Page 1

Subsidiary of Mercury Aircraft, Inc.

N

N

N

N

1135 N.W. 159th DR., MIAMI, FL 33169

PHONE (305) 625-2451, (800) 762-7565, FAX (305) 623-0475, E-mail: sales@atlasfoodserv.com

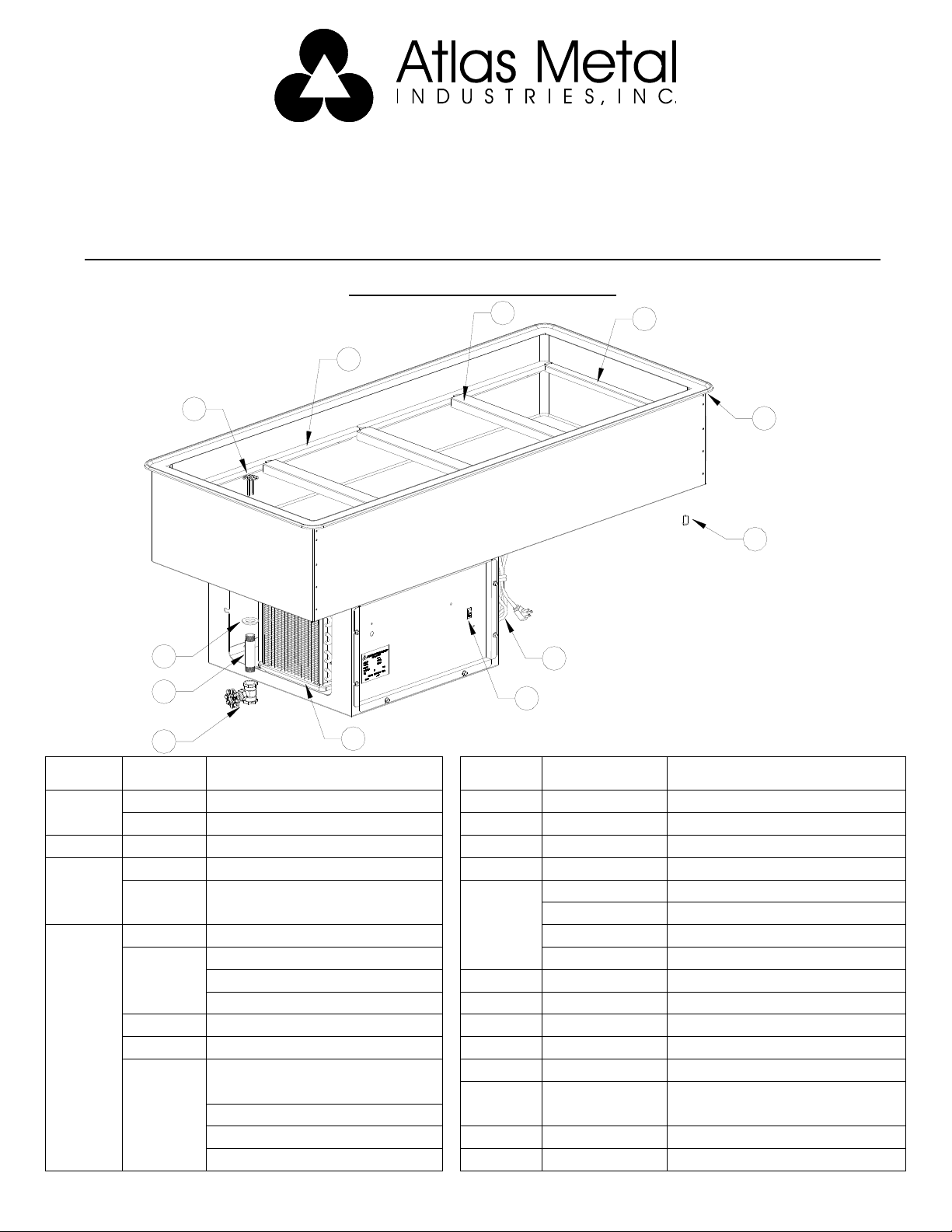

PARTS LIST FOR RECESSED MECHANICAL COLD PANS

12

11

RM & RML SERIES

1

4

2

7

8

3

5

6

RM-4 SHOWN

10

ITEM

UMBER

1

2 86-3202 Perforated Snap- In Drain 7 1003-0 Power Cord with Plug

3

4

PART

UMBER

S80103-0 Separator Channel (RM)

