Atlas Copco Cobra mk1, Cobra TT Instructions Manual

ASB

2000-02

© Copyright 2000, ATLAS COPCO BEREMA AB No 9800 0088 01a

STOCKHOLM • SWEDEN

Overhauling instructions Motor breaker

Cobra mk1

Cobra TT

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

Innehåll

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Transmission unit . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hammer unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tightening torque loads . . . . . . . . . . . . . . . . . . . . . . 5

Special assembly instructions . . . . . . . . . . . . . . . . . 5

Service schedule . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Design and function . . . . . . . . . . . . . . . . . . . . . . . 7

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Hammer mechanism . . . . . . . . . . . . . . . . . . . . . . . . 7

Service tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Engine covers . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Dismantling of the machine . . . . . . . . . . . . . . . . . . 12

Dismantling of the covers . . . . . . . . . . . . . . . . . . . 12

Service cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Front cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Rear cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Filter cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fan cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Starter cover . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Starter mechanism . . . . . . . . . . . . . . . . . . . . . . . 14

Replacing starter rope with starter pulley in place 14

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Replacement of starter rope, starter pulley and

spring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Reassembly of starter mechanism . . . . . . . . . . . . 15

Filter housing and carburettor . . . . . . . . . . . . . . 16

Dismantling of filter housing . . . . . . . . . . . . . . . . . 16

Dismantling and reassembly of

choke control and lever . . . . . . . . . . . . . . . . . . . . . 16

Dismantling of carburettor and diaphragm valve. . 16

Engine and hammer mechanism . . . . . . . . . . . . 17

Dismantling of muffler, stabilizer brace and

engine mounting bolts . . . . . . . . . . . . . . . . . . . . . . 17

Dismantling of the engine from the machine. . . . . 17

Dismantling of the muffler, heat shield and

fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dismantling of the anti-vibration springs . . . . . . . . 18

Dismantling of the tool holder . . . . . . . . . . . . . . . . 18

Dismantling of the tool shank . . . . . . . . . . . . . . . . 19

Dismantling and reassembly of the tool latch . . . . 19

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Dismantling and reassembly of

the hammer piston and hammer piston guide. . . . 20

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Dismantling of the drive piston . . . . . . . . . . . . . . . 21

Dismantling and reassembly of

the connecting rod bearings . . . . . . . . . . . . . . . . . 21

Dismantling of plastic bushes . . . . . . . . . . . . . . . . 22

Mounting the engine on the fixture . . . . . . . . . . . . 22

Dismantling of the cooling fan . . . . . . . . . . . . . . . . 22

2

Safety regulations

!

This symbol, plus a word, is used to draw

your attention to safety hazards. Read the

instructions accompanying this symbol

carefully.

The words WARNING and CAUTION have the fol

-

lowing significance:

WARNING Indicates a hazard or hazardous

procedure which COULD result

in serous injury or death if the

warning is not observed.

CAUTION Indicates a hazard or hazardous

procedures which COULD result

in serous injury or damage to

equipment if the warning is not

observed.

!

WARNING

The machine must not be modified with

out the manufacturer’s authorization.

Use only original parts and accessories

approved by Atlas Copco. If modifica

tions are made that are not approved by

Atlas Copco, serious harm to yourself

or others may result.

Use only authorized parts. Any damage or malfunction caused by

the use of unauthorized parts is not covered by warranty or

product liability.

Any unauthorized use or copying of the contents or any part

thereof is prohibited. This applies in particular to trademarks,

model designations, part numbers and drawings.

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

Dismantling of the electronic unit, carriers and

flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Dismantling of the engine cylinder and piston. . . . 23

Dismantling of the transmission cover. . . . . . . . . . 24

Dismantling of the fan side crankcase. . . . . . . . . . 24

Dismantling of the hammer crankshaft gear wheel 25

Dismantling of the hammer crankshaft . . . . . . . . . 25

Dismantling of the hammer crankshaft bearing. . . 26

Dismantling of the engine crankshaft . . . . . . . . . . 26

Dismantling and reassembly of the engine crankshaft

bearing and seal . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Reassembly of engine crankshaft . . . . . . . . . . . . . 27

Reassembly of crankshaft seal . . . . . . . . . . . . . . . 27

Reassembly of hammer crankshaft bearing . . . . . 27

Reassembly of locking ring . . . . . . . . . . . . . . . . . . 27

Reassembly of hammer crankshaft. . . . . . . . . . . . 28

Reassembly of locking ring on

hammer crankshaft . . . . . . . . . . . . . . . . . . . . . . . . 28

Reassembly of hammer crankshaft gear wheel . . 28

Dismantling of transmission cover

needle bearing and seal . . . . . . . . . . . . . . . . . . . . 29

Reassembling the transmission cover needle

bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Dismantling of the engine crankshaft bearing

and seal on the fan side crankcase. . . . . . . . . . . . 29

Fitting the engine crankshaft bearing on

the fan side crankcase. . . . . . . . . . . . . . . . . . . . . . 29

Reassembly of the drive piston connecting rod

and engine crankcase . . . . . . . . . . . . . . . . . . . . . . 30

Assembly of fan side crankcase seal . . . . . . . . . . 30

Reassembly of transmission cover . . . . . . . . . . . . 31

Reassembly of the transmission cover seal . . . . . 31

Reassembly of the engine piston and cylinder . . . 31

Reassembly of the carrier, flywheel and

electronics unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Reassembly of cooling fan . . . . . . . . . . . . . . . . . . 32

