Atlas Copco GA18, GA22, GA30C, GA30, GA11 User Manual

...

Atlas Copco Stationary Air Compressors

GA5-7-11C-11-15-18-22-30C-30-37-45-55C-55-75-90C and

GA30 W-37 W-45 W-55C W-55 W-75 W-90C W

With Elektronikon I or Elektronikon II regulator

User manual for Elektronikon® I and II regulators

Compressor type: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Unit serial No. compressor: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air dryer type: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Unit serial No. dryer: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor type: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Motor serial No.: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Delivery date: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . First start-up date: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Plan: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Owner's machine No.: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selected lubricants

Compressor: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Capacity: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bearing grease type, electric motor: . . . . . . . . . . . . . . . . . . . . . . . . .

Dryer gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printed Matter Nos.

Atlas Copco compressor instruction book: . . . . . . . . . . . . . . . . . . . . Atlas Copco air dryer instruction book: . . . . . . . . . . . . . . . . . . . . . . . . . .

Atlas Copco compressor parts list: . . . . . . . . . . . . . . . . . . . . . . . . . . Atlas Copco air dryer parts list: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Atlas Copco logbook: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Atlas Copco Representative

Name: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Address: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Telephone: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Contact persons: Service: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Telex: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Parts: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E-mail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY PRECAUTIONS

To be read attentively and acted accordingly before installing, operating or repairing the unit.

These recommendations apply to machinery processing or consuming air or inert gas. Processing of any other gas requires

additional safety precautions typical to the application which are not included herein.

If necessary, install a suction duct. Never obstruct the air inlet. Care

shall be taken to minimize the entry of moisture with the inlet air.

4. The aspirated air shall be free from flammable fumes or vapours,

e.g. paint solvents, that can lead to internal fire or explosion.

5. Air-cooled units shall be installed in such a way that an adequate

flow of cooling air is available and that the exhausted air does not

recirculate to the inlet.

6. Arrange the air intake so that loose clothing of people cannot be

sucked in.

7. Ensure that the discharge pipe from the compressor to the aftercooler,

air dryer or air net is free to expand under heat and that it is not in

contact with or close to flammable material.

8. No external force may be exerted on the air outlet valve; the connected

pipe must be free of strain.

9. If remote control is installed, the unit shall bear an obvious sign

reading:

DANGER: This machine is remotely controlled and may start

without warning.

As a further safeguard, persons switching on remotely controlled

units shall take adequate precautions to ensure that there is no one

checking or working on the machine. To this end, a suitable notice

shall be affixed to the start equipment.

10. On units with automatic start-stop system, a sign stating "This

machine may start without warning" shall be attached near the

instrument panel.

11. In multiple compressor systems manual valves shall be installed to

isolate each compressor. Non-return valves (check valves) shall not

be relied upon for isolating pressure systems.

12. Never remove or tamper with the safety devices, guards or insulations

fitted on the unit. Every pressure vessel or auxiliary installed outside

the unit to contain air above atmospheric pressure shall be protected

by a pressure-relieving device or devices as required.

13. Pipework or other parts with a temperature in excess of 80 degrees

celsius and which may be accidentally touched by personnel in normal operation shall be guarded or insulated. Other high-temperature

pipework shall be clearly marked.

OWNERSHIP DATA

In addition to normal safety rules which should be observed with stationary

air compressors and equipment, the following safety directions and

precautions are of special importance.

When operating this unit, the operator must employ safe working practices

and observe all related local work safety requirements and ordinances.

The owner is responsible for maintaining the unit in a safe operating

condition. Parts and accessories shall be replaced if unsuitable for safe

operation.

Installation, operation, maintenance and repair shall only be performed

by authorized, trained, competent personnel.

Normal ratings (pressures, temperatures, time settings, etc.) shall be

durably marked.

Any modification on the compressor or air dryer shall only be performed

in agreement with Atlas Copco and under supervision of authorized,

competent personnel.

If any statement in this book, especially with regard to safety, does not

comply with local legislation, the stricter of the two shall apply.

These precautions are general and cover several machine types and

equipment; hence some statements may not apply to the unit(s) described

in this book.

Installation

Apart from general engineering practice in conformity with the local

safety regulations, the following directives are specially stressed:

1. A compressor or air dryer shall be lifted only with adequate equipment

in conformity with local safety rules.

Loose or pivoting parts shall be securely fastened before lifting. It is

strictly forbidden to dwell or stay in the risk zone under a lifted load.

Lifting acceleration and retardation shall be kept within safe limits.

Wear a safety helmet when working in the area of overhead or lifting

equipment.

2. Any blanking flanges, plugs, caps and desiccant bags shall be

removed before connecting up the pipes. Distribution pipes and

connections shall be of correct size and suitable for the working

pressure.

3. Place the unit where the ambient air is as cool and clean as possible.

2920 1377 03 1/2 (continued on inside of cover)

Atlas Copco Stationary Air Compressors

Important

This book applies exclusively to the above-mentioned compressors with

Elektronikon I or II regulator from following serial numbers onwards:

GA5 up to GA11C: AII-145 000

GA11 up to GA30C: AII-268 500

GA30 up to GA55C: AII-380 000

GA55 up to GA90C: AII-474 000

No. 2920 1461 03

Replaces 2920 1461 02

Registration code: APC G5-11C/2002 / 38 / 984

APC G11-30C / 38 / 989

APC G30-55C / 38 / 980

APC G55-90C / 38 / 985

2003-09

GA5-7-11C-11-15-18-22-30C-30-37-45-55C-55-75-90C and

GA30 W-37 W-45 W-55C W-55 W-75 W-90C W

With Elektronikon I or Elektronikon II regulator

User manual for Elektronikon® I and II regulators

·

Copyright 2003, Atlas Copco Airpower n.v., Antwerp, Belgium.

Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in

particular to trademarks, model denominations, part numbers and drawings.

·

This instruction book meets the requirements for instructions specified by the machinery

directive 98/37/EC and is valid for CE as well as non-CE labelled machines.

www.atlascopco.com

2920 1461 03

2

User manual

Page

7 Scrolling through all screens . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.1 Calling up outlet/dewpoint temperatures . . . . . . . . . . . . 9

7.2 Calling up running hours . . . . . . . . . . . . . . . . . . . . . . . . 9

7.3 Calling up loading hours . . . . . . . . . . . . . . . . . . . . . . . . 9

7.4 Calling up motor starts . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.5 Calling up/resetting service timer. . . . . . . . . . . . . . . . . 10

7.6 Automatic restart after voltage failure . . . . . . . . . . . . . 10

7.7 Set of parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.8 Calling up/modifying unloading pressure . . . . . . . . . . 11

