Atlas Copco ga37, GA18WVSD, GA30WVSD, GA37WVSD, GA45WVSD User Manual

...

User manual

2920 1456 03 1

Atlas Copco Stationary Air Compressors

GA18, -30, -37, -45, -50, -55, -75, -90 (W) VSD

User manual for Elektronikon® II regulator

1. This manual must be used together with the instruction books for GA18 up to -90 (W) VSD

compressors.

2. From following serial numbers onwards:

- GA18-30 VSD: AII 297 500

- GA37-55 VSD: AII 355 000

- GA75-90 VSD: AII 494 500

Copyright 2003, Atlas Copco Airpower n.v., Antwerp, Belgium.

Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in

particular to trademarks, model denominations, part numbers and drawings.

This instruction book meets the requirements for instructions specified by the machinery directive

98/37/EC and is valid for CE as well as non-CE labelled machines.

No. 2920 1456 03

(Replaces No. 2920 1456 02)

Registration code: APC G18-30 VSD/2002 / 38 / 977

APC G37-55 VSD/2003 / 38 / 975

APC G75-90 VSD/2000 / 38 / 987

2003-07 www.atlascopco.com

User manual

2920 1456 03 2

Contents Page

1 General description............................................................................................................................ 3

1.1 Controlling the compressor............................................................................................................ 3

1.2 Protecting the compressor............................................................................................................. 4

1.2.1 Shut-down and fan motor overload......................................................................................... 4

1.2.2 Shut-down warning.................................................................................................................. 4

1.2.3 Warning ................................................................................................................................... 4

1.3 Service warning ............................................................................................................................. 4

1.4 Automatic restart after voltage failure ............................................................................................ 4

