Atlas Copco CA3500DCO, CA6000DC, CA3600DCO, CA5000DCO, CA6000DCO Instruction Manual

Instruction manualInstruction manual

Operating & MaintenanceOperating & Maintenance

4812160101_A.pdf4812160101_A.pdf

Vibratory rollerVibratory roller

CA3500DCOCA3500DCO

CA3600DCOCA3600DCO

CA5000DCOCA5000DCO

CA6000DCOCA6000DCO

EngineEngine

Cummins QSB 4.5 (IIIA/T3) / (IIIB/T4i)Cummins QSB 4.5 (IIIA/T3) / (IIIB/T4i)

Deutz TCD 2012 L6 (IIIA/T3) / TCD 6.1 L6 (IIIB/T4i) Deutz TCD 2012 L6 (IIIA/T3) / TCD 6.1 L6 (IIIB/T4i)

Serial numberSerial number

10000145x0A010028 -10000145x0A010028 10000146x0A00xxxx -10000146x0A00xxxx 10000147x0A00xxxx -10000147x0A00xxxx 10000148x0A00xxxx -10000148x0A00xxxx 10000133x0A00xxxx -10000133x0A00xxxx 10000129x0A008983 -10000129x0A008983 10000135x0A00xxxx -10000135x0A00xxxx 10000131x0A00xxxx -10000131x0A00xxxx -

Translation of original instructionTranslation of original instruction

Reservation for changesReservation for changes

Printed in SwedenPrinted in Sweden

4812160101_A.pdf2014-07-04

Table of Contents

Introduction .............................................................................................................................. 1

The machine ............................................................................................... 1

Intended use ............................................................................................... 1

Warning symbols......................................................................................... 1

Safety information ....................................................................................... 1

General ....................................................................................................... 2

CE marking and Declaration of conformity.................................................. 3

Safety - General instructions.................................................................................................... 5

Safety - when operating ........................................................................................................... 7

Driving near edges ...................................................................................... 7

Slopes ......................................................................................................... 8

Safety (Optional) ...................................................................................................................... 9

Air conditioning............................................................................................ 9

Special instructions ................................................................................................................ 11

Standard lubricants and other recommended oils and fluids .................... 11

Higher ambient temperatures, above +40°C (104°F)................................ 11

Temperatures............................................................................................ 11

High pressure cleaning ............................................................................. 11

Fire fighting ............................................................................................... 12

Roll Over Protective Structure (ROPS), ROPS approved cab .................. 12

Welding ..................................................................................................... 12

Battery handling ........................................................................................ 12

Jump starting (24V)................................................................................... 13

Technical specifications ......................................................................................................... 15

Vibrations - Operator station ..................................................................... 15

Noise level................................................................................................. 15

Electrical system ....................................................................................... 15

Dimensions, side view............................................................................... 16

Dimensions, top view ................................................................................ 17

Weights and volumes................................................................................ 18

4812160101_A.pdf 2014-07-04

Working capacity....................................................................................... 18

General ..................................................................................................... 20

Liquid-filled tyres (Ballasted tyres).............................................. 21

Hydraulic system....................................................................................... 21

Automatic Climate Control (ACC) (Optional)............................................. 21

Tightening torque ...................................................................................... 22

Machine description ............................................................................................................... 23

Diesel engine, Cummins ........................................................................... 23

Diesel engine, Deutz ................................................................................. 23

Electrical system ....................................................................................... 23

Propulsion system/Transmission .............................................................. 23

Brake system ............................................................................................ 24

Steering system ........................................................................................ 24

Vibration system........................................................................................ 24

Cab............................................................................................................ 24

FOPS and ROPS ...................................................................................... 24

Identification ............................................................................................................ 25

Product and component plates ................................................................. 25

Product identification number on the frame .............................................. 25

Machine plate............................................................................................ 26

Explanation of 17PIN serial number.......................................................... 26

Engine plates ............................................................................................ 27

Decals...................................................................................................................... 28

Location - decals ....................................................................................... 28

Safety decals............................................................................................. 29

Info decals................................................................................................. 31

Instruments/Controls ............................................................................................... 32

Control panel and controls ........................................................................ 32

Function descriptions ................................................................................ 33

Warning indication - membrane panel (Keypad)....................................... 35

4812160101_A.pdf2014-07-04

Display explanations ................................................................................. 36

Machine alarm........................................................................................... 39

Dynapac Sub System (DSS)..................................................................... 40

"MAIN MENU" ........................................................................................... 41

"USER SETTINGS" .................................................................... 41

"SERVICE MENU"...................................................................... 42

"ABOUT"..................................................................................... 43

"MACHINE SETTINGS".............................................................. 43

Operator help when starting...................................................................... 44

Operator help Workmode.......................................................................... 44

Display when activating choice via the button set..................................... 45

DCO view and status .................................................................. 45

Error messages (DCO) ............................................................... 46

Instruments and controls, cab ................................................................... 47

Function description of instruments and controls in the cab ..................... 48

Using the cab controls............................................................................... 49

Defroster ..................................................................................... 49

Heat ............................................................................................ 49

AC/ACC ...................................................................................... 49

ACC - Control panel .................................................................................. 50

Main display screen .................................................................................. 50

ACC - Operation menus............................................................................ 50

Electrical system...................................................................................................... 52

Fuses in the main switchbox (Cummins) .................................................. 53

Fuses at master switch (Cummins)........................................................... 53

Fuse box at master switch (Cummins)...................................................... 54

Fuses in the main switchbox (Deutz) ........................................................ 54

Fuses at master switch (Deutz)................................................................. 55

Fuse box at master switch (Deutz)............................................................ 56

Operation ............................................................................................................................... 57

4812160101_A.pdf 2014-07-04

Before starting ......................................................................................................... 57

Master switch - Switching on..................................................................... 57

Operator's seat - Adjustment..................................................................... 57

Operator's seat, comfort - Adjustments..................................................... 58

Control panel, adjustments ....................................................................... 58

Parking brake ............................................................................................ 59

Display - Control........................................................................................ 59

Interlock..................................................................................................... 60

Operator position....................................................................................... 60

View .......................................................................................................... 61

Starting .................................................................................................................... 62

Starting the engine .................................................................................... 62

Driving ..................................................................................................................... 63

Operating the roller ................................................................................... 63

Machine with TC (Anti-Spin) ....................................................... 63

Slopes (TC (Anti-Spin))............................................................... 64

Interlock/Emergency stop/Parking brake - Check ..................................... 65

Dynapac Compaction Meter (DCM) including Active Bouncing Control

(ABC) - Optional........................................................................................ 65

Setting limit................................................................................................ 66

Operation CMV ......................................................................................... 67

Vibration .................................................................................................................. 67

Different operating modes......................................................................... 68

Advice when using DCO ........................................................................... 70

Braking .................................................................................................................... 71

Normal braking.......................................................................................... 71

Emergency braking ................................................................................... 71

Switching off.............................................................................................. 72

Parking .................................................................................................................... 72

Chocking the drums .................................................................................. 72

