Atlas Copco QAS 60 Pd Instruction Manual

QAS 60 Pd S2A APP

Instruction Manual

for AC Generators

English

ATLAS COPCO - PORTABLE ENERGY DIVISION

www.atlascopco.com

Printed matter N°

2954 6280 00

04/2012

QAS 60 Pd

Instruction Manual for AC Generators

Instruction manual ..................................................................................5

Circuit diagrams ...................................................................................111

Original instructions

- 4 -

Warranty and Liability Limitation

Use only authorized parts.

Any damage or malfunction caused by the use of unauthorized parts is not covered by

Warranty or Product Liability.

The manufacturer does not accept any liability for any damage arising from modifications,

additions or conversions made without the manufacturer's approval in writing.

Neglecting maintenance or making changes to the setup of the machine can result in major

hazards, including fire risk.

While every effort has been made to ensure that the information in this manual is correct,

Atlas Copco does not assume responsibility for possible errors.

Copyright 2012, Atlas Copco Airpower n.v., Antwerp, Belgium.

Any unauthorized use or copying of the contents or any part thereof is prohibited.

This applies in particular to trademarks, model denominations, part numbers and drawings.

- 5 -

Contents

1 Safety precautions for on-

site generators ............................8

1.1 Introduction........................................8

1.2 General safety precautions ............... 9

1.3 Safety during transport and

installation........................................10

1.4 Safety during use and

operation .......................................... 11

1.5 Safety during maintenance

and repair..........................................12

1.6 Tool applications safety ..................14

1.7 Battery safety precautions..............14

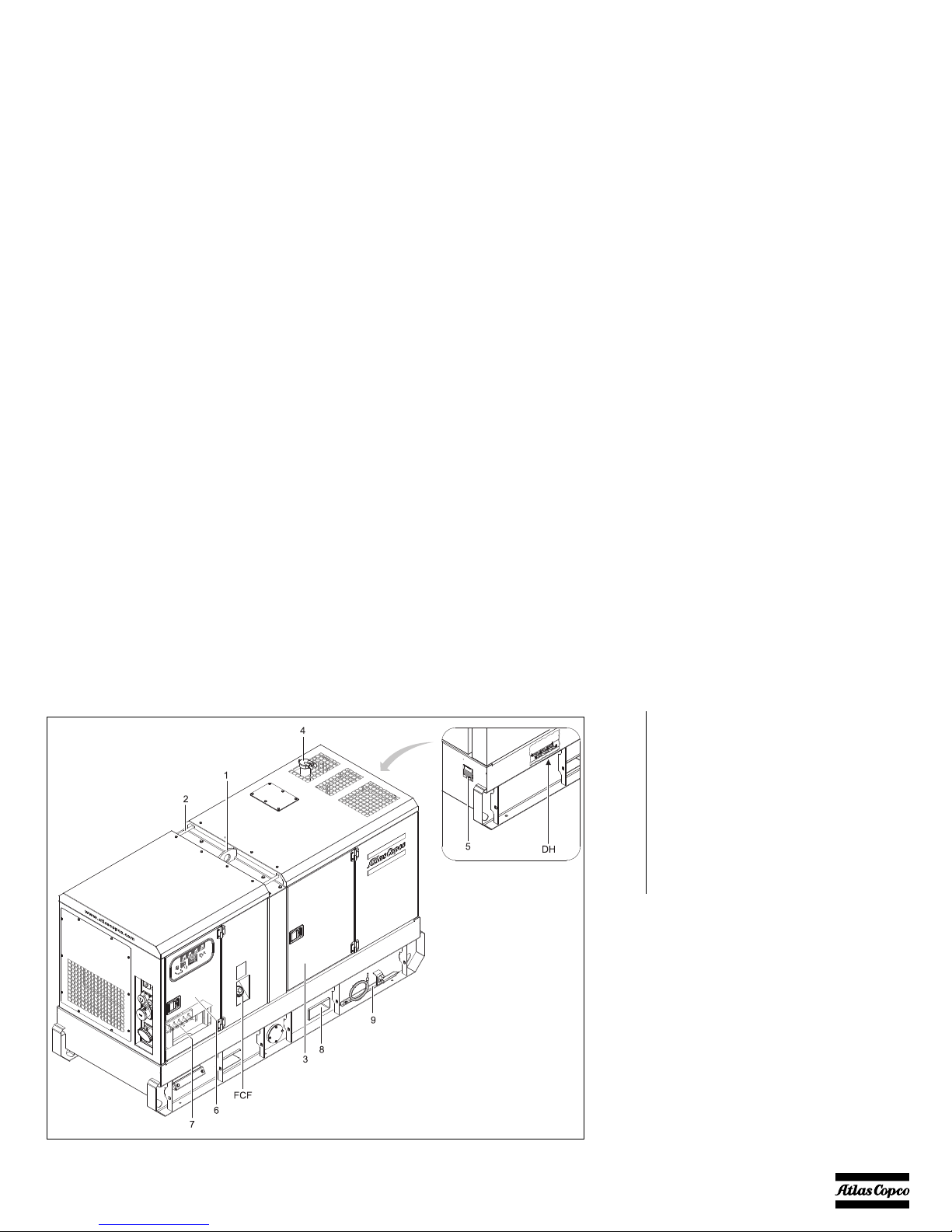

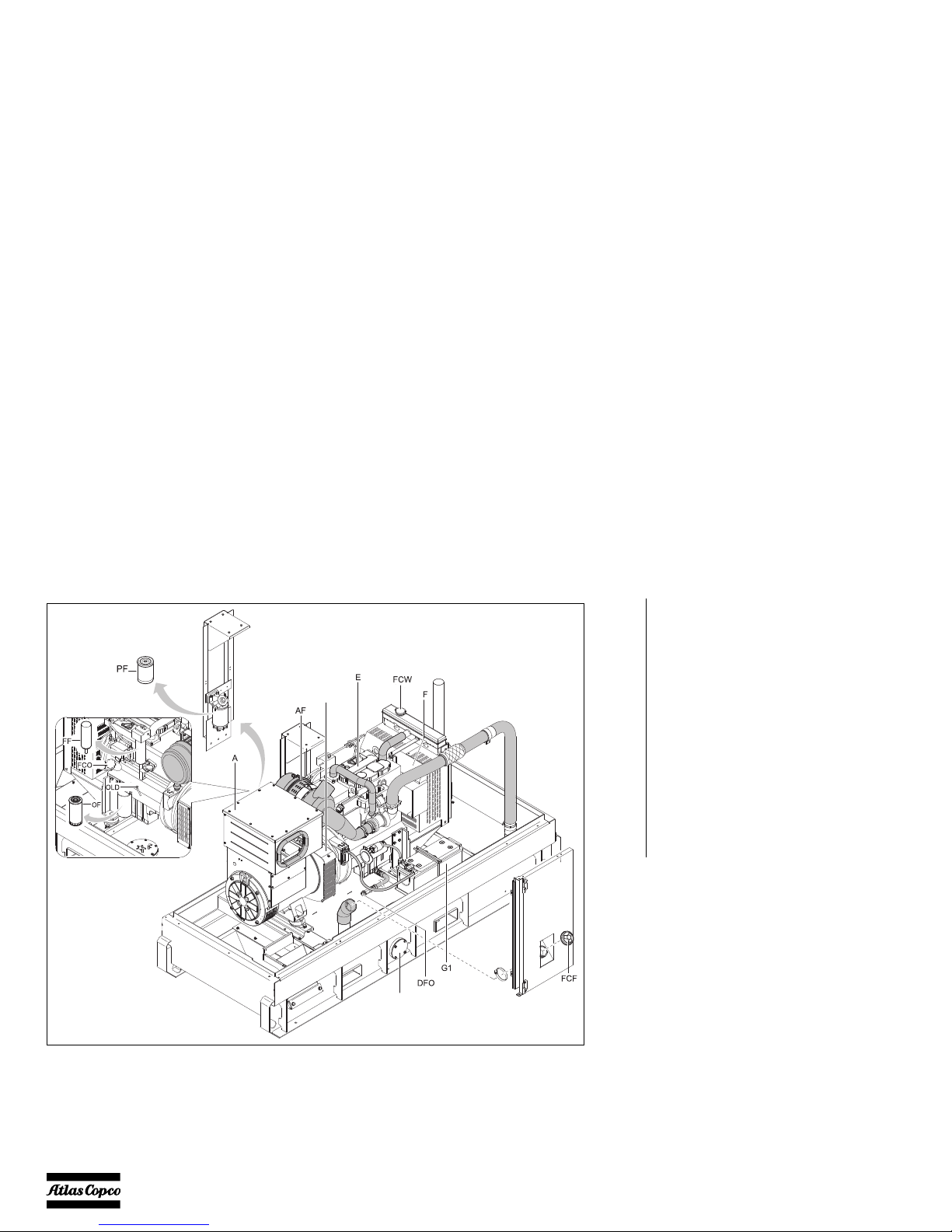

2 Main parts .................................15

2.1 General description .........................15

2.2 Markings ...........................................17

2.3 Mechanical features.........................17

2.3.1 Engine and alternator ...................... 17

2.3.2 Cooling system.................................17

2.3.3 Safety devices ..................................18

2.3.4 Bodywork..........................................18

2.3.5 Control panel ....................................18

2.3.6 Data plate and serial number..........18

2.3.7 Drain plugs and filler caps ...............18

2.3.8 Spillage free skid..............................18

2.4 Electrical features.............................19

2.4.1 Control and indicator panels ...........19

2.4.1.1 Qc1002™ controller..........................19

2.4.1.2 Qc2002™ controller..........................20

2.4.1.3 Qc4002™ MkII controller .................21

2.4.2 Output terminal board .....................22

3 Installation and

connection.................................23

3.1 Lifting ................................................23

3.2 Installation........................................23

3.2.1 Indoor installation ............................23

3.2.2 Outdoor installation .........................23

3.3 Connecting the generator ...............24

3.3.1 Precautio ns for non-lin ear and

sensitive loads ..................................24

3.3.2 Quality, minimum section and

maximum length of cables..............24

3.3.3 Connecting the load.........................25

4 Operating instructions............. 26

4.1 Before starting..................................26

4.2 Operating and setting Qc1002™ ....26

4.2.1 Starting..............................................26

4.2.2 During operation ..............................27

4.2.3 Stopping............................................27

4.2.4 Setting the Qc1002™ .......................28

4.2.4.1 Pushbutton and LED functions ........28

4.2.4.2 Qc1002™ menu overview................28

4.2.4.3 Qc1002™ menu description ............29

4.2.4.4 Parameter list....................................31

4.2.4.5 LOG list..............................................33

4.2.4.6 Remote start operation....................33

4.3 Operating and setting Qc2002™ ....34

4.3.1 Starting..............................................34

4.3.2 During operation ..............................34

4.3.3 Stopping............................................35

4.3.4 Setting the Qc2002™ .......................35

4.3.4.1 Pushbutton and LED functions ........35

4.3.4.2 Qc2002™ menu overview................37

4.3.4.3 Qc2002™ menu description ............37

4.3.4.4 Parameter list....................................40

4.3.4.5 LOG list..............................................45

Congratulations on the purchase of your AC generator. It is a solid, safe and reliable machine, built according to the latest technology. Follow the instructions in this

booklet and we guarantee you years of troublefree operation. Please read the following instructions carefully before starting to use your machine.

