Atlas Copco DC 200, DC 1000, DC 400, DC 1200, DC 2000 Safety And Operating Instructions Manual

...

Safety and operating instructions

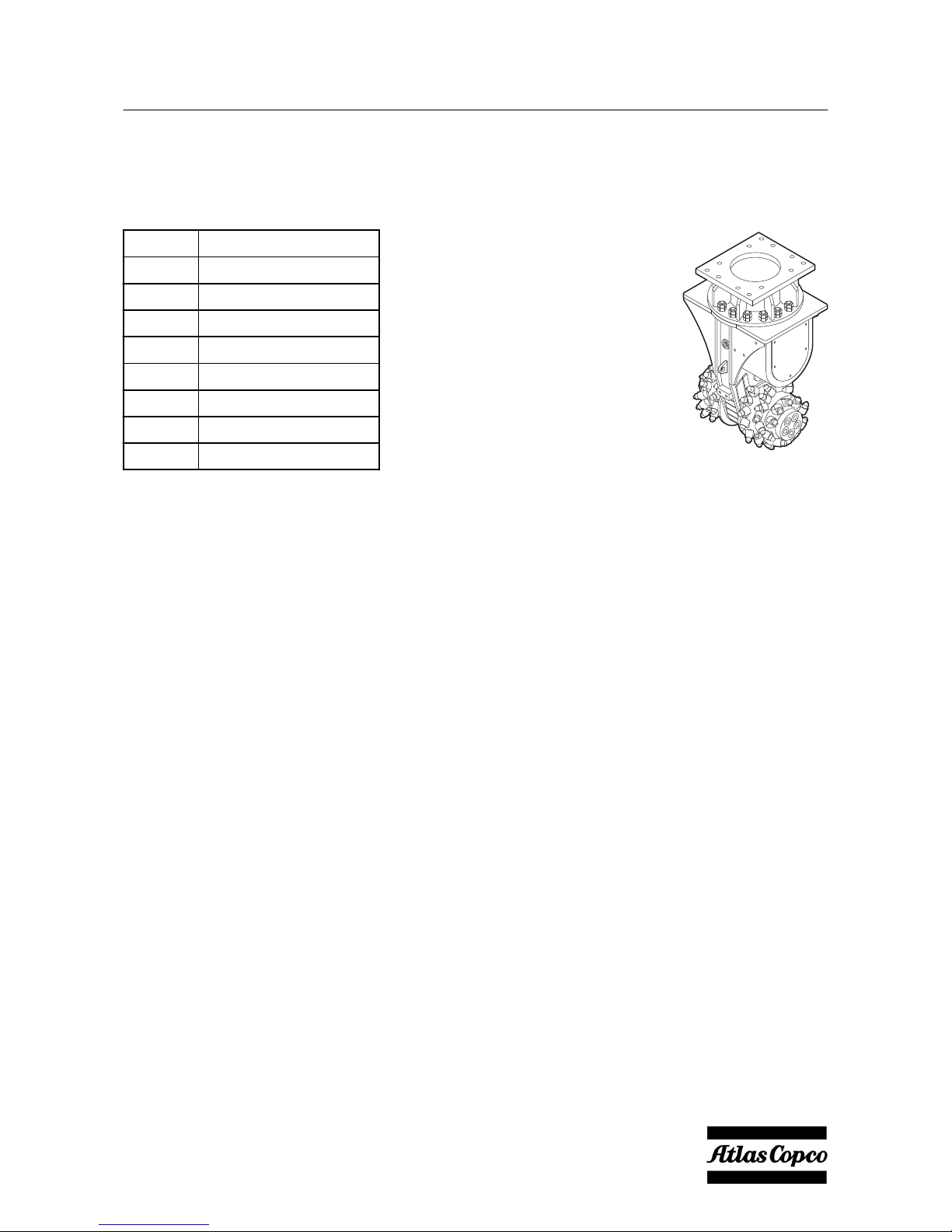

Transverse Drum Cutters

DC 200

DC 400

DC 600

DC 1000

DC 1200

DC 2000

DC 2100

DC 2900

Valid from serial number

DEQ161115

DEQ140244

DEQ140245

DEQ140246

DEQ161163

DEQ132047

DEQ140172

DEQ161168

DC

200, 400, 600, 1000, 1200, 2000, 2100, 2900

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Contents

Introduction .................................................................................................................................................... 7

About these Safety and Operating Instructions .................................................................................... 7

Safety instructions ......................................................................................................................................... 8

Signal words ............................................................................................................................................. 8

Qualification .............................................................................................................................................. 9

Intended use .............................................................................................................................................. 9

Use other than intended ........................................................................................................................... 9

Protective equipment ............................................................................................................................. 10

Carrier, precautions ................................................................................................................................ 10

Transport, precautions ........................................................................................................................... 10

Hydraulic installation, precautions ....................................................................................................... 11

Media/consumables, precautions .......................................................................................................... 11

Explosion and fire, precautions ............................................................................................................ 12

Electrical shock, precautions ................................................................................................................ 12

Falling stones, precautions ................................................................................................................... 12

Emissions, precautions ......................................................................................................................... 13

Handling machines, precautions .......................................................................................................... 13

Repair, precautions ................................................................................................................................ 14

Maintenance works not allowed by Atlas Copco ................................................................................. 14

Changes to the hydraulic attachment, precautions ............................................................................ 14

Environmental pollution, precautions .................................................................................................. 15

Overview ....................................................................................................................................................... 16

Equipment description ........................................................................................................................... 16

Function ................................................................................................................................................... 16

Modules ................................................................................................................................................... 16

Signs / labels ........................................................................................................................................... 18

Name plate .......................................................................................................................................... 18

Labels .................................................................................................................................................. 19

Applications ............................................................................................................................................ 19

Working area and hazardous area ........................................................................................................ 19

Removing the packaging ....................................................................................................................... 20

Scope of delivery .................................................................................................................................... 20

Standard round attack picks ................................................................................................................ 21

Transport ...................................................................................................................................................... 22

Transport using a crane ......................................................................................................................... 22

Transport using a forklift truck .............................................................................................................. 23

Transport using a truck .......................................................................................................................... 23

Installation .................................................................................................................................................... 24

Media/consumables ................................................................................................................................ 24

Mineral hydraulic oil ............................................................................................................................. 24

Non-mineral hydraulic oil ..................................................................................................................... 24

Gear oil ................................................................................................................................................ 24

Preconditions for the carrier ................................................................................................................. 24

Preconditions for adapter plate ............................................................................................................. 25

Manufacturing the adapter plate ........................................................................................................... 25

Attaching the hydraulic attachment to the carrier ............................................................................... 26

Mechanical mounting aspects ............................................................................................................. 26

First installation .................................................................................................................................... 27

Making the hydraulic connections ........................................................................................................ 28

Mechanical mounting aspects ............................................................................................................. 29

Removing the hydraulic attachment from the carrier ......................................................................... 30

Operation ...................................................................................................................................................... 31

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Contents

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

3

Preparations before starting .................................................................................................................. 32

Commissioning ....................................................................................................................................... 33

Checks during commissioning ............................................................................................................. 33

Switching the transverse drum cutter on and off ................................................................................ 33

Functional test ........................................................................................................................................ 33

Correct operation .................................................................................................................................... 34

Prohibited operation ............................................................................................................................... 35

Cylinder end positions ......................................................................................................................... 35

Moving the carrier ................................................................................................................................ 35

Lifting/Transporting .............................................................................................................................. 35

Impacting/chopping .............................................................................................................................. 36

Activities after use .................................................................................................................................. 36

Turning the transverse drum cutter ...................................................................................................... 36

Maintenance ................................................................................................................................................. 38

Maintenance works not allowed by Atlas Copco ................................................................................. 39

Maintenance schedule ........................................................................................................................... 40

Depressurising the hydraulic system ................................................................................................... 41

Cleaning ................................................................................................................................................... 41

Checking bolted connections ................................................................................................................ 41

Checking the hydraulic attachment and adapter plate for cracks ..................................................... 42

Checking the adapter plate bolts for wear ........................................................................................... 42

Change gear oil ....................................................................................................................................... 42

