Page 1

ATAVRAUTO200

..............................................................................................

User Guide

Page 2

Table of Contents

Section 1

Introduction ........................................................................................... 1-1

1.1 Overview ...................................................................................................1-1

Section 2

Using the ATAVRAUTO200.................................................................. 2-3

2.1 Overview ...................................................................................................2-3

2.2 Power Supply ............................................................................................2-4

2.3 Oscillator Sources .....................................................................................2-4

2.4 On-board Resources.................................................................................2-4

2.5 In-System Programming ...........................................................................2-8

2.6 Debugging...............................................................................................2-11

Section 3

Technical Specifications ..................................................................... 3-13

Section 4

Technical Support............................................................................... 4-14

Section 5

Complete Schematics......................................................................... 5-17

ATAVRAUTO200 User Guide i

7698A–AUTO–01/07

Page 3

Section 1

Introduction

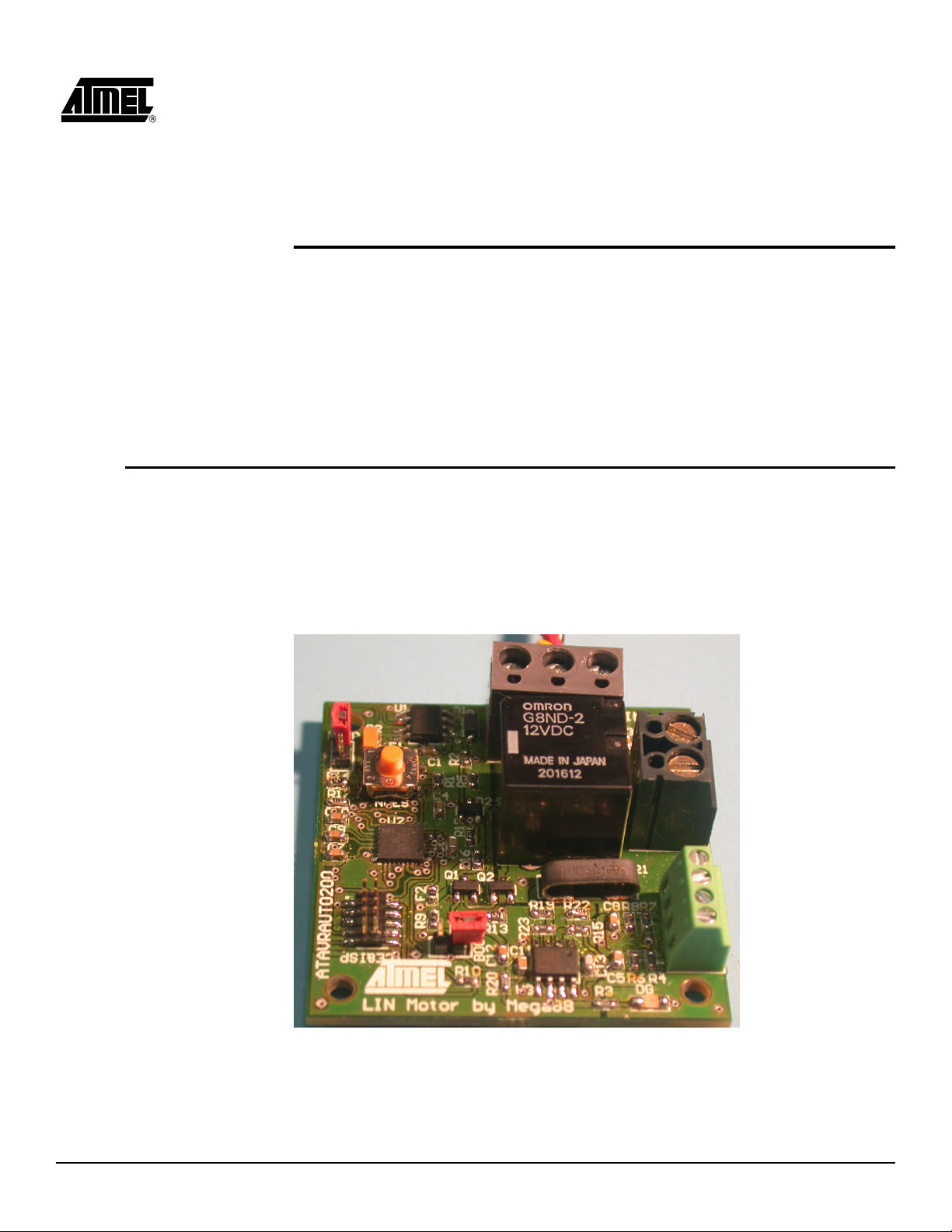

Congratulations on your purchase of the ATAVRAUTO200 board. This board includes

