Atlas Copco POWER FOCUS 6000 Pocket Manual

POWER FOCUS 6000

POCKET GUIDE

Release 2.3

Overview of the Power Focus 6000

and Tensor STR System

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

FUNCTIONALITY MANAGEMENT SYSTEM ..................................................... 16

Introduction .............................................................................................. 16

Main benefits ............................................................................................ 16

Order and distribute licenses to customer portal ..................................... 17

Distribution from customer portal ............................................................ 17

FMS Server based .................................................................................... 18

FMS USB device/non network based ....................................................... 19

TIGHTENING STRATEGIES ................................................................................ 20

Turbo Tight® Tightening Strategy ................................................................. 20

Fine-tuning the Turbo Tight® Tightening strategy ....................................... 20

Reduced cycle times ................................................................................20

Reduced reaction force ........................................................................... 21

Easy set-up .............................................................................................. 21

Sustainability ................................................................................................ 22

How are cycle times reduced? ................................................................22

How is reaction force reduced? ............................................................... 22

How come set-up is so easy? .................................................................. 22

How does Turbo Tight® provide energy savings? .....................................22

Two Step Tightening Strategy ...................................................................... 23

Fine-tuning the Two Step Tightening strategy ........................................... 23

Quick Step Tightening Strategy .................................................................... 24

Three Step Tightening Strategy ................................................................... 25

Rotate Strategy .............................................................................................. 26

Target Torque Limits ...................................................................................... 26

Target Angle Limits ....................................................................................... 27

Stop Stage ..................................................................................................... 28

Soft Stop ........................................................................................................29

SYSTEM OVERVIEW .............................................................................................6

Power Focus 6000 Controller ......................................................................... 6

Intelligent Application Module (IAM) ............................................................. 7

Tensor STR Cable ............................................................................................ 7

Accessories And Communication Interfaces ................................................8

POWER FOCUS 6000 HARDWARE ...................................................................... 9

Power ...............................................................................................................9

Line voltage ..................................................................................................... 9

Normal Environmental Conditions ................................................................ 9

Size and Weight ..............................................................................................9

Display .............................................................................................................. 9

Communication ............................................................................................. 10

Audio .............................................................................................................. 10

Connections ................................................................................................... 10

IAM ..................................................................................................................11

POWER FOCUS 6000 SOFTWARE .....................................................................12

Menu Overview ............................................................................................. 12

Tightening Menu ........................................................................................... 12

Batch Sequence Menu ..................................................................................12

Sources Menu ................................................................................................ 12

Tool Menu ...................................................................................................... 12

Virtual Station Menu ..................................................................................... 13

Controller Menu ............................................................................................ 13

Accessories Menu ......................................................................................... 13

Reports Menu ................................................................................................13

Settings Menu................................................................................................13

Basic Programming ....................................................................................... 14

Open Protocol ................................................................................................ 15

CONTENTS

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

CABLE MANAGEMENT ...................................................................................... 40

Use of a cable clamp bracket ....................................................................41

Smaller bending radius for greater accessibility. ......................................43

Innovative ‘Cable Twist’ design .................................................................43

Centralized strain relief to prevent lead damage.......................................44

FIELDBUS ............................................................................................................ 45

TOOL TALK 2 ........................................................................................................ 46

User Authentication .................................................................................. 46

Plant Structure .......................................................................................... 46

Multiple Controller Upgrade ..................................................................... 47

Controller Programming ............................................................................ 47

TOOLSNET 8 .......................................................................................................48

Simple setup in combination with Atlas Copco controllers ......................48

Simple Data Analysis ................................................................................ 48

Production Alarms .................................................................................... 49

Dashboard ................................................................................................ 49

Traceability ................................................................................................ 49

Tool Service Information ........................................................................... 50

VIRTUAL STATIONS ............................................................................................30

Introduction ............................................................................................. 30

Setting up a Virtual Station ........................................................................ 31

Key Benefits .............................................................................................. 31

STR TOOL.............................................................................................................32

Overview ........................................................................................................ 32

Models ............................................................................................................ 33

Tool Modules ................................................................................................. 33

Handle module ......................................................................................... 33

HMI ........................................................................................................... 33

Motor ........................................................................................................ 34

Torque transducer ..................................................................................... 34

Gears and Angle head ...............................................................................34

ETT front part ............................................................................................ 34

Accessories (attached to the tool (ETV/ETD)) ..............................................35

Certifications .................................................................................................. 36

EC declaration ................................................................................................ 36

Harmonized standards ............................................................................. 36

Other directives ........................................................................................ 36

IP 54 protection ........................................................................................ 37

Service/Maintenance Intervals ................................................................. 37

STR TOOL ACCESSORIES ................................................................................... 38

Local customization .................................................................................. 39

CONTENTS

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

6 7

SYSTEM OVERVIEW

The core Power Focus 6000 systems consist of the following parts:

• Power Focus 6000 controller

• Intelligent Application Module (IAM)

• Tensor STR tool

• Tensor STR cable

• Accessories and communication interfaces

In the image below you can see how these different parts fit together as a

system in a typical customer environment.

