INST

L

S

E

S

E

S

E

To

next

From:

device

ALLA

TION AND MAINTENANCE INSTRUCTIONS

AGB02

Fire

Str

obe Light

Specifications

V

oltage R

ange:

Power Consumption: 35mA 1.5W Max

Flash

Frequency:

Oper

ating T

Brightness: 120 cd/m2

IP Rating: IP54

Standard:

Clause 9.7 of BS5839, EN54-23: 2010, HKFSD circular 4/2001, UL1638

General Description

AGB02 Fire Strobe Light utilizes super bright LEDs which generates a

high-intensity light, visible from all sides of the lens to provide a visible

notification signal for the purpose of life safety and property protection.

It is ideal to be installed at hotels, apartments, hospitals, commercial

buildings, residential buildings, shopping malls or wherever visible

alarms are required.

Having considered power saving for the fire alarm system, we adopted

the best quality LEDs, which consume less current while maintaining

the brightness comparable to the traditional Xenon strobe does.

Besides, customers can also save on material costs by slashing the

battery and the battery charger size. For facilitating the wiring work,

our strobes can achieve self synchronization through power cables

and no additional signal cables or equipment are required.

emper

ature:

DC or F

1-2.5 Hz

-10° C

ull-Wave R

self-Synchronized

to 65° C

ectified 24-volt models – 18

NO

TICE: This manual shall be left with the owner/user of this equipment.

Fir

e Alarm System Considerations

Power Supply Considerations

P

anels typically supply DC filter

r

ectified) voltage

number of units used in a zone based on the type of panel supply. Be

certain the sum of all the de

capability of the panel.

