SQS3

Scalable Quality

Solution 3

The scalable software solution that error-proofs

your product assembly.

Scalable

Traceability

Optimization

Quality

Assurance

Error

Proong

Maintenance

Production

Start Up

Smart

Connected

Assembly

Quality

Solution 3

The Scalable Quality Solution 3 is a

comprehensive software solution driving quality,

process reliability, transparency as well as product

safety.

This error proo ng software helps to achieve

zero defects and to reduce costs of rework, scrap

or warranty claims.

The advent of Industry 4.0 brings rapid changes

and new challenges.

With our Smart Connected Assembly concept,

which combines software, hardware and smart

accessories, you maintain quality control in

complex production systems and increase uptime

in production for critical operations.

The four core

values of Scalable

Quality Solution 3

Reductions in

Defects

New Product

Introduction

Improved

Productivity

Human

Interaction

2

3

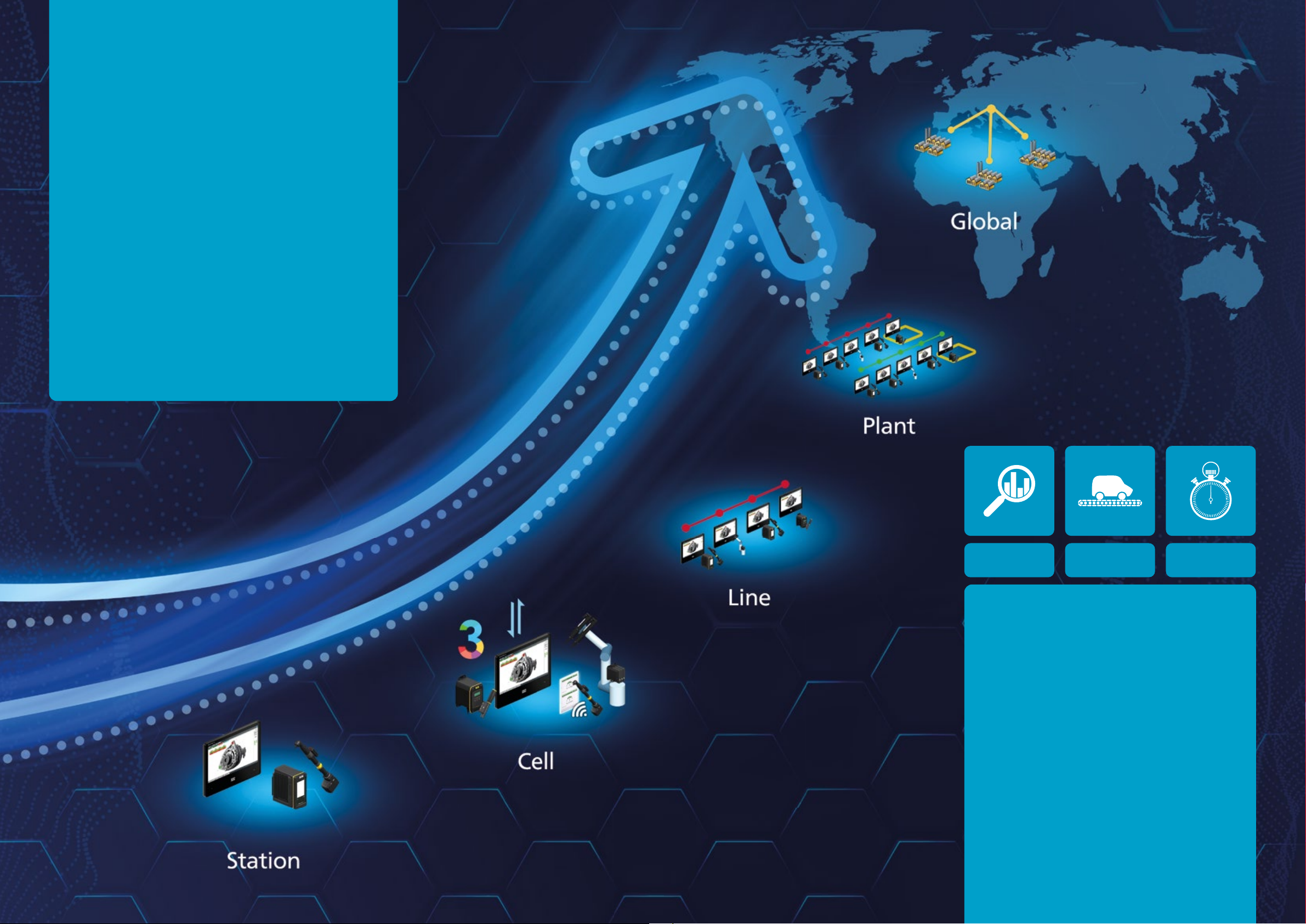

From stand-alone

station to complete

shop oor solution

The Scalable Quality Solution 3 (SQS3) eliminates errors

in product assembly regardless of whether you start with

a single station, a production cell or whether you want to

manage the process of your assembly line.

