Atlas Copco GA11, GA15, GA30C, GA18, GA22 Instruction Book

Atlas Copco Stationary Air Compressors

GA11 - GA15 - GA18 - GA22 - GA30C

With Elektronikon I and Elektronikon II regulator

Instruction book

Important

1. From following serial number onwards: AII-268 500

2. This book must be used together with the "User manual for Elektronikon I and II regulators", Printed

Matter No. 2920 1461 0x.

·

Copyright 2002, Atlas Copco Airpower n.v., Antwerp, Belgium.

Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in

particular to trademarks, model denominations, part numbers and drawings.

·

This instruction book meets the requirements for instructions specified by the machinery

directive 98/37/EC and is valid for CE as well as non-CE labelled machines.

No. 2920 1462 00

Registration code: APC G11-30C / 38 / 994

2002-10

www.atlascopco.com

Instruction book

This instruction book describes how to handle the machines to ensure safe operation, optimum efficiency and long service life.

Read this book before putting the machine into operation to ensure correct handling, operation and proper maintenance from the

beginning. The maintenance schedule comprises measures for keeping the machine in good condition.

Keep the book available for the operator and make sure that the machine is operated and that maintenance is carried out according

to the instructions. Record all operating data, maintenance performed, etc. in an operators logbook available from Atlas Copco.

Follow all relevant safety precautions, including those mentioned on the cover of this book.

Repairs must be carried out by trained personnel from Atlas Copco who can be contacted for any further information.

In all correspondence always mention the type and the serial number, shown on the data plate.

For all data not mentioned in the text, see sections Preventive maintenance schedule and Principal data.

The company reserves the right to make changes without prior notice.

Contents

Page

1 Leading particulars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.1 Compressor variants . . . . . . . . . . . . . . . . . . . . . . 3

1.1.2 Air flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.3 Oil system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.4 Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1.5 Condensate drain system . . . . . . . . . . . . . . . . . . 4

1.2 Unloading/loading system . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.1 Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.2 Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Elektronikon II regulator . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.1 Main functions . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.2 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.3.4 Calling up other menus . . . . . . . . . . . . . . . . . . 13

1.4 Elektronikon I regulator . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4.1 Main functions . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4.2 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.4.3 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.4.4 Scrolling through all screens . . . . . . . . . . . . . . 15

1.4.5 Pictographs used on the screen . . . . . . . . . . . . 15

1.5 Air dryer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.5.1 Compressed air circuit . . . . . . . . . . . . . . . . . . . 18

1.5.2 Refrigerant circuit . . . . . . . . . . . . . . . . . . . . . . 18

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.1 Dimension drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2 Installation proposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.4 Electric cable size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5 Pictographs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1 Before initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.2 User manual . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.3 Outdoor/altitude operation . . . . . . . . . . . . . . . . 23

3.2 External compressor status indication/remote control . 23

3.2.1 External compressor status indication . . . . . . . 23

3.2.2 Remote control . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3 Remote starting/stopping . . . . . . . . . . . . . . . . . . . . . . . 23

3.4 Initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.5 Before starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.6 Operating GA Workplace/Workplace FF . . . . . . . . . . . 25

3.6.1 Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.6.2 During operation . . . . . . . . . . . . . . . . . . . . . . . 25

Page

3.6.3 Checking the display . . . . . . . . . . . . . . . . . . . . 25

3.6.4 Manual control . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.6.5 Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.7 Operating GA Pack/Pack FF. . . . . . . . . . . . . . . . . . . . . 27

3.7.1 Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.7.2 During operation . . . . . . . . . . . . . . . . . . . . . . . 27

3.7.3 Checking the display . . . . . . . . . . . . . . . . . . . . 27

3.7.4 Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.8 Taking out of operation at end of compressor

service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1 Drive motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2 Service actions for GA Pack/Pack FF . . . . . . . . . . . . . 28

4.3 Service plans for GA Workplace/Workplace FF . . . . . 28

4.4 Preventive maintenance schedule . . . . . . . . . . . . . . . . . 29

4.5 Oil specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.5.1 Atlas Copco Roto-injectfluid . . . . . . . . . . . . . . 30

