Atlas Copco Secoroc G10, Secoroc G10L Operator Instructions And Spare Parts List

Secoroc Rock Drilling Tools

Secoroc Pneumatic Tools

Secoroc G10/G10L Pneumatic Pick Hammer

Operator's instructions / Spare parts list

Foreword

Thank you for selecting the Secoroc pick hammer G10/G10L.

These instructions were developed to help you get the best performance and

productivity from the use of your new pick hammer.

Please refer to them also for the correct maintenance of the pick hammer.

2

Table of Contents

Scope of application ................................................... 4

Specification .......................................................... 4

Safety instructions ..................................................... 5

Operation ............................................................ 6

Using the pick hammer for the first time ................................ 6

Preparations before starting .......................................... 6

Fitting the insertion tool .............................................. 7

Before fitting the insertion tool ......................................7

Fitting the insertion tool............................................8

Start and Stop ...................................................... 8

Starting the pick hammer ..........................................8

Stopping the pick hammer .........................................8

Starting a cut ....................................................... 8

Operating ......................................................... 9

Maintenance ....................................................... 9

Once a shift (after 8 hours of operation) ..............................9

Once a week (after 40 hours of operation) .............................9

Once a month (after 200 hours of operation)...........................9

Selection of spare parts .............................................. 9

Storage .......................................................... 10

Scrapping and waste disposal ....................................... 10

Trouble shooting ..................................................... 10

Spare parts list and exploded drawing ................................... 12

3

Scope of application

The Secoroc pneumatic pick hammer G10/G10L is a machine with D-handle,

designed for light demolition and plant work. The machine can be used both

horizontally and vertically. No other use is permitted.

