Atlas Copco PowerMACS 4000 User Manual

User guide

PowerMACS 4000

Atlas Copco Tools and Assembly Systems

9836 3521 01

2010-11

Edition 10.3.0

Contents

Contents

1 Introduction ....................................................................................................................................... 15

1.1 Introduction - Overview ....................................................................................................................... 15

1.1.1 ToolsTalk PowerMACS, the friendly user interface ................................................................. 16

1.1.2 Intelligent tightening controllers, TCs ....................................................................................... 16

1.2 Tightening and Gauging ....................................................................................................................... 18

1.2.1 Gauging Functions .................................................................................................................... 18

1.2.2 Gauging Applications ................................................................................................................ 18

1.2.2.1 Torque To Turn Gauging Application ....................................................................... 19

1.2.2.2 Valve Lash Gauging Application ............................................................................... 20

1.3 Installing ToolsTalk PowerMACS ....................................................................................................... 21

2 System Architecture .......................................................................................................................... 23

2.1 System Architecture - Overview .......................................................................................................... 23

2.2 System Structure ................................................................................................................................... 24

2.3 Hardware Structure ............................................................................................................................... 26

2.3.1 Tightening Controller ................................................................................................................ 27

2.3.1.1 PTC Description......................................................................................................... 30

2.3.1.2 TC Description ........................................................................................................... 32

2.3.1.3 The TC HMI Menu System ....................................................................................... 34

2.3.2 Version conflict message........................................................................................................... 38

2.3.3 Console Computer (CC) ............................................................................................................ 38

2.3.4 Ethernet ..................................................................................................................................... 39

2.3.5 Peripheral Devices..................................................................................................................... 40

2.4 Automatic update of TC, Servo and Spindle ........................................................................................ 41

2.4.1 Automatic update Overview ...................................................................................................... 41

2.4.2 General function ........................................................................................................................ 41

2.4.3 Replacement of the System TC and Backup TC ....................................................................... 43

2.4.4 Replacement of TC3 – TCn....................................................................................................... 43

2.4.5 Updating a system with new software ....................................................................................... 43

2.4.6 Troubleshooting ........................................................................................................................ 43

2.4.7 Automatic Update of Servo software ........................................................................................ 44

2.4.8 Automatic Update of Spindle software ..................................................................................... 45

3 Basic Functions .................................................................................................................................. 47

3.1 Basic Functions - Overview ................................................................................................................. 47

3.2 Windows ............................................................................................................................................... 48

3.3 Help ...................................................................................................................................................... 51

3.4 The File menu ....................................................................................................................................... 52

3.5 How to Start up ..................................................................................................................................... 54

3.6 Viewing ................................................................................................................................................ 57

9836 3521 01 3

Contents

3.6.1 Assembly Overview .................................................................................................................. 57

3.6.1.1 Station Views ................................................................................................ ............. 60

3.6.2 System Map ............................................................................................................................... 61

3.6.3 View Cycle Data ....................................................................................................................... 64

3.6.4 View Statistics ................................................................................................ ........................... 66

3.6.5 View Trace ................................................................................................................................ 68

3.6.5.1 Select which trace to display ...................................................................................... 69

3.6.5.2 View of trace curves .................................................................................................. 72

3.6.5.3 Select Trace ................................................................................................................ 80

3.6.6 View Tightening Path ................................................................................................................ 81

3.6.7 View Event Log ........................................................................................................................ 82

3.6.8 View I/O signals ........................................................................................................................ 85

3.7 Reporter ................................................................................................................................................ 86

3.7.1 Predefined reporter settings ....................................................................................................... 86

3.7.2 New reporter .............................................................................................................................. 87

3.7.3 Remove reporter ........................................................................................................................ 90

3.7.4 Edit reporter .............................................................................................................................. 91

3.7.4.1 Adding Cycle Data Variables .................................................................................... 93

3.7.4.2 Layout of Cycle Data ................................................................................................. 95

3.7.4.3 Cycle Data layout example ........................................................................................ 98

3.7.4.4 Reporter Preview ..................................................................................................... 103

3.7.4.5 Advanced Event settings .......................................................................................... 104

3.7.4.6 Advanced CD settings .............................................................................................. 104

3.8 Security ............................................................................................................................................... 106

3.8.1 Registering groups................................................................................................................... 106

3.8.2 Registering users ..................................................................................................................... 107

3.8.3 Login and Logout .................................................................................................................... 108

3.9 Printing ............................................................................................................................................... 110

4 Set Up and Maintenance ................................................................................................................. 111

4.1 Set Up and Maintenance - Overview .................................................................................................. 111

4.2 Setups and How to handle them ......................................................................................................... 112

4.2.1 Backwards compatibility ......................................................................................................... 113

4.2.1.1 PLC conversion ........................................................................................................ 114

4.2.1.2 Compatibility between PM4000 Tightening and Gauging ................................ ....... 115

4.2.1.3 Upgrade of PLC environment .................................................................................. 115

4.3 Set up of a new system ....................................................................................................................... 116

4.3.1 Creating a new system using the Set Up Wizard ..................................................................... 116

4.4 System Map ................................................................................................................................ ........ 124

4.4.1 Logical view ............................................................................................................................ 125

4.4.1.1 System node ............................................................................................................. 126

4.4.1.2 Station node ............................................................................................................. 126

4 9836 3521 01

Contents

4.4.1.3 Bolt node .................................................................................................................. 128

4.4.1.4 Programs node ......................................................................................................... 128

4.4.1.5 Reporters node ......................................................................................................... 129

4.4.2 Hardware node ........................................................................................................................ 130

4.4.2.1 TC node .................................................................................................................... 131

4.4.2.2 Spindle node............................................................................................................. 133

4.4.2.3 Other device nodes ................................................................................................... 134

4.5 Station Set Up ..................................................................................................................................... 135

4.5.1 Advanced Station Settings....................................................................................................... 137

4.5.1.1 Work piece identifier ............................................................................................... 138

4.5.1.2 Multiple identifiers ................................................................................................ ... 138

4.5.1.3 PLC Event handling ................................................................................................ . 142

4.5.1.4 Conversion table ...................................................................................................... 142

4.6 Spindle Set Up .................................................................................................................................... 145

4.6.1 General page ............................................................................................................................ 145

4.6.2 Calibration page ...................................................................................................................... 146

4.6.3 Application page ..................................................................................................................... 147

4.6.3.1 Application External Equipment .............................................................................. 148

4.6.4 Angle Channels page ............................................................................................................... 149

4.6.4.1 Angle Double Transducer Check ............................................................................. 149

4.6.5 Torque Channels page ............................................................................................................. 151

4.6.5.1 Torque Double Transducer Check .......................................................................... 151

4.6.6 Diagnostic page ....................................................................................................................... 153

4.6.6.1 Static Zero Offset ..................................................................................................... 153

4.6.6.2 Dynamic Zero Offset and Angle Count ................................................................... 154

4.6.6.3 Flying Zero Offset ................................................................................................ .... 154

4.6.6.4 Order of execution ................................................................................................... 155

4.6.7 Motortune page ....................................................................................................................... 156

4.6.8 Automatic transducer protections ............................................................................................ 157

4.7 I/O ....................................................................................................................................................... 158

4.7.1 Local I/O ................................................................................................................................. 161

4.8 ID device Set Up ................................................................................................................................ 162

4.9 Assembly Overview Set Up ............................................................................................................... 163

4.10 PLC Parameters Set Up ...................................................................................................................... 167

4.11 SRAM ................................................................................................................................................. 168

4.12 Options ............................................................................................................................................... 169

4.12.1 Set Customer step names ......................................................................................................... 171

4.12.2 Set Customer error codes ........................................................................................................ 172

4.13 Setup Problems ................................................................................................................................... 174

4.14 Table Export and Import ..................................................................................................................... 175

4.15 Table Copy ......................................................................................................................................... 177

9836 3521 01 5

Contents

4.16 Handling of the setup in the target system .......................................................................................... 178

4.16.1 Backup of the setup ................................................................................................................. 178

4.16.2 Replacement of TCs ................................................................................................................ 180

4.17 Maintenance ....................................................................................................................................... 181

4.17.1 Select Target System ............................................................................................................... 184

4.17.2 Test Bolts ................................................................................................................................ 186

4.17.3 Calibration procedures in PowerMACS .................................................................................. 190

4.17.3.1 General ................................................................................................................... 190