7.9 Calling up/modifying loading pressure . . . . . . . . . . . . 11

7.10 Calling up/modifying dewpoint warning temperature . 11

7.11 Calling up/modifying service timer setting . . . . . . . . . 12

7.12 Calling up/modifying unit for pressure . . . . . . . . . . . . 12

7.13 Calling up/modifying unit for temperature . . . . . . . . . 12

7.14 Selection between Y-D/DOL starting . . . . . . . . . . . . . . 12

7.15 Activating automatic restart after voltage failure. . . . . 13

7.16 Selecting local/remote control . . . . . . . . . . . . . . . . . . . 13

7.17 Modifying parameter set . . . . . . . . . . . . . . . . . . . . . . . . 13

8 Settings

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.1 Unloading/loading pressures . . . . . . . . . . . . . . . . . . . . 14

8.2 Element outlet temperature . . . . . . . . . . . . . . . . . . . . . . 14

8.3 Dewpoint temperature. . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.4 Service timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Contents

PART 1 - ELEKTRONIKON I REGULATOR

Page

1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Automatic control of the compressor . . . . . . . . . . . . . . 3

1.2 Protecting the compressor . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Automatic restart after voltage failure . . . . . . . . . . . . . . 3

2 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Pictographs used on the screen . . . . . . . . . . . . . . . . . . . 4

3.2 Main screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3 Scrolling through all screens . . . . . . . . . . . . . . . . . . . . . 5

4 Shut-down warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Compressor element outlet temperature . . . . . . . . . . . . . 5

4.2 Dewpoint temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 Shut-down

5.1 Compressor element outlet temperature . . . . . . . . . . . . . 6

5.2 Motor overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 Service warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PART 2 - ELEKTRONIKON II REGULATOR

Page

1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1 Automatic control of the compressor . . . . . . . . . . . . . 15

1.2 Protecting the compressor . . . . . . . . . . . . . . . . . . . . . . 15

1.3 Automatic restart after voltage failure . . . . . . . . . . . . . 15

2 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.1 LEDs/buttons/keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2 Pictographs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3 Function keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3 Menu-driven control programs . . . . . . . . . . . . . . . . . . . . . 19

3.1 Function of control programs . . . . . . . . . . . . . . . . . . . . 19

3.2 Main screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3 Calling up other menus . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Quick look at actual compressor status . . . . . . . . . . . . . . . 20

5 Status data menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 No message exists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 A shut-down message exists . . . . . . . . . . . . . . . . . . . . . 20

5.3 A shut-down warning message exists . . . . . . . . . . . . . . 21

5.4 A service warning message exists . . . . . . . . . . . . . . . . 21

5.5 A warning message exists . . . . . . . . . . . . . . . . . . . . . . . 21

6 Measured data menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 Counters menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 Test menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page

9 Modify params menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10 Modifying parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10.1 Modifying loading/unloading pressures . . . . . . . . . . . . 23

11 Modifying protection settings . . . . . . . . . . . . . . . . . . . . . . . 23

11.1 Modifying settings for compressor element . . . . . . . . . 24

12 Modifying service plans. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

13 Programming clock function. . . . . . . . . . . . . . . . . . . . . . . . 25

13.1 Programming start/stop/pressure band commands . . . 25

13.2 To activate/deactivate the timer . . . . . . . . . . . . . . . . . . 26

13.3 To modify a command . . . . . . . . . . . . . . . . . . . . . . . . . 26

13.4 To add a command . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

13.5 To delete commands . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

14 Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

14.1 Programming compressor control modes . . . . . . . . . . . 28

15 Service menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

16 Saved data menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

17 Programmable settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

17.1 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

17.2 Protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

17.3 Service plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2920 1461 03

3

User manual

PART 1

ELEKTRONIKON I REGULATOR

1.3 Automatic restart after voltage failure

For compressors leaving the factory, this function is made

inactive. If desired, the function can be activated. Consult

Atlas Copco.

Warning If activated and provided the module was in the

automatic operation mode, the compressor will

automatically restart if the supply voltage to the

module is restored.