4.5.2 Mineral oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.6 Oil and oil filter change . . . . . . . . . . . . . . . . . . . . . . . . 30

4.7 Storage after installation . . . . . . . . . . . . . . . . . . . . . . . . 30

4.8 Service kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5 Adjustments and servicing procedures . . . . . . . . . . . . . . . 31

5.1 Air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2 Coolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.3 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6 Problem solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7 Principal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1 Readings on display . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2 Motor overload relay, fuses and circuit breaker. . . . . . 33

7.3 Fan control switch (Full Feature) . . . . . . . . . . . . . . . . . 34

7.4 Compressor specifications . . . . . . . . . . . . . . . . . . . . . . 34

7.4.1 Reference conditions . . . . . . . . . . . . . . . . . . . . 34

7.4.2 Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.4.3 Specific data of GA 7.5 bar . . . . . . . . . . . . . . . 35

7.4.4 Specific data of GA 8.5 bar . . . . . . . . . . . . . . . 35

7.4.5 Specific data of GA 10 bar . . . . . . . . . . . . . . . . 36

7.4.6 Specific data of GA 13 bar . . . . . . . . . . . . . . . . 36

7.4.7 Specific data of GA 100 psi . . . . . . . . . . . . . . . 37

7.4.8 Specific data of GA 125 psi . . . . . . . . . . . . . . . 37

7.4.9 Specific data of GA 150 psi . . . . . . . . . . . . . . . 38

7.4.10 Specific data of GA 175 psi . . . . . . . . . . . . . . . 38

7.5 Conversion list of SI units into US/British units . . . . . 39

8 Instructions for use of air receiver . . . . . . . . . . . . . . . . . . . 39

2

2920 1462 00

Instruction book

1 Leading particulars

1.1 General description

GA11 up to GA30C are stationary, single-stage, oil-injected

screw compressors driven by an electric motor. The

compressors are air-cooled.

1.1.1 Compressor variants

GA Pack

GA Pack are enclosed in a sound-insulated bodywork. The

compressors are controlled by the Atlas Copco Elektronikon

I regulator (Fig. 1.1). The electronic control module is fitted

to the door at the front side. An electric cabinet comprising the

motor starter is located behind this panel.

GA Pack FF

GA Pack FF (Full-Feature) are also controlled by the Atlas

Copco Elektronikon® I regulator (Fig. 1.1). They are

additionally provided with an air dryer integrated in the soundinsulated bodywork. The dryer removes condensate from the

compressed air by cooling the air to near freezing point and

automatically draining the condensate. See section 1.5.

GA Workplace

GA Workplace are enclosed in a sound-insulated bodywork.

The compressors are controlled by the Atlas Copco

Elektronikon® II regulator (Fig. 1.2). The electronic control

module is fitted to the door at the front side. An electric cabinet

comprising the motor starter is located behind this panel. A

condensate trap with automatic drain system is provided.

GA Workplace FF

GA Workplace FF (Full-Feature) are also controlled by the Atlas

Copco Elektronikon® II regulator (Fig. 1.2). They are

additionally provided with an air dryer integrated in the soundinsulated bodywork. The dryer removes condensate from the

compressed air by cooling the air to near freezing point and

automatically draining the condensate. See section 1.5.