4.17.3.2 Torque .................................................................................................................... 192

4.17.3.3 Angle ................................................................................................ ...................... 194

4.17.3.4 Wind Up Coefficient .............................................................................................. 195

4.17.3.5 Current (torque) ..................................................................................................... 197

4.17.4 Event Statistics ........................................................................................................................ 198

4.17.5 Service Log ............................................................................................................................. 199

4.17.6 Replace ID String .................................................................................................................... 200

4.17.7 Configure Target System......................................................................................................... 201

4.17.7.1 Advanced mode ..................................................................................................... 202

4.17.7.2 Restart of TC’s after download .............................................................................. 203

4.17.7.3 Information fields ................................ ................................................................ ... 203

4.17.7.4 Prepare TC for download of software .................................................................... 207

4.17.7.5 Change Net Data .................................................................................................... 209

4.17.8 Clear data ................................................................................................................................ 210

4.17.9 Compare programs .................................................................................................................. 211

4.17.10 Check for System Conflicts ................................................................................................ 213

4.17.11 TC Crash Log ..................................................................................................................... 214

5 PLC ................................................................................................................................................... 215

5.1 PLC - Overview .................................................................................................................................. 215

5.2 General ............................................................................................................................................... 216

5.3 System Globals ................................................................................................................................... 218

5.3.1 Station variables ...................................................................................................................... 218

5.3.1.1 Loosening cycles ...................................................................................................... 225

5.3.2 Bolt variables .......................................................................................................................... 231

5.3.3 ID device variables .................................................................................................................. 235

5.3.4 Multiple identifier variables .................................................................................................... 236

5.3.5 GM DeviceNet variables ......................................................................................................... 238

5.3.6 DC PLUS variables ................................................................................................................. 240

5.3.7 Globals .................................................................................................................................... 243

5.3.8 Bolt specific commands .......................................................................................................... 244

5.3.9 Device commands ................................................................................................................... 247

5.4 Programming the PLC ........................................................................................................................ 249

5.5 PLC Console ................................ ................................ ................................................................ ....... 254

6 9836 3521 01

Contents

5.6 PLC Parameters .................................................................................................................................. 256

5.7 Display PLC Status ............................................................................................................................. 257

6 Tightening......................................................................................................................................... 258

6.1 Tightening - Overview........................................................................................................................ 258

6.2 Create a new Tightening Program ...................................................................................................... 259

6.3 The Tightening Program form ............................................................................................................ 260

6.3.1 Tightening Program step operations ........................................................................................ 262

6.4 The Mode Table form ......................................................................................................................... 264

6.5 Tightening Program ............................................................................................................................ 266

6.5.1 Program Properties .................................................................................................................. 268

6.5.1.1 Program Common properties ................................................................................... 268

6.5.1.2 Program User variables ............................................................................................ 268

6.5.1.3 Program Settings ...................................................................................................... 270

6.5.2 Step – Control ......................................................................................................................... 273

6.5.2.1 DT - Run until Dyna-TorkTM ................................................................................... 274

6.5.2.2 DT2 - Run until Dyna-TorkTM, method 2................................................................. 276

6.5.2.3 DT3 - Run until Dyna-TorkTM, method 3................................................................. 277

6.5.2.4 T - Run until Torque ................................................................................................ 278

6.5.2.5 TC - Run until Torque with Current Control ........................................................... 279

6.5.2.6 AO - Run until Angle with overshoot compensation ............................................... 280

6.5.2.7 A - Run until Angle .................................................................................................. 282

6.5.2.8 Y1 - Run until Yield point, method 1 ...................................................................... 283

6.5.2.9 Y2 - Run until Yield point, method 2 ...................................................................... 284

6.5.2.10 LT - Loosen until torque ........................................................................................ 285

6.5.2.11 RA - Release angle ................................................................................................. 287

6.5.2.12 PA - Run until Projected angle ............................................................................... 289

6.5.2.13 TD - Run until Torque has decreased..................................................................... 290

6.5.2.14 TI - Run until Time ................................................................................................ 291

6.5.2.15 E1 - Run Engage method 1 .................................................................................... 291

6.5.2.16 E2 - Run Engage method 2 .................................................................................... 291

6.5.2.17 NS - Run until next step ......................................................................................... 291

6.5.2.18 GS - Run Gear Shift ............................................................................................... 292

6.5.2.19 PLC - Run PLC step............................................................................................... 292

6.5.2.20 JOG - Run until digital input goes high / low ........................................................ 293

6.5.2.21 W - Wait ................................................................................................................. 293

6.5.2.22 TA – Run Torque-Angle with no stop ................................................................... 294

6.5.2.23 SR – Socket Release .............................................................................................. 300

6.5.2.24 ADT-Angle Delta Torque ...................................................................................... 301

6.5.2.25 SG - Snug Gradient ................................................................................................ 303

6.5.2.26 D - Diagnostic Step ................................ ................................................................ 304

6.5.2.27 BCT – Backlash correction (only available for Gauging) ...................................... 305

9836 3521 01 7

Contents

6.5.2.28 POS - Run to Position (only available for Gauging) .............................................. 305

6.5.3 Step – Restriction .................................................................................................................... 307

6.5.3.1 Fail Safe Torque ....................................................................................................... 308

6.5.3.2 Fail Safe Time .......................................................................................................... 309

6.5.3.3 Fail Safe Angle ........................................................................................................ 310

6.5.3.4 Min Torque Restriction ............................................................................................ 311

6.5.3.5 Gradient ................................................................................................................... 313

6.5.3.6 Cross Thread and Gradient ...................................................................................... 315

6.5.3.7 Torque Profile .......................................................................................................... 316

6.5.3.8 Angle Difference ...................................................................................................... 318

6.5.3.9 Torque Difference .................................................................................................... 319

6.5.4 Step – Check ........................................................................................................................... 320

6.5.4.1 Result values from checks ........................................................................................ 321

6.5.4.2 Check peak torque ................................................................................................ .... 322

6.5.4.3 Check torque in angle window ................................................................................. 324

6.5.4.4 Check torque in time window .................................................................................. 325

6.5.4.5 Check mean torque .................................................................................................. 326

6.5.4.6 Check angle .............................................................................................................. 327

6.5.4.7 Check Post view Torque .......................................................................................... 329

6.5.4.8 Check T/T3 (Current as Torque) .............................................................................. 331

6.5.4.9 Check shut off torque ............................................................................................... 332

6.5.4.10 Check torque rate ................................................................................................... 333

6.5.4.11 Check Zero Crossing (only available for Gauging) .............................................. 336

6.5.4.12 Check time ............................................................................................................. 338

6.5.4.13 Check Yield Point Angle ....................................................................................... 338

6.5.4.14 Check Stick Slip ..................................................................................................... 340

6.5.4.15 Delta T (only available for Gauging) ..................................................................... 342

6.5.4.16 Low Spot Torque (only available for Gauging) ..................................................... 343

6.5.4.17 Check Position (only available for Gauging) ......................................................... 343

6.5.4.18 Check Backlash angle (only available for Gauging) .............................................. 344

6.5.4.19 Check external input (only available for Gauging) ................................................ 344

6.5.5 Step – Rejects .......................................................................................................................... 345

6.5.5.1 Checking the bolt status ........................................................................................... 346

6.5.5.2 Deciding what to do ................................................................................................. 347

6.5.5.3 Configuring Reject Management ............................................................................. 350

6.5.5.4 Advanced RM Actions ............................................................................................. 352

6.5.5.5 Cycle RM ................................................................................................................. 353

6.5.5.6 Reject management states ........................................................................................ 355

6.5.5.7 Reject management examples .................................................................................. 361

6.5.6 Step – Ramps & Other ............................................................................................................ 363

6.5.6.1 Ramps & Other – Ramps ......................................................................................... 364

8 9836 3521 01

Contents

6.5.6.2 Ramps & Other – Other ........................................................................................... 365

6.5.6.3 Ramps & Other – Store Position (only available for Gauging) ................................ 366

6.5.6.4 Ramps & Other – Signals at step start and end (only available for Gauging) .......... 367

6.5.7 Zones (only available for Gauging) ......................................................................................... 368

6.6 Bolt Monitoring .................................................................................................................................. 369

6.6.1 Monitoring Check – Final Peak Torque .................................................................................. 372

6.6.2 Monitoring Check – Angle ...................................................................................................... 373

6.6.3 Monitoring Check – Torque Rate ............................................................................................ 376

