Atlas Copco FD450, FD300, FD380, FD260, FD700 Instruction Book

...

Atlas Copco Air Dryers

FD(W)260, -300, -380, -450, -700

Instruction Book

Important:

This book applies exclusively to FD dryers as from following serial numbers onwards and filled with

refrigerant R404a; see data plate:

FD260: AIQ-124 045

FD300: AIQ-140 200

FD380: AIQ-129 800

FD450: AIQ-140 550

FD700: AIQ-750 005

This instruction book meets the requirements for instructions specified by the machinery

directive 89/392/EEC and is valid for CE as well as non-CE labelled machines

No. 2920 1351 01

Registration code: APC FD / 38 / 988

Replaces No. 2920 1351 00 and for FD700 only 2920 1371 00

1998-03

*2920135101*

Instruction book

This instruction book describes how to handle and operate the subject machine(s) to ensure safe operation, optimum working

economy and long service life.

Read this book before putting the machine into operation to ensure correct handling, operation and proper maintenance from

the beginning. The maintenance schedule contains a summary of the measures for keeping the dryer in good repair. The

maintenance procedures are simple but must be carried out regularly.

Keep the book available for the operator(s) and make sure that the dryer is operated and that the maintenance actions are carried

out according to the instructions. Record all operating data, maintenance work effected, etc. in an operator's logbook available

from Atlas Copco. Follow all applicable safety precautions, amongst others those mentioned on the cover of this book.

Repair operations must be performed by trained personnel from Atlas Copco, who can also be contacted if any further information

is desired.

In all correspondence always mention the dryer type and the complete serial number, shown on the data plate.

For all specific data not mentioned in the text, consult section "Principal data".

The company reserves the right to make changes without prior notice.

Contents

Page

1 Leading particulars . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 General description. . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Air circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Refrigeration circuit . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Automatic regulation system . . . . . . . . . . . . . . . . . 8

1.5 Electrical system . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Dimension drawings . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Installation proposal . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Installation instructions. . . . . . . . . . . . . . . . . . . . . 13

2.4 Pictographs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Initial start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 During operation . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2

Page

3.4 Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.5 Possible causes of unstable or too high pressure

dewpoint temperature . . . . . . . . . . . . . . . . . . . . . . 16

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Automatic expansion valve. . . . . . . . . . . . . . . . . . 17

5.2 Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Problem solving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7 Principal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.1 Limitations/nominal conditions . . . . . . . . . . . . . . 19

7.2 Specific data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8 Conversion list of SI units into British/US units . . . 20

2920 1351 01

Instruction book

1 LEADING PARTICULARS

1.1 General description

The FD air dryers remove moisture from compressed air by

cooling the air to near freezing point. This causes water and

oil to condense. The condensate is automatically drained. The

air is warmed up before leaving the dryer.

On air-cooled dryers, the condenser has a cooling fan controlled

by a condenser pressure switch. W ater-cooled dryers have an

automatic regulating valve in the water outlet of the condenser.

FD260 up to -700 are air-cooled, while FD260 W up to -700

W are water-cooled dryers. The suffix W is not mentioned

further in the book where the descriptions are valid for both

air- and water-cooled dryers.

