Atlas Copco PN 3500, PN 3500 X Repair Instructions

1

PAGE

Repair Instructions No.179.11/97

PN 3500 / PN 3500 X

Special Tools

Required

■

Forcing disks 4931 599 021

■

Special pliers 4931 599 057

■

(Dis-) Assembly tool 4931 5990 84

■

Sleeve 4931 599 038

■

Screw locking device Omnifit 80 4931 945 651

Important!

■

Before beginning the maintenance work, perform an initial check with a high voltage test according

to VDE (see chapter Electrical and Mechanical Test Instructions).

■

Before all repair work, pull the power plug from the socket!

Disassembly

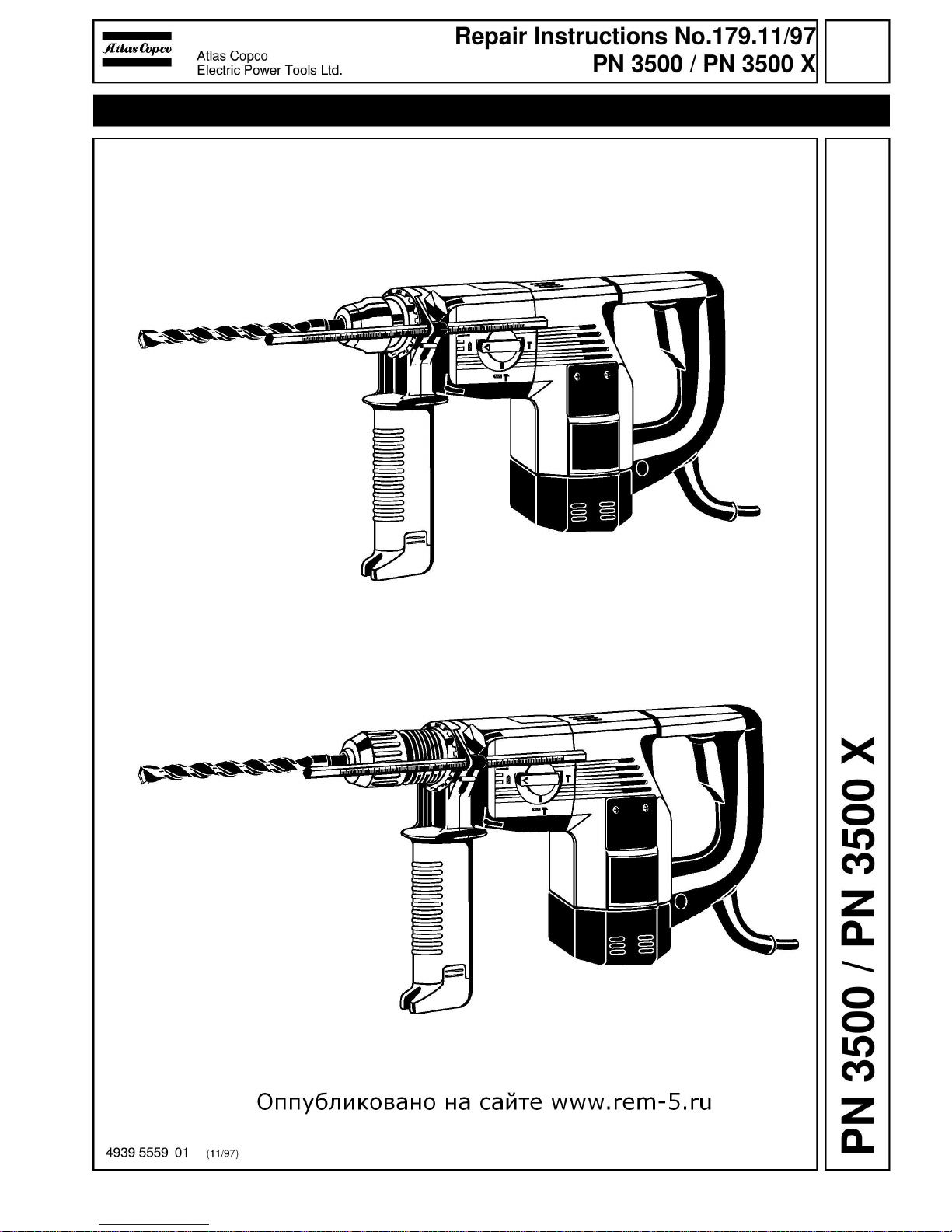

Removing the

carbon brushes

1

Loosen the two screws (6) on both sides

and remove the respective service covers (5).