6.6.4 Monitoring Check – Monitoring Yield point torque and angle ............................................... 379

6.7 Result variables .................................................................................................................................. 382

6.7.1 Statuses .................................................................................................................................... 382

6.7.2 Station level result variables.................................................................................................... 383

6.7.3 Bolt level result variables ........................................................................................................ 385

6.7.3.1 Errors ....................................................................................................................... 390

6.7.3.2 Warnings .................................................................................................................. 394

6.7.4 Step level result variables ........................................................................................................ 395

6.8 Servo and spindle protections ............................................................................................................. 399

6.8.1 Stall protection ........................................................................................................................ 399

6.8.2 How to avoid the problems ..................................................................................................... 399

7 SPC and Statistics ............................................................................................................................ 401

7.1 SPC - Overview .................................................................................................................................. 401

7.2 SPC, Statistical Process Control ......................................................................................................... 402

7.2.1 Data Collection ........................................................................................................................ 402

7.2.2 Calculations for subgroups ...................................................................................................... 403

7.2.3 Calculations and checks .......................................................................................................... 403

7.2.4 SPC constants .......................................................................................................................... 407

7.3 SPC set up .......................................................................................................................................... 408

7.4 Shift Reports and Shift Set Up............................................................................................................ 410

7.4.1 Shift Set Up ............................................................................................................................. 411

8 Peripheral Devices ........................................................................................................................... 413

8.1 Peripheral Devices - Overview ........................................................................................................... 413

8.2 Add a device ................................................................ ................................................................ ....... 415

8.3 Status of a device ................................................................................................................................ 417

8.4 Standard Accessory Devices............................................................................................................... 418

8.4.1 Stacklight................................................................................................................................. 418

8.4.2 Indicator Box ........................................................................................................................... 419

8.4.3 Operator Panel ................................................................ ................................ ......................... 421

8.5 I/O Device .......................................................................................................................................... 423

8.6 Printer on TC ...................................................................................................................................... 424

8.7 Printer or File on CC .......................................................................................................................... 424

8.8 PLC ..................................................................................................................................................... 425

8.9 ID device ............................................................................................................................................ 429

9836 3521 01 9

Contents

8.10 ToolsNet ............................................................................................................................................. 436

8.11 Ethernet Protocols .............................................................................................................................. 439

8.12 Fieldbus Interface ............................................................................................................................... 480

8.9.1 Type specific parameters ......................................................................................................... 430

8.9.1.1 Barcode scanner ....................................................................................................... 430

8.9.1.2 Pepperl + Fuchs escort memory ............................................................................... 431

8.9.1.3 Allen Bradley escort memory .................................................................................. 432

8.9.1.4 Omron escort memory ............................................................................................. 433

8.9.1.5 Euchner card reader ................................................................................................. 435

8.11.1 Open Protocol .......................................................................................................................... 442

8.11.1.1 Automatic/manual mode ........................................................................................ 443

8.11.1.2 Supported message types ....................................................................................... 445

8.11.1.3 TC Status Record Formats ..................................................................................... 448

8.11.1.4 TC Result Record Formats ..................................................................................... 449

8.11.2 DaimlerChrysler PFCS ................................................................................................ ............ 451

8.11.2.1 Supported message types ....................................................................................... 452

8.11.2.2 PFD Result Record Formats................................................................................... 452

8.11.3 FSH ......................................................................................................................................... 453

8.11.3.1 Supported message types ....................................................................................... 454

8.11.3.2 TC Result Record Formats ..................................................................................... 455

8.11.4 DC PLUS ................................................................................................................................ 456

8.11.4.1 Parameters for PDT ................................................................................................ 457

8.11.4.2 Parameters for PQD ............................................................................................... 459

8.11.4.3 Handling of PN, KN and LI, in protocol version PDT ........................................... 461

8.11.4.4 Handling of QO and FP ......................................................................................... 462

8.11.4.5 SAW / WIS ............................................................................................................ 463

8.11.4.6 SPS ......................................................................................................................... 465

8.11.4.7 VBA ....................................................................................................................... 466

8.11.4.8 SSE......................................................................................................................... 467

8.11.4.9 TC Result Formats for PDT ................................................................................... 468

8.11.4.10 TC Result Format for PQD .................................................................................. 470

8.11.4.11 Selecting the data to report ................................................................................... 472

8.11.4.12 Selecting the data to report ................................................................................... 472

8.11.5 I-P.M. ...................................................................................................................................... 473

8.11.5.1 Mapping of data ..................................................................................................... 473

8.11.5.2 Value sent as Maintenance Sequence (AFO-number)............................................ 475

8.11.5.3 Possible error codes ............................................................................................... 476

8.11.5.4 Characteristic Identifications ................................................................................. 477

8.11.5.5 Parameter Identifications ....................................................................................... 477

8.11.6 Audi XML ............................................................................................................................... 478

8.12.1 Access to PLC data ................................................................................................................. 485

10 9836 3521 01

Contents

8.12.1.1 PLC Areas .............................................................................................................. 487

8.12.1.2 Complex data types ................................................................................................ 488

8.12.1.3 Set up shared variables ........................................................................................... 491

8.12.1.4 Fieldbus form ......................................................................................................... 495

8.12.2 Access to Process data ............................................................................................................. 498

8.12.2.1 Using the extended format ..................................................................................... 504

8.12.3 Fieldbus specific Information .................................................................................................. 506

8.12.3.1 DeviceNet .............................................................................................................. 506

8.12.3.2 Profibus DP and DP-V1 ......................................................................................... 510

8.12.3.3 ProfiNet IO............................................................................................................. 514

8.12.3.4 Modbus TCP .......................................................................................................... 518

8.12.3.5 Ethernet/IP ............................................................................................................. 523

8.12.3.6 CC-Link ................................................................................................................. 526

8.13 Serial Communication ........................................................................................................................ 529

8.13.1 Accesses from External communication device ...................................................................... 530

8.13.2 Access to PLC data ................................................................................................................. 532

8.13.3 Access to Process data ............................................................................................................. 534

8.13.4 Serial Communication Protocol Information .......................................................................... 534

8.13.4.1 JBUS ...................................................................................................................... 536

8.13.4.2 Siemens 3964R ...................................................................................................... 537

8.13.4.3 Telemechanique UNI-TE ....................................................................................... 538

8.13.4.4 SATT Comli........................................................................................................... 540

8.13.4.5 Allen-Bradley Data Highway (Plus) ...................................................................... 541

8.14 API, Application Programmers Interface ........................................................................................... 542

8.14.1 Subscriptions ........................................................................................................................... 546

8.14.2 Object model ........................................................................................................................... 547

8.14.3 Enumerators exported by the API ........................................................................................... 548

8.14.4 Api object ................................................................................................................................ 550

8.14.4.1 Properties ............................................................................................................... 550

8.14.4.2 GetPLCBoolEx ...................................................................................................... 551

8.14.4.3 SetPLCBoolEx ....................................................................................................... 551

8.14.4.4 GetPLCByteEx ...................................................................................................... 552

8.14.4.5 SetPLCByteEx ....................................................................................................... 552

8.14.4.6 GetPLCIntEx .......................................................................................................... 553

8.14.4.7 SetPLCIntEx .......................................................................................................... 553

8.14.4.8 GetPLCRealEx ....................................................................................................... 554

8.14.4.9 SetPLCRealEx ....................................................................................................... 554

8.14.4.10 GetPLCStringEx .................................................................................................. 555

8.14.4.11 SetPLCStringEx ................................................................................................... 555

8.14.4.12 GetPLCBool ......................................................................................................... 556

8.14.4.13 SetPLCBool ......................................................................................................... 556

9836 3521 01 11

Contents

8.14.4.14 GetPLCByte ......................................................................................................... 557

8.14.4.15 SetPLCByte.......................................................................................................... 557

8.14.4.16 GetPLCInt ............................................................................................................ 558

8.14.4.17 SetPLCInt ............................................................................................................. 558

8.14.4.18 GetPLCReal ......................................................................................................... 559

8.14.4.19 SetPLCReal .......................................................................................................... 559

8.14.4.20 GetPLCString ....................................................................................................... 560

8.14.4.21 SetPLCString ....................................................................................................... 560

8.14.4.22 GetCycleData ....................................................................................................... 561

8.14.4.23 GetCycleDataBin ................................................................................................. 561

8.14.4.24 GetLastCycleData ................................................................................................ 562