all elements necessary for designers to quickly develop code related to LIN communication node implementing the ATmega88 and for prototyping and testing of new designs.

1.1 Overview

This document describes the ATAVRAUTO200 dedicated to the ATmega88 AVR micro

controllers. This board is designed to allow an easy evaluation of the product using

demonstration firmware.

To increase its demonstrative capabilities, this stand alone board has numerous onboard resources (motor relay, motor FET, hall sensor inputs, current measurements,

power supply measurement, LIN, push buttons).

Figure 1-1. ATAVRAUTO200

ATAVRAUTO200 User Guide 1-1

7698A–AUTO–01/07

Page 4

Introduction

1.2 ATAVRAUTO200 features

The ATAVRAUTO200 provides the following features:

ATmega88 QFN32

AVR Studio® software interface

(1)

,

Power supply

– Regulated 5V

– From LIN connector (LIN network power supply)

JTAG connector:

– for on-chip In Situ Programming (ISP)

– for on-chip debugging using JTAG ICE

DC Motor connector

– DC Motor power supply output

– Hall effect sensor(s) power supply and input(s)

Serial interface:

– 1 LIN interface 1.3 and 2.0 compliant (firmware library available on the ATMEL

website for LIN 1.3).

On-board resources:

– 1 LIN transceiver with internal regulator

– Relay for DC motor control

– Shunt Resistor for motor current measurement

– Speed/Position measurement Inputs

– Power supply measurement

System clock:

– Internal RC oscillator

Dimension: 45 mm x 45 mm

Note: The ATmega88 is supported by AVR Studio, version 4.12 or higher. For up-to-

date information on this and other AVR tool products, please consult our web

site. The newest version of AVR Studio, AVR tools and this user guide can be

found in the AVR section of the Atmel web site, http://www.atmel.com.