2

Remove the cables (3) and pull the brush

holders (4) from the housing.

3

Put the springs (1) aside (see illustration)

and pull out the carbon brushes (2).

4

Pull the carbon brush cables together with

the carbon brushes (2) from the housing.

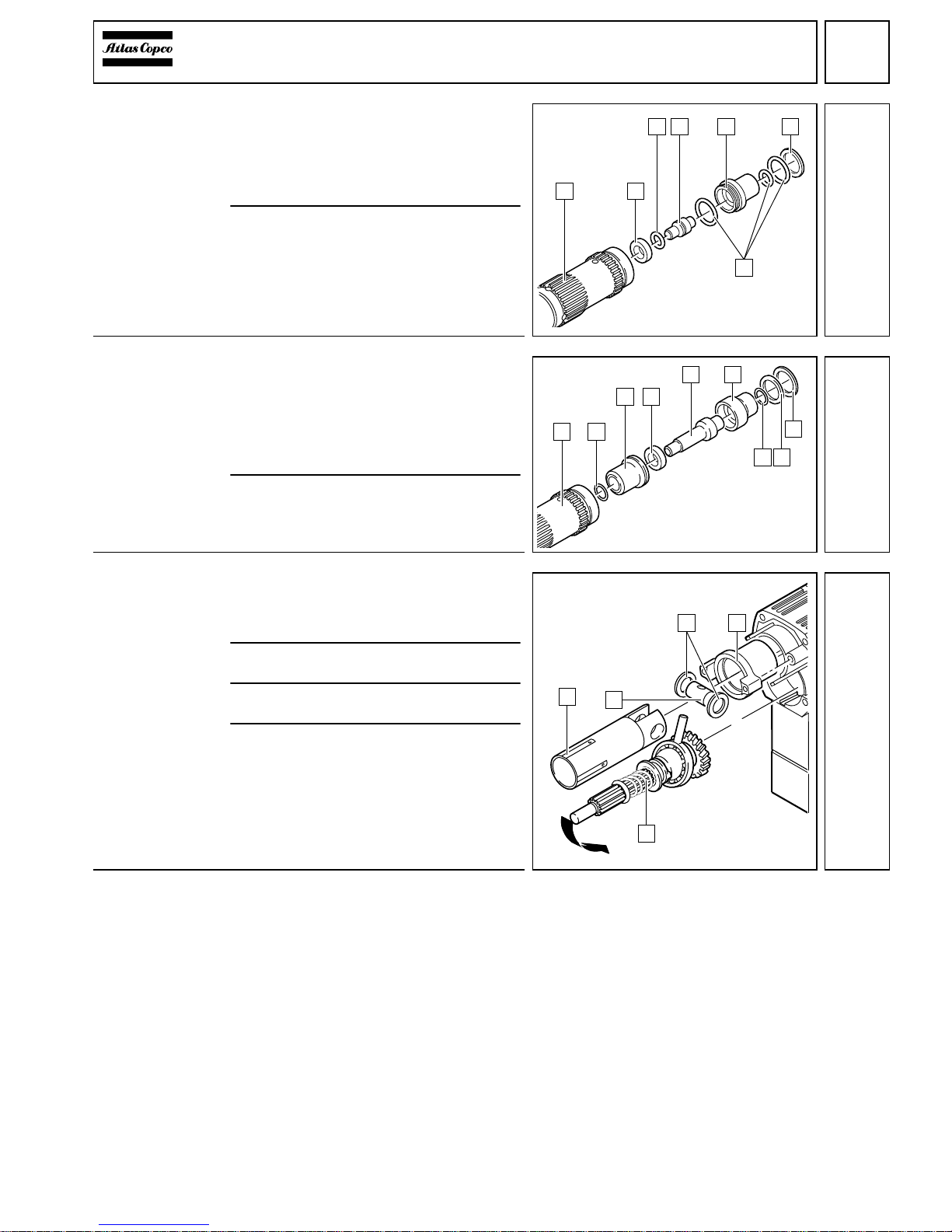

Only applicable

for PN 3500:

Dismantling the

SDS-Plus-reception

1

Remove the rubber cap (1).