curr

ent found in the subsequent charts and must be the current

specified for the type of panel power sup

System Wiring

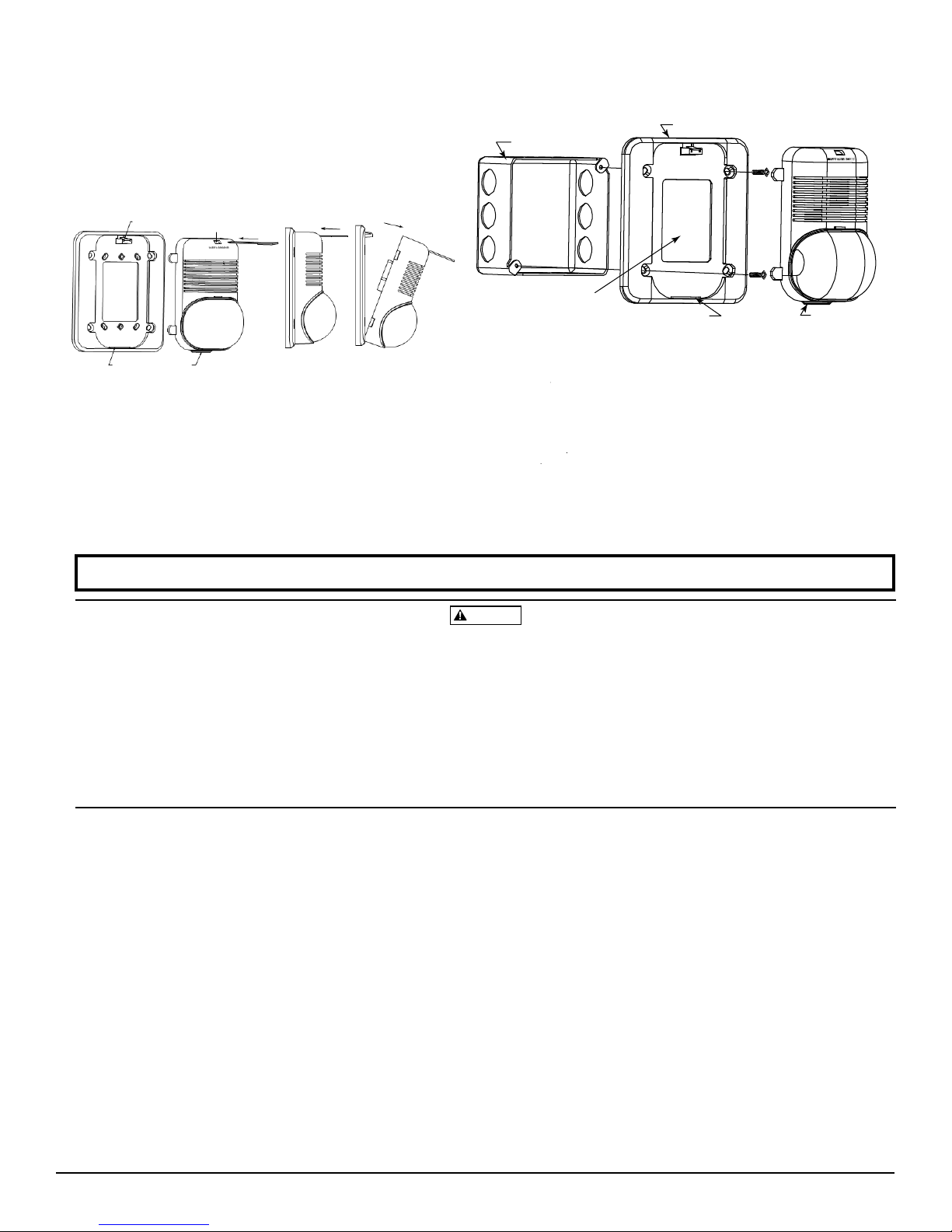

Figur

e 1. Strobes power

(+)

FACP

or

MODULE

(–)

. The system design engineer must calculate the

Calculations ar

: Self-Synchr

ed in tandem by a 2-wir

(+)

T

R

O

B

(–)

(+)

device

or EOL

(–)

ed v

oltage or FWR (full-wav

vice curr

ents do not exceed the curr

e based on using the de

ply used.

onized Devices

(+)

T

R

O

B

(–)

+24V GND

e cir

sticker

(+)

(–)

cuit:

(+)

T

R

O

B

(–)

jumpers

FACP, module

or previous

ent

vice

to 28 volts

Wire

Sizes

The designer must be sure that the last de

v

oltage to oper

v

oltage available to the last device, it is necessary to consider the v

dr

op due to the r

v

oltage dr

the system, it is best to consider all of the de

of the supply cir

ate the de

esistance of the wire.

op. Gener

ally,

cuit (simulates “wor

vice within its r

for purposes of determining the wir

vice on the cir

ated v

oltage

The thicker the wire,

vices as “lumped”

st case”).

. When calculating

e size necessary for

T

ypical wire size r

18 AWG solid:

16 AWG solid:

14 AWG solid:

12 AWG solid:

Ex

ample: Assume you have 10

mA average and 2

return). The v

10 de

vices x 3 ohms/1,000 ft. x 2

e

The same number of devices using 12 A

dr

op. The same de

Consult y

v

oltage range to determine acceptable voltage drop.

Note: If class “A

the single wire length in this calculation.

Flash Rate

Strobes ar

may be selected using the jumper plugs located on the printed circuit board.

You can discover the sticker to find the jumpers.

Figur

e 2. Jumper Setting

E

O

NO

TE: Always power do

1

esistance:

000 Ft. of 14 AWG

oltage at the end of the loop is 0.050 amps per de

our panel manufactur

” wiring is installed, the wir

Selections

e factory set for 1.5Hz (90 flashes per minute). Four frequencies

The right jumper is plugged: 1Hz (60 flashes per minute)

No jumper is plugged: 1.5Hz (90 flashes per minute)

The left jumper is plugged: 2Hz (120 flashes per minute)

Both jumpers are plugged: 2.5Hz (150 flashes per minute)

Approximately 8 ohms/1,000 ft.

Approximately 5 ohms/1,000 ft.

Approximately 3 ohms/1,000 ft.

