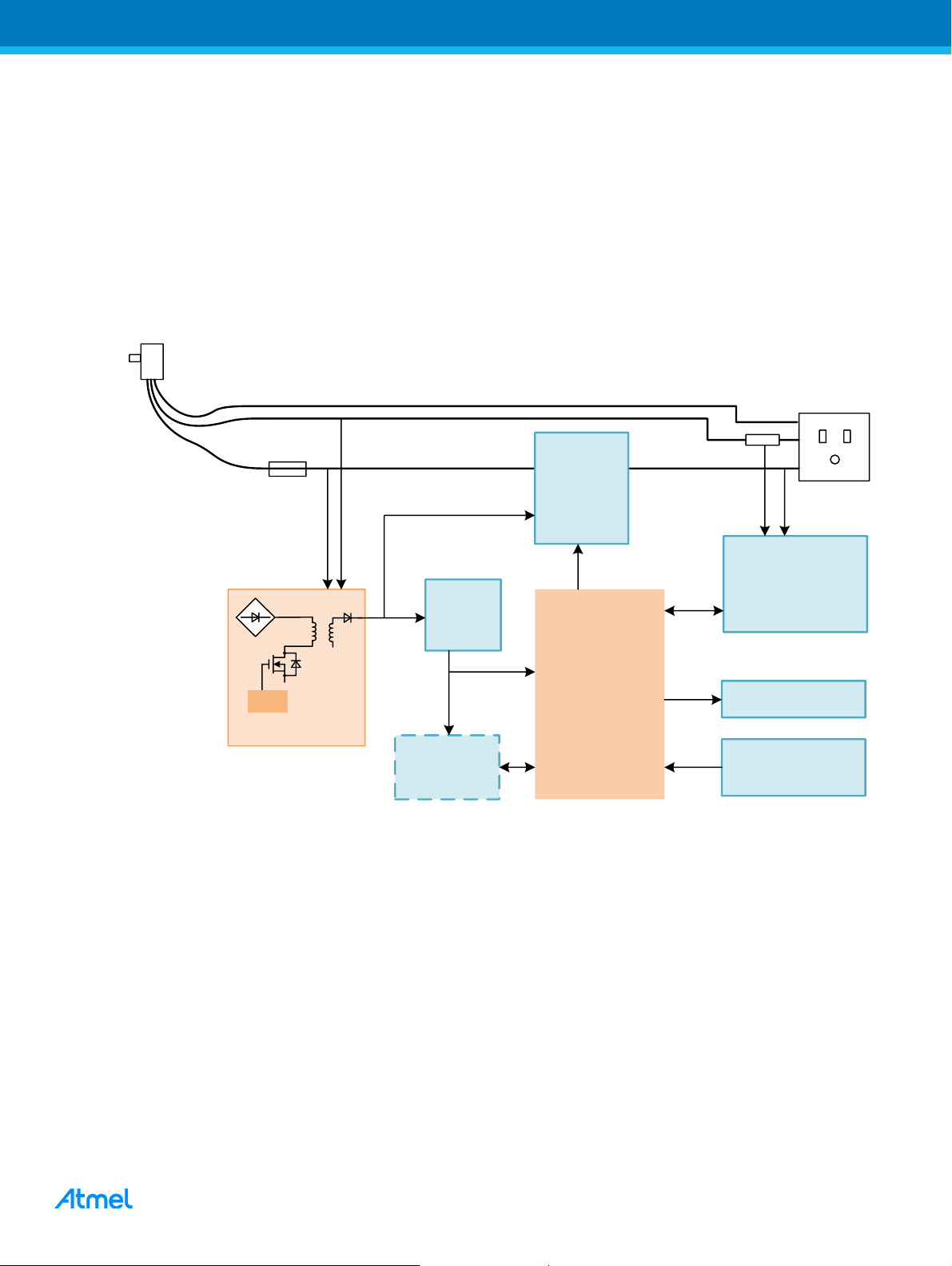

1 Overview

The smart plug consists of three PCBs: Power board, MCU board, and Touch board. The MCU board is

vertically mounted to the Power board and the Touch board is connected to the MCU board by a pin connector.

Touch Board: Touch pad and LEDs.

MCU Board: ATSAMW25, 32KHz crystal, DataFlash footprint (not mounted).

Power Board: Socket and Plug, AC-DC, DC-DC, Power Measurement, Relay.

1.1 System Overview

Figure 1-1. System Block Diagram

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

4

4

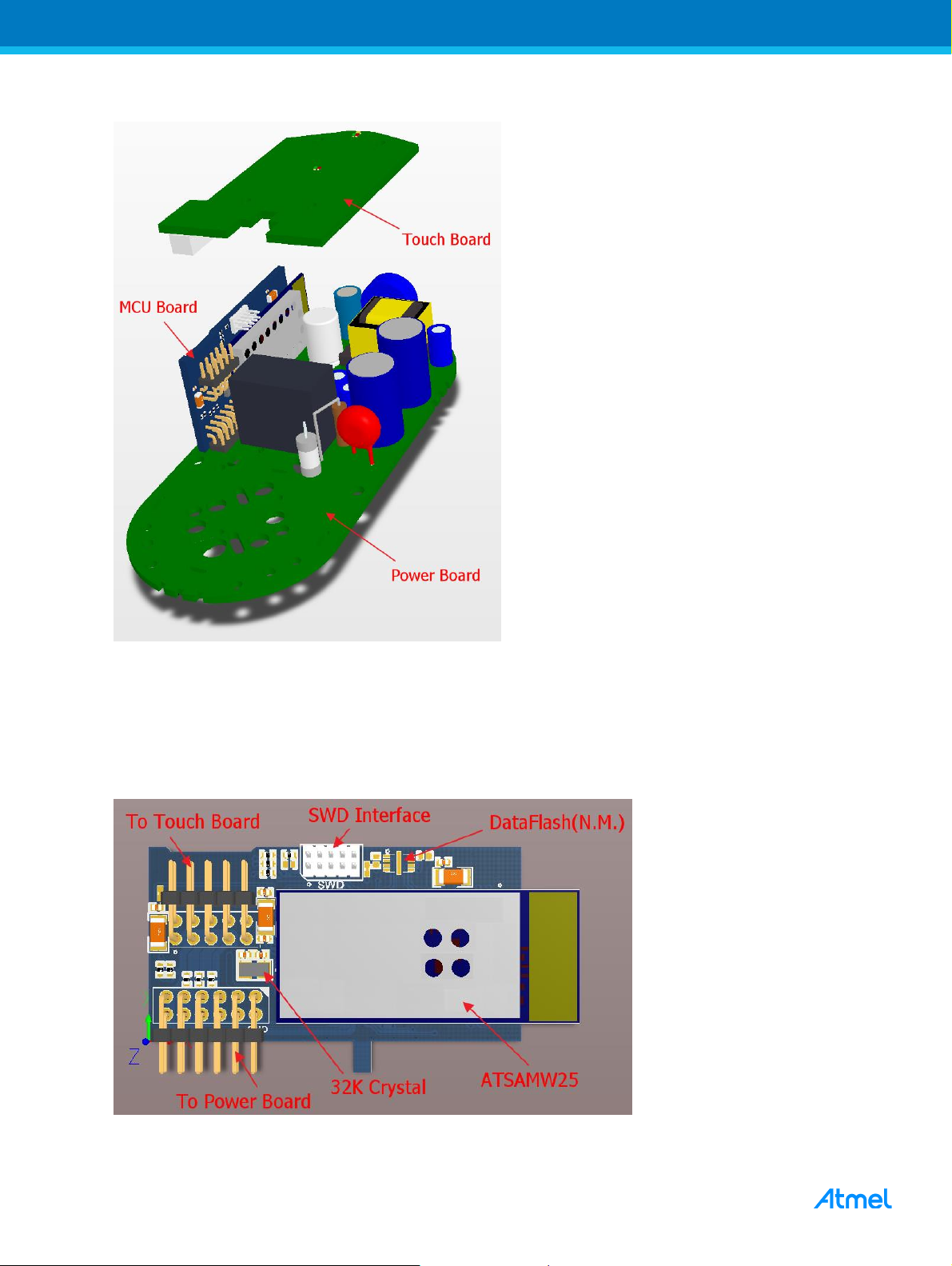

Figure 1-2. Overview of the Smart Plug Kit PCBs

2 MCU Board

2.1 MCU Board Overview

Figure 2-1. MCU Board Overview

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

5

5

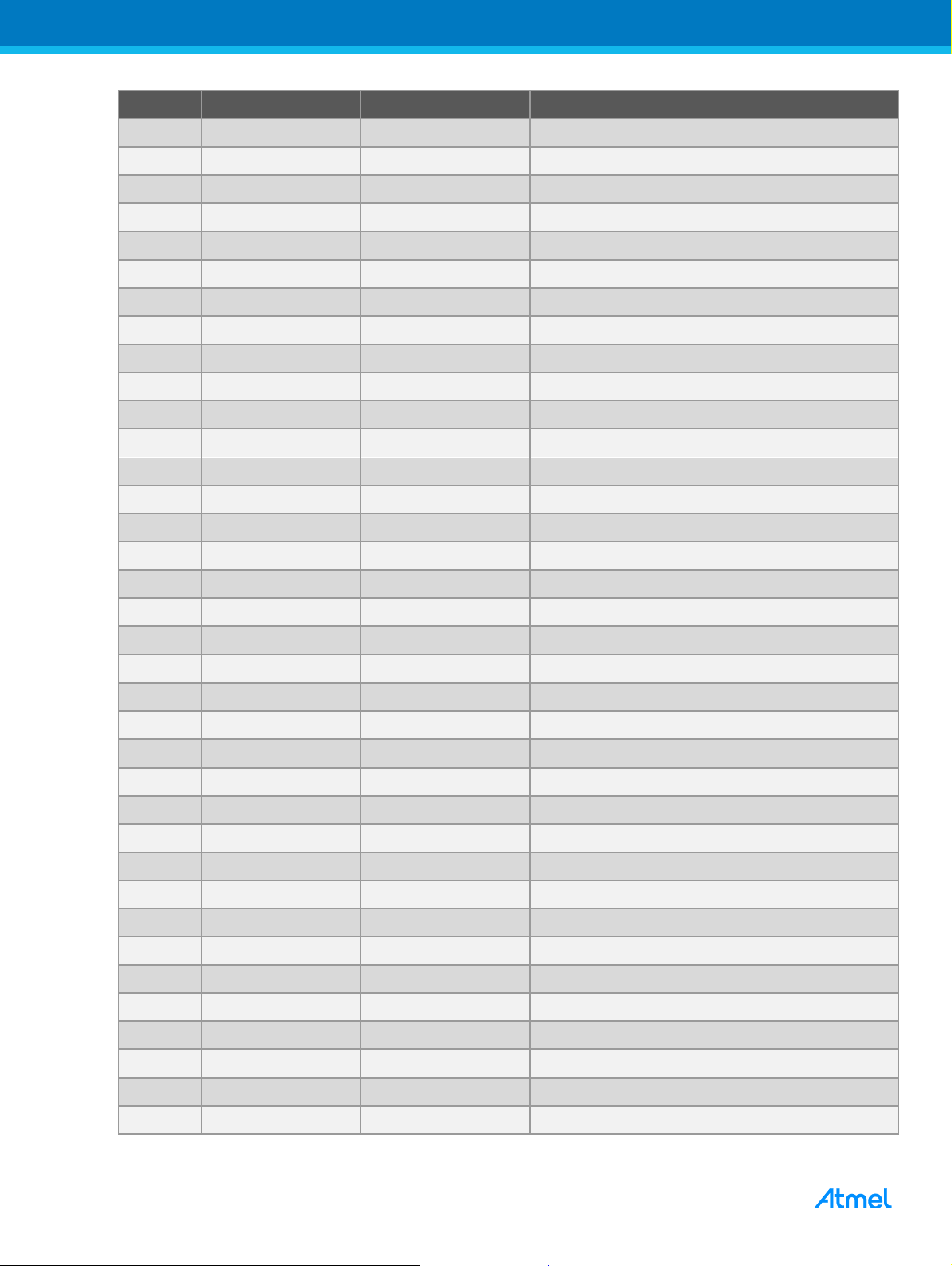

Pin #

SAM W25 function

System function

Description

0

GND

GND

Heat sink pads in the bottom

1

GND

GND

2 UART TXD

Wi-Fi TXD

For ATWINC1500 firmware upgrade

3

UART RXD

Wi-Fi RXD

For ATWINC1500 firmware upgrade

4

Wi-Fi Chip En

NC

5

Wi-Fi GPIO_1

RTC

Not Used

6

NC

NC

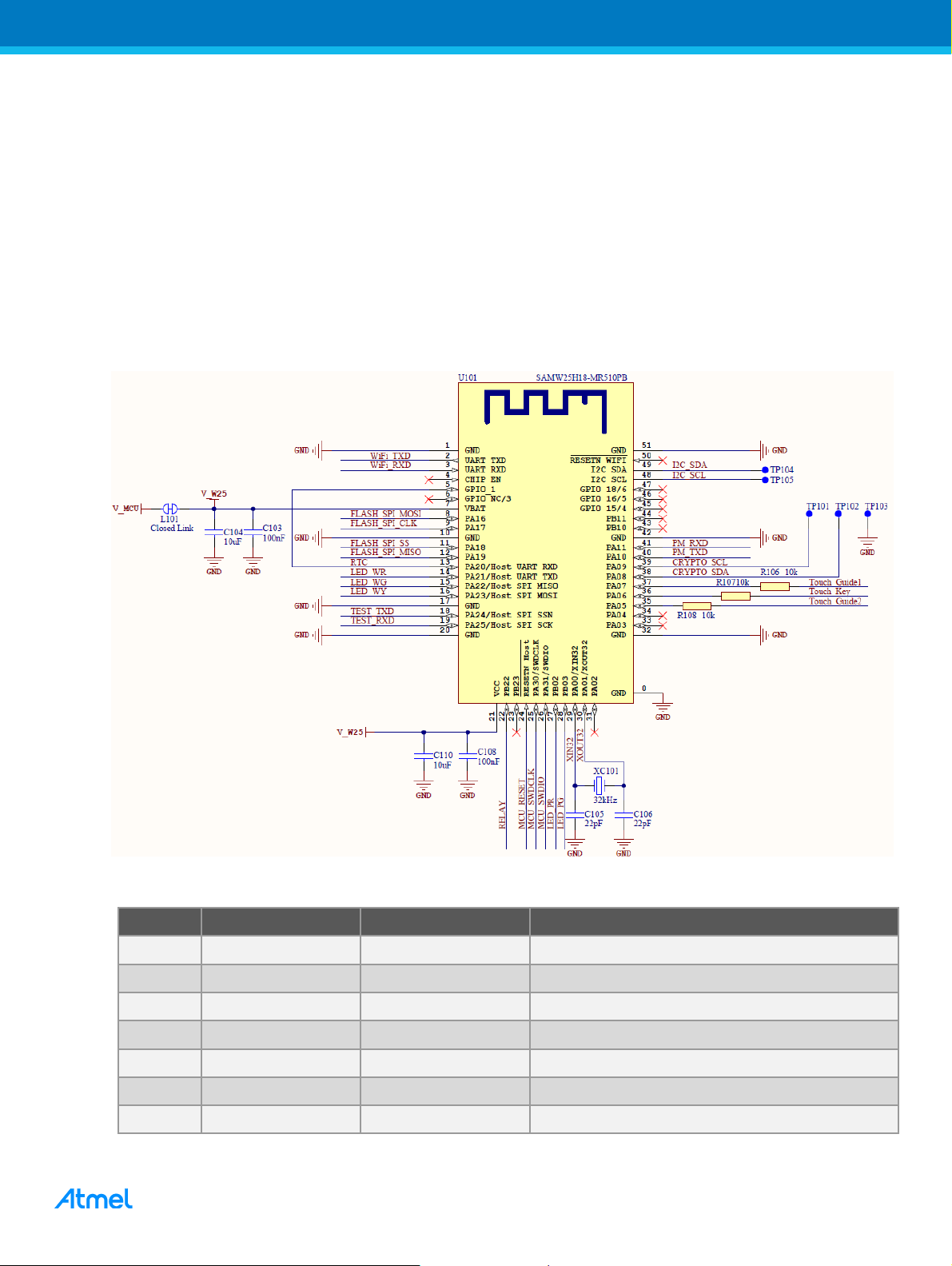

2.2 ATSAMW25

The Atmel SmartConnect SAM W25 is a low-power Wi-Fi certified module. This highly integrated module offers

the ideal solution for designers seeking Wi-Fi connectivity. The SAM W25 integrates an 802.11 IP stack on top

of the Wi-Fi core and fully covers RF certifications.

The SAM W25 module is based on Atmel’s industry-leading WINC1500 Wi-Fi core combined with Atmel’s

latest ARM Cortex-M0+ based microcontroller (SAM D21) technology. This turnkey system provides an

integrated software solution with application and security protocols such as TLS and integrated network

services (TCP/IP stack).

ATSAMW25 is the control center of the smart plug kit. It covers all the intelligent functions including the Wi-Fi

connection, touch button, relay control, temperature sensing and protection, LED indicators, and timing.

Figure 2-2. Schematic for ATSAMW25

Table 2-1. ATSAMW25 Pinout

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

6

6

Pin #

SAM W25 function

System function

Description

7

VBAT

VCC

Power supply

8

PA16

Flash SPI MOSI

DataFlash Interface

9

PA17

Flash SPI CLK

DataFlash Interface

10

GND

GND

11

PA18

Flash SPI SS

DataFlash Interface

12

PA19

Flash SPI MISO

DataFlash Interface

13

PA20

RTC

Not Used

14

PA21

LED WR

Red LED for Wi-Fi

15

PA22

LED WG

Green LED for Wi-Fi

16

PA23

LED WY

Yellow LED for Wi-Fi

17

GND

GND

18

PA24

Test TXD

Fixture test interface

19

PA25

Test RXD

Fixture test interface

20

GND

GND

21

VCC

VCC

Power supply

22

PB22

Relay

Relay ON/OFF

23

PB23

NC 24

RESET_N

MCU Reset

SAM D21 reset pin

25

PA30

MCU SWDCLK

SWD SWDCLK pin

26

PA31

MCU SWDIO

SWD SWDCLK pin

27

PB02

LED PR

Red LED for Power

28

PB03

LED PG

Green LED for Power

29

PA00

XIN32

32kHz External Crystal

30

PA01

XOUT32

32kHz External Crystal

31

PA02

NC

32

GND

GND

33

PA03

NC 34

PA04

NC 35

PA05

Touch Guard 2

Touch Guard sensor

36

PA06

Touch Key

Touch key sensor

37

PA07

Touch Guard 1

Touch Guard sensor

38

PA08

Crypto SDA

Reserved interface for internal crypto

39

PA09

Crypto SCL

Reserved interface for internal crypto

40

PA10

PM TXD

Interface for Power Measurement device

41

PA11

PM RXD

Interface for Power Measurement device

42

GND

GND

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

7

7

Pin #

SAM W25 function

System function

Description

43

PB10

NC 44

PB11

NC 45

Wi-Fi GPIO_15

NC 46

Wi-Fi GPIO_16

NC 47

Wi-Fi GPIO_18

NC 48

Wi-Fi I2C SCL

I2C SCL

Reserved interface for internal WINC1500

49

Wi-Fi I2C SDA

I2C SDA

Reserved interface for internal WINC1500

50

Wi-Fi Reset_n

NC 51

GND

GND

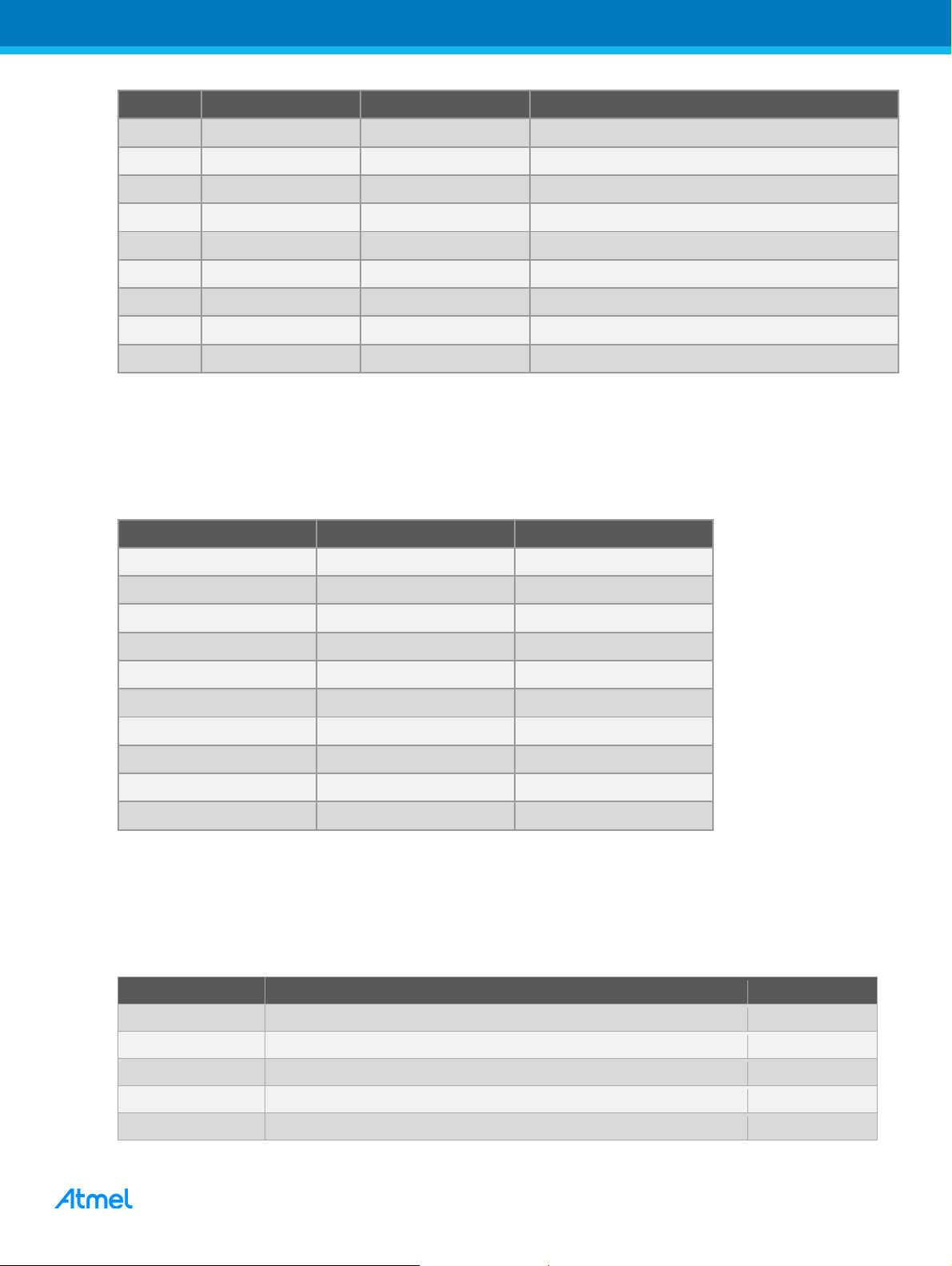

SWD header pin

Pin definition

ATSAMW25 pin

1

SWDCLK

25

2

GND

3

NC 4

VCC

5 SWDIO

26 6 RESET

24 7 NC 8

NC 9

NC 10

NC

Touch header pin

Pin definition

ATSAMW25 pin

1

GND (External power input if onboard power is not available)

2 VCC (External power input if onboard power is not available)

3

Touch Guard Sensor 1

37

4

Power LED Green

28 5 Touch Key Sensor

36

2.3 Programming Interface

Since SAM W25 uses the SAM D21 as the controller, the user can use the SWD interface to Program and

debug the device.

Table 2-2. Pin Definition of SWD Interface

2.4 Header to Touch Board

The Touch Board is connected to MCU Board through a 10-pin header, it contains the tracks for the touch

sensors and LEDs. The header also makes it possible to power the MCU externally.

Table 2-3. Header to Touch Board

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

8

8

6

Power LED Red

27

7

Touch Guard Sensor 2

35 8 Wi-Fi LED Red

14 9 Wi-Fi LED Yellow

16

10

Wi-Fi LED Green

15

Power header pin

Pin definition

ATSAMW25 pin

1

VCC

2

GND

3

Wi-Fi TXD (Reserved for Wi-Fi firmware upgrade on fixture)

2

4

Wi-Fi RXD (Reserved for Wi-Fi firmware upgrade on fixture)

3 5 Test RXD (Reserved for fixture)

19

6

Test TXD (Reserved for fixture)

18

7

Power Measurement RXD (Interface for MCU and power measurement

device)

41

8

Power Measurement TXD (Interface for MCU and power measurement

device)

40

9

MCU Reset (Reserved for fixture)

24

10

Relay Control

22

11

MCU SWDIO (Reserved for fixture)

26

12

MCU SWDCLK (Reserved for fixture)

25

2.5 Header to Power Board

The MCU Board is mounted directly on the Power Board by a 12-pin header.

Table 2-4. Header to Power Board

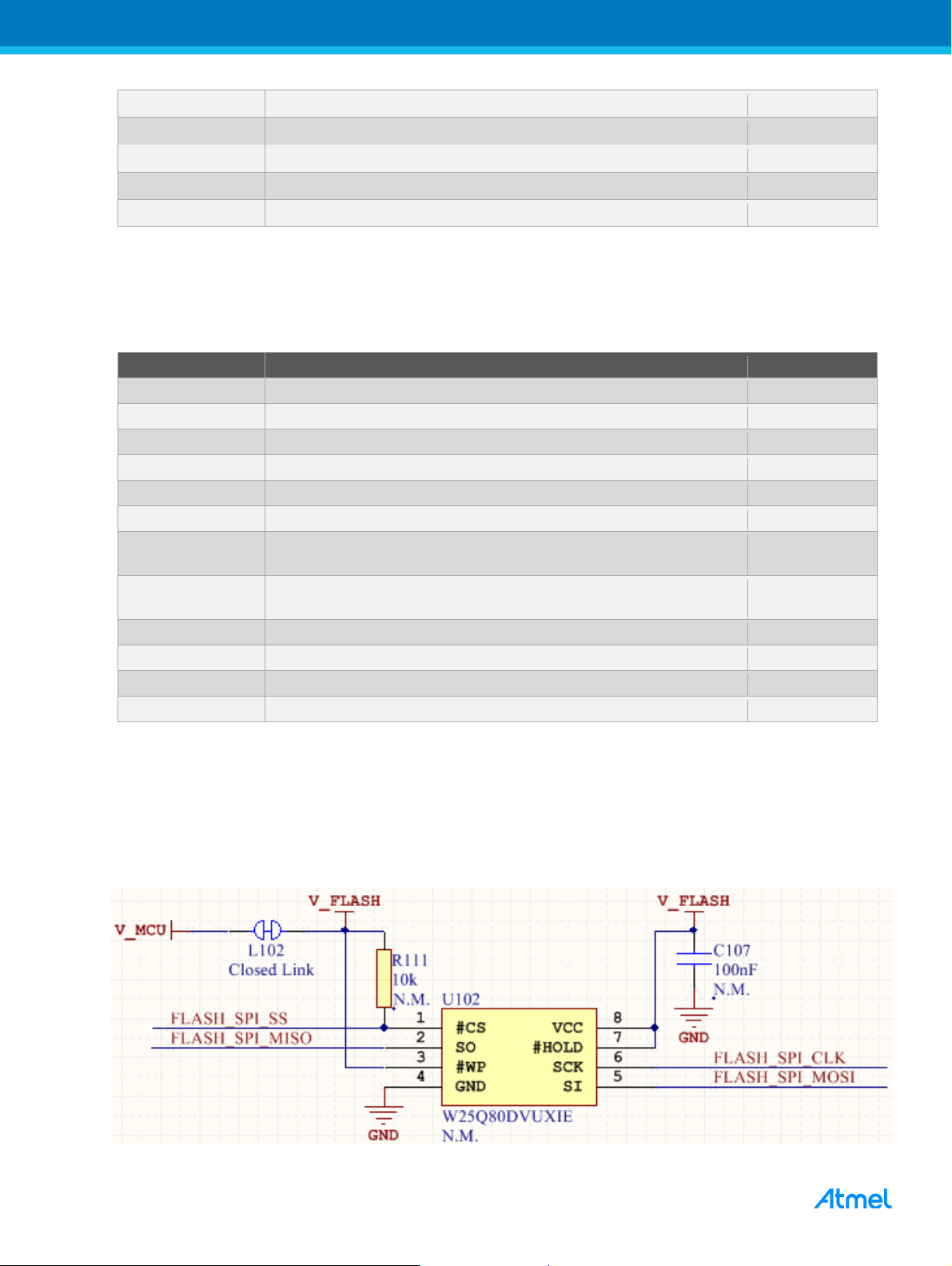

2.6 DataFlash (Not Mounted)

Space for a DataFlash device is reserved (but not mounted) on the board. This can be used to store more data

locally if needed.

Figure 2-3. Schematic of DataFlash Part

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

9

9

Designator

Value

Vendor

Part Number

Description

C107

100nF

Murata

GRM155R71H104KE14

Ceramic capacitor, SMD 0402, X7R, 50V, 10%

R111

10k

Yageo

RC0402FR-0710KL

Thick film resistor, SMD 0402, 1/16W, 1%

U102

1M Byte

Winbond

W25Q80DVUXIE

Serial Flash, 8-lead USON 2*3mm

Pin name on DataFlash

Pin name on ATSAMW25

ATSAMW25 pin

FLASH_SPI_SS

PA18

11

FLASH_SPI_MISO

PA19

12

FLASH_SPI_MOSI

PA16

8

FLASH_SPI_CLK

PA17

9

Table 2-5. BoM for the DataFlash Part if Mounted

Table below shows the pin definition of SAM W25 for DataFlash.

Table 2-6. Pin Definition of DataFlash and SAM W25

3 Touch Board

3.1 Touch Board Overview

The Touch board contains the Touch sensors and the LEDs for Wi-Fi and Power.

Figure 3-1. Touch Board Overview

3.2 Touch Sensors

Touch sensors are designed based on the self-capacitor using the QTouch technology.

Except the Touch Key which handles the ON/OFF/Reset function, another two touch sensors act as the touch

guard. The touch guard sensors will prevent some scenarios from spurious triggering.

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

1

10

Pad name on touch board

Pin name on ATSAMW25

ATSAMW25 pin

Touch Key

PA06

36

Touch Guard 1

PA07

37

Touch Guard 2

PA05

35

LED name on touch board

Active logic

Pin name on ATSAMW25

ATSAMW25 pin

Wi-Fi Yellow

1

PA23

16

Wi-Fi Green

1

PA22

15

Wi-Fi Red

1

PA21

14

Power Green

1

PB03

28

Power Red

1

PB02

27

Table 3-1. Pin definition of Touch Sensor and SAM W25

3.3 LEDs for Wi-Fi and Power

All LEDs including the Wi-Fi and Power LEDs are driven by the ATSAMW25 GPIOs directly, Logic 1 enables

the LEDs.

Note: For better output current performance, the I/O pins needs be set to high drive strength: DRVSTR = 1.

Different color LEDs are used to indicate different status of the plug.

3.3.1 Wi-Fi LED

Yellow blink: Plug in SoftAP mode, not connected (waiting for Phone to connect)

Yellow: Plug in SoftAP mode, connected to a phone (during this period, Phone App sends

SSID/password to plug)

Green blink: Plug in STA mode, connecting to home Access Point (AP)

Green: Plug in STA mode, connected to home AP, connection is good

Red: In error state

3.3.2 Power LED

Green when ON

Red when OFF

3.3.3 LED Pin Definition on SAM W25

Table 3-2. Pin Definition of LEDs and SAM W25

4 Power Board

4.1 Power Board Overview

The Power Board contains an AC-DC converter, a DC-DC converter, the power measurement circuit, relay,

and the plug and socket.

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

1

11

Figure 4-1. Power Board Overview

4.2 AC-DC

The AC-DC part transforms the 100V~240V AC input voltage into a 12V/120mA (typical) DC output.

The 12V DC supplies the relay and the DC-DC converter.

Figure 4-2. Schematic of AC-DC Part

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

1

12

Wire

Type

Start to end

Turns

Tape

N1

2UEW Φ 0.15x1P

3-1

70Ts

1Ts

N2

2UEW Φ 0.15x1P

4-5

23Ts

2Ts

N4

TRWB Φ 0.35x1P

7-6

24Ts

3Ts

The transformer T301 is a custom component with the parameters below.

Figure 4-3. Transformer Design

Table 4-1. Wire Definition of Transformer

4.3 The Fuse

If broken, the fuse F301 (12A) should be changed by the professional person.

4.4 DC-DC

The DC-DC converter converts the DC voltage level from 12V to 3.3V for the SAM W25 module. The MP1470

is a typical buck DC-DC converter, with the output range set to 3.16V to 3.36V.

Figure 4-4. Schematic of DC-DC Part

4.5 Power Measurement

The ATM90E26 works as the power measurement device to get the actual output power.

There are two signals sampled by ATM90E26, one is the voltage which comes from the L line, another is the

differential voltage based on the current in sense resistor R311.

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

1

13

Figure 4-5. Sampled Signal of Power Measurement

The power measurement device will calculate and output the sampled voltage, current, and power to SAM

W25 through the UART port. Considering the different power supply system, 2 optocouplers are used to isolate

the SAM W25 and M90E26.

Figure 4-6. Schematic of Power Measurement

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

1

14

Pin Name for Uart

Pin name on ATSAMW25

ATSAMW25 pin

PWR_PM_TXD

PA10

40

PWR_PM_RXD

PA11

41

Table 4-2. Pin Definition of Power Measurement and SAM W25

4.6 Power Measurement Calibration

Before using the ATM90E26 in user application, some parameters need be calculated, such as GL, Ugain,

Igain, and PL_Contant.

MC: Pulse constant of the energy meter, unit is imp/kWh or imp/kvarh; Assume MC = 10000

Un: Reference voltage, unit is V; Assume Un = 220V

Ib: Basic current, unit is A; Assume Ib = 1A

GL: L line current circuit gain

VL: Sampling voltage of the L line circuit at Ib, unit is mV

VU: Sampling voltage of the voltage circuit at Un, unit is mV

4.6.1 Calculation of the GL

With the shunt resistor = 1mΩ, Max. current I = 10A.

When, GL = 24

VLsample = 1mΩ * 10A * 24 = 240mV

4.6.2 Calculation of the Ugain

The default Ugain is based on the condition below:

Ugain = 26400 (6720H), Voltage divider coefficient = 880,

Assume Un = 220V, VL = 220 / (880 + 1)

Considering the voltage divider resistors used in smart plug, Voltage divider coefficient = (430 + 430) = 860

So, Ugain = 26400 * (220 / (860 + 1)) / (220 / (880 + 1)) = 27013 (6985H)

4.6.3 Calculation of the Igain

From AN 46102,

R = 200µΩ, I = 5A, Lgain = 24 <=> Igain = 31251 (7A13H) by default

In SmartPlug solution,

R = 1mΩ, I = 2A, Lgain = 24 <=> Igain = 31251 * (1000 * 2A * 24) / (200 * 10A * 24) = 62502 (F426H)

4.6.4 Calculation of the PL_Constant

PL_Constant = int (838860800 * GL * VL * Vu / MC * Un * Ib)

= 838860800 * 24 * 1 * (220 / (860 + 1)) / 10000 * 220 * 1 = 2338287(23ADEFH)

4.7 The Relay

The relay is cascaded in the AC input and output. So, the Relay can direct control the ON/OFF of the AC

output.

The rated current of the relay is 10A, this means the output power is limited to Max 2200W (@ 220V AC).

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

1

15

Relay Contorl Name

Active Logic

Pin name on ATSAMW25

ATSAMW25 pin

PWR_RELAY

1

PB22

22

Note: Some electronic devices may generate a surge current far larger than the rated current; damaging the

relay by welding the contact shut. When this happens the output will be always ON and the kit will be

out of control. If this happens you must cut the input voltage manually immediately. From testing it has

been observed that a surge current of bigger than 50A can make the contactor adhere.

Figure 4-7. Schematic of Relay Control

Table 4-3. Pin Definition of Relay

4.8 Plug and Socket

There are three types of the Plug and Socket: US, EU, and CN. They share the same PCB.

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

1

16

Figure 4-8. US, EU, and CN standard of Plug and Socket

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

1

17

5 PCB Assembly

5.1 PCB Stack Structure

The touch board is assembled in the front case of the kit, and the power board together with the MCU board is

fixed in the rear case.

When the front and rear case are closed, make sure the touch board connector is aligned with the MCU board

pin header.

Figure 5-1. PCB Stack Structure Overview

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

1

18

6 Reprogram the Kit

6.1 Open the Kit

If the user needs to reprogram the kit with custom code, the kit needs be opened first.

Figure 6-1. Remove the Silica Gel and Screws

Figure 6-2. Open the Kit

6.2 Power Supply

There are two methods to power the Kit while reprogramming: Onboard AC power and external DC power.

6.2.1 Onboard AC Power

At first, connect the programming tools and Kit with the 10-pin SWD connector.

Then, plug the Kit into the AC socket and the kit will be powered by the onboard power supply.

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

1

19

After programming, the user needs to remove the kit from the AC socket first and then disconnect the

programmer/debugger from the SWD header.

Note: The user needs be very carefully during operation and avoid touching any of the components since

they are not isolated and can easily lead to an electrical shock.

Figure 6-3. Kit Powered by the Onboard AC Input

6.2.2 External DC power

As described in the MCU board chapter, the kit can also be powered by an external 3.3VDC supply.

Before connecting the 3.3VC, the user needs to make sure the kit is not connected to the AC input.

Connect the 3.3V power supply on pin1 and pin2 of Touch header and make sure the polarity is correct.

Note: It is recommended to use the external DC to power the board while reprogramming since it is far safer

than the AC power.

Figure 6-4. Kit Powered by the External DC Input

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

2

20

Figure 6-5. External Power Input

Note: The Power Pins in on the touch header is connected in parallel with the power supply (3.3V) on the

power board. Never connect an external power supply while the onboard power is available.

6.3 Programming Tools

The smart plug uses the SWD as the programming and debug\interface, it supports all tools which supports the

SWD interface. Some tools support a direct connection with the 1.27mm pitch, 10-pin socket. Figures below

show the connection example of programming tools.

Figure 6-6. Atmel-ICE Connection

Figure 6-7. JTAGICE3 Connection

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

2

21

For other programming tools which do not have the 1.27mm pitch, 10-pin socket, the user needs to connect the

SWD lines manually.

6.4 Programming

Connect the kit to a PC with Atmel Studio installed.

Click Tools → Device Programming to open the programming dialog. Then, program the kit as show below.

Note: The Device selector must be set to ATSAMD21G18A.

Figure 6-8. Reprogramming Flow by Atmel Studio

Programming steps:

1. Select the programming tool.

2. Choose device (must be ATSAMD21G18A) and select the interface (must be SWD).

3. Apply the setting.

4. To ensure the correct connection, press ‘Read’ to get the device signature and target voltage.

5. Browse to the folder where the code located, and select it.

6. Program the device. The status can be displayed in the information frame below.

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

2

22

Doc Rev.

Date

Comments

42698B

07/2016

A new section 4.3 (The Fuse) is added.

In section 4.7, the “Note”. “less than” has been corrected to “bigger than”.

42689A

03/2016

Initial document release.

7 Revision History

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

2

23

Atmel Corporation 1600 Technology Drive, San Jose, CA 95110 USA T: (+1)(408) 441.0311 F: (+1)(408) 436.4200 │ www.atmel.com

© 2016 Atmel Corporation. / Rev.: Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016.

Atmel®, Atmel logo and combinations thereof, Enabling Unlimited Possibilities®, QTouch®, and others are registered trademarks or trademarks of Atmel Corporation

in U.S. and other countries. ARM®, ARM Connected® logo, and others are the registered trademarks or trademarks of ARM Ltd. Other terms and product names may

be trademarks of others.

DISCLAIMER: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any intellectual property right

is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN THE ATMEL TERMS AND CONDITIONS OF SALES LOCATED ON THE

ATMEL WEBSITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY WARRANTY RELATING TO ITS PRODUCTS

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT

SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES

FOR LOSS AND PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no representations or warranties with respect to the accuracy or completeness of the contents of this

document and reserves the right to make changes to specifications and products descriptions at any time without notice. Atmel does not make any commitment to update the information

contained herein. Unless specifically provided otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel products are not intended,

authorized, or warranted for use as components in applications intended to support or sustai n life.

SAFETY-CRITICAL, MILITARY, AND AUTOMOTIVE APPLICATIONS DISCLAIMER: Atmel products are not designed for and will not be used in connection with any applications where

the failure of such products would reasonably be expected to result in significant personal injury or death (“Sa fety-Cr itical Appl ications”) without an At mel officer's specific written conse nt.

Safety-Critical Applications include, without limitation, life support devices and systems, equipment or systems for the operation of nuclear facilities and weapons systems. Atmel

products are not designed nor intended for use in military or aerospace applications or environments unless specifically designated by Atmel as military-grade. Atmel products are not

designed nor intended for use in automotive applications unless specifically designated by Atmel as automotive-grade.

AT16225: Atmel Smart Plug Hardware User Guide [APPLICATION NOTE]

Atmel-42689B-Atmel-Smart-Plug-Hardware-User-Guide_AT16225_ApplicationNote_07/2016

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Microchip:

ATSMARTPLUGUS ATSMARTPLUGEU ATSMARTPLUGCN ATSMARTPLUG-CN ATSMARTPLUG-US

ATSMARTPLUG-EU

Loading...

Loading...