1-2 ATAVRAUTO200 User Guide

7698A–AUTO–01/07

Page 5

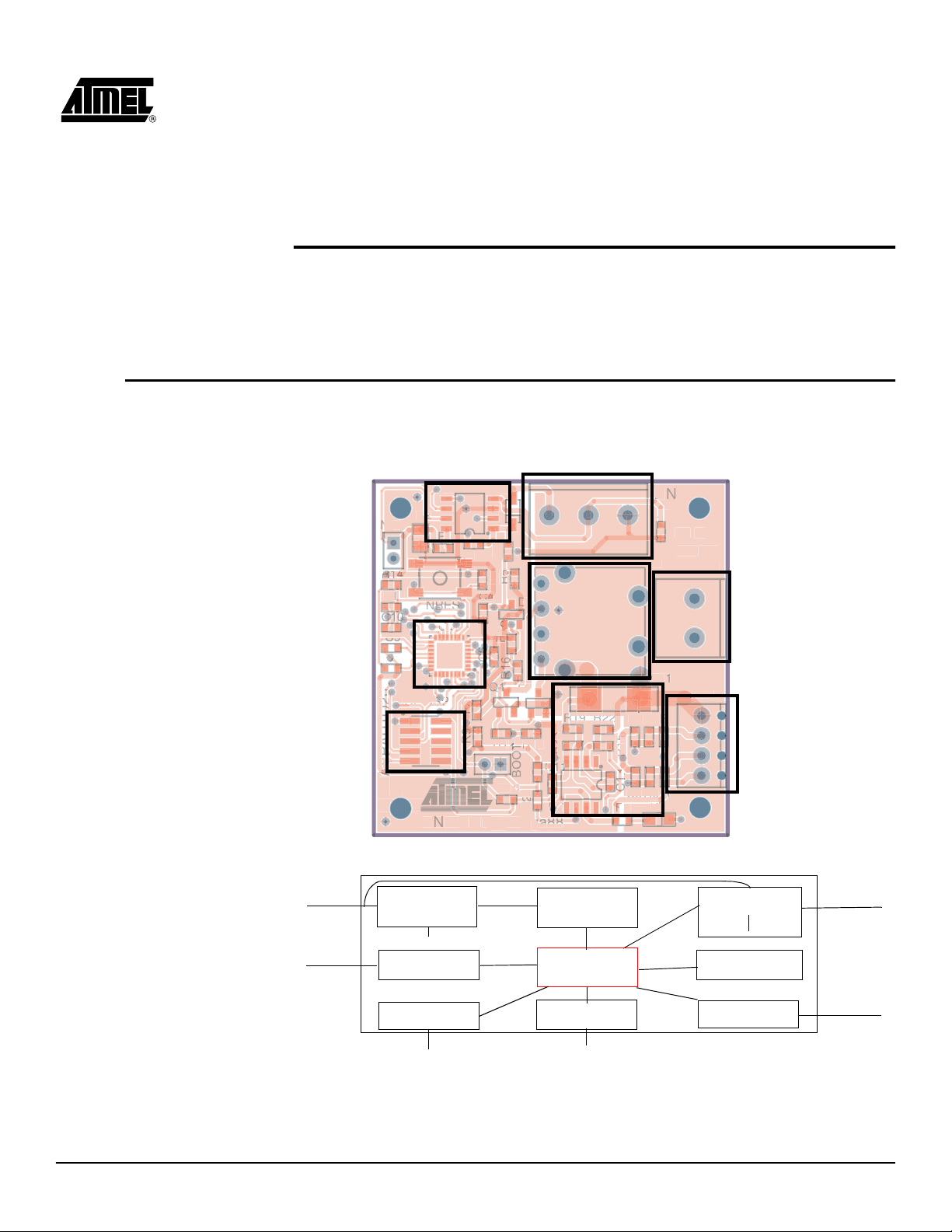

2.1 Overview

AT

AV

LIN

Connector

Motor Relay

Hall

Motor

Current

ATmega88

ISP

LIN

Measurement

Connector

Connector

Sensor

Transceiver

Regulator

Connector

ATmega88

JTAG

Power supply

Measurement

Lin Transceiver

Power supply

12 Vdc

from LIN

LIN

Network

DC Motor

Relay

Motor Shunt

Position sensor

Motor

Output

Motor ring

Hall sensor

ISP

ISP & Debugger

(AVR Studio)

ISP

(AVR Studio)

Section 2

Using the ATAVRAUTO200

Figure 2-1. Board Overview

Figure 2-2. Block Diagram

ATAVRAUTO200 User Guide 2-3

7698A–AUTO–01/07

Page 6

Using the ATAVRAUTO200

2.2 Power Supply

The on-board power supply circuitry is supplied through the LIN connector.

2.2.1 LIN powered The LIN connector power line is used to provide VBAT to the ATAVRAUTO200 LIN

transceiver.

A LIN network has to be connected to have your LIN interface function (Input supply

from 8 up to 18V DC, see Figure 2-3 on page 5) .

2.3 Oscillator Sources

The ATAVRAUTO200 board allows only one oscillator source:

Internal RC oscillator (Default configuration).

Note: The “Divide by 8” Fuse is configured by default. The first step in the demonstra-

tion application is to clear the prescaler to have the internal RC oscillator running at 8MHz:

CLKPR = (1<<CLKPCE); //! Clear Prescaler

CLKPR = 0;

2.3.1 Interal RC oscillatorn

A LIN Slave node with a run-time oscillator calibration can be used with the internal RC

oscillator.