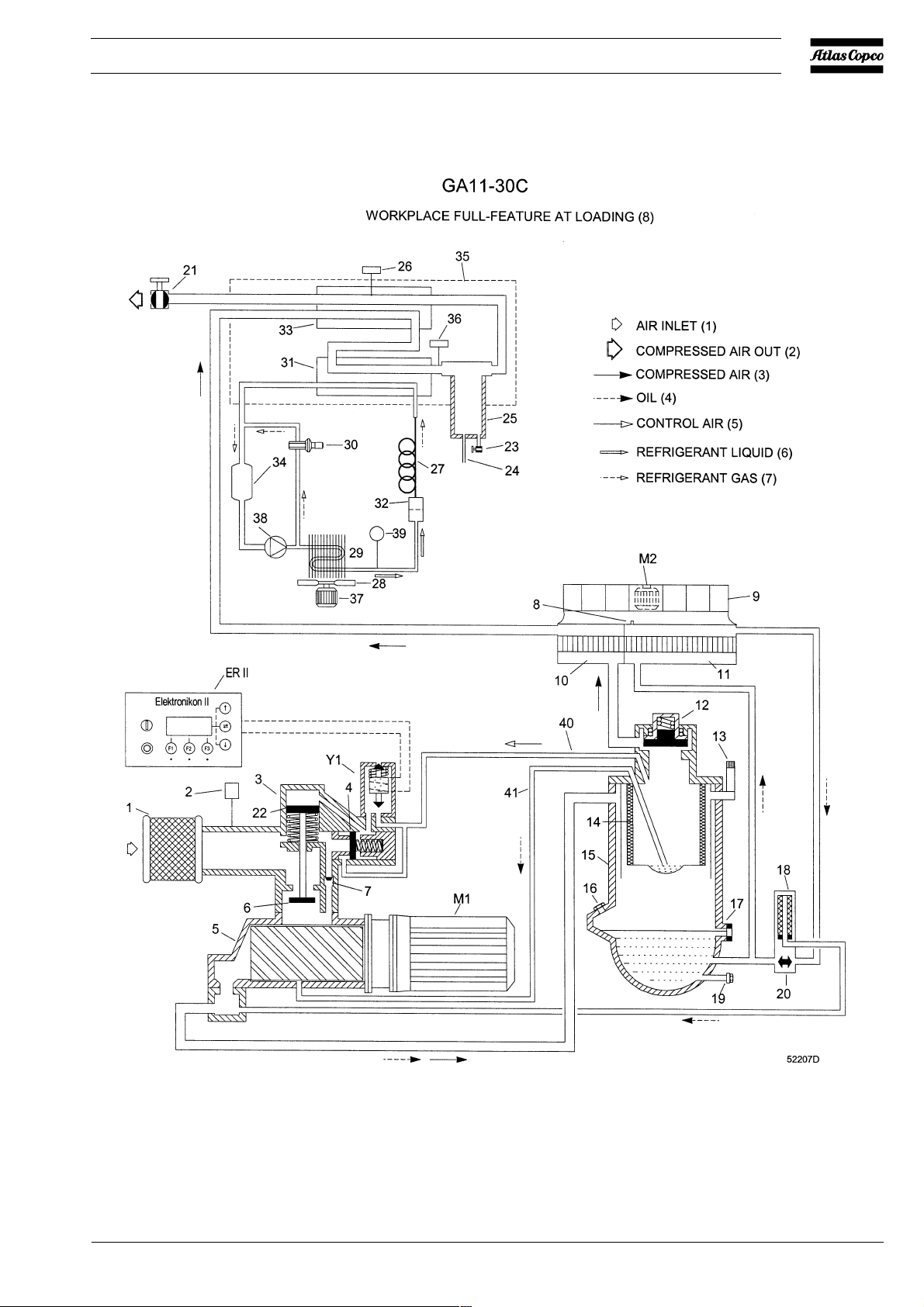

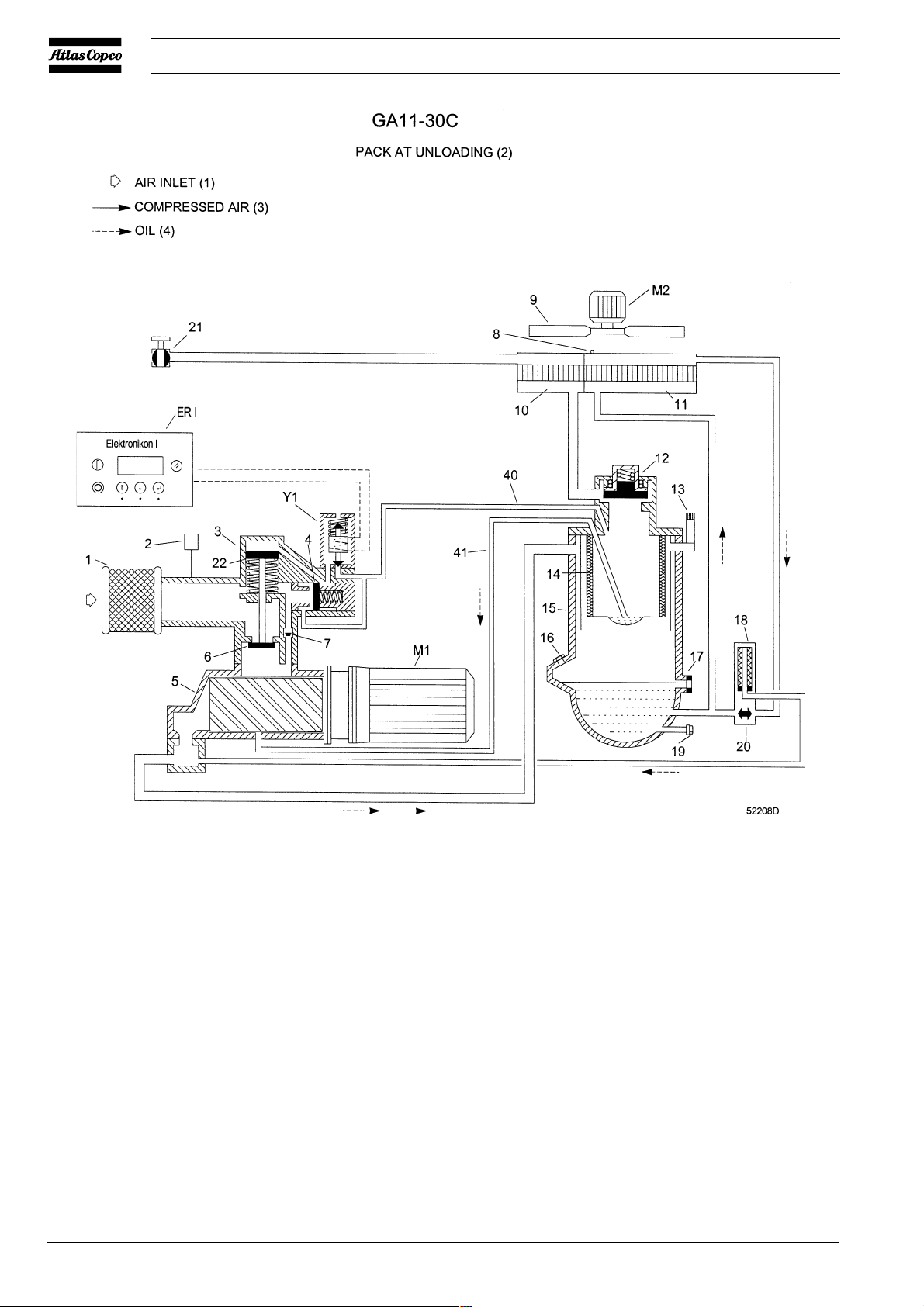

1.1.2 Air flow (Figs. 1.7 and 1.8)

Air drawn through filter (1) and open inlet valve (6) into

compressor element (5) is compressed. Compressed air and

oil flow through air receiver/oil separator (15) and air cooler

®

(10) to outlet valve (21).

Minimum pressure valve (12) prevents the receiver pressure

from dropping below a minimum pressure.

1.1.3 Oil system (Figs. 1.7 and 1.8)

Air pressure forces the oil from air receiver (15) through oil

cooler (11) and filter (18) to compressor element (5) and the

lubrication points.

The system comprises a by-pass valve (20). When the oil is

warm, the valve allows all oil to pass through the cooler.

1.1.4 Cooling system (Figs. 1.7 and 1.8)

The cooling system comprises air cooler (10) and oil cooler

(11). The cooling air is generated by fan (9).