Power Focus 6000 Controller

Power Focus controllers are recognized around the

globe for their outstanding tightening capabilities. The

platform meets the need to enhance error-proofing,

connectivity and flexibility, and is the first to introduce

software ergonomics to the industry. This won the

Power Focus 6000 the prestigious Red Dot design

award in 2012. Learn more about the functionality

of the software or the hardware connections in the

respective chapter.

Intelligent Application Module (IAM)

The intelligent Application Module (IAM) stores all the

• Tightening results

• Events

• Configuration

• Logs

• Software

Carry all information in the palm of your hand and transfer it easy from one

controller to another. The module is located on the inside of the door to the

controller and is available in three different versions:

• IAM Critical control

• IAM Process control

• IAM Process+ control

For a complete overview of the included functionality please see respective

chapter.

The Atlas Copco Tensor STR tool is a complete tool designed to work with

optimal performance together with the Power Focus 6000 controller.

Tensor STR

This Tensor power tool is a result of years of research and development to

improve productivity and quality without compromising ergonomics. Major

ergonomics improvements have been made possible by using the latest and

greatest technology available.

Tensor STR Cable

Atlas Copco has been producing assembly tool cables

since 1987 and has unrivaled experience in the

field. Flexibility and durability have steadily

improved since the introduction of the

company’s first generation cables,

resulting in today’s optimum

cable performance.

Atlas Copco’s flat-cable

design combines

maximum flexibility

(for access to difficult

applications) with

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

8 9

maximum durability.

Accessories And Communication Interfaces

The system connects perfectly to accessories and communication interfaces.

Most handheld tools are supported and the Power Focus 6000 system

has full connectivity with our QIF offerings and software products such as

ToolsNet 8 or ToolsNet 4000 and ToolsTalk 2.

The system also communicates with interfaces such as Fieldbus, Open

Protocol or customer specific protocols, creating a seamless integrated

solution in the customer environment.

POWER FOCUS 6000 HARDWARE

Power

Power Focus operates on a single-phase 115 or 230 VAC line voltage.

Power rating 1500 W

Line voltage

100-120 / 200-240 VAC (50-60 Hz) Power Focus has a function for sensing the

line voltage automatically. This means that the Power Focus automatically

switches to the voltage you connect to it.

Normal Environmental Conditions

The equipment is designed to be safe under the following conditions:

• Indoor use

• Altitude up to 2 000 m

• Maximum relative humidity 80% for temperatures

up to 31 °C decreasing linearly to 50% relative

humidity at 50 °C

Size and Weight

Height: 316 mm (14.44 inches)

Width: 146 mm (5.75 inches)

Depth: 293 mm (11.54 inches)

Weight: 10.8 kg (23.81 pounds)

Display

7” resistive touch screen display

480 x 800 pixels

LED back light

Back light lifetime 70 000 hours

316 mm

146 mm

293 mm

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

10 11

Communication

• W-LAN wireless networking; IEEE 802.11a/b/g/n

compatible

• Bluetooth 2.1 (3.0 ready) + EDR (Enhanced Data

Rate) wireless technology

• 10/100 Mb/s Ethernet (RJ-45 connector)

Audio

Mono speaker

Ambient Temperature

5...+50 °C (41...122 °F)

Transient over voltages typically present on the mains

supply.

Connections

• 2 x 2.0 High Speed USB ports

• 2 x 10/100 Ethernet ports

• 4 x digital inputs (24V -15% +20%)

• 4 x digital outputs (24V ±20%, 1A)

• 1 x I/O bus

• 1 x aux. input (24V ±10%, 0.5A min)

• 1 x aux. output (24V, 1.5A max)

• 1 x emergency stop circuit class 3

• 2 x comm. ports (daisy chain)

• 1 x fan power output connector

• 1 x remote start switch

• 1 x Anybus CC connector

• 1 x IAM connector

• 1 x tool cable connector

IAM

With a memory capacity of 8 GB the IAM (Intelligent Application Module)

stores all the data for the Power Focus 6000: Licenses, results, events,

configurations, controller Firmware and service logs.