While every effort has been made to ensure that the information in this manual is correct, Atlas Copco does not assume responsibility for possible errors. Atlas Copco

reserves the right to make changes without prior notice.

- 6 -

4.4 Operating and setting

Qc4002™ MkII ..................................46

4.4.1 Starting ............................................. 46

4.4.2 During operation .............................. 46

4.4.3 Stopping ........................................... 46

4.4.4 Setting the Qc4002™ MkII ............... 47

4.4.4.1 Pushbutton and LED functions ........47

4.4.4.2 Qc4002™ MkII menu

overview ........................................... 49

4.4.4.3 Changing settings ............................ 52

4.4.4.4 Standard modes...............................53

4.4.4.5 Standard applications......................54

4.4.4.6 Paralleling ......................................... 60

4.4.4.7 Overview of applications .................61

5 Maintenance..............................64

5.1 Maintenance schedule.....................64

5.1.1 Use of maintenance schedule.........69

5.1.2 Use of service paks .......................... 69

5.2 Preventing low loads.......................70

5.3 Alternator maintenance

procedures........................................70

5.3.1 Measuring the alternator

insulation resistance ........................70

5.4 Engine maintenance procedures....70

5.4.1 Engine oil level check ......................70

5.4.2 Engine oil and oil filter change .......71

5.4.3 Coolant check ...................................71

5.4.3.1 Monitoring coolant condition .........71

5.4.3.2 Topping up of coolant ..................... 72

5.4.3.3 Replacing the coolant ......................72

5.5 Adjustments and service

procedures........................................73

5.5.1 Cleaning coolers...............................73

5.5.2 Cleaning the fuel tank ......................73

5.5.3 Battery care.......................................74

5.5.3.1 Electrolyte .........................................74

5.5.3.2 Activating a dry-charged battery ....74

5.5.3.3 Recharging a battery........................74

5.5.3.4 Make-up distilled water ...................74

5.5.3.5 Periodic battery service ...................74

5.5.4 Servicing air filter engine ................75

5.5.4.1 Main parts .........................................75

5.5.4.2 Recommendation .............................75

5.5.4.3 Cleaning the dust trap......................75

5.5.4.4 Replacing the air filter element.......75

5.5.5 Replacing fuel filter element ...........76

5.6 Engine consumable specifications .76

5.6.1 Engine fuel specifications ................76

5.6.2 Engine oil specifications ..................76

5.6.3 Engine coolant specifications..........78

6 Checks and trouble

shooting.....................................79

6.1 Checks ...............................................79

6.1.1 Checking voltmeter P4.....................79

6.1.2 Checking ammeters P1, P2 and P3 .79

6.2 Engine troubleshooting...................79

6.3 Alternator troubleshooting .............82

6.4 Solving controller alarms ................83

6.4.1 Qc1002™ and Qc2002™

alarms and remedies .......................83

6.4.1.1 Alarm overview ................................83

6.4.1.2 Fail classes ........................................84

6.4.1.3 Solving alarms..................................84

6.4.2 Qc4002™ MkII alarms and

remedies ...........................................87

6.4.2.1 Fail Classes .......................................87

6.4.2.2 Diagnostics menu.............................87

6.4.2.3 Solving alarms..................................88

7 Storage of the generator......... 89

7.1 Storage..............................................89

7.2 Preparing for operation after

storage ..............................................89

8 Disposal..................................... 90

8.1 General..............................................90

8.2 Disposal of materials .......................90

9 Options available for

QAS 60 units............................. 91

9.1 Circuit diagrams...............................91

9.2 Overview of the electrical options .91

9.3 Description of the electrical

options ..............................................92

9.3.1 Automatic battery charger...............92

9.3.2 Battery switch ...................................92

9.3.3 Engine coolant heater ......................92

9.3.4 Outlet sockets (S) - Set 1..................93

- 7 -

9.3.5 Outlet sockets (S) - Set 2 .................94

9.3.6 Outlet sockets (S) - Set 3 .................95

9.3.7 Single frequency with

electronic speed control (SF) ..........96

9.3.8 Dual frequency with

electronic speed control (DF) ..........96

9.3.9 Electronic speed regulator ..............96

9.3.10 Dual voltage (2V) .............................. 97

9.3.11 Earth leakage relay...........................98

9.3.12 IT-relay ..............................................99

9.3.13 “Electricité de France” (EDF).........101

9.3.14 COSMOS™ .....................................101

9.3.15 COC box ..........................................101

9.4 Overview of the mechanical

options ............................................102

9.5 Desciption of the mechanical

options ............................................102

9.5.1 External fueltank connection

(with/without quick couplings) ......102

9.5.2 Undercarriage (axle, towbar,

towing eyes) ...................................103

9.5.3 Integrated spark arrestor ...............103

9.5.4 Air inlet shut-off valve ...................103

10 Technical specifications

for QAS 60 units...................... 104

10.1 Readings on gauges ......................104

10.2 Settings of switches ...................... 104

10.3 Specifications of the engine/

alternator/unit................................ 104

10.4 Conversion list of SI units into

British units ....................................110

10.5 Dataplate.........................................110

- 8 -

1 Safety precautions for on-site generators

To be read attentively and acted accordingly before towing, lifting, operating, performing maintenance or repairing the generator.

1.1 Introduction

The policy of Atlas Copco is to provide the users of their

equipment with safe, reliable and efficient products.

Factors taken into account are among others:

- the intended and predictable future use of the

products, and the environments in which they are

expected to operate,

- applicable rules, codes and regulations,

- the expected useful product life, assuming proper

service and maintenance,

- providing the manual with up-to-date information.

Before handling any product, take time to read the

relevant instruction manual. Besides giving detailed

operating instructions, it also gives specific information

about safety, preventive maintenance, etc.

Keep the manual always at the unit location, easy

accessible to the operating personnel.

See also the safety precautions of the engine and

possible other equipment, which are separately sent

along or are mentioned on the equipment or parts of the

unit.

These safety precautions are general and some

statements will therefore not always apply to a particular

unit.

Only people that have the right skills should be allowed

to operate, adjust, perform maintenance or repair on

Atlas Copco equipment. It is the responsibility of

management to appoint operators with the appropriate

training and skill for each category of job.

Skill level 1: Operator

An operator is trained in all aspects of operating the unit

with the push-buttons, and is trained to know the safety

aspects.

Skill level 2: Mechanical technician

A mechanical technician is trained to operate the unit the

same as the operator. In addition, the mechanical

technician is also trained to perform maintenance and

repair, as described in the instruction manual, and is

allowed to change settings of the control and safety

system. A mechanical technician does not work on live

electrical components.

Skill level 3: Electrical technician

An electrical technician is trained and has the same

qualifications as both the operator and the mechanical

technician. In addition, the electrical technician may

carry out electrical repairs within the various enclosures

of the unit. This includes work on live electrical

components.

Skill level 4: Specialist from the manufacturer

This is a skilled specialist sent by the manufacturer or its

agent to perform complex repairs or modifications to the

equipment.

In general it is recommended that not more than two

people operate the unit, more operators could lead to

unsafe operating conditions. Take necessary steps to

keep unauthorized persons away from the unit and

eliminate all possible sources of danger at the unit.

When handling, operating, overhauling and/or

performing maintenance or repair on Atlas Copco

equipment, the mechanics are expected to use safe

engineering practices and to observe all relevant local

safety requirements and ordinances. The following list is

a reminder of special safety directives and precautions

mainly applicable to Atlas Copco equipment.

Neglecting the safety precautions may endanger people

as well as environment and machinery:

- endanger people due to electrical, mechanical or

chemical influences,

- endanger the environment due to leakage of oil,

solvents or other substances,

- endanger the machinery due to function failures.

All responsibility for any damage or injury resulting

from neglecting these precautions or by non-observance

of ordinar y caution and du e care required in handling,

operating, maintenance or repair, also if not expressly

mentioned in this instruction manual, is disclaimed by

Atlas Copco.

- 9 -

The manufacturer does not accept any liability for any

damage arising from the use of non-original parts and for

modifications, additions or conversions made without

the manufacturer’s approval in writing.

If any statement in this manual does not comply with

local legislation, the stricter of the two shall be applied.

Statements in these safety precautions should not be

interpreted as suggestions, recommendations or

inducements that it should be used in violation of any

applicable laws or regulations.

1.2 General safety precautions

1 The owner is responsible for maintaining the unit in

a safe operating condition. Unit parts and

accessories must be replaced if missing or

unsuitable for safe operation.

2 The supervisor, or the responsible person, shall at

all times make sure that all instructions regarding

machinery and equipment operation and

maintenance are strictly followed and that the

machines with all accessories and safety devices, as

well as the consuming devices, are in good repair,

free of abnormal wear or abuse, and are not

tampered with.

3 Whenever there is an indication or any suspicion

that an internal part of a machine is overheated, the

machine shall be stopped but no inspection covers

shall be opened before sufficient cooling time has

elapsed; this to avoid the risk of spontaneous

ignition of oil vapour when air is admitted.

4 Normal ratings (pressures, temperatures, speeds,

etc.) shall be durably marked.

5 Operate the unit only for the intended purpose and

within its rated limits (pressure, temperature,

speeds, etc.).

6 The machinery and equipment shall be kept clean,

i.e. as free as possible from oil, dust or other

deposits.

7 To prevent an increase in working temperature,

inspect and clean heat transfer surfaces (cooler fins,

intercoolers, water jackets, etc.) regularly. See the

maintenance schedule.

8 All regulating and safety devices shall be

maintained with due care to ensure that they

function properly. They may not be put out of

action.

9 Pressure and temperature gauges shall be checked

regularly with regard to their accuracy. They shall

be replaced whenever outside acceptable tolerances.

10 Safety devices shall be tested as described in the

maintenance schedule of the instruction manual to

determine that they are in good operating condition.

11 Mind the markings and information labels on the

unit.

12 In the event the safety labels are damaged or

destroyed, they must be replaced to ensure operator

safety.

13 Keep the work area neat. Lack of order will increase

the risk of accidents.