At ambiant temperature and normal Vcc, the internal oscillator is precise enough to be

compliant with LIN 1.3 and 2.0 specifications. For wider temperature and/or power

ranges, a run-time calibration of the internal RC oscillator can be used as explained in

the application note AVR140: “ATMega48/88/168 family run-time calibration of the internal RC oscillator” available on the Atmel website.

2.4 On-board Resources

2.4.1 LIN & Power supply

The LIN screwed connector allows the user to select his own connector.

Note: The LIN power supply input is reverse voltage protected.

LIN transceiver control is realized by the micrcontroller. All modes depend on microcontroller’s ports configuration.

2-4 ATAVRAUTO200 User Guide

7698A–AUTO–01/07

Page 7

Using the ATAVRAUTO200

+VBat

G

N

D

L

I

N

V

IN

3.55 V

AD C

1

×=

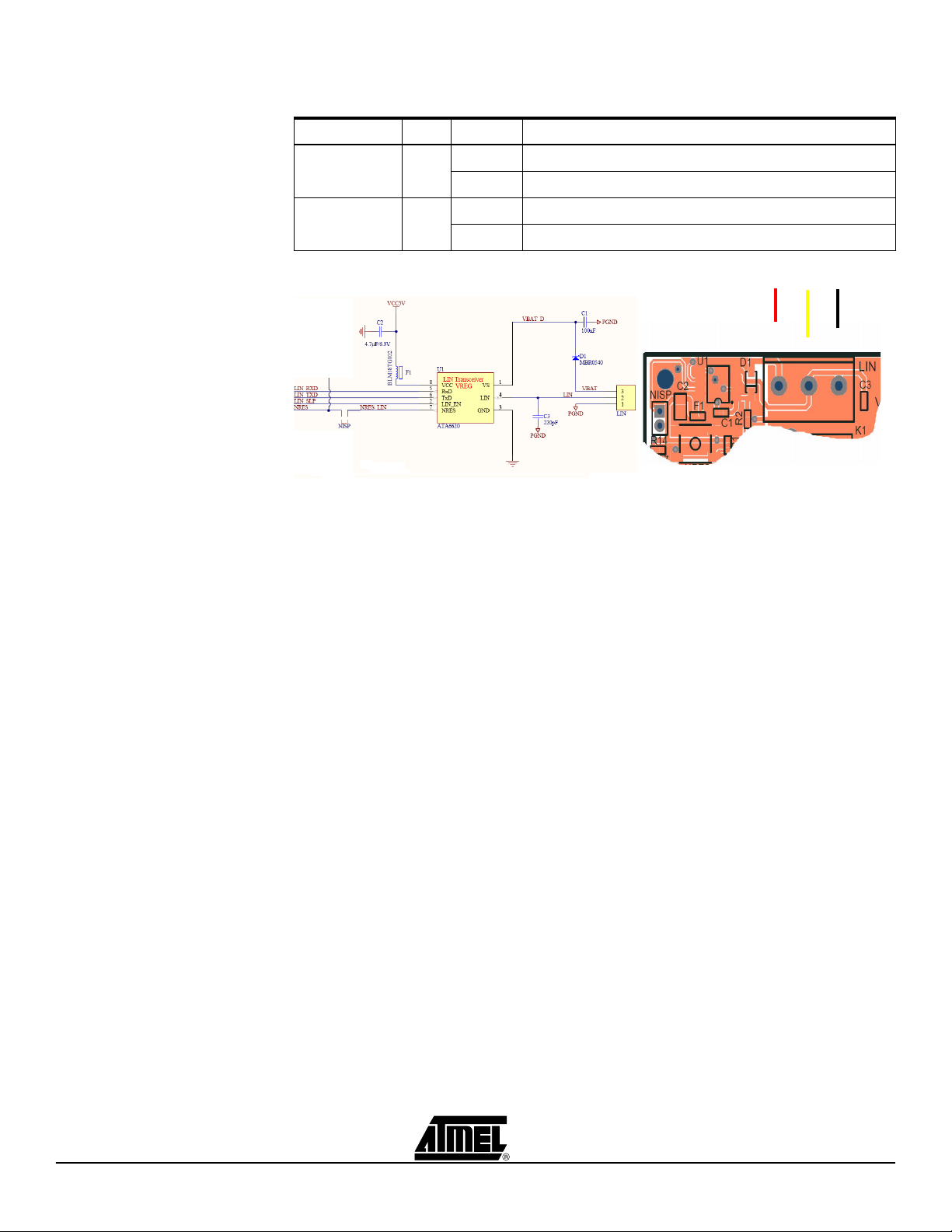

Table 2-1. LIN ressources

Function Port State Description

LIN_NSLP PD2 Low LIN transceiver in Sleep mode

High LIN transceiver in normal mode

NRES_LIN PC6 Low Perform MCU reset when NISP Jumper is inserted

High No Action

Figure 2-3. LIN transceiver and power supply

Note: The LIN transceiver undervoltage protection can be disabled by removing the

NISP jumper.

Note: The NISP jumper has to be removed when programming.

2.4.2 Power supply measurement

The voltage measurement is realized with a bridge of resistors. The read value is 0.281

of the LIN power supply (47 KΩ / (47 KΩ + 120 KΩ)). Input voltage on channel 1 of the

ADC is limited to 5.1V by a zener diode. This will give a voltage reading range from 0 to

18.1V with Vcc as reference.

The power supply measurement can be performed using the A/D converter. See the

ATmega48/88/168 datasheet for how to use the ADC. The input voltage value (VIN) is

calculated with the following expression:

Where: V

V

ADC7

IN

= Input voltage value (V)

= Voltage value on ADC-1 input (V)

ATAVRAUTO200 User Guide 2-5

7698A–AUTO–01/07

Page 8

Using the ATAVRAUTO200

2.4.3 Motor relay

Figure 2-4. Power supply measurement through ADC1