If needed, this data is easily transferred to other Power Focus 6000 by simply

removing and inserting the IAM.

Firmware updates are secure, as old firmware is kept available. This allows

you to quickly switch back to old firmware if needed.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

12 13

POWER FOCUS 6000 SOFTWARE

Menu Overview

The menus is intuitive and easy to use. Navigate in the controller interface

by either tapping on a menu item or swiping across the display to scroll

through items. The web interface is identical to the controller display,

enabling configuration and programming via a web-browser on a connected

computer.

Tightening Menu

The Tightening menu lists the tightening program(Pset)

available for configuration, stored on the controller.

Batch Sequence Menu

The Batch menu lists the batch programs (Batch sequences)

stored in the controller.

Sources Menu

The Sources menu lists hardware accessories or functions

controlling the selection of a tightening program, for example

a Pset or a batch sequence. This is also where you configure

scanners you may be using with your tools.

Tool Menu

The Tool menu gives you access to information about the

connected tool, perform tool calibration, motor tuning, and set

up tool maintenance.

Virtual Station Menu

Tools and accessories are connected to the controller but

assigned to a virtual station. The task selection is also done in

the virtual station.

Controller Menu

The Controller menu makes sure you can administer and install

new controller software, view information about the hardware

devices installed on the controller, and export or import

configurations and reports.

Accessories Menu

The Accessories menu enables you to configure the internal

I/Os and the hardware accessories that can be used with

the controller such as I/O Expander, Stacklight, Operator

Panel, Socket selector and Scanner. The Scanner can also be

configured via other menus, such as the Sources menu.

Reports Menu

The Reports menu gives you access to historical tightening

results, events, and NOK ratio.

Settings Menu

The Settings menu is where you can set up the

controller on a LAN, configure PIN, language date and

time. This is also where you set torque unit to be used,

set tool alarms, configure Wi-Fi channels for wireless

tools, as well as configure how to display events.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