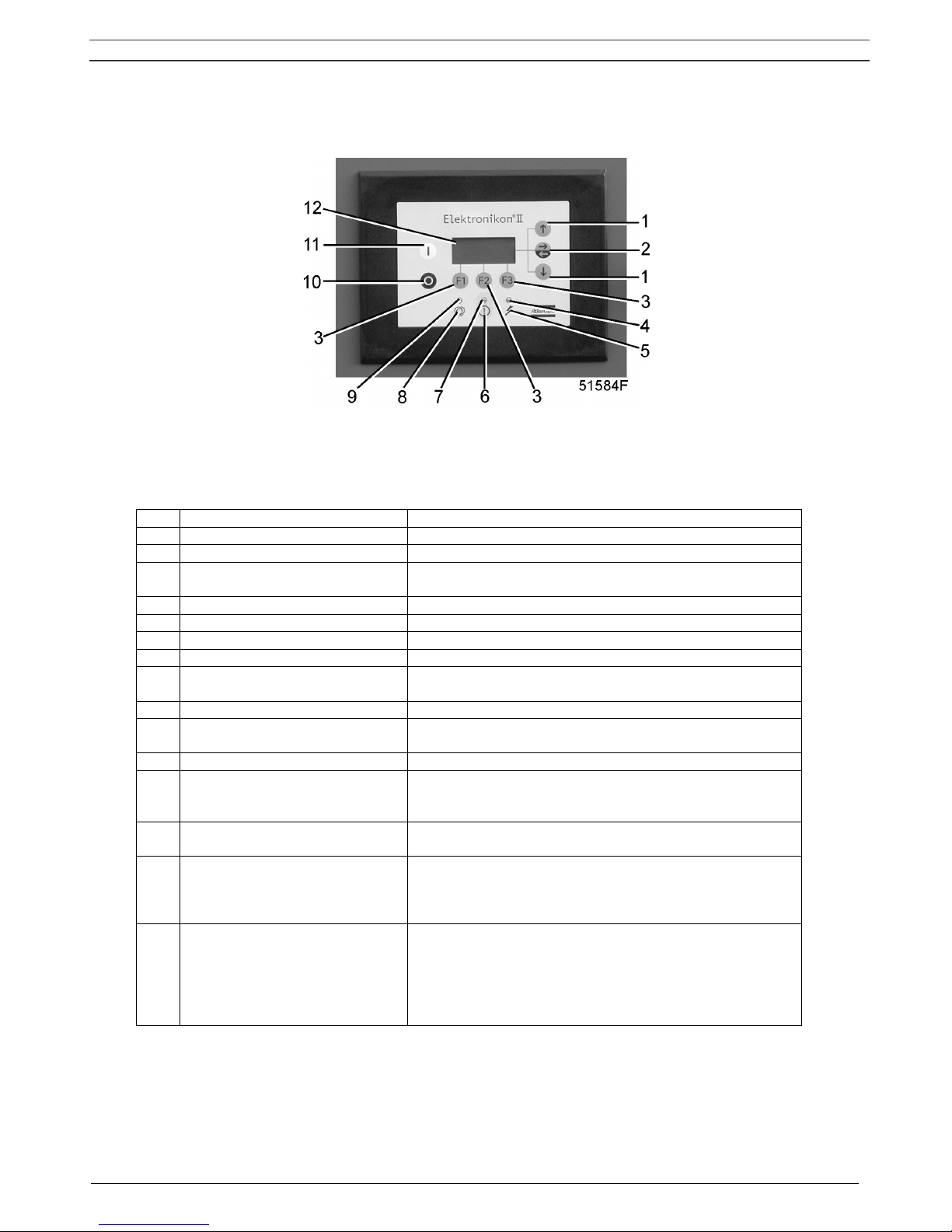

2 Control panel (Fig. 2.1)....................................................................................................................... 5

3 Display - keys...................................................................................................................................... 6

3.1 Display (12-Fig. 2.1)....................................................................................................................... 6

3.2 Scroll keys (1-Fig. 2.1)................................................................................................................... 6

3.3 Tabulator key (2-Fig. 2.1) .............................................................................................................. 7

3.4 Function keys (3-Fig. 2.1) .............................................................................................................. 7

4 Menu-driven control programs ......................................................................................................... 7

4.1 Function of control programs ......................................................................................................... 9

4.2 Main screen ................................................................................................................................... 9

4.3 Calling up other menus................................................................................................................ 10

5 Quick look at actual compressor status ........................................................................................10

6 Status data menu.............................................................................................................................. 11

6.1 No message exists....................................................................................................................... 11

6.2 A shut-down message exists ....................................................................................................... 11

6.3 A shut-down warning message exists ......................................................................................... 12

6.4 A service warning message exists............................................................................................... 13

6.5 A warning message exists ........................................................................................................... 14

7 Measured data menu........................................................................................................................ 14

8 Counters menu ................................................................................................................................. 14

9 Test menu.......................................................................................................................................... 15

10 Modify params – modifying compr./motor settings.................................................................... 16

11 Modifying parameters .................................................................................................................... 17

12 Modifying protection settings ....................................................................................................... 18

13 Modifying service plans................................................................................................................. 20

14 Programming Clock function ........................................................................................................ 22

14.1 Programming start/stop/pressure band commands................................................................... 22

14.2 To activate/deactivate the timer................................................................................................. 24

14.3 To modify a command ............................................................................................................... 25

14.4 To add a command.................................................................................................................... 26

14.5 To delete a command ................................................................................................................ 27

15 Configuration menu ....................................................................................................................... 28

16 Service menu .................................................................................................................................. 30

17 Saved data menu ............................................................................................................................ 32

18 Programmable settings.................................................................................................................. 33

18.1 Compr./motor ............................................................................................................................. 33

18.2 Parameters ................................................................................................................................ 33

18.3 Protections ................................................................................................................................. 34

18.4 Service plan ............................................................................................................................... 34

User manual

2920 1456 03 3

1 General description

The electronic regulator automatically controls the compressor, i.e.:

- matching the compressor output to the air consumption

- stopping the compressor whenever necessary

- restarting the compressor when required

In order to control the compressor and to read and modify programmable parameters, the regulator

has a control panel provided with:

- LEDs indicating the status of the compressor

- a display indicating the operating conditions, a service need or a fault

- keys to control the compressor and to have access to the data collected by the regulator

- buttons to manually start and stop the compressor

- an emergency stop button or isolator switch

In general, the regulator has following functions:

- controlling the compressor

- protecting the compressor

- monitoring components subject to service

- automatic restart after voltage failure (made inactive)

1.1 Controlling the compressor

The regulator matches the air output to the air consumption by speed regulation of the motor.