Oil change intervals ............................................................................................................................. 42

Preparation .......................................................................................................................................... 42

Drain off gear oil .................................................................................................................................. 42

Fill up gear oil ...................................................................................................................................... 43

Check the round attack picks ................................................................................................................ 44

Replace round attack picks ................................................................................................................... 44

Replace round attack pick with knock on retainer ............................................................................... 45

Replace round attack pick with retaining sleeve .................................................................................. 46

Replace round attack picks with quick snap retainer ........................................................................... 47

Replace round attack picks with retaining ring .................................................................................... 48

Replace cutter drums ............................................................................................................................. 49

Disassemble cutter drums ................................................................................................................... 49

Assemble cutter drums ........................................................................................................................ 50

Assemble and disassemble rotatable upper part ................................................................................ 52

Disassemble rotatable upper part ........................................................................................................ 52

Assemble rotatable upper part ............................................................................................................. 52

Checking hydraulic lines ....................................................................................................................... 53

Checking and cleaning the hydraulic oil filter of the carrier .............................................................. 53

Replace hydraulic hoses ........................................................................................................................ 54

Actions following maintenance ............................................................................................................. 54

Bolt connections/ Tightening torques .................................................................................................. 55

Troubleshooting ........................................................................................................................................... 57

Faults table .............................................................................................................................................. 57

Cutter drums do not turn / are blocked ................................................................................................ 58

Cutter drums turn too slowly ................................................................................................................. 58

Transverse drum cutter stops moving with light pressure ................................................................ 58

Unusual oscillation of the cutter drums ............................................................................................... 59

Round attack picks do not turn ............................................................................................................. 59

Unusually loud gear noise ..................................................................................................................... 59

Unusually loud noise from the hydraulic motor .................................................................................. 59

Overpressure cover for the hydraulic motor deformed, oil leak on sealing surface, oil leak at the

pressure limiting valve ........................................................................................................................... 60

Behaviour following fault elimination ................................................................................................... 60

Repair ............................................................................................................................................................ 61

Contents DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

4 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Sending in the hydraulic attachment for repairs ................................................................................. 61

Storage .......................................................................................................................................................... 62

Transverse drum cutter .......................................................................................................................... 62

Short storage ....................................................................................................................................... 62

Long storage ........................................................................................................................................ 62

Cutter drums ........................................................................................................................................... 62

Round attack picks ................................................................................................................................. 62

Disposal ........................................................................................................................................................ 63

Transverse drum cutter .......................................................................................................................... 63

Hydraulic hoses ...................................................................................................................................... 63

Hydraulic oil ............................................................................................................................................ 63

Gear oil .................................................................................................................................................... 63

Technical specifications .............................................................................................................................. 64

Appendix ................................................................................................................................................. 66

Hydraulic installation version 1 for hydraulic hammer ......................................................................... 66

Hydraulic installation version 2 for hydraulic shear systems ............................................................... 67

Hydraulic settings DC 200 ................................................................................................................... 68

Hydraulic settings DC 400 ................................................................................................................... 69

Hydraulic settings DC 600 ................................................................................................................... 70

Hydraulic settings DC 1000 ................................................................................................................. 71

Hydraulic settings DC 1200 ................................................................................................................. 72

Hydraulic settings DC 2000 ................................................................................................................. 73

Hydraulic settings DC 2100 ................................................................................................................. 74

Hydraulic settings DC 2900 ................................................................................................................. 75

EC Declaration of Conformity (EC Directive 2006/42/EC) ........................................................................ 76

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Contents

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

5

Introduction

Thank you for choosing an Atlas Copco product!

We have been working according to a customeroriented approach since 1873. Our innovative and

ergonomic solutions help our customers lower

costs and achieve better business results.

Atlas Copco has a worldwide, comprehensive

sales and service network of Customer Centers

and dealers. Our professionals are specialists with

a thorough product knowledge and considerable

application experience.

This allows us to offer our customers effective

service and know-how throughout the world,

enabling them to achieve greater operating

efficiency.

Construction Tools GmbH

P.O. Box: 102152

Helenenstraße 149

D - 45021 Essen

Tel.: +49 201 633-0

About these Safety and

Operating Instructions

The aim of these Instructions is to familiarise you

with the safe and effective operation of the

hydraulic attachment. You will also find instructions

for regular maintenance activities for the hydraulic

attachment in this document.

Please read these Instructions carefully prior to the

first attachment and use of the hydraulic

attachment.

The different designation of the texts means as

follows:

►

Action step in a safety instruction

♦

Action step

1.

2.

Established operation process

A

B

C

Explanation of the elements of a drawing

•

•

•

Listing

Symbols used in illustrations have the following

meanings:

permitted operation

prohibited operation

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

7

Safety instructions

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

Read these Safety and operating instructions and

specifically all safety instructions before using the

hydraulic attachment. This will:

•

prevent the risk of injuries and fatal accidents

for yourself and others,

•

protect the hydraulic attachment and other

property against material damage,

•

protect the environment against environmental

damage.

Follow all instructions in these Safety and

operating instructions.

Store these Safety and operating instructions in

the document compartment of the carrier cab.

Anyone

•

transporting,

•

installing or removing,

•

operating,

•

maintaining,

•

repairing,

•

storing or

•

disposing of

the hydraulic attachment must have read and

understood these Safety and operating

instructions.

These Safety and operating instructions belong to

the hydraulic attachment. Keep it for the life of the

product. Ensure, if applicable, that any received

amendment is incorporated in the instructions.

Hand over the Safety and operating instructions if

ever you lend, rent out or sell the hydraulic

attachment.

All safety regulations listed in this manual comply

with the laws and regulations of the European

Union. Also observe the additional national/

regional regulations.

Hydraulic attachment operation outside the

European Union is subject to the laws and

regulations valid in the country of use. Please

observe any other, more stringent regional

regulations and legislation.

Read the carrier manufacturer's Safety and

operating Instructions before attaching the

hydraulic attachment to the carrier and operating it.

Observe all instructions.

Signal words

The signal words Danger, Warning, Caution, and

Notice are used as follows in these Safety and

operating instructions:

DANGER indicates a hazardous situation

which, if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation

which, if not avoided, could result

in death or serious injury.

CAUTION indicates a hazardous situation

which, if not avoided, could result

in minor or moderate injury.

NOTICE The signal word NOTICE is used

to address practices related to

possible property damage but not

related to personal injury.

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

8 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Qualification

Transporting the hydraulic attachment is only

permitted if carried out by people who:

•

are authorised to operate a crane or a forklift

truck according to the applicable national

provisions,

•

know all the relevant national/regional safety

provisions and accident prevention rules,

•

have read and understood the safety and

transport chapter of these Safety and operating

instructions.

First installation and commissioning of the

hydraulic attachment is only permitted if carried out

by people who:

•

are authorised by Construction Tools GmbH,

•

know all the relevant national/regional safety

provisions and accident prevention rules,

•

have read and understood these Safety and

operating instructions.

Installing, maintaining, storing and disposing of

the hydraulic attachment are only permitted if

carried out by people who:

•

know all the relevant national/regional safety

provisions and accident prevention rules,

•

have read and understood these Safety and

operating instructions.

Operating the hydraulic attachment is only

permitted if carried out by qualified carrier drivers.

Carrier drivers are qualified if they:

•

have been trained to operate a carrier

according to the national regulations,

•

know all the relevant national/regional safety

provisions and accident prevention rules,

•

have read and understood these Safety and

operating instructions.

Testing the hydraulic installation is only

permitted if carried out by professionals.

Professionals are people who are authorised to

approve a hydraulic installation for operation

according to the national regulations.

Repairing the hydraulic attachment is only

permitted if carried out by professionals trained by

Construction Tools GmbH. These professionals

must have read and understood these Safety and

operating instructions. They must follow all safety

instructions and guidelines for repair. Otherwise

the operational safety of the hydraulic attachment

is not guaranteed.

Personnel (carrier operator, maintenance

personnel) must receive instructions from the

operator regularly. For the purpose of improved

traceability, the provision of instructions must be

recorded.

