Atlas Copco LBB 36J H060-U Owner's Manual

LBB 36J H060-U

Printed Matter No. 9836 4880 00 Pistol-grip Drills

Valid from Serial No. A1160001 Product instructions

2009-06

8421 0408 48LBB 36J H060-U 6000 r/min

Table of content

• Safety and operating instructions

• Exploded views and spare part tables

• Service instructions

WARNING

To reduce risk of injury, everyone using,

installing, repairing, maintaining, changing

accessories on, or working near this tool MUST

read and understand these instructions before

performing any such task.

DO NOT DISCARD - GIVE TO USER

Table of content

Safety and operating instructions ....................................................3

Spare part list ................................................................................8

Service instructions .....................................................................12

© Atlas Copco Tools - 9836 4880 00

2

LBB 36J H060-UTable of content

Safety instructions

Important information for safer drilling

and tapping

This manual follows the EC Machines Directive

(98/37/EEC) regarding operator's instructions and

relevant parts of standards from CEN TC 255 "Handheld power driven non-electric tools – Safety".

These instructions concern operation, handling of

machine, inserted tool and equipments as well as

maintenance.

Neglect to follow these long established recom-

mendations may cause serious hazards.

Make sure that the operator has fully understood

the following recommendations and has full access

to them.

T pay strict attention to following measures the

operator has to take in order to avoid risks

of misuse or accident

Installation

Follow the instructions for air preparation given in

the written instructions supplied with the machine.

When lubrication is recommended – use recommended lubricants only.

Check hose size and air pressure.

Avoid the risk of whipping hose – regularly check

hose, hose tting and clamp conditions.

Check that the exhaust air is directed to avoid

blowing dust or air from the work piece onto the

operator or other persons. Arrange for barriers if

possible.

When necessary, use exhaust hose and arrange for

dust collection.

A Pneumatically driven power tools are not

generally insulated for coming into contact

with electric power sources.

Explosive atmosphere must not be ignited –

to prevent injury and property loss from fire

use other non sparking process.

Choose insert tools according to the application,

power and speed of your machine.

Use sharp drill bits to avoid breakage or seizing

in hole.

If the machine is suspended by a balancer – regularly check the condition of hooks and suspension

yoke.

Avoid accidents when using the machine

To prevent vision loss - always wear impact resistant eye protection.

Isolate work by using barriers between work sta-

tions

Before using the power tool, check that the throttle

safety latch (if any) is working and that the tool stops

when releasing trigger.

Remove chuck keys and wrenches immediately

after use.

To avoid injury from touching rotating inserted

tool – disconnect power tool from air supply when

changing inserted tool or any adjustment operation.

Mind your hands, hair, clothing and jewellery –

always keep well away from rotating parts and cutting edges.

Don't point at other persons – drill the work ...

not people.

Use clamp or vice to hold the workpiece during

operation.

Predrill slightly larger than core diameter of nal

drill to increase rate of material removal and to

minimize reaction force when breaking through.

Keep proper footing and balance at all times –

stand alert for unexpected tool reaction or breakage

of inserted tool.

Use a support handle to take up static reaction

force and sudden reaction when breaking through,

particularly when drilling holes larger than 6.5 mm

in metal.

For heavy screw feed drills support handle or reaction bar must always rest against a xed point.

Spindle torque is high and may break an arm or leg

when drawn in or trapped.

When drilling in unknown areas and walls proceed

with extreme care. Be alert for hidden gas, water and

electric lines.

If the energy supply is broken – immediately re-

lease throttle.

When not using the machine lay it aside in such

a way that the risk of unintentional start or other

people getting injured by the inserted tool is minimised.

Long term risks when using the machine

To prevent gradual loss of hearing due to exposure to high noise levels – wear ear protection if the

tool itself or the process generates a high noise.

Vibration may be harmful to hands and arms

– reduce total time of exposure to vibration caused

by improperly working drill bits or other inserted

tools.

Avoid inhaling dust resulting from drilling op-

eration.

The dust may be harmful to health.

Use a dust extraction system or an approved dust

mask when necessary.

3

© Atlas Copco Tools - 9836 4880 00

Safety and operating instructionsLBB 36J H060-U

Maintenance

Good service life and safe function is offered if the

instructions for lubrication, maintenance and overhaul supplied with the machine are followed.

Use genuine Atlas Copco replacement kits and

parts only.

Warning

Make sure you are familiar with the operating instructions before you use this machine.

This machine, its attachments and accessories is

intended to be used for drilling, reaming, countersinking.

If using other accessories carefully follow the instructions concerning speed limits, support handle

(for taking up sudden reaction forces) as well as

personal protection needed for the application.

For product liability and safety reasons any

modication to the machine, its attachments or accessories must be agreed in advance with an authorized technical representative of the manufacturer.

