Atlas Copco RE Qualifier II User Manual

RE Qualifier System Manual i

TABLE OF CONTENTS

Quick Start Guide............................................................................1

Introduction .....................................................................................3

Main Screen ....................................................................................3

Passwords ........................................................................................5

AutoCal™ .......................................................................................6

V iewing A Run ................................................................................8

Resetting the Batch .......................................................................10

More Options ................................................................................11

Editing Parameter Sets ..................................................................12

Selecting a New Parameter ...........................................................15

Globalizing a Parameter ...............................................................16

Editing I/O Options .......................................................................17

Editing the Time and Date ............................................................19

Resetting the Total and/or Batch ..................................................20

Viewing Past Statuses ...................................................................21

Choosing a New Password ...........................................................22

Adjusting the Display ...................................................................23

I/O Structure .................................................................................24

RS-232 Connector

I/O Connector

Remote Transducer Connector

Dip-Switch Settings ......................................................................26

Dip-Switch

Test Modes

Part Numbers ................................................................................27

1 RE Qualifier System Manual

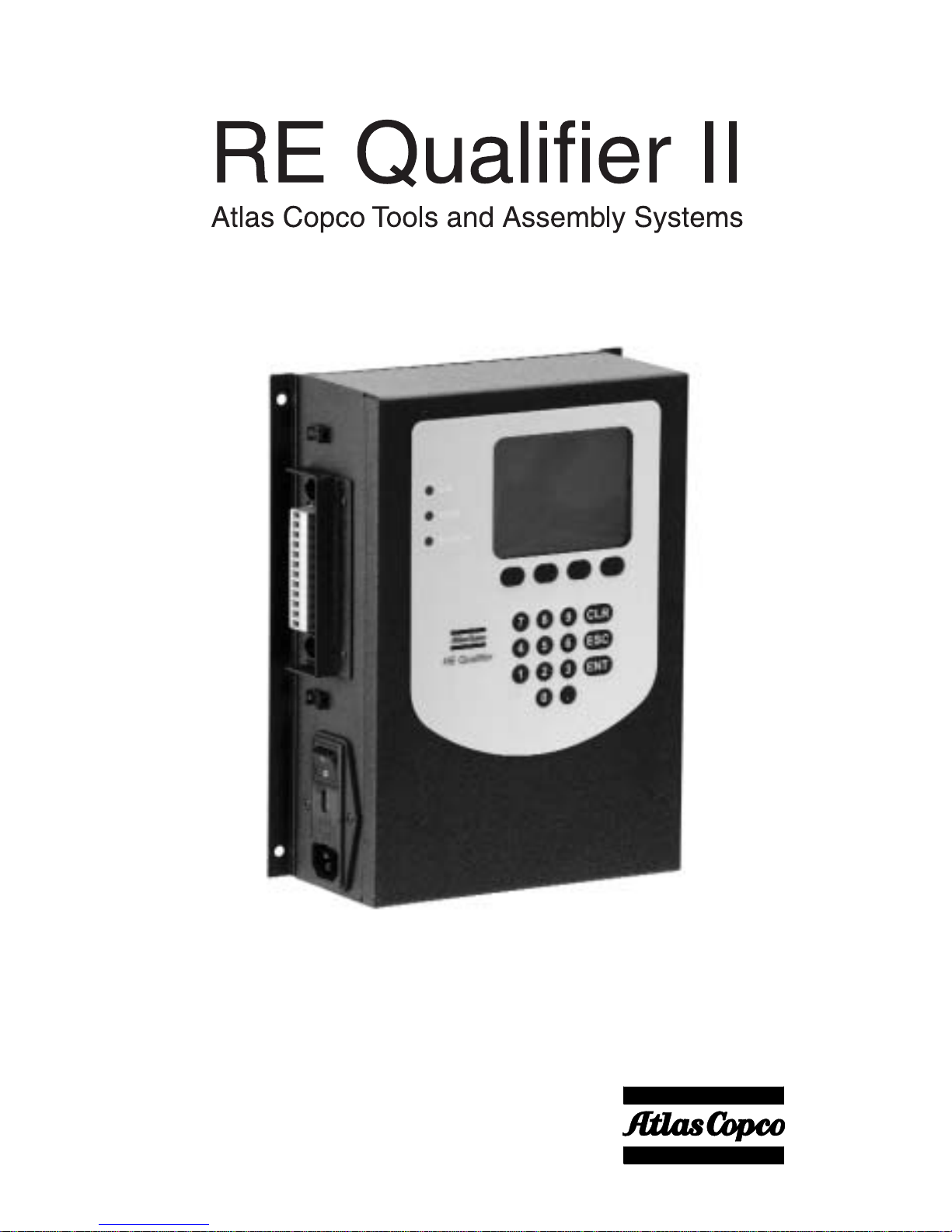

Step 1:

Power up the unit and wait for the

MAIN screen to appear. Once it

is in view, press the AUTO CAL

soft-key.

