Page 1

Installation Guide

BC12-17-2

Dual Off-Set Hang Point Beam Clamp

The BC12-17-2 channel style beam clamp to provide a load rated overhead rigging point

from structural I-Beams with ange widths ranging between 12” and 17” and with ¼” to

1” thick anges. This beam clamp model provides a fast, easy and safe way to suspend

direct loads, bridles and hitches from overhead.

Important: : Rigging overhead system requires professional experience. Improperly

installed equipment can result in property damage, personal injury, death and/or liability

to the installing contractor. Do not suspend if in doubt about the integrity of the structure.

NOTE:

Do not exceed the working load limit of 980 lbs / 445 Kg..

The BC12-17-2 is not to be used for suspending personnel.

Recommended torque = 40-50 ft/lb

Contents:

Be sure that all of the following items are included in this kit before proceeding:

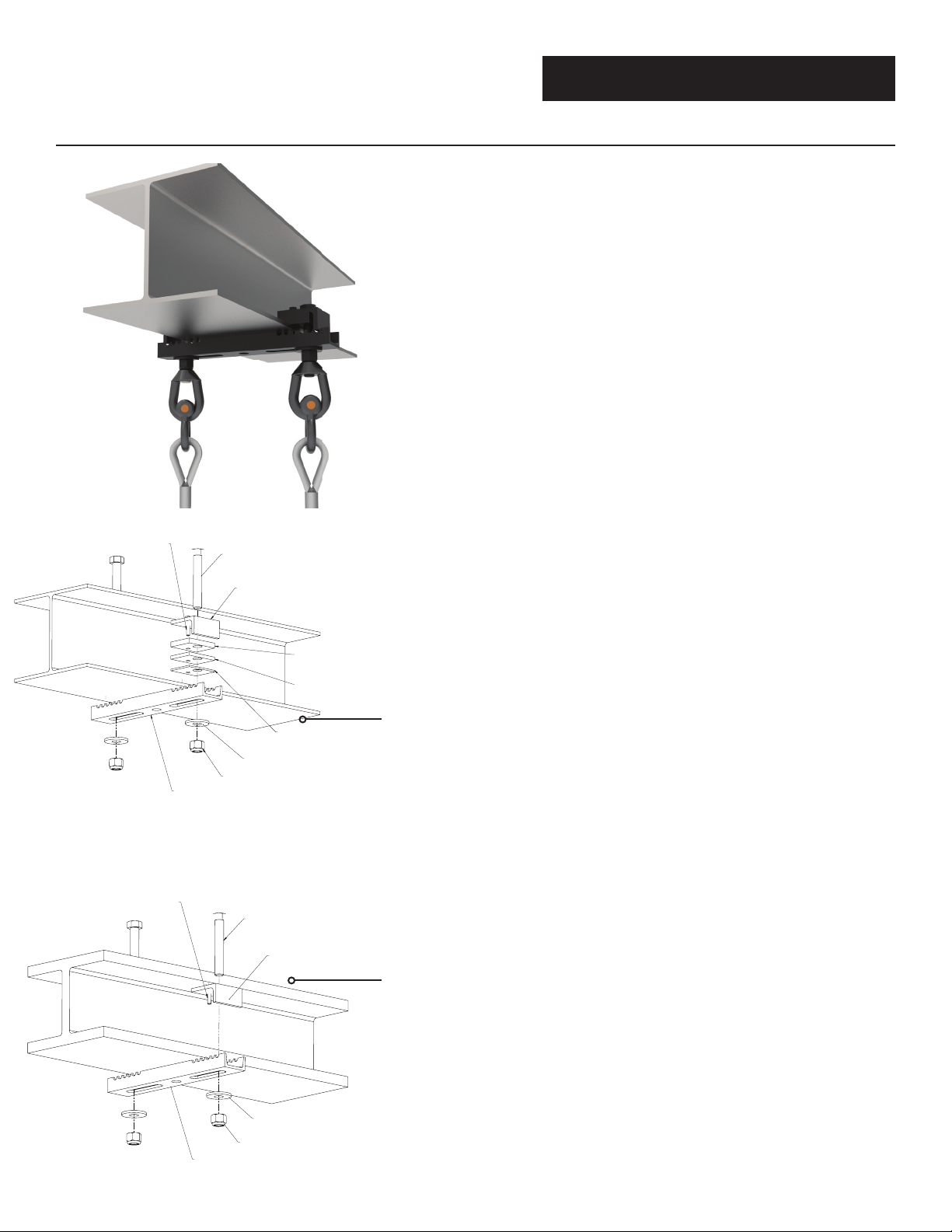

Figure 1

SPACER PLATE

ALIGNMENT SCREW (2X)

Figure 2

SPACER PLATE

ALIGNMENT SCREW (2X)

DISCARD IF NO SPACER PLATE IS USED

HEX TAP BOLT

5/8-11X 4.5" LONG, G8 (2X)

7-8244

LOCKING ANGLE TABS (2X)

BEAM CLAMP CHANNEL

NYLOC NUT, 5/8-11, G8

7-8295

3/8" SPACER PLATE (2X)

7-8293

1/4" SPACER PLATE (2X)

7-8291

1/8" SPACER PLATE (2X)

FLAT WASHER, 5/8 USS (2X)

HEX TAP BOLT

5/8-11X 4.5" LONG, G8 (2X)

7-8244

LOCKING ANGLE TABS (2X)

1 pc 12”-17” Beam clamp assembly

2 pcs 5/8 Eyenut

1 pc Instruction sheet

Installation Procedure:

Step 1:

Determine the thickness of the I-beam’s ange to properly select the right spacer plate to

use. Remove the 5/8” nyloc nut and at washer to test fi t the locking plate and spacers.