4812160101_A.pdf2014-07-04

Master switch ............................................................................................ 73

Long-term parking.................................................................................................................. 75

Engine ....................................................................................................... 75

Battery....................................................................................................... 75

Air cleaner, exhaust pipe........................................................................... 75

Fuel tank ................................................................................................... 75

Hydraulic reservoir .................................................................................... 75

Tires (All-weather)..................................................................................... 75

Hoods, tarpaulin ........................................................................................ 76

Miscellaneous ........................................................................................................................ 77

Lifting ....................................................................................................................... 77

Locking the articulation ............................................................................. 77

Lifting the roller.......................................................................................... 78

Lifting the roller with jack:.......................................................................... 78

Unlocking the articulation .......................................................................... 79

Towing/Recovering.................................................................................................. 79

Short distance towing with the engine running.......................................... 80

Short distance towing when the engine is inoperative. ............................. 81

Towing the roller........................................................................................ 82

Transport ................................................................................................................. 82

Securing CA1500-CA4600 for loading ...................................................... 83

Securing CA5000 for loading .................................................................... 85

Securing CA5500/6000/6500 for loading .................................................. 87

Operating instructions - Summary ......................................................................................... 89

Preventive maintenance ........................................................................................................ 91

Acceptance and delivery inspection.......................................................... 91

Warranty.................................................................................................... 91

Maintenance - Lubricants and symbols ................................................................................. 93

Maintenance symbols ............................................................................... 94

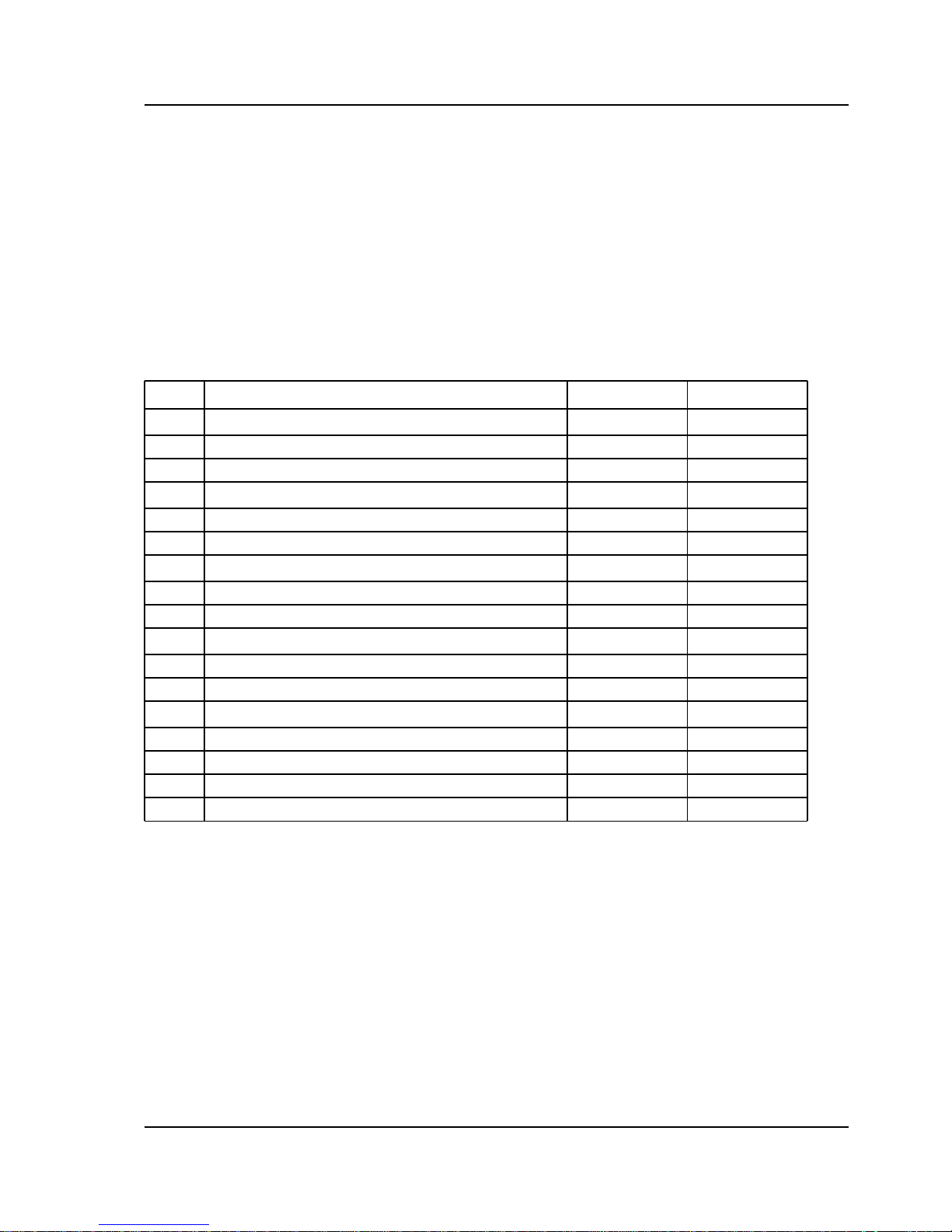

Maintenance - Maintenance schedule ................................................................................... 95

4812160101_A.pdf 2014-07-04

Service and maintenance points ............................................................... 95

General ..................................................................................................... 95

Periodic service (service message) - Optional.......................................... 96

Every 10 hours of operation (Daily)........................................................... 97

After the FIRST 50 hours of operation ...................................................... 97

Every 50 hours of operation (Weekly)....................................................... 97

Every 250 / 750 / 1250 / 1750 hours of operation ..................................... 98

Every 500 / 1500 hours of operation ......................................................... 98

Every 1000 hours of operation .................................................................. 99

Every 2000 hours of operation ................................................................ 100

Every other year...................................................................................... 101

Maintenance, 10h ................................................................................................................ 103

Scrapers - Check, adjustment................................................................. 103

Air circulation - Check ............................................................................. 104

Coolant level - Check .............................................................................. 104

Diesel engine Check oil level ................................................................. 105

Fuel tank - Filling..................................................................................... 105

Hydraulic reservoir - Check fluid level..................................................... 106

Maintenance - 50h ............................................................................................................... 107

Hydraulic filter - Replacement ................................................................. 107

Tires - Air pressure - Wheel nuts - Tightening ........................................ 109

Drum gearbox - Oil change ..................................................................... 109

Steering hitch - Tightening ...................................................................... 110

Air cleaner

- Check hoses and connections .............................................................. 111

Drum - Oil change ................................................................................... 111

Gearbox - Oil change .............................................................................. 113

Maintenance - 250 / 750 / 1250 / 1750h .............................................................................. 115

Rear axle differential - Check oil level..................................................... 115

Rear axle planetary gears - Check oil level............................................. 116

4812160101_A.pdf2014-07-04

Drum - Checking the oil level .................................................................. 116

Gearbox - Checking the oil level ............................................................. 117

Drum gearbox - Checking the oil level .................................................... 118