Step2:

Enter the password to access programming functions. All units

ship from the factory with a

default password of 0 1 0 4.

Step 3:

Be sure the transducer is plugged

into the RE Qualifier and that the

tool is connected to the transducer.

Then press the NEXT soft-key.

Step 4:

Run the tool on the target fastener

and then press the NEXT soft-key.

Be certain to run the fastener from

beginning to end, allowing the

tool to clutch out.

Step 5:

Check the screen and be sure the

calibration was successful. If not,

return to step 1. If the calibration

succeeded, proceed to step 6.

Press any key to continue.

Step 6:

If the batch count needs programmed, press the MORE softkey.

Quick Start Guide

RE Qualifier System Manual 2

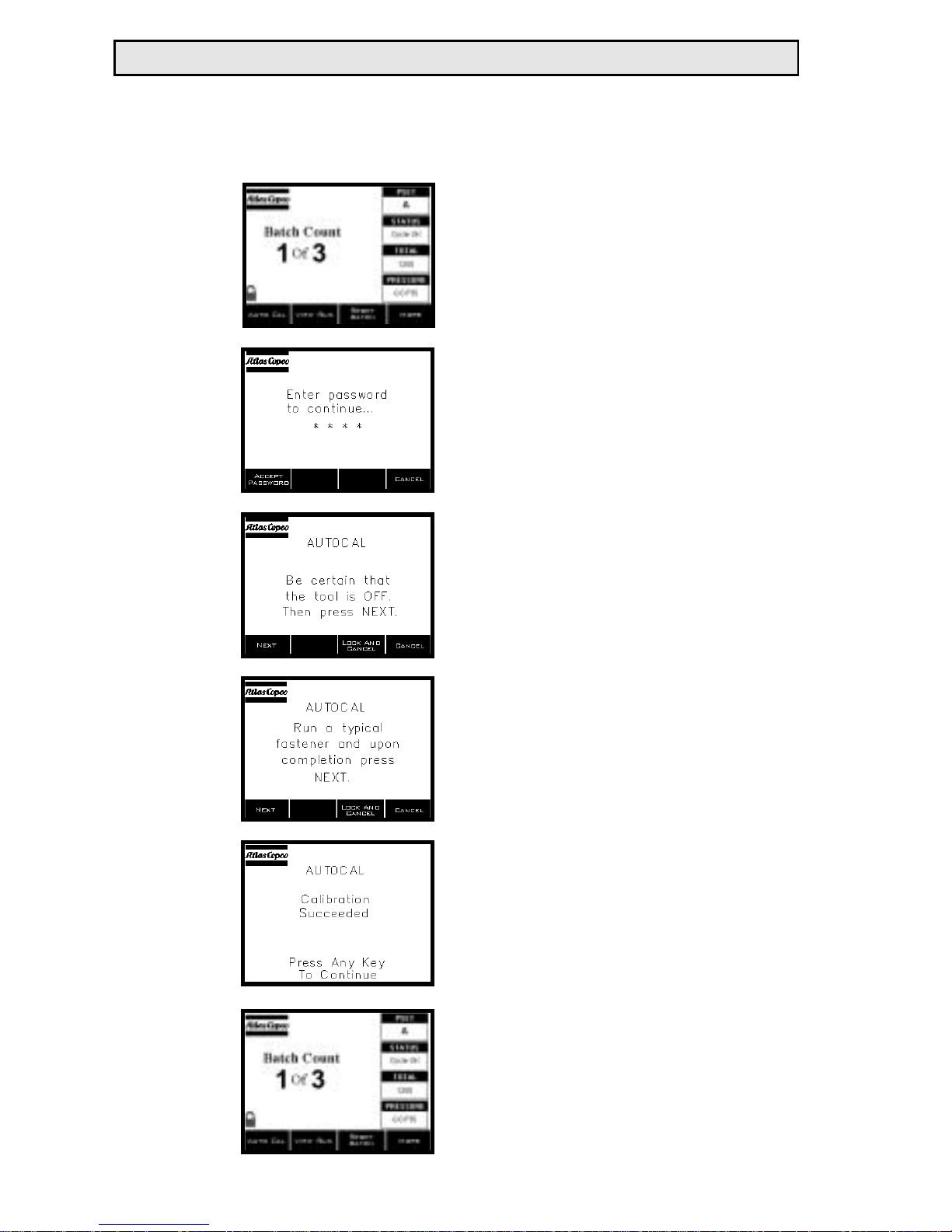

Step 7:

Once the MORE OPTIONS screen

is in view, press ‘1’ on the keypad

in order to EDIT THE PARAMETER.

Step 8:

Select the current parameter by

pressing the number on the keypad adjacent to the desired parameter.

Step 9:

Press the ‘8’ key in order to edit

the number of fasteners in a batch.

Step 10:

Enter the desired number for the

batch setting. When complete hit

ENT.

Step 11:

When the EDIT PARAMETER

screen re-appears, press the

LOCK AND RETURN soft-key.

Step 12:

The unit will return to the MAIN

screen and be locked. Run several

fasteners to ensure that the unit is

working properly.

Introduction

This document is an operations guide for the Atlas Copco RE

Qualifier II. The RE Qualifier monitors a pneumatic signal from

inside any Atlas Copco tool equipped with an RE port. By analyzing the pneumatic signal, the RE Qualifier can aid in the manufacturing process by determining if a fastener has been installed

properly and also by counting the number of fasteners that have

been installed.