14 When working on the unit, wear safety clothing.

Depending on the kind of activities these are: safety

glasses, ear protection, safety helmet (including

visor), safety gloves, protective clothing, safety

shoes. Do not wear the hair long and loose (protect

long hair with a hairnet), or wear loose clothing or

jewellery.

15 Take precautions against fire. Handle fuel, oil and

anti-freeze with care because they are inflammable

substances. Do not smoke or approach with naked

flame when handling such substances. Keep a fireextinguisher in the vicinity.

16a On-site generators (with earthing pin):

Earth the generator as well as the load properly.

16b On-site generators IT:

Note: This generator is built to supply a sheer

alternating current IT network.

Earth the load properly.

- 10 -

1.3 Safety during transport and

installation

To lift a unit, all loose or pivoting parts, e.g. doors and

towbar, shall first be securely fastened.

Do not attach cables, chains or ropes directly to the

lifting eye; apply a crane hook or lifting shackle meeting

local safety regulations. Never allow sharp bends in

lifting cables, chains or ropes.

Helicopter lifting is not allowed.

It is strictly forbidden to dwell or stay in the risk zone

under a lifted load. Never lift the unit over people or

residential areas. Lifting acceleration and retardation

shall be kept within safe limits.

1 Before towing the unit:

- check the towbar, the brake system and the

towing eye. Also check the coupling of the

towing vehicle,

- check the towing and brake capability of the

towing vehicle,

- check that the towbar, jockey wheel or stand leg

is safely locked in the raised position,

- ascertain that the towing eye can swivel freely on

the hook,

- check that the wheels are secure and that the

tyres are in good condition and inflated correctly,

- connect the signalisation cable, check all lights

and connect the pneumatic brake couplers,

- attach the safety break-away cable or safety

chain to the towing vehicle,

- remove wheel chocks, if applied, and disengage

the parking brake.

2 To tow a unit use a towing vehicle of ample

capacity. Refer to the documentation of the towing

vehicle.

3 If a unit is to be backed up by a towing vehicle,

disengage the overrun brake mechanism (if it is not

an automatic mechanism).

4 In case of transporting a non-trailer unit on a truck,

fasten it to the truck by attaching straps via fork lift

holes, via the holes in the frame at the front and

back or via the lifting beam. To prevent damage,

never put straps on the roof surface of the unit.

5 Never exceed the maximum towing speed of the

unit (mind the local regulations).

6 Place the unit on level ground and apply the parking

brake before disconnecting the unit from the towing

vehicle. Unclip the safety break-away cable or

safety chain. If the unit has no par king br ake or

jockey wheel, immobilize the unit by placing

chocks in front of and/or behind the wheels. When

the towbar can be positioned vertically, the locking

device must be applied and kept in good order.

7 To lift heavy parts, a hoist of ample capacity, tested

and approved according to local safety regulations,

shall be used.

8 Lifting hooks, eyes, shackles, etc., shall never be

bent and shall only have stress in line with their

design load axis. The capacity of a lifting device

diminishes when the lifting force is applied at an

angle to its load axis.

9 For maximum safety and efficiency of the lifting

apparatus all lifting members shall be applied as

near to perpendicular as possible. If required, a

lifting beam shall be applied between hoist and

load.

10 Never leave a load hanging on a hoist.

11 A hoist has to be installed in such a way that the

object will be lifted perpendicular. If that is not

possible, the necessary precautions must be taken to

prevent load-swinging, e.g. by using two hoists,

each at approximately the same angle not exceeding

30° from the vertical.

12 Locate the unit away from walls. Take all

precautions to ensure that hot air exhausted from the

engine and driven machine cooling systems cannot

be recirculated. If such hot air is taken in by the

engine or driven machine cooling fan, this may

cause overheating of the unit; if taken in for

combustion, the engine power will be reduced.

13 Generators shall be stalled on an even, solid floor,

in a clean location with sufficient ventilation. If the

floor is not level or can vary in inclination, consult

Atlas Copco.

14 The electrical connections shall correspond to local

codes. The machines shall be earthed and protected

against short circuits by fuses or circuit breakers.

15 Never connect the generator outlets to an

installation which is also connected to a public

mains.

16 Before connecting a load, switch off the

corresponding circuit breaker, and check whether

frequency, voltage, current and power factor

comply with the ratings of the generator.

17 Before transportation of the unit, switch off all the

circuit breakers.

- 11 -

1.4 Safety during use and

operation

1 When the unit has to operate in a fire-hazardous

environment, each engine exhaust has to be

provided with a spark arrestor to trap incendiary

sparks.

2 The exhaust contains carbon monoxide which is a

lethal gas. When the unit is used in a confined

space, conduct the engine exhaust to the outside

atmosphere by a pipe of sufficient diameter; do this

in such a way that no extra back pressure is created

for the engine. If necessary, install an extractor.

Observe any existing local regulations.

Make sure that the unit has sufficient air intake for

operation. If necessary, install extra air intake ducts.

3 When operating in a dust-laden atmosphere, place

the unit so that dust is not carried towards it by the

wind. Operation in clean surroundings considerably

extends the intervals for cleaning the air intake

filters and the cores of the coolers.

4 Never remove a filler cap of the cooling water

system of a hot engine. Wait until the engine has

sufficiently cooled down.

5 Never refill fuel while the unit is running, unless

otherwise stated in the Atlas Copco Instruction

Book (AIB). Keep fuel away from hot parts such as

air outlet pipes or the engine exhaust. Do not smoke

when fuelling. When fuelling from an automatic

pump, an earthing cable should be connected to the

unit to discharge static electricity. Never spill nor

leave oil, fuel, coolant or cleansing agent in or

around the unit.

6 All doors shall be shut during operation so as not to

disturb the cooling air flow inside the bodywork

and/or render the silencing less effective. A door

should be kept open for a short period only e.g. for

inspection or adjustment.

7 Periodically carry out maintenance works according

to the maintenance schedule.

8 Stationary housing guards are provided on all

rotating or reciprocating parts not otherwise

protected and which may be hazardous to

personnel. Machinery shall nev er be put into

operation, when such guards have been removed,

before the guards are securely reinstalled.

9 Noise, even at reasonable levels, can cause irritation

and disturbance which, over a long period of time,

may cause severe injuries to the nervous system of

human beings.

When the sound pr essur e level, at any point where

personnel normally has to attend, is:

- below 70 dB(A): no action needs to be taken,

- above 70 dB(A): noise-protective devices should

be provided for people continuously being

present in the room,

- below 85 dB(A): no action needs to be taken for

occasional visitors staying a limited time only,

- above 85 dB(A): room to be classified as a noisehazardous area and an obvious warning shall be

placed permanently at each entrance to alert

people entering the room, for even relatively

short times, about the need to wear ear

protectors,

- above 95 dB(A): the warning(s) at the

entrance(s) shall be completed with the

recommendation that also occasional visitors

shall wear ear protectors,

- above 105 dB(A): special ear protectors that are

adequate for this noise level and the spectral

composition of the noise shall be provided and a

special warning to that effect shall be placed at

each entrance.

10 The unit has parts of which the temperature can be

in exess of 80 °C (176 °F), and which may be

accidentally touched by personnel when opening

the machine during or just after operation.

Insulation or safety guards protecting these parts

shall not be removed before the parts have cooled

down sufficiently, and must be re-installed before

operating the machine. As it is not possible to

insulate or protect all hot parts by guards (e.g.

exhaust manifold, exhaust turbine), the operator /

service engineer must always be aware not to touch

hot parts when opening a machine door.

11 Never operate the unit in surroundings where there

is a possibility of taking in flammable or toxic

fumes.

12 If the working process produces fumes, dust or

vibration hazards, etc., take the necessary steps to

eliminate the risk of personnel injury.

13 When using compressed air or inert gas to clean

down equipment, do so with caution and use the

appropriate protection, at least safety glasses, for

the operator as well as for any bystander. Do not

apply compressed air or inert gas to your skin or

direct an air or gas stream at people. Never use it to

clean dirt from your clothes.

- 12 -

14 When washing parts in or with a cleaning solvent,

provide the required ventilation and use appropriate

protection such as a breathing filter, safety glasses,

rubber apron and gloves, etc.

15 Safety shoes shoul d be com pulsory in any

workshop and if there is a risk, however small, of

falling objects, wearing of a safety helmet should be

included.

16 If there is a risk of inhaling hazardous gases, fumes

or dust, the respiratory organs must be protected and

depending on the nature of the hazard, so must the

eyes and skin.

17 Remember that where there is visible dust, the finer,

invisible particles will almost certainly be present

too; but the fact that no dust can be seen is not a

reliable indication that dangerous, invisible dust is

not pr esent in the air.

18 Never operate the generator in excess of its limits as

indicated in the technical specifications and avoid

long no-load sequences.

19 Never operate the generator in a humid atmosphere.

Excessive moisture causes worsening of the

generator insulation.

20 Do not open electrical cabinets, cubicles or other

equipment while voltage is supplied. If such cannot

be avoided, e.g. for measurements, tests or

adjustments, have the action carried out by a

qualified electrician only, with appropriate tools,

and ascertain that the required bodily protection

against electrical hazards is applied.

21 Never touch the power terminals during operation

of the machine.

22 Whenever an abnormal condition arises, e.g.

excessive vibration, noise, odour, etc., switch the

circuit breakers to OFF and stop the engine. Correct

the faulty condition before restarting.

23 Check the electric cables regularly. Damaged cables

and insufficient tightening of connections may

cause electric shocks. Whenever damaged wires or

dangerous conditions are observed, switch the

circuit breakers to OFF and stop the engine.

Replace the damaged wires or correct the dangerous

condition before restarting. Make sure that all

electric connections are securely tightened.

24 Avoid overloading the generator. The generator is

provided with circuit breakers for overload

protection. When a breaker has tripped, reduce the

concerned load before restarting.

25 If the generator is used as stand-by for the mains

supply, it must not be operated without control

system which automatically disconnects the

generator from the mains when the mains supply is

restored.

26 Never remove the cover of the output terminals

during operation. Before connecting or

disconnecting wires, switch off the load and the

circuit breakers, stop the machine and make sure

that the machine cannot be started inadvertently or

there is any residual voltage on the power circuit.

27 Running the generator at low load for long periods

will reduce the lifetime of the engine.

28 When operating the generator in Remote or Auto

mode, observe all relevant local legislation.

1.5 Safety during maintenance

and repair

Maintenance, overhaul and repair work shall only be

carried out by adequately trained personnel; if required,

under supervision of someone qualified for the job.

1 Use only the correct tools for maintenance and

repair work, and only t ools which are in good

condition.

2 Parts shall only be replaced by genuine Atlas Copco

replacement parts.

3 All maintenance work, other than routine attention,

shall only be undertaken when the unit is stopped.

Steps shall be taken to prevent inadvertent starting.

In addition, a warning sign bearing a legend such as

“work in progress; do not start” shall be attached to

the starting equipment.