The regulator takes into account a number of programmable settings, such as:

- net pressure setpoint

- indirect stop offset

- direct stop offset

- proportional band

- integration time

- minimum speed

- minimum stop time

- maximum speed limit

- power recovery time (if automatic restart after voltage failure is activated)

If the net pressure keeps on rising when the compressor runs at minimum speed, the regulator will

stop the compressor. The regulator restarts the motor as soon as the net pressure approaches the

net pressure setpoint.

The regulator stops the compressor whenever necessary:

- Indirect stop: i.e. the compressor runs at minimum speed and the net pressure rises to the

indirect stop level.

- Direct stop: i.e. the compressor runs at a speed in between minimum and maximum and the

net pressure rises above the direct stop setpoint.

Both settings are programmable; see section 18.

User manual

2920 1456 03 4

1.2 Protecting the compressor

1.2.1 Shut-down and fan motor overload

If the compressor element outlet temperature exceeds the programmed shut-down level, the

compressor will be stopped. This will be indicated on the control display.

The compressor will also be stopped in case of overload of the fan motor.

1.2.2 Shut-down warning

If the compressor element outlet temperature exceeds a programmed value just below the shut-down

level, this will also be indicated to warn the operator before the shut-down level is reached.

1.2.3 Warning

A warning message also appears if:

- On water-cooled compressors, the cooling water outlet temperature exceeds the warning level.

- On Full-Feature compressors, the dewpoint temperature exceeds the warning level.

1.3 Service warning

A number of service operations are grouped in plans (called Service plans A, B and C). Each Service

plan has a programmed time interval. If a time interval is exceeded, a message will appear on display

(12-Fig. 2.1) to warn the operator to carry out the service actions belonging to that plan.

1.4 Automatic restart after voltage failure

The regulator has a built-in function to automatically restart the compressor if the voltage is restored

after voltage failure. For compressors leaving the factory, this function is made inactive. If desired,

the function can be activated. Consult Atlas Copco.

Warning

If activated and provided the module was in the automatic operation mode, the compressor will

automatically restart if the supply voltage to the module is restored within a programmed time

period.

The power recovery time (the period within which the voltage must be restored to have an automatic

restart) can be set between 10 and 3600 seconds or to Infinite. If the power recovery time is set to

Infinite, the compressor will always restart after a voltage failure, no matter how long it takes to restore

the voltage. A restart delay can also be programmed, allowing e.g. two compressors to be restarted

one after the other.