Reassembly of plastic bushes. . . . . . . . . . . . . . . . 33

Reassembly of driver piston . . . . . . . . . . . . . . . . . 33

Reassembly of tool shank . . . . . . . . . . . . . . . . . . . 33

Fitting the hammer cylinder on the tool holder . . 33

Reassembly of anti-vibration springs . . . . . . . . . . 34

Dismantling and reassembly of right handle . . . . . 34

Dismantling and reassembly of fuel filter. . . . . . . . 35

Dismantling and reassembly of throttle handle . . . 35

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Reassembly of fuel tank and muffler . . . . . . . . . . . 36

Reassembly of engine . . . . . . . . . . . . . . . . . . . . . . 36

Fitting the muffler and stabilizer brace . . . . . . . . . 37

Reassembly of filter housing . . . . . . . . . . . . . . . . 37

Reassembly of machine covers . . . . . . . . . . . . . . 38

Throttle cable adjustment . . . . . . . . . . . . . . . . . . . 38

Front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

Technical data

Rated power 2.0 kW (2.7 hp)

Sound pressure level 96 dB(A)

Weight 24 kg (.020”)

Length 927 mm (.020”)

Depth 331 mm (.020”)

Width across handles 661 mm (.020”)

Width, handles folded 390 mm (.020”)

Width across machine 320 mm (.020”)

Tool shank 32 × 160 mm

32 × 152 mm

28 × 152 mm

28 × 160 mm

Engine

Type Single cylinder, fan-cooled 2-stroke engine

Cylinder volume 90 cc

Engine speed, machine under load,

full speed when tamping in sand 5800–6200 rpm (Cobra mk1)

6500+/-100 rpm (Cobra TT)

Engine speed, machine under no load, idling 1800–2200 rpm

Max. speed under no-load conditions 7500 rpm

Ignition Breakerless, transistor type with integral speed

restrictor set to 7700 rev/min

Spark plugs Champion RCJ8

Electrode gap 0.6-0.7mm

Fuel system Diaphragm carburettor

Fuel: Petrol 90-100 octane, leaded or unleaded

Fuel mixture 2 % (1:50)

Tank capacity 1.0 l

Fuel consumption 1.3 l/h

Cooling system Fan-cooled

Starter device Magnapull

Transmission unit

Gear oil Diesel engine oil SAE 15W/40 API:CD

Oil capacity 0.1 litre

Transmission ratio 1:4.3

(The transmission ratio

is a primary number selected at random )

4

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

Hammer unit

Hammer frequency 24 Hz (Cobra mk1)

27 Hz (Cobra TT)

Impacts/min 1440 (Cobra mk1)

1620 (Cobra TT)

Impact energy 60 J at 24 Hz (Cobra mk1)

40 J at 27 Hz (Cobra TT)

Lubrication Hammer mechanism lubricated in its own oil bath

Hammer mechanism oil Diesel engine oil

SAE 15W/40 API:CD

Oil capacity 0.1 litre

Oil consumption 0.015 l/h

Tightening torque loads

Note: The indicated tightening torque loads are for oiled threads.

Flywheel 35 Nm

Fan (A) 25 Nm

Fan (B) (plastic) 8 Nm

Nuts and screws for covers 10 Nm

M8 Engine / Hammer cylinder 23 Nm

M8 Tool holder 20 Nm

M5 Engine cylinder screws 10 Nm

M5 Diaphragm valve screws 8 Nm

M6 Studs on crankcase halves 4–5 Nm

Decompression valve 20 Nm

Spark plug 20Nm

Special assembly instructions

Reassembly of KM nut and gear wheel, see fig. 47.

Degrease the transmission shaft and gear wheel taper with denatured alcohol or pure petrol.

Locate the gear wheel on the transmission shaft taper. Screw the KM nut by hand until it makes contact with

the gear wheel. Then tighten the nut by half a turn (180°) using service tool S18.

Reassembly or dismantling of starter device spring.

Always wear safety gloves and safety glasses when reassembling or dismantling the starter spring.

5

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

Service schedule

The machine service interval is based on an operat

-

ing time of 10 hammering hours per week.

1. Daily service or service after every rental.

Service time: 5 minutes.

1.1 Check the oil level in the hammer cylinder.

The correct oil level is up to the thread in the

filler pipe with the machine standing upright.

Use diesel engine oil SAE 15W/40, API:CD for

the best function and service life.

Note: The oil capacity of the hammer cylinder is

0.1 litre.

1.2 Clean the air filter, filter housing and cover.

When working under extremely dusty conditions, replacement of the air filter may be necessary

Note: Do not use compressed air to clean the

air filter, as it may damage the filter material.