Specification

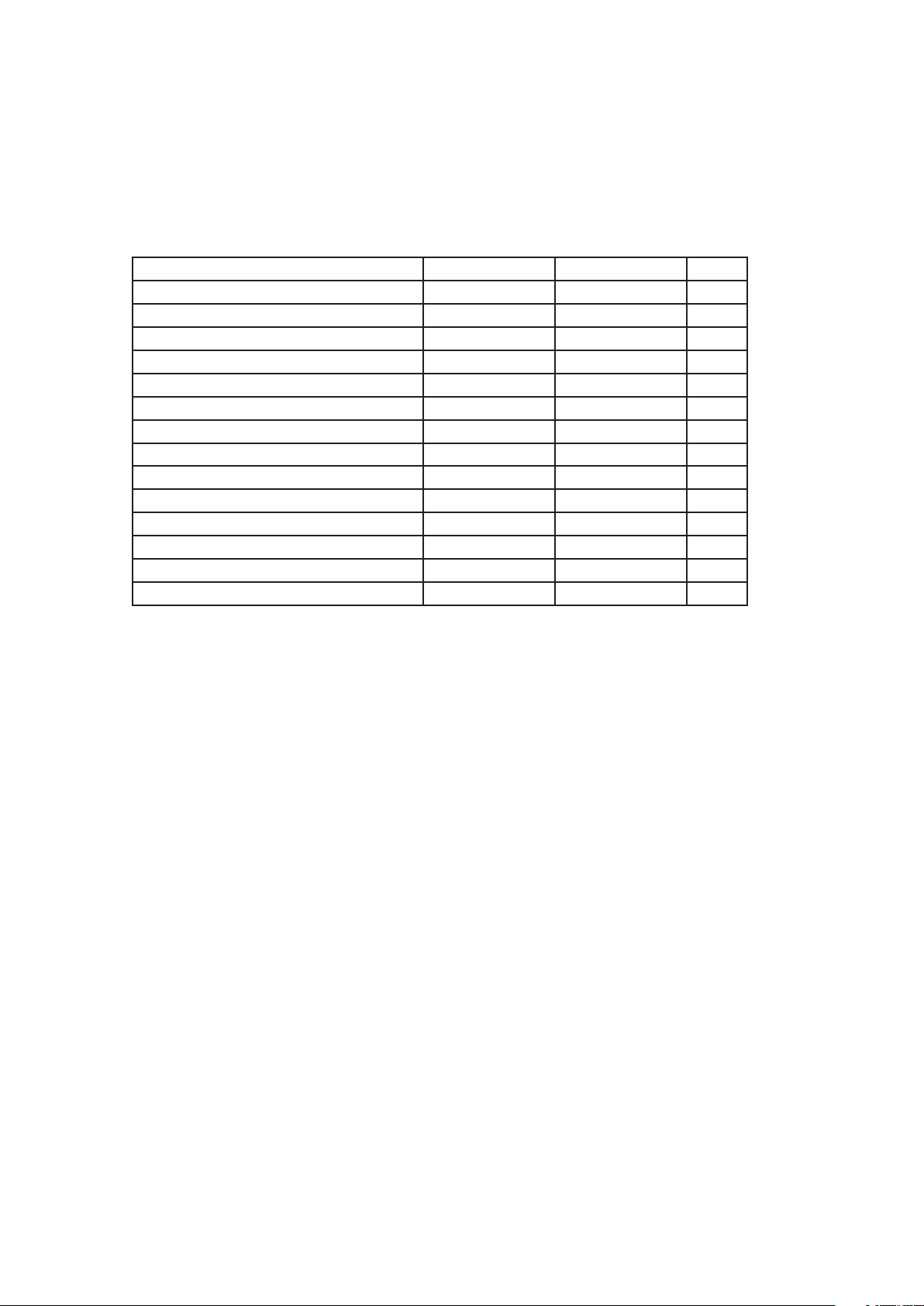

Pneumatic pick hammer G10 G10L

Weight 10.6 10.6 kg

Dimension (L x W x H) 575x170x90 575x170x90 mm

Cylinder diameter 38 38 mm

Piston stroke 155 155 mm

Working pressure 4–5 4–5 bar(e)

Impact energy (at 5.0 bar (e)) ≥39 ≥39 J

Impact energy (at 4.0 bar (e)) ≥32 ≥32 J

Air consumption (at 5.0 bar (e)) ≤20 ≤20 l/s

Air consumption (at 4.0 bar (e)) ≤16 ≤16 l/s

Impact frequency (at 5.0 bar (e)) ≥16.5 ≥16.5 Hz

Impact frequency (at 4.0 bar (e)) ≥15 ≥15 Hz

Air hose inner diameter 16 16 mm

Working temperature -30 to +50 -30 to +50 ºC

Shank size R25x75 R24x70 mm

4

Safety instructions

To reduce the risk of serious injury or death to yourself or others, carefully read

through this instruction booklet before putting the pick hammer to use. Always

follow the instructions given in this manual.

h Always wear a safety helmet, impact resistant eye protection with side protection

and ear protectors during breaking. Any local regulations that exist must also be

observed.

h When breaking in certain minerals, there is a risk of spark generation. Before

starting work, check that the machine is approved (in accordance with local

regulations) for work under such conditions.

h Always take great care when using the machine. The insertion tool is subjected to

heavy loading and can break, with a risk of injury to personnel.

h Check that the hoses used are of the right quality, and that all hose connections

are in good condition and properly tightened.

h Before starting work on any of the systems, make sure that the air and water

systems are un-pressurized.

h The machine is not electrically insulated. If the machine comes into contact

with electricity serious injuries or death may result. To reduce the risk of such

injury or death, never operate the machine near any electric wire or other source

of electricity. Make sure that there are no concealed wires or other sources of

electricity.

h Exposure to crystalline silica (sometimes called 'silica dust') as a result of

breaking in rock may cause silicosis, cancer or death. To reduce silica exposure,

use respiratory protective equipment.

h A compressed air hose that comes loose can lash around and cause personal

injury or death. Check that the compressed air connections are not damaged and

that they are properly attached.

5

Loading...

Loading...