S85008-0 Separator Channel (RML) 6 7020-0 Nylon Spacer

S83432-0 Pan Rail End RM’S (2 Req’d) 8 1069-1 Switch with Light

S83442-0

S83438-0 Pan Rail Sides for RM-1 (2 Req’d) 2029-6 1/3 H.P. Compressor

S83440-0

S83439-0 Pan Rail Sides for RM-3 (2 Req’d) 12 49-1028 Grommet

S83441-0 Pan Rail Sides for RM-5 (4 Req’d) 13 22-1397 Thermostat (Not Shown)

S83443-0

DESCRIPTION

Pan Rail Ends for RM-1, RML,

(2 Req’d)

Pan Rail Sides for RM-2 (2 Req’d)

Pan Rail Sides for RM-4 (4 Req’d)

Pan Rail Sides for RM-6 (6 Req’d) 11 30-3130 PVC Nipple

Pan Rail Sides for RML Only

Pan Rail Sides for RML-2 (4 Req’d)

Pan Rail Sides for RML-3 (6 Req’d) 16 494-54(not shown 1/4 Expansion Valve RM-4-5-6

Pan Rail Sides for RML-4 (8 Req’d) 17 494-53(not shown 1/8 Expansion Valve RM-2-3

9

ITEM

UMBER

5 7002-0+Model # Vinyl Bead Gasket

9

10

14 2024-2 Drier (Not Shown))

15 2027-0

PART

UMBER

2029-0 1/5 H.P. Compressor

2029-5 1/4 H.P. Compressor

2029-7 1/2 H.P. Compressor

3016-2 Stop Valve

DESCRIPTION

0.031 Cap Tube (for 1/5 H.P) Comp.

(Not Shown)