On engine-driven units the battery shall be

disconnected and removed or the terminals covered

by insulating caps.

On electrically driven units the main switch shall be

locked in open position and the fuses shall be taken

out. A warning sign bearing a legend such as “work

in progress; do not supply voltage” shall be attached

to the fuse box or main switch.

4 Prior to stripping an engine or other machine or

undertaking major overhaul on it, prevent all

movable parts from rolling over or moving.

- 13 -

5 Make sure that no tools, loose parts or rags are left

in or on the machine. Never leave rags or loose

clothing near the engine air intake.

6 Never use flammable solvents for cleaning (fire-

risk).

7 Take safety precautions against toxic vapours of

cleaning liquids.

8 Never use machine parts as a climbing aid.

9 Observe scrupulous cleanliness during maintenance

and repair. Keep away dirt, cover the parts and

exposed openings with a clean cloth, paper or tape.

10 Never weld on or perform any operation involving

heat near the fuel or oil systems. Fuel and oil tanks

must be completely purged, e.g. by steam-clean ing,

before carrying out such operations. Never weld on,

or in any way modify, pressure vessels. Disconnect

the alternator cables during arc welding on the unit.

11 Support the towbar and the axle(s) securely if

working underneath the unit or when removing a

wheel. Do not rely on jacks.

12 Do not remove any of, or tamper with, the sound-

damping material. Keep the material free of dirt and

liquids such as fuel, oil and cleansing agents. If any

sound-damping material is damaged, replace it to

prevent the sound pressure level from increasing.

13 Use only lubricating oils and greases recommended

or approved by Atlas Copco or the machine

manufacturer. Ascertain that the selected lubricants

comply with all applicable safety regulations,

especially with regard to explosion or fire-risk and

the possibility of decomposition or generation of

hazardous gases. Never mix synthetic with mineral

oil.

14 Protect the engine, alternator, air intake filter,

electrical and regulating components, etc., to

prevent moisture ingress, e.g. when steam-cleaning.

15 When performing any operation involving heat,

flames or sparks on a machine, the surrounding

components shall first be screened with nonflammable material.

16 Never use a light source with open flame for

inspecting the interior of a machine.

17 When repair has been completed, the machine shall

be barred over at least one revolution for

reciprocating machines, several revolutions for

rotary ones to ensure that there is no mechanical

interference within the machine or driver. Check the

direction of rotation of electric motors when starting

up the machine initially and after any alteration to

the electrical connection(s) or switch gear, to check

that the oil pump and the fan function properly.

18 Maintenance and repair work should be recorded in

an operator’s logbook for all machinery. Frequency

and nature of repairs can reveal unsafe conditions.

19 When hot parts have to be handled, e.g. shrink

fitting, special heat-resistant gloves shall be used

and, if requi red, other body pr otection shall be

applied.

20 When using cartridge type breathing filter

equipment, ascertain that the correct type of

cartridge is used and that its useful service life is not

surpassed.

21 Make sure that oil, solvents and other substances

likely to pollute the environment are properly

disposed of.

22 Before clearing the generator for use after

maintenance or overhaul, submit it to a testrun,

check that the AC power performance is correct and

that the control and shutdown devices function

correctly.

- 14 -

1.6 Tool applications safety

Apply the proper tool for each job. With the knowledge

of correct tool use and knowing the limitations of tools,

along with some common sense, many accidents can be

prevented.

Special service tools are available for specific jobs and

should be used when recommended. The use of these

tools will save time and prevent damage to parts.

1.7 Battery safety precautions

When servicing batteries, always wear protecting

clothing and glasses.

1 The electrolyte in batteries is a sulphuric acid

solution which is fatal if it hits your eyes, and which

can cause burns if it contacts your skin. Therefore,

be careful when handling batteries, e.g. when

checking the charge condition.

2 Install a sign prohibiting fire, open flame and

smoking at the post where batteries are being

charged.

3 When batteries are being charged, an explosive gas

mixture forms in the cells and might escape through

the vent holes in the plugs.

Thus an explosive atmosphere may form around the

battery if ventilation is poor, and can remain in and

around the battery for several hours after it has been

charged. Therefore:

- never smoke near batteries being, or having

recently been, charged,

- never break live circuits at battery terminals,

because a spark usually occurs.

4 When connecting an auxiliary battery (AB) in

parallel to the unit battery (CB) with booster cables:

connect the + pole of AB to the + pole of CB, then

connect the - pole of CB to the mass of the unit.

Disconnect in the reverse order.

- 15 -

2 Main parts

2.1 General description

The QAS 60 Pd is an AC generator, built for continuous running at sites where no electricity is available or as stand-by in cases of interruption of the mains. The generator

operates at 50/60 Hz, 230/240 V in line-to-neutral mode and 400/480 V in line-to-line mode. The QAS 60 Pd generator is driven by a fluid-cooled diesel engine,

manufactur ed by PERKINS. An overview of the main parts is given in the diagram below.

1 Lifting beam

2 Guiding rod

3 Side doors

4 Engine exhaust

5 Data plate

6 Door, access to control and indicator panel

7 Output terminal board

8 Hole for forklift

9 Earthing rod

DH Drain and access hole (in the frame)

FCF Filler cap fuel

- 16 -

A Alternator

AF Air filter

C Coupling

DFO Drain flexible engine oil

DH Drain and access hole (in the frame)

DPF Drain plug fuel

EEngine

FFan

FCF Filler cap fuel

FCO Filler cap engine oil

FCW Filler cap coolant

FF Fuel filter

G1 Battery

OF Oil filter

OLD Engine oil level dipstick

PF Pre fuel filter

RRadiator

DPF, DH

C

- 17 -

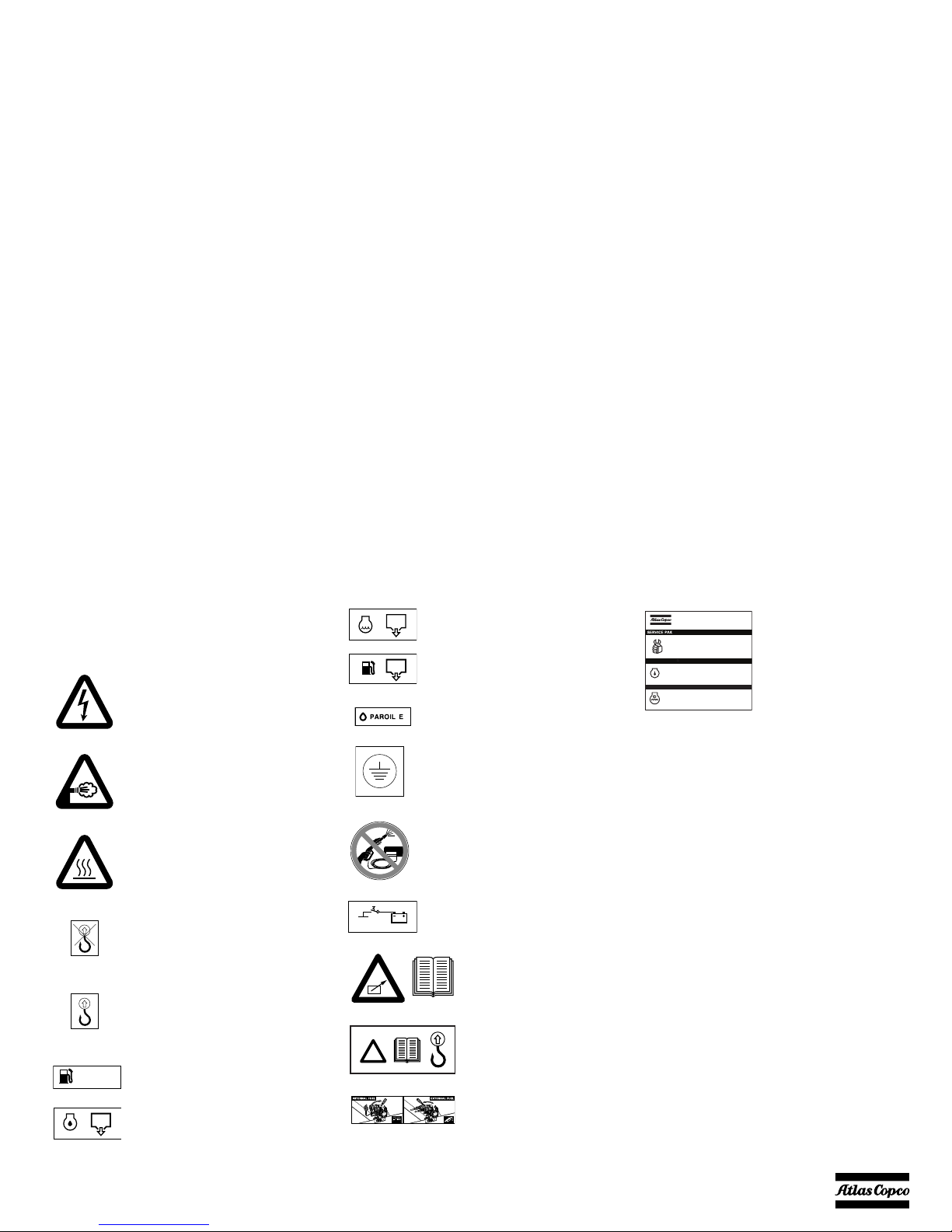

2.2 Markings

A brief description of all markings provided on the

generator is given hereafter.

2.3 Mechanical features

The mechanical features described in this chapter are

standard provided on this generator. For all other

mechanical features, see “Overview of the

mechanical options” on page 102.

2.3.1 Engine and alternator

The alternator is driven by a fluid-cooled diesel

engine. The engine’s power is transmitted through a

direct disc coupling.

The generator houses a single bearing alternator with

a dedicated voltage regulator.

The synchronous brushless alternator has Class H

rotor and stator windings in an IP23 housing.

2.3.2 Cooling system

The engine is provided with a water cooler. The

cooling air is generated by a fan, driven by the engine.

Indicates the presence of electric shock

hazards. Enclosures marked with these

symbols should only be opened by

trained or instructed people.

Indicates that the engine exhaust is a

hot and harmf ul gas, which is to xic in

case of inhalation. Always make sure

that the unit is operated outside or in a

well-ventilated room.

Indicates that these parts can become

very hot during operation (e.g. engine,

cooler, etc.). Always make sure that

these parts are cooled down before

touching them.

Indicates that the guiding rods may not

be used to lift the generator. Always

use the lifting rod in the roof of the

generator to lift it.

Indicates a lifting point of the

generator.

Indicates that the generator may be

refuelled with diesel fuel only.

Indicates the drain for the engine oil.

diesel

Indicates the drain for the coolant.

Indicates the drain plug for the engine

fuel.

Use PAROIL E only.