DC Motor can be operated through a relay. It is supplied with Vbat, -Vbat or 0V.

The relay allows the motor to be operated in two rotating directions, or to be stopped.

Table 2-2. Motor Relay commands

Function Port State Description

Mot_A PB1 Low/ Relay coil1 OFF (Normaly closed switch activated)

High Relay coil1 ON (Normaly opened switch activated)

Mot_B PB2 Low Relay coil2 OFF (Normaly closed switch activated)

High Relay coil2 ON (Normaly opened switch activated)

Table 2-3. Logical command table

Mot_A Mot_B Motor Supply Description

L L 0V Motor stopped

L H -Vbat Motor running (Direction B)

H L +Vbat Motor running (DirectionA)

H H 0V Motor stopped

Figure 2-5. Motor on board command schematics

2-6 ATAVRAUTO200 User Guide

7698A–AUTO–01/07

Page 9

2.4.4 Current measurement

V

ADC-0

Ga i n V

shunt

Ga i n R shunt I××=× 30,16 0.005 I××= =( )

V

ADC-0

0.151 I×=

+Vcc

Hall1

Hall2

GND

Using the ATAVRAUTO200

Motor current is measured using a shunt resistor. External differential amplifier (on

board) is connected to ADC to measure shunt resistor voltage.

Amplifer output (current image voltage) is connected to

ADC0 pin for current acquisition

AIN1 pin to detect max current peak (compared to AIN0 through internal analog

comparator)

The current measurement (I) can be performed using the A/D converter. See the

ATmega48/88/168 datasheet for how to use the ADC. The input voltage value (V

ADC-0

is calculated with the following expression:

Analog comparator allows peak current detection. It provides interrupts on analog comparator output change. See the ATmega48/88/168 datasheet for how to use the Analog

comparator. Comparison voltage is determined for a 12A peak which leads to:

)

V

AIN0

= 1.5V

Figure 2-6. Current Acquisition chain and current Peak detection

2.4.5 Speed/Position measurement inputs

A screw connector with 4 inputs can be used to plug two hall effect sensors. The two hall

effect sensors inputs are connected to the two external interrupt pins (INT0 and INT1) of

the microcontroller.