User manual

2920 1456 03 5

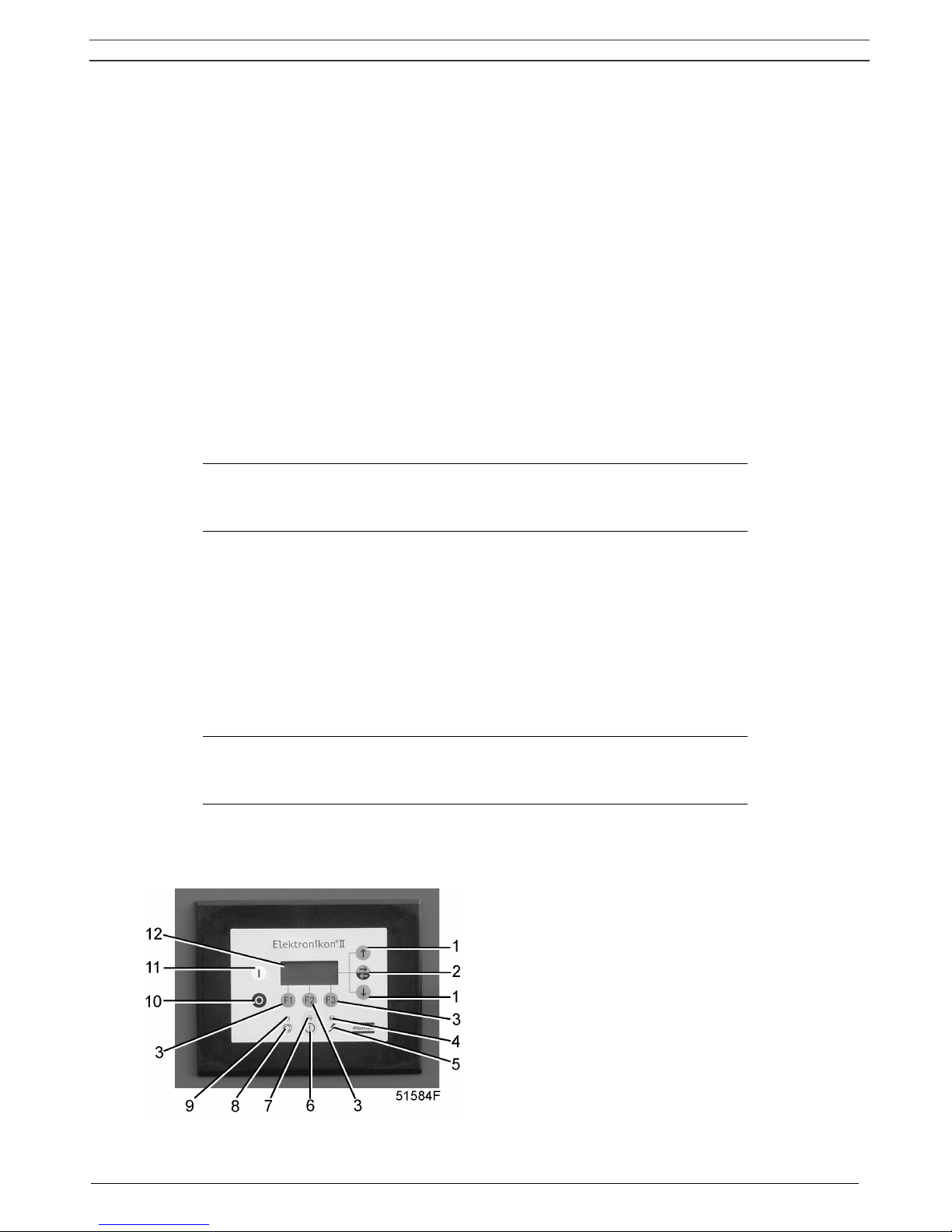

2 Control panel (Fig. 2.1)

Fig. 2.1 Control panel

LEDs/buttons/keys

Ref. Designation Function

1 Scroll keys Keys to scroll through the display.

2 Tabulator key

Key to select the parameter indicated by a horizontal

arrow.

3 Function keys Keys to control and program the compressor. See below.

4 Voltage on LED Indicates that the voltage is switched on.

5 Pictograph Voltage on.

6 Pictograph Alarm.

7 General alarm LED

Is normally out. Is alight or blinks in case of an abnormal

condition. See below.

8 Pictograph Automatic operation.

9 Automatic operation LED

Indicates that the regulator is automatically controlling the

compressor.

10 Stop button Push button to stop the compressor. LED (9) goes out.

11 Start button

Push button to start the compressor. LED (9) lights up

indicating that the regulator is operative (in automatic

operation).

12 Display

Indicates messages concerning the compressor operating

condition, a service need or a fault.

On GA37 VSD (200 V)

Isolator switch

Switch to isolate the compressor from the mains or to stop

the compressor immediately in case of emergency. The

compressor will be depressurized automatically when the

isolator switch is switched off.

On GA18/30/37/45/50/55/75/90

VSD:

Emergency stop button

Push button to stop the compressor immediately in case

of emergency. After remedying the trouble, unlock the

button by pulling it out and press the Rset key.

Note:

Previously produced compressors may be equipped with

an isolator switch

.

User manual

2920 1456 03 6

Function keys

The keys are used:

- To call up or to program settings

- To reset a motor overload, shut-down or service message, or an emergency stop

- To have access to all data collected by the regulator

The functions of the keys vary depending on the displayed menu. The actual function is abbreviated

and indicated on the bottom line of the display just above the relevant key. The most common

abbreviations are listed below.