14 15

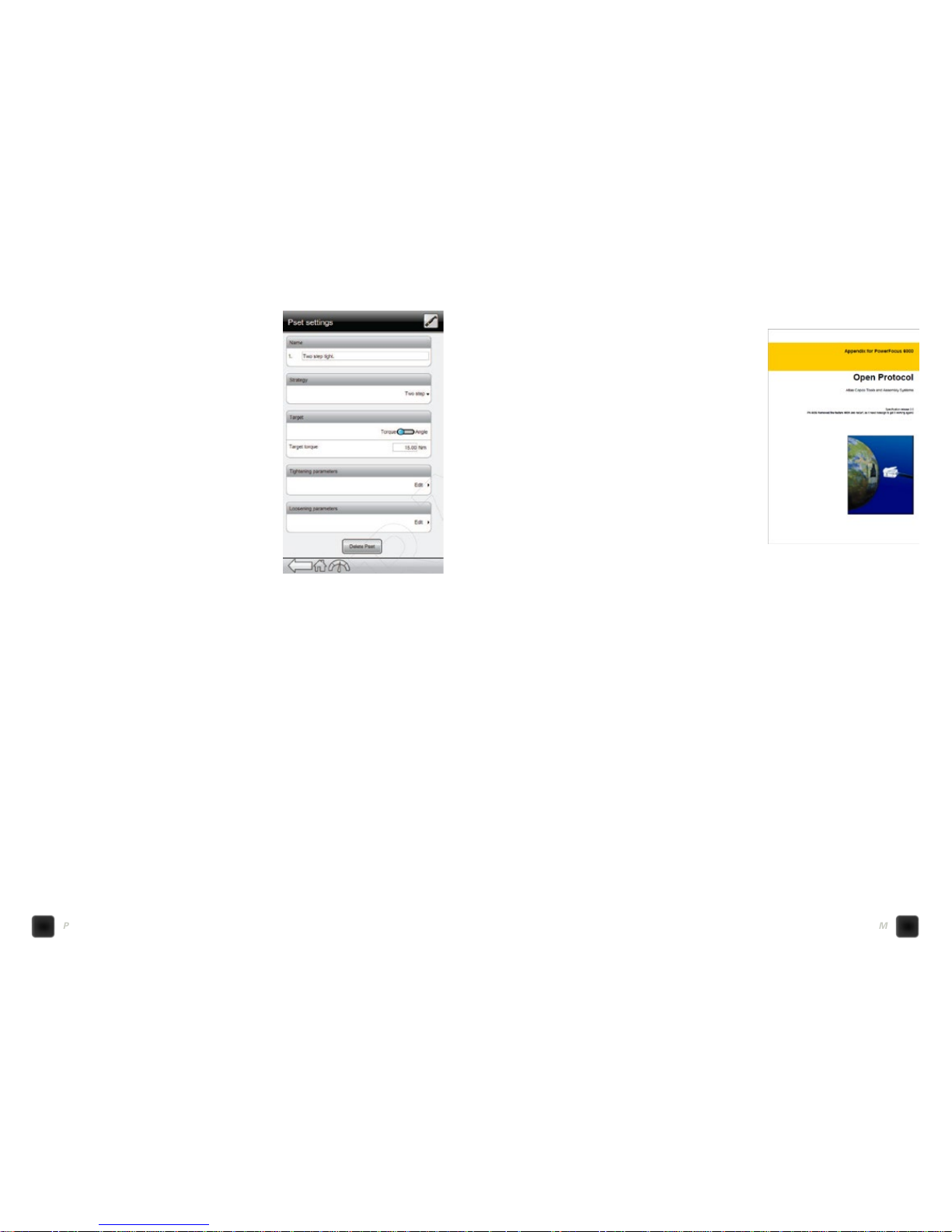

Basic Programming

The power focus 6000 tightening programs

need parameters such as target torque or

target angle to be set in order to perform a

tightening. Other settings – soft start, self

tap, and torque compensation – are optional,

just as setting which tightening strategy

to use. Monitor the tightening progress

by adding limits for torque, or specified

tightening angle.

In the general Pset settings you can set up

and manage the Psets by naming them and

making general tightening settings. Choose

tightening strategy, manual or quick prog

mode, and set the Pset target value.

To the right you can see a configured Pset

named Two step tight that uses a two step

tightening strategy set to the Target torque of

15 Nm

By clicking on “two step” in the strategy

box you can change strategy from two step

to TurboTight etc. Find more configuration

options by clicking on edit under tightening

parameters or loosing parameters.

For more information regarding

programming please use the power focus

6000 configuration guide with detailed

information on each menu item and the

configuration.

Open Protocol

The Power Focus 6000 enables communication

trough open protocol. The Atlas Copco Open

Protocol is a standard communication protocol

developed to facilitate communication

between our controllers and external parties in

the customer’s production processes.

Open Protocol is an interface for building

applications for remote control or data

subscription of controllers. It is platform

independent and can be implemented

on Linux, PLC, printers, and all Windows

platforms. The Open Protocol supports

Ethernet connection with the Power Focus

6000.

An Open Protocol message consists of

three parts; header, data field and message

end. Depending on type of communication,

a package includes the message and an

encapsulation before and after.

The MID, or message ID, is represented by a

four digit number (for example MID 0062 for

Vehicle ID Number upload). Each MID can have several revisions. Usually

a new revision is created when more data is included and the length of

the message needs to be increased. MID revisions are added to ensure

backwards compatibility.

For a full overview of what information, or MIDs (Message IDs) and

revisions, are supported with the Power Focus 6000 please see the Open

Protocol Appendix (picture above) provided in the Marketing and Support

Web Portal. The main value with Open Protocol is to provide a standard

and easy-to-use communication protocol. It can be set up in minutes and

integrated with your production processes in your plant. Through the years

“Open Protocol” has become an industry standard to communicate with

tightening equipment on assembly lines.