Figure 2-7. Hall sensor effect interface

ATAVRAUTO200 User Guide 2-7

7698A–AUTO–01/07

Page 10

Using the ATAVRAUTO200

2.4.6 LED

2.4.7 BOOT

The ATAVRAUTO200 includes one green LED implemented on one I/O pin. It is connected to the “ PortD Pin3” of the ATm ega48/88/168. To light O n the LED, the

corresponding port pin must drive a low level. To light Off the LED, the corresponding

port pin must drive a high level.

Figure 2-8. LED schematic

An additional jumper (BOOT) has been added. This jumper is available for custom use.

For example : the BOOT jumper can be used to switch from the application to the bootloader by firmware (Not implemented in the example) by reading the pin7 of PortB.

Figure 2-9. BOOT Jumper

2.5 In-System Programming

The ATmega88 can be programmed using specific SPI serial links. This sub section

will explain how to connect the programmer.

The Flash, EEPROM memory (and all Fuse and Lock Bit options ISP-programmable)

can be programmed individually or with the sequential automatic programming option.

Note: If debugWire fuse is enabled, AVR ISP can’t be used. If debugWire fuse is dis-

Note: When programming, the NISP jumper has to be removed.

abled, JTAGICE mkII have to be used in ISP mode to enable debugWire fuse.

2-8 ATAVRAUTO200 User Guide

7698A–AUTO–01/07

Page 11

2.5.1 Using the ATAVRAUTO900 Adaptator

JTAGICE

ISP

The arrow has to be in front of the point

An additionnal adaptator has to be used to program the board using IPS or JTAG mode.

The 10 pins connector is used for the JTAGICE mkII device and the 6 pins connector is

used for the AVRISP device. To plug the ATAVRAUTO900 connector to the board, the

arrow (on the adaptator) has to be in front of the point (on the board).

Figure 2-10. ATAVRAUTO900 Connection

Table 2-4. ICE Connector

Using the ATAVRAUTO200

PIN Function

1 TCK

2 GND

3 TDO

4 VCC

5 TMS

6 NRES

7 VCC

8 NC

9 TDI

10 GND

Table 2-5. ISP Connector

PIN Function

1 MISO

2 VCC

3 SCK

4 MOSI

5 NRES

6 GND

ATAVRAUTO200 User Guide 2-9

7698A–AUTO–01/07

Page 12

Using the ATAVRAUTO200

AVR ISP

JTAGICE mkII

2.5.2 Programming with AVR ISP Programmer

The AVR ISP programmer is a compact and easy-to-use In-System Programming tool

for developing applications with ATmega88. Due to its small size, it is also an excellent

tool for field upgrades of existing applications. It is powered by the ATAVRAUTO200

and an additional power supply is thus not required.

The AVR ISP programming interface is integrated in AVR Studio.

To program the device using AVR ISP programmer, connect the AVR ISP to the adaptato r (A TA V RAUT O9 00 ) and co n ne ct th e ad a ptat or to the c on nec t or of the

ATAVRAUTO200.

Figure 2-11. Programming from AVR ISP programmer using ATAVRAUTO900.

Note: See AVR Studio® on-line Help for information.

2.5.3 Programming with AVR JTAGICEmkII

The ATmega48/88/168 can be programmed using specific JTAG link: 3-wire debugWIRE inte rfac e . To u se the AVR J T A GICEmkII w i t h an ATAVRAUTO200 thr

ATAVRAUTO900 adaptator has to be be used. Then the JTAG probe can be connected

to the ATAVRAUTO200 as shown in the following Figure 2-12.

To use the JTAGICEmkII in ISP mode the 3 jumpers “SCK”, “MISO” and “MOSI” of the

adaptator (ATAVRAUTO900) should be connected.

Figure 2-12. JTAGICE mkII probe connecting through debugWIRE interface

Note: When the debugWIRE Enable (DWEN) Fuse is programmed and Lock bits are

Note: See AVR Studio® on-line Help for information.

unprogrammed, the debugWIRE system within the target device is activated.