Radiator - Check/Cleaning ...................................................................... 118

Rubber elements and fastening screws - Check..................................... 119

Battery

- Check condition .................................................................................... 119

Air conditioning (Optional)

- Inspection.............................................................................................. 120

Automatic Climate Control (Optional) - Inspection .................................. 120

Maintenance - 500 / 1500h .................................................................................................. 121

Air cleaner

Checking - Change the main air filter...................................................... 121

Backup filter - Change............................................................................. 122

Air cleaner

- Cleaning................................................................................................ 122

Rear axle differential - Check oil level..................................................... 123

Rear axle planetary gears - Check oil level............................................. 123

Drum - Checking the oil level .................................................................. 124

Gearbox - Oil change .............................................................................. 125

Drum gearbox - Checking the oil level .................................................... 125

Radiator - Check/Cleaning ...................................................................... 126

Fuel pre-filter - Replacement................................................................... 126

Replacing the fuel filter............................................................................ 127

Diesel engine - Oil and Filter change ...................................................... 128

Controls and moving joints - Lubrication ................................................. 128

Seat bearing - Lubrication ....................................................................... 129

Maintenance - 1000h ........................................................................................................... 131

Hydraulic filter - Replacement ................................................................. 131

Air cleaner

Checking - Change the main air filter...................................................... 132

Backup filter - Change............................................................................. 133

4812160101_A.pdf 2014-07-04

Air cleaner

- Cleaning................................................................................................ 134

Rear axle differential - Oil change........................................................... 135

Rear axle planetary gear - Oil change .................................................... 135

Drum - Checking the oil level .................................................................. 136

Gearbox - Oil change .............................................................................. 137

Drum gearbox - Oil change ..................................................................... 137

Radiator - Check/Cleaning ...................................................................... 138

Fuel pre-filter - Replacement................................................................... 138

Replacing the fuel filter............................................................................ 139

Diesel engine - Oil and Filter change ...................................................... 140

Seat bearing - Lubrication ....................................................................... 141

Hydraulic reservoir - Draining.................................................................. 141

Fuel tank - Draining (Optional) ................................................................ 142

Air conditioning (Optional)

Fresh air filter - Change .......................................................................... 142

Steering hitch - Tightening ...................................................................... 143

Maintenance - 2000h ........................................................................................................... 145

Hydraulic reservoir - Oil change.............................................................. 145

Hydraulic filter - Replacement ................................................................. 146

Drum gearbox - Oil change ..................................................................... 147

Air cleaner

Checking - Change the main air filter...................................................... 147

Backup filter - Change............................................................................. 148

Air cleaner

- Cleaning................................................................................................ 148

Rear axle planetary gear - Oil change .................................................... 149

Rear axle differential - Oil change........................................................... 150

Drum - Oil change ................................................................................... 150

Gearbox - Oil change .............................................................................. 152

Radiator - Check/Cleaning ...................................................................... 152

4812160101_A.pdf2014-07-04

Fuel pre-filter - Replacement................................................................... 153

Replacing the fuel filter............................................................................ 153

Diesel engine - Oil and Filter change ...................................................... 154

Seat bearing - Lubrication ....................................................................... 155

Hydraulic reservoir - Draining.................................................................. 155

Fuel tank - Draining (Optional) ................................................................ 156

Air conditioning (Optional)

Fresh air filter - Change .......................................................................... 156

Automatic Climate Control (Optional)

- Overhaul ............................................................................................... 157

Drying filter - Check................................................................................. 157

Steering hitch - Tightening ...................................................................... 158

4812160101_A.pdf 2014-07-04

Introduction

4812160101_A.pdf2014-07-04

Introduction

The machine

CA3500/3600DCO are models of Dynapac's

medium-heavy earth compaction rollers. The machine

is a D (smooth drum) variant with optimized

compaction system "Compaction Optimizer" (CO).

CA5000/6000DCO are models of Dynapac's heavy

earth compaction rollers. The machine is a D (smooth

drum) variant with optimized compaction system

"Compaction Optimizer" (CO).

Intended use

All types of base courses and subbase courses can be

compacted.

Dynapac Compaction Optimizer (DCO) optimizes the

compaction work by continuously adjusting the

compaction effect to the composition of the surface. It

can be used together with another roller accessory,

the Dynapac Compaction Analyzer (DCA), which

enables the compaction results to be documented and

stored.

The cab and safety-related accessories are described

in this manual. Other accessories, such as tachograph

"and "Analyzer" (DCA) are described in separate

instructions.

Warning symbols

WARNING ! Marks a danger or a hazardous

procedure that can result in life threatening or

serious injury if the warning is ignored.

WARNING ! Marks a danger or a hazardous

procedure that can result in life threatening or

serious injury if the warning is ignored.

CAUTION ! Marks a danger or hazardous

procedure that can result in damage to the

machine or property if the warning is ignored.

CAUTION ! Marks a danger or hazardous

procedure that can result in damage to the

machine or property if the warning is ignored.

Safety information

It is recommended to at least train operators in

handling and daily maintenance of the machine

in accordance with the instruction manual.

It is recommended to at least train operators in

handling and daily maintenance of the machine

in accordance with the instruction manual.

Passengers are not allowed on the machine, and

you must sit in the seat when operating the

machine.

Passengers are not allowed on the machine, and

you must sit in the seat when operating the

machine.

1

Introduction

4812160101_A.pdf 2014-07-04

The safety manual supplied with the machine

must be read by all roller operators. Always

follow the safety instructions. Do not remove

the manual from the machine.

The safety manual supplied with the machine

must be read by all roller operators. Always

follow the safety instructions. Do not remove

the manual from the machine.

We recommend that the operator reads the

safety instructions in this manual carefully.

Always follow the safety instructions. Ensure

that this manual is always easily accessible.

We recommend that the operator reads the

safety instructions in this manual carefully.

Always follow the safety instructions. Ensure

that this manual is always easily accessible.

Read the entire manual before starting the

machine and before carrying out any

maintenance.

Read the entire manual before starting the

machine and before carrying out any

maintenance.

Ensure good ventilation (extraction of air by fan)

where the engine is run indoors.

Ensure good ventilation (extraction of air by fan)

where the engine is run indoors.

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

General

This manual contains instructions for machine

operation and maintenance.

The machine must be correctly maintained for

maximal performance.

The machine should be kept clean so that any

leakages, loose bolts and loose connections are

discovered at as early a point in time as possible.

Inspect the machine every day, before starting.

Inspect the entire machine so that any leakages or

other faults are detected.

Check the ground under the machine. Leakages are

more easily detected on the ground than on the

machine itself.

THINK ENVIRONMENT ! Do not release oil,

fuel and other environmentally hazardous

substances into the environment. Always send

used filters, drain oil and fuel remnants to

environmentally correct disposal.

THINK ENVIRONMENT ! Do not release oil,

fuel and other environmentally hazardous

substances into the environment. Always send

used filters, drain oil and fuel remnants to

environmentally correct disposal.