Abbreviation Designation Function

Add

Add To add compressor start/stop commands (day/hour)

Back

Back To return to a previously shown option or menu

Canc

Cancel

To cancel a programmed setting when programming

parameters

Del

Delete To delete compressor start/stop commands

Help

Help To find the Atlas Copco internet address

Lim

Limits To show limits for a programmable setting

Main

Main To return from a menu to the main screen (Fig. 4.2)

Menu

Menu

Starting from the main screen (Fig. 4.2): to have access to

submenus

Menu

Menu Starting from a submenu, to return to the previous menu

Mod

Modify To modify programmable settings

Prog

Program To program modified settings

Rset

Reset To reset a timer or message

Rtrn

Return To return to a previously shown menu

Xtra

Extra To find information regarding the installed modules

3 Display - keys

3.1 Display (12-Fig. 2.1)

The display has four lines of 16 characters. A typical display is shown in Fig. 4.2. It indicates:

1. On the first three lines:

- the name of the sensor of which the actual reading is displayed

- the unit of measurement and actual reading of the sensor

- messages regarding the compressor operating condition (compressor off, etc.), a service need

(e.g. for the oil filter and air filter) or a fault (e.g. shut-down)

2. On the fourth line, just above the three function keys (F1/F2/F3), the actual functions of these

keys.

3.2 Scroll keys (1-Fig. 2.1)

These keys, labelled with vertical arrows, allow to scroll through the display.

As long as a downward pointing arrow is shown at the utmost right position of the display, the key (1)

with the same symbol can be used to see the next item.

As long as an upward pointing arrow is shown at the utmost right position of the display, the key (1)

with the same symbol can be used to see the previous item.

User manual

2920 1456 03 7

3.3 Tabulator key (2-Fig. 2.1)

This key, labelled with two horizontal arrows, allows the operator to select the parameter indicated by

a horizontal arrow. Only the parameters followed by an arrow pointing to the right are accessible for

modifying.

3.4 Function keys (3-Fig. 2.1)

The keys are used:

- to call up or program settings

- to reset an active fan motor overload, shut-down or service message

- to have access to all data collected by the regulator

The function keys allow to make the required selection from a menu of possibilities. The functions of

the keys vary depending on the displayed menu. The actual function is abbreviated and indicated on

the bottom line of the display just above the relevant key. Only the active and relevant functions at a

moment are shown.