Indicates the different earthing

connections on the generator.

Indicates that the alternator should not

be cleaned with high pressurised

water.

Indicates the battery switch.

Indicates that the unit may

start automatically and that

the instruction book has to

be consulted prior to use.

Read the instruction manual

before using the lifting eye.

Indicates the 3-way valve.

Indicates the partnumbers of

the different service packs

and of the engine oil. These

parts can be ordered to the

factory.

XXXXXXXXXXXXXXX

Engine oil

PAROIL E PAROIL Extra

Engine coolant PARCOOL EG

XXXXXXXXX

XXXX XXXX XX

XXXXXXXXX

XXXX XXXX XX

XX XXXXXXX

XXXX XXXX XX

XXXX XXXX XX

XX XXXXXXX

XXXX XXXX XX

XXXX XXXX XX

XX XXXXXXX

XXXX XXXX XX

XX

XXXXXXX

XXXX XXXX XX

XX XXXXXXX

XXXX XXXX XX

XX XXXXXXX

XXXX XXXX XX

- 18 -

2.3.3 Safety devices

The engine is equipped with low oil pressure and high

oil temperature shut-down switches.

2.3.4 Bodywork

The alternator, the engine, the cooling system, etc. are

enclosed in a sound-insulated bodywork that can be

opened by means of side doors (and service plates).

The generator can be lifted by using the lifting eye

integrated in the bodywork (roof). To be able to lift

the QAS 60 by means of a forklift, rectangular holes

are provided in the frame.

The earthing rod, connected to the generator’s earth

terminal is located at the bottom of the frame on the

outside.

2.3.5 Control panel

The control panel grouping volt and amp meters,

control switch etc., is placed at the rear end.

2.3.6 Data plate and serial number

The generator is furnished with a data plate showing

the product code, the unit number and the power

output (see “Dataplate” on page 110).

The serial number is located on the right-hand front

side of the frame.

2.3.7 Drain plugs and filler caps

The drain holes for the engine oil, the coolant and the

plug for the fuel, are located and labelled on the

frame. The fuel drain plugs are located; one at the

bottom of the frame and the other at the cubicle side

of the frame.

The drain flexible for engine oil can be brought to the

outside of the generator through the drain hole.

The filler cap for the engine coolant is accessible via

an opening in the roof. The fuel filler cap is located in

the side panel.

2.3.8 Spillage free skid

A Spillage free skid with forklift slots allows the

customer to transport the generator easily with a

forklift. It avoids accidental spilling of engine fluids

and thus helps to protect the environment.

The leaking fluid can be removed via drain holes,

secured by drain plugs. Tighten the plugs firmly and

check for leakages. When removing the leaking fluid,

observe all relevant local legislation.

The drain hole can also be used to

guide external fueltank connections.

When connecting an external

fueltank, use the 3-way valves. Refer

to External fueltank connection

(with/without quick couplings).

!

- 19 -

2.4 Electrical features

The electrical features described in this chapter are

standard provided on this generator. For all other

electrical features, see “Overview of the electrical

options” on page 91.

2.4.1 Control and indicator panels

To operate the generator, one of the following control

panels is installed.