Page 2

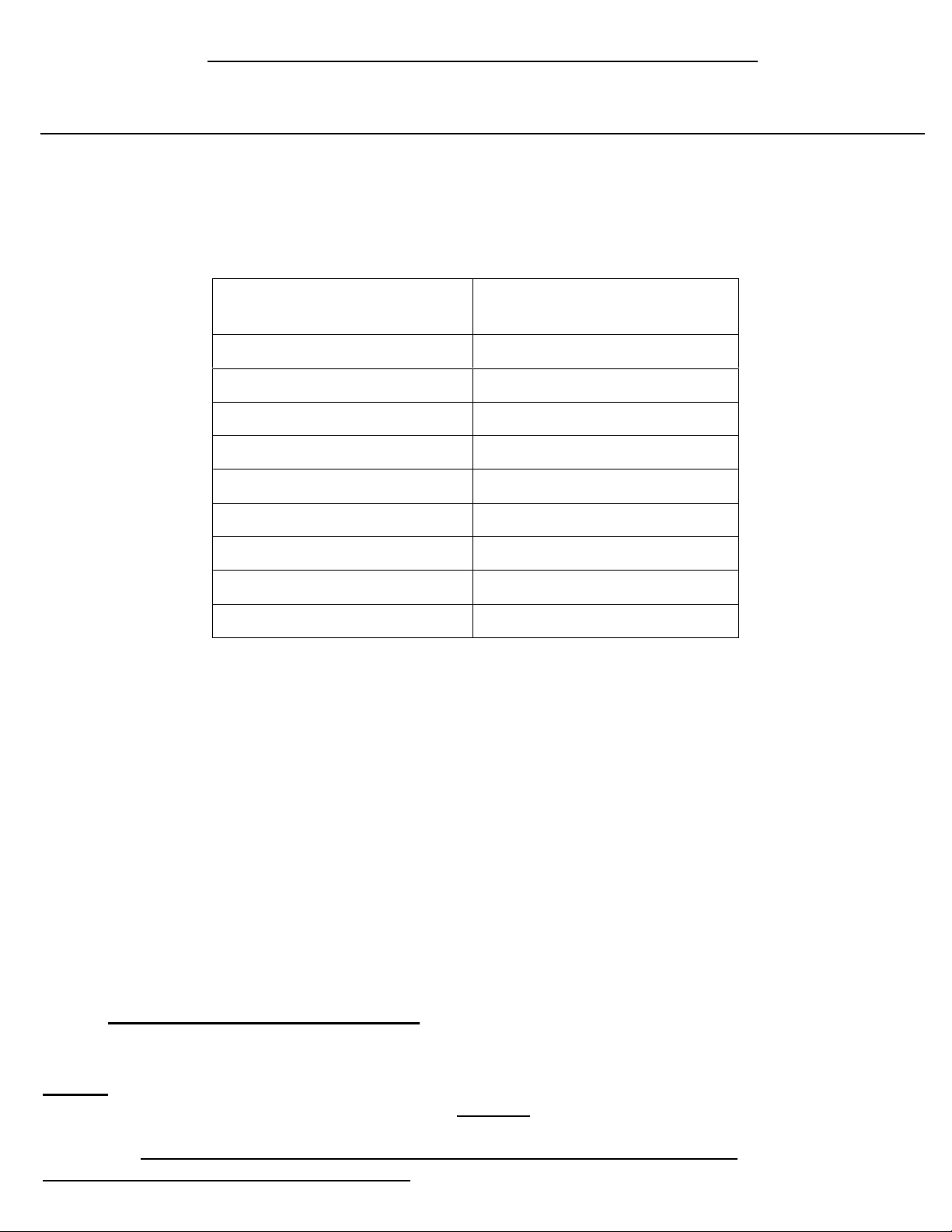

RECESSED MECHANICAL COLD PANS

RM & RML SERIES

INSTALLATION

Provide the correct counter cut-out opening (see chart below) and drop in. The vinyl gasket assures complete seating.

A non-toxic silicone seal may be used between the gasket and counter top (not required).

Note: Units are supplied with a nipple and gate valve to be connected for draining.

--------------------------------------------------------------------------------------------------------------------------------------------The unit should be level for draining purposes. When installing unit in a counter, it is recommended that the operator

side of the counter be completely open for air circulation. When this is not possible, such as in an island counter, it is

recommended that two grill openings are provided approximately 18” x 18” of free air for intake and exhaust at the

opposite ends of the counter. Also the counter must have an opening of approximately 24” x 14” to access the

compressor for maintenance. Then the compressor can be reached by removing four (4) screws from the control and

rear panels.

The unit is supplied with a power cord and NEMA plug. Refer to the data plate on the compressor housing for the

amperage and voltage information. Use a licensed electrician when installing power source.

------------------------------------------------------------------------------------------------------------------------------------------Note: see TABLE# 1 for BTU/HR and evaporator temperatures.

-------------------------------------------------------------------------------------------------------------------------------------------

MODEL NUMBER CUT-OUT SIZE

RM-1 24 1/2 X 16 1/2

RM-2 24 1/2 X 30 1/4

RM-3 24 1/2 X 44

RM-4 24 1/2 X 57 3/4

RM-5 24 1/2 X 71 1/2

RM-6 24 1/2 X 85 1/4

RML-2 16 1/2 X 46 1/2

RML-3 16 1/2 X 68 1/4

RML-4 16 1/2 X 90

OPERATION

This unit should be turned on one hour before serving and turned off after completing the serving period. The

thermostat has been pre-set at the factory.

All food products must be 34-35 degrees when placed in the unit. Food products must be 3 inches below the top of

the unit. Note: The unit should not operate 24/7.

-------------------------------------------------------------------------------------------------------------------------------------------

MAINTENANCE

NEVER CLEAN PANS WITH A CHLORIDE BASED PRODUCT. CHLORIDES OR IMPROPER CLEANING

COULD SCAR, MARK AND/OR CORRODE PANS. DO NOT

PRODUCTS. TO CLEAN USE SOAPY WARM WATER, RINSE THOROUGHLY TO REMOVE ALL

RESIDUES. FAILURE TO MEET THESE CONDITIONS WILL VOID WARRANTY.

CLEAN CONDENSER COIL REGULARLY.

USE STEEL WOOL OR ABRASIVE

Loading...

Loading...