2

Introduction

4812160101_A.pdf2014-07-04

This manual contains instructions for periodic

maintenance normally carried out by the operator.

Additional instructions for the engine can be

found in the manufactuer's engine manual.

Additional instructions for the engine can be

found in the manufactuer's engine manual.

If the roller is equipped with a Step IIIB/4i diesel

engine and a particle filter (DPF-filter), the engine

will automatically burn out soot. See more under

the sections "Machine description" and

"Operation".

If the roller is equipped with a Step IIIB/4i diesel

engine and a particle filter (DPF-filter), the engine

will automatically burn out soot. See more under

the sections "Machine description" and

"Operation".

CE marking and Declaration of conformity

(Applies to machines marketed in EU/EEC)

This machine is CE marked. This shows that on

delivery it complies with the basic health and safety

directives applicable for the machine in accordance

with machinery directive 2006/42/EC and that it also

complies with other directives applicable for this

machine.

A "Declaration of conformity" is supplied with this

machine, which specifies the applicable directives and

supplements, as well as the harmonized standards

and other regulations that are applied.

3

Introduction

4812160101_A.pdf 2014-07-04

4

Safety - General instructions

4812160101_A.pdf2014-07-04

Safety - General instructions

(Also read the safety manual)

1. The operator must be familiar with the contents of the OPERATION section

before starting the roller.

1. The operator must be familiar with the contents of the OPERATION section

before starting the roller.

2. Ensure that all instructions in the MAINTENANCE section are followed.2. Ensure that all instructions in the MAINTENANCE section are followed.

3. Only trained and/or experienced operators are to operate the roller.

Passengers are not permitted on the roller. Remain seated at all times when

operating the roller.

3. Only trained and/or experienced operators are to operate the roller.

Passengers are not permitted on the roller. Remain seated at all times when

operating the roller.

4. Never use the roller if it is in need of adjustment or repair.4. Never use the roller if it is in need of adjustment or repair.

5. Only mount and dismount the roller when it is stationary. Use the intended

grips and rails. Always use the three-point grip (both feet and one hand, or

one foot and both hands) when mounting or dismounting the machine.

Never jump down from the machine.

5. Only mount and dismount the roller when it is stationary. Use the intended

grips and rails. Always use the three-point grip (both feet and one hand, or

one foot and both hands) when mounting or dismounting the machine.

Never jump down from the machine.

6. The ROPS (Roll Over Protective Structure) should always be used when the

machine is operated on unsafe ground.

6. The ROPS (Roll Over Protective Structure) should always be used when the

machine is operated on unsafe ground.

7. Drive slowly in sharp bends.7. Drive slowly in sharp bends.

8. Avoid driving across slopes. Drive straight up or straight down the slope.8. Avoid driving across slopes. Drive straight up or straight down the slope.

9. When driving close to edges, ditches or holes, make sure that at least 2/3 of

the drum width is on previously compacted material (solid surface).

9. When driving close to edges, ditches or holes, make sure that at least 2/3 of

the drum width is on previously compacted material (solid surface).

10. Make sure that there are no obstacles in the direction of travel, on the

ground, in front of or behind the roller, or overhead.

10. Make sure that there are no obstacles in the direction of travel, on the

ground, in front of or behind the roller, or overhead.

11. Drive particularly carefully on uneven ground.11. Drive particularly carefully on uneven ground.

12. Use the safety equipment provided. The seat belt must be worn on machines

fitted with ROPS/ROPS-cab.

12. Use the safety equipment provided. The seat belt must be worn on machines

fitted with ROPS/ROPS-cab.

13. Keep the roller clean. Clean any dirt or grease that accumulates on the

operator platform immediately. Keep all signs and decals clean and legible.

13. Keep the roller clean. Clean any dirt or grease that accumulates on the

operator platform immediately. Keep all signs and decals clean and legible.

14. Safety measures before refueling:

- Stop the engine

- Do not smoke.

- No naked flames in the vicinity of the roller.

- Earth the filling equipment nozzle to the tank opening to avoid sparks.

14. Safety measures before refueling:

- Stop the engine

- Do not smoke.

- No naked flames in the vicinity of the roller.

- Earth the filling equipment nozzle to the tank opening to avoid sparks.

15. Before repairs or service:

- Chock the drums/wheels and under the strike-off blade.

- Lock the articulation if necessary

15. Before repairs or service:

- Chock the drums/wheels and under the strike-off blade.

- Lock the articulation if necessary

5

Safety - General instructions

4812160101_A.pdf 2014-07-04

16. Hearing protection is recommended if the noise level exceeds 85 dB(A). The

noise level can vary depending on the equipment on the machine and the

surface the machine is being used on.

16. Hearing protection is recommended if the noise level exceeds 85 dB(A). The

noise level can vary depending on the equipment on the machine and the

surface the machine is being used on.

17. Do not make any changes or modifications to the roller that could affect

safety. Changes are only to be made after written approval has been given

by Dynapac.

17. Do not make any changes or modifications to the roller that could affect

safety. Changes are only to be made after written approval has been given

by Dynapac.

18. Avoid using the roller before the hydraulic fluid has reached its normal

working temperature. Braking distances can be longer than normal when the

fluid is cold. See instructions in the STOP section.

18. Avoid using the roller before the hydraulic fluid has reached its normal

working temperature. Braking distances can be longer than normal when the

fluid is cold. See instructions in the STOP section.

19. For your own protection always wear:

- helmet

- working boots with steel toecaps

- ear protectors

- reflecting clothing/high visibility jacket

- working gloves

19. For your own protection always wear:

- helmet

- working boots with steel toecaps

- ear protectors

- reflecting clothing/high visibility jacket

- working gloves

6

Safety - when operating

4812160101_A.pdf2014-07-04

Safety - when operating

Prevent persons from entering or remaining in

the danger area, i.e. a distance of at least 7 m

(23 ft) in all directions from operating machines.

Prevent persons from entering or remaining in

the danger area, i.e. a distance of at least 7 m

(23 ft) in all directions from operating machines.

The operator may allow a person to remain in

the danger area, but should then observe

caution and operate the machine only when the

person is visible or has given clear indications

of where he or she is.

The operator may allow a person to remain in

the danger area, but should then observe

caution and operate the machine only when the

person is visible or has given clear indications

of where he or she is.