8.14.4.25 GetLastCycleDataBin .......................................................................................... 562

8.14.4.26 GetCycleDataById ............................................................................................... 562

8.14.4.27 SubscribeCD ........................................................................................................ 563

8.14.4.28 RecNewCD .......................................................................................................... 563

8.14.4.29 FlushCDQueue ..................................................................................................... 563

8.14.4.30 RewindCDQueue ................................................................................................. 563

8.14.4.31 GetEvent .............................................................................................................. 564

8.14.4.32 GetEventEx ................................ ................................................................ .......... 565

8.14.4.33 GetEventObj ........................................................................................................ 565

8.14.4.34 SubscribeEvent .................................................................................................... 566

8.14.4.35 RecNewEvent ...................................................................................................... 566

8.14.4.36 FlushEventQueue ................................ ................................................................ . 566

8.14.4.37 RewindEventQueue ............................................................................................. 566

8.14.4.38 GetTrace ............................................................................................................... 567

8.14.4.39 GetTraceEx .......................................................................................................... 567

8.14.4.40 GetLastTrace ........................................................................................................ 567

8.14.4.41 SubscribeTrace ..................................................................................................... 568

8.14.4.42 RecNewTrace ....................................................................................................... 568

8.14.4.43 FlushTraceQueue ................................................................................................. 568

8.14.4.44 RewindTraceQueue .............................................................................................. 569

8.14.4.45 SubscribeStStatus ................................................................................................. 569

8.14.4.46 RecNewStStatus ................................................................................................... 569

8.14.4.47 GetSetup ............................................................................................................... 570

8.14.4.48 SetSetup ............................................................................................................... 570

8.14.4.49 GetSetupItem ....................................................................................................... 571

8.14.4.50 SetSetupItem ........................................................................................................ 571

8.14.4.51 GetSystemDesc .................................................................................................... 572

8.14.4.52 GetStationDesc .................................................................................................... 572

8.14.4.53 GetDateAndTime ................................ ................................................................ . 573

8.14.4.54 SetDateAndTime .................................................................................................. 573

12 9836 3521 01

Contents

8.14.4.55 GetTime ............................................................................................................... 574

8.14.4.56 SetTime ................................................................................................................ 574

8.14.5 System object .......................................................................................................................... 575

8.14.5.1 Properties ............................................................................................................... 575

8.14.6 Stations object (collection) ...................................................................................................... 576

8.14.6.1 Properties ............................................................................................................... 576

8.14.6.2 Item ........................................................................................................................ 576

8.14.6.3 Exists ...................................................................................................................... 577

8.14.7 Station object ........................................................................................................................... 578

8.14.7.1 Properties ............................................................................................................... 578

8.14.8 Bolts object (collection) .......................................................................................................... 579

8.14.8.1 Properties ............................................................................................................... 579

8.14.8.2 Item ........................................................................................................................ 579

8.14.8.3 Exists ...................................................................................................................... 580

8.14.9 Bolt object ............................................................................................................................... 581

8.14.9.1 Properties ............................................................................................................... 581

8.14.10 TraceData object ................................................................................................................ 582

8.14.10.1 Properties ............................................................................................................. 582

8.14.11 Channels object (collection) ................................ ................................ ............................... 583

8.14.11.1 Properties ............................................................................................................. 583

8.14.11.2 Item ...................................................................................................................... 583

8.14.11.3 Exists .................................................................................................................... 584

8.14.12 Channel object .................................................................................................................... 585

8.14.12.1 Properties ............................................................................................................. 585

8.14.12.2 GetSampleValueNo ............................................................................................. 585

8.14.12.3 GetSampleValueTime .......................................................................................... 585

8.14.12.4 GetSampleValues ................................................................................................. 586

8.14.13 StepBounds object (collection) .......................................................................................... 587

8.14.13.1 Properties ............................................................................................................. 587

8.14.13.2 Item ...................................................................................................................... 587

8.14.13.3 Exists .................................................................................................................... 588

8.14.14 StepBound object ............................................................................................................... 589

8.14.14.1 Properties ............................................................................................................. 589

8.14.15 EventData object ................................................................................................................ 590

8.14.15.1 Properties ............................................................................................................. 590

8.14.16 How to use the API ............................................................................................................ 591

8.15 GM DeviceNet .................................................................................................................................... 596

8.15.1 Interface definition input ......................................................................................................... 598

8.15.2 Interface definition output ....................................................................................................... 600

8.15.2.1 Indication schema .................................................................................................. 601

8.16 ACTA 3000 ........................................................................................................................................ 604

9836 3521 01 13

Contents

8.17 Process data ........................................................................................................................................ 606

8.17.1 Data types ................................................................................................................................ 608

8.17.2 Layout of Cycle data in Process data ...................................................................................... 608

8.17.3 Layout of Events in Process data ............................................................................................ 609

8.17.4 Layout of Traces in Process data ............................................................................................. 610

8.17.5 Layout of Setup Item Descriptions .......................................................................................... 611

8.17.5.1 Bolt......................................................................................................................... 612

8.17.5.2 Spindle, Parameters ................................................................................................ 613

8.17.5.3 Spindle, Channel data ............................................................................................ 614

8.17.5.4 Program, General data ............................................................................................ 615

8.17.5.5 Program, Trace data ............................................................................................... 616

8.17.5.6 Program, Monitoring data ...................................................................................... 617

8.17.5.7 Sequence and Program, Step, Control data ............................................................ 618

8.17.5.8 Sequence and Program, Step, Speed data .............................................................. 618

8.17.5.9 Sequence and Program, Step, Speed, Ramp down data ......................................... 619

8.17.5.10 Sequence and Program, Step, Other data ............................................................. 620

8.17.5.11 Sequence and Program, Step, Surveillance data .................................................. 621

8.17.6 Layout of Setups...................................................................................................................... 621

9 Specification ..................................................................................................................................... 623

9.1 Specification ................................................................ ................................................................ ....... 623

9.2 Requirements ToolsTalk PC ............................................................................................................... 624

10 Appendix........................................................................................................................................... 625

10.1 List of events ...................................................................................................................................... 625

10.2 ToolsTalk PowerMACS command line .............................................................................................. 653

10.3 Cycle Data Storage ............................................................................................................................. 654

10.3.1 Store 5000 Cycle Data ............................................................................................................. 654

10.3.1.1 Storing and retrieving cycle data ............................................................................ 655

10.4 Configuration of the Conversion Box ................................................................................................. 657

10.5 Fatal Software Errors .......................................................................................................................... 660

11 References......................................................................................................................................... 663

11.1 References to external documents ...................................................................................................... 663

12 Glossary of Terms ............................................................................................................................ 665

12.1 Glossary .............................................................................................................................................. 665

14 9836 3521 01

Introduction

1 Introduction

1.1 Introduction - Overview

The PowerMACS 4000 system is the seventh generation of tightening systems from Atlas Copco Tools

and Assembly Systems. It is the perfect solution for all tightening applications in your assembly plant,

however complex.

Building on the successfull PowerMACS concept the PowerMACS 4000 delivers even more performance

and benefits to customers by increased intelligence in tightening controllers and simplified configuration

through the new ToolsTalk PowerMACS software.

PowerMACS 4000 supports all known tightening and process monitoring methods and builds further on

the proven PowerMACS concept to deliver even more performance using the new intelligent QST

spindles.

PowerMACS 4000 is not only the most productive, cost-effective and user-friendly tightening system on

the market today, it also offers an impressive new level of installation flexibility.

