Atlas Copco GA55, GA5, GA90C User Manual

6060560 │COMPRESSOR 460/60/3 116CFM │Cu

┌─Item Text ──────────────────────────────────────────────────────────────────┐

│ COMPRESSOR 460/60/3 116 CFM 150 PSI │

│ │

│ Manufacturer: ATLAS COPCO │

│ Mfr Part No : GA22FF │

│ Size : 116 CFM @ 150 PSI │

│ Add'l Info : ROTARY SCREW, SINGLE STAGE, OIL INJECTED, │

│ AIR COOLED, FULL FEATURE UNIT │

│ WITH INTEGRATED REFRIGERATED DRYER, │

│ COMPRESSOR FAILURE DRY CONTACTS. │

│ 30 HP, │

│ 460V, 3 PHASE, 60 HZ │

│ 40 IN LONG X 31 IN WIDE X 71 IN HIGH 1318 LBS. │

│ EACH COMPRESSOR INCLUDES: FOOD GRADE LUBRICANT (GA-FG) │

│ AND GENERAL ALARM CONTACTS │

└──────────────────────────────────────────────────────────────────────────────────┘

Atlas Copco Stationary Air Compressors

Important

1. This Manual applies exclusively to the compressors equipped with the Atlas Copco Elektronikon

regulator.

2. This Manual must be used together with the relevant Instruction books for the compressors.

*2920120705*

No. 2920 1207 05

Registration code:APC G5-10/'98 / 38 / 995

APC G11-22 / 38 / 983

APC G30-45/'98 / 38 / 995

APC G55-90C/'96 / 38 / 988

Replaces 2920 1207 04

1999-04

GA5 up to GA90C

Web-site: http://www.atlascopco-compressors.com

•

Copyright 1999, Atlas Copco Airpower n.v., Antwerp, Belgium.

Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies

in particular to trademarks, model denominations, part numbers and drawings.

• This instruction book meets the requirements for instructions specified by the machinery directive

89/392/EEC and is valid for CE as well as non-CE labelled machines.

User Manual for Elektronikon

regulator

2920 1207 05

2

User manual

Contents

Page

10.3 Calling up running hours and service level . . . . . 14

10.4 Service reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

11 Test submenu: display test . . . . . . . . . . . . . . . . . . . . . 14

11.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

11.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

12 Modify settings submenu: modifying settings for

regulation, protection and service. . . . . . . . . . . . . . . 15

12.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

12.3 Modifying compressor regulation settings . . . . . . 15

12.3.1 Modifying the loading pressure. . . . . . . . . 15

12.4 Modifying protection settings. . . . . . . . . . . . . . . . 16

12.4.1 Element outlet temperature . . . . . . . . . . . . 16

12.4.2 Dewpoint temperature . . . . . . . . . . . . . . . . 17

12.4.3 Cooling water outlet temperature . . . . . . . 17

12.5 Modifying service settings . . . . . . . . . . . . . . . . . . 18

13 Timer submenu: programming compressor start/stop

commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

13.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

13.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

13.2.1 To program start/stop commands . . . . . . . 19

13.2.2 To activate/deactivate the timer . . . . . . . . 19

13.2.3 To display the list of commands . . . . . . . . 19

13.2.4 To modify a command. . . . . . . . . . . . . . . . 19

13.2.5 To add a command . . . . . . . . . . . . . . . . . . 20

13.2.6 To delete a command. . . . . . . . . . . . . . . . . 20

14 Configuration submenu: reprogramming time,

date, display language, units, motor start mode

and date format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

14.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

14.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

15 Saved data submenu: calling up compressor

data saved by regulator . . . . . . . . . . . . . . . . . . . . . . . 21

15.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

15.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

15.2.1 Example of the last shut-down data . . . . . 21

16 More function: quick look at actual compressor

status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

16.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

16.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

17 Manually loading/unloading . . . . . . . . . . . . . . . . . . . 23

17.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

17.2 Manually unloading . . . . . . . . . . . . . . . . . . . . . . . 23

17.3 Manually loading . . . . . . . . . . . . . . . . . . . . . . . . . 23

18 Programmable settings. . . . . . . . . . . . . . . . . . . . . . . . 23

18.1 Regulation settings . . . . . . . . . . . . . . . . . . . . . . . . 23

18.2 Protection settings. . . . . . . . . . . . . . . . . . . . . . . . . 24

18.3 Service settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Page

1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Controlling the compressor . . . . . . . . . . . . . . . . . . 3