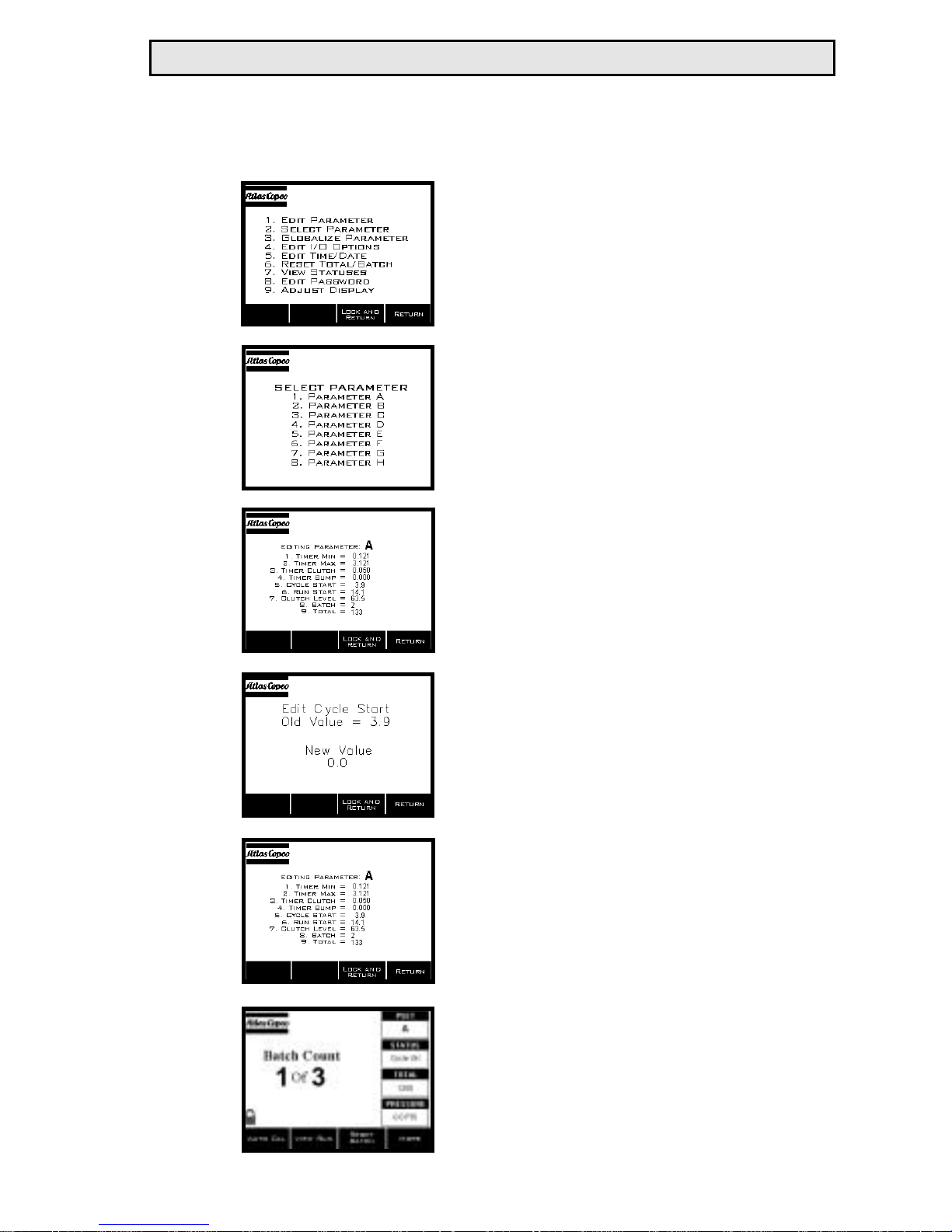

Main Screen

To the left is an example of what the main screen looks like.

During normal operations, when the unit is monitoring fastening

processes, this is the screen that will be in use.

Along the right hand side of

the screen, four boxes appear

vertically and are labeled

PSET, STATUS, TOTAL, and

PRESSURE.

The box labeled PSET will

contain a letter corresponding

to the parameter set that is

currently in use. The RE

Qualifier has eight different parameter sets (A - H).

The STATUS box will be empty when the tool is in cycle. After

the completion of a cycle, this box will hold the status from the

last fastening process. Cycle OK, Batch OK, Rej Tmin, Rej

Tmax, and No Clutch are all statuses that may appear in this

area. Cycle OK indicates that the last fastener was installed properly. Batch OK means that the last group of fasteners that make

up the previous assembly have been installed properly. Rej Tmin

informs the operator that the minimum run timer was violated and

that the last fastener was not installed properly. Rej Tmax indi-

3 RE Qualifier System Manual

cates that the maximum run timer was violated. The status No

Clutch informs the user that the tool’s clutch did not complete the

fastening process.

The box labeled TOTAL displays the number of batches that have

been completed since the last reset. This number will start at 0

and count up to 65,535 before rolling back over to zero. This

value can be reset through the use of the keypad.

A live pressure indication will appear in the final box labeled

PRESSURE. This pressure value is given in PSI and it represents

the pressure inside the tool’s port.

In the center of the screen, a batch count and the number of fasteners in the batch appears. This information is represented as

COUNT of BATCH. The count is the number of fasteners that

have been completed towards the programmed batch setting. The

batch is a number that is programmed into the current parameter.

The batch should represent the number of fasteners in the assembly under construction.

Along the bottom of the screen are several “soft” key indications.

Below each of these soft key indicators is a button. The function

of the button will change as different screens are accessed. The

text in the soft key indicators will also change to inform the user

of the current function of the button below it.

Above the left most soft key on the main screen is an icon that

resembles a padlock. The padlock will be in one of two states,

either open or closed. If the padlock is closed, the unit is locked

and a password will have to be entered in order to access programming features. If the padlock is open, programming features

are readily available through the selections on the soft-keys.