2. Every week or after 10 hammering hours.

Service time: 10 minutes. Measures under

Point 1, plus:

2.1 Remove the spark plug. Clean with a wire brush

and reset the gap to 0.6-0.7mm.

3. Every month or after 50 hammering hours.

Service time: 20 minutes. Measures under

Point 1, plus:

3.1 Replace the spark plug. All Atlas Copco’s spark

plugs are preset to 0.6–0.7 mm.

3.2 Replace the air filter.

3.3 Remove and clean the decompression valve.

3.4 Clean any deposits from the exhaust pipe and

the muffler. Always replace the seals.

3.5 Check the gap between the flywheel magneto

and the electronics unit.

The correct gap is 0.25 – 0.3 mm.

3.6 Examine the starter rope for wear, and replace if

worn or damaged.

3.7 Check the oil level in the gearbox by unscrewing

the oil plug. The correct oil level is at the bottom

edge of the filler hole with the machine standing

upright. If necessary, top up with diesel engine

oil SAE 15W40 API:CD.

Note: The oil capacity of the gearbox is 0.1 litre

4. Every three months or after 150 hammering

hours.

Service time: 30 minutes. Measures under

Points 1 and 3, plus:

4.1 Examine the scraper ring and sealing ring of the

hammer piston guide for wear. Oil running along

the tool shank is an indication that the scraper

ring is worn. The scraper ring and the sealing

ring can be replaced easily.

See Chapter: Dismantling and reassembly of

hammer piston guide

4.2 Examine the stabilizer brace and the ball joints

for wear, and replace if worn or damaged.

5. Every six months or after 250 hammering

hours.

Service time: 60 minutes. Measures under

Points 1, 3 and 4, plus:

5.1 Examine the starting device carriers for wear

and the function of the carrier springs. Replace if

necessary.

5.2 Replace the fuel filter.

5.3 Replace the crankcase ventilation filter.

5.4 Examine the fuel cap ‘O’ ring for wear and replace if necessary.

5.5 Examine the anti-vibration springs for wear.

5.6 Replace the piston ring and O-ring on the drive

piston and the piston ring and O-ring on the

hammer piston.

5.7 Examine the tool shank for wear. Use the gauge

supplied with the machine. Replace the tool

shank if it has exceeded the wear threshold.

6. Every twelve months or after 500 hammering

hours.

Service time: 5 hours. Measures under

Points 1, 3, 4 and 5, plus:

6.1 Dismantle the engine from the hammer cylinder.

Examine the hammer piston connecting rod

bearings for wear, and replace if necessary.

6.2 Examine the gearbox gear wheels for wear. Dismantle the flywheel and examine the gear wheel

for wear. Remove the transmission cover and

examine the crankshaft gear wheel for wear.

Note: If any of the gear wheels are worn and

need to be replaced, both gear wheels must be

replaced.

6.3 Dismantle the engine cylinder and examine the

cylinder for wear. Dismantle the piston rings and

try the rings in the cylinder. The gap between

the ends of the piston rings must not exceed

0.45 mm. Piston ring groove clearance should

not exceed 0.15 mm.

6.4 Dismantle the engine. Replace the bearings and

seals of the engine and the hammer crankshaft.

6.5 Examine the hammer piston for wear. Replace

the piston rod if it is scratched, or if the hammer

surface of the piston rod is worn or damaged.

6.6 Examine the diaphragm valve for wear and

damage, and replace if necessary.