1.2 Protecting the compressor . . . . . . . . . . . . . . . . . . . 3

1.2.1 Shut-down and motor overload . . . . . . . . . . 3

1.2.2 Shut-down warning . . . . . . . . . . . . . . . . . . . 3

1.2.3 Control of motor rotation direction. . . . . . . 3

1.2.4 Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Monitoring components subject to service (service

warning) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Automatic restart after voltage failure . . . . . . . . . . 3

2 Control panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Indicators, keys and buttons . . . . . . . . . . . . . . . . . . 4

2.2 Pictographs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Display - keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Scroll keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Tabulator key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Function keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

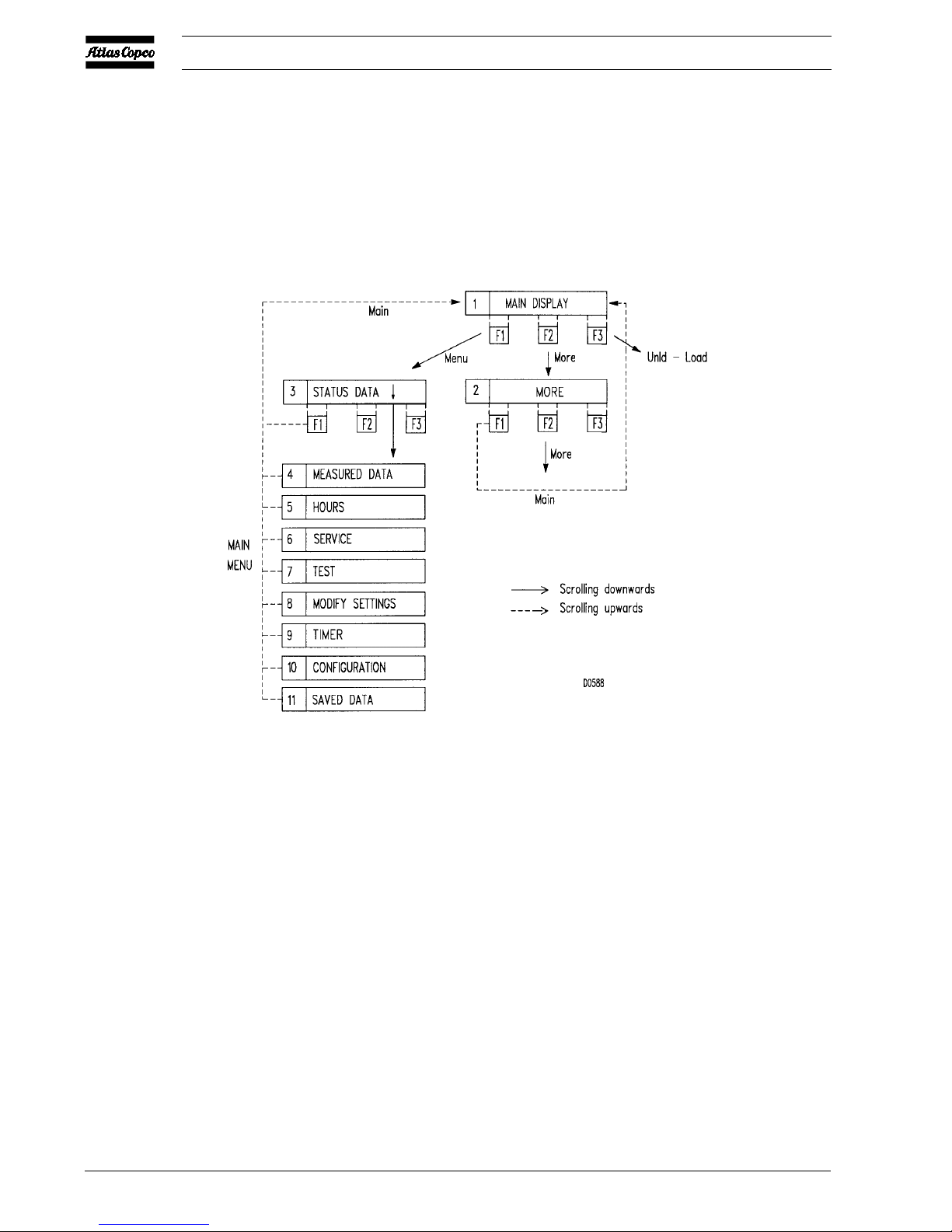

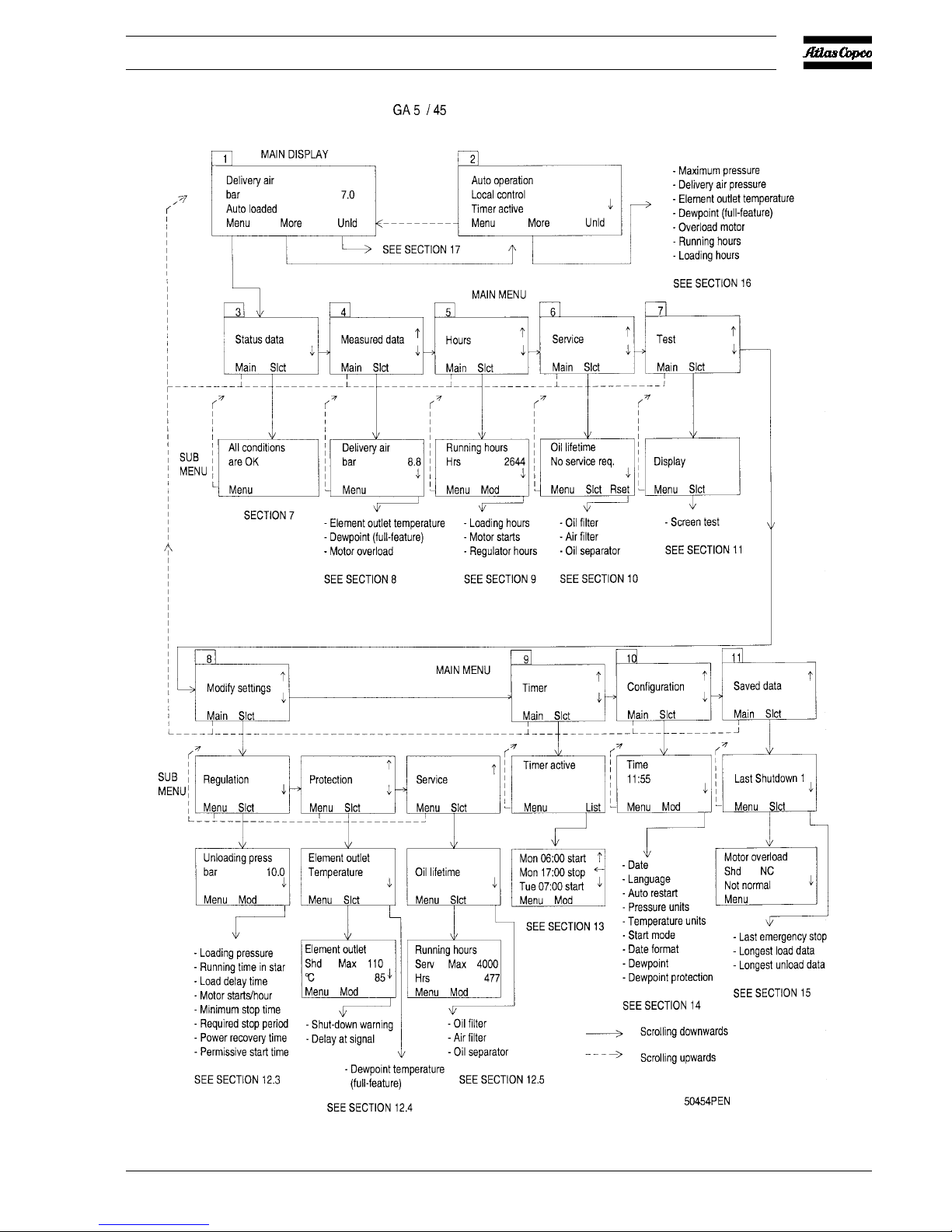

4 Menu-driven control programs. . . . . . . . . . . . . . . . . . 5

4.1 Function of control programs . . . . . . . . . . . . . . . . . 5

4.2 Selecting a menu. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2.1 Main display . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2.2 Calling up other menus . . . . . . . . . . . . . . . . 9

4.2.3 Returning to the main menu or main display9

5 Main display: compressor status in short/gateway

to all functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Main menu: gateway to other functions . . . . . . . . . 10

6.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 Status data submenu: calling up status of protection

functions and resetting . . . . . . . . . . . . . . . . . . . . . . . . 10

7.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7.2.1 No shut-down warning message or

shut-down message exists . . . . . . . . . . . . . 11

7.2.2 A shut-down message exists . . . . . . . . . . . 11

7.2.3 A shut-down warning message exists . . . . 11

7.2.4 A warning message exists . . . . . . . . . . . . . 11

7.3 Shut-down reset . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.4 Reset of motor overload . . . . . . . . . . . . . . . . . . . . 12