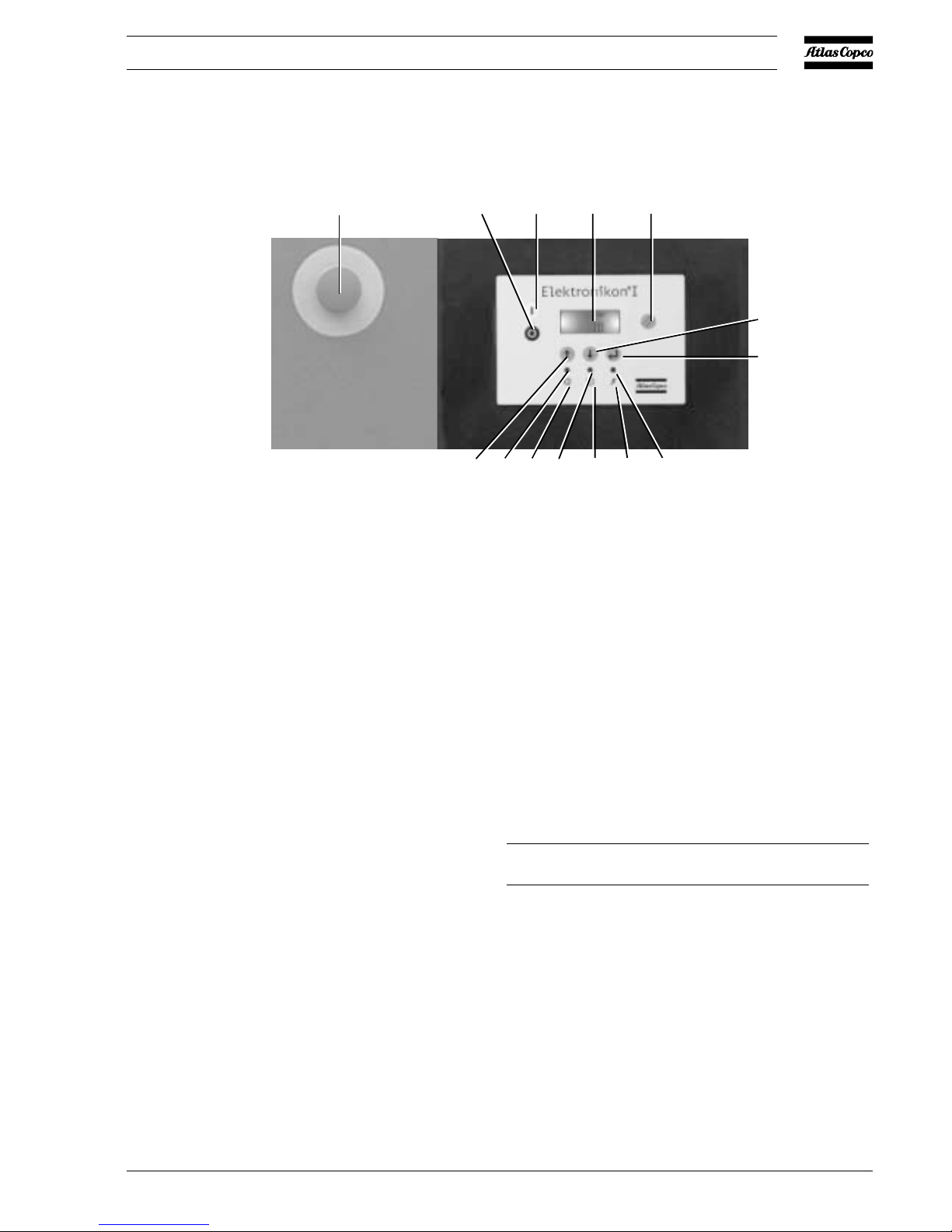

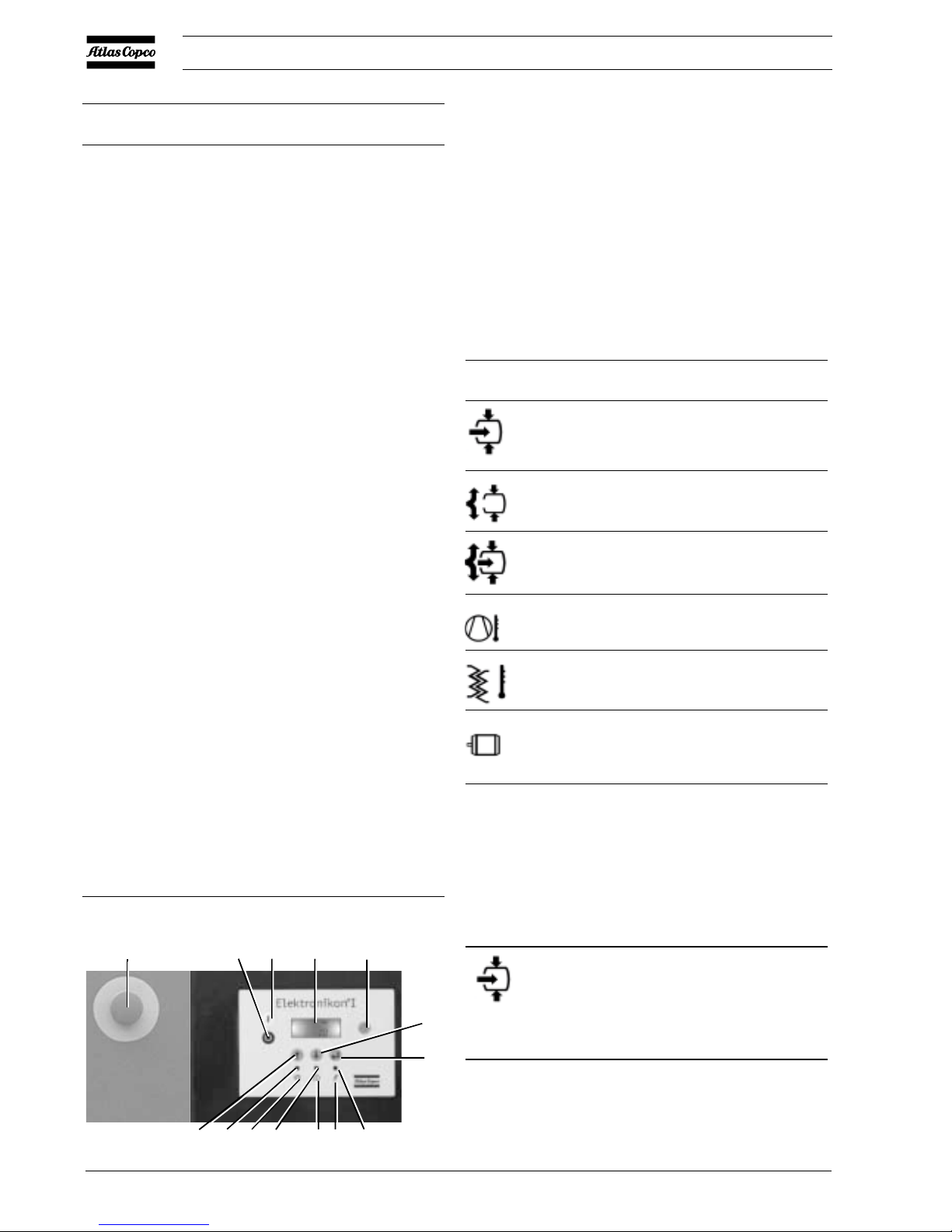

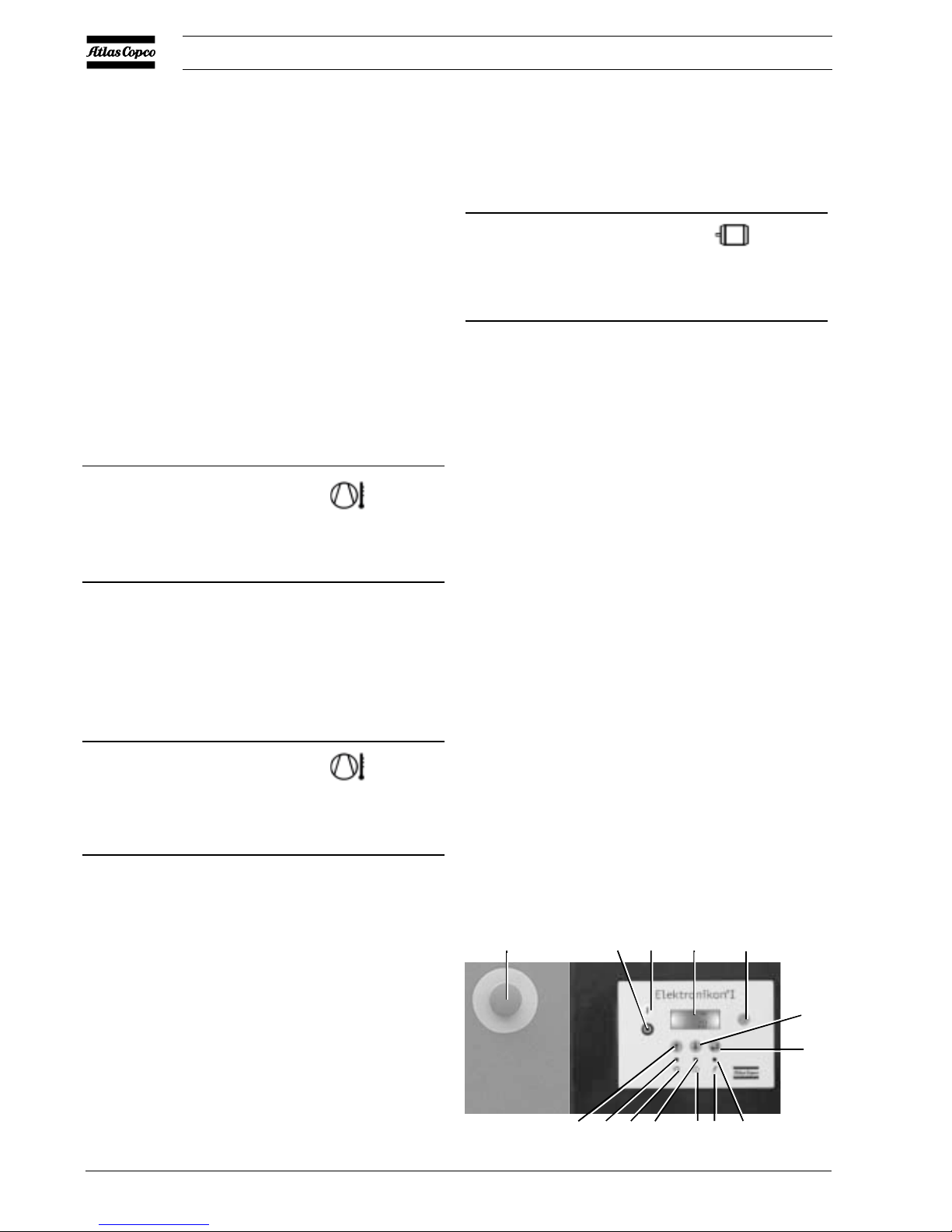

2 Control panel

Ref. Designation Function

1 Stop button Push button to stop the

compressor. LED (10) goes out.