6.7 Replace the tank cover.

6

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

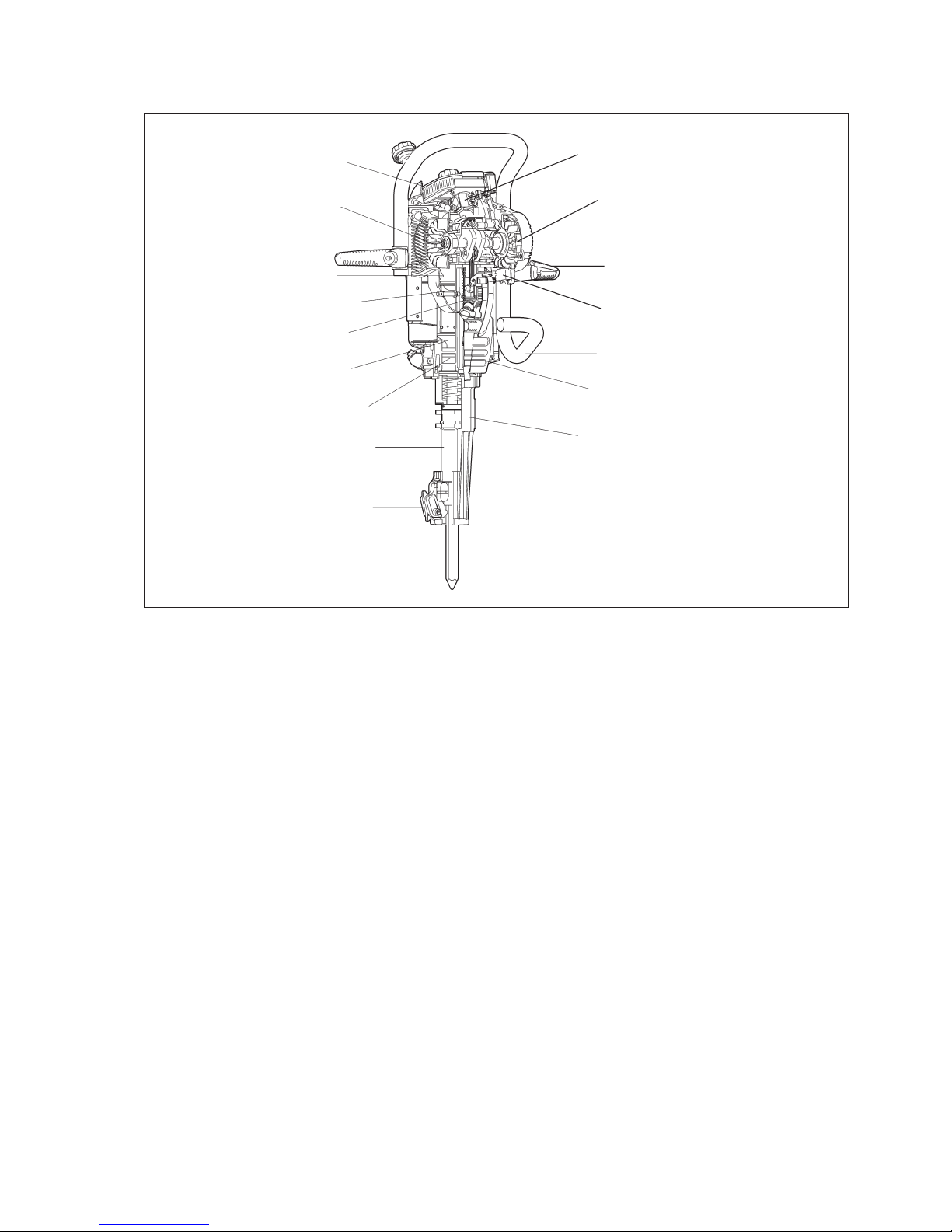

Design and function

Engine

The machine is powered by a single-cylinder,

air-cooled two-stroke engine. The engine is

equipped with a diaphragm carburettor, which is controlled by changes in pressure inside the crankcase.

The carburettor feeds the fuel mixture into the cylinder via a diaphragm valve. The engine is automatically lubricated by the oil in the fuel mixture.

The speed of the engine can be varied by the hand

throttle, which is connected to the carburettor butterfly valve.

The maximum speed of the engine is restricted by an

electronic speed restrictor, which is incorporated in

the breakerless ignition system.

The power transmission between the engine and

hammer mechanism is via a gear assembly.

Hammer mechanism

Before starting the engine, the hammer piston rests

on the tool shank. When the engine is started, the

drive piston commences to move up and down in the

hammer cylinder.

When the handles are pushed down, the tool raises

the hammer piston in the hammer cylinder and the

hammer mechanism is activated.

When the machine is lifted, the tool drops down onto

the tool latch. The hammer piston moves into its

lower position, where it stops, and the hammer

mechanism is disengaged.

This operational system also means that the machine can stand on a tool without engaging the hammer piston.