To prevent personal injury:

Familiarize yourself with the enclosed leaet

“General Safety Instructions for Drilling and Tapping.

Warning

Dismantling and assembly precautions

The rotor blades (vanes) in the tool have a PTFE

content. The normal Health and Safety recommendations concerning PTFE must be observed when

handling these rotor blades. Particles from wear of

blades might be found in the machine housing or on

the blades. These particles must not get in contact

with open re. Wash your hands before smoking as

PTFE-particles heated by the glow can produce

fumes which may give rise to allergic reaction.

General information

EC DECLARATION OF CONFORMITY

We, Atlas Copco Tools AB, S-105 23 STOCKHOLM SWEDEN declare under our sole responsibility that our product (with type and serial number,

see front page) and in combination with our accessor-

ies, to which this declaration relates is in conformity

with the appropriate standard(s):

EN 792-3

and in accordance with the following directive(s):

98/37/EEC

Stockholm, October 2006

Lennart Remnebäck, General Manager

Signature of issuer

Installation

Air quality

• For optimum performance and maximum machine

life we recommend the use of compressed air with

a maximum dew point of +10°C. We also recommend the installation of an Atlas Copco refrigeration-type air dryer.

• Use a separate air lter of type Atlas Copco FIL.

This lter removes solid particles larger than 15

microns and also removes more than 90 % of liquid water. The lter must be installed as close

as possible to the machine/equipment and prior

to any other air preparation unit such as REG or

DIM (please see Air Line Accessories in our main

catalogue). Blow out the hose before connecting.

Models which need air lubrication:

• The compressed air must contain a small quantity

of oil.

We strongly recommend that you install an Atlas

Copco oil-fog lubricator (DIM). This should be

set according to air consumption by the air line

tool according to the following formula:

L = Air consumption (litre/s).

(May be found in our sales literature).

D = Number of drops per min (1 drop = 15 mm3)

L* 0.2 = D

this applies to the use of long work cycle air line

tools. A single point lubricator type Atlas Copco

Dosol can also be used for tools with short running

cycles.

Information about Dosol settings may be found

under Air Line Accessories in our main catalogue.

Lubrication-free models:

• In the case of lubrication-free tools it is up to the

customer to decide on the peripheral equipment

to be used. However, it is no disadvantage if the

compressed air contains a small quantity of oil

© Atlas Copco Tools - 9836 4880 00

4

LBB 36J H060-USafety and operating instructions

e.g. supplied from a fog lubricator (DIM) or Dosol

system.

This does not apply to turbine tools, which should

be kept oil free.

Compressed air connection

• The machine is designed for a working pressure

(e) of 6–7 bar = 600–700 kPa = 87–102 psi.

• Blow out the hose before connecting.