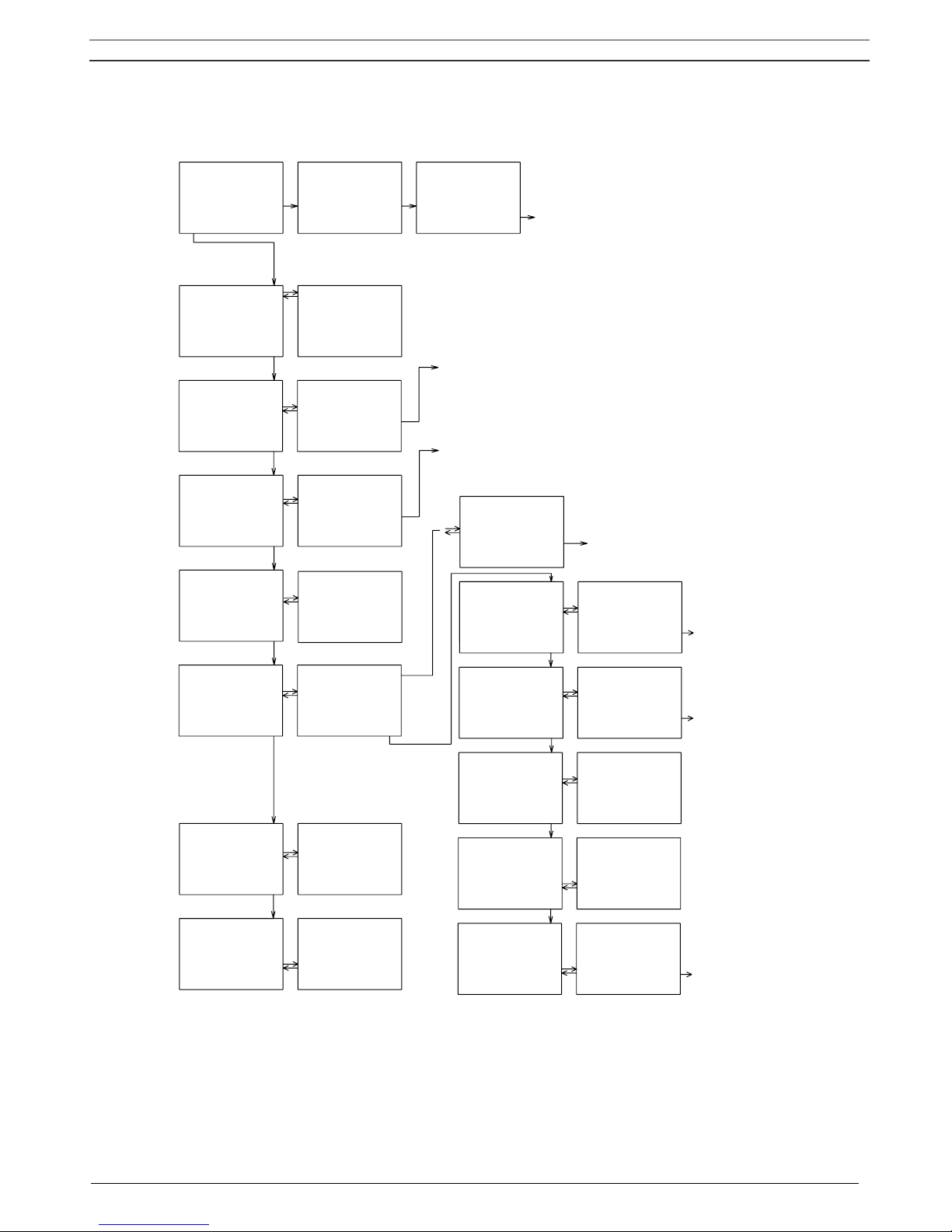

4 Menu-driven control programs

To facilitate programming and controlling the compressor, menu-driven programs are implemented in

the electronic module.

A simplified menu flow is shown in Fig. 4.1.

User manual

2920 1456 03 8

Compressor Out

bar 7.0

rpm 2500 ↓

Menu

Auto Operation

Local Control

Timer Active ↓

Main Help Xtra

Max Pressure ↑

bar 7.5

↓

Main Help Xtra

Status data →

Measured data

Counters ↓

Main

All Conditions

Are OK

Menu

Status data ↑

Measured data →

Counters ↓

Main

Compressor Out

Bar 7.0

↓

Menu

Measured data ↑

Counters →

Test ↓

Main

Counters ↑

Test →

Modify Params ↓

Main

Test ↑

Modify Params →

Service ↓

Main

Modify Params ↑

Service →

Saved data ↓

Main

Loaded hours

hrs 2107

↓

Menu

Compr Motor ↑

Parameters →

Protections ↓

Menu

Setpoint 1

bar 7.0

↓

Menu Mod

Parameters ↑

Protections →

Service Plan ↓

Menu

Compressor Out

Bar 6.8

↓

Menu

Protections ↑

Service Plan →

Clock Function ↓

Menu

Service Timer

Running hours →

hrs 130 ↓

Menu

Service Timer

Running hours →

hrs 130 ↓

Menu

Modify Params ↑

Service

Saved data →

Main

Last Shutdown 1 →

Last Shutdown 2

Last Shutdown 3 ↓

Menu

51591PEN

Service Plan ↑

Clock Function →

Configuration ↓

Menu

Clock Function

Not Activated →

Menu Mod

Time

10:54

↓

Menu Mod

-Compres Speed

-Loaded Hours

-Motor Starts

-Module Hours

-Accumulated Vol

-Compressor Out

-DP Oil Separ

-Element Outlet

-Dewpoint

-Cool Water In

-Cool Water Out

-DP Oil Separ

-Element Outlet

-Dewpoint

-Cool Water In

-Cool Water Out

-ER Water In

-ER Water Out

-Emergency Stop

-Rem Start/Stop

-Overl Fanmotor

-Condens drain

-DD filter

-PD filter

-Motor Starts

-Module Hours

-Accumulated Vol

-Setpoint 2

-Indir Stop Level

-Direct Stop Lev

-Proport Band

-Integrat Time

-Minimum speed

-Max RPM Reduct

Display test ↑

Safety valve

Regreasing ↓

Menu

-DP Oil separator

-Element outlet

-Dewpoint

-Cool Water In

-Cool Water Out

-ER Water In

-ER Water Out

-Emergency Stop

-Rem Start/Stop

-Overl Fanmotor

-Condens drain

-DD filter

-PD filter

-Date

-Date format

-Language in use

-Unit for pressure

-Unit for temperature

-Unit for vibration

-Unit fot level

-Setpoint sel

-CCM (control mode)

-Auto restart

-Password

Service Plan ↑

Clock Function

Configuration →

Menu

Compr Motor →

Parameters

Protections ↓

Menu

Fan Mot St/Day

Number

↓

Menu Mod

-Min Stop Time

-Power Rec Time

-Restart delay

-Commun Time-out

-ER Water In

-ER Water Out

-Emergency Stop

-Rem Start/Stop

-Overl Fanmotor

-Condens drain

-DD filter

-PD filter

Fig. 4.1 Menu flow

User manual

2920 1456 03 9

4.1 Function of control programs

Program/Function Description

Main screen

Shows in short the operation status of the compressor. It is the gateway

to all functions. See Fig. 4.1.