R E SE T p in i s c on f i g ur ed as co mm un ic a ti on ga t ew ay be tw e en

ATmega48/88/168 and JTAG. JTAGICE mkII must have control over it.

2-10 ATAVRAUTO200 User Guide

7698A–AUTO–01/07

Page 13

2.6 Debugging

2.6.1 Debugging with AVR JTAGICEmkII

The ATAVRAUTO200 can be used for debugging with JTAG ICE MK II.

Connect the JTAG ICE mkII as shown in Figure 2-12 for debugging, please refer to AVR

Studio Help information.

Using the ATAVRAUTO200

ATAVRAUTO200 User Guide 2-11

7698A–AUTO–01/07

Page 14

-12 ATAVRAUTO200 User Guide

7698A–AUTO–01/07

Page 15

Section 3

Technical Specifications

System Unit

– Physical Dimensions...............................................L=45 x W=45 x H=8 mm

– Weight ........................................................................................................25 g

Operating Conditions

– Internal Voltage Supply ..... ...................................................................... 5.0V

– External Voltage Supply .....................................................................7V -18V

ATAVRAUTO200 User Guide 3-13

7698A–AUTO–01/07

Page 16

Section 4

Technical Support

For Technical support, please contact avr@atmel.com. When requesting technical support, please include the following information:

Which target AVR device is used (complete part number)

Target voltage and speed

Clock source and fuse setting of the AVR

Programming method (ISP, JTAG or specific Boot-Loader)

Hardware revisions of the AVR tools, found on the PCB

Version number of AVR Studio. This can be found in the AVR Studio help menu.