The compressor will stop after

running in unloaded condition for

about 30 seconds.

2 Start button Push button to start the

compressor. LED (10) lights up

indicating that the regulator is

operative (in automatic operation).

3 Display Indicates the compressor operating

condition, measured values and

programmed parameters.

1 General description

1.1 Automatic control of the compressor

The regulator maintains the net pressure between programmable

limits by automatically loading and unloading the compressor.

A number of programmable settings, e.g. the unloading and

loading pressures, the minimum stop time and the maximum

number of motor starts are taken into account.

The regulator stops the compressor whenever possible to reduce

the power consumption and restarts it automatically when the

net pressure decreases.

1.2 Protecting the compressor

Shut-down

If the compressor element outlet temperature exceeds the

programmed shut-down level, the compressor will be stopped.

This will be indicated on display (3). The compressor will

also be stopped in case of overload of drive motor (M1) and,

for air-cooled compressors, also the fan motor (M2).

Shut-down warning

If the compressor element outlet temperature or dewpoint

temperature (Full-Feature compressors) exceeds a programmed

value below the shut-down level, this will also be indicated to

warn the operator before the shut-down level is reached.

Service warning

If the service timer exceeds a programmed value, this will be

indicated on display (3) to warn the operator to carry out some

service actions.

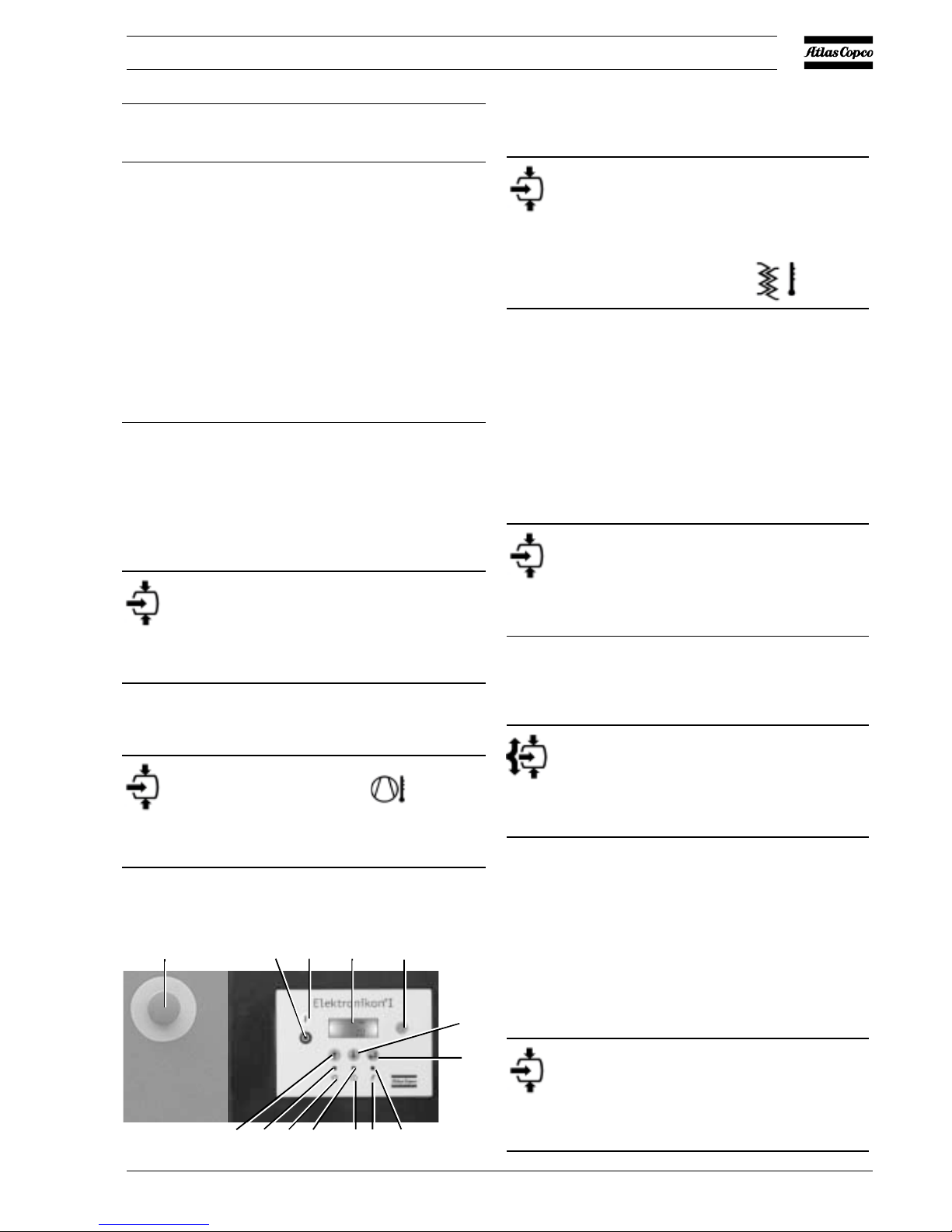

Control panel

10

11

8

9

7

6

3

21

4

5

12

13

52238F

S3

2920 1461 03

4

User manual

Ref. Designation Function

4 Reset key Key to reset the service timer, a

shut-down condition, etc.

5 Enter key Key to select or validate a

parameter, to open a sub-display

or to return to a previous display.

6 Voltage on LED Indicates that the voltage is

switched on.

7 Pictograph Voltage on

8 General alarm LED Is alight if a warning condition

exists.

8 General alarm LED Blinks in case of a shut-down or

emergency stop condition.

9 Pictograph Alarm

10 Automatic Indicates that the regulator is

operation LED automatically controlling the

compressor: the compressor is

loaded, unloaded, stopped and

restarted depending on the air

consumption and the limitations

programmed in the regulator.

11 Pictograph Automatic operation

12 Downwards Key to scroll downwards through

scroll key the screens or to decrease a setting.

13 Upwards scroll key Key to scroll upwards through the

screens or to increase a setting.

S3 Emergency stop Push button to stop the compressor

button immediately in case of emergency.

After remedying the trouble,

unlock the button by pulling it out

and press reset key 4.