7

Air Filter

Cooling Fan

Drive piston

Decompression valve

Engine cylinder

Hammer piston

Hammer piston guide

Tool chuck

Tool latch

Carburettor

Starter mechanism

Throttle

Electronic unit

Fuel tank

Muffler

Tool holder

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

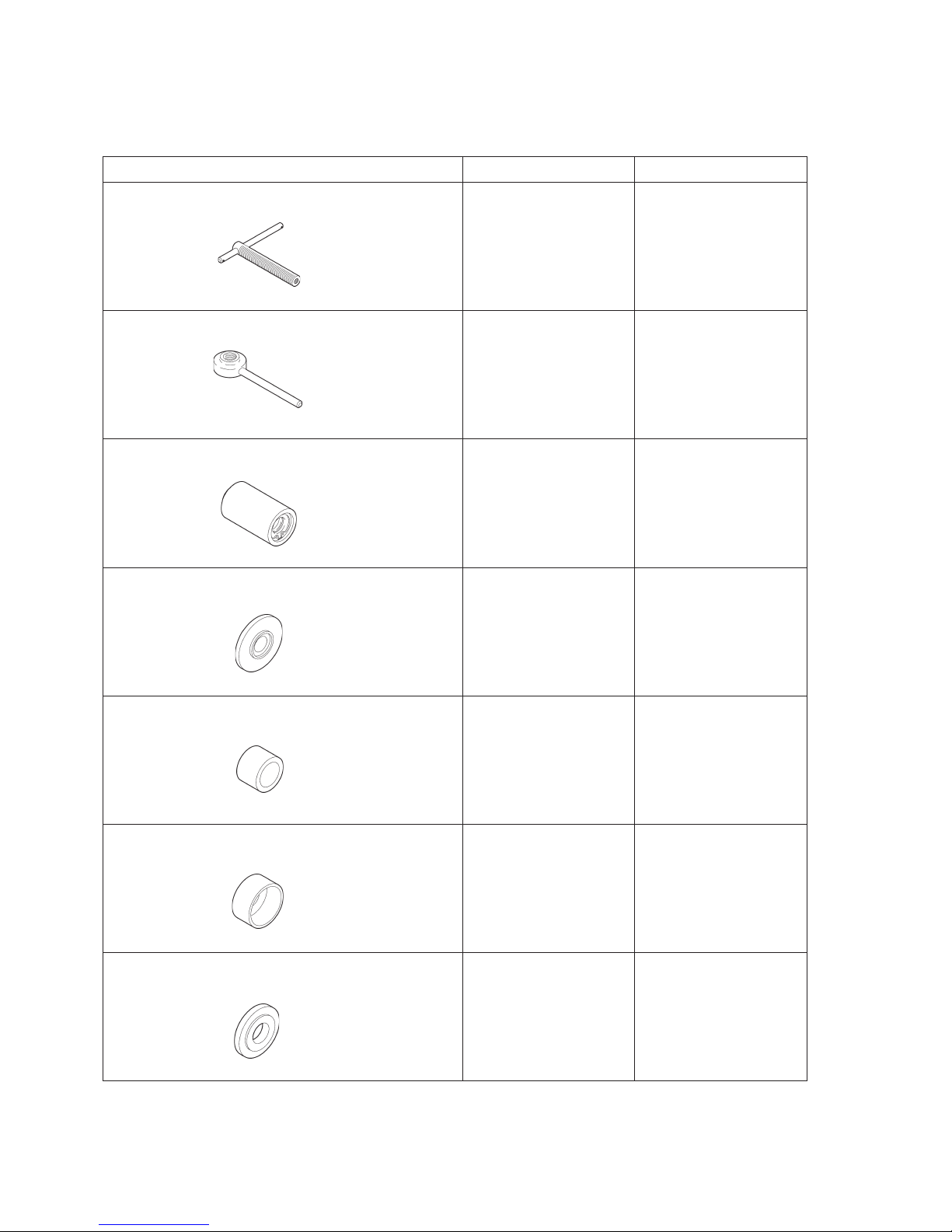

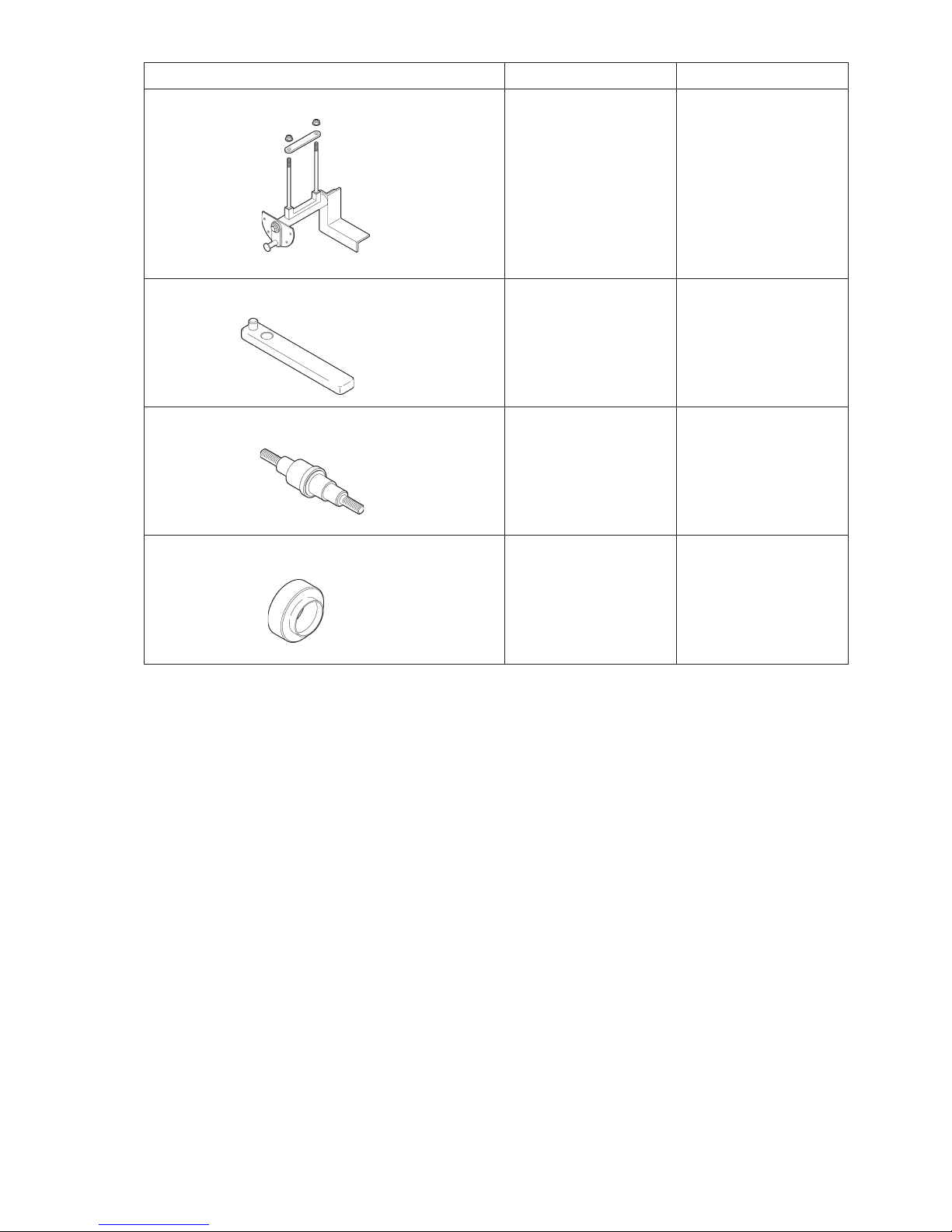

Service tools

(Complete set: order number 9234 0003 94)