8 Measured data submenu: calling up measured data 12

8.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9 Hours submenu: calling up running hours, loading

hours, regulator hours and motor starts . . . . . . . . . 13

9.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

10 Service submenu: calling up and resetting service

messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10.1 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10.2 Calling up service messages . . . . . . . . . . . . . . . . . 14

2920 1207 05

3

User manual

1 GENERAL DESCRIPTION

The electronic regulator automatically controls the compressor,

i.e.:

- Loading and unloading the compressor

- Stopping the compressor whenever possible

- Restarting the compressor when required

In order to control the compressor and to read and modify

programmable parameters, the regulator has a control panel

provided with:

- LEDs indicating the status of the compressor

- A display indicating the operating conditions, a service need

or a fault

- Keys to control the compressor and to have access to the

data collected by the regulator

- Buttons to manually start and stop the compressor

- An emergency stop button

In general, the regulator has following functions:

- Controlling the compressor

- Protecting the compressor

- Monitoring components subject to service

- Automatic restart after voltage failure (made inactive)

1.1 Controlling the compressor

The regulator maintains the net pressure between programmable

limits by automatically loading and unloading the compressor

depending on the air consumption.

The regulator takes into account a number of programmable

settings, such as:

- Unloading pressure

- Loading pressure

- Minimum stop time

- Maximum number of motor starts

The regulator stops the compressor whenever possible (when

the expected unloading period exceeds a programmed value) to

reduce the power consumption and restarts it automatically when

the net pressure decreases. In case the expected unloading period

is below a programmed value, the regulator keeps the compressor

running to prevent too-short standstill periods.

When the compressor has stopped automatically and the net

pressure decreases, the regulator will start the compressor before

the net pressure has dropped to the loading pressure to prevent

the net pressure from falling under the programmed minimum

level.

When stopping the compressor manually, the regulator will

unload the compressor for 30 seconds and then stop the

compressor. 1)

1.2 Protecting the compressor

1.2.1 Shut-down and motor overload

If the compressor element outlet temperature exceeds the

programmed shut-down level, the compressor will be stopped.

This will be indicated on the control display.

The compressor will also be stopped in case of overload of the

drive motor or fan motor. 2)

1.2.2 Shut-down warning

If the compressor element outlet temperature exceeds a

programmed value just below the shut-down level, this will also

be indicated to warn the operator before the shut-down level is

reached.

1.2.3 Control of motor rotation direction

Regulators for GA90C and for later production GA30 up to -75

are provided with a control function for correct rotation direction

of the motor: a message will appear on the display of the regulator

if the rotation direction is wrong. In this case, switch off the

voltage and reverse two incoming lines.

1.2.4 Warning

A warning message also appears if the cooling water temperature

or dewpoint temperature exceeds the warning level. See section

7.2.4.

1.3 Monitoring components subject to

service (service warning)

The regulator continuously monitors critical components (oil,

oil filter, oil separator and air filter). Each input is compared to

programmed limits. Exceeding these limits causes a message

on the control display to warn the operator to replace the

indicated component.

1.4 Automatic restart after voltage failure

The regulator has a built-in function to automatically restart the

compressor if the voltage is restored after voltage failure. For

compressors leaving the factory, this function is made inactive.

If desired, the function can be activated. Consult Atlas Copco.

Footnotes chapter 1

1) If the compressor was running at that moment in automatic

unloading condition for 10 seconds, it will remain running

unloaded for 30 - 10 = 20 seconds before stopping.

2) For GA30 up to GA90C only.

2920 1207 05

4

User manual

Fig. 2.1. Control panel

2 CONTROL PANEL

2.1 Indicators, keys and buttons (Fig. 2.1)

Ref. Designation Function

1 Automatic Indicates that the regulator is

operation LED automatically controlling the

compressor: the compressor is

loaded, unloaded, stopped and

restarted depending on the air

consumption and the limitations

programmed in the regulator.

2 Voltage on LED Indicates that the voltage is

switched on.

3 General alarm LED Is alight if a warning or shut-down

warning condition exists or if a

sensor is out of order. See section

7.

Blinks in case of shut-down, if a

sensor with shut-down function

(e.g. TT11) is out of order or after

an emergency stop. See section 7.