52144F

2920 1462 00

Fig. 1.1 Elektronikon I regulator

52143F

Fig. 1.2 Elektronikon II regulator

3

Instruction book

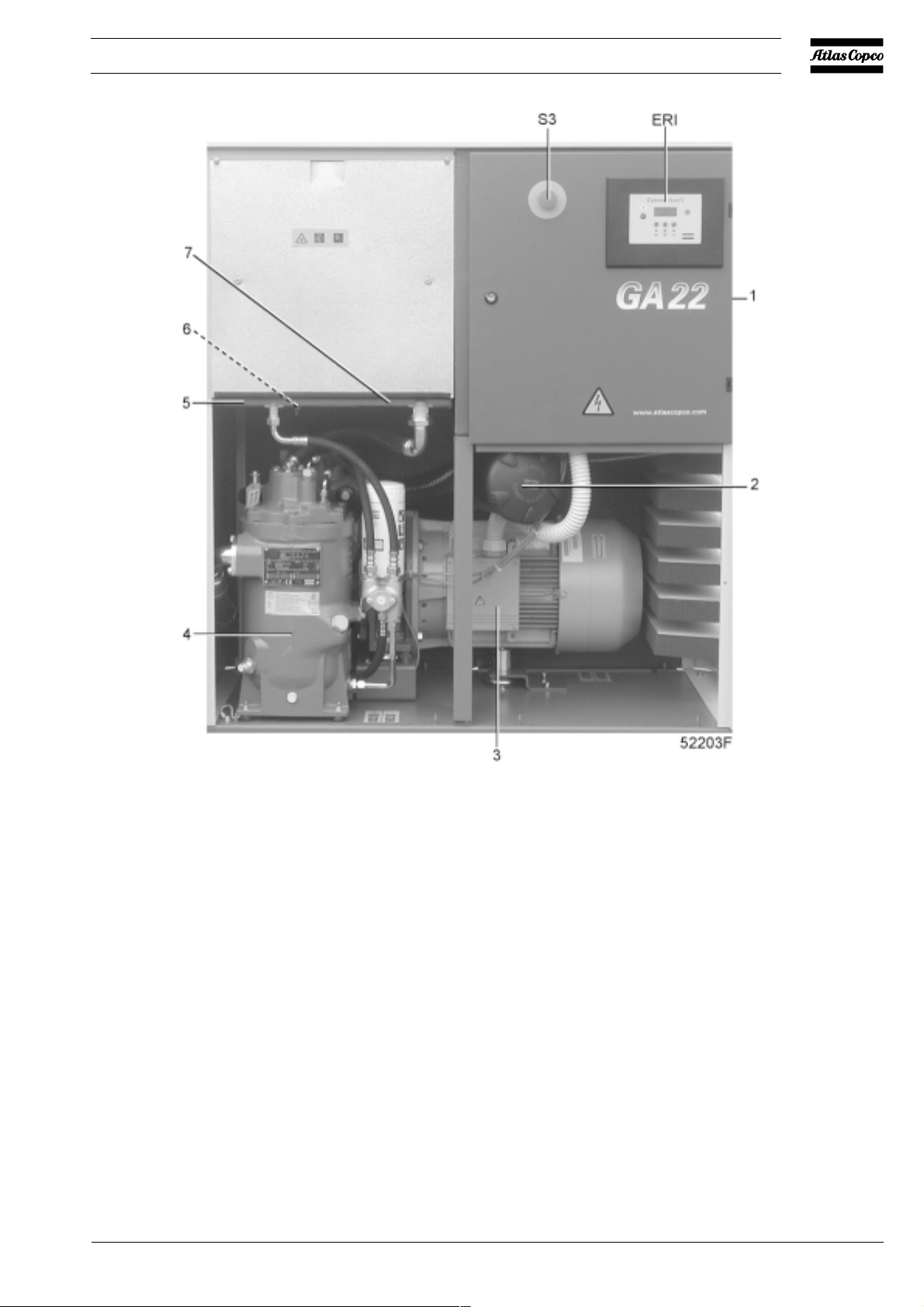

ER II Elektronikon II regulator

S3 Emergency stop button

1 Air outlet

Fig. 1.3 Front view GA30C Workplace Full-feature

1.1.5 Condensate drain system (Fig. 1.6)

All variants except for GA Pack are provided with a condensate

trap in the air outlet system. The trap is equipped with a valve

for automatic condensate draining during operation (2) and a

manually operated valve (1) for draining after stopping the

compressor.