RE Qualifier System Manual 4

Passwords

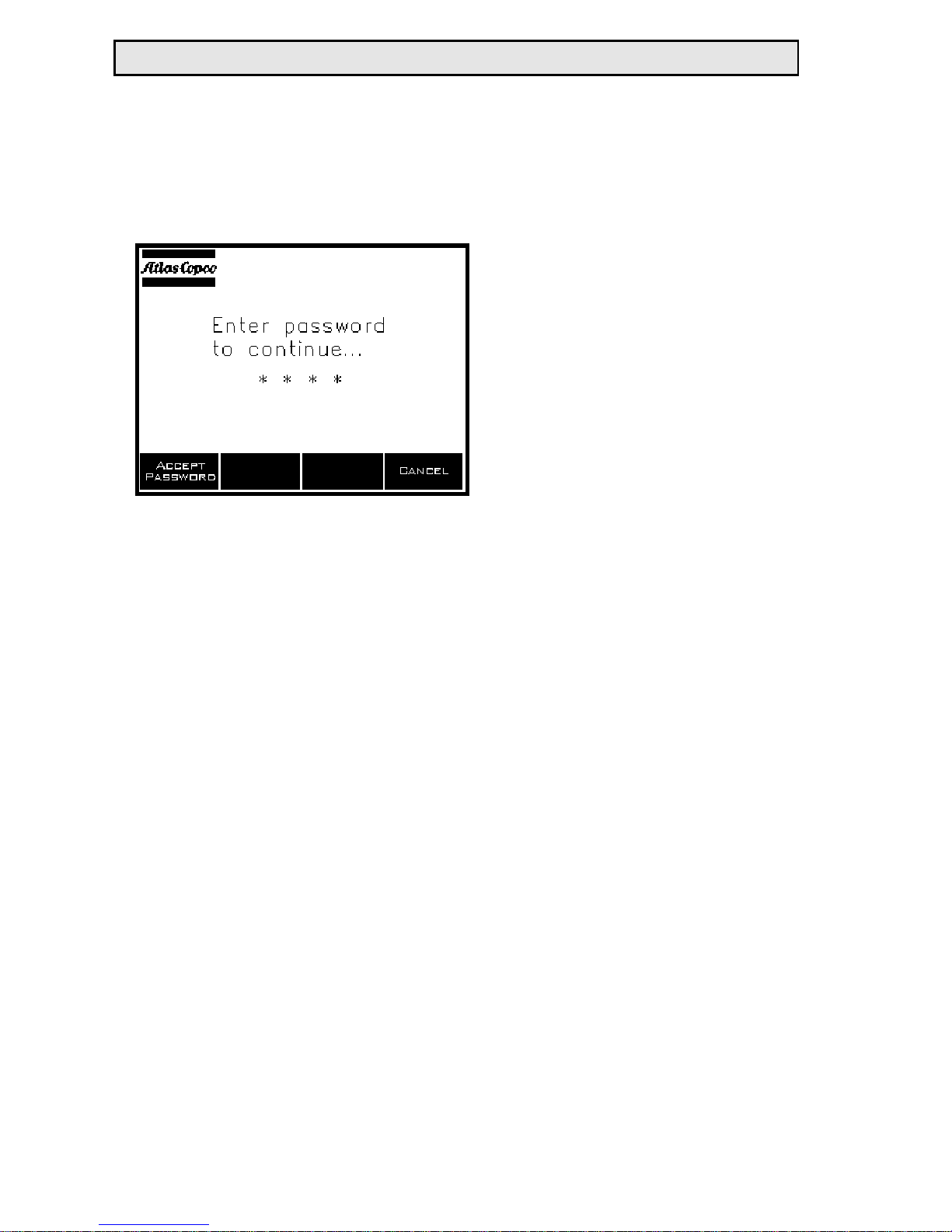

Users will be prompted to enter a password any time the unit is

locked and a programming function is accessed. All units are

shipped with the initial password set to 0 1 0 4.

Once prompted to enter a

password, use the keypad to

enter the four digit code. If

any mistakes are made during

the entry process, the CLR

button can be used to remove

one digit at a time.

As each digit is entered, an asterisk (*) will appear indicating that

a number has been entered. Once all four numbers have been

entered in the proper sequence, the user can press either the

Accept Password soft-key or the ENT button.

If the user wishes to return to the main screen without entering

the password, either the Cancel soft-key or the ESC button may

be pressed.

If the password is entered properly, the user will be taken to the

function that was requested prior to the Enter Password screen

appearing. The password can be changed to any four digit code.