4 Display Indicates messages concerning the

compressor operating condition, a

service need or a fault. See section

3.1.

5 Function keys Keys to control and program the

compressor. See section 3.4.

6 Scroll keys Keys to scroll through the display .

See section 3.2.

7 Tabulator key Key to go to the next field of the

display. See section 3.3.

8 Start button Push button to start the

compressor. LED (1) lights up

indicating that the regulator is

operative (in automatic operation).

The LED goes out after unloading

the compressor manually .

9 Stop button Push button to stop the

compressor. LED (1) goes out.

The compressor will stop after

running in unloaded condition for

30 seconds. See also section 1.1.

S3 Emergency Maintained-action push button to

stop button stop the compressor immediately

in case of emergency. After

remedying the trouble, unlock the

button by turning it to the left or

by pulling it out.

2.2 Pictographs (Fig. 2.1)

Ref. Designation

10 Emergency stop

11 Automatic operation

12 Voltage on

13 Alarm

Delivery air

bar 7.0

Auto loaded

Menu More Unld

F1 F2 F3

Fig. 2.2. Typical example of a display

411 122

1

3

5

S3

10

6

7

9

8

50503F

13

2920 1207 05

5

User manual

3 DISPLAY - KEYS

3.1 Display (4-Fig. 2.1)

The display has four lines of 16 characters. A typical display is

shown in Fig. 2.2. It indicates:

1. On the first three lines:

- The name of the sensor of which the actual reading is

displayed

- The unit and actual reading of the sensor

- Messages regarding the compressor operating condition

(compressor loaded, off, etc.), a service need (e.g. for

the oil filter and air filter) or a fault (e.g. shut-down)

2. On the fourth line, just above the three function keys (F1/

F2/F3), the actual functions of these keys.

3.2 Scroll keys (6-Fig. 2.1)

These keys, labelled with vertical arrows, allow to scroll through

the display.

As long as a downwards pointing arrow is shown at the utmost

right position of the display, the key (6) with the same symbol

can be used to see the next item.

As long as an upwards pointing arrow is shown at the utmost

right position of the display, the key (6) with the same symbol

can be used to see the previous item.

3.3 Tabulator key (7-Fig. 2.1)

This key, labelled with two horizontal arrows, allows the operator

to go to the next field of the display, e.g. during modifying of

programmable parameters.

3.4 Function keys (5-Fig. 2.1)

The keys are used:

- To manually load/unload the compressor

- To call up or program settings

- To reset an active motor overload, shut-down or service

message, or an emergency stop

- To have access to all data collected by the regulator

The function keys allow to make the required selection from a

menu of possibilities. The functions of the keys vary depending

on the displayed menu. The actual function is abbreviated and

indicated on the bottom line of the display just above the relevant

key. Only the active and relevant functions at a moment are

shown.

4 MENU-DRIVEN CONTROL

PROGRAMS

In order to facilitate programming and controlling, menu-driven

control programs have been implemented in the regulator.

4.1 Function of control programs (Figs. 4.1

up to 4.3)

Program See Function

section

MAIN 5 Shows in short the operation status

DISPLAY of the compressor. Is the gateway

to all functions.

MAIN MENU 6 Is the gateway to other functions

via submenus.

SUBMENUS

Status data 7 Calling up the status of the

compressor protection functions

(shut-down and shut-down

warning). Resetting of a shutdown and motor overload.

Measured data 8 Calling up the actual measured

temperature at the compressor

element outlet, the dewpoint (on

compressors with integrated air

dryer) and the status of the motor

overload protection. On GA55 up

to -90C also the actual pressure

difference over the oil separator,

the status of the fan motor overload

protection and on water-cooled

compressors also the actual cooling

water outlet temperature.

Hours 9 Calling up the running hours,

loading hours, regulator hours and

number of motor starts.

Service 10 Calling up and resetting the service

messages for the oil, oil filter, oil

separator, air filter.

Test 11 Display test.

Modify settings 12 Modifying the settings for

regulation (e.g. loading and

unloading), for protection (e.g.

temperature shut-down level) and

for service (e.g. for the oil).

Timer 13 Programming the compressor

start/stop commands.

Configuration 14 Programming the time, date,

display language, units, motor start

mode and date format. On GA5

up to GA45, dewpoint tempera-

ture display mode and the

dewpoint protection.

2920 1207 05

6

User manual

Fig. 4.1. General menu flow

2920 1207 05

7

User manual

Fig. 4.2. Menu flow for regulator of GA5/45

Loading...

Loading...