2

Remove the spacer (2).

3

Depress the sliding sleeve (4) and lever

off the locking ring (3) with aid of a screwdriver.

4

Remove the sliding sleeve (4) and the retaining ring (5).

5

Depress the retaining disk (7) and press

out the ball (6) with aid of a screwdriver or

remove it with a magnet.

6

Remove the retaining disk (7) and the

spring (8).

1

2

3

4

5

6

3

2

1

1 2 3 5

6 7 8

4

2

2

PAGE

Repair Instructions No.179.11/97

PN 3500 / PN 3500 X

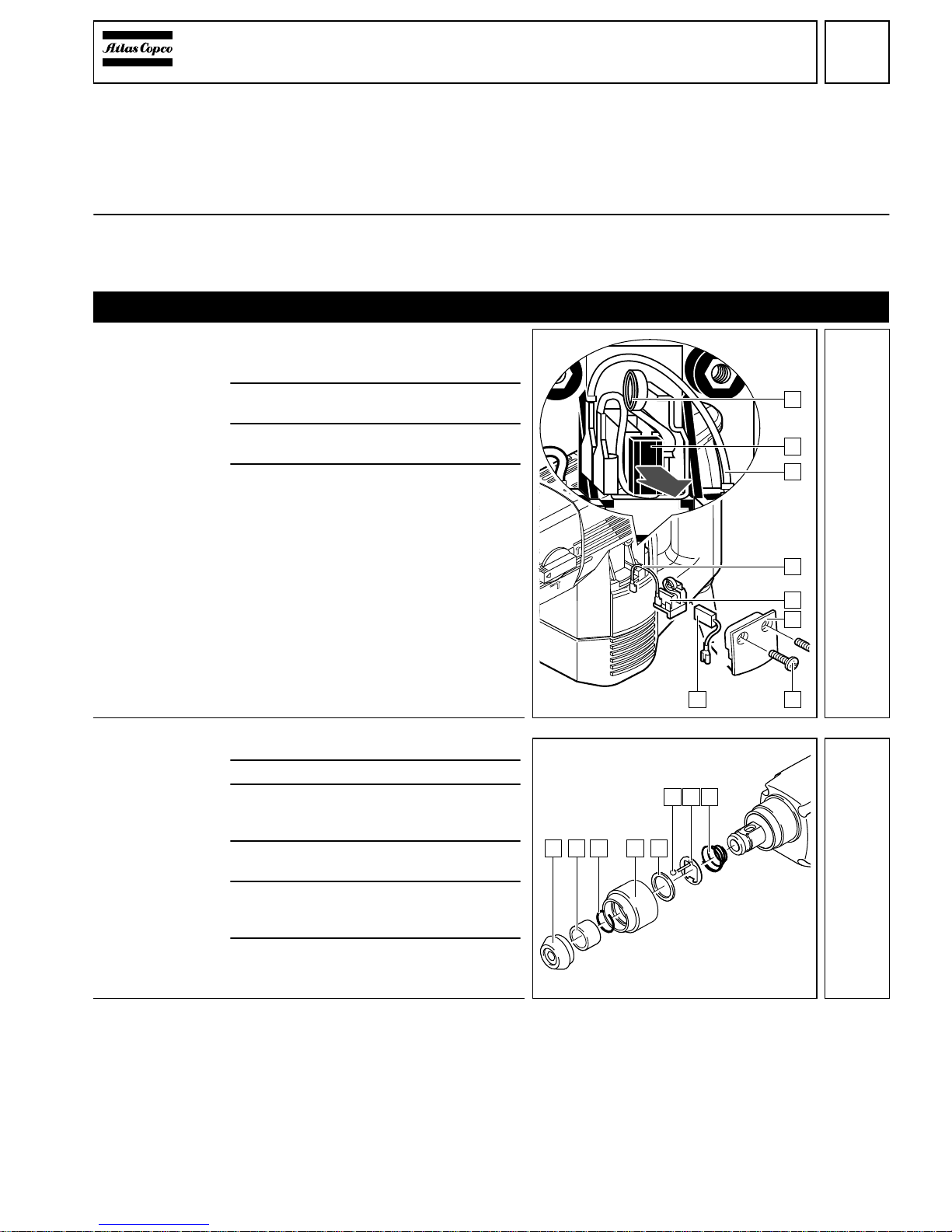

Only applicable

for PN 3500 X:

Dismantling the

FIXTEC-reception

1

Removing the locking sleeve (2):

☞

Fix the locking sleeve (2) in a pullingoff device (3) and press it out. At the

same time, press down the spindle (1)

with a suitable sleeve.