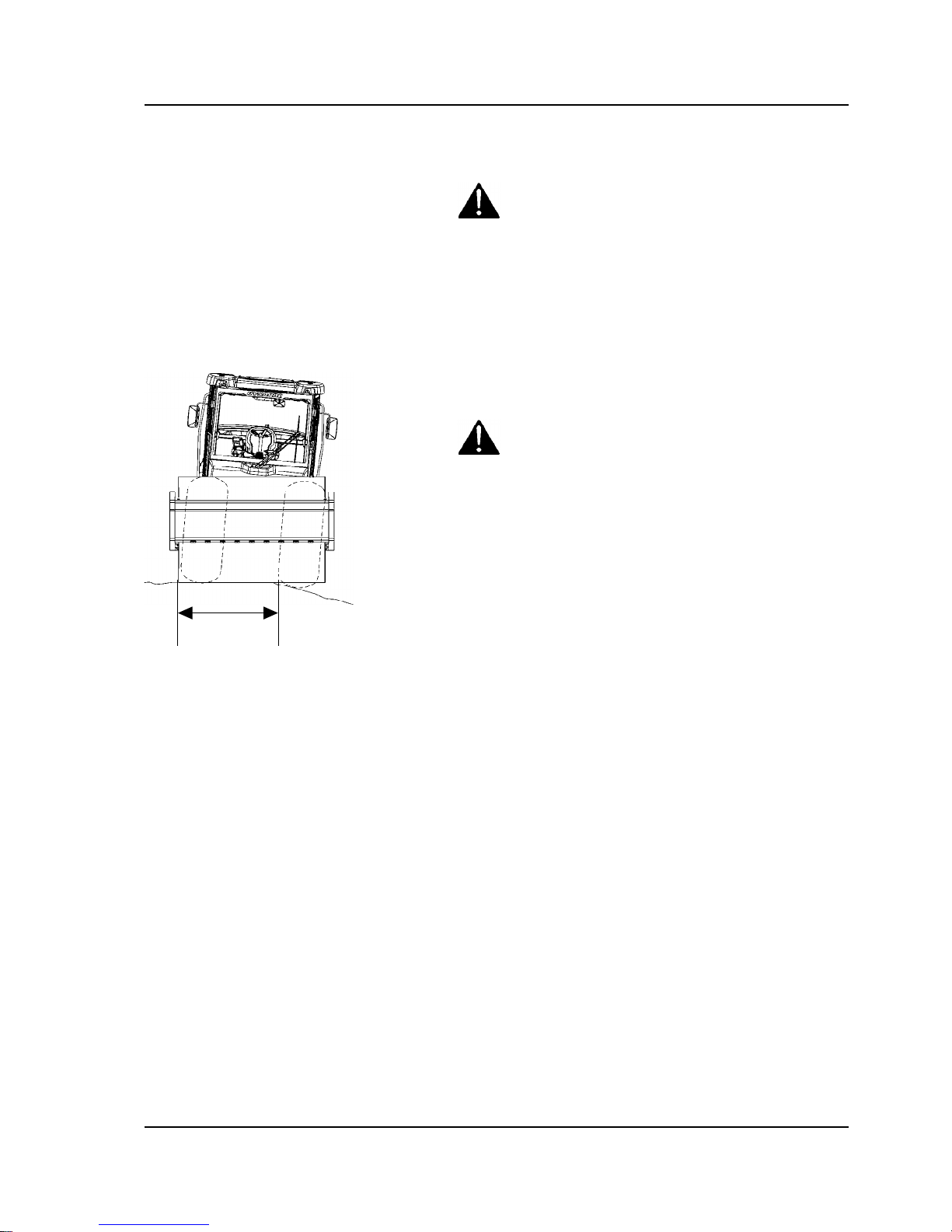

Driving near edges

Fig. Position of drum when driving near

an edge

Minimum

2/3

When driving near an edge, minimum 2/3 of the drum

width must be on solid ground.

Keep in mind that the machine's center of gravity

moves outwards when steering. For example, the

center of gravity moves to the right when you

steer to the left.

Keep in mind that the machine's center of gravity

moves outwards when steering. For example, the

center of gravity moves to the right when you

steer to the left.

7

Safety - when operating

4812160101_A.pdf 2014-07-04

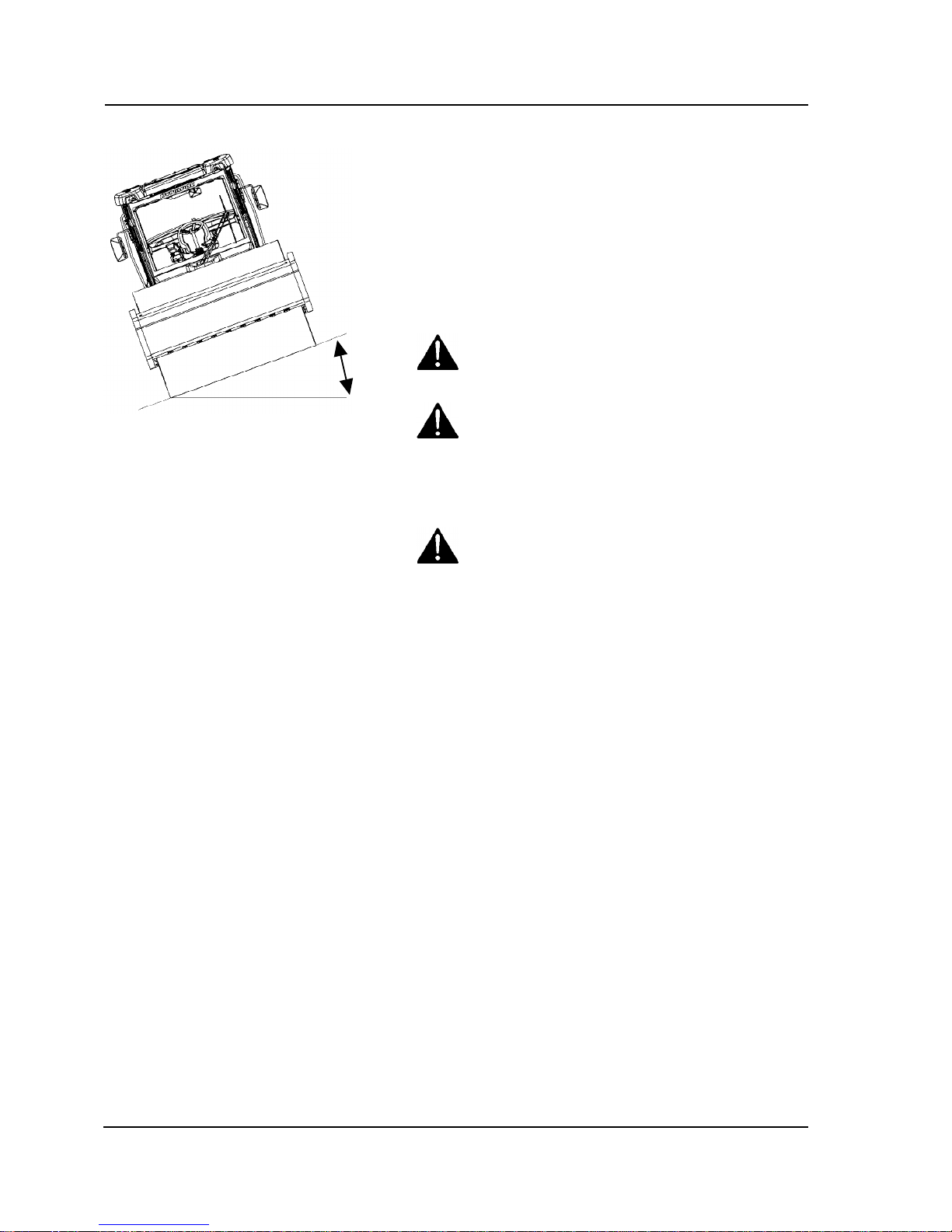

Slopes

Fig. Operating on slopes

Max 20° or 36%

This angle has been measured on a hard, flat surface

with the machine stationary.