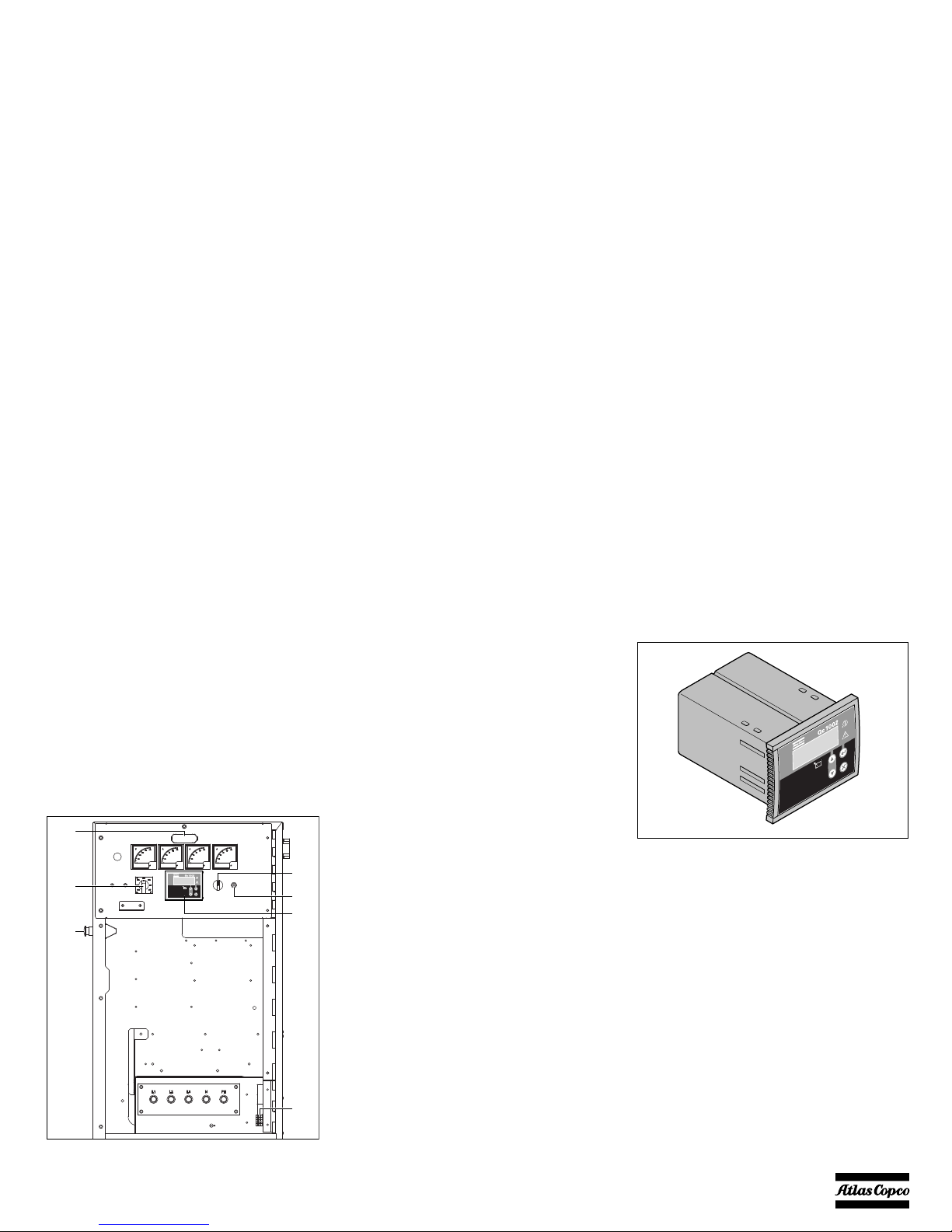

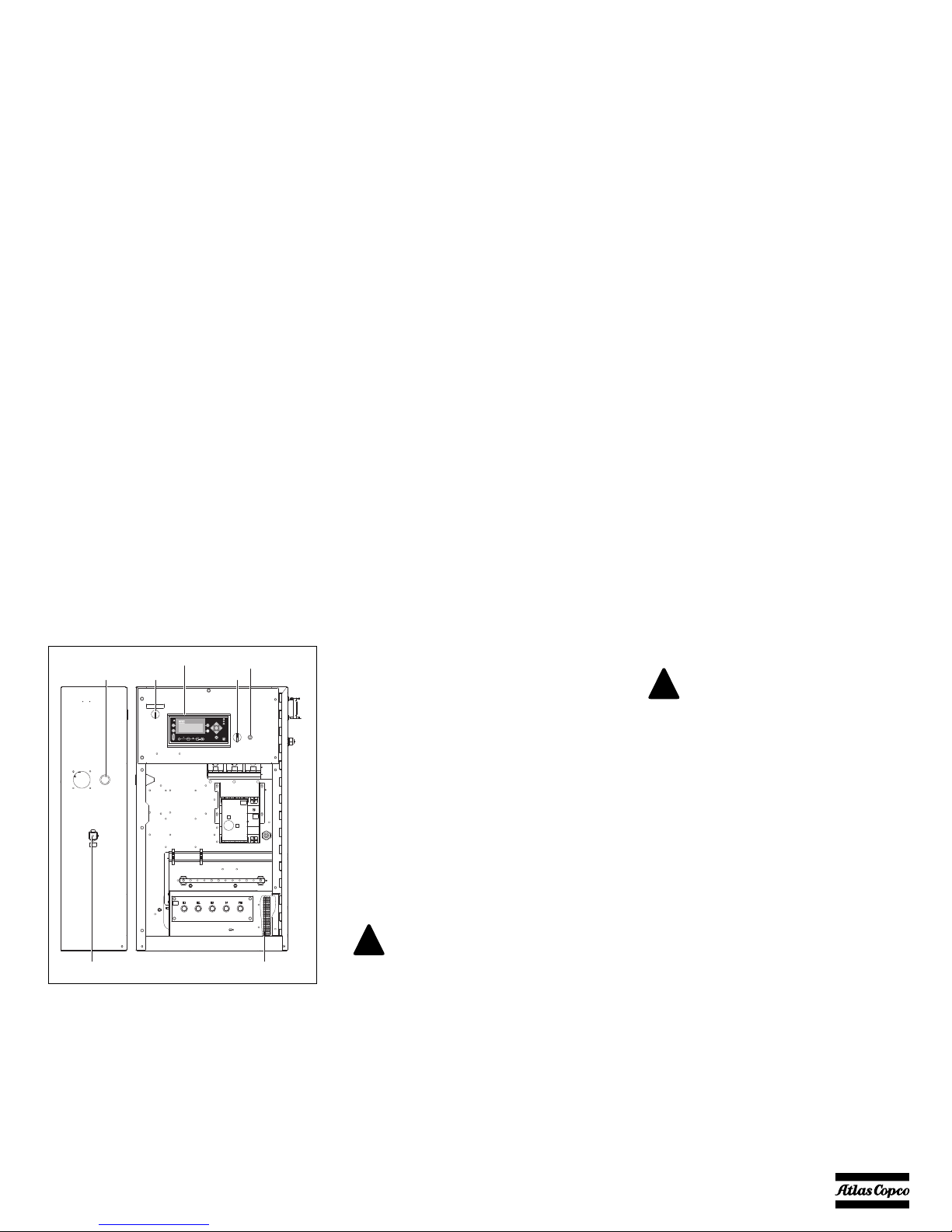

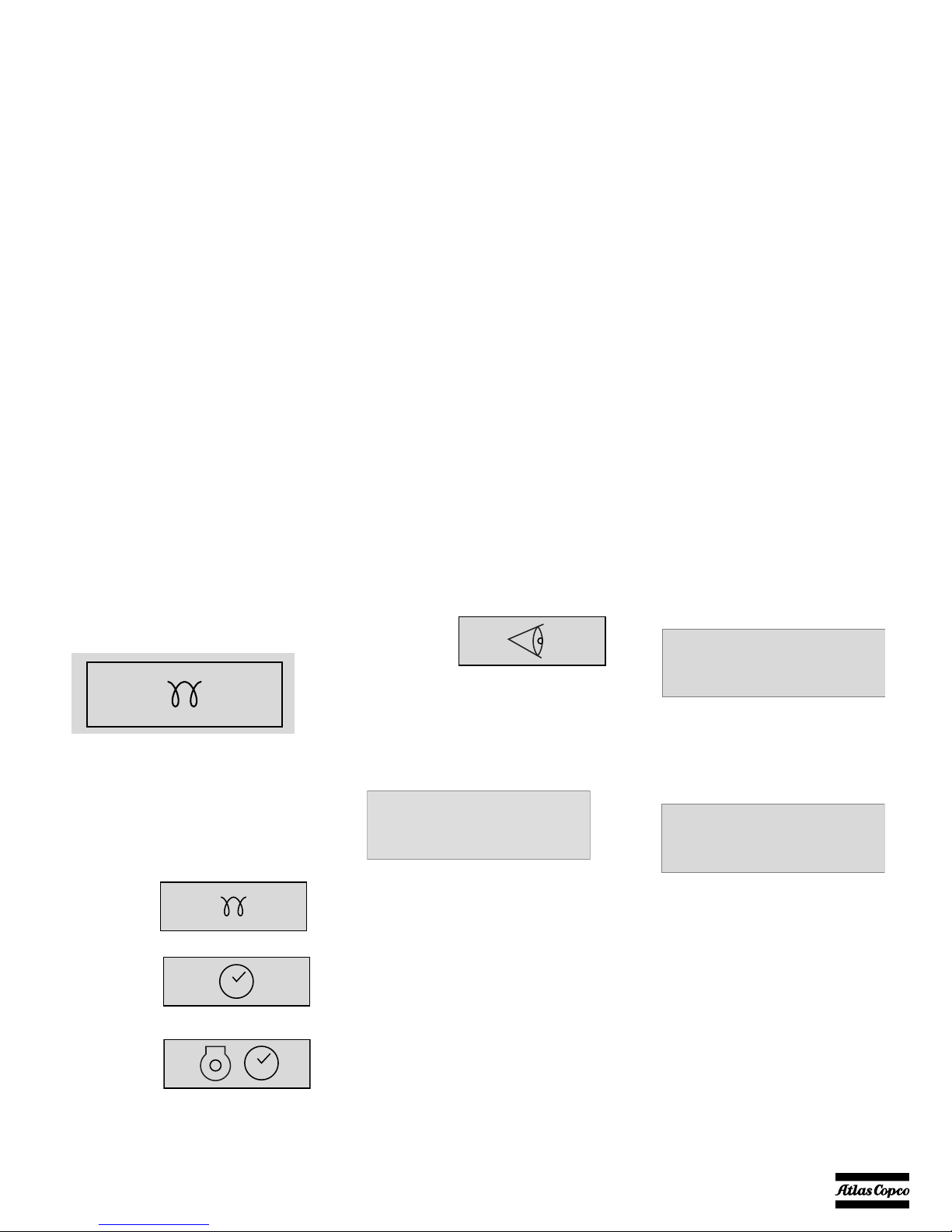

2.4.1.1 Qc1002™ controller

General description Qc1002™ control panel

A1 .......Qc1002™ display

F10......Fuse

The fuse activates when the current from the

battery to the engine control circuit exceeds

its setting. The fuse can be reset by pushing

the button.

H0 .......Panel light

S2 .......Emergency stop button

Push the button to stop the generator in case

of an emergency. When the button is

pressed, it must be unlocked, before the

generator can be restarted. The emergency

stop button can be secured in the locked

position with the key, to avoid unauthorized

use.

S20 ..... ON/OFF/REMOTE switch

To start up the unit (locally or remote).

X25 .....Terminal strip

Qc1002™ Module

The Qc1002™ module is located inside the control

panel. This control module will carry out all

necessary tasks to control and protect a generator,

regardless of the use of the generator.

This means that the Qc1002™ module can be used for

several applications.

Qc 1002

145

X25

S20

F10

A1

S2

S4

H0

Qc 1002

145

- 20 -

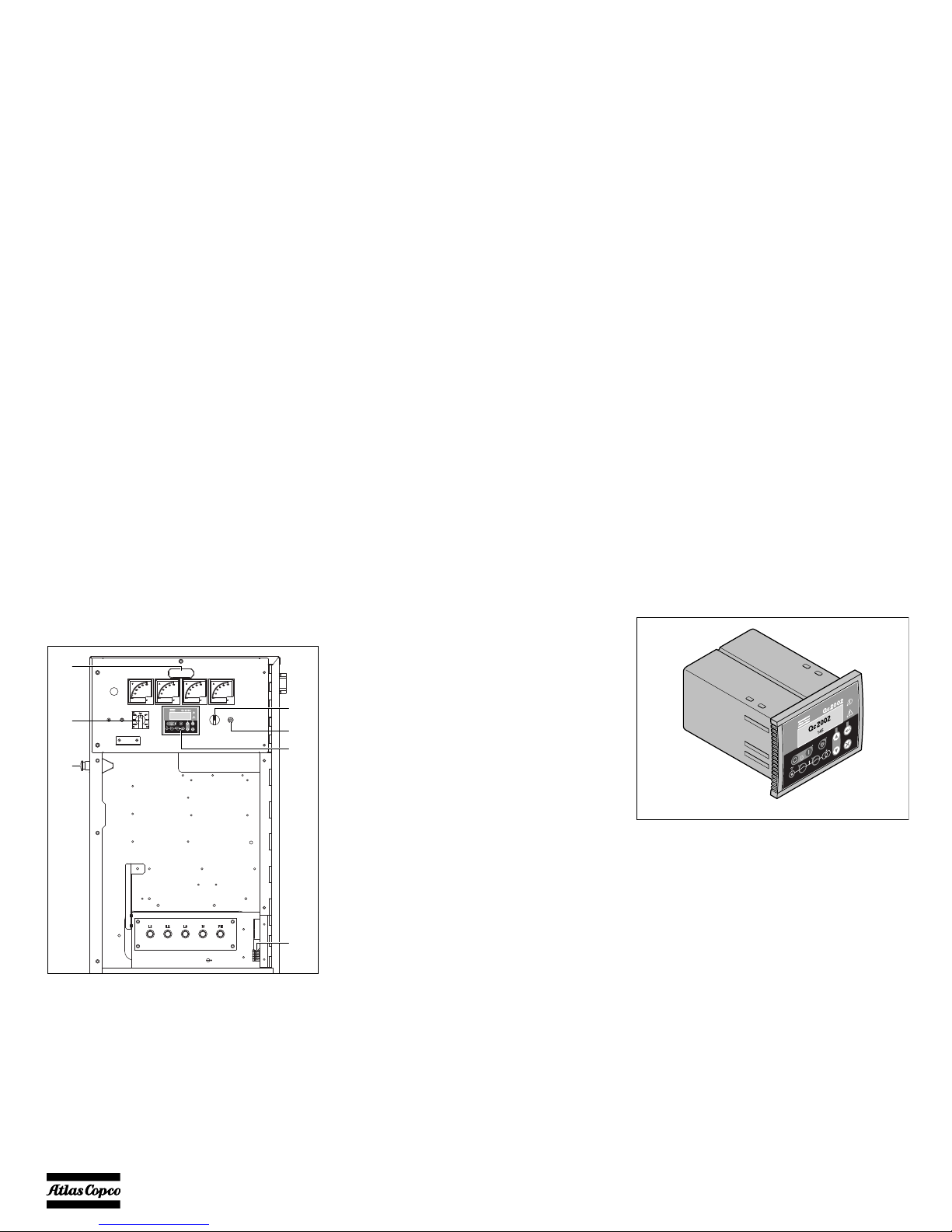

2.4.1.2 Qc2002™ controller

General description Qc2002™ control panel

A1 .......Qc2002™ display

F10...... Fuse

The fuse activates when the current from the

battery to the engine control circuit exceeds

its setting. The fuse can be reset by pushing

the button.

H0 .......Panel light

S2 .......Emergency stop button

Push the button to stop the generator in case

of an emergency. When the button is

pressed, it must be unlocked, before the

generator can be restarted. The emergency

stop button can be secured in the locked

position with the key, to avoid unauthorized

use.

S20 ..... ON/OFF switch

Position O: No voltage is applied to the

Qc2002™ module, the generator will not

start.

Position I: Voltage is applied to the

Qc2002™ module, it is possible to start up

the generator.

X25 .....Terminal strip

Qc2002™ Module

The Qc2002™ module is located inside the control

panel. This control module will carry out all

necessary tasks to control and protect a generator,

regardless of the use of the generator.

This means that the Qc2002™ module can be used for

several applications.

G

X25

S20

F10

A1

S2

S4

H0

- 21 -

2.4.1.3 Qc4002™ MkII controller

General description Qc4002™ MkII control panel

A2 .......Qc4002™ MkII display

F10......Fuse

The fuse (10 A) activates when the current

from the batt ery to the engine control circuit

exceeds its setting. The fuse can be reset by

pushing the button.

S2 .......Emergency stop button

Push the button to stop the generator in case

of an emergency. When the button is

pressed, it must be unlocked, before the

generator can be restarted. The emergency

stop button can be secured in the locked

position with the key, to avoid unauthorized

use.

S12 ..... Frequency selector switch (50 Hz/

60 Hz)

Allows to choose the frequency of the output

voltage: 50 Hz or 60 Hz.

S20 ..... ON/OFF switch

Position O: No voltage is applied to the

Qc4002™ MkII module, the generator will

not start.

Position I: Voltage is applied to the

Qc4002™ MkII module, it is possible to

start up the generator.

X25 .....Connection block

Inside the cubicle. Allows customer

connections.

X30 .....Connector X30

Connector for communication with other

generators with Qc4002™ MkII when

paralleling, both in ALS and PMS mode. An

adapter can be plugged in. See page 58.

T1

T2

T3

M3

Q1

X30

50Hz - 60Hz

X1

Qc4002

G

!

OK

LOG

S20

F10

S12S2

A2

X25X30

Changing the output frequency is

only allowed when the unit has

stopped.

!

Refer to circuit diagram for the

correct connection.

!