Approximately 2 ohms/1,000 ft.

de

vices on a zone and each r

wiring (total length=outgoing +

000 ft =3 v

vices using 18 A

er’

s specifications

olts dr

WG wir

WG wir

e will pr

e length may be up to 4 times

wn de

vices before setting jumpers.

op.

e will pr

, as w

oduce only 2 v

oduce 8 v

ell as the oper

cuit has sufficient

the

olt

age

the less

equir

vice x

AGB02-25

the

on the end

es 50

olts

olts dr

op.

ating

-00

Mounting Diagrams

Figur

e 3: Removal of str

To r

emove

strobe fr

sc rewdriver

screwdriver

str

obe module, disengage the Locking Rib

fr

om the mounting plate.

PLASTI C SNAP LEVE R

as sho

to r

elease the snap, pull back on the str

obe fr

om mounting plate:

om mounting plate, insert sui table slotted

wn to unlock snap. While

INSER T SCREW DRIVER

pushing in the slotted

obe

, and lift the str

. Hinge the

obe away

TAB SL OT

TAB

Please r

The

str

obe will not w

from the fire/security panel monitoring the

off for an

visual warning.

y r

eason, the horn/str

The signal strobe may not be seen. The electr

uses e

xtr

The str

emely reliable LED lights. It flashes at least once every second.

obe must not be installed in dir

intensity (over 60 foot candles) where the visual flash might be disr

egar

ded or not seen. The str

ATM

w

arr

ants its enclosed str

workmanship under normal use and service for a

date of manufacture.

No agent, repr

authority to incr

The Company’s obli

r

eplacement of an

materi

als or w

y

ear

period commencing with the date of manufacture.

ATM’s

orkmanship under normal use and service during the two

service

defective units postage pr

2

ork without power.

ATM

esen

tative,

ease or

alter the obligations or limitations of this Warr

gation of this Warranty shall be limited to the repair or

y part of the strobe

number for a R

efer to inser

t for the Limitations of Fir

The

str

obe gets its power

alarm system. If power is cut

obe will not provide the desir

onic visual w

ect sunlight or ar

obe ma

y not be seen b

obe

to be free from defects in materials and

y the visually impair

period of two year

makes no

dealer

other e

, or employ

xpr

ess w

arranty for this strobe

ee of the Compan

which is found to be defective in

eturn Authorization number

epaid to ATM or the distributor.

The Limitations of

ed audio or

arning signal

eas of high

Two-Year Limited War

s fr

y has the

After phoning

, send

Figur

e 4:

Str

obe with mounting plate and back box

4-INCH BACK BOX

MOUNT ING P LATE

WALL OPENING MUST

EQUAL PLATE OPENING

1. Mount plate to back bo

is

equal to the plate opening.

2. Complete field wiring.

3. Insert locking rib into slot on plate

4. Press into plate, unit will make a “click” when it has locked into

place.

Scr

ew types used for mounting: 8-32 x

WARNING

Str

obes

The signal strobe may cause seizures.

photic response to visual stimuli with seizures, such as per

epilepsy,

str

obe signals

The signal strobe cannot oper

power supplies produce interrupted power.

light

terrupted source of power in or

ed.

ranty

om

anty

Please include a note describing the malfunction and suspected cause

of failure.

.

which ar

modifications, or alter

.

no case shall the Compan

damages for breach of this or an

whatsoever,

negligence or fault. Some states do not allo

of

incidental or consequential damages, so the above

exclusion may not apply to you. This Warranty giv

rights, and you may also have

AGB02-25

LOCK ING RIB SLOT

x using screws A, making sure w

.

3⁄

4

flat head

e Alar

m Systems

Individuals who have

should avoid pr

, including this str

olonged exposur

obe

, ar

e activ

ate fr

om coded power supplies

e to environments in which

ated.

The strobe must have

der to operate correctly.

The Compan

y shall not be obligated to r

e found to be defective because of damage

ations occurring after the date of man

y be liable for an

y other Warr

y consequential or incidental

anty

even if the loss or damage is caused by the Company’s

w the e

other rights which vary fr

LOCK ING RIB

all opening

positiv

sons with

. Coded

an unin-

epair or replace units

, unreasonable use

ufacture.

, e

xpr

essed or

xclusion or limitation

es y

ou specific legal

om state to state

implied

limitation or

-00

e

,

In

.

Loading...

Loading...