The steering angle was zero, the vibration was

switched OFF and all tanks were full.

Always take into consideration that loose ground,

steering the machine, vibration on, machine speed

across the ground and raising the center of gravity can

all cause the machine to topple at smaller slope

angles than those specified here.

To exit the cab in an emergency, release the

hammer on the rear right post and break the rear

window.

To exit the cab in an emergency, release the

hammer on the rear right post and break the rear

window.

It is recommended that ROPS (Roll Over Protective

Structure) or a ROPS-approved cab is always used

when driving on slopes or unsafe ground. Always

wear a seat belt.

It is recommended that ROPS (Roll Over Protective

Structure) or a ROPS-approved cab is always used

when driving on slopes or unsafe ground. Always

wear a seat belt.

Where possible, avoid driving across slopes.

Drive instead straight up and down sloping

ground.

Where possible, avoid driving across slopes.

Drive instead straight up and down sloping

ground.

8

Safety (Optional)

4812160101_A.pdf2014-07-04

Safety (Optional)

Air conditioning

The system described in this manual is an AC/ACC

type (Automatic climate control)

Fig. Cab

The system contains pressurized refrigerant. It is

forbidden to release refrigerants into the

atmosphere.

The system contains pressurized refrigerant. It is

forbidden to release refrigerants into the

atmosphere.

The cooling system is pressurized. Incorrect

handling can result in serious personal injury. Do

not disconnect or undo the hose couplings.

The cooling system is pressurized. Incorrect

handling can result in serious personal injury. Do

not disconnect or undo the hose couplings.

The system must be recharged with approved

refrigerant as required by authorized personnel.

The system must be recharged with approved

refrigerant as required by authorized personnel.

The refrigerant contains a tracing agent, enabling

leak-tracing to be performed using UV light.

The condenser is located together with other radiators,

and the drying filter is located on the right-hand side of

the radiator stand.

9

Safety (Optional)

4812160101_A.pdf 2014-07-04

10

Special instructions

4812160101_A.pdf2014-07-04

Special instructions

Standard lubricants and other recommended

oils and fluids

Before leaving the factory, the systems and

components are filled with the oils and fluids specified

in the lubricant specification. These are suitable for

ambient temperatures in the range -15°C to +40°C

(5°F - 105°F).

The maximum temperature for biological

hydraulic fluid is +35°C (95°F).

The maximum temperature for biological

hydraulic fluid is +35°C (95°F).

Higher ambient temperatures, above +40°C

(104°F)

For operation of the machine at higher ambient

temperatures, however maximum +50°C (122°F), the

following recommendations apply:

The diesel engine and hydraulic system can be run at

this temperature using normal oil, but in other

components that use transmission oil, Shell Spirax S3

AX85W/140, API GL-5 or equivalent must be used.

Temperatures

The temperature limits apply to standard versions of

rollers.

Rollers equipped with additional equipment, such as

noise suppression, may need to be more carefully

monitored in the higher temperature ranges.

High pressure cleaning

Do not spray directly onto electrical components.

Do not use a high-pressure water jet on the

instrument panel/display.

Do not use a high-pressure water jet on the

instrument panel/display.

Detergent that can destroy electrical parts, or

which is conductive, must not be used.

Detergent that can destroy electrical parts, or

which is conductive, must not be used.

In certain cases there is an electrical control lever

and associated electronic control unit (ECU) in

the engine compartment, which must not be

washed with a high-pressure jet or with any water

at all. It is sufficient to wipe these off.

The same applies to the engine electronic control

unit (engine ECU).

In certain cases there is an electrical control lever

and associated electronic control unit (ECU) in

the engine compartment, which must not be

washed with a high-pressure jet or with any water

at all. It is sufficient to wipe these off.

The same applies to the engine electronic control

unit (engine ECU).

Place a plastic bag over the fuel filler cap and secure

11

Special instructions

4812160101_A.pdf 2014-07-04

with a rubber band. This is to avoid high pressure

water entering the vent hole in the filler cap. This could

cause malfunctions, such as the blocking of filters.

Place a plastic bag over the exhaust pipe and secure

with a rubber band to avoid water in the muffler.

Never aim the water jet directly at the fuel tank

cap. This is particularly important when using a

high-pressure cleaner.

Never aim the water jet directly at the fuel tank

cap. This is particularly important when using a

high-pressure cleaner.

Fire fighting

If the machine catches fire, use an ABC-class powder

fire extinguisher.

A BE-class carbon dioxide fire extinguisher can also

be used.

Roll Over Protective Structure (ROPS), ROPS

approved cab

If the machine is fitted with a Roll Over

Protective Structure (ROPS, or ROPS approved

cab) never carry out any welding or drilling in

the structure or cab.

If the machine is fitted with a Roll Over

Protective Structure (ROPS, or ROPS approved

cab) never carry out any welding or drilling in

the structure or cab.

Never attempt to repair a damaged ROPS

structure or cab. These must be replaced with

new ROPS structure or cabs.

Never attempt to repair a damaged ROPS

structure or cab. These must be replaced with

new ROPS structure or cabs.

Welding

When carrying out welding on the machine, the

battery must be disconnected and the

electronics disconnected from the electrical

system.

When carrying out welding on the machine, the

battery must be disconnected and the

electronics disconnected from the electrical

system.

If possible, remove the part(s) to be welded

from the machine.

If possible, remove the part(s) to be welded

from the machine.

Battery handling

When removing batteries, always disconnect the

negative cable first.

When removing batteries, always disconnect the

negative cable first.

When fitting batteries, always connect the

positive cable first.

When fitting batteries, always connect the

positive cable first.

12

Special instructions

4812160101_A.pdf2014-07-04

Dispose of old batteries in an environmentally

friendly way. Batteries contain toxic lead.

Dispose of old batteries in an environmentally

friendly way. Batteries contain toxic lead.

Do not use a quick-charger for charging the

battery. This may shorten battery life.

Do not use a quick-charger for charging the

battery. This may shorten battery life.