Intended use

Only attach the transverse drum cutter to a

hydraulic carrier of a suitable load-bearing

capacity. Read the carrier manufacturer's Safety

and operating instructions before attaching the

transverse drum cutter to the carrier and operating

it. Observe all instructions.

The transverse drum cutter is intended exclusively

for mounting on a hydraulic excavator or, following

agreement with the Atlas Copco Customer Center/

dealer in your area, with another carrier.

The transverse drum cutter serves exclusively to

cut:

•

Rock

•

Concrete (reinforced and non-reinforced)

•

Asphalt

•

Frozen soil

•

Ice

Furthermore, the transverse drum cutter is suitable

for cutting ditches and tunnels. The transverse

drum cutter can be used to a depth of 30 m under

water.

When cutting with the transverse drum cutter,

check the compressive strengths of the rock to be

cut (see chapter Technical specifications).

Intended use also includes adhering to all

specifications contained in this manual.

Any further use which exceeds or is contrary to the

intended use is considered inappropriate use.

Use other than intended

Misusing the transverse drum cutter or the boom

can lead to dangerous situations.

•

Do not use the transverse drum cutter in areas

with a risk for explosions.

•

Do not cut any materials other than those

mentioned in chapter Intended use.

•

Do not carry out any impacting work.

•

Do not operate the transverse drum cutter if

picks are broken.

•

Do not use the transverse drum cutter as a

device for lifting people or materials.

•

Do not use the transverse drum cutter as a

surface for carrying or transporting machines,

materials or tools.

•

Do not use the transverse drum cutter to take

the weight of the carrier.

Claims of any kind as a result of damages arising

from misuse are excluded.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

9

Protective equipment

Personal protective equipment must comply with

the applicable health and safety regulations.

Always wear the following personal protective

equipment:

•

protective helmet

•

safety glasses with side protectors

•

protective gloves

•

protective shoes

•

warning vest

•

Light respiratory protection

•

Protective work clothing

Protective work clothing is tight-fitting work

clothing with low resistance to tearing, with tight

sleeves and without projecting parts. It is

primarily used to protect against entanglement

by moving machine parts. Do not wear rings,

chains or other jewellery.

Carrier, precautions

WARNING Falling carrier

If the load-bearing capacity of the carrier used is

insufficient, the carrier will not be stable. It can

topple over and cause injuries and damage.

Using a carrier whose load-bearing capacity is too

high will greatly burden the hydraulic attachment

causing it to wear faster.

►

Only attach the hydraulic attachment to a

hydraulic carrier of a suitable load-bearing

capacity.

►

The carrier must remain stable at all times.

►

Read the carrier manufacturer's Safety and

operating Instructions before attaching the

hydraulic attachment to the carrier and

operating it. Observe all instructions.

Transport, precautions

WARNING Risk of death due to suspended

loads

When lifting loads these can swing out and fall.

This can result in serious injuries or even death.

►

Never stand underneath or in the swinging

range of suspended loads.

►

Only move loads under supervision.

►

Only use approved lifting equipment and lifting

gear with sufficient load bearing capacity.

►

Do not use worn lifting gear (ropes, belts,

chains, shackles etc.).

►

Do not place lifting gear such as ropes and

belts on sharp edges or corners, do not knot

these or twist them.

►

When leaving the workplace, set down the load.

WARNING Injury due to swivelling load

When transporting the load by crane it can swivel

and cause severe injuries and considerable

damage to property.

►

Ensure that no personnel, objects or obstacles

are located in the swivel range of the load.

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

10 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Hydraulic installation,

precautions

WARNING Hydraulic pressure too high

If the hydraulic pressure is too high, the parts of

the hydraulic attachment will be exposed to

excessively high loads. Parts can break loose or

burst causing serious injuries.

►

Lay the drain line of the pressure relief valve

directly in the tank to ensure the safe

functioning of the pressure relief valve!

►

The pressure relief valve must be set at the

maximum static pressure.

►

The pressure relief valve setting must be

checked to ensure that the maximum static

pressure (see chapter Technical specifications)

of the hydraulic installation is not exceeded at

any time. Attach a lead seal to the pressure

relief valve.

►

Prior to their first use, the safety facilities on the

hydraulic installation must be checked by a

professional/authorised monitoring body for

their quality (CE mark etc.), suitability and

proper functioning.

►

If any significant changes are made to the

hydraulic installation, a new acceptance

inspection is to be carried out in accordance

with the relevant national safety provisions.

WARNING Hot hydraulic oil squirting out

The hydraulic system is under high pressure.

Hydraulic lines may spring a leak or burst.

Hydraulic oil squirting out can lead to serious

injury.

►

When attaching the hydraulic attachment do not

route any hydraulic lines through the carrier's

cab.

►

Only use hydraulic lines which comply with the

following quality requirements:

Hydraulic hoses with 4 reinforcement steel

wires 4SP and 4SH according to DIN EN 856,

Hydraulic hoses with high tensile steel wire

braid 1SN and 2SN according to DIN EN 853,

Hydraulic pipes, seamless cold-drawn steel

pipes to DIN EN 10305.

Media/consumables,

precautions

WARNING Hot hydraulic oil under high

pressure

Hydraulic oil will squirt out under high pressure if

there is a leakage. The jet of oil might penetrate

people's skin and cause permanent damage. Hot

hydraulic oil can cause burns.

►

Never use your hands to find leaks.

►

Always keep your face away from a possible

leak.

►

If hydraulic oil has penetrated your skin consult

a doctor immediately.

WARNING Hydraulic oil spills

Spilt hydraulic oil can make a floor slippery. If

people slip they can be injured. Hydraulic oil is

environmentally harmful and must not penetrate

the ground or enter the water table or water

supplies.

►

Make sure not to spill any hydraulic oil.

►

Immediately clean the floor if you have spilt

hydraulic oil.

►

Observe all safety and environmental protection

provisions when handling hydraulic oil.

WARNING Skin infections/diseases due to

oil and grease

Hydraulic oil and grease can cause rashes (or

even eczema) if they come into contact with the

skin.

►

Avoid all skin contact with hydraulic oil and

grease.

►

Use a suitable skin protection product.

►

Always wear safety gloves when working with

hydraulic oil or grease.

►

Immediately clean any skin that has been

contaminated by oil or grease with water and

soap.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

11

Explosion and fire,

precautions

DANGER Explosion and fire

Explosions cause serious injury or death.

If the hydraulic attachment encounters explosives

in operation, it may cause an explosion.

►

Never operate the hydraulic attachment in the

direct vicinity of explosives.

►

Make sure that no explosives are hidden in the

ground.

►

Check gas line position plans of the complete

construction area.

DANGER Explosion and fire

Operating the hydraulic attachment may create

sparks which ignite highly flammable gases.

This may lead to fire or an explosion.

►

Never work in an environment with highly

flammable substances.

►

Make sure that there are no hidden sources of

gas in the work area.

►

Check gas line position plans of the complete

construction area.

DANGER Explosion and fire

Dust-rich air can form an explosive atmosphere

which may ignite when operating the hydraulic

attachment.

This may lead to fire or an explosion.

►

Never operate the hydraulic attachment in an

explosion-hazard atmosphere.

►

Always provide sufficient ventilation when

working in buildings or in a confined area.

Electrical shock, precautions

DANGER Electrical shock

Any contact of the hydraulic attachment with

electric circuits or other sources of electricity will

lead to an electric shock, resulting in serious injury

or death. The hydraulic attachment is not

electrically insulated.

►

Never work in the vicinity of electric circuits or

other sources of electricity.

►

Make sure that there are no hidden circuits in

the work area.

►

Check wiring diagrams.

Falling stones, precautions

DANGER Fragments flying around

Fragments of material which come loose while

operating the hydraulic attachment may be flung

away and can cause serious injury if people are hit

by them. Small objects falling from a great height

can also cause serious damage.

During hydraulic attachment operation the danger

zone is considerably greater than during the

excavation operation due to fragments of stone

and pieces of steel flying around, and for this

reason the danger zone must, depending on the

type of material to be worked on, be enlarged

correspondingly, or secured in a suitable manner

through corresponding measures.

►

Secure the danger zone.

►

Ensure that no persons are within a distance of

15 metres during cutting work.