1.2 Unloading/loading system

1.2.1 Unloading (Fig. 1.8)

If the air consumption is less than the air output of the

compressor, the net pressure increases. When the net pressure

reaches the unloading pressure, solenoid valve (Y1) is deenergized. The plunger of the valve returns by spring force:

4

2920 1462 00

Instruction book

ER I Elektronikon I regulator

1 Air outlet

2 Air filter

3 Drive motor

Fig. 1.4 GA22 Pack

1. The control pressure present in the chambers of loading

plunger (22) and unloading valve (4) is vented to atmosphere

via solenoid valve (Y1).

2. Loading plunger (22) moves upwards and causes inlet valve

(6) to close the air inlet opening.

3. Unloading valve (4) is opened by receiver pressure. The

pressure from air receiver (15) is released towards unloader

(3).

Air output is stopped (0 %), the compressor runs unloaded.

4 Air receiver/oil separator

5 Oil cooler

6 Oil cooler vent plug

7 Air cooler

1.2.2 Loading (Fig. 1.7)

When the net pressure decreases to the loading pressure,

solenoid valve (Y1) is energized. The plunger of solenoid valve

(Y1) moves upwards against spring force:

1. Control pressure is fed from air receiver (15) via solenoid

valve (Y1) to loading plunger (22) and unloading valve (4).

2. Unloading valve (4) closes the air blow-off opening.

Loading plunger (22) moves downwards and causes inlet

valve (6) to open fully.

Air output is resumed (100 %), the compressor runs loaded.

