Atlas Copco Secoroc GM RH Operator Instructions Manual

Secoroc Grinding Equipment

Secoroc GM RH

Operator's instructions and Spare parts list

Contents

Safety instructions

Safety instructions .............................................. 3

Technical data ...................................................... 4

General ................................................................4

Applications .........................................................4

Technical description ..........................................4

Controls and other parts ....................................5

General care instructions ...................................6

Grinding ............................................................... 7

Maintenance ........................................................ 8

Accessories and consumables ...........................9

Spare parts list ............................................................ 10

Grinding unit ..................................................... 11

Rotation head .................................................... 11

Guide unit .......................................................... 12

Arm unit ............................................................. 12

Bit holders ......................................................... 13

Before using the machine, read through these instruc-

tions carefully.

Important safety information is given at various points

in these instructions.

Special attention must be paid to the safety information

contained in frames and accompanied by a warning symbol

(triangle) and a “signal word“, as shown below:

DANGER

indicates an immediate risk that WILL result in serious

injury or death if the warning is not observed.

WARNING

indicates hazards or hazardous procedures which COULD

result in serious injury or death if the warning is not observed.

CAUTION

indicates hazards or hazardous procedures which COULD

result in injury or damage to equipment if the caution is not

observed.

Hydraulic unit .................................................... 14

Hydraulic diagram ............................................ 14

Electric unit ........................................................ 15

Wiring diagram ................................................. 15

Any unauthorized use or copying of all or part of the contents of

this publication is prohibited. This applies in particular to trademarks, model denominations, spare part numbers and drawings.

Subject to alteration without prior notice.

© Copyright 2000-2013

Atlas Copco Secoroc, Fagersta, Sweden

It can be dangerous to use the

machine if the care and maintenance instructions are not

followed carefully.

Before using the machine, read

the operator’s instructions carefully and then put them in a safe

place for future reference.

Emergency STOP

Always replace damaged or illegible signs

Use approved spare parts only. Any damage or malfunction that can be attributed to the use of unauthorized spare

parts is not covered by the machine warranty and invalidates product liability.

Also observe the following general safety instructions:

Make sure that there are no other personnel close to the

grinding machine while grinding is in progress.

Always wear goggles, protective clothing, steel toe safety

shoes, gloves and ear protectors during grinding. Any local

regulations must also be observed.

Wear an approved dust mask or arrange an effective

dust-extraction system. This is especially important when

grinding indoors.

The machine must not be used for any purpose other

than that for which it is intended. See “Applications“.

The machine must not be modied without the permission of the manufacturer. Modications not approved by

Atlas Copco Secoroc can incur the risk of serious injury to

yourself and others.

Before intervening in the oil or electrical systems, make

sure there is no pressure in the oil system and that the electrical system is shut down.

Beware of the risk of re and explosion that could be

initiated by sparks from the grinding work.

Before using the machine, visually check the hoses and

electric wiring for any damage. If any visible damage is

detected, replace before using machine.

Do not use the grinder when there is risk of:

seismic event, lightning or hydraulic hose burst.

32

Technical data

Specifications Tophammer Universal

Max. distance between bit

holder and grinding wheel

Drill bit diameter 35 - 127 mm 35 - 165 mm

Max. grip size n/a

Min. distance between

buttons

Rec. Oil pressure, min-max 150-210 bar 150-210 bar

Oil consumption 12 l/min 15 l/min

Cooling liquid consumption max 10 l/h max 10 l/h

Voltage +/- 24-28 VDC +/- 24-28 VDC

Current 6 A 6 A

Speed, spindle 9 500 rpm 12 000 rpm

Weight 81 kg 85 kg

Sound pressure during

grinding*

Sound power level during

grinding**

Vibration level during

grinding***

Manufactured: Atlas Copco Secoroc, Fagersta, Sweden

230 mm 230 mm

110 mm (QL6,

COP66)

3,5 mm 3,5 mm

85 dB (A) 85 dB (A)

95 dB (A 95 dB (A

< 2,5 m/s² < 2,5 m/s²

General

The Secoroc GM RH grinding machine is fully hydraulic powered and designed to be attached to a drill rig. It grinds cemented-carbide buttons and the surrounding body steel in the same

operation using a diamond-coated grinding wheel. The machine

has an automatic feeding device, which makes it simple to use.

Applications

The Secoroc GM RH is intended for grinding threaded and

tapered button bits up to 127 mm in diameter and DTH and COPROD bits up to 165 mm, and has a high grinding capacity.