POCKET GUIDE TO POWER FOCUS 6000 SYSTEM POCKET GUIDE TO POWER FOCUS 6000 SYSTEM

16 17

FUNCTIONALITY MANAGEMENT SYSTEM

Introduction

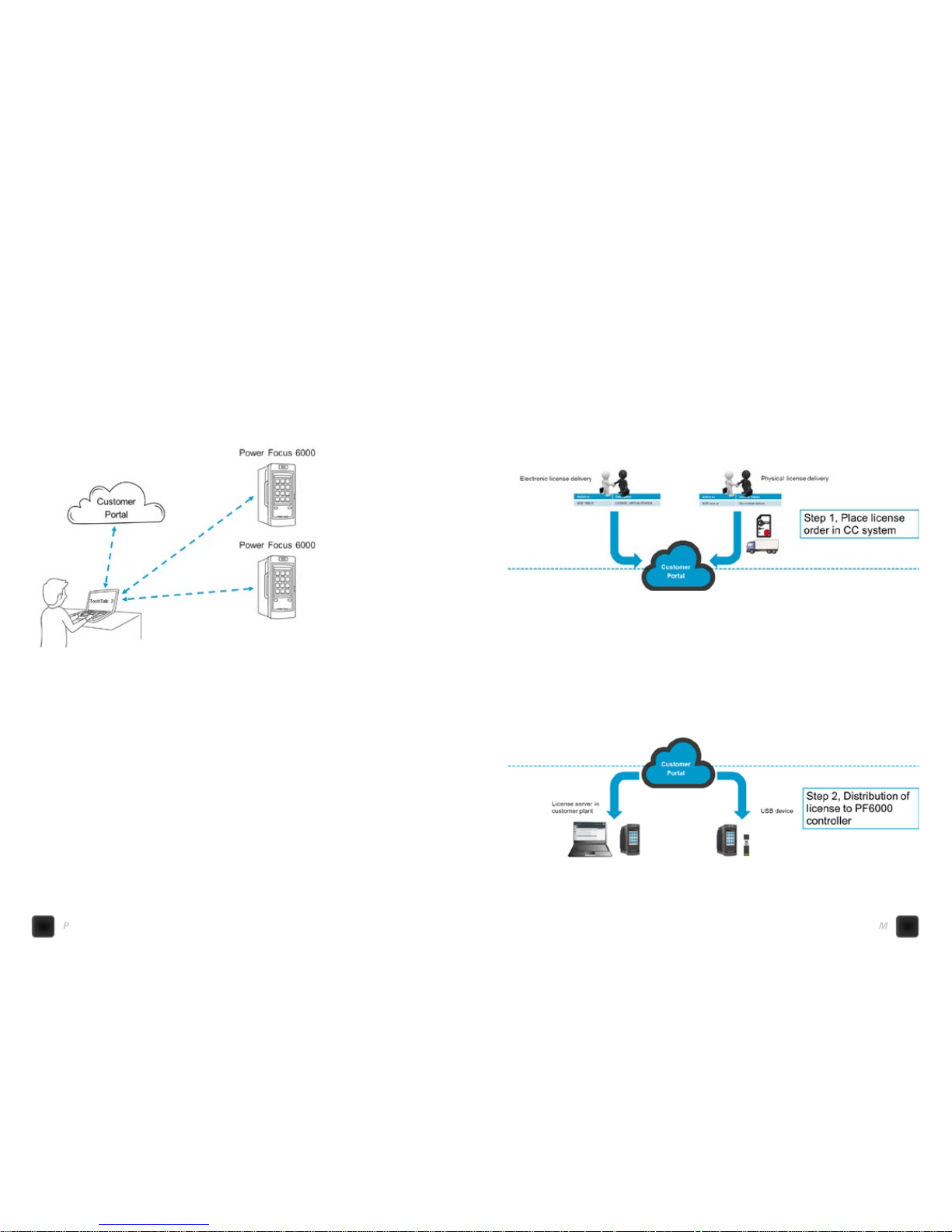

Atlas Copco Functionality Management System (FMS) is our new licensing

platform and it is a completely new way of delivering and administering

functionality available on Power Focus 6000 controllers. FMS is meant as

a way to simplify the way that functionality is added and removed from a

controller based on the actual needs on a station.

The customer portal is used for activating controller functionality, for getting

an overview of previous purchase orders and to map available features

to a USB license device or a functionality management system server. All

features that has been purchased is easily available from the customer

portal. This gives traceability of the functionality that has been bought and

also easy access in case a license has been lost.

Main benefits

• Flexible rebalancing

• Customizable and upgradable

• Instant delivery

• Trial licences

Order and distribute licenses to customer portal

There are two ways to distribute features and licenses to the customer

portal, electronic or physical delivery. The electronic delivery is made

automatically once the order is put in the local CC system and the features

is automatically linked to the customer account in the customer portal. The

physical delivery is carried out from PTD as a physical license paper from

PTD and a manual registration is required to link the features to the account

in the customer portal.

Distribution from customer portal

Once the licenses and features are delivered and linked to the customer

portal there are two ways to distribute the features to the controllers; a

server based solution (electronic way) and a non-network required solution

(physical way). The network based solution is meant for production facilities

where it is needed to re-balance and move functionality quickly and

efficiently between virtual stations. The physical way is the FMS USB license

device solution and is perfect for customers where an IP-based network is

not available and the need for rebalancing is not as big.

Loading...

Loading...