2

To remove the balls (4) (six pieces):

☞

Depress the seal ring (6) and remove

the balls with aid of a magnet.

3

Remove the remaining parts:

- seal ring (6)

- outer spring (7)

- ejector ring (5)

- inner spring (8) and

- washer (9).

Detaching the

gear housing

1

Switch the lever (4) to the "0"-position and

break it off with aid of pliers. The lever (4)

gets destroyed.

☞

Should this not be possible, fix the lever (4) in a vice and break it off by moving the machine to and fro. Remove

any broken part from inside the machine.

2

Remove the four housing screws (1).

3

Only applicable for PHE 3500 X:

Open the locking ring (2) on the spindle

with aid of special pliers (5) (service tool)

and remove it together with the gear housing (3).

Removing the

spindle

1

Remove the two screws (1).

2

Remove the straight pin (5).

3

Remove the planetary gear (4) and the

ring gear (3).

4

Remove the complete spindle sleeve (2)

from the cylinder.

1

2

3

5 6 7 8 9

42

2

1 3

5

2

4

3

1 2

5 4 3

4

3

PAGE

Repair Instructions No.179.11/97

PN 3500 / PN 3500 X

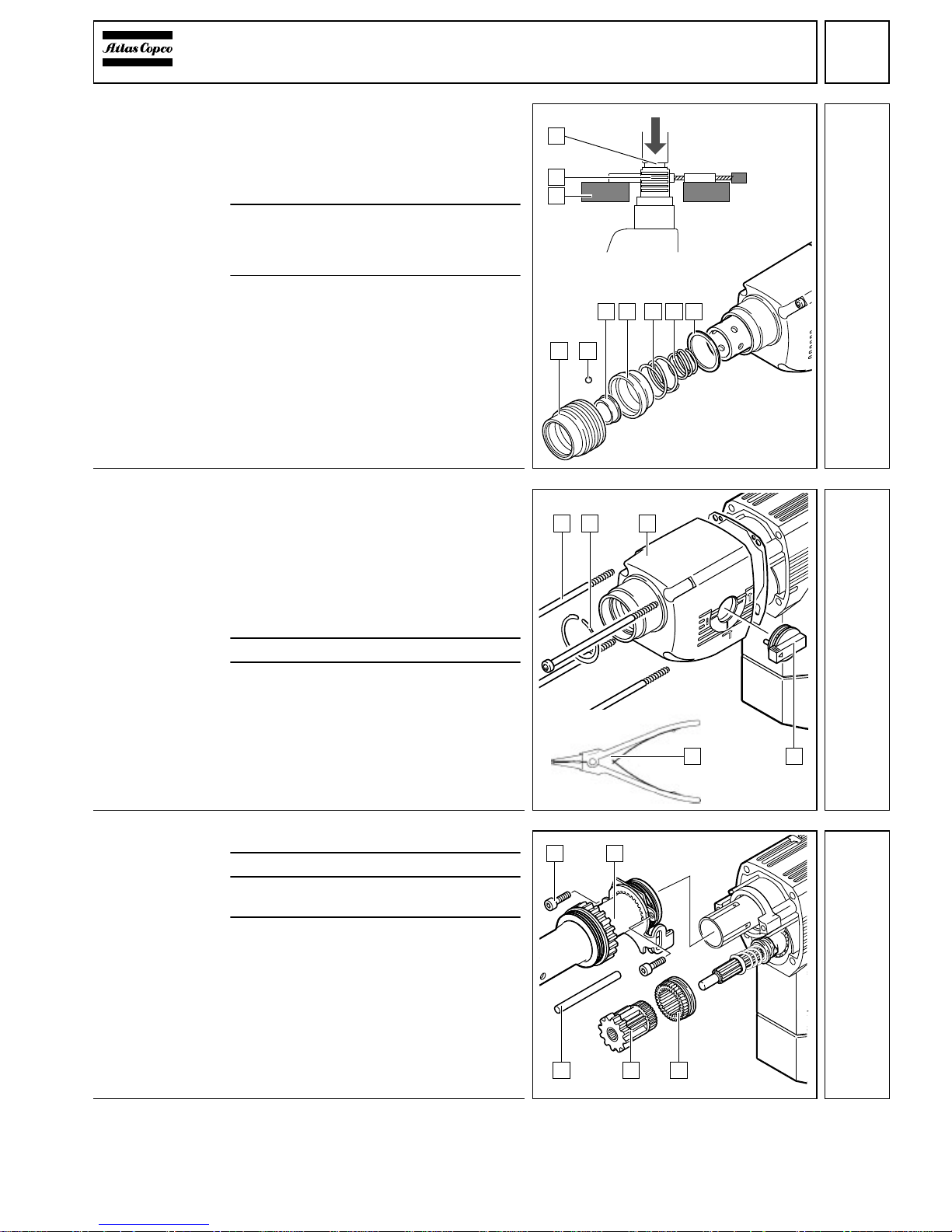

Removing the

striker

1

Place the spindle vertically.

2

Briefly hit the plunger (1) with a mandrel.

The striker (2) comes free.

Dismantling the

spindle (removing the outer

parts)

1

Removing the rear thrust bearing (7):

Lever off the special locking ring (8) with

aid of a screwdriver.

2

The thrust bearing can be removed in the

following component parts:

- washer

- thrust bearing washer

- two compensating washers and

- profile ring with damper O-ring.

3

Remove the retaining disk (6) and the

locking slide (5).

4

Removing the spindle wheel (3):

Press the spindle wheel (3) with a sleeve

against the disk springs (1) - the locking

ring (4) is released and can be removed

with pliers. Remove the spindle wheel (3).

5

Remove the ratchet (2) and the disk

springs (1).

Dismantling the

spindle (removing the inner

locking ring)

1

☞

In the middle of the spindle (1) there

are four deairing holes and one service

boring (3).

The service boring (3) has the smallest

diameter.

2

Turn the round wire locking ring (2) with

aid of the service tool (4931 599 084)

such that one end projects the service boring (3) by approx. 2 mm.

3

Put a screwdriver through the service

boring (3) and place it under the locking

ring (2).

4

Move the screwdriver to and fro and at the

same time turn the locking ring (2) with aid

of the service tool in direction of arrow.

☞

Turn the locking ring (2) until it is completely levered off the groove.

5

Press the locking ring (2) from the spindle.