5 RE Qualifier System Manual

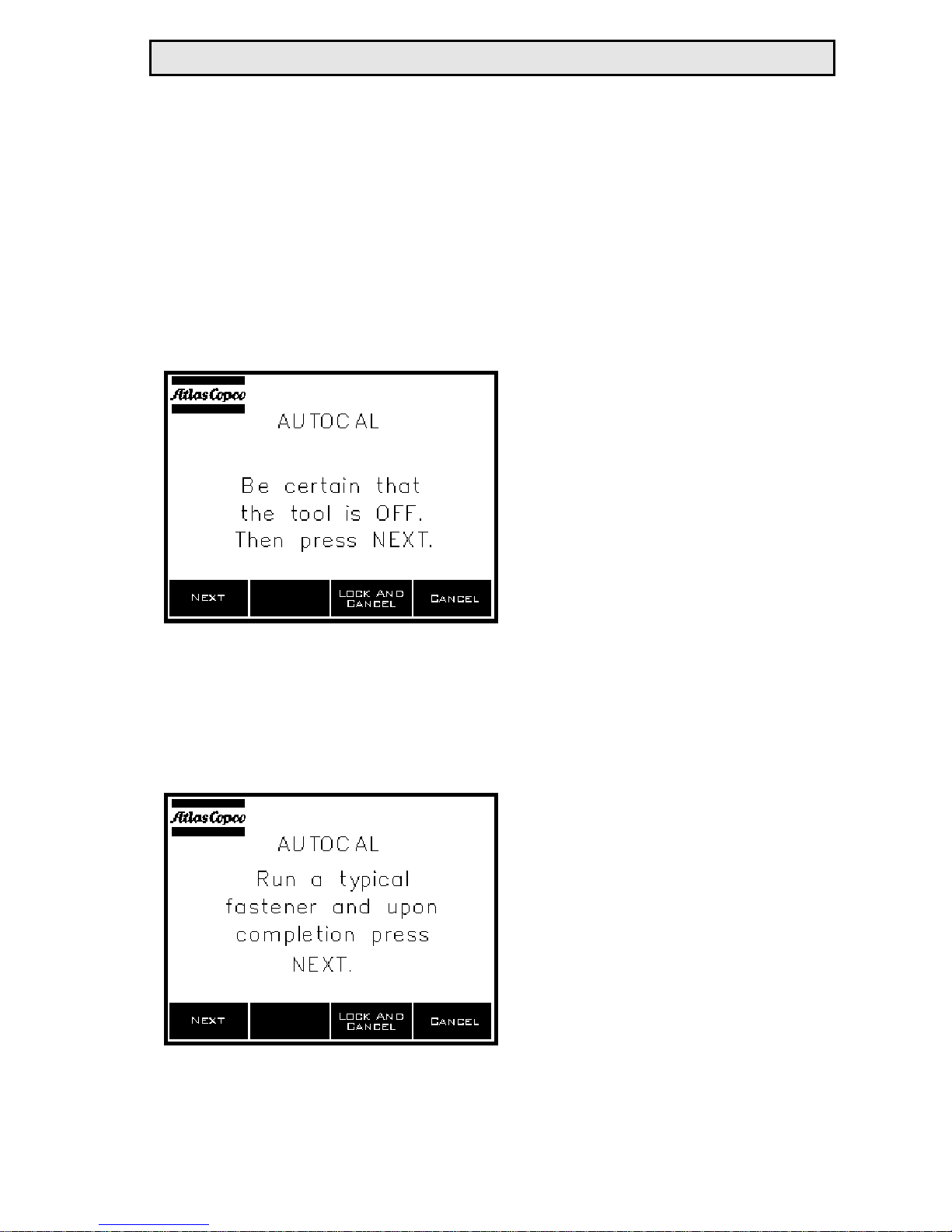

AutoCal™

The RE Qualifier has been programmed to automatically recognize the pneumatic signature from several different types of tools.

In order to calibrate the RE Qualifier using this feature, press the

AutoCal™ soft-key while the unit is showing the main screen.

If the unit is locked, enter the password when prompted for it.

The first screen in the

AutoCal™ process will say,

“AUTOCAL .. Be certain that

the tool is OFF. Then press

NEXT.”. At this point be

sure the pressure transducer is

connected to both the tool

and to the RE Qualifier and

push the soft-key labeled

NEXT.

After pressing NEXT, the screen will state, “AUTOCAL .. Run a

typical fastener and upon completion press NEXT.”. Tighten a

target fastener using the tool that the RE Qualifier is monitoring.

During this process, run the

fastener completely allowing

the tool’s clutch mechanism

to turn off the tool. If you

make a mistake during this

part of the process, run another fastener. The RE Qualifier

will use the very last fastening process it sees as the

basis for the calibration.

RE Qualifier System Manual 6

At the end of the fastening sequence, release the tool and press

the NEXT soft-key. The REQualifier will try to set-up it’s

calibration parameters using

the pneumatic signature from

the last run.

Once the calibration attempt

is complete, the RE Qualifier

will inform the user if the calibration was successful or

not. In either case, pressing

any key on the key-pad will return the user to the main screen.

7 RE Qualifier System Manual

Loading...

Loading...