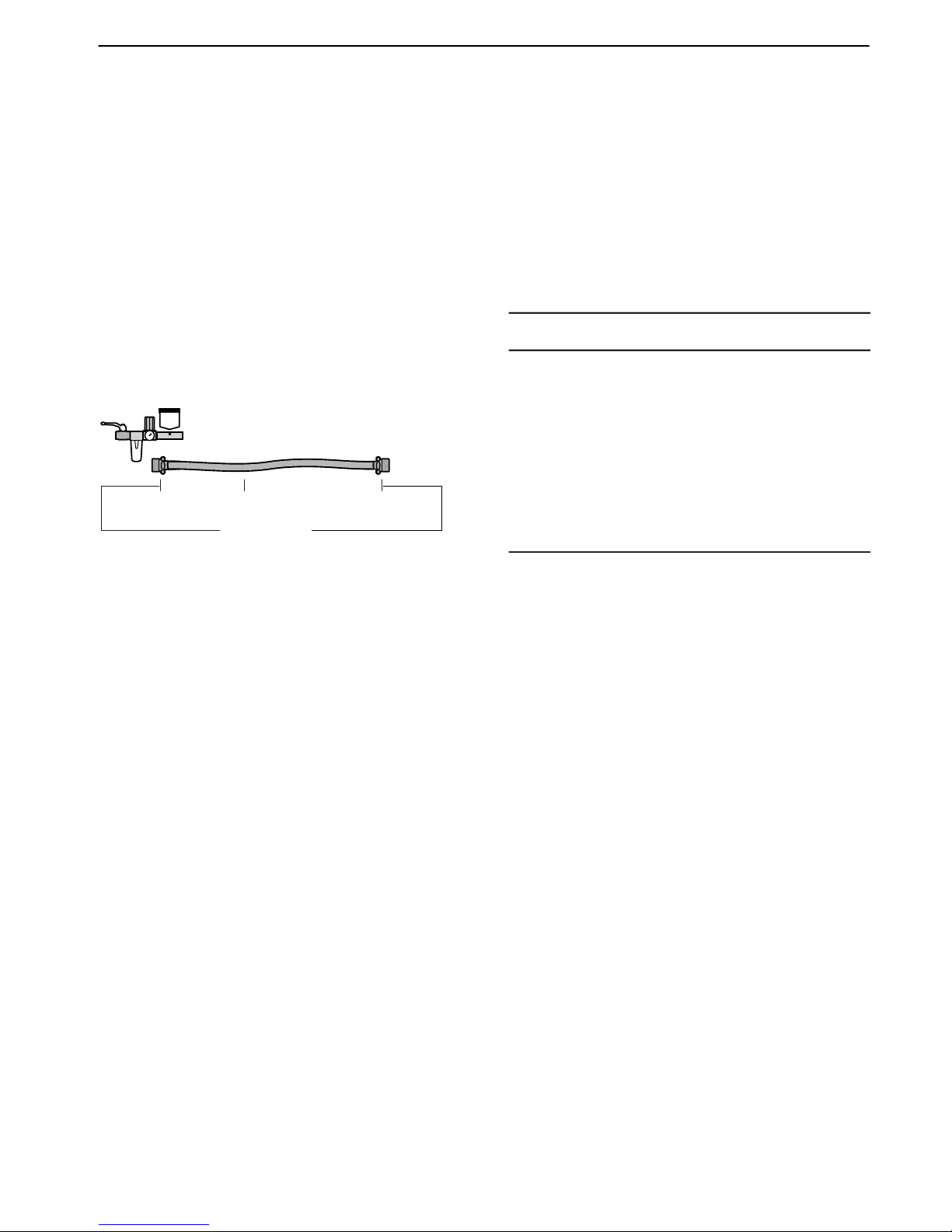

Installation proposal

Choosing the correct couplings, hose and clamps can

be a troublesome digging into details. To save your

time and to ensure correct capacity of the airline installation, from the tapping point to the tool, we offer

you an installation proposal.

Nipple 1/2" BSPT

7.6 m CABLAIR 13

8202 1180 39

Nipple 3/8" BSPT+

Reduction 3/8"-1/4" BSP

BALL VALVE + MIDI F/R 15 + DOS 15B

8202 0845 66

ip30

Filtered, regulated and injection lubricated

air for a max. air flow of 19 l/s

For more information please read, Atlas Copco Industrial Power Tools catalogue Ordering No. 9837

3000 01.

Maintenance

Rust protection and internal cleaning

Water in the compressed air, dust and wear particles

cause rust and sticking of vanes, valves etc.

This can be prevented by ushing with oil (some

drops), running the tool for 5–10 seconds and absorbing the oil in a cloth. Protect the tool this way before

longer standstills.

Overhaul and lubrication

The tool should be checked regularly at six-monthly

intervals. If it is in heavy duty service or not running

properly, it should be taken out of service more often

for inspection.

Regarding instruction for dismantling and assembly, see separate Service Manual.

The throttle valve, planetary gears, needle bearings

and ball bearings must be lubricated with grease

when the tool is dismantled for the regular overhauls.

Molykote BR2 Plus gives long intervals between

lubrications.

A Clean the motor parts and apply a thin layer

of gleitmo 585 KC grease (180 g – Ordering

No. 4080 0871 80) onto the vanes and inner

surface of cylinder and end plates.

Assemble the motor and check that it is running free. Add two drops of oil through the

air inlet and run the motor (machine) at idling

speed for 5-10 seconds.

The strainer in the adapter should be cleaned regularly to prevent choking with resultant decrease in

capacity

Lubricating guide for Grinder/ Sander

(except turbine) and Drill

Air lubricationGeneral purpose

Bearings

Brand

Energol E46Energrease LS-EP2BP

Spheerol EP L2Castrol

Arox EP46Beacon EP2Esso

Chopin 46Rembrandt EP2Q8

Almo oil 525Mobilegrease XHP 222Mobil

Tonna R32Alvania EP2Shell

Aries 32Multifak EP2Texaco

See “Lubrication” in

Operating instructions

BR2 PlusMolycote

Useful information

C Log in to Atlas Copco www.atlascopco.com

You can nd all kind of information concerning

Atlas Copco Tools products, accessories, spare parts,

published matters on our WEB site!

Spare parts

Parts without ordering number are not delivered

separately for technical reasons.

The use of other than genuine Atlas Copco replacement parts may result in decreased tool performance

and increased maintenance and may, at the company

option, invalidate all warranties.

Warranty

Contact the Atlas Copco sales representative within

your area to claim a product. Warranty will only be

approved if the product has been installed, operated

and overhauled according to the operating instructions delivered with the tool.

Please also see the delivery conditions applied by

the local Atlas Copco company.

Atlas Copco Service Products

To maintain the highest standard of quality in your

assembly operation, you need reliable tools that

perform efciently at all times. We offer customized

5

© Atlas Copco Tools - 9836 4880 00

Safety and operating instructionsLBB 36J H060-U

Loading...

Loading...