►

Ensure that no persons are within a distance of

50 metres during cutting work on reinforced

steel.

►

Stop the hydraulic attachment immediately if

anyone enters the danger zone.

►

Close the windscreen and the side windows of

the driver's cab.

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

12 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Emissions, precautions

WARNING Noise hazard

Operating the hydraulic attachment creates a loud

noise. Long term high sound pressure level can

affect your hearing.

►

Wear suitable hearing protection.

WARNING Lung disease

Dust may be generated when operating the

hydraulic attachment. If dust from rocks or silica

dust, produced when operating the hydraulic

attachment on rocks, concrete, asphalt or other

such materials, is inhaled this may lead to silicosis

(dust lungs, a severe lung disease). Silicosis is a

chronic disease which may lead cancer and death.

►

Wear a suitable breathing mask.

WARNING Vibration hazards

When working with the transverse drum cutter

severe vibrations can occur and may cause

considerable significant injuries and chronic

damage to health.

►

Operate the transverse drum cutter with a

constant load, in order to minimise existing

vibrations.

►

Avoid abrupt starting up or stopping of the

cutter drums.

WARNING Risk of death if exhaust gases

are not vented

When working in buildings or tunnels, exhaust

gases from the carrier (diesel motor) can collect

and cause poisoning or even death.

►

Effectively vent exhaust gases from buildings or

tunnels using a ventilation system.

►

Keep the cabin doors of the carrier closed.

WARNING Hot surfaces

The cutter drums of the transverse drum cutter can

become very hot in operation. Skin contact with hot

surfaces results in severe burns to the skin.

►

Always wear heat-resistant protective work

clothes and protective gloves, when working in

close proximity to hot surfaces.

►

Prior to all work, check the transverse drum

cutter to ensure that all surfaces have cooled to

the ambient temperature.

Handling machines,

precautions

WARNING Injuries due to incorrect

operation

Incorrect operation can result in severe injuries

and may cause considerable damage to property.

►

Carry out all operating steps in accordance with

these Safety and operating instructions.

►

Prior to starting work, ensure that:

•

All covers and safety devices are installed

and are fully functional.

•

No persons are in the hazardous area.

►

Never switch off any safety devices during

operations or bridge these.

WARNING Injuries due to unclean

workplace

A dirty workplace can cause accidents and may

result in severe injuries.

►

Always keep the accesses to the carrier cabin

clean.

►

Always keep the cabin windows clean.

►

Do not leave parts or objects lying around the

working area.

WARNING Injuries due to missed

inspection and repair work

Disregarding or neglecting daily inspections can

result in serious accidents and lead in turn to the

severe injuries associated with them.

►

Carry out all daily inspections before and after

work.

►

Report any faults or damage to maintenance

personnel immediately and instruct them to

repair them.

►

Only restart the carrier once the fault or

damage has been repaired.

WARNING Narcotics, alcohol and drugs

Narcotics, alcohol and medicinal drugs make their

users less alert and affect their ability to

concentrate. Negligence and incorrectly assessing

a situation can result in serious injury or death.

►

Never work on or with the hydraulic attachment

when under the influence of narcotics, alcohol

or drugs which affect your alertness.

►

Never allow other people who are under the

influence of narcotics, alcohol or drugs which

affect their alertness to work on or with the

hydraulic attachment.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

13

Repair, precautions

Maintenance work must be conducted exclusively

by authorised and trained maintenance personnel.

Maintenance works not allowed by Atlas

Copco

Some maintenance activities must be carried out

exclusively by Atlas Copco. If such maintenance

activities are required, consult the Atlas Copco

customer center/Dealer in your area in order to

ensure that they proceed safely.

The following maintenance activities are not

allowed by Atlas Copco:

•

Repairs to the gear

•

Replacing wear sleeves and pick boxes

•

Welding work on the cutter drums

•

Welding work on the gear housing

Changes to the hydraulic

attachment, precautions

WARNING Changes to the hydraulic

attachment

Changes to the hydraulic attachment or the

adapter plate may lead to serious injury.

►

Never carry out any changes to the hydraulic

attachment or the adapter plate.

►

Only use original parts or accessories approved

by Atlas Copco.

►

Modifications that entail new hazards may

require a new procedure for assessing

conformity.

WARNING Injuries due to the use of

incorrect spare parts

The use of incorrect or defective spare parts can

result in risks to personnel as well as damage,

malfunctioning or a total failure of the transverse

drum cutter.

►

Only use original parts or accessories approved

by Atlas Copco.

►

If there are any questions, consult the Atlas

Copco Customer Center/dealer in your area.

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

14 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Environmental pollution,

precautions

NOTICE Environmental pollution due to hydraulic

oil

Hydraulic oil is permanently environmentally

harmful. Escaped hydraulic oil will lead to

groundwater and soil contamination. Organisms

may die.

►

Collect any hydraulic oil which escapes to avoid

environmental pollution. For minor volumes use

an absorbing medium (in case of an emergency

use soil). In case of major leakages contain the

hydraulic oil. It must not drain off and penetrate

the ground or enter the water table or water

supplies.

►

Collect contaminated absorbing medium or soil

in a watertight box/container and close it tight.

►

Contact an authorized waste management

company.

►

Dispose of all contaminated material in

accordance with the applicable environmental

regulations.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

15

Overview

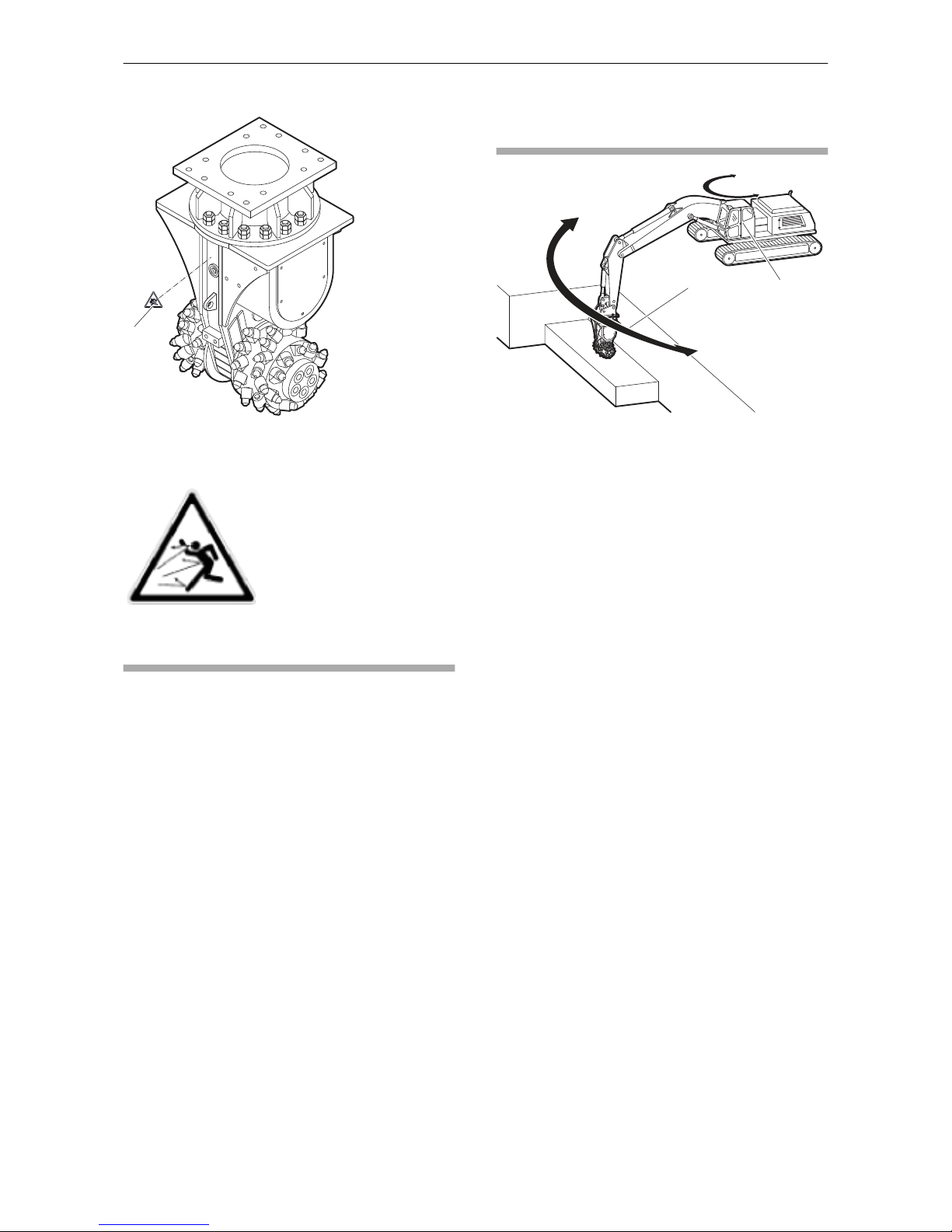

Equipment description

The illustration gives an overview of the main parts

and components of the hydraulic attachment.