3 Display

The display shows:

- the compressor operating status by means of pictographs

- the air outlet pressure

- the actual temperature at the compressor element outlet

- the actual dewpoint temperature (FF compressors)

The display also shows all measured and programmed

parameters, see section 7.

3.1 Pictographs used on the screen

Pictograph Explanation

Compressor status UNLOAD

Running hours

Element outlet temperature

Dewpoint temperature

Motor or motor overload

3.2 Main screen

When the voltage is switched on, the Main screen is shown

automatically, showing in short the operation status of the

compressor and the outlet pressure:

bar

6.8

Main screen, typical example

The screen shows that the compressor is running loaded (the

horizontal arrow blinks) and that the outlet pressure is 6.8 bar(e).

Compressor status LOAD (during loaded running,

the horizontal arrow blinks)

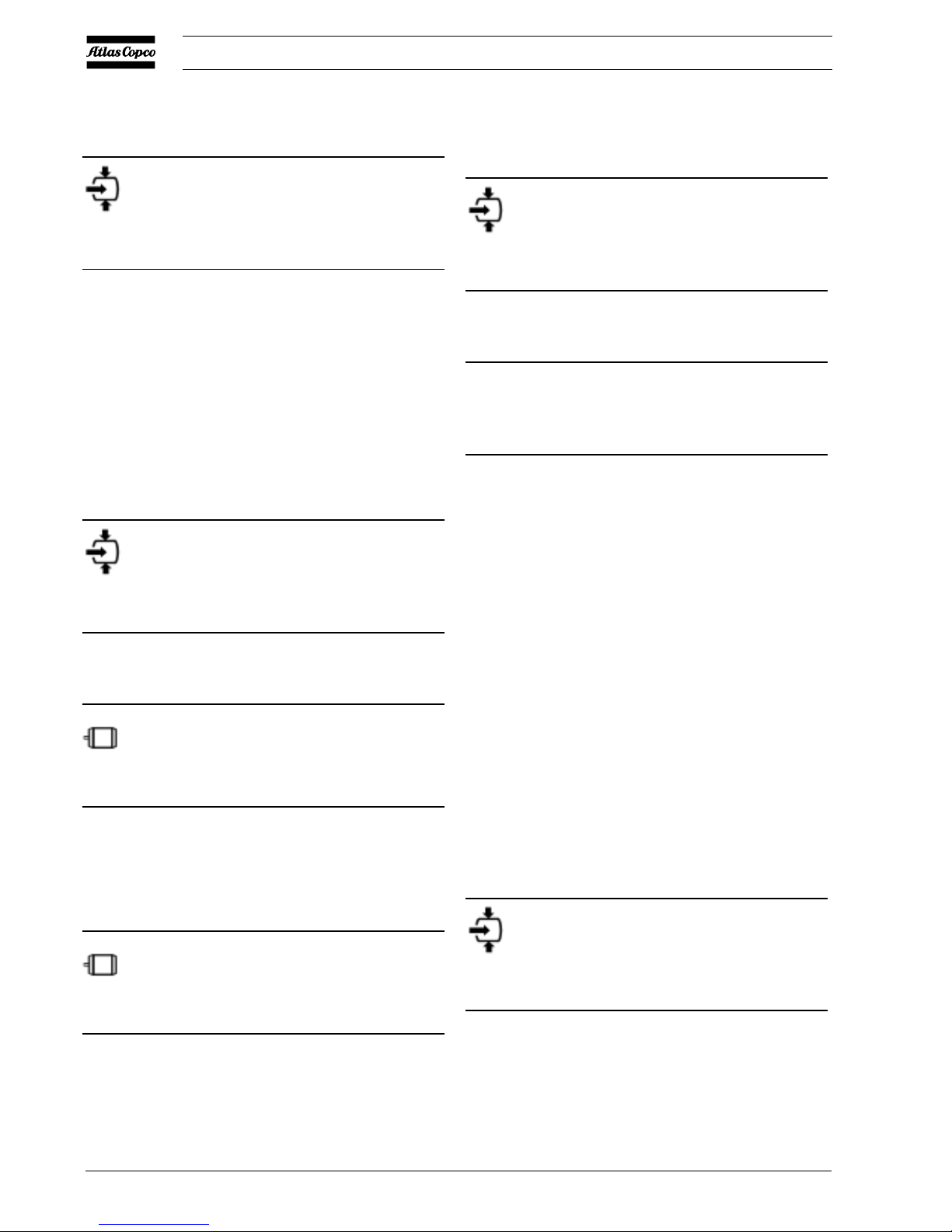

10

11

8

97 6

3

21

4

5

12

13

52236F

S3

2920 1461 03

5

User manual

Important

Always consult Atlas Copco in case "t" or "test" appears on the

display

3.3 Scrolling through all screens

It is possible to scroll downwards and upwards through a

number of screens by means of the upwards/downwards arrow

keys (12 and 13). See section 7.

4 Shut-down warning

A shut-down warning message will appear in case of:

- too high a temperature at the outlet of the compressor

element

- too high a dewpoint temperature (FF compressors)

4.1 Compressor element outlet temperature

1. In case the outlet temperature of the compressor element

exceeds the shut-down warning level (110 °C, not

programmable), alarm LED (8) will light up and the related

pictograph will appear blinking:

Blinking

bar

6.6

Warning screen, element outlet temperature

2. Press arrow key (12), r000 (register 000) appears.

3. Press arrow key (12), the actual compressor element

temperature appears:

Blinking

C

111

Warning screen, element outlet temperature

The screen shows that the temperature at the outlet of the

compressor element is 111 °C.

4. It remains possible to scroll through other screens (using

keys 12 and 13) to check the actual status of other

parameters.

5. Press button (1) to stop the compressor and wait until the

compressor has stopped.

6. Switch off the voltage, inspect the compressor and remedy.

7. The warning message will disappear as soon as the warning

condition disappears.

4.2 Dewpoint temperature

1. In case the dewpoint temperature exceeds the shut-down

warning level (programmable), alarm LED (8) will light up

and the related pictograph will appear blinking:

Blinking

bar

6.6

Warning screen, dewpoint temperature

2. Press arrow key (12), r000 (register 000) appears.

3. Press arrow key (12), the actual dewpoint temperature

appears:

Blinking

°C

9

Warning screen, dewpoint temperature

The screen shows that the dewpoint temperature is 9 °C.

4. It remains possible to scroll through other screens (using

keys 12 and 13) to check the actual status of other

parameters.

5. Press button (1) to stop the compressor and wait until the

compressor has stopped.

6. Switch off the voltage, inspect the compressor and remedy.

7. The warning message will disappear as soon as the warning

condition disappears.

2920 1461 03

6

User manual

5 Shut-down

The compressor will be shut down in case:

- the temperature at the outlet of the compressor element

exceeds the shut-down level

- of error of the outlet pressure sensor

- of overload of the drive motor and, on air-cooled

compressors, also the fan motor

5.1 Compressor element outlet temperature

1. In case the outlet temperature of the compressor element

exceeds the shut-down level (120 °C, not programmable),

the compressor will be shut down, alarm LED (8) will blink,

automatic operation LED (10) will go out and following

screen will appear:

Blinking

Shut-down screen, element outlet temperature

2. Press enter key (5), r000 (register 000) appears.

3. Press arrow key (12), the actual compressor element

temperature appears:

Blinking

°C

122

Shut-down screen, element outlet temperature

The screen shows that the temperature at the outlet of the

compressor element is 122 °C.