Tool Order No. Designation

S1 9234 0003 58 Puller key

S2 9234 0003 59 Puller handle

S3 9234 0003 57 Puller sleeve

S4 9234 0003 71 Ring

S5 9234 0003 72 Ring

S6 9234 0003 68 Ring

S7 9234 0003 69 Ring

8

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

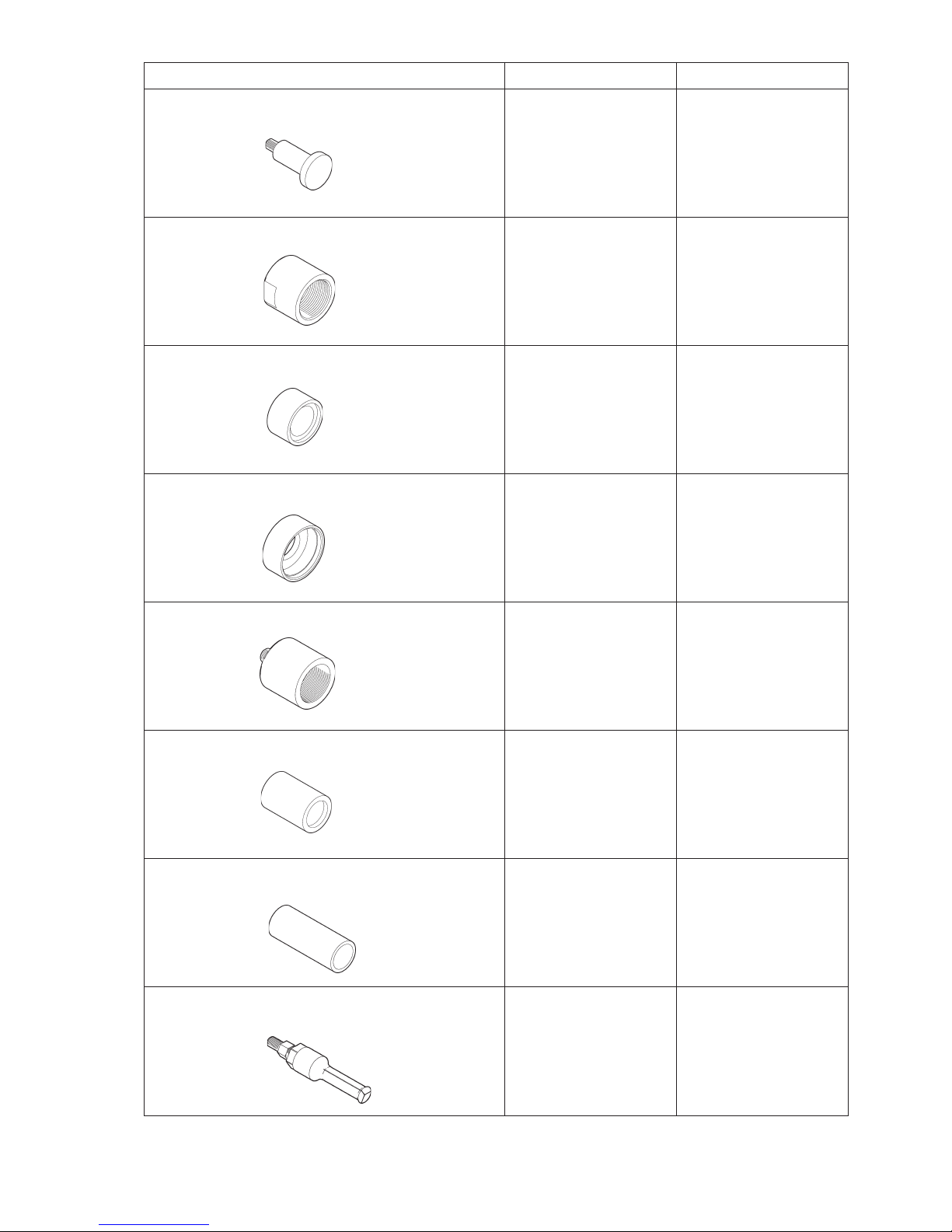

Tool Order No. Designation

S8 9234 0003 84 Tool

S9 9234 0003 83 Protective bush

S10 9234 0003 85 Ring

S11 9234 0003 70 Ring

S12 9234 0003 81 Tool

S13 9234 0003 74 Ring

S14 9234 0003 73 Ring

S15 9234 0003 93 Puller

9

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

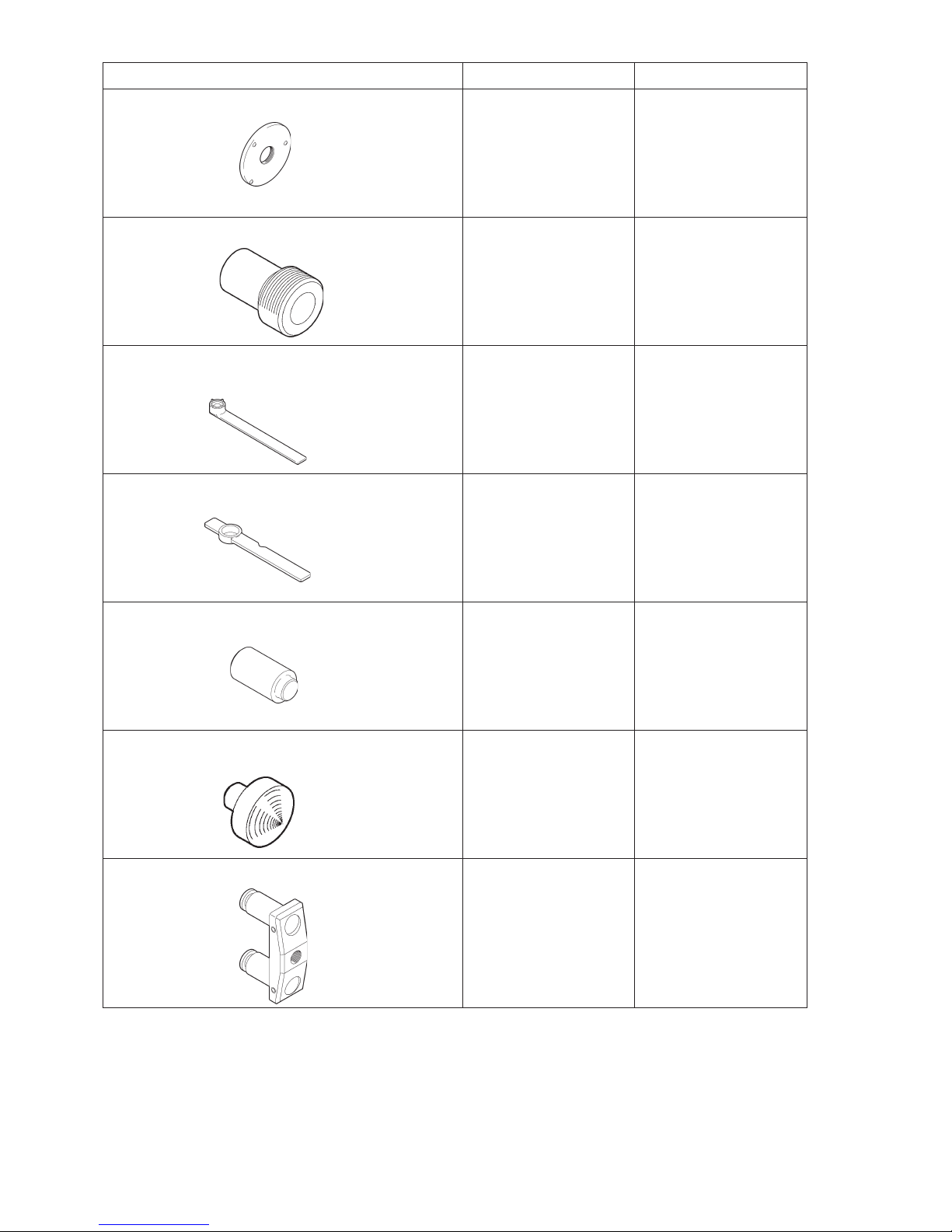

Tool Order No. Designation

S16 9234 0003 86 Ring

S17 9234 0003 80 Puller

S18 9234 0003 52 Tool

S19 9234 0003 49 Tool

S20 9234 0003 75 Tool

S21 9234 0003 82 Point

S22 9234 0003 53 Puller

10

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