Actual details may differ.

D

E

F

A

B

C

A. Gear housing

B. Round attack pick

C. Pick box

D. Cutter drum

E. Transport lug

F. Rotatable upper part

Function

The operation of a transverse drum cutter is

described in a simplified version below:

The transverse drum cutter is an attachment for

hydraulic carriers. The cutter drums are powered

by the hydraulic motor and the gear of the

transverse drum cutter. The round attack picks are

attached to the cutter drums at a defined angle. A

rotating motion of the cutter drums facilitates the

cutting process and thus reduces the size of the

rock.

Modules

Cutter drums

The transverse drum cutter is equipped with one

left and one right cutter drum. These cutter drums

are fastened by means of screws and special

clamping sleeves directly to the drive shafts. A

certain number of pick boxes are attached to the

surface of the cutter drums. These hold the round

attack picks in position.

The cutter drums can be designed with charging

spirals (see arrow).

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

16 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Transport lug

E

The transport lug (E) serves as an anchor point for

the lifting gear when transporting the transverse

drum cutter.

Rotatable upper part

The transverse drum cutter is fastened to a

suitable adapter plate on the carrier boom via the

rotatable upper part. The rotatable upper part is

bolted to the adapter plate. Additionally, the

transverse cutter drum can be rotated via the

rotatable upper part relative to the axis of the

boom.

Gear housing

The gear housing contains a spur gear driven by a

hydraulic motor. The gear's drive shafts turn the

cutter drums. The hydraulic motor transfers the

drive moment through the gear to the cutter drums.

Round attack picks

The round attack picks are made of steel and have

a brazed tungsten carbide tip. The round attack

picks are held in the pick boxes.

The appearance of the round attack picks may

deviate from the image shown here.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

17

Pick boxes

The pick boxes are welded onto the cutter drums

for holding round attack picks. Some pick boxes

may have a wear sleeve, which can be exchanged.

Signs / labels

WARNING Missing warnings

The name plate and the labels on the hydraulic

attachment contain important information about the

hydraulic attachment and for personal safety. A

missing warning can lead to overlooking or

misinterpretation of possible risks and cause

personal hazards. The signs and labels must

always be clearly legible.

►

Immediately replace any defective name plates

and labels.

►

Use the spare parts list to order new name

plates and labels.

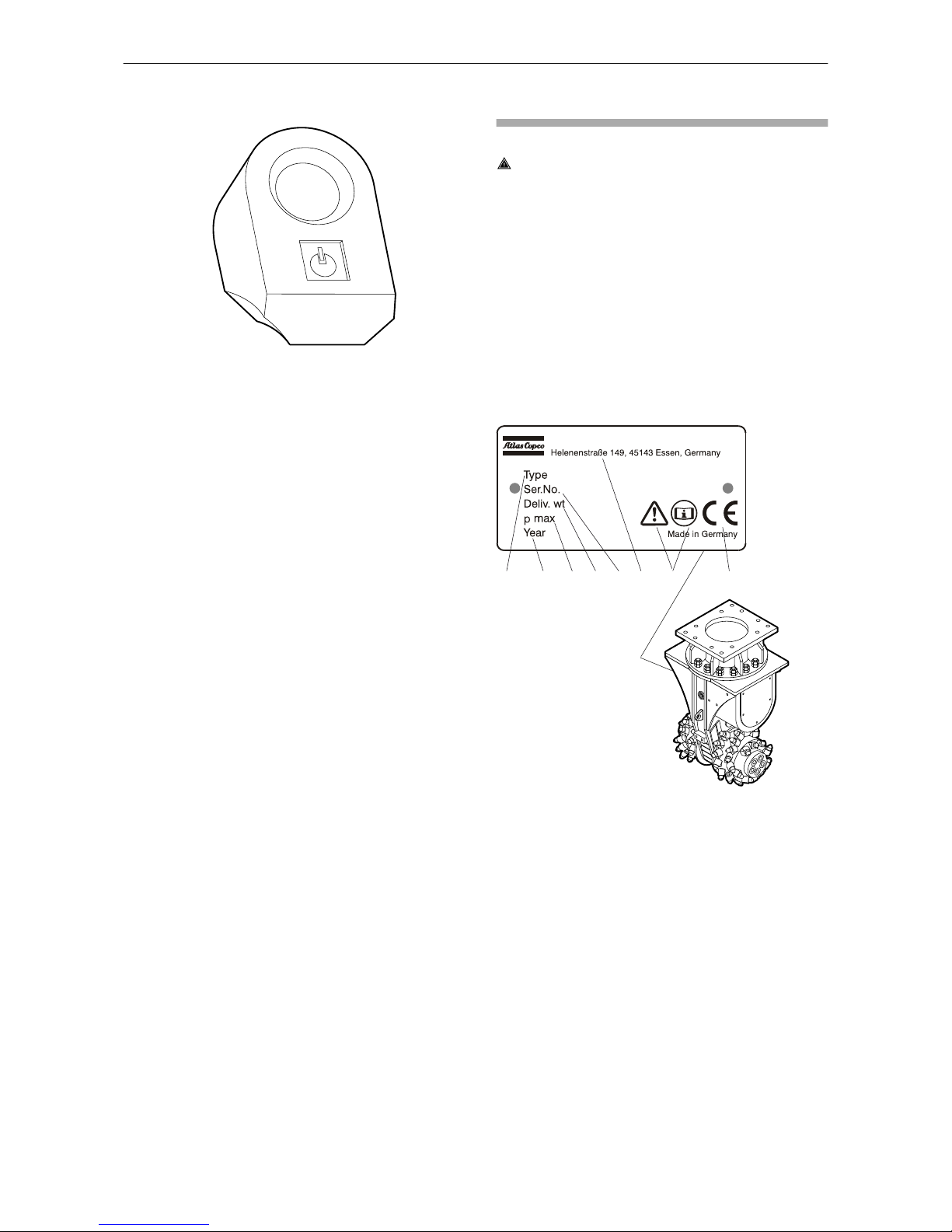

Name plate

A B C D E F G H

Construction Tools GmbH

A. Model

B. Year of construction of hydraulic attachment

C. Max. hydraulic pressure

D. Weight of hydraulic attachment

E. Serial number

F. Name and address of manufacturer

G. The warning symbol and the book symbol

indicate that the Safety and Operating

Instructions must be read prior to use of the

hydraulic tool and in particular the chapter on

Safety.

H. The CE symbol indicates that the hydraulic

attachment was produced in conformity with

CE. You can find further information about this

in the enclosed EC Declaration of Conformity.

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

18 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Labels

A

A. Danger zone

Danger zone

No persons should be within the

danger zone. Fragments of

material which come loose while

operating the hydraulic

attachment may be flung away

and can cause serious injury if

people are hit by them. Small

objects falling from a great height

can also cause serious damage.

Applications

The transverse drum cutter is suitable for use in

trenching and tunnelling, for demolition and

renovation works, quarrying and in special

underground engineering.

Working area and hazardous

area

B

A

A. Working area for operating personnel

B. Hazardous area when working with the

transverse drum cutter

•

The working area for the operating personnel is

in the cabin of the carrier.

•

The hazardous area is in the direct vicinity of

the transverse drum cutter.

•

Whilst operating the transverse drum cutter, the

minimum distance around the carrier is 15

metres.