1

2

5

1 72 3 5 6 84

1

3

4

6

1

2 3

7

4

PAGE

Repair Instructions No.179.11/97

PN 3500 / PN 3500 X

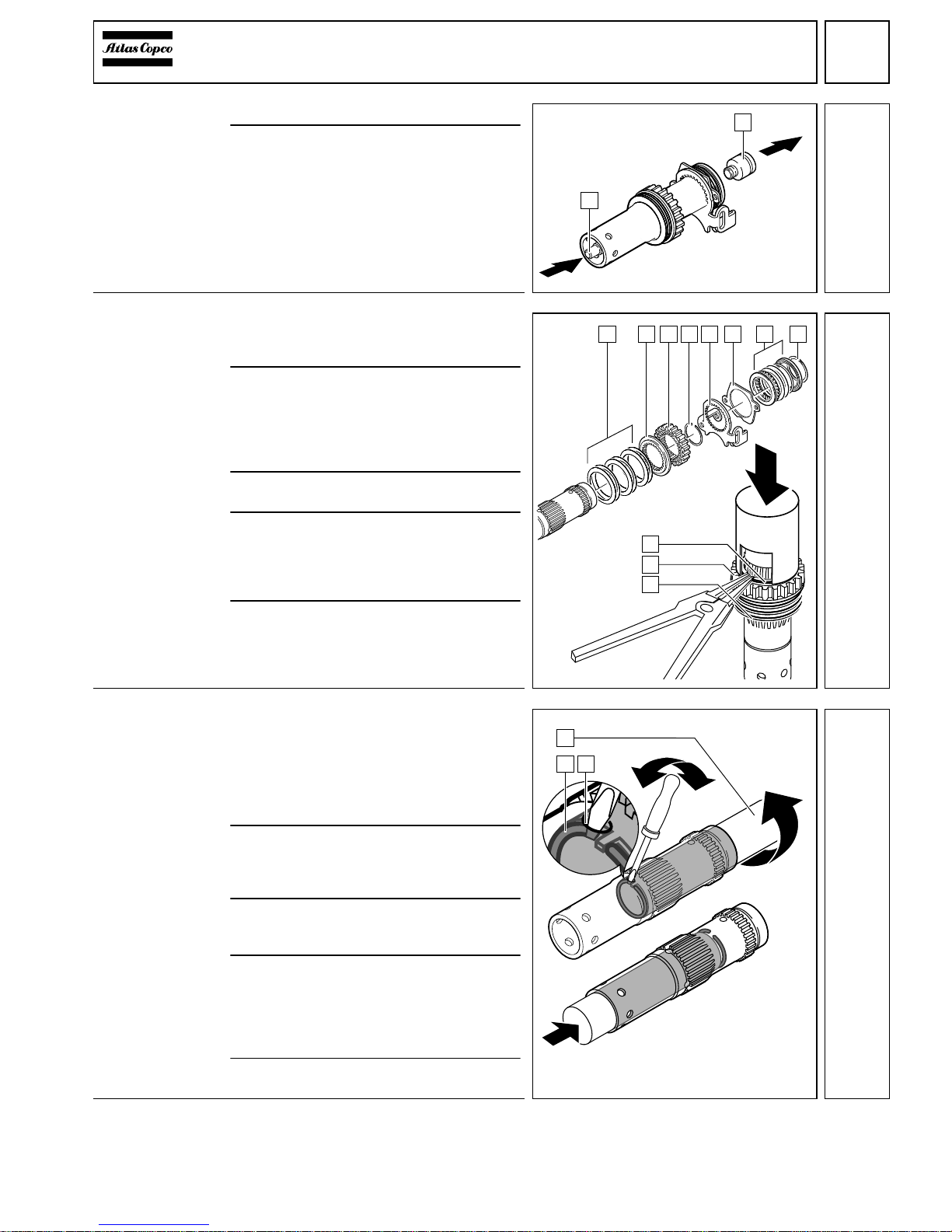

Only applicable

for PN 3500:

Dismantling the

spindle (removing the inner

parts)

1

Press the following parts from the

spindle (1):

- washer (6)

- pressure sleeve (5)

- plunger (4) and

- brake disk (2).

2

Remove the O-rings (3) and (7).

Only applicable

for PN 3500 X:

Dismantling the

spindle (removing the inner

parts)

1

Press the following parts from the

spindle (1):

- washer (9)

- pressure sleeve (6)

- plunger (5)

- brake disk (4) and

- pressure sleeve (3).

2

Remove the O-rings (2), (7) and (8).

Removing the

back gear shaft

and the cylinder

1

Pull out the bearing housing (4).

If necessary, loosen the bearing housing (4) by hitting the gear housing lightly

with a plastic hammer.

2

Remove the back gear shaft (5) by turning

or canting it (see arrow in illustration).

3

Completely remove the cylinder (1) and

the back gear.

4

Push out the bolt (2) by hand and remove

the two disks (3).

