Atlas Metal PT Parts List

Subsidiary of Mercury Aircraft, Inc.

1135 N.W. 159th DR., MIAMI, FL 33169

PHONE (305) 625-2451, (800) 762-7565, FAX (305) 623-0475, E-mail:

sales@atlasfoodserv.com

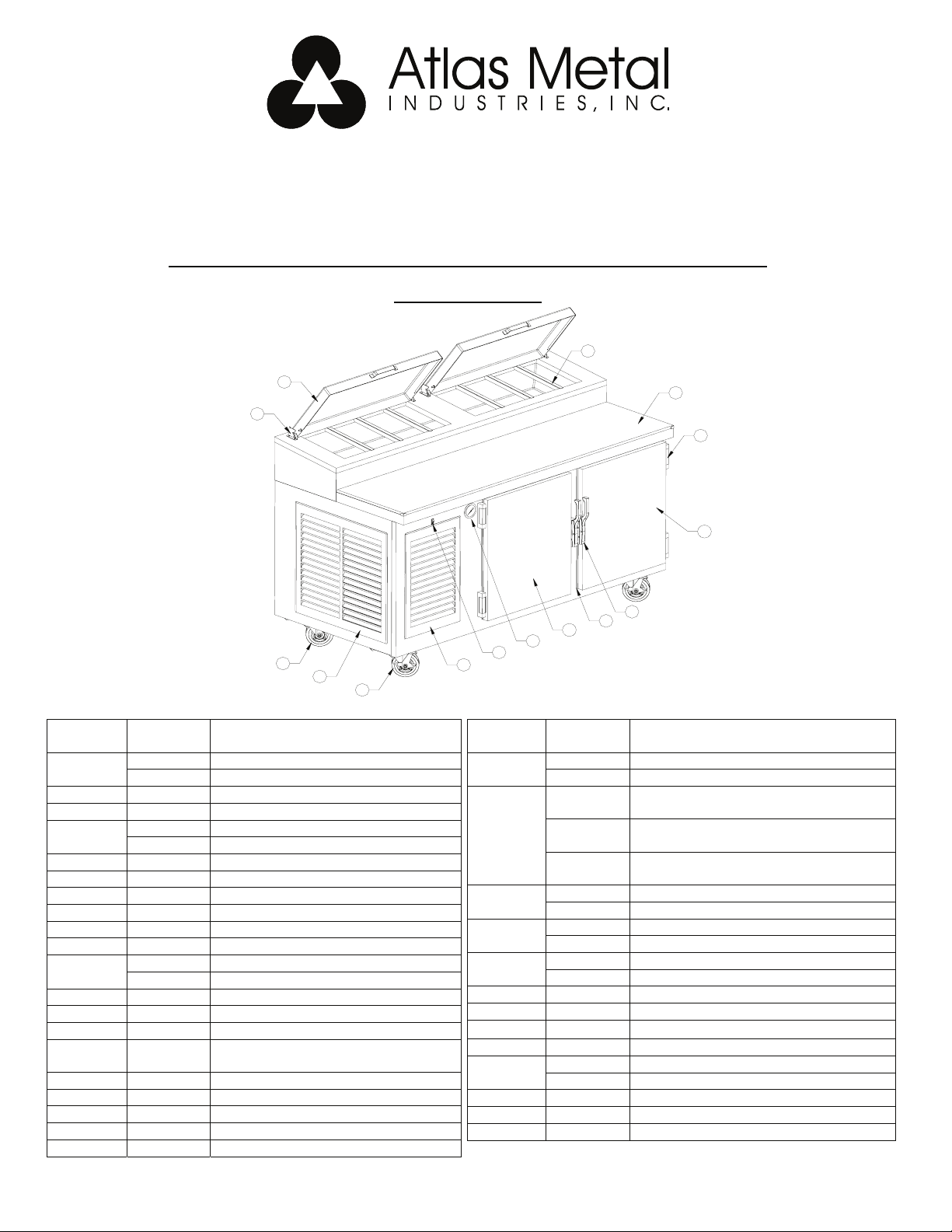

PARTS LIST-PIZZA PREPARATION TABLE

PT SERIES

3

1

2

14

12

13

ITEM

NUMBER

1

PART

NUMBER

DESCRIPTION

S81453-0 Lid Assembly (PT-68 & PT-88)