•

When cutting reinforced concrete, the minimum

distance around the carrier is 50 metres.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

19

Removing the packaging

◆

Remove all the packaging material.

◆

Dispose of it in accordance with the applicable

provisions.

◆

Check that the delivery is complete.

◆

Check the delivery for visual damage.

◆

If any defects are found, consult the Atlas

Copco Customer Center/dealer in your area.

Scope of delivery

The transverse drum cutter is delivered complete

with:

•

Transverse drum cutter including rotatable

upper part

•

Safety and operating instructions

•

Spare parts list

•

EC Declaration of Conformity

•

Hoses:

- Pressure line

- Tank line including precharge valve

- Leakage oil line

•

Overpressure cover plate including O-ring and

screws

•

Set of standard round attack picks including

retainers (see table below)

•

Set of tools for round attack pick assembly and

disassembly (see table below)

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

20 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

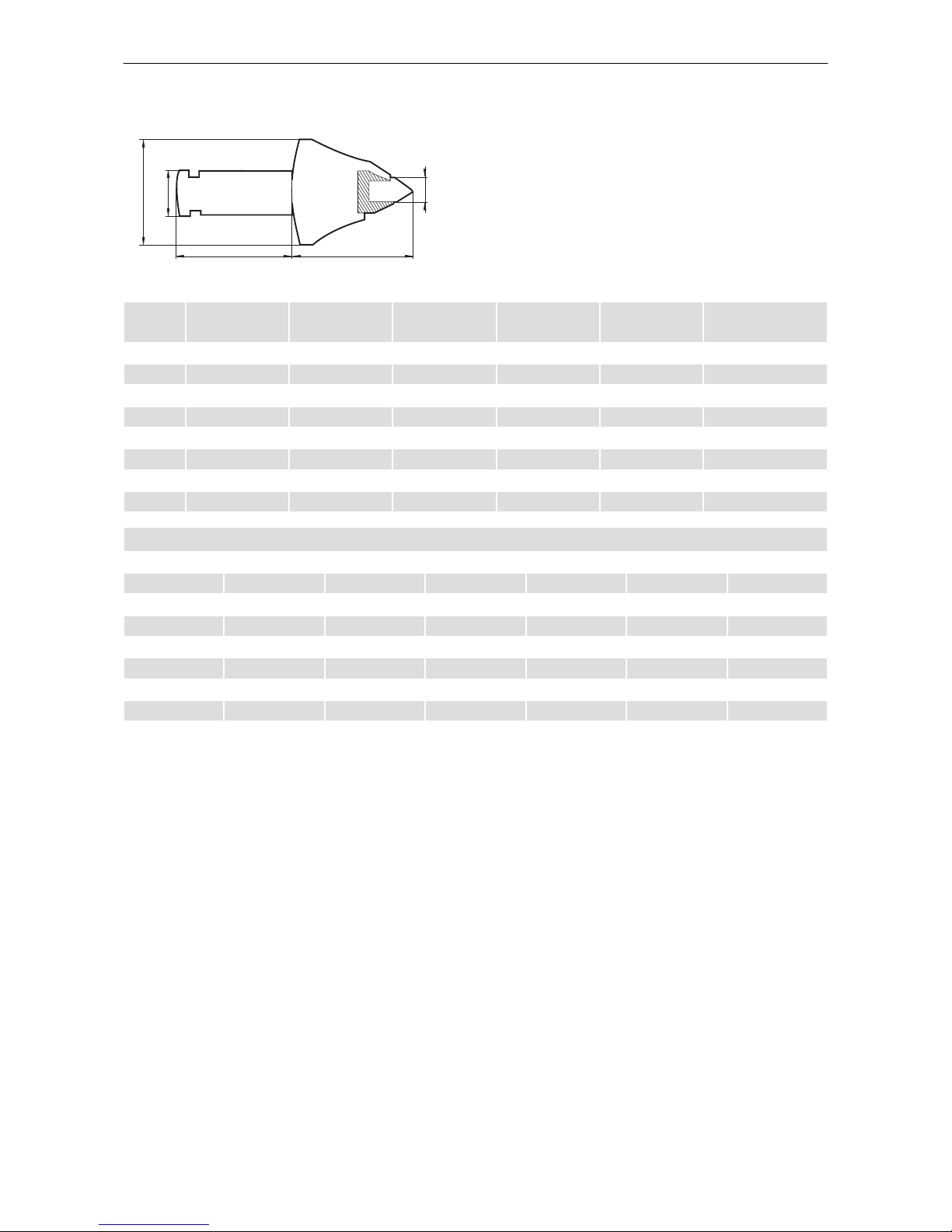

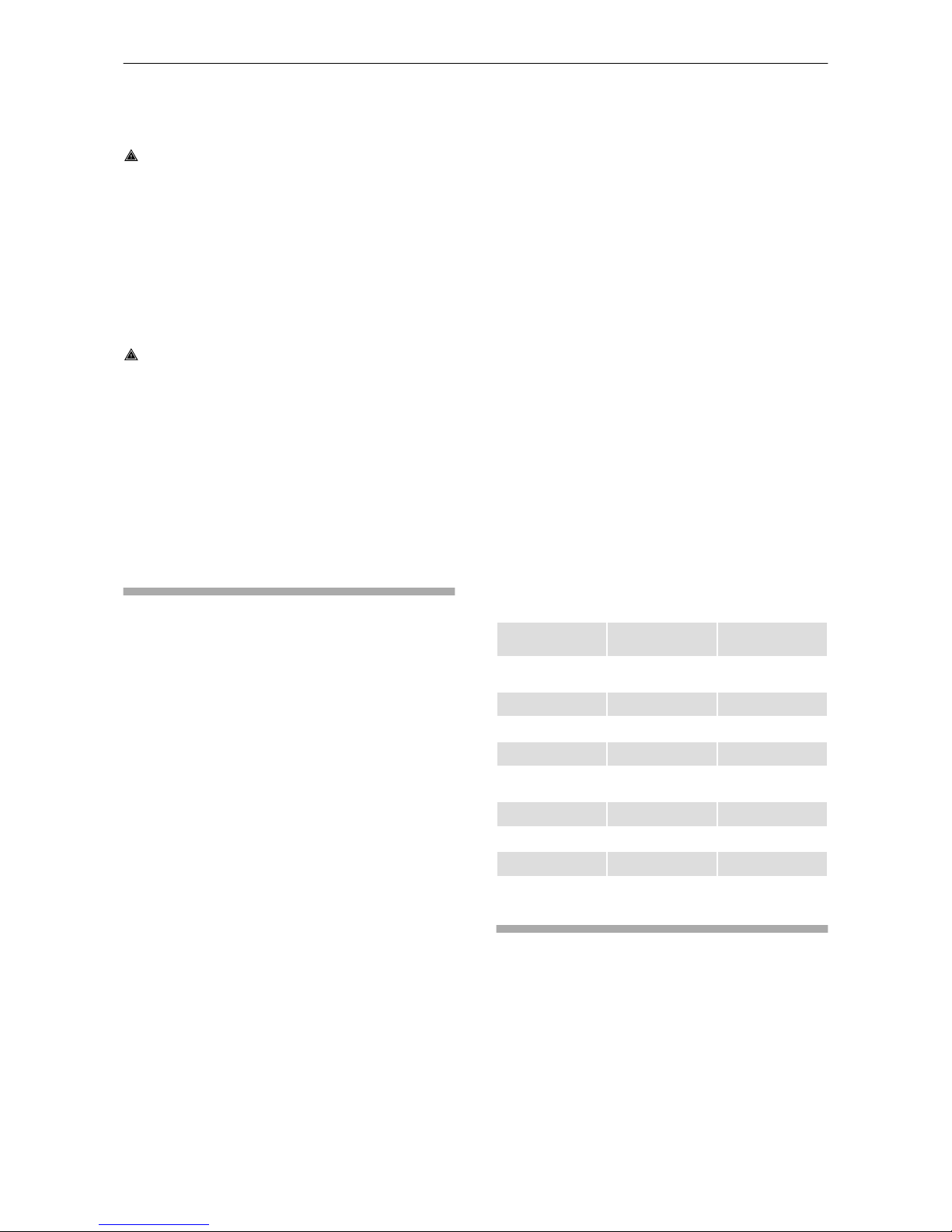

Standard round attack picks

Ø

T

L

H

L

S

Ø

H

Ø

S

Type Ø

S

Shaft diameter

L

S

Shaft length

Ø

H

Head diameter

L

H

Head length

Ø

T

Tip diameter

Locking system

DC 200 11.4 mm (0.45 in.) 26.0 mm (1.02 in.) 24.0 mm (0.94 in.) 28.0 mm (1.10 in.) 11.5 mm (0.45 in.) Knock on retainer