9836 3521 01 15

Introduction

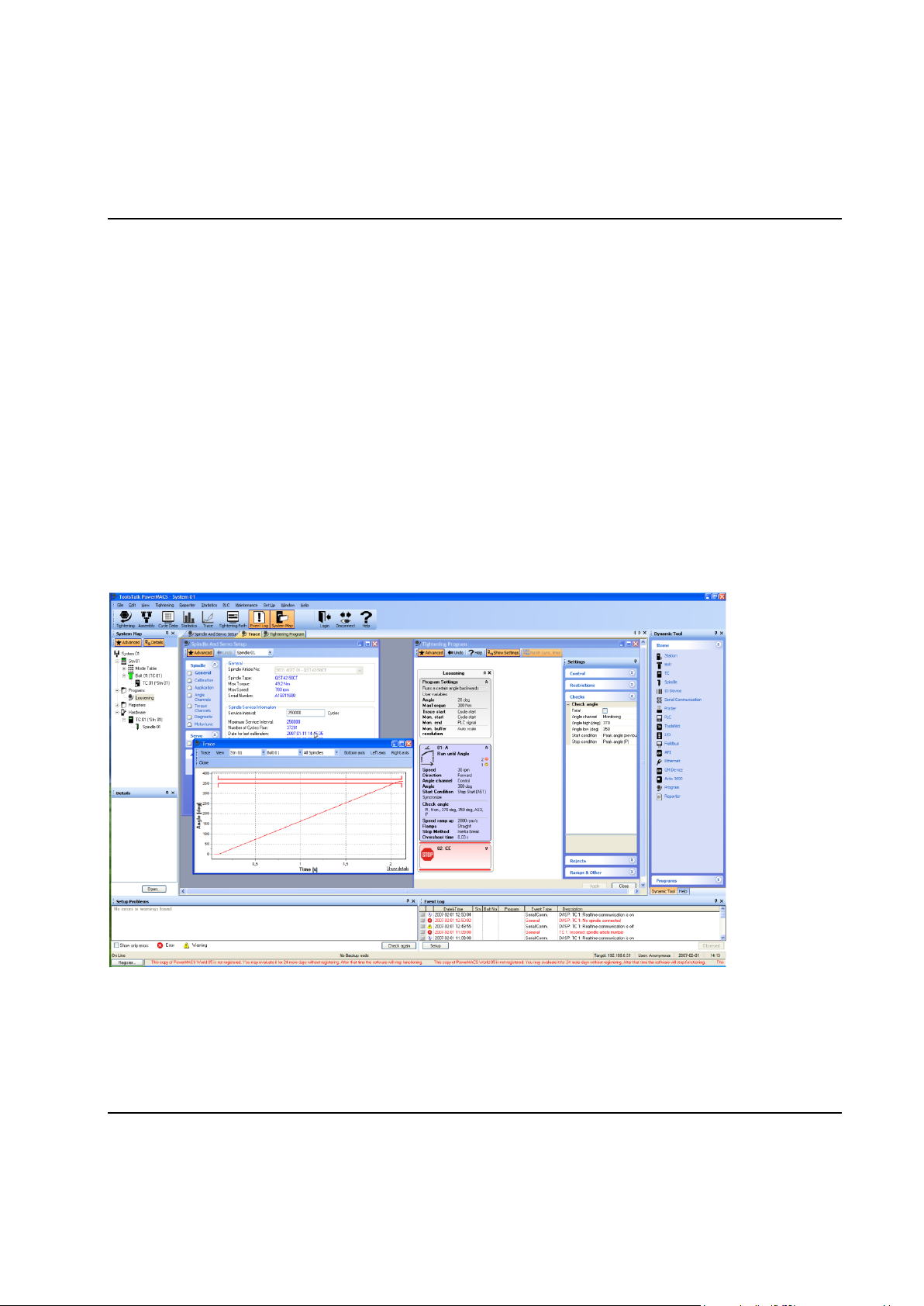

1.1.1 ToolsTalk PowerMACS, the friendly user interface

The new improved ToolsTalk PowerMACS (TTPM) builds on the experiences from the earlier WinTC and

with increased simplicity and flexibility make the user experience more rewarding without loosing any

functionality.

Simplicity has been greatly increased by the introduction of the Basic and Advanced concepts into

ToolsTalk PowerMACS, most functionality is hidden for inexperienced users but available at a mouse-click

for more those who feel they need the extra functionality.

Increased user friendliness by drag & drop functionality.

Full reporting ToolsTalk PowerMACS offers full reporting of tightening results, set values and limits. An

easily adapted annunciator shows the tightening results in read-at-a-glance graphics. The combined

SystemMap shows the tightening status of the bolts and the status of all equipped hardware. The system

provides reports for any chosen parameters, trace curves, and advanced SPC and log files.

User guides Accessible via Hyperlinks, the software includes SetUp Wizards, Tutorials, Tightening

Templates which guide you through the most common tightening sequences, Spare Parts Lists with

drawings and article numbers, service, fault-finding and FAQ functions, and a complete on-line manual.

If you need to configure the system for Ethernet or Fieldbus communication, the PowerMACS 4000 Set

Up Wizards make the task simple.

API for easy access ToolsTalk PowerMACS includes the popular Application Program Interface (API)

enabling the engineer to access data from the Tightening Controller. For example: read and write PLC,

cycle and trace data and store cycle data to media. All internal and external communications are via

Ethernet TCP/IP thin wire 100 Mbit/s.

PowerMACS 4000 can be tailored to any assembly process. A built-in PLC (IEC 61131-3), fully

programmable using the ToolsTalk interface, supports various in-station control requirements.

1.1.2 Intelligent tightening controllers, TCs

PowerMACS 4000 is modular in concept, utilizing the new improved intelligent Tightening Controller (TC)

with state-of-the-art software and a wide range of peripheral support and communication possibilities. The

TC is designed for IP43 and is easy to integrate into a production line as a stand-alone unit or integrated

in a panel.

Even more expanded capacity than it‟s predecessor it is an attractive piece of industrial design, the

PowerMACS 4000 TC is equipped with an impressive amount of memory, more than enough to handle

the Real- Time Operative System, Application Programs and the PLC program.

Tightening controllers are now separated in the Primary Tightening Controller (TC) featuring more

connectability and external communication possibilities and the more basic tightening controller (TC).

One Primary TC (PTC) is configured as a System TC and the rest as Spindle TCs. In a system all Spindle

TCs can be replaced without needing to download the setup once again. One system can include a

maximum of 15 stations. Up to 50 TC's can be connected in one system, controlling 50 nut runners.

16 9836 3521 01

Introduction

Full interchangeability means fewer spare parts are required, maintenance time is reduced and availability

is increased.

All common interfaces All PTC's are designed to interface with Ethernet, the most common Fieldbuses,

and industrial PLCs. The Application Program Interface (API) ensures easy external access to the system.

Peripherals simply added A wide range of peripherals can be connected to the PowerMACS 4000 TC

including printers, bar code readers, operator table, operator annunciators, etc.

Flexible installation The plug-and-play modular design of the TC means maximum installation flexibility.

Series communication in line control and data collection enables the PowerMACS TC's to be discreetly

integrated into the production line by the connection of two cables. The appropriate reporting system and

suitable operator interface can be mounted next to the work area.

9836 3521 01 17

Introduction

1.2 Tightening and Gauging

There are two types of PM4000 products:

PM4000 Tightening

PM4000 Gauging

PM4000 Tightening contains all functions needed for normal tightening of bolts. It can read and write

Tightening setups on disk or a TC. It cannot read or write a Gauging setup.

PM4000 Gauging has all the functions of PM4000 Tightening but also additional functions for gauging

applications. It can read a Tightening setup from file and convert it to a Gauging setup but not vice versa.

1.2.1 Gauging Functions

The following functions are only avaliable if you run PM4000 Gauging:

Step BCT

Step Run to Position

Step Wait, PLC signal addition

Check Delta T

Check Low Spot

Check Pos

Check Peak T, additions

Zones (within step)

Store positions

Backlash compensation

1.2.2 Gauging Applications

PM4000 Gauging can be used for applications where turning and measuring of torque and angle with high

precision is needed. Examples:

Torque To Turn

Valve lash

Indexer

Hub nuts

18 9836 3521 01

Introduction

1

2

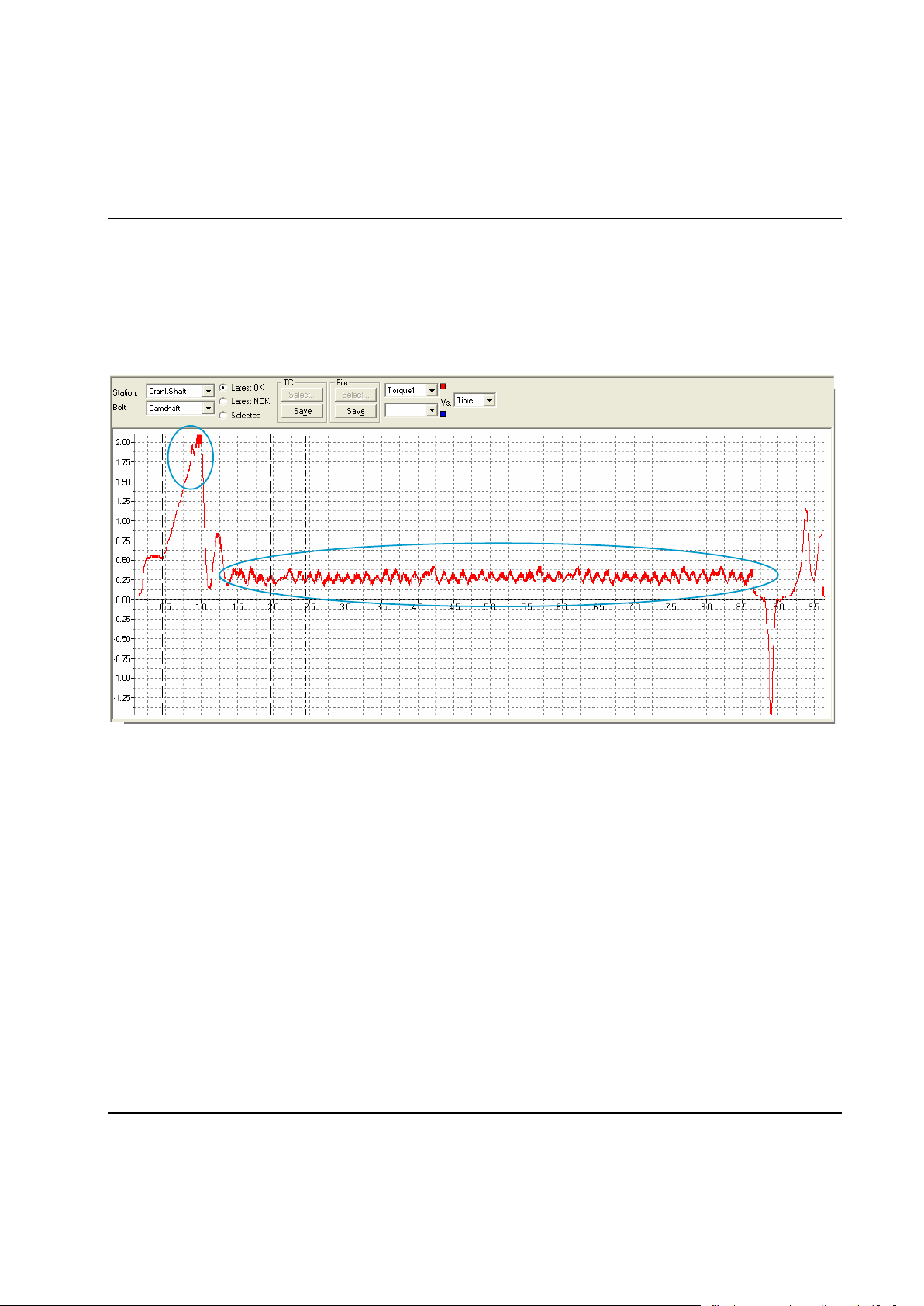

1.2.2.1 Torque To Turn Gauging Application

An example of a Torque To Turn application is when an engine manufacturer wants to rotate the crank or

cam shaft under controlled conditions for the first time. Metal chips, burrs, sharp edges (spot distortions)

may cause excessive drag and eventually lead to early bearing shell failure and warranty repairs.

With PM4000 Gauging it is easy to create a program that rotates the shaft 360 or 720 degrees and

continuously monitor the torque and angle.

The curve present torque vs. time. There are two critical points.

1. Break-Away

2. Low Torque Rotation Test

To check break-away the torque is gently increased without rotation. If the torque reaches a preset limit

before any rotation starts the test stops immediately, preventing any damage.

If the break-away torque is within limits the rotation starts and the torque is monitored for the full rotation at

slow speed. Any friction out of limit indicates mechanical problems that should be corrected.

The combination of the two tests will show up any mechanical problems at a very early stage, before the

motor has been built into e.g. a vehicle. This eliminates the risk that the motor later experience expensive

service warranties.

9836 3521 01 19

Introduction

1.2.2.2 Valve Lash Gauging Application

In a Valve Lash application a bolt and a nut should be rotated and locked to each other to achieve a

specific valve lash. This can be done with a special coaxial spindle, e.g. QMX 42-2RT.

It is easy to create a program that operates the two spindles in a controlled way to make up perfectly

adjusted valve lash.