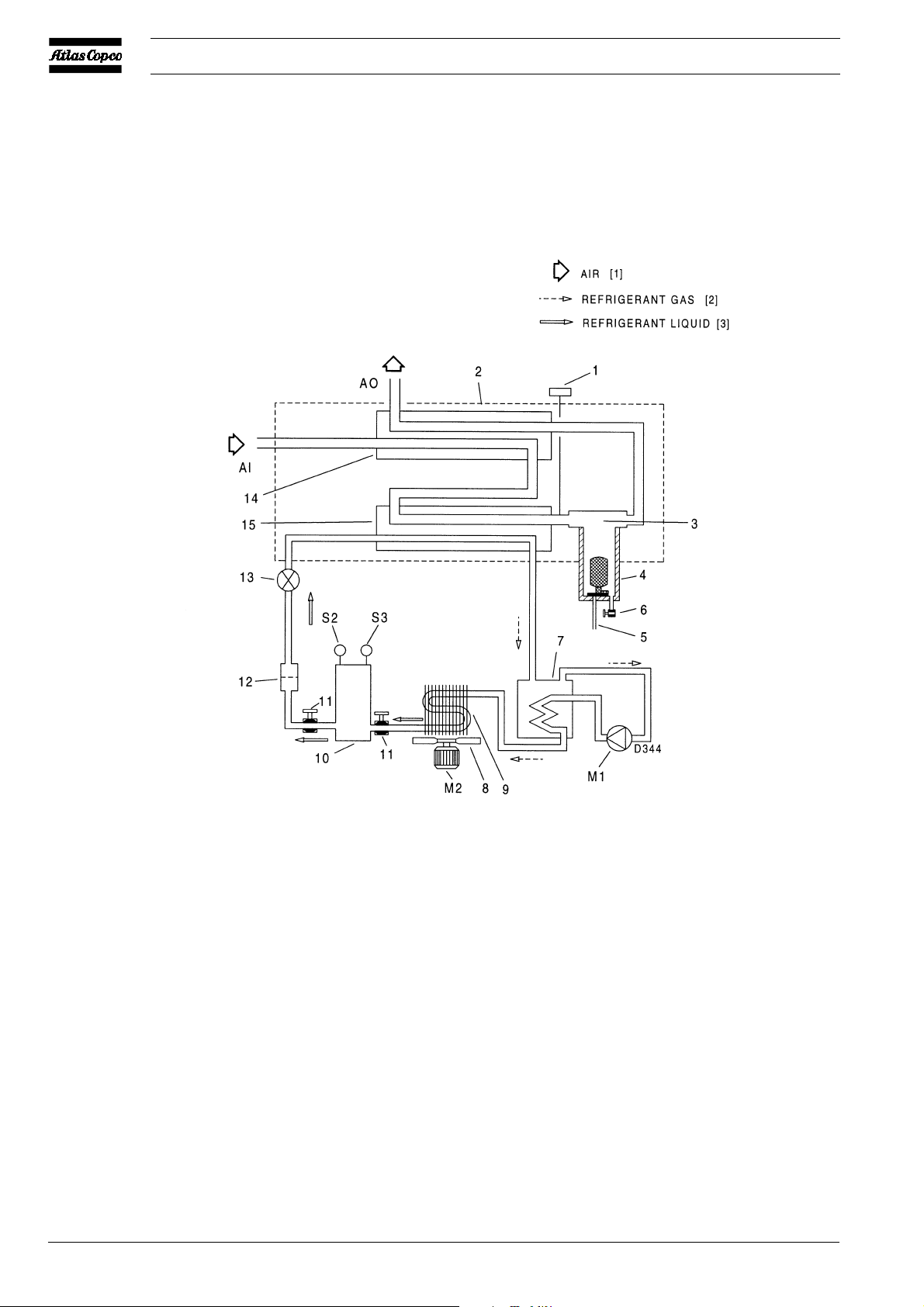

1.2 Air circuit (Fig. 2)

Compressed air enters air/air heat exchanger (14) and is precooled by the outgoing, cold, dried air. Water and oil in the

incoming air start to condense. The air then flows through air/

refrigerant heat exchanger/evaporator (15) where the refrigerant

evaporates and withdraws heat from the air. This cools the air

to close to the evaporating temperature of the refrigerant. More

water and oil in the air condense. The cold air then flows

through separator (3) where all the condensate is separated from

the air. The condensate collects in condensate trap (4) and is

automatically drained. From separator (3) the cold dried air

flows through air/air heat exchanger (14), where it is warmed

up by the incoming air to approx. 10°C (18°F) below the

incoming air temperature. Reheating the dried air reduces its

relative humidity, so that condensation in the air net cannot

occur unless the air is cooled to below the pressure dewpoint

temperature indicated by gauge (1).

2920 1351 01

F6837

Fig. 1. Front view of FD450

3

Instruction book

AI. Air inlet connection

AO. Air outlet connection

M1. Refrigerant compressor/motor

M2. Condenser cooling fan motor

S2. High pressure shut-down switch

S3. Fan control switch

1. Pressure dewpoint temperature

gauge

Fig. 2. Air and refrigerant flow diagram, air-cooled dryers

4

2. Insulating block

3. Cyclone condensate separator

4. Condensate trap with automatic

discharge

5. Automatic condensate drain hose

6. Manual condensate drain valve

7. Liquid separator

8. Fan

9. Refrigerant condenser

10. Liquid refrigerant receiver

11. Refrigerant shut-off valve

12. Liquid refrigerant dryer/filter

13. Refrigerant expansion valve

14. Air/air heat exchanger

15. Air/refrigerant heat exchanger/

evaporator

2920 1351 01

Instruction book

1.3 Refrigeration circuit (Fig. 2)

Compressor (M1) delivers hot, high-pressure refrigerant gas,

which flows, via the coil of liquid separator (7), through

condenser (9) where most of the refrigerant condenses. On

air-cooled condensers, a fan control switch (S3) stops and starts

the fan motor (M2) at falling or rising condenser pressure. On

water-cooled condensers, an automatic valve (3-Figs. 5)

regulates the cooling water flow, thus controlling the

temperature, which is directly dependent on the pressure. The

cooled refrigerant then collects in receiver (10).

The liquid leaves the receiver (10) via its syphon outlet and

flows through liquid refrigerant filter/dryer (12) to expansion

valve (13) where it expands to evaporating pressure.