DC 400 20.0 mm (0.79 in.) 41.0 mm (1.61 in.) 38.0 mm (1.50 in.) 45.0 mm (1.77 in.) 12.0 mm (0.47 in.) Retainer sleeve

DC 600 22.0 mm (0.87 in.) 56.5 mm (2.22 in.) 38.0 mm (1.50 in.) 42.0 mm (1.65 in.) 12.0 mm (0.47 in.) Knock on retainer

DC 1000 25.0 mm (0.98 in.) 78.5 mm (3.09 in.) 60.0 mm (2.36 in.) 64.0 mm (2.52 in.) 17.0 mm (0.67 in.) Quick snap retainer

DC 1200 25.0 mm (0.98 in.) 78.5 mm (3.09 in.) 60.0 mm (2.36 in.) 64.0 mm (2.52 in.) 17.0 mm (0.67 in.) Quick snap retainer

DC 2000 30.0 mm (1.18 in.) 80.0 mm (3.15 in.) 70.0 mm (2.76 in.) 75.0 mm (2.95 in.) 17.0 mm (0.67 in.) Quick snap retainer

DC 2100 30.0 mm (1.18 in.) 80.0 mm (3.15 in.) 70.0 mm (2.76 in.) 75.0 mm (2.95 in.) 17.0 mm (0.67 in.) Quick snap retainer

DC 2900 30.0 mm (1.18 in.) 80.0 mm (3.15 in.) 70.0 mm (2.76 in.) 75.0 mm (2.95 in.) 19.0 mm (0.75 in.) Quick snap retainer

Set of tools for round attack pick

Type A B C D E F

DC 200

DC 400 x x x

DC 600 x x x x

DC 1000 x x x

DC 1200 x x x

DC 2000 x x x

DC 2100 x x x

DC 2900 x x x

A. Knock out tool

B. Knock out tool for stuck picks

C. Mounting tool for knock on retainer

D. Dismantling tool for knock on retainer

E. Puller tool for quick snap retainers

F. Puller for retainer sleeve picks

Special accessories as ordered:

•

e.g. adapter plate with Allen screws and pairs of lock washers

•

e.g. base plate to construct an adapter plate with Allen screws and pairs of lock washers

•

e.g. hydraulic fittings for the carrier

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

21

Transport

WARNING Hoist tipping over / hydraulic

attachment falling

The hydraulic attachment is heavy. The hoist/lifting

equipment and/or hydraulic attachment tipping

over or falling may cause serious injury and

material damage.

►

Only transport the hydraulic attachment with

lifting equipment with the right load-bearing

capacity for the weight of the hydraulic

attachment.

►

Only lift and secure the hydraulic attachment

with lifting gear (ropes, chains, shackles etc.)

with the right load-bearing capacity for the

weight to be lifted.

►

Make sure that there is nobody near or under

the suspended hydraulic attachment.

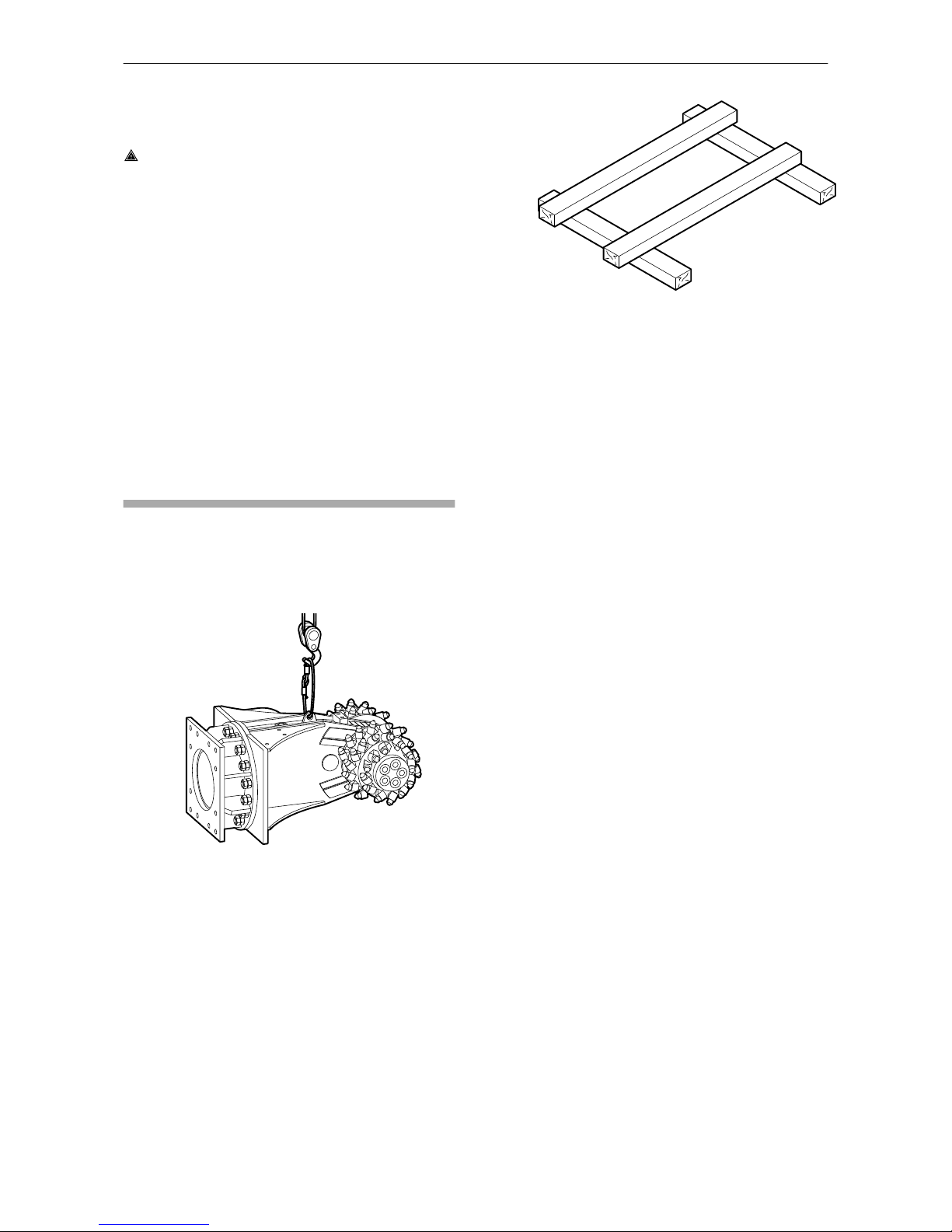

Transport using a crane

The transverse drum cutter is equipped with

transport lugs, for lifting by crane.

◆

Secure the hydraulic attachment with ropes or

chains as shown in the following illustration.

◆

Slowly lift the hydraulic attachment.

Ensure that the transverse drum cutter hangs

straight, if applicable observe any eccentric

centre of gravity.

◆

Place the transverse drum cutter on the

assembly stand.