Up to 10 stations can be connected, even diff erent products

or variations of products.

SQS3 ensures product quality, process reliability and

transparency as well as product safety at each assembly

station.

It guides your operators through the assembly process

leaving no room for error or oversight.

Reductions in

Defects

New Product

Introduction

Improved

Productivity

Your bene ts

• Step-by-step visual operator guidance as well as

part and tool veri cation minimize defects

• Save money with less need for rework

• Target zero defect through rework ability

• Improved productivity and lower production

costs. Align up to 10 stations including

pre-station check and rework without

server installation

• Save time by using our remote centralized

con guration

• Greatly reduces training time for new operators

• Easy con guration to update process change

and new product introduction to the line

4

5

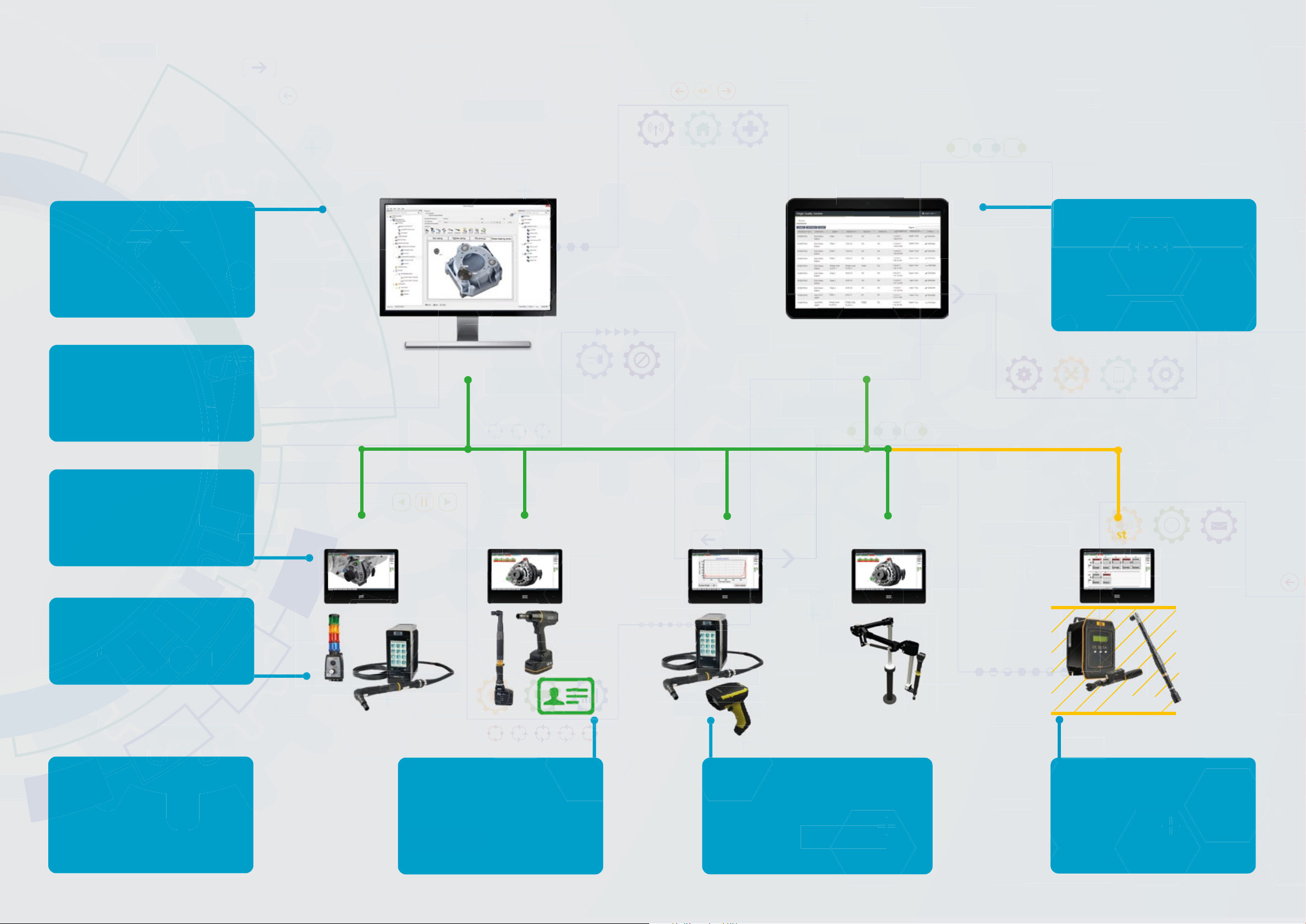

Ready for Industry 4.0:

The functions of SQS3

Central management of

workstations

Organizes SQS3 functions of

all workstations across the

shop oor from a single, easy

con guration interface.