20 9836 3521 01

Introduction

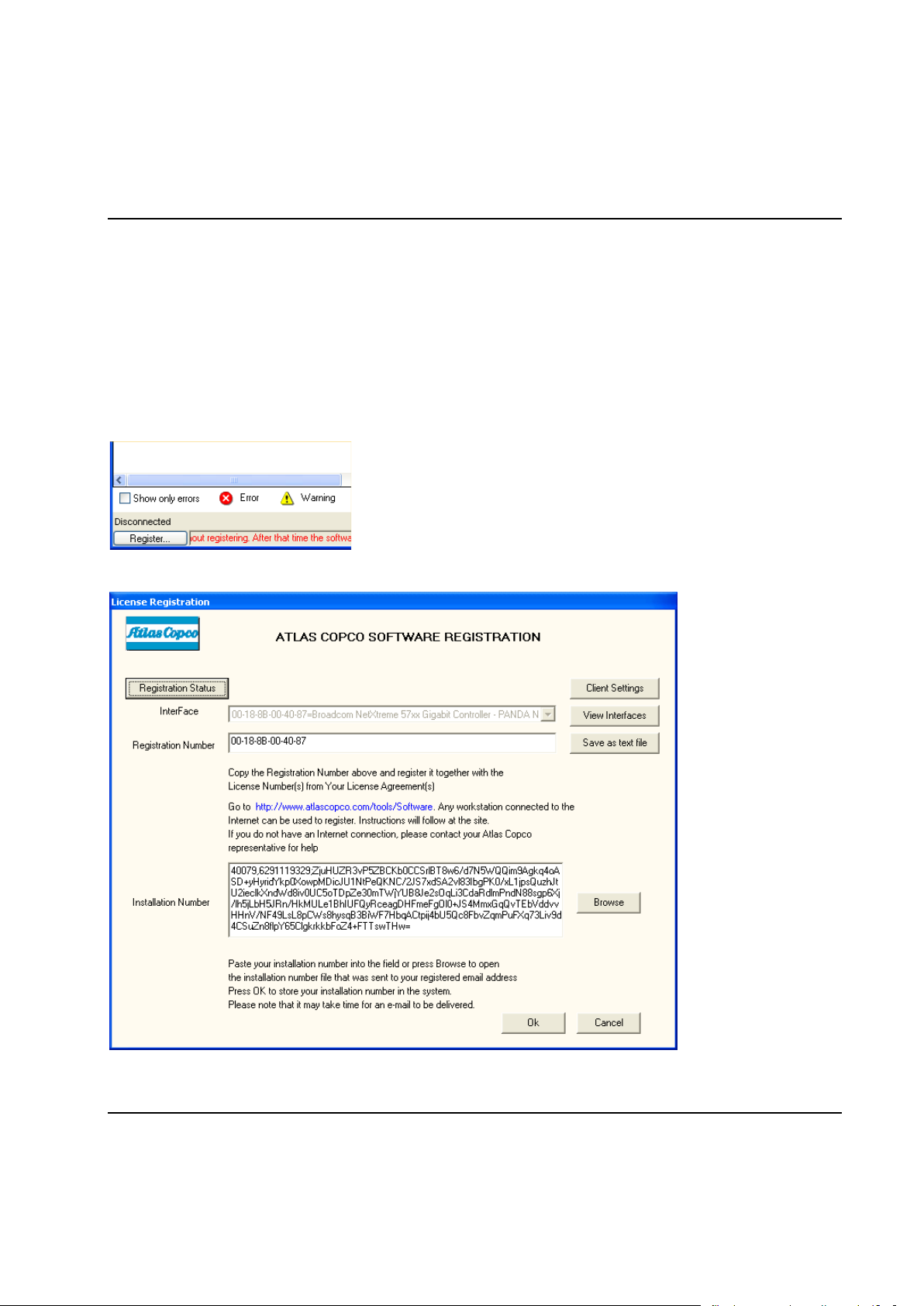

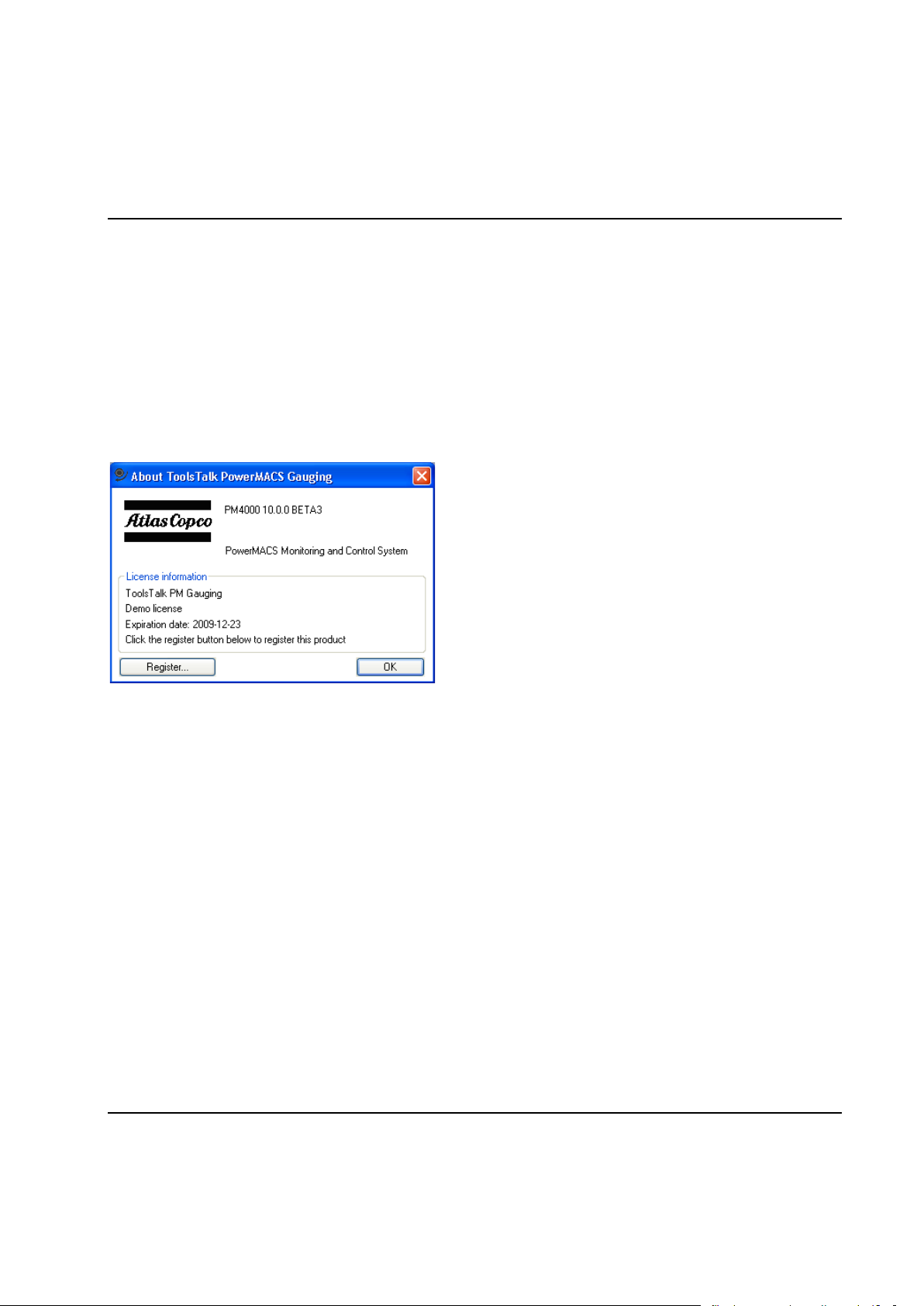

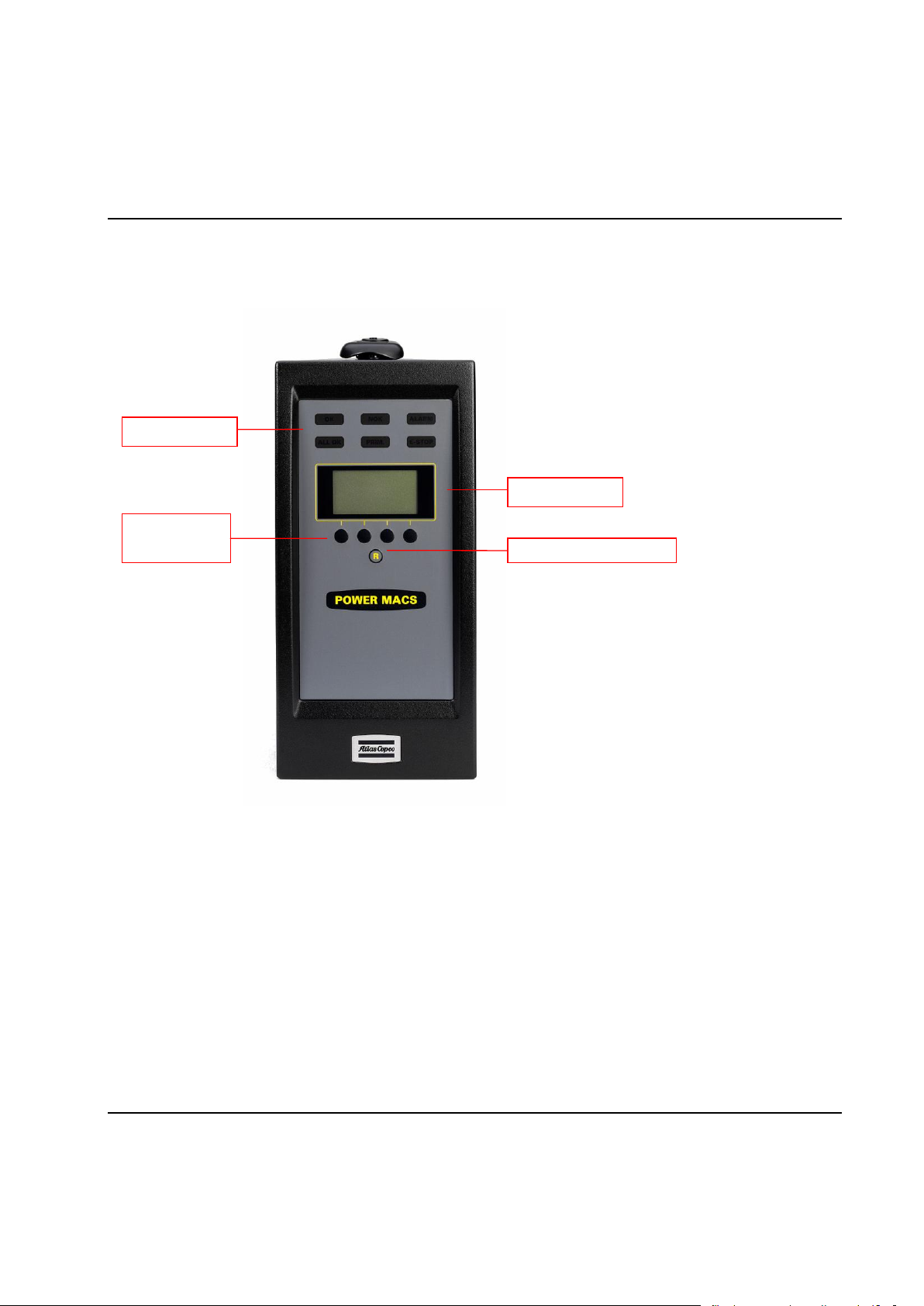

1.3 Installing ToolsTalk PowerMACS

You can install ToolsTalk PowerMACS from CD or from a hard disk. To install PM4000 Tightening you

excecute the file “PM4000 10.X.X ToolsTalk.exe” located in the folder ToolsTalk. PM4000 Gauging is

installed with the file “PM4000 10.X.X ToolsTalk Gauging.exe” located in the folder ToolsTalk Gauging.

After installing ToolsTalk PowerMACS you have up to 90 days to register it.

Register buttons are found at the bottom left part of the window for an unregistered ToolsTalk, and in the

Help-About window.

To register, press a Register button to invoke the below form, and follow the instructions.

9836 3521 01 21

Introduction

When registering please note that there are two types of products:

PM4000 Tightening

PM4000 Gauging

The license only covers one of the products. For more information on differences between these products

see Tightening and Gauging.

Until registered ToolsTalk PowerMACS will display an extra status bar at the bottom of the main window

showing you the number of days left of the evaluation period. When this time expires the application will

no longer be possible to start and is automatically shut down if it is running.