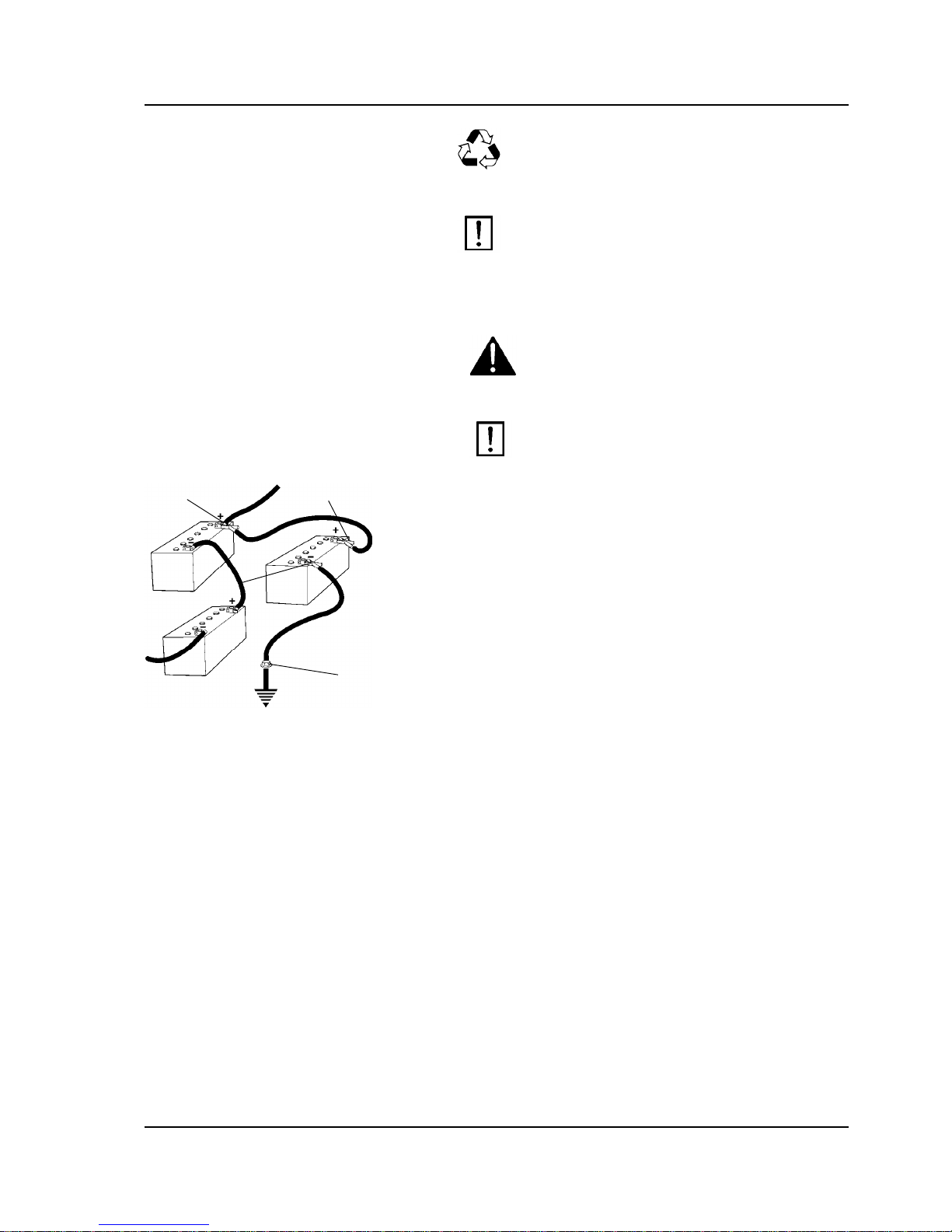

Jump starting (24V)

Do not connect the negative cable to the

negative terminal on the dead battery. A spark

can ignite the oxy-hydrogen gas formed

around the battery.

Do not connect the negative cable to the

negative terminal on the dead battery. A spark

can ignite the oxy-hydrogen gas formed

around the battery.

Check that the battery used for jump starting

has the same voltage as the dead battery.

Check that the battery used for jump starting

has the same voltage as the dead battery.

24V

12V

12V

Fig. Jump starting

1

2

3

4

Turn the ignition and all power consuming equipment

off. Switch off the engine on the machine which is

providing jump start power.

Jump leads must have 24V.

First connect the jump start battery's positive terminal

(1) to the flat battery's positive terminal (2).Then

connect the jump start battery's negative terminal (3)

to, for example, a bolt (4) or the lifjting eye on the

machine with the flat battery.

Start the engine on the power providing machine. Let it

run for a while. Now try to start the other machine.

Disconnect the cables in the reverse order.

13

Special instructions

4812160101_A.pdf 2014-07-04

14

Technical specifications

4812160101_A.pdf2014-07-04

Technical specifications

Vibrations - Operator station

(ISO 2631)

The vibration levels are measured in accordance with the operational cycle described in

EU directive 2000/14/EC on machines equipped for the EU market, with vibration switched

on, on soft polymer material and with the operator’s seat in the transport position.

The vibration levels are measured in accordance with the operational cycle described in

EU directive 2000/14/EC on machines equipped for the EU market, with vibration switched

on, on soft polymer material and with the operator’s seat in the transport position.

Measured whole-body vibrations are below the action value of 0.5 m/s² as specified in Directive

2002/44/EC. (Limit is 1.15 m/s²)

Measured whole-body vibrations are below the action value of 0.5 m/s² as specified in Directive

2002/44/EC. (Limit is 1.15 m/s²)

Measured hand/arm vibrations also were below the action level of 2.5 m/s² specified in the same

directive. (Limit is 5 m/s²)

Measured hand/arm vibrations also were below the action level of 2.5 m/s² specified in the same

directive. (Limit is 5 m/s²)

Noise level

The noise level is measured in accordance with the operational cycle described in EU

directive 2000/14/EC on machines equipped for the EU market, on soft polymer material

with vibration switched on and the operator's seat in the transport position.

The noise level is measured in accordance with the operational cycle described in EU

directive 2000/14/EC on machines equipped for the EU market, on soft polymer material

with vibration switched on and the operator's seat in the transport position.

Guaranteed sound power level, L

wA

103 dB (A)Guaranteed sound power level, L

wA

103 dB (A)

Sound pressure level at the driver's ear (platform/ROPS), L

pA

XX dB (A)Sound pressure level at the driver's ear (platform/ROPS), L

pA

XX dB (A)

Sound pressure level at the operator's ear (cab), L

pA

72 ±3 dB (A)Sound pressure level at the operator's ear (cab), L

pA

72 ±3 dB (A)

Electrical system

Machines are EMC tested in accordance with EN

13309:2000 'Construction machinery'

15

Technical specifications

4812160101_A.pdf 2014-07-04

Dimensions, side view

Dimensions mm inDimensions mm in

A Wheelbase, drum and wheelA Wheelbase, drum and wheel

CA3500, CA3600 2990 118CA3500, CA3600 2990 118

CA5000, CA6000 3100 122CA5000, CA6000 3100 122

L Length, standard equipped rollerL Length, standard equipped roller

CA3500, CA3600 6000 236CA3500, CA3600 6000 236

CA5000, CA6000 6240 246CA5000, CA6000 6240 246

H1 Height, with ROPS/cabH1 Height, with ROPS/cab

CA3500, CA3600 2870 113CA3500, CA3600 2870 113

CA5000, CA6000 2890 114CA5000, CA6000 2890 114

H2 Height, without ROPSH2 Height, without ROPS

CA3500, CA3600 2267 89CA3500, CA3600 2267 89

CA5000, CA6000 2267 89CA5000, CA6000 2267 89

D Diameter, drum (D)D Diameter, drum (D)