2920 1462 00

5

Instruction book

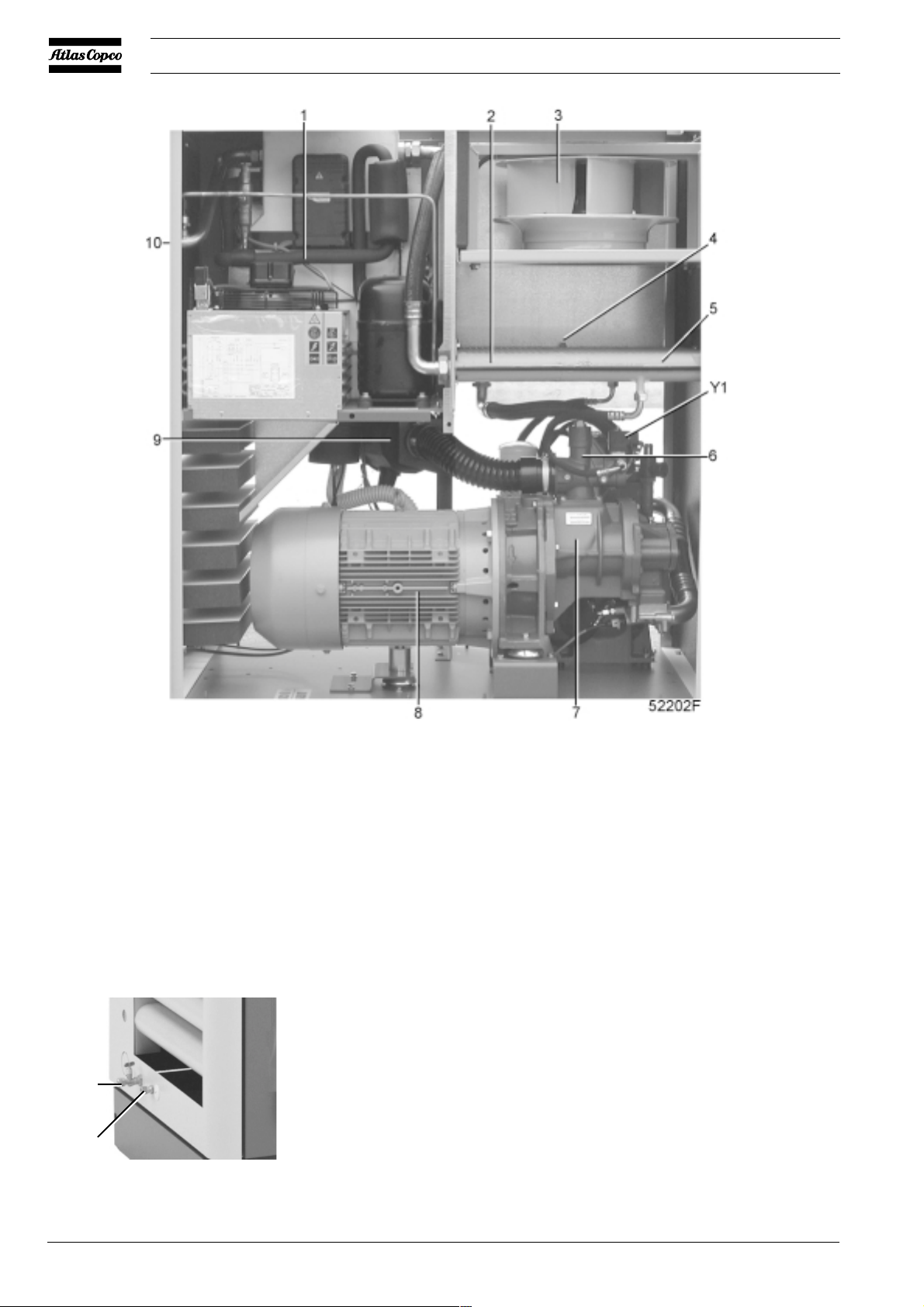

1 Dryer

2 Air cooler

3 Fan

4 Oil cooler vent plug

1

2

51 100F

5 Oil cooler

6 Unloader

7 Compressor element

8 Drive motor

Fig. 1.5 GA22 Workplace Full-Feature

1 Condensate drain valve

2 Automatic condensate drain

Fig. 1.6 Condensate outlets

9 Air filter

10 Air outlet

Y1 Loading solenoid valve

6

2920 1462 00

Instruction book

2920 1462 00

Fig. 1.7 GA Workplace Full-feature during loading

7

Instruction book

ER I Elektronikon I regulator

ER II Elektronikon II regulator

M1 Drive motor

M2 Motor, compressor cooling fan

Y1 Loading solenoid valve

1 Air filter

2 Air filter service indicator

3 Unloader

4 Unloading valve

5 Compressor element

6 Inlet valve

7 By-pass valve

8 Vent plug, oil circuit

9 Compressor cooling fan

10 Air cooler

11 Oil cooler

8

Fig. 1.8 GA Pack during unloading

12 Minimum pressure valve

13 Safety valve

14 Oil separator element

15 Air receiver

16 Oil filler plug

17 Oil level indicator

18 Oil filter

On Full-feature also:

26 Pressure sensor

27 Capillary tube

28 Condenser cooling fan

29 Refrigerant condenser

30 Hot gas by-pass valve

31 Air/refrigerant heat exchanger/

19 Oil drain plug

20 Oil cooler by-pass valve

21 Air outlet valve

22 Loading plunger

23 Manual condensate drain valve

24 Automatic condensate outlet

25 Condensate trap

40 Flexible, control air

41 Flexible, oil scavenging

32 Liquid refrigerant dryer/filter

33 Air/air heat exchanger

34 Accumulator

35 Insulating block

36 Temperature sensor

37 Motor, condenser fan

38 Refrigerant compressor

39 Fan control switch

Figs. 1.7 and 1.8 Air-oil and unloading-loading systems

evaporator

2920 1462 00

Instruction book

1.3 Elektronikon II regulator

GA Workplace and Workplace FF are provided with the

Elektronikon II regulator (Fig. 1.9).

1.3.1 Main functions

1.3.1.1 Automatic control of the compressor

The regulator maintains the net pressure between programmable

limits by automatically loading and unloading the compressor.

A number of programmable settings, e.g. the unloading and

loading pressures, the minimum stop time and the maximum

number of motor starts are taken into account.

The regulator stops the compressor whenever possible to reduce

the power consumption and restarts it automatically when the

net pressure decreases. In case the expected unloading period

is too short, the compressor is kept running to prevent tooshort standstill periods.