T1 L1 L2 L3 1X1 PE

In expansion valve (13) some of the expanding liquid refrigerant

evaporates, for which the required heat is withdrawn from the

refrigerant itself.

The refrigerant enters the heat exchanger/evaporator (15) where

it withdraws heat from the compressed air by further

evaporation. Dependent on the compressed air load, all, or

almost all, refrigerant evaporates at constant pressure and

temperature. The vapour refrigerant leaving evaporator (15)

flows into liquid separator (7). The liquid separator prevents

any droplets from entering compressor (M1) because warm

refrigerant, leaving the compressor, flows through the coil of

the liquid separator and evaporates the surrounding liquid.

From liquid separator (7) the refrigerant gas is sucked in by the

compressor.

2920 1351 01

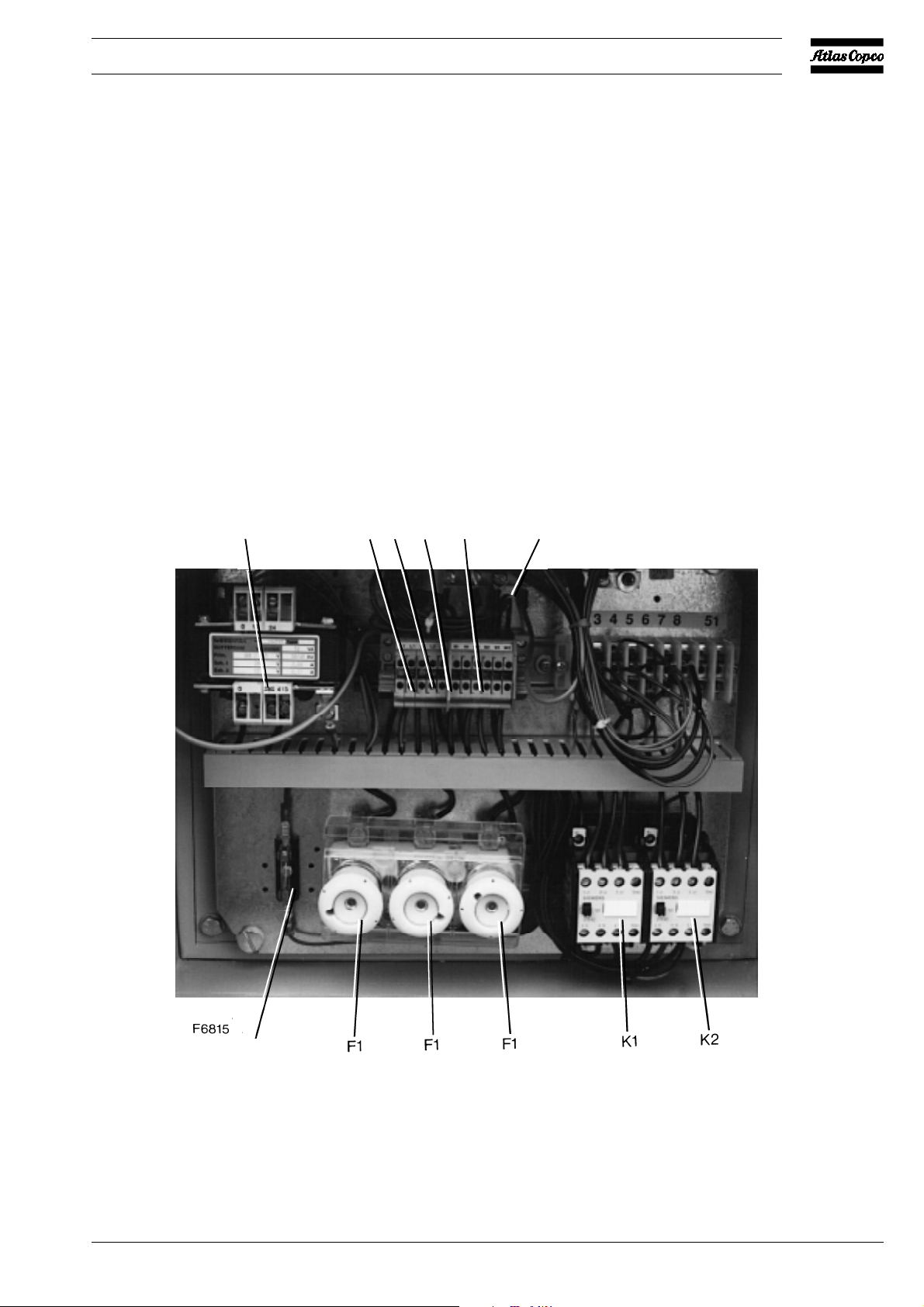