4. Switch off the voltage and remedy the trouble.

5. After remedying and when the shut-down condition has

disappeared, switch on the voltage and restart the

compressor.

5.2 Motor overload

1. In case of motor overload, the compressor will be shut down,

alarm LED (8) will blink, automatic operation LED (10)

will go out and following screen will appear:

Blinking

Shut-down screen, motor overload

2. Switch off the voltage and remedy the trouble.

3. After remedying and when the shut-down condition has

disappeared, switch on the voltage and restart the

compressor.

10

11

8

97 6

3

21

4

5

12

13

52236F

S3

2920 1461 03

7

User manual

6 Service warning

A service warning will appear when the service timer has

reached the programmed time interval.

1. In case the service timer exceeds the programmed time

interval, alarm LED (8) will light up.

2. Press arrow key (12): r000 is shown (register 000).

Press enter key (5), S (S standing for Service)

appears. Use key (12) to scroll to r005 (register 005)

and press enter key (5), the actual reading of the service

timer will be shown in kHrs (hours x 1000) .

Example: 4.002 indicates that the compressor has run for

4002 hours since previous service.

3. Press enter key (5) and key (12) to scroll to r001

(register 001). Press key (5) to check the running hours,

which are shown in kHrs (hours x 1000).

Example of running hours screen:

kHrs

8.000

The screen shows that the number of running hours is 8000.

4. Stop the compressor, switch off the voltage and carry

out the service actions as explained in the maintenance

schedule in the related Instruction book.

Important

- The longer interval service actions must include the

shorter interval actions.

In the example above, carry out all service operations

belonging to the 8000 running hours interval as well as

those belonging to the 4000 running hours interval.

- If using mineral oil instead of Atlas Copco Rotoinjectfluid, the service timer interval has to be decreased:

500 running hours for 13 bar (175 psi) units and 1000

running hours for 7.5-10 bar (100-150 psi) units.

5. After servicing, reset the service timer (see section 7.5).

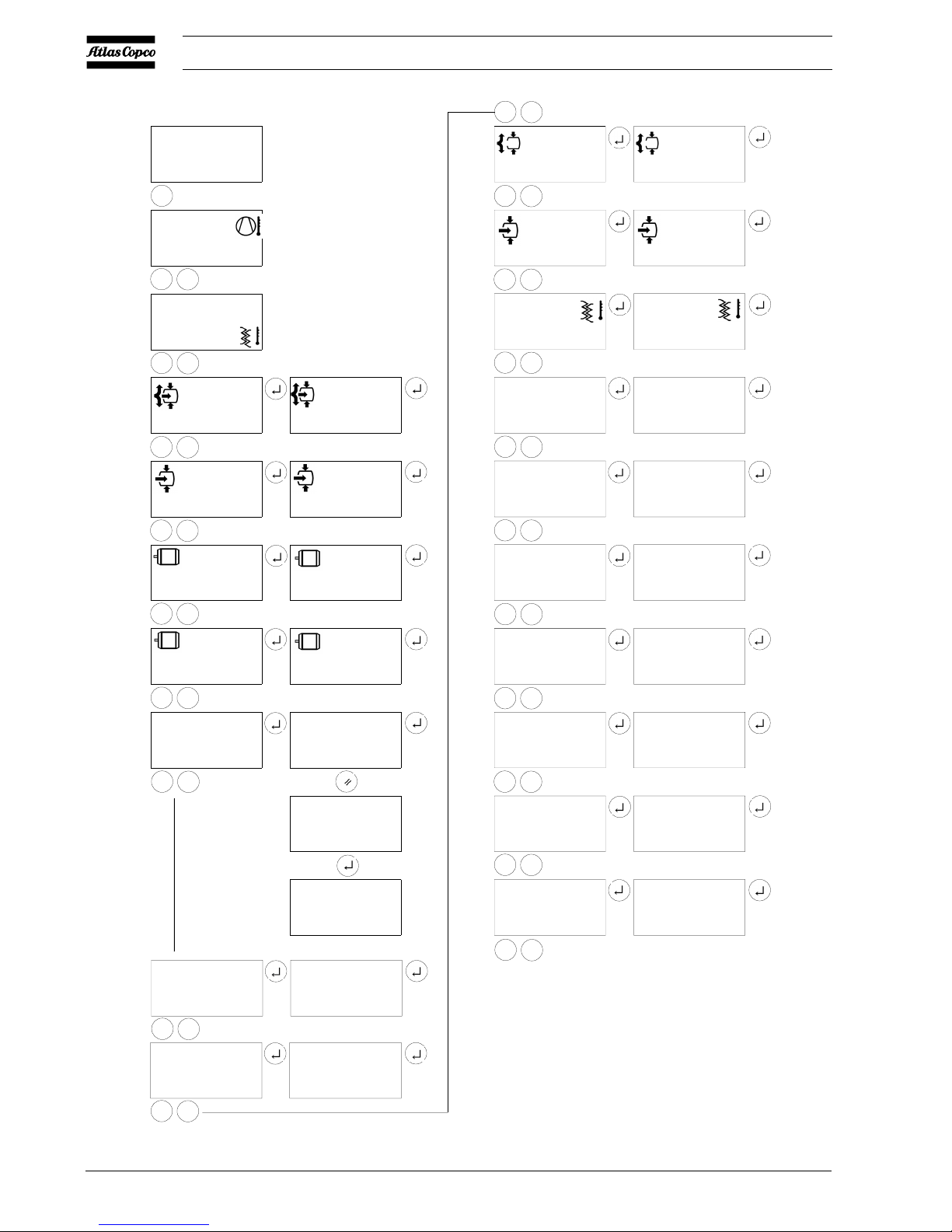

7 Scrolling through all screens

Scroll keys (12 and 13) can be used to scroll through all screens.

The screens are divided in register screens (numbered as r001,

r002,...) and parameter screens (numbered as P001,

P002,...).

During scrolling, the numbers of the screens appear consecutively.

For most screens, the unit of measurement and the related

pictograph are shown together with the screen number.

In case of a warning or shut-down, an extra register screen (r000)

is accessible.

Example:

kHrs

r001

The screen shows the screen number (r001), the unit used (kHrs

or hours x 1000) and the related pictograph for running hours.

Press enter key (5) to call up the actual running hours.