Warning A number of time-based automatic start/stop

commands may be programmed (consult the User

manual for Elektronikon I and II regulators). Take

into account that a start command will be executed

(if programmed and activated), even after

manually stopping the compressor.

1.3.1.2 Protecting the compressor

Shut-down

If the compressor element outlet temperature exceeds the

programmed shut-down level, the compressor will be stopped.

This will be indicated on display (3). The compressor will

also be stopped in case of overload of the drive motor and the

fan motor.

Shut-down warning

If the compressor element outlet temperature exceeds a

programmed value below the shut-down level, this will also be

indicated to warn the operator before the shut-down level is

reached.

Service warning

A number of service operations are grouped in plans (called

Service plans A, B and C). Each Service plan has a programmed

time interval. If a time interval is exceeded, a message will

appear on display (3) to warn the operator to carry out the

service actions belonging to that plan.

Warning

On Full-feature compressors, a warning message also appears

if the dewpoint temperature exceeds the warning level.

52227F

1 Stop button

2 Start button

3 Display

4 Scroll keys

5 Tabulator key

S3

1

6 Voltage on LED

7 General alarm LED

8 Automatic operation LED

9 Function keys

Fig. 1.9 Control panel, Elektronikon II

2

8

9

11

3

10

4

5

4

9

9

12

7

6

10 Pictograph, alarm

11 Pictograph, automatic operation

12 Pictograph, voltage on

S3 Emergency stop button

2920 1462 00

9

Instruction book

1.3.1.3 Automatic restart after voltage failure

For compressors leaving the factory, this function is made

inactive. If desired, the function can be activated. Consult

Atlas Copco.

Warning If activated and provided the module was in the

automatic operation mode, the compressor will

automatically restart if the supply voltage to the

module is restored within a programmed time

period.

The power recovery time (the period within which the voltage

must be restored to have an automatic restart) can be set between

10 and 600 seconds or to Infinite. If the power recovery time

is set to Infinite, the compressor will always restart after a

voltage failure, no matter how long it takes to restore the voltage.

A restart delay can also be programmed, allowing e.g. two

compressors to be restarted one after the other.

1.3.2 Control panel (Fig. 1.9)

Ref. Designation Function

1 Stop button Push button to stop the

compressor. LED (8) goes out.

The compressor will stop after

running in unloaded condition for

about 30 seconds.

Ref. Designation Function

2 Start button Push button to start the

compressor. LED (8) lights up

indicating that the regulator is

operative (in automatic operation).

The LED goes out after unloading

the compressor manually.

3 Display Indicates messages concerning the

compressor operating condition, a

service need or a fault.

4 Scroll keys Keys to scroll through the display.

5 Tabulator key Key to select the parameter

indicated by a horizontal arrow.

Only the parameters followed by

an arrow pointing to the right are

accessible for modifying.

6 Voltage on LED In dic ates t hat the voltage is

switched on.

7 General alarm LED Is alight if a warning, service

warning or shut-down warning

condition exists or if a sensor is

out of order.

7 General alarm LED Blinks in case of shut-down, if a

sensor with shut-down function is

out of order or after an emergency

stop.

10

52227F

S3

Fig. 1.9 Control panel, Workplace / Workplace FF

1

2

11

8

9

10

3

4

5

4

9

9

12

7

6

2920 1462 00

Instruction book

Ref. Designation Function

8 Automatic Indicates that the regulator is

operation LED automatically controlling the

compressor: the compressor is

loaded, unloaded, stopped and

restarted depending on the air

consumption and the limitations

programmed in the regulator.

9 Function keys Keys to control and program the

compressor. See below.

10 Pictograph Alarm

11 Pictograph Automatic operation

12 Pictograph Voltage on

S3 Emergency

stop button Push button to stop the compressor

immediately in case of emergency.

After remedying the trouble,

unlock the button by pulling it out.

2920 1462 00

See Fig. 1.11 for denomination of components

Fig. 1.10 Electric cabinet, GA Workplace / Workplace FF (typical example)

11

Instruction book

12

2920 1462 00

Loading...

Loading...