CA3500, CA3600 1518 60CA3500, CA3600 1518 60

CA5000 1536 60.5CA5000 1536 60.5

CA6000 1546 60.9CA6000 1546 60.9

S Thickness, drum amplitude, Nominal (D)S Thickness, drum amplitude, Nominal (D)

CA3500, CA3600 34 1.3CA3500, CA3600 34 1.3

CA5000 43 1.7CA5000 43 1.7

CA6000 48 1.9CA6000 48 1.9

P N/AP N/A

K1 Clearance, tractor frame 450 18K1 Clearance, tractor frame 450 18

K2 Clearance, drum frameK2 Clearance, drum frame

CA3500, CA3600 442 17.5CA3500, CA3600 442 17.5

CA5000, CA6000 450 18CA5000, CA6000 450 18

16

Technical specifications

4812160101_A.pdf2014-07-04

Dimensions, top view

Dimensions mm inDimensions mm in

B Width, standard equipped rollerB Width, standard equipped roller

CA3500, CA3600 2304 91CA3500, CA3600 2304 91

CA5000, CA6000 2340 92CA5000, CA6000 2340 92

O1 Overhang, left frame sideO1 Overhang, left frame side

CA3500, CA3600 87 3.4CA3500, CA3600 87 3.4

CA5000, CA6000 105 4.1CA5000, CA6000 105 4.1

O2 Overhang, right frame sideO2 Overhang, right frame side

CA3500, CA3600 87 3.4CA3500, CA3600 87 3.4

CA5000, CA6000 105 4.1CA5000, CA6000 105 4.1

R1 Turn radius, externalR1 Turn radius, external

CA3500, CA3600 5600 220CA3500, CA3600 5600 220

CA5000, CA6000 5800 228CA5000, CA6000 5800 228

R2 Turning radius, innerR2 Turning radius, inner

CA3500, CA3600 3210 126CA3500, CA3600 3210 126

CA5000, CA6000 3330 131CA5000, CA6000 3330 131

W1 Width, tractor section 2130 84W1 Width, tractor section 2130 84

W2 Width, drum 2130 84W2 Width, drum 2130 84

17

Technical specifications

4812160101_A.pdf 2014-07-04

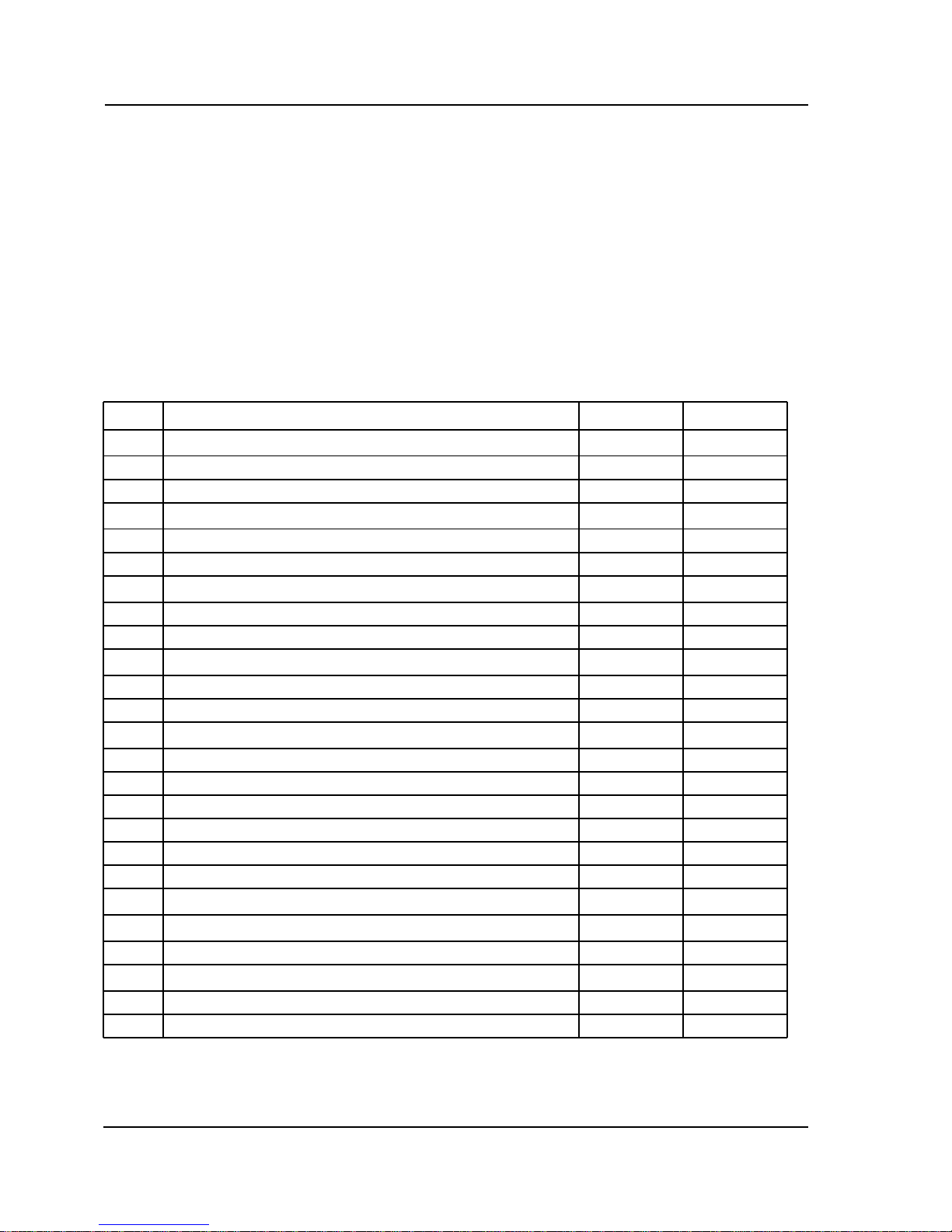

Weights and volumes

WeightsWeights

Service weight CabService weight Cab

CA3500 12 250 (kg)CA3500 12 250 (kg)

27 010 (lbs)27 010 (lbs)

CA3600 12 670 (kg)CA3600 12 670 (kg)

27 940 (lbs)27 940 (lbs)

CA5000D 16 500 (kg)CA5000D 16 500 (kg)

36 380 (lbs)36 380 (lbs)

CA6000D 19 820 (kg)CA6000D 19 820 (kg)

43 700 (lbs)43 700 (lbs)

Fluid volumesFluid volumes

Fuel tank 272 liters 72 gal

Fuel tank 272 liters 72 gal

Working capacity

Compaction dataCompaction data

Static linear loadStatic linear load

CA3500, CA3600 35 (kg/cm)CA3500, CA3600 35 (kg/cm)

196 (pli)196 (pli)

CA5000 50 (kg/cm)CA5000 50 (kg/cm)

280 (pli)280 (pli)

CA6000 60 (kg/cm)CA6000 60 (kg/cm)

336 (pli)336 (pli)

18

Loading...

Loading...