Status data

Calling up the status of the compressor protection functions:

- shut-down

- shut-down warning

- service warning

- warning

Resetting of a shut-down, motor overload and service condition.

Measured data

Calling up:

- actually measured data

- the status of a number of inputs, such as the fan motor overload

protection

Counters

Calling up the:

- loaded hours

- number of motor starts

- regulator (module) hours

- accumulated volume

Test Allows a display test.

Modify Params

Modifying the parameters for:

- compr./motor settings (e.g. setpoints)

- parameters (e.g. minimum stop time)

- protections (e.g. air temperature shut-down level)

- service plans

- clock functions (automatic compressor start/stop/pressure band

commands)

- configuration (time, date, display language, …)

Service Calling up service plans and resetting the timers.

Saved data Calling up the saved data: last shut-down, last emergency stop data

4.2 Main screen

When the voltage is switched on, the Main screen is shown automatically, showing in short the

operation status of the compressor.

Compressor out

bar 7.0

rpm 2500

↓

Menu

F1 F2 F3

Fig. 4.2 Main screen, typical example

If the function keys or arrow keys are not used for some minutes, the display will automatically return

to the Main screen.

Whenever displayed on a submenu screen, press the key Main to return to the Main screen.

User manual

2920 1456 03 10

4.3 Calling up other menus

Starting from the Main screen:

- Use the ↓ key (1) for a quick look at the actual compressor status (see section 5).

- Press the key Menu (F1); the option Status data will be followed by a horizontal arrow:

- either press the tabulator key (2) to select this menu

- or use the ↓ key (1) to scroll until the desired submenu is followed by a horizontal arrow and

then press tabulator key (2) to select this menu.

5 Quick look at actual compressor status

Procedure

1. Starting from the Main screen (see section 4.2), press the ↓ key: A screen similar to the one

below appears:

Auto Operation

Local Control

Timer Active

Main Help Xtra

↓

F1 F2 F3

Fig. 5.1 Example of an actual compressor status display

Line 1 indicates the automatic or manual operation status of the regulator:

<<Auto operation>> means that the regulator automatically adapts the operation of the

compressor, i.e. matching the compressor output to the air consumption.

Line 2 indicates whether the regulator operates in local control or remote control mode:

<<Local control>> means that the start/stop buttons on the keyboard are activated.

<<Remote control>> means that these functions are controlled remotely. Consult Atlas Copco.

Line 3 indicates whether the timer which generates time-based start and stop commands is activated

or not. See section 14.

See section 2 for the functions of keys Main, Help and Xtra.

2. Press the ↓ key to get other data (actual compressor conditions of the compressor) as shown in

Fig. 4.1.

User manual

2920 1456 03 11

6 Status data menu

The status data submenu gives information regarding the status of the compressor protection

functions (shut-down, shut-down warning, service warning and warning) and allows resetting of a shutdown, motor overload and service condition.

Procedure

Starting from the Main screen (see section 4.2):

- Press the key Menu (F1): the option Status data will be followed by a horizontal arrow.

- Press the tabulator key (2).

6.1 No message exists

In this case, LED (7) is out and the message on the display indicates that all conditions are normal

(Fig. 6.1):

All conditions

are OK

Menu

F1 F2 F3

Fig. 6.1 Example of a status data screen

6.2 A shut-down message exists

In case the compressor is shut down, LED (7) will blink.

In case of a shut-down due to too high a temperature at the compressor element outlet, a screen

similar to the one below will appear:

Element Outlet

C 122

Shd Max 120

Menu ** ** Rset

F1 F2 F3

Fig. 6.2 Example of a status data screen

Loading...

Loading...