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

22 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

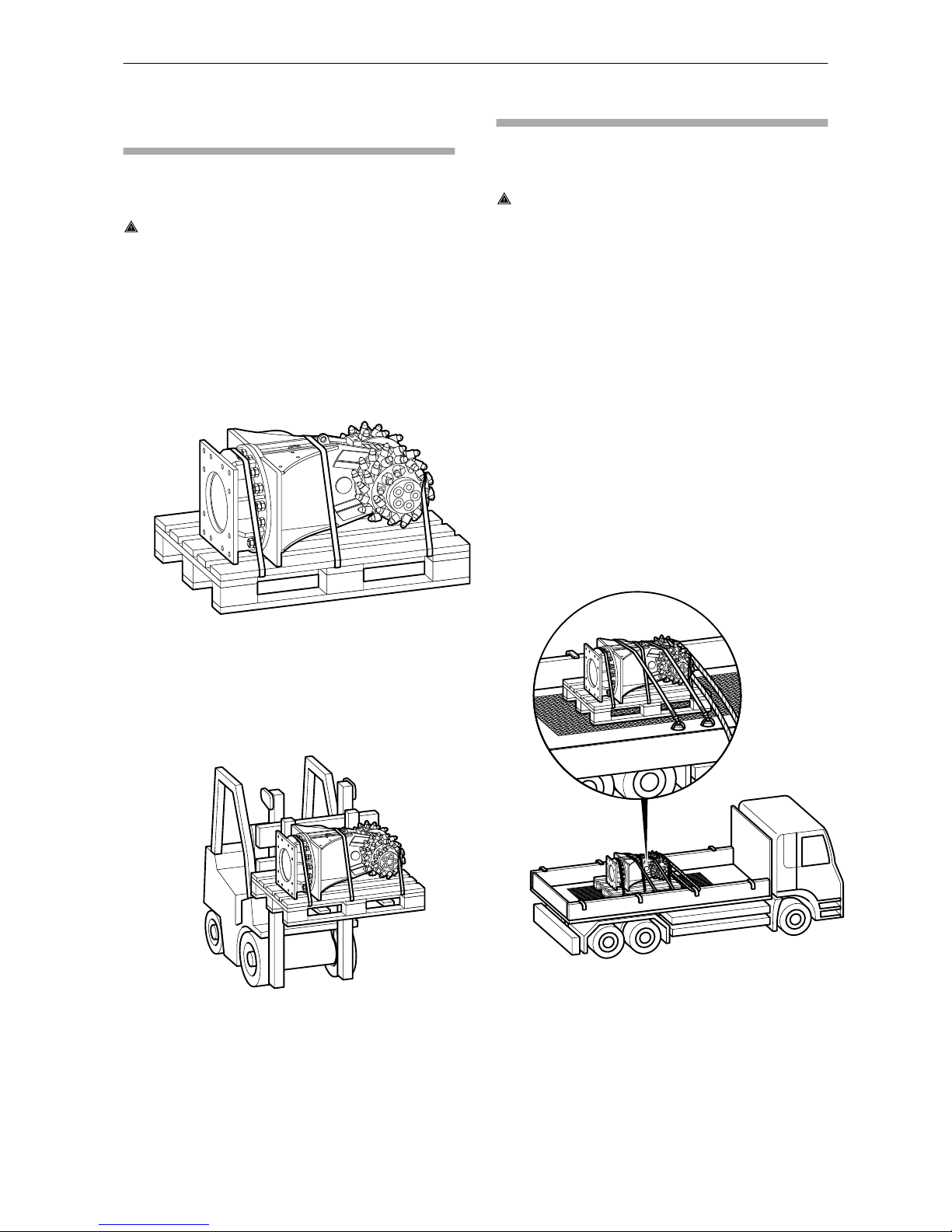

Transport using a forklift

truck

Always transport the transverse drum cutter whilst

secured to the assembly stand.

WARNING Hydraulic attachment tipping

over

The hydraulic attachment tipping off the fork of the

forklift truck or the assembly stand may cause

serious injury.

►

Place the hydraulic attachment on the assembly

stand.

►

Strap the hydraulic attachment to the assembly

stand using suitable strapping, as shown in the

illustration below.

►

Move the forks of the forklift truck under the

assembly stand so that the centre of gravity is

between the prongs.

◆

Move the forks of the forklift truck under the

assembly stand so that the hydraulic

attachment cannot tip over.

◆

Slowly lift the assembly stand with the hydraulic

attachment.

◆

Transport the assembly stand with the hydraulic

attachment to the location provided for.

Transport using a truck

Always transport the transverse drum cutter whilst

secured to the assembly stand.

WARNING Hydraulic attachment tipping

over / slipping

The hydraulic attachment slipping or tipping over

and falling from the loading area of a lorry may

cause serious injury.

►

Place the hydraulic attachment on the assembly

stand.

►

Strap the hydraulic attachment to the assembly

stand using suitable strapping (see illustration

in chapter Transport using a forklift truck).

►

Place the assembly stand with the hydraulic

attachment on an anti-slip mat.

►

Secure the hydraulic attachment to the loading

area with ropes or chains; use any available

transport lugs.

◆

Secure the hydraulic attachment on the

assembly stand and the loading surface as

shown in the following illustration.

◆

Observe all the applicable national/regional

regulations on securing loads.

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

23

Installation

WARNING Hot hydraulic oil squirting out

The hydraulic system is under high pressure. If

hydraulic connections come loose or are

disconnected, hydraulic oil will squirt out under

high pressure. Hydraulic oil squirting out can lead

to serious injury.

►

Depressurise the hydraulic system before

connecting or disconnecting the hydraulic

circuits of the hydraulic attachment (see chapter

Depressurising the hydraulic system).

WARNING Risk of death due to defective

first installation and commissioning

Faults during the first installation or commissioning

can lead to life-threatening situations and may

cause considerable damage to property.

►

Have the first installation and commissioning

exclusively conducted by authorised specialist

personnel.

►

Do not undertake unauthorised first installation

and commissioning.

Media/consumables

The following consumables are used when

operating the hydraulic attachment:

Mineral hydraulic oil

All hydraulic oil brands prescribed by the carrier

manufacturer are also suitable for use when

operating the hydraulic attachment.

However, the oil should comply with viscosity class

HLP 32 or higher.

In summer and in hot climates, oils of viscosity

class HLP 68 or higher should be used.

In all other respects the regulations of the carrier

manufacturer are to be taken into consideration.

Optimum viscosity range = 30 - 60 cSt

Max. start viscosity = 2000 cSt

Max. oil temperature = 80 °C

Special conditions apply to using the hydraulic

attachment at low temperatures (see chapter Low

ambient temperature).

◆

Check the oil filter!

An oil filter must be integrated in the tank line of

the hydraulic system. The maximum mesh

width allowed for the oil filter is 50 microns; it

must have a magnetic separator.

Non-mineral hydraulic oil

NOTICE Mixed hydraulic oil

Never mix mineral and non-mineral hydraulic oils!

Even small traces of mineral oil mixed in with nonmineral oil can result in damage to both the

hydraulic attachment and the carrier. Non-mineral

oil loses its biodegradability.

►

Only use one type of hydraulic oil.

If you are using non-mineral oil it is imperative that

the name of the oil in use be indicated when

returning the hydraulic attachment for repair.

In order to protect the environment or on technical

grounds, hydraulic oils are currently being used

which are not classified as HLP mineral oils.

Before using hydraulic oils of this kind it is

imperative to ask the carrier manufacturer whether

operations with such fluids are possible.

Our hydraulic attachments are basically designed

for use with mineral oils. Consult the Atlas Copco

Customer Center/Dealer in your area before using

other hydraulic oils approved by the carrier

manufacturer. Following initial assembly and after

any workshop repairs, our hydraulic attachments

are subjected to a test run on a test bed powered

by mineral oil.

Gear oil

Media /

consumables

Temperature range Part number

AC Fluid Traction

Gear 100

-15 to +40 °C

5 l (1.32 gal)

4812 0082 71

20 l (5.28 gal)

4812 0082 72

209 l (55.21 gal)

4812 0082 73

AC Fluid Gearbox

100

-20 to +30 °C

5 l (1.32 gal)

4812 0082 74

20 l (5.28 gal)

4812 0082 75

209 l (55.21 gal)

4812 0082 76

Preconditions for the carrier

The carrier must fulfil the following criteria in order

that a transverse drum cutter can be attached to it:

•

A complete hydraulic hammer or shearer line

right to the end of the carrier boom must be

available.

•

The motor's pressure line is set to max. 350

bar.

•

The pressure of the tank line is at least 5 bar

above the pressure of the case drain line.

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900

24 © Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

Loading...

Loading...