Try a different combination of single, double of all three spacer plates (fi gure 1).

Step 2:

Re-install the 5/8” nyloc nut and at washer when the appropriate spacer plate is

determined. Attach the beam clamp to the structure’s I-beam (Figure 1 and 2).

FLAT WASHER, 5/8 USS (2X)

NYLOC NUT, 5/8-11, G8

BEAM CLAMP CHANNEL

Page 2

Installation Guide

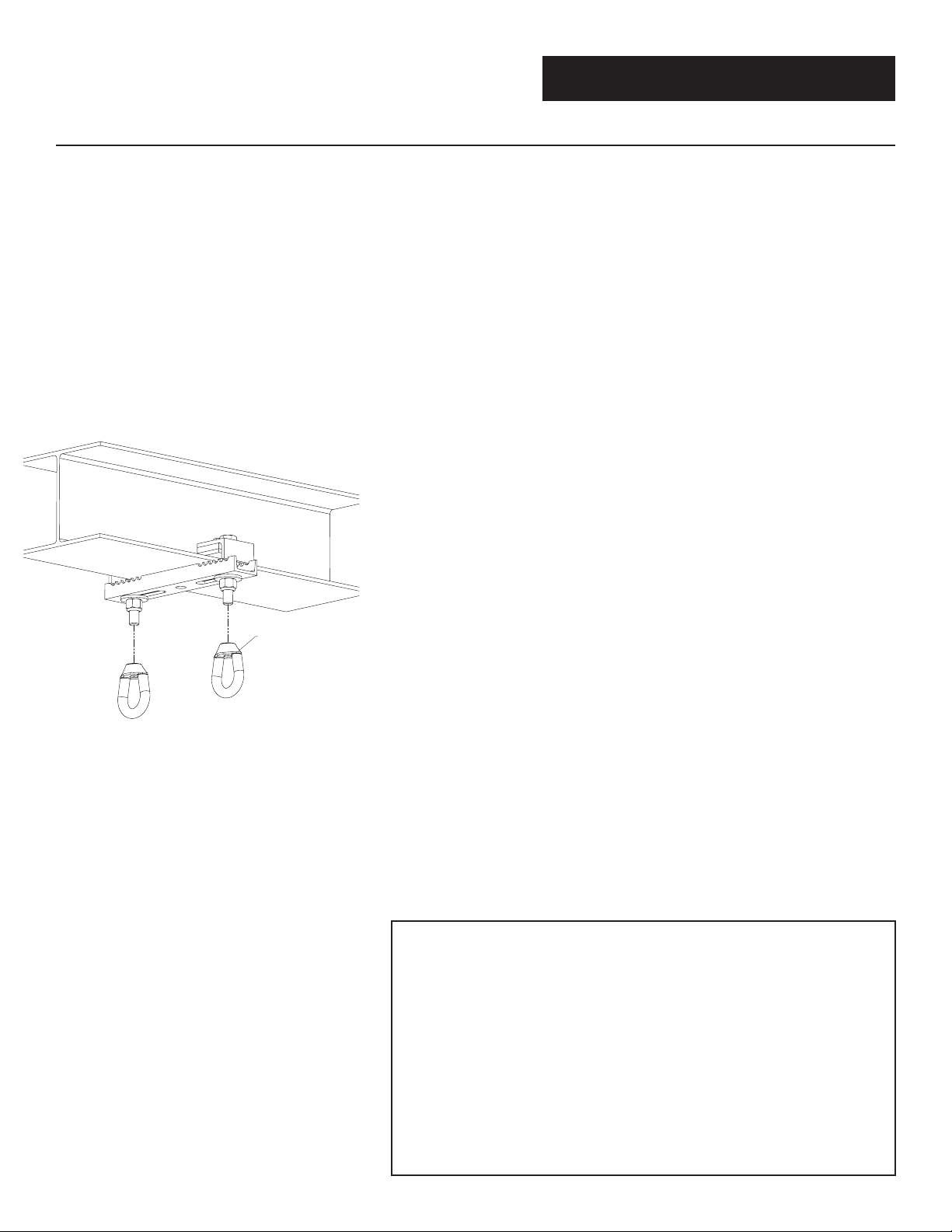

Figure 3

BC12-17-2

Dual Off-Set Hang Point Beam Clamp

Step 3:

Center the beam clamp on the bottom of the I-beam’s ange. Position the locking

channel’s locking angle tabs with the appropriate spacer plates above the I-beam’s

anges. Slide the locking channel tabs against the sides and get the bolt as close as

possible to the anges. Make sure the locking channel tabs are seated on the channel’s

grooves. Tighten the nuts permanently.

EYENUT 5/8-11 (2X)

Step 4:

Attach the eye-nuts on the threads of the bolt, tighten permanently (Figure 3).

Recommended torque = 40-50 ft/lb

Step 5: Check System

Check all connections to make sure all bolts and nuts are tightened.

Step 6:

Suspend equipment evenly to the provided eyenuts on the beam clamp using load rated

hardware (Figure 4).

Note to installers:

Due to the wide variety of wall structures, materials and mounting methods, the

installing contractor must exercise proper judgment in selecting the mounting area and

hardware.

As a guide, the installation, when complete should be capable of supporting 5 to 10

times the actual applied load. Always use a backup safety system such as a safety

cable.

To assure a trouble-free installation, read through and follow these instructions

carefully before beginning. If you have doubts about the integrity of the structure

you are mounting to or you are not sure about the proper hardware to use, consult a

structural and/or hardware specialist.

Loading...

Loading...