F2

F1. Fuses, fan motor

F2. Fuse, secondary side (24 V) of transformer

K1. Motor contactor, refrigerant compressor

K2. Motor contactor, condenser cooling fan

Fig. 3. Electric cubicle of FD260

L1/3. T erminal, mains

PE. Earth terminal

T1. T ransformer

1X1. T erminal strip

5

Instruction book

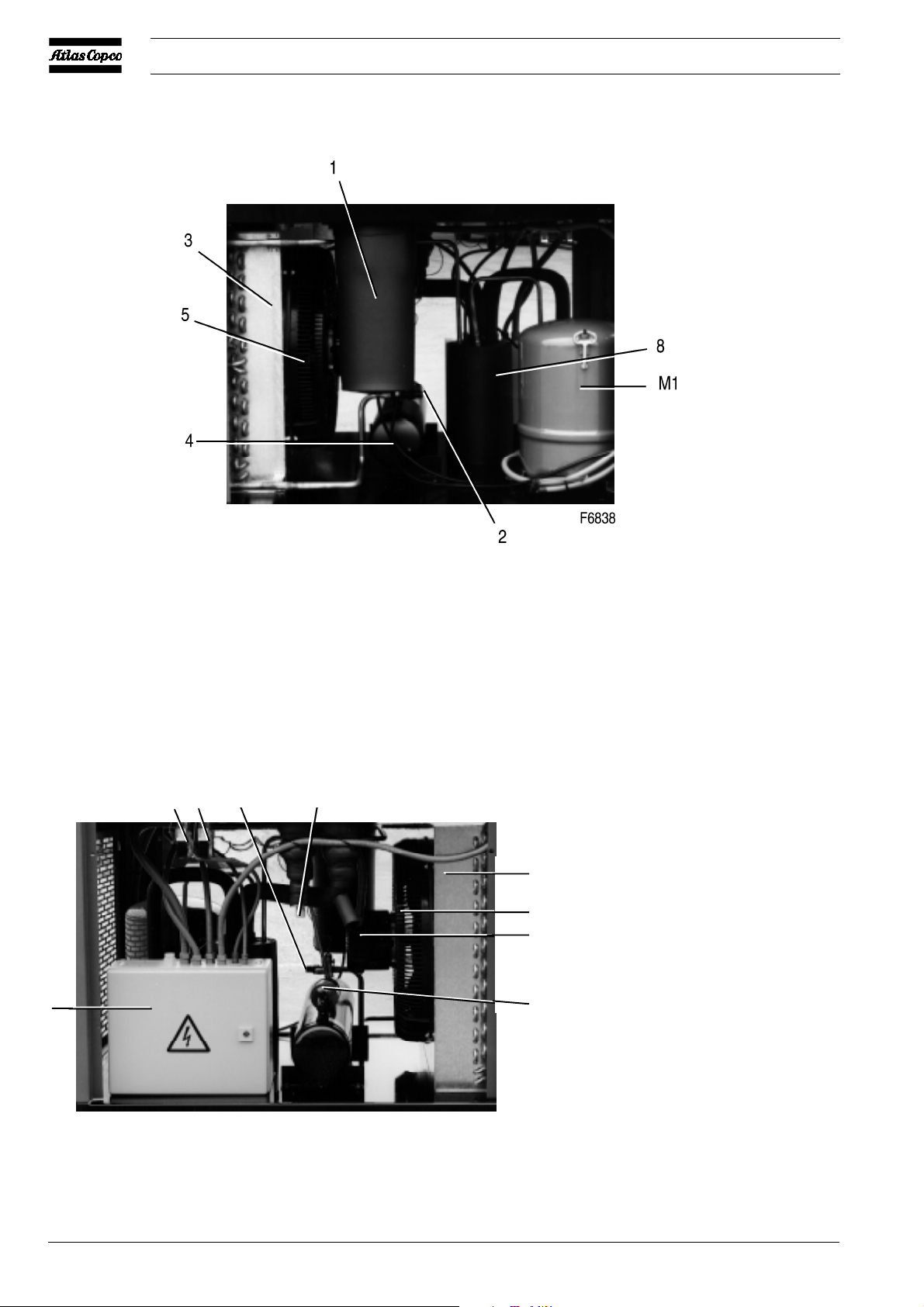

Fig. 4a

S3 S2 2 7

3

5

M2

M1. Refrigerant compressor/motor

M2. Condenser cooling fan motor

S2. High pressure shut-down switch

S3. Fan control switch

9

6

1. Condensate trap with automatic

discharge

2. Refrigerant shut-off valve

3. Condenser

4. Liquid refrigerant receiver

5. Fan

F6839

6. Refrigerant dryer/filter

7. Refrigerant expansion valve

8. Liquid separator

9. Electric cubicle

Fig. 4b

6

Figs. 4. Side views of FD450

2920 1351 01

Loading...

Loading...