Tool interlock

Enables and disables DC tools

and wrenches via the controller.

Use automatic program or job

selection.

Visual operator guidance

Step-by-step visual operator

guidance guarantees that

everything is done right the rst

time, every single time.

Station 1

Central con guration

Station 2

Consolidated data collection

Traceability of all assembly actions

(torque, parts, digital I/O, manual

confirmation) and missed tasks

from all stations and all products.

Easy and convenient access to

collected data via web UI.

Aggregated data

Station 4Station 3 Rework station

Digital I/O capability

Enables easy connectivity of

external I/O devices eliminating

the need for a PLC.

Rework

Basic pick-to-light/pick-bylight

Visually guides operators in

picking parts from bins based on

digital I/O capability.

User access control

Prevents unauthorized system

access enforcing user roles and

privileges.

6

Part veri cation and

documentation

Identi es parts by means of serial

numbers or product IDs to ensure the

correct parts are being used to build

a product.

Product rework

Detection of errors in production

process and automatic guidance

through the repair process at

dedicated rework stations.

7

SQS3 Product

Components

Con gurator

The SQS3 Con gurator is the graphical user

interface used for building and maintaining

assembly processes in SQS3.

All connected workstations and their devices

can be con gured through one single interface.

The con guration can be done either at the

workstation on the shop oor or remotely,

for instance from an offi ce desk. Updated

con gurations can be applied to the workstations immediately or at a scheduled time.

Web UI for result data

Operator Guidance

The SQS3 Operator Guidance drives the assembly

work ow at the workstation.

It interlocks with tools and other devices, guides

the operator and processes result data for

traceability and product repair purposes.

T

he web UI of the Scalable Quality Solution

3

is the single point of access to all assembly

data captured by SQS3 stations. It combines

traceability for all products and across all

workstations into one simple interface.

The web UI is responsive; suitable for desktop

PCs, laptops, tablets and smartphones.

Dashboard

The web UI also off ers you a dashboard for

each SQS3 station, grouping and displaying its

information in graphical tiles. The tiles show

real-time information about the stations’ health

condition (processors, memory and drives), their

connections and NOK trends,

in case result data is being stored in the database

of the Scalable Quality Solution 3.

Event Log

The web UI’s event log lists critical station events,

such as the loss of a connection to a device

or when tightening tools get locked, because

the operator has used up all of his tightening

attempts.

Messaging

From the web UI, users can send messages to the

operator guidance of any SQS3 station;

even to multiple stations at once.

Sent messages will be stored on the SQS3 station

for reuse whenever needed.

8

9

Applications

for SQS3

Assembly in complex

processes

(e.g. pre- and subassembly, CKD- and pilot

production, axle and engine assembly)

Challenge:

• Increased complexity for human factor in

all operations by reducing 90% of normal

process stations to a CKD plant

Solution:

• SQS3 stations for process control and operator

guidance instead of printed hand-outs

• Consolidated collection of result data replaces

manual recording

• Operator identi cation to track performance

• Pick-to-light for generic material selection

Bene t:

• High product quality, rework rates reduced by

30%

• Saved time and reduced costs

Improved

Productivity

30%

less rework approved by

one of our CKD-plant

customers

Reductions in

Defects

Human

Interaction

Product rework or repair

Challenge:

• No control of repair processes

• Quality issues due to wrongly repaired

products

Solution:

• SQS3 for error-proo ng with new stations

installed in the line to capture assembly

results and product status

• Repair of NOK tasks right away or later repair

in dedicated rework station

• Repair process is controlled as rigorously as

the regular assembly

Bene t:

• Avoidance of product recalls or eld repair

• Reduction of line stops

• Guaranteed product quality

• Traceability in stations

10

11

Applications

for SQS3

Backup and training

station

Challenge:

• No backup solution in case of tool controller

failures

• Product quality endangered

• Possibility of line stop if multiple

controllers fail

Solution:

• SQS3 mounted on a mobile cart

• All critical station processes con gured into

the SQS3

• Added traceability with operator login and

barcode scanning

• Repair process is controlled with the same

rigour as the regular assembly

• SQS3 EasyStart included

Bene t:

• Reduction of line stops

• Traceability of every step

• Save time through standardized and traceable

employee training

Reductions in

Defects

70%

reduction in tool related

line stops approved by

one of our customers

New Product

Introduction

Improved

Productivity

Prototype station

Challenge:

• Tools used in the prototype area are often not

the same as in the main line

• Product rework rate is high

Solution:

• SQS3 at prototype station records process

results, including tightening and manual

operations

• Engineers test, improve and verify assembly

process for prototypes before going into

production

• Operators train new assembly routines

Bene t:

• Reduction of line stops during production

• Increased product quality

• Less rework due to fewer operator errors

• Saved costs in operator trainings

12

13

Smart

Connected

Tools

Use Scalable Quality Solution 3 in combination

with Atlas Copco tools and controllers to

strenghten product quality. Connect SQS3

with the tools and controllers that best t your

product build process to optimize traceability,

product quality and to reduce costs.

Power Focus 6000

Expand your error proo ng and traceability

possibilities: Chose the Power Focus 6000 as your

perfect platform for any safety critical assembly.

In combination with hand held or xture tools

and bundled with our Scalable Quality Solution

3, the Power Focus 6000 helps you to make your

everyday-production easier and more effi cient

through zero-defect strategy.

Good for your product quality and cost savings.

MTF 6000

Get full process control, improved quality and an

optimized tightening process with MT Focus 6000

and Scalable Quality Solution 3 when working in

low-torque-segments like electronics.

While the compact system reveals and eliminates

tightening issues, you can support your operators

through the process with the Operator Guidance.

MTF 6000 and SQS3 are your perfect combination

to gain a complete error-proof workstation.

Reduce down time, setup time and assure full

traceability.

Key applications:

Car media, surgical robots, MRI machines.

Mechatronic System

Increase the quality of your manual tightening

joints considerably with the error proo ng

functionalities of the MWR Mechatronic system.

Perfect support even for tightening in limited

working space.

Expand your prospects of connectivity and error

proo ng by combining the Scalable Quality

Solution 3 with the Focus Controller and the

MWR mechatronic wrenches.

Key applications:

Hydraulic connections, brake pedals, anti-lock

brakes, wheel alignment, tube nuts and product

repair.

STwrench

The modular STwrench controller with

smartHEAD is a state-of-the-art, four-patent

wrench for any critical tightening where extreme

tolerances are a must-have.

Measuring exact torque and angle of your

assembly tasks, the STwrench also checks the

residual torque on an already tightened joint.

Bundle the STwrench with SQS3 to get perfect

traceability and error proo ng of your processes

and to ensure perfect quality of your products.

Key applications in production:

Safety critical tightening, hydraulic hoses,

diffi cult access joints, rework stations.

14

15

EasyStart SQS

for saving time and money

Bene t from EasyStart SQS for a fast and effi cient

start of operations through a standardized and

proven process from installation to training.

Your bene ts

Time and

cost saving

Right

Assessment of process

con guration requirements

System and process con guration

check and optimization

Con guration backup and

documentation

rst time

Trouble-free and

effi cient start of

operations

Minimizes risks

in production

quality

Globally stan-

16

Operator training including

certi cate

Additional services can be added

dardized process

for every step

17

Ordering data

Traceability

Optimization

Quality

Assurance

Error

Proong

Maintenance

Production

Start Up

Smart

Connected

Assembly

Description Ordering No.

SQS3 Standard software package, single license 8434 2380 02

SQS3 Standard edition, single license

(without software installation package)

SQS3 Standard edition, 2 licences

(without software installation package, packed in a small box)

SQS3 Tool

(electronic delivery)

SQS3 Tool, single license 8434 2380 10

SQS3 Tool, 2 licenses 8434 2380 11

SQS3 PLC

(electronic delivery)

SQS3 PLC, single license 8434 2380 13

SQS3 PLC, 2 licenses 8434 2380 14

SQS3 Connect

(electronic delivery)

SQS3 Connect, single license 8434 2380 16

SQS3 Connect, 2 licenses 8434 2380 17

SQS3 Rework

(electronic delivery)

SQS3 Rework, single license 8434 2380 19

8434 2380 03

8434 2380 04

8434 2380 09

8434 2380 12

8434 2380 15

8434 2380 18

22

SQS3 Upgrade

(electronic delivery)

SQS3 Upgrade, single license 8434 2380 21

8434 2380 20

23

9833 2047 01– EN 01/2020 © Atlas Copco AB, Stockholm, Sweden.

Atlas Copco AB

(publ) SE-105 23 Stockholm, Sweden

Phone: +46 8 743 80 00

Reg. no: 556014-2720

atlascopco.com

Loading...

Loading...