- 22 -

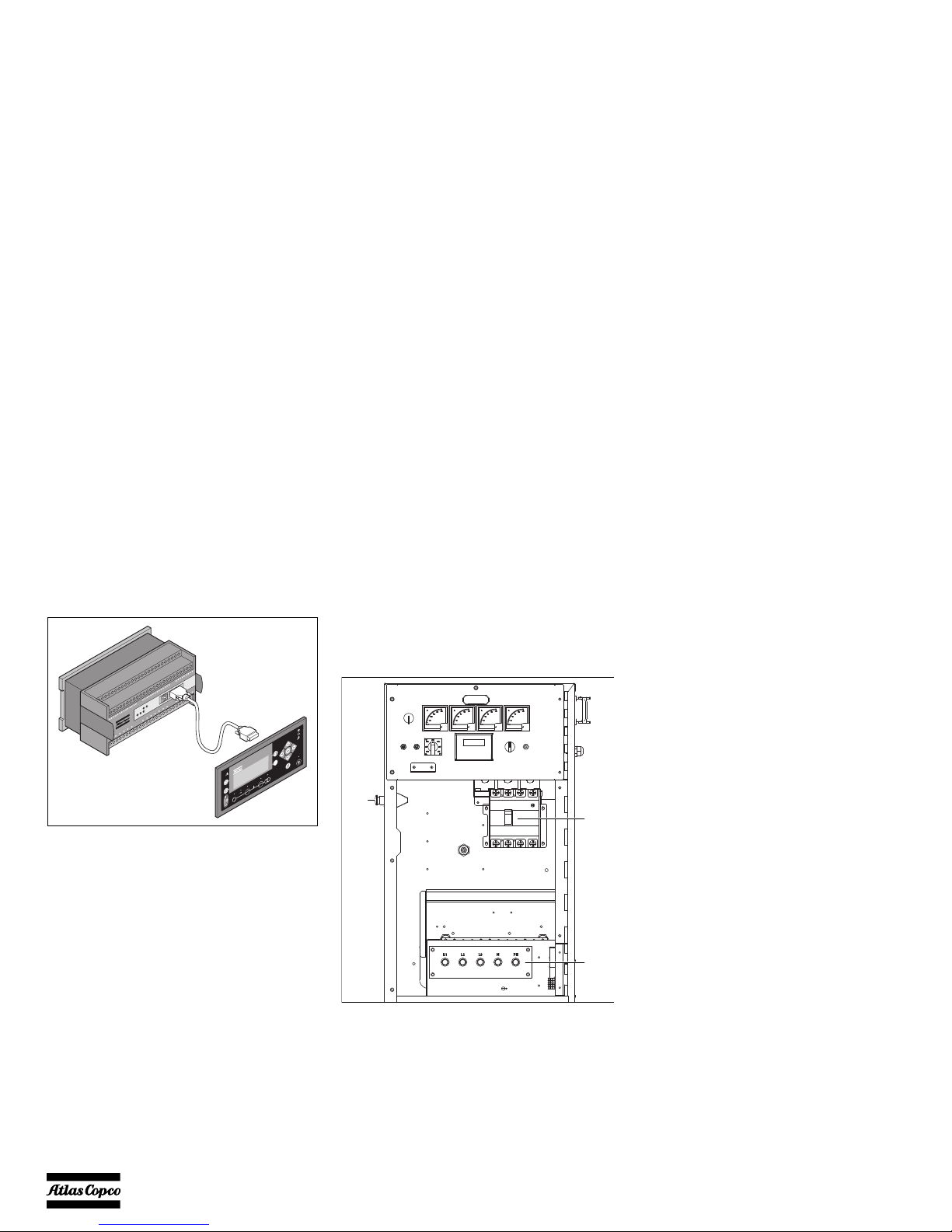

Qc4002™ MkII module

The Qc4002™ MkII module is located inside the

control panel, and communicates with a display unit,

located in front of the control panel. This control

module will carry out all necessary tasks to control

and protect a generator, regardless of the use of the

generator.

This means that the Qc4002™ MkII module can be

used for several applications.

2.4.2 Output terminal board

The cubicle provides a terminal board for easier

connection of cables. It is situated below the control

and indicator panel.

S2........Emergency stop button

Push the button to stop the generator in case

of an emergency. When the button is

pressed, it must be unlocked, by turning it

anti-clockwise, before the generator can be

restarted. The emergency stop button can be

secured in the locked position with the key,

to avoid unauthorized use.

Q1 .......Main circuit breaker

Interrupts the power supply to X1 when a

short-circuit occurs at the load side, or when

the earth leak detector (30 mA) or the

overcurrent protection (100 A) is activated

or when the shunt trip is energized. It must

be reset manually after eliminating the

problem.

X1 ....... Main power supply (400 V AC)

Terminals L1, L2, L3, N (= neutral) and PE

(= earthing), hidden behind the control panel

door and behind a small transparent door.

w

w

w

.

a

t

l

a

s

c

o

p

c

o

.

c

o

m

Q

c4002

G

!

O

K

L

O

G

X1

Q1

S2

- 23 -

3 Installation and connection

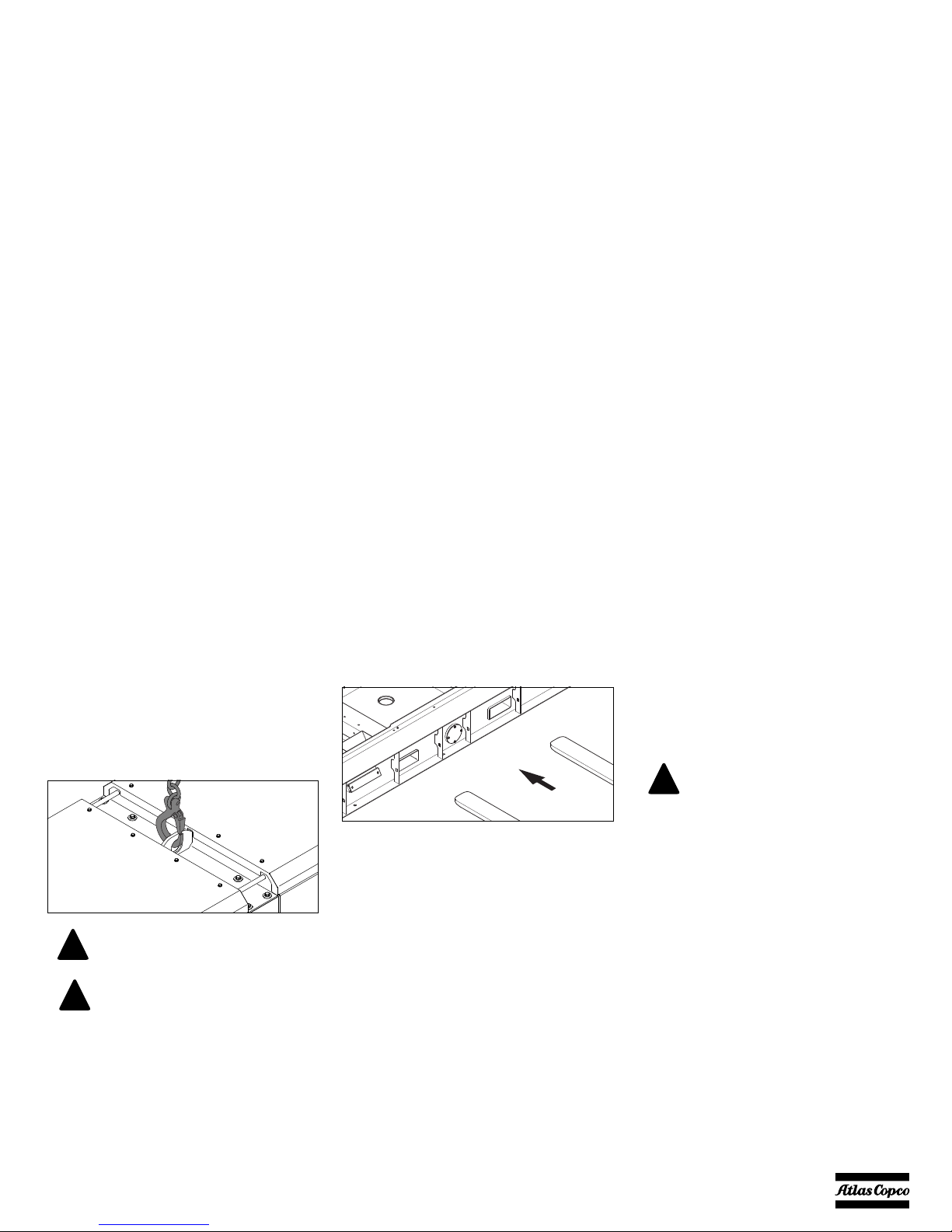

3.1 Lifting

The lifting eye, to lift the generator by means of a

hoist, is integrated in the bodywork and easily

accessible from the outside. The recesses in the roof

have guiding rods at both sides.

When lifting the generator, the hoist has to be placed

in such a way that the generator, which must be

placed level, will be lifted vertically.

To be able to lift the generator by means of a forklift,

rectangular holes are provided at the bottom of the

frame.

3.2 Installation

3.2.1 Indoor installation

If the generator is operated indoors, install an exhaust

pipe of sufficient diameter to duct the engine exhaust

towards the outside. Check for sufficient ventilation

so that the cooling air is not recirculated.

3.2.2 Outdoor installation

– Place the generator on a horizontal, even and solid

floor. The generator can operate in a slant position

not exceeding 15° (in both senses: front/rear and

left/right).

– The generator should be kept with the doors

closed, in order to avoid the ingress of water and

dust. Dust ingress reduces the lifetime of filters

and may reduce your generator's performance.

– Check that the engine exhaust is not directed

towards people.

– Locate the rear end of the generator upwind, away

from contaminated windstreams and walls. Avoid

recirculation of exhaust air from the engine. This

causes overheating and engine power decrease.

Never use the guiding rods to lift the

generator.

Lifting acceleration and retardation

must be kept within safe limits (max.

2 g).

Helicopter lifting is not allowed.

!

!

For more information about indoor

installation, consult your local Atlas

Copco dealer.

!

- 24 -

– Leave enough space for operation, inspection and

maintenance (at least 1 meter at each side).

– Check that the inner earthing system is in

compliance with the local legislation.

– Use coolant for the engine cooling system. Refer

to the Engine instruction book for the proper

coolant mixture.

– Check the tightness of the bolts and nuts.

– Install the earthing rod as near as possible to the

generator and make sure not to have a contact

voltage higher than 25 V.

– Check that the cable end of the earthing rod is

connected to the earth terminal.

3.3 Connecting the generator

3.3.1 Precautions for non-linear and

sensitive loads

The most common non-linear, 3-phase loads are

thyristor/rectifier-co ntrolled loads, such as convertors

supplying voltage to variable speed motors,

uninterruptable power supplies and Telecom

supplies. Gas-discharge lighting arranged in singlephase circuits generate high 3rd harmonics and risk

for excessive neutral current.