S51560-0 Lid Assembly (PT-88)

2 90-9900 Lid Cover Bracket

3 S80109-0 1/6 Pan Dividers

4

9017-0 Thermoplastic Cutting Board (PT-68)

9018-0 Thermoplastic Cutting Board (PT-88)

5 6053-8 Hinge & Cover

6 S81452-0 Door for PT-68 & 88

7 6055-1 Slam Action Latch

8 97-104 Door Gasket

9 113-5 Thermometer

10 1069-1 Front Switch

11

S84051-0 Front Grill (PT-68)

S84050-0 Front Grill (PT-88)

12 S84053-0 End Grill (PT-68 & PT-88)

13 6012-11 Casters with Brakes

14 6012-10 Casters without Brakes

15 S84052-0

Back Grill (PT-68 & PT-88)

(Not Shown)

16 S81454-0 Tray Rack (Not Shown)

17 69-973 Wire Shelf (Not Shown) (PT-68 & 88)

18 22-1406 Thermostat for Base (Not Shown)

19 2044-1 Thermostat for Rail (Not Shown)

20 2060-1 Cond. Water Evaporator (Not Shown)

4

5

6

7

8

6

9

10

11

ITEM

NUMBER

21

22

23

24

25

PT -68

SHO WN

PART

NUMBER

DESCRIPTION

1149-0 Wire Hamess (Double) (PT-88) (Not Shown)

1150-0 Wire Hamess (Single) PT-68) (Not Shown)

2029-0

2006-4

2002-4

1/5 H.P. Compressor (PT-68 & PT-88 Rail)

(Not Shown)

1/4 H.P. Compressor (PT-68 Base)

(Not Shown)

1/3 H.P. Compressor (PT-88 Base)

(Not Shown)

100-1004 Power Cord (PT-68) (Not shown)

1000-2 Power Cord (PT-88) (Not Shown)

2023-0 Drier Bottom

2025-0 Drier Condiment rail

2026-0 .042 Cap. Tube on 1/4 & 1/3 Comp

2027-0 .031 Cap. Tube on 1/5 Comp

26 2013-0 Fan Motor (Not Shown)

27 S81441-0 Fan Guard (Not Shown)

28 2014-5 Fan Blade (Not Shown)

29 S81419-0 Fan Bracket (Not Shown)

30

2119-0 Evap. Coil (PT-68 Base) (Not Shown)

2020-1 Evap. Coil (PT-88 Base) (Not Shown)

31 S81454-0 Tray Rack Assembly (Not Shown)

32 6151-6 Pilaster (Not Shown)

33 6151-1 Snap-In Shelf Support (Not Shown)

PIZZA PREPARATION TABLE

PT SERIES

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

OPERATION

Location of the unit is important. There must be adequate ventilation for the compressors. A minimum clearance of 6

inches must be provided at the vent locations on the side and front of the unit.

The supply cord is accessible through the end grill, which pulls out. Extend the cord completely, snap grill back into

place and plug into a proper outlet (see chart below).

MODEL NUMBER AMPS

PT-68 10.5 5-15P

PT-88 12.8 5-20P

These units are equipped with two (2) compressors and two (2) thermostats. The thermostat controlling the top cold

rail is located in the compressor compartment and the thermostat that controls the bottom rail is located on the blower

housing inside the refrigerator compartment. The thermostats have an off position and numbers from 1 through 7

(number 7 is the coldest).

The top condiment rail should be defrosted at least once a week by turning the thermostat to the off position.

DO NOT STORE ANY FOODS IN CONDIMENT RAIL WHILE DEFROSTING.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

NEMA PLUG

MAINTENANCE

NEVER CLEAN THE UNIT WITH A CHLORIDE BASED PRODUCT. CHLORIDES OR IMPROPER

CLEANING COULD SCARE, MARK AND/OR CORRODE METAL. DO NOT USE STEEL WOOL OR

ABRASIVE PRODUCTS. TO CLEAN USE SOAPY WARM WATER, RINSE RESIDUE THOROUGHLY.

FAILURE TO MEET THESE CONDITIONS WILL VOID WARRANTY.

CLEAN CONDENSER COIL REGULARLY.

Loading...

Loading...