22 9836 3521 01

System Architecture

2 System Architecture

2.1 System Architecture - Overview

This section describes the architecture of the PowerMACS 4000 system. It includes the descriptions of the

hardware components, including computers and devices, the structures of the system, station and

spindles.

9836 3521 01 23

System Architecture

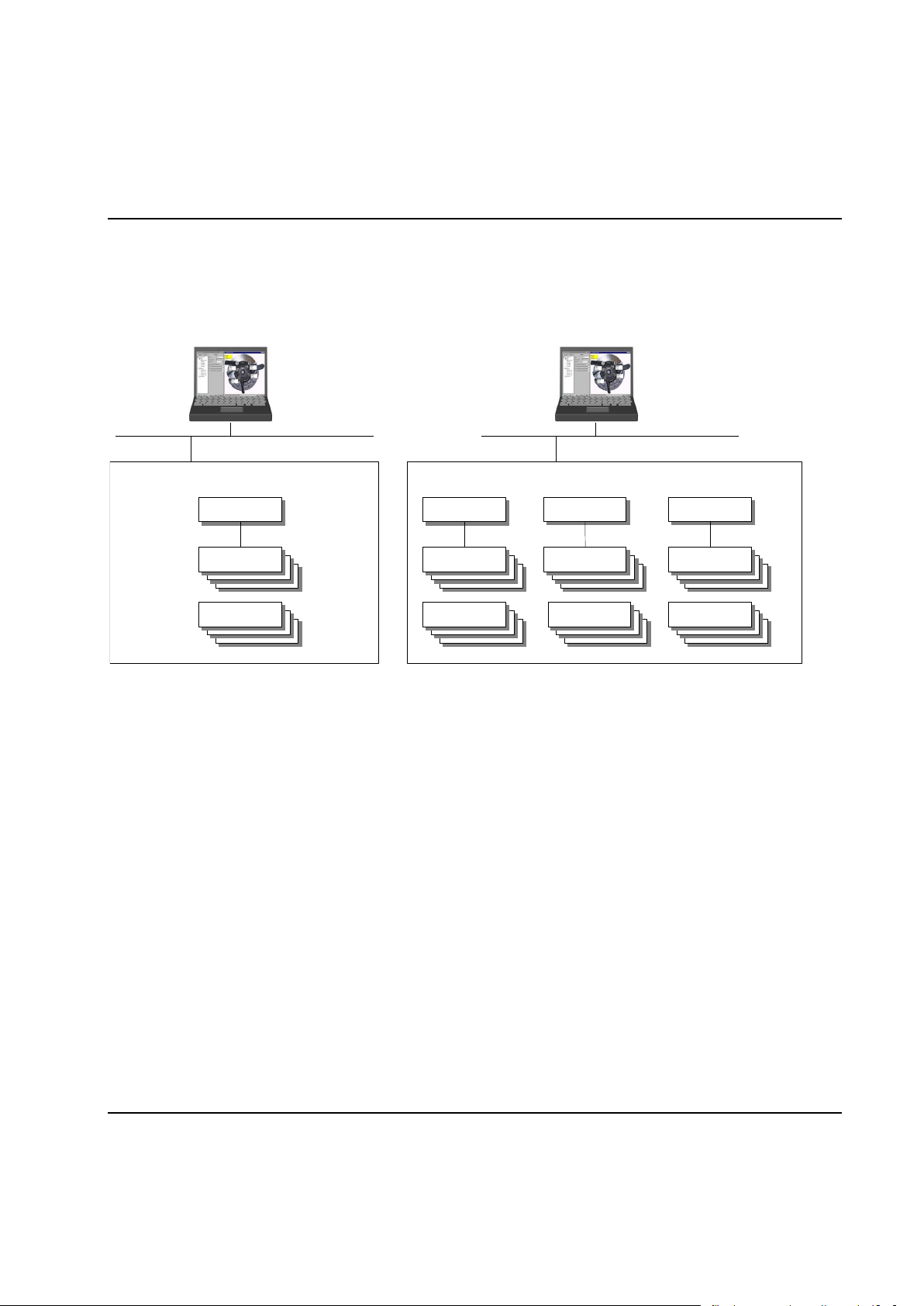

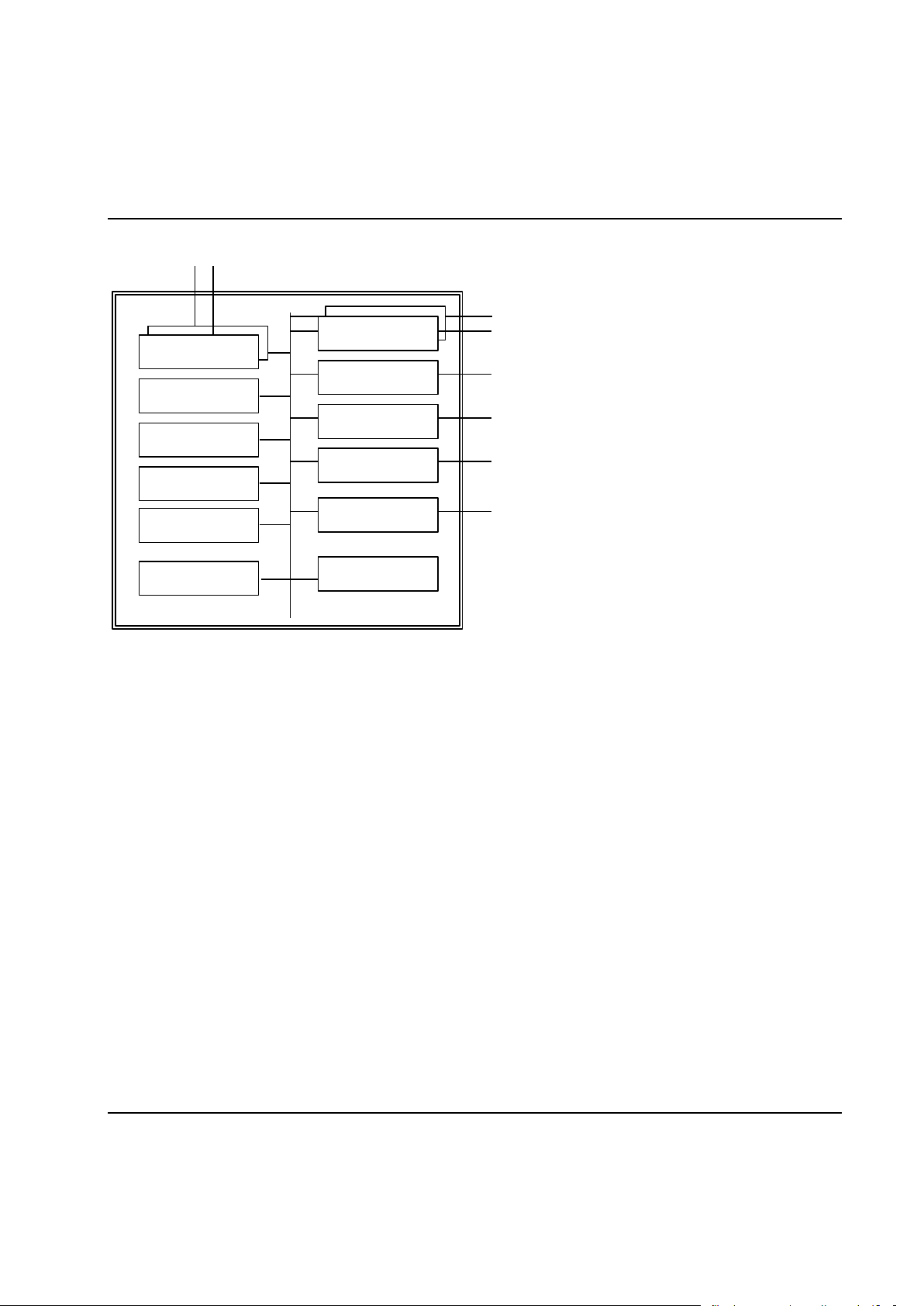

A one station PowerMACS System

Bolt

Station

Spindle

A three station PowerMACS System

Bolt

Station

Bolt

Station

Bolt

Station

Spindle

Spindle

Spindle

2.2 System Structure

A PowerMACS System consists of one or more stations where each station may control one or more

bolts.

System

A system comprises one or more Tightening Controllers linked together. A system works autonomously,

performing the programmed tightening task(s).