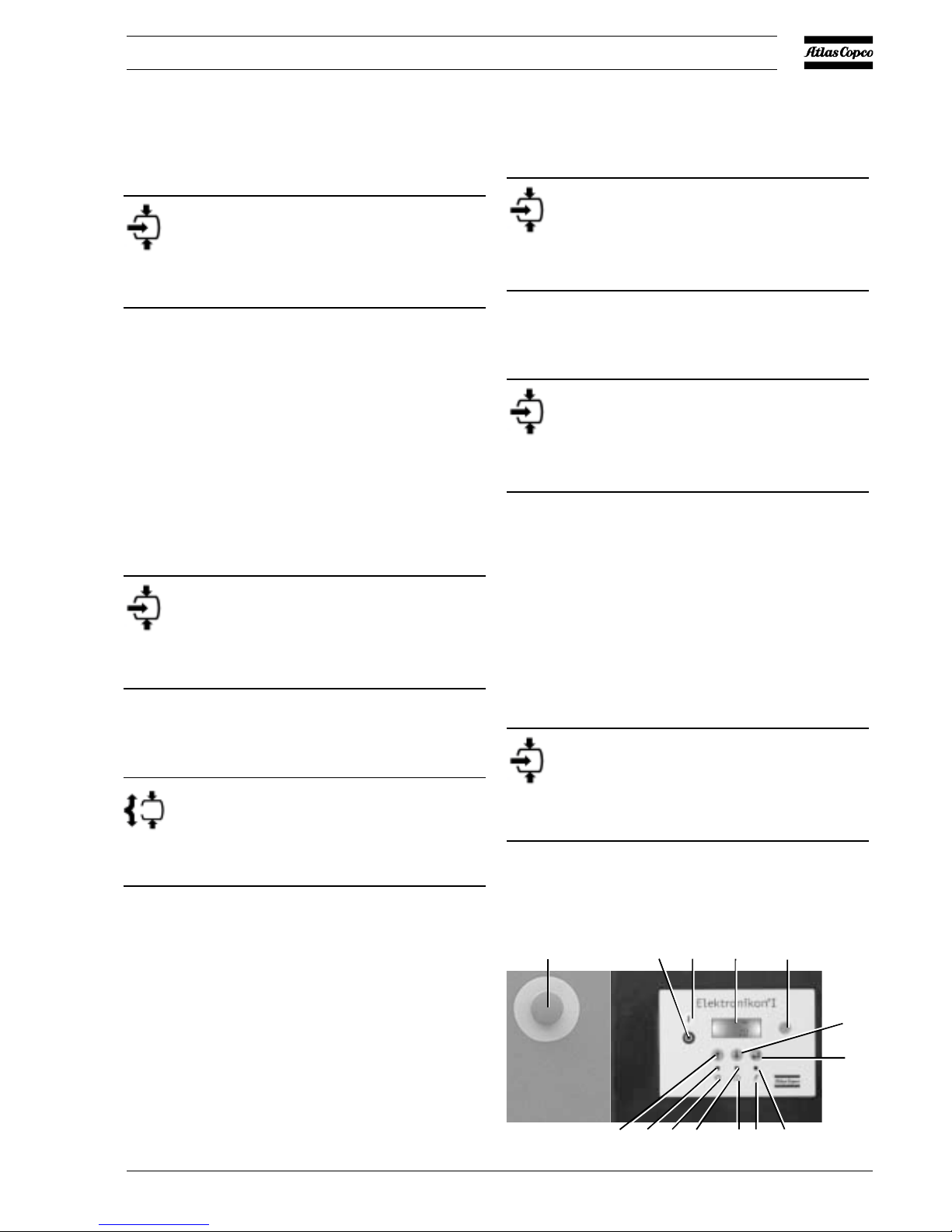

Overview of the screens

Register Show

screens

r001 Running hours (x1000 hrs)

r002 Loading hours (x1000 hrs)

r003 Motor starts (x1000)

r004 Motor starts (x1)

r005 Service timer reading

r006 Status of function "Automatic restart after voltage

failure"

r007 Programmed set of parameters

2920 1461 03

8

User manual

°C

82

°C

4

Bar

7.0

kHrs

r001

kHrs

4.039

r003

kHrs

3.161

3

158

kHrs

4.002

kHrs

"4.002"

r004

kHrs

r002

kHrs

r005

K

L

bar

P001

°C

P003

kHrs

P004

°C °F

P006

P007

P008

P009

P010

Bar

7.0

Bar

6.4

°C

8

kHrs

4.000

Mpa psi "bar"

"°C " °F

I

0000

"0"

0000

L

K

L

K

L

K

L

K

L

K

L

K

L

K

L

K

L

K

L

K

L

K

L

K

L

kHrs

0.000

K

L

K

L

bar

P002

K

L

K

L

Mpa psi bar

P005

K

L

52588PEN

K

L

K

L

r007

r006

1234

0

Simplified menu flow

2920 1461 03

9

User manual

Parameter Used for

screens

P001 Unload pressure setting

P002 Load pressure setting

P003 Warning level setting for dewpoint temperature

P004 Setting of service timer

P005 Setting of unit for pressure

P006 Setting of unit for temperature

P007 Selection between Y-D or DOL starting

P008 Selection for function "Automatic restart after

voltage failure" (active or not, only for Atlas

Copco)

P009 Selection between Local/Remote control

P010 Changing set of programmed parameters (only

for Atlas Copco)

7.1 Calling up outlet and dewpoint

temperatures

Starting from the Main screen:

bar

6.6

1. Press arrow key (12), the outlet temperature will be shown:

°C

83

The screen shows that the outlet temperature is 83 °C.

2. Press arrow key (12), the dewpoint temperature will be

shown:

°C

3

The screen shows that the dewpoint temperature is 3 °C.

3. Use keys (12 and 13) to scroll downwards or upwards

through the screens.

7.2 Calling up running hours

Starting from the Main screen:

bar

6.6

1. Press arrow key (12) until r001 is shown and then press

enter key (5):

kHrs

2.381

The screen shows the unit used (kHrs or hours x 1000) and

the value 2.381: the running hours of the compressor are 2381

hours.

7.3 Calling up loading hours

Starting from the Main screen:

bar

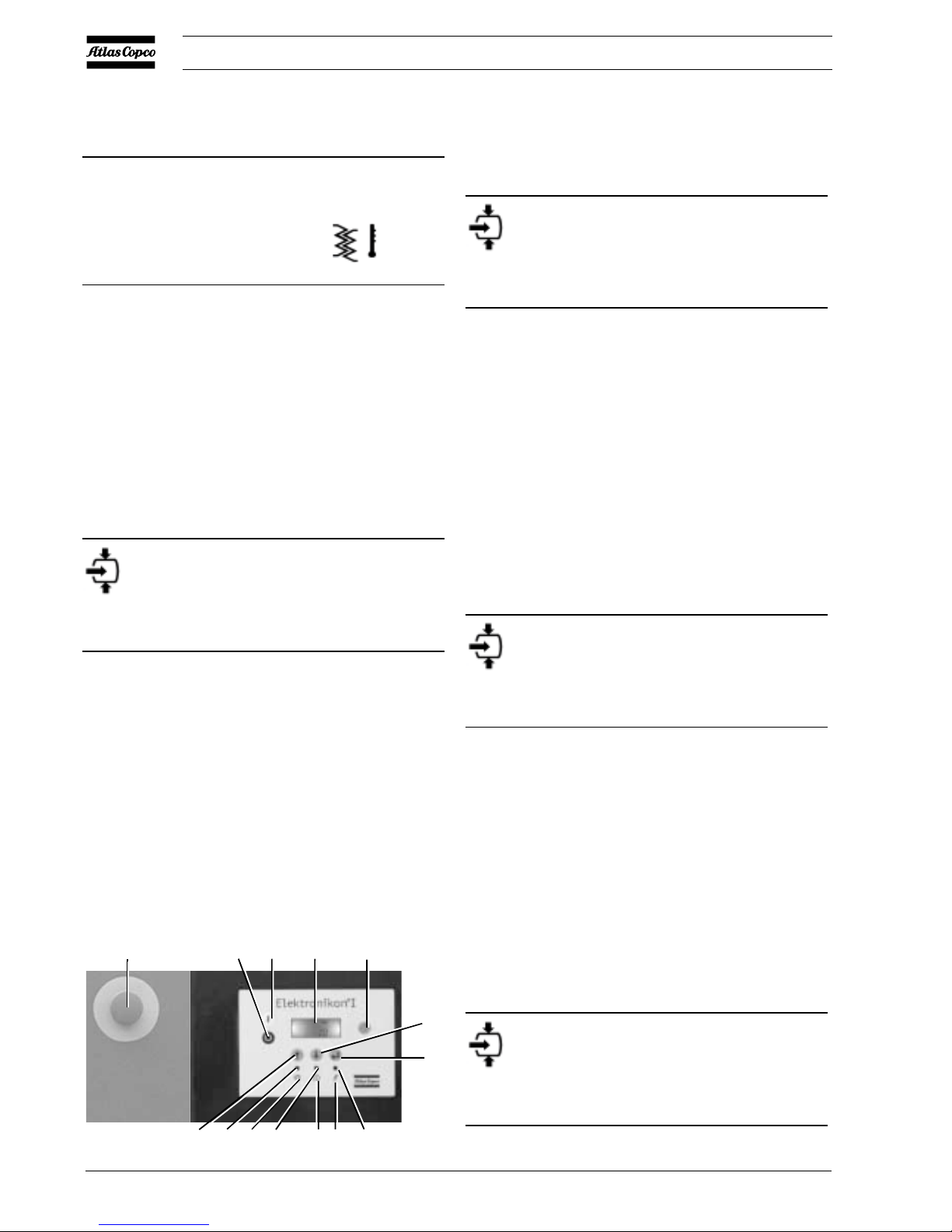

6.6

10

11

8

97 6

3

21

4

5

12

13

52236F

S3

2920 1461 03

10

User manual

1. Press arrow key (12) until r002 is shown and then press

enter key (5):

kHrs

1.755

The screen shows the unit used (kHrs or hours x 1000) and

the value 1.755: the loading hours of the compressor are 1755

hours.

7.4 Calling up motor starts

Starting from the Main screen:

bar

6.6

1. Press arrow key (12) until r003 is shown and then press

enter key (5):

3

This screen shows the number of motor starts times 1000. Press

enter key (5) to return to the register screens.

2. Press arrow key (12) until r004 is shown and then press

enter key (5):

226

This screen shows the number of motor starts to be added to

the reading in register r003. In this example, the number of

motor starts is 3226.

7.5 Calling up/resetting service timer

Starting from the Main screen:

bar

6.6

1. Press arrow key (12) until r005 is shown and then press

enter key (5):

kHrs

1.191

The screen shows the unit used (kHrs or hours x 1000) and

the value 1.191: the compressor has run for 1191 hours since

previous service.

Resetting the service timer

After servicing (see section 6), the timer has to be reset:

1. Scroll to register screen r005, the reading (e.g. 4.000)

will appear.

2. Press reset key (4), the reading will blink (indicating that

resetting is possible).

3. Press enter key (5) to reset the timer to "0.000" or press

reset key (4) to cancel the operation.

7.6 Automatic restart after voltage failure

Starting from the Main screen:

bar

6.6

Press arrow key (12) until r006 is shown and press enter key

(5):

- if 0 appears, the function Automatic restart after voltage

failure is not active

- if 1 appears, the function Automatic restart after voltage

failure is active

2920 1461 03

11

User manual

7.7 Set of parameters

Starting from the Main screen:

bar

6.6

Press arrow key (12) until r007 is shown and press enter key

(5): the number shown indicates the set of parameters which

are programmed ex-factory.

7.8 Calling up/modifying Unloading pressure

Starting from the Main screen:

bar

6.6

1. Press arrow key (12) until P001 is shown and press the

enter key (5):

bar

7.0

The screen shows the setting of the unloading pressure: 7.0

bar(e).

2. Use arrow keys (12 and 13) to modify this setting.

3. Press enter key (5) to program the new value and to return

to the parameter screens.

7.9 Calling up/modifying Loading pressure

Starting from the Main screen:

bar

6.6

1. Press arrow key (12) until P002 is shown and then press

enter key (5):

bar

6.4

The screen shows the setting of the loading pressure: 6.4 bar(e).

2. Use arrow keys (12 and 13) to modify this setting.

3. Press enter key (5) to program the new value and to return

to the parameter screens.

7.10 Calling up/modifying Dewpoint

warning temperature

Starting from the Main screen:

bar

6.6

10

11

8

97 6

3

21

4

5

12

13

52236F

S3

2920 1461 03

12

User manual

1. Press arrow key (12) until P003 is shown and press enter

key (5):

°C

8

The screen shows the warning setting for the dewpoint

temperature: 8 °C.

2. Use arrow keys (12 and 13) to modify this setting.

3. Press enter key (5) to program the new value and to return

to the parameter screens.

7.11 Calling up/modifying Service timer

setting

Starting from the Main screen:

bar

6.6

1. Press arrow key (12) until P004 is shown and then press

"enter" key (5): the setting of the service timer is shown in

"kHrs" (hours x 1000). Example: 4.000 means the timer

is set at 4000 running hours.

2. Use arrow keys (12 and 13) to modify this setting.

3. Press enter key (5) to program the new value and to return

to the parameter screens.

7.12 Calling up/modifying unit for pressure

Starting from the Main screen:

bar

6.6

1. Press arrow key (12) until P005 is shown and press enter

key (5): the possible settings are shown: MPa, psi and

bar; the actually used unit is blinking.

2. Use arrow keys (12 and 13) to select another unit for

pressure.

3. Press enter key (5) to program the new unit and to return to

the parameter screens.

7.13 Calling up/modifying unit for

temperature

Starting from the Main screen:

bar

6.6

1. Press arrow key (12) until P006 is shown and then press

enter key (5): the possible settings are shown: °C and

°F; the actually used unit is blinking.

2. Use arrow keys (12 and 13) to select another unit for

temperature.

3. Press enter key (5) to program the new unit and to return to

the parameter screens.

7.14 Selection between Y-D or DOL starting

Starting from the Main screen:

bar

6.6

10

11

8

97 6

3

21

4

5

12

13

52236F

S3

Loading...

Loading...