Loads most sensitive to voltage distortion include

incandescent lamps, discharge lamps, computers, Xray equipment, audio amplifiers and elevators.

Consult Atlas Copco for measures against the adverse

influence of non-linear loads.

3.3.2 Quality, minimum section and

maximum length of cables

The cable connected to the terminal board of the

generator must be selected in accordance with local

legislation. The type of cable, its rated voltage and

current carrying capacity are determined by

installation conditions, stress and ambient

temperature. For flexible wiring, rubber-sheathed,

flexible core conductors of the type H07 RN-F

(Cenelec HD.22) or better must be used.

The following table indicates the maximum allowable

3-phase currents (in A), in an ambient temperature of

40°C, for cable types (multiple and single core PVC

insulated conductors and H07 RN-F multiple core

conductors) and wire sections as listed, in accordance

with VDE 0298 installation method C3. Local

regulations remain applicable if they are stricter than

those proposed below.

The genera tor is wired fo r a TNsystem to IEC 364-3, i.e. one point in

the power source directly earthed in this case the neutral. The exposed

conductive parts of the electric

installation must be directly

connected to the functional earth.

If operating the generator in

another power system, e.g. an ITsystem, other protective devices

required for these types must be

installed. In any case only a qualified

electrician is authorized to remove

the connection between the neutral

(N) and earth terminals in the

terminal box of the alternator.

!

Non-linear loads draw currents with

high contents in harmonics, causing

distortion in the wave form of the

voltage generated by the alternator.

!

Wire section Max. current (A)

(mm

²

)

Multiple core Single core H07 RN-F

2.5 222521

4 303328

6 384236

10 53 57 50

16 71 76 67

25 94 101 88

35 114 123 110

50 138 155 138

70 176 191 170

95 212 228 205

- 25 -

The lowest acceptable wire section and the

corresponding maximum cable or conductor length

for multiple core cable or H07 RN-F, at rated current

(20 A), for a voltage drop e lower than 5% and at a

power factor of 0.80, are respectively 2.5 mm² and

144 m. In case electric motors must be started,

oversizing the cable is advisable.

The voltage drop across a cable can be determined as

follows:

e = Voltage drop (V)

I = Rated current (A)

L = Length of conductors (m)

R = Resistance (/km to VDE 0102)

X = Reactance (/km to VDE 0102)

3.3.3 Connecting the load

3.3.3.1 Site distribution panel

If outlet sockets are provided, they must be mounted

on a site distribution panel supplied from the terminal

board of the generator and in compliance with local

regulations for power installations on building sites.

3.3.3.2 Protection

– Check whether frequency, voltage and current

comply with the ratings of the generator.

– Provide a load cable, without excessive length,

and lay it out in a safe way without forming coils.

– Open the door of the control and indicator panel

and the transparent door in front of the terminal

board X1.

– Provide the wire ends with cable lugs suited for

the cab le terminals.

– Loosen the cable clamp and push the wire ends of

the load cable through the orifice and clamp.

– Connect the wires to the proper terminals (L1, L2,

L3, N and PE) of X1 and tighten the bolts

securely.

– Tighten the cable clamp.

– Close the transparent door in front of X1.

e

3IL R cos X sin+

1000

---------- ------------ ------------- ------------- ------------- ------------ -------

=

For safety reasons, it is necessary to

provide an isolating switch or

circuit breaker in each load circuit.

Local legislation may impose the use

of isolating devices which can be

locked.

!

- 26 -

4 Operating instructions

4.1 Before starting

– With the generator standing level, check the

engine oil level and top up if necessary. The oil

level must be near to, but not exceed the high mark

on the engine oil level dipstick.

– Check the coolant level in the expansion tank of

the engine cooling system. The coolant level must

be near to the FULL mark. Add coolant if

necessary.

– Drain any water and sediment from the fuel pre-

filter. Check the fuel level and top up if necessary.

It is recommended to fill the tank after the day’s

operation to prevent water vapor in a nearly empty

tank from condensing.

– Drain leaking fluid from the frame.

– Check the vacuum indicator of the air filter. If the

red part shows completely, replace the filter

element.

– Press the dust evacuator of the air filter to remove

dust.

– Check the generator for leakage, tightness of wire

terminals, etc. Correct if necessary.

– Check that circuit breaker Q1 is switched off.

– Check that fuse F10 has not tripped and that the

emergency stop is in the OUT position.

– Check that the load is switched off.

– Check that the earth fault protection (N13) has not

tripped (reset if necessary).

4.2 Operating and setting

Qc1002™

4.2.1 Starting

To start up the unit locally, proceed as follows:

– Switch on the battery switch, if applicable.

– Switch off circuit breaker Q1. This is not

necessary when a plant contactor is installed

between Q1 and the load.

– Put the starter switch S20 in position I (ON). The

unit starts a preheating cycle which takes 12

seconds.

– The unit will start.

In cold conditions the unit might not start from the

first attempt. The controller will take 3 start

attempts.

– Switch on circuit breaker Q1 in case no contactor

is installed.

In your own interest, always strictly

observe all relevant safety

instructions.

Do not operate the generator in

excess of the limitations mentioned

in the Technical Specifications.

Local rules concerning the setting

up of low voltage power installations

(below 1000 V) must be respected

when connecting site distribution

panels, switch gear or loads to the

generator.

At each start-up and at any time a

new load is connected, the earthing

and protections (GB trip and earth

leakage relay) of the genera tor must

be verified. Earthing must be done

either by the earthing rod or, if

available, by an existing, suitable

earthing installation. The protective

system against excessive contact

voltage is not effective unless a

suitable earthing is made.

!

- 27 -

To start up the unit from a remote location,

proceed as follows:

– Put the starter switch S20 in position .

– Switch on circuit breaker Q1.

– Put the remote start/stop switch in position start.

The unit starts a preheating cycle which takes 12

seconds.

– The unit will start.

In cold conditions the unit might not start from the

first attempt. The controller will take 3 start

attempts.

– An external contactor can be connected and

controlled by the Qc1002™.

4.2.2 During operation

Regularly carry out following checks:

– Check the analogue meters (P1-P4) and the

controller display for normal readings.

– Check for leakage of oil, fuel or coolant.

– Check, by means of the generator gauges, that the

voltage between the phases is identical and that

the rated current is not exceeded.

– When single-phase loads are connected to the

generator output terminals, keep all loads wellbalanced.

– If circuit breakers have tripped during operation,

switch off the load and stop the generator. Check

and, if necessary, decrease the load.

4.2.3 Stopping

To stop the unit locally, proceed as follows:

– Switch off the load.

– Switch off circuit breaker Q1.

– Stop the engine by putting the starter switch S20

in position O.

– Lock all doors to avoid unauthorized access.

To stop the unit when the starter switch is in

position , proceed as follows:

– Switch off the load.

– Stop the engine by putting the remote start/stop

switch in position stop or by putting the starter

switch S20 in position O.

– Lock all doors to avoid unauthorized access.

Avoid to let the engine run out of

fuel. If it happened, priming will

speed up the starting.

Avoid long low-load periods

(< 30%). In this case, an output

drop and higher oil consumption of

the engine could occur. Refer to

‘Preventing low loads’.

!

!

The generator’s doors may only

remain opened for short periods

during operation, to carry out

checks for example.

!

- 28 -

4.2.4 Setting the Qc1002™

4.2.4.1 Pushbutton and LED functions

Following pushbuttons are used on the

Qc1002™:

Following LEDs are used on the Qc1002™:

4.2.4.2 Qc1002™ menu overview

At Qc1002™, the LCD will show following

information:

–in Normal condition (scroll through the

information using UP and DOWN):

• Status (eg: preheat, crank, run, cooldown,

extended stop time, …)

• Controller type & version

• Parameter list

•Alarm list

• LOG list

• Service Timer 1 & Service Timer 2

• Battery Voltage

• Coolant temperature

• Oil pressure

•Fuel level

• Voltage - frequency - running hours

–in Alarm condition (scroll through the

information using UP and DOWN):

• a list of all active Alarms

It's possible to scroll through the views, using the UP

and DOWN buttons. The scrolling is continuous.

If a Special status comes up, the Status Display is

shown.

If an Alarm comes up, the Alarm Display is shown.

1

ENTER: Is used to select and

confirm changed settings in the

Parameter list.

2UP: Is used to scroll through the

display information and to adjust

parameter value upwards.

3

DOWN: Is used to scroll through

the display information and to

adjust parameter value

downwards.

4

BACK: Is used to leave the

Alarm pop-up window, to leave

the Parameter list and to leave

menu's without change.

Qc 1002

145

1

2

4

3

1Power Green LED indicates that the unit is

powered up.

2Remote Green LED indicates that the Remote

Mode is selected.

4Alarm Flashing red LED indicates that an

alarm is present. A continuous red

LED indicates that the alarm has been

acknowledged by the user. The exact

alarm is shown on the display.

2

1

3

Qc 1002

145

- 29 -

4.2.4.3 Qc1002™ menu description

Status display (pop-up window)

In case special stat uses are entered, a pop-up window

will automatically be entered for as long as the status

is active.

The background screen is not updated when the status

pop-up window is active.

These special statuses are:

If a special status has elapsed, the active view will be

entered again automatically.

If an Alarm comes up, the Alarm Display is shown.

Controller type and version display

This view shows the controller type and the ASW

version number.

Parameter display

This view shows a number of Parameter settings and

gives access to them.

An overview is given in “Parameter list” on page 31.

Alarm list display

This view shows the number of active alarms and

gives access to them.

An overview is given in “Solving alarms” on page 84.

PREHEAT

START OFF/

EXTENDED

STOP TIMER

COOLDOWN

DIAGNOSTIC

Qc1002

vX.XX.X

Parameter

Alarm List

0 Alarm(s)

- 30 -

LOG list display

This view shows the alarm memory and gives access

to it.

An overview is given in “LOG list” on page 33.

Service timer 1 & Service timer 2 display

This view shows both Service timers. The service

timer indication is shown when service time has run

out. It can be removed by resetting the timers or

acknowledging the Service timer indication.

The service timer indications count and give an alarm

when value is reached.

Resetting the Service Timers can be done through the

Parameter display.

Battery Voltage display

This view shows the Battery voltage and the running

hours.

Coolant temperature display

This view shows the Coolant temperature and the

running hours.

See also “Parameter list” on page 31 for selection

between °C and °F.

Oil pressure display

This view shows the Oil pressure and the running

hours.

See also “Parameter list” on page 31 for selection

between bar and psi.

Fuel level display

This view shows the Fuel level and the running hours.

LOG List

Service 1

Service 2

59h

59h

13.2 VBattery

00168.1h

62˚CWater

00168.1h

3.2barOil

00168.1h

75%Fuel

00168.1h

Loading...

Loading...