1 2

3 5 6

7

4

8

1 2

3

5 6

7 8

9

4

8

1

2

3

5

4

9

5

PAGE

Repair Instructions No.179.11/97

PN 3500 / PN 3500 X

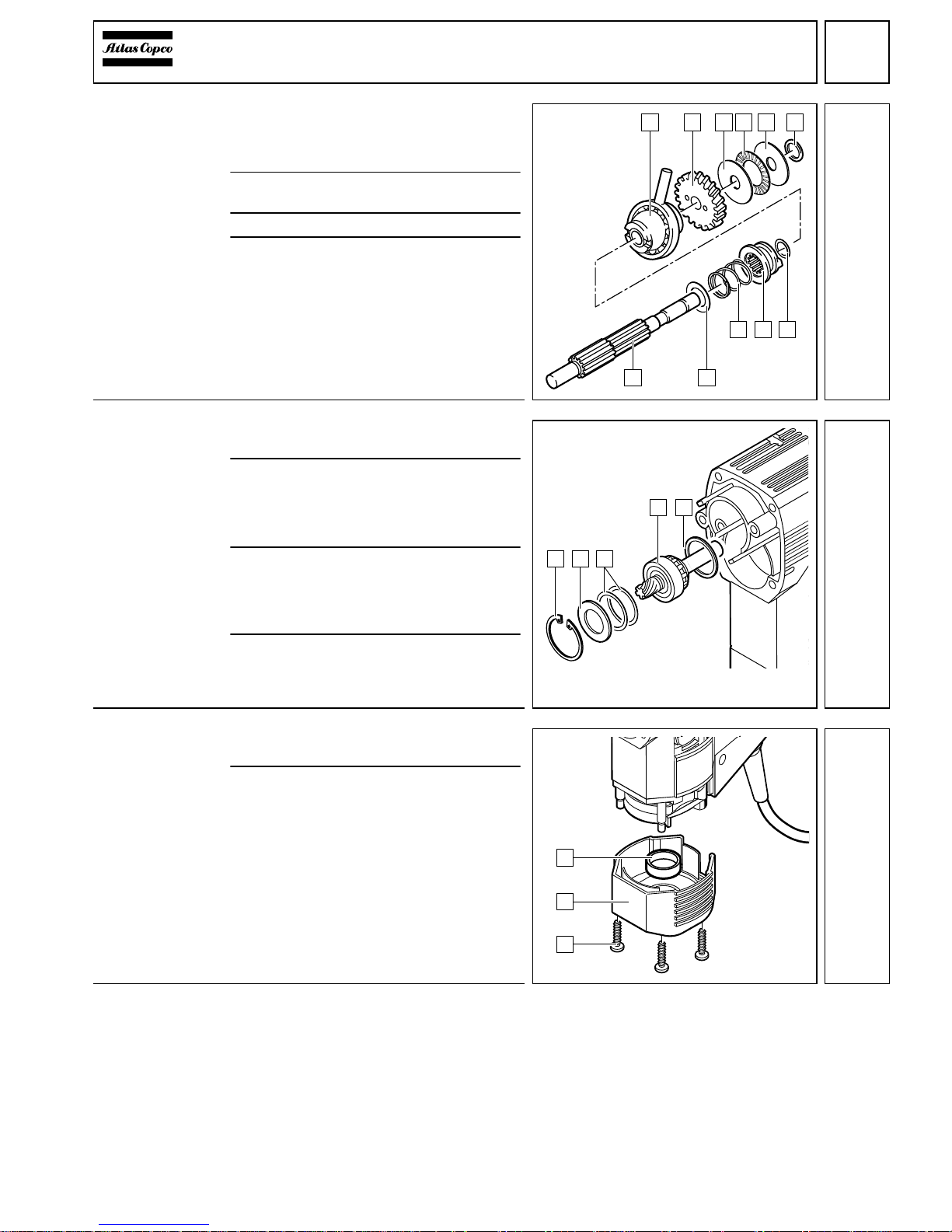

Dismantling the

back gear shaft

1

Remove the rubber O-ring (6).

☞

Attention! The rubber O-ring (6) fits

tightly and is difficult to remove.

2

Remove the washer (5) and the thrust

bearing (4) as well as the disk (3).

3

Press off the back gear wheel (2).

4

Remove the remaining parts from the

back gear shaft (B):

- tumble drive (1)

- washer (7)

- coupling box (8)

- spring (9) and

- washer (A).

Removing the

angle drive

1 Remove the locking ring (1) with aid of

special pliers.

2 Remove the angle drive (4) together with

the disk (2), the washers (3) as well as the

support ring (5).

If necessary, hit the gear housing lightly

with a plastic hammer for support.

3

☞

Depending on the tolerance of the

bearing the tool can be equipped with

two or three washers (3).

4 If this bevel wheel will be used again,

please note the number of the washers.

Mount the same number when re-assembling.

Removing the

motor cover

1 Loosen the four screws (1) and remove

the motor cover (2).

2 Remove the rubber cap (3) in case of

damage.

B A

9 7

1 2 3 54 6

8

10

1 3

4 5

2

11

3

2

1

Loading...

Loading...