Tool Order No. Designation

S23 9234 0003 66 Engine fixture

S24 9234 0003 51 Tool

S25 9234 0004 55 Tool

S26 9234 0004 57 Ring

11

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

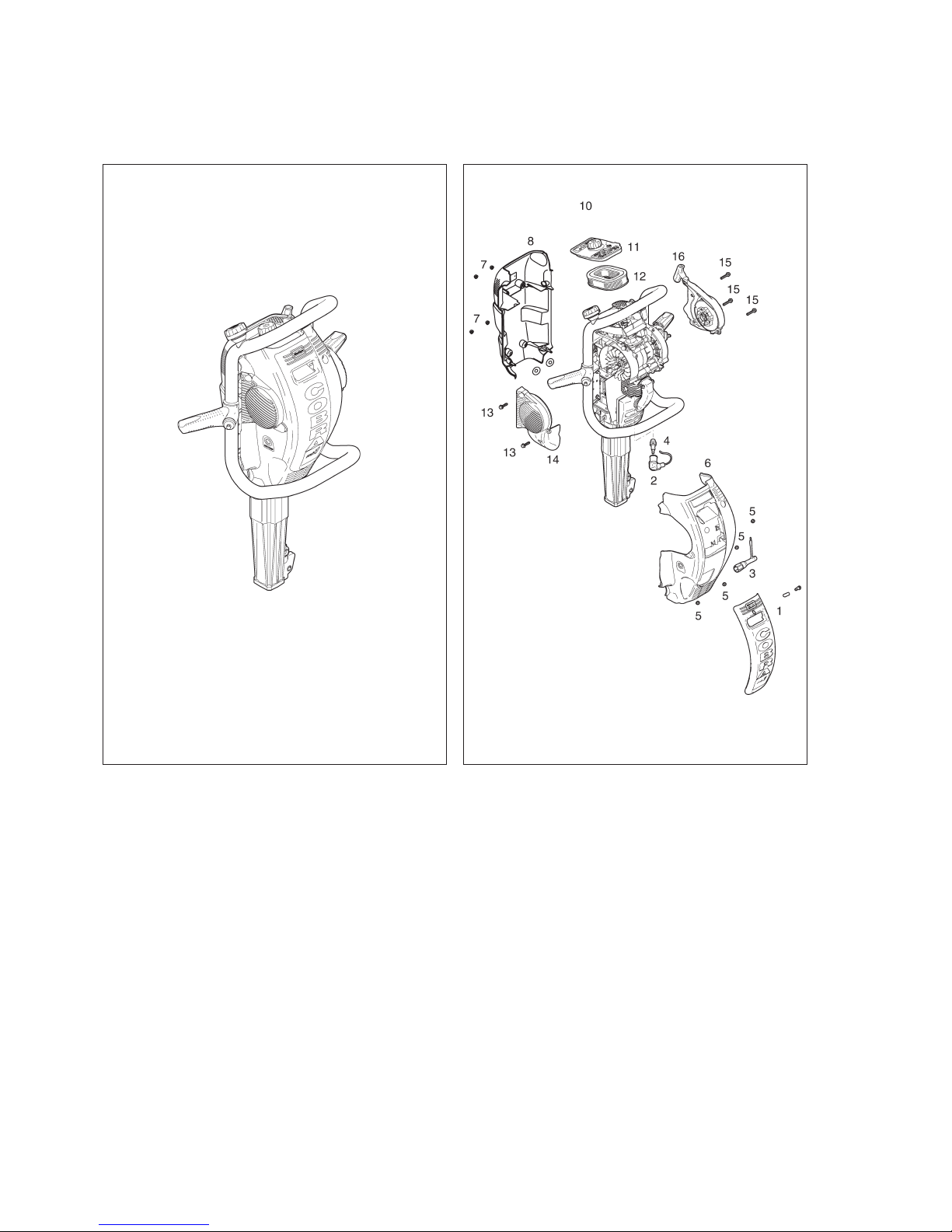

Engine covers

Dismantling of the machine

General

Follow the instructions in this handbook carefully.

Use the tools listed under the heading ”Service tools”

on pages 9-12.

To avoid injury, always allow the machine to cool

down before service.

Always clean all loose dirt carefully from the machine

before servicing is carried out. Wash the parts in paraffin or a similar solvent. Do not use corrosive acids,

as this may cause damage to certain components.

Empty the fuel tank to prevent petrol from leaking

out.

Empty the oil from the hammer cylinder.

Remove the spark plug.

Spare part numbers are provided in a separate

spare parts list.

Use only Atlas Copco original spare parts.

Dismantling of the covers

Service cover

Dismantle the service cover (1) from the machine.

Pull the ignition cable (2) from the spark plug (4) and

use the spark plug spanner (3) to remove the spark

plug.

Clean the electrodes with a steel brush and adjust

the electrode gap to 0.6-0.7 mm.

Note: To guarantee reliable starting and running, the

spark plug must be checked every week and replaced after 50 hammering hours.

Front cover

Remove the four nuts (5), push down the fuel tank,

and lift out the front cover (6).

Examine the cover for damage or cracks, and re

-

place if necessary.

12

Fig. 1 Fig. 2

Crowder Supply Co., Inc. • 8495 Roslyn St., Commerce City, CO 80022 • Toll Free: 888-883-5144 • www.CrowderSupply.com

www.CrowderSupply.com • Toll Free: 888-883-5144

Loading...

Loading...