Technical description

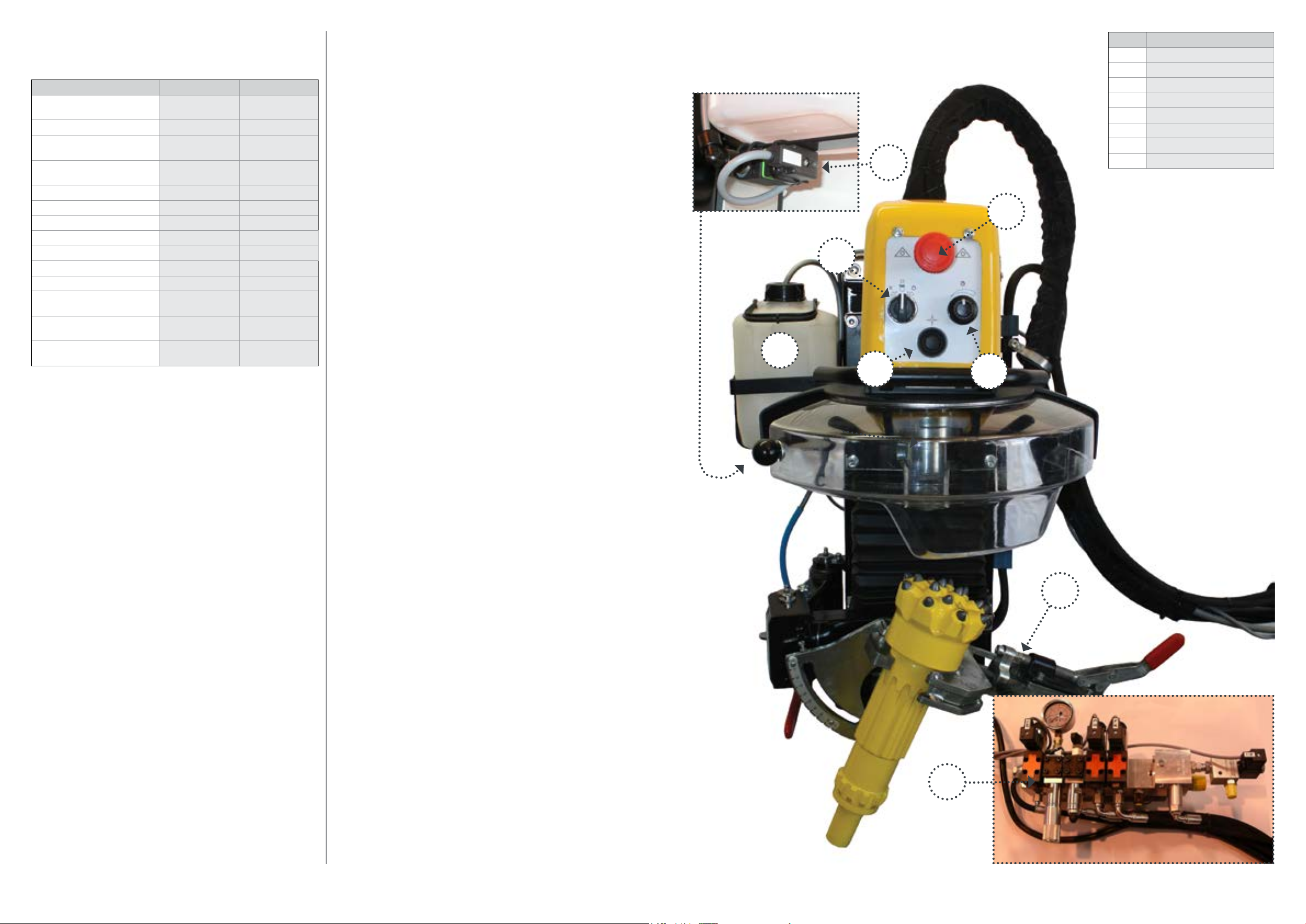

The Secoroc GM RH consists principally of the following component assemblies:

A rack with the guide and feed cylinder.

A grinding unit with the spindle and orbital rotation. The

control panel is mounted on the grinding unit.

Controls and other parts

1

4

2

6

Ref.No. Description

1 Pump

2 Water tank

3 Emergency stop

4 Start/stop knob

5 Timer

6 Centring button

7 Bit holder

8 Hydraulic unit

3

5

* Equivalent continuous A-weighted sound pressure level measured at operator’s ear level during grinding. Possible spread due

to measuring method and production factors: 3 dB(A).

** Sound power level established in accordance with

EN 61029-1. Possible spread due to measuring method and

production factors: 3 dB(A). Average value for frequency range

100-6300 Hz.

*** Vibration measurement according to EN 61029-1.

Tophammer: A clamping device for threaded and tapered

bits (only for Tophammer bits).

Universal: A universal clamping device (for Tophammer-,

DTH- and COPROD bits).

A hydraulic valve unit.

A box with the electrical components.

A coolant pump with a coolant plastic can. Use water as cool-

ant medium. Add anti-freeze liquid (for example washer uid) to

prevent freezing.

A local emergency stop.

- The emergency stop function does not deactivate the drill rig,

only the grinding machine.

- When resetting the grinding machine emergency stop, the orbital movement will continue to it’s starting position.

7

8

54

Loading...

Loading...