PC operating system and version/build

PC processor type and speed

A detailed description of the problem

ATAVRAUTO200 User Guide 4-15

7698A–AUTO–01/07

Page 17

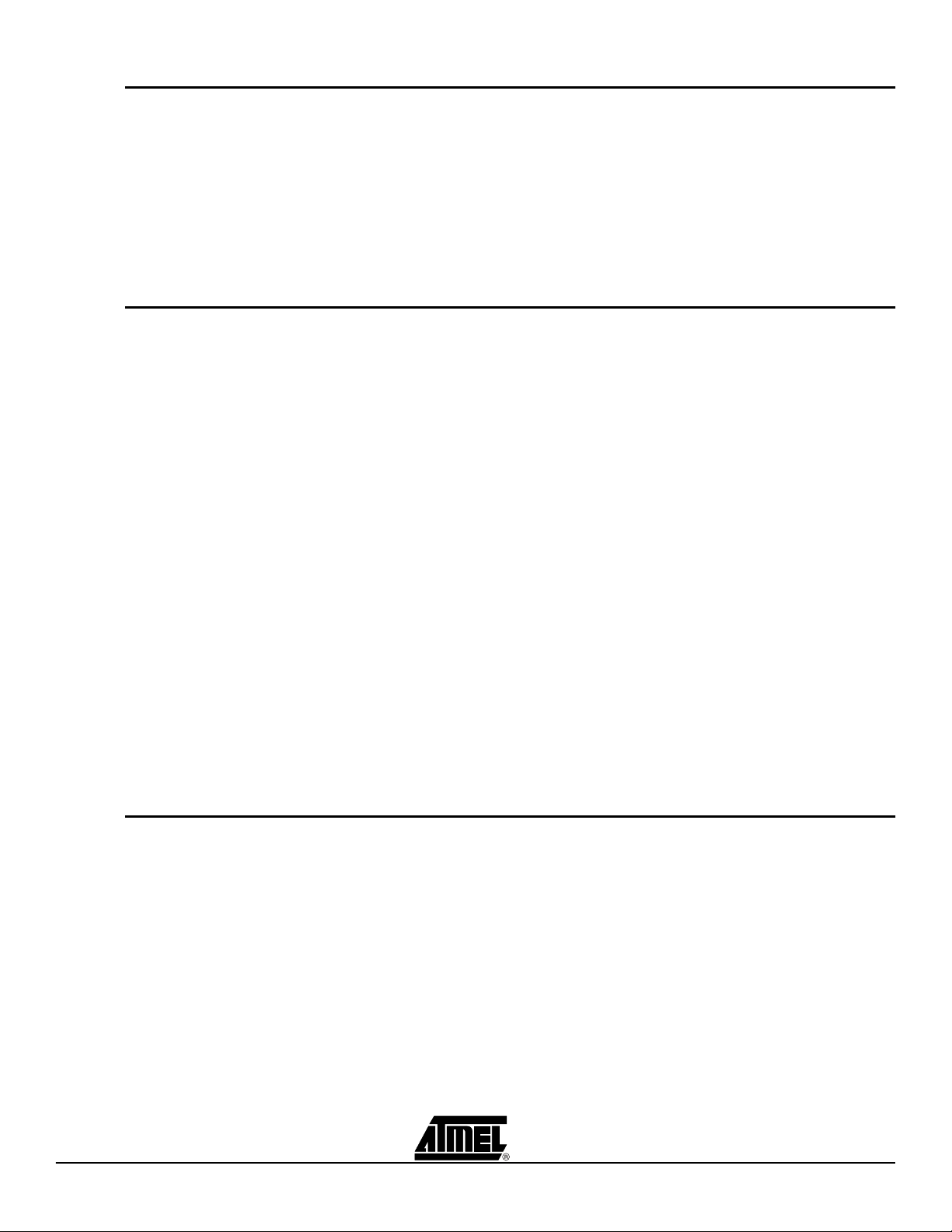

Section 5

Complete Schematics

On the next pages, the following documents of ATAVRAUTO200 are shown:

Complete schematics,

Bill of materials,

Assembly drawing.

ATAVRAUTO200 User Guide 5-15

7698A–AUTO–01/07

Page 18

Complete Schematics

Figure 5-1. ATAVRAUTO200 schematic

5-16 ATAVRAUTO200 User Guide

7698A–AUTO–01/07

Page 19

Figure 5-2. ATAVRAUTO200 Bill of Materials

Complete Schematics

ATAVRAUTO200 User Guide 5-17

7698A–AUTO–01/07

Page 20

Complete Schematics

LIN Motor by Mega88

C1

R10

C6

C4

R1

R12

Q1

BOOT

R16

R18

R5

R2

R20

U3

R3

C12

C11

R13

R23

R15C13

C5R6

DG

R4

R19 R22

Q2

D2

C8R8R7

HALL

R21

K1

C3

MOT

PM-06

V1.0

ATAVRAUTO200

C10

R17

NISP

R14

C7

C9

C2

ICE&ISP

U2

F1

NRES

R9 F2

U1

D1

LIN

Figure 5-3. ATAVRAUTO200 assembly drawing

5-18 ATAVRAUTO200 User Guide

7698A–AUTO–01/07

Page 21

© 2007 Atmel Corporation. All rights reserved.

Atmel®, logo and combinations thereof, Everywhere You Are

® ,

AVR®, AVR Studio® and others are

registered trademarks or trademarks of Atmel Corporation or its subsidiaries. Windows® and others are registered trademarks

or trademarks of Microsoft Corporation in the US and/or other countries. Other terms and product names may be trademarks of others.

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

Eas t Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

Eas t Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Pos tfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

Disclaimer: Atmel Corporation makes no w arranty for the use of its products, other t han those expressly contained in the Company’s standard

warranty which is detailed in Atmel’s Terms and Conditions located on the Compa ny’s web site. The Com pany assum es no responsibility for any

errors whic h may appear in this docu ment, reserves the right to change devices or specifications detailed herein at any time without notice, and

does not make any comm itment to update the information contained herein. No licenses to patents or other intellectual property of Atmel are

granted by the Company in conne ction with the sale of Atmel products, expressly or by implication. Atmel’s products are not authorized for use

as critical components in life support devices or systems .

Printed on recycled paper.

7698A–